A Long-Term Analysis of the Possibility of Water Recovery for Hydroponic Lettuce Irrigation in Indoor Vertical Farm. Part 1: Water Recovery from Exhaust Air

Abstract

:Featured Application

Abstract

1. Introduction

2. Materials and Methods

2.1. Weather Data

2.2. Description of Vertical Indoor Farming Facility and Set-Up Parameters of Growing Plants

2.3. Calculation of the Required Supplied Airflow

2.4. Cross-Flow Heat and Mass Exchanger

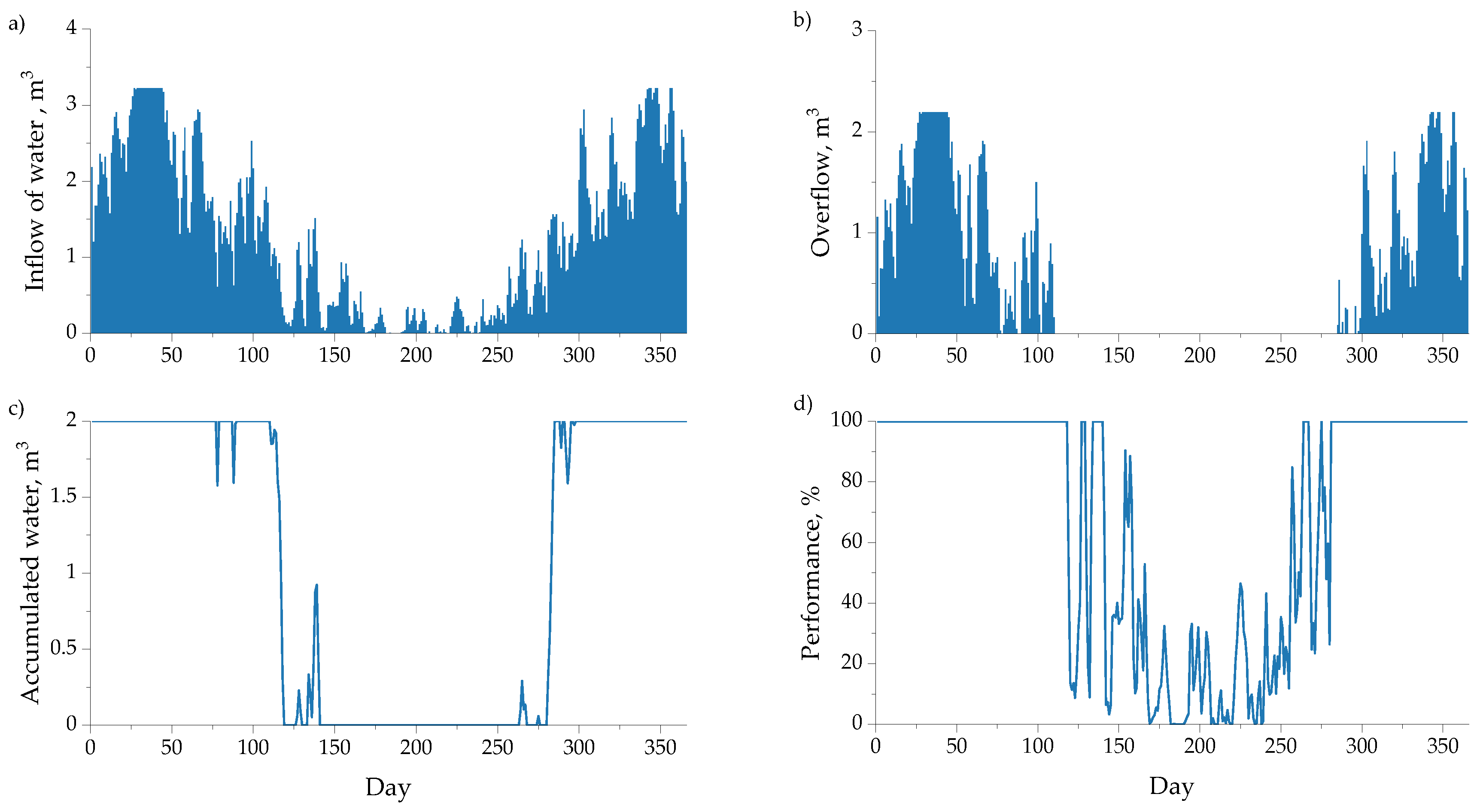

3. Results and Discussion

4. Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Pandey, D. Agricultural Sustainability and Climate Change Nexus. In Contemporary Environmental Issues and Challenges in Era of Climate Change, 1st ed.; Singh, P., Singh, R.P., Srivastava, V., Eds.; Springer: Singapore, 2020; pp. 77–97. [Google Scholar]

- Vitoshkin, H.; Haslavsky, V. Thermal Analysis and Climate Control of Experimental two-level Hydroponic Growth Cell. In Proceedings of the 6th World Congress on Mechanical, Chemical, and Material Engineering (MCM’20), Virtual Conference, Prague, Czech Republic, 16–18 August 2020. [Google Scholar]

- Touliatos, D.; Dodd, I.C.; Mcainsh, M. Vertical farming increases lettuce yield per unit area compared to conventional horizontal hydroponics. Food Energy Secur. 2016, 5, 184–191. [Google Scholar] [CrossRef] [Green Version]

- Al-Kodmany, K. The vertical farm: A review of developments and implications for the vertical city. Buildings 2018, 8, 24. [Google Scholar] [CrossRef] [Green Version]

- Bamsey, M.T.; Zabel, P.; Zeidler, C.; Gyimesi, D.; Schubert, D.; Kohlberg, E.; Mengedoht, D.; Rae, J.; Graham, T. Review of Antarctic Greenhouses and Plant Production Facilities: A Historical Account of Food Plants on the Ice. In Proceedings of the 45th International Conference on Environmental Systems, Bellevue, WA, USA, 12–16 July 2015. [Google Scholar]

- Zabel, P.; Bamsey, M.; Schubert, D.; Tajmar, M. Review and analysis of over 40 years of space plant growth systems. Life Sci. Space Res. 2016, 10, 1–16. [Google Scholar] [CrossRef]

- Wheeler, R.M. Agriculture for space: People and places paving the way. Open Agric. 2017, 2, 14–32. [Google Scholar] [CrossRef]

- Gitelson, I.I.; Terskov, I.A.; Kovrov, B.G.; Lisovskii, G.M.; Okladnikov, Y.N.; Sid’ko, F.Y.; Trubachev, I.N.; Shilenko, M.P.; Alekseev, S.S.; Pan’kova, I.M.; et al. Long-Term Experiments on Man’s Stay in Biological Life-Support System. Adv. Space Res. 1989, 9, 65–71. [Google Scholar] [CrossRef]

- Edeen, M.A.; Pickering, K.D. Biological and Physical-Chemical Life Support Systems Integration-Results of the Lunar Mars Life Support Phase III Test. SAE Int. J. Aerosp. 1998, 107, 776–789. [Google Scholar] [CrossRef]

- Tako, Y.; Masuda, T.; Tsuga, S.; Arai, R.; Komatsubara, O.; Nozoe, S.; Aibe, Y.; Shinohara, M.; Suzuki, M.; Ishioka, M.; et al. Outline of Material Circulation-Closed Habitation Experiments Conducted in 2005–2007 Using Closed Ecology Experiment Facilities. SAE Technical Paper 2009-01-2580; 12 July 2009; Available online: https://www.sae.org/publications/technical-papers/content/2009-01-2580/ (accessed on 14 December 2020).

- Guo, S.; Dong, W.; Ai, W.; Feng, H.; Tang, Y.; Huang, Z.; Shen, Y.; Ren, J.; Qin, L.; Zeng, G.; et al. Research on regulating technique of material flow for 2-person and 30-day integrated CELSS test. Acta Astronaut. 2014, 100, 140–146. [Google Scholar] [CrossRef]

- Tikhomirov, A.A.; Ushakova, S.A.; Velichko, V.V.; Trifonov, S.V.; Tikhomirova, N.A.; Kalacheva, G.S. A small closed ecosystem with an estimated portion of human metabolism. Life Sci. Space Res. 2018, 19, 63–67. [Google Scholar] [CrossRef] [PubMed]

- Armanda, D.T.; Guinée, J.B.; Tukker, A. The second green revolution: Innovative urban agriculture’s contribution to food security and sustainability-A review. Glob. Food Sec. 2019, 22, 13–24. [Google Scholar] [CrossRef]

- Benke, K.; Tomkins, B. Future food-production systems: Vertical farming and controlled-environment agriculture. Sustain. Sci. Pract. Policy 2017, 13, 13–26. [Google Scholar] [CrossRef] [Green Version]

- Avgoustaki, D.D.; Xydis, G. Plant factories in the water-food-energy Nexus era: A systematic bibliographical review. Food Secur. 2020, 12, 253–268. [Google Scholar] [CrossRef]

- Al-ismaili, A.M.; Weatherhead, E.K. Steady-state simulation of the seawater greenhouse condenser. Agric. Eng. Int. CIGR J. 2018, 20, 52–60. [Google Scholar]

- Perret, J.S.; Sablani, S.S. Development of a Humidification-Dehumidification System in a Quonset Greenhouse for Sustainable Crop Production in Arid Regions. Biosyst. Eng. 2005, 91, 349–359. [Google Scholar] [CrossRef]

- Algarni, S.; Saleel, C.A.; Mujeebu, M.A. Air-conditioning condensate recovery and applications-Current developments and challenges ahead Kingdom of Saudi Arabia. Sustain. Cities Soc. 2018, 37, 263–274. [Google Scholar] [CrossRef]

- Eades, W.G. Energy and water recovery using air-handling unit condensate from laboratory HVAC systems. Sustain. Cities Soc. 2018, 42, 162–175. [Google Scholar] [CrossRef]

- Licina, D.; Sekhar, C. Energy and water conservation from air handling unit condensate in hot and humid climates. Energy Build. 2012, 45, 257–263. [Google Scholar] [CrossRef]

- Ghimire, S.R.; Johnston, J.M.; Garland, J.; Edelen, A.; Cissy, X.; Jahne, M. Life cycle assessment of a rainwater harvesting system compared with an AC condensate harvesting system. Resour. Conserv. Recycl. 2019, 146, 536–548. [Google Scholar] [CrossRef]

- Deshko, V.I.; Ya, A.; Sukhodub, I.O. Heat and mass transfer in cross-flow air-to-air membrane heat exchanger in heating mode. Appl. Therm. Eng. 2016, 100, 133–145. [Google Scholar] [CrossRef]

- Liu, P.; Rafati, M.; Ge, G.; Justo, M.; Martin, H.; Fathieh, F.; Simonson, C. A theoretical model to predict frosting limits in cross-flow air-to-air flat plate heat/energy exchangers. Energy Build. 2016, 110, 404–414. [Google Scholar] [CrossRef]

- Anisimov, S.; Jedlikowski, A.; Pandelidis, D. Frost formation in the cross-flow plate heat exchanger for energy recovery. Int. J. Heat Mass Transf. 2015, 90, 201–217. [Google Scholar] [CrossRef]

- Jedlikowski, A.; Anisimov, S.; Danielewicz, J.; Karpuk, M.; Pandelidis, D. Frost formation and freeze protection with bypass for counter-flow recuperators. Int. J. Heat Mass Transf. 2017, 108, 585–613. [Google Scholar] [CrossRef]

- Amani, M.; Foroushani, S.; Sultan, M.; Bahrami, M. Comprehensive review on dehumidification strategies for agricultural greenhouse applications. Appl. Therm. Eng. 2020, 181, 115979. [Google Scholar] [CrossRef]

- Dubicki, A.; Dubicka, M.; Szymanowski, M. Klimat Wrocławia. In Środowisko Wrocławia-Informator; Smolnicki, K., Szykasiuk, M., Eds.; Dolnośląska Fundacja Ekorozwoju: Wrocław, Poland, 2002; pp. 9–20. [Google Scholar]

- V-farm.co.uk. VF5219-5 Layer NFT System. Available online: https://v-farm.co.uk/products/vf-5219-5-layer-nft-system (accessed on 24 November 2020).

- Anderson, M.S.; Ewert, M.K.; Keener, J.F.; Wagner, S.A. Life Support Baseline Values and Assumptions Document; National Aeronautics and Space Administration: Houston, TX, USA, 2018; pp. 1–233. [Google Scholar]

- Graamans, L.; Baeza, E.; van den Dobbelsteen, A.; Tsafaras, I.; Stanghellini, C. Plant factories versus greenhouses: Comparison of resource use efficiency. Agric. Syst. 2018, 160, 31–43. [Google Scholar] [CrossRef]

- Hydroponics Ventilation Basics. Available online: https://ventsworld.com/wp-content/uploads/2014/03/HYDROPONICS_booklet_10_2013_eng.pdf (accessed on 24 November 2020).

- Ahn, B.L.; Park, J.W.; Yoo, S.; Kim, J.; Leigh, S.B.; Jang, C.Y. Savings in cooling energy with a thermal management system for LED lighting in office buildings. Energies 2015, 8, 6658–6671. [Google Scholar] [CrossRef] [Green Version]

- Graamans, L.; van den Dobbelsteen, A.; Meinen, E.; Stanghellini, C. Plant factories; crop transpiration and energy balance. Agric. Syst. 2017, 153, 138–147. [Google Scholar] [CrossRef]

- Shibata, T.; Iwao, K.; Takano, T. Effect of Vertical Air Flowing on Lettuce Growing in a Plant Factory. Acta Hortic. 1995, 399, 175–182. [Google Scholar] [CrossRef]

- Pacak, A.; Jedlikowski, A.; Karpuk, M.; Anisimov, S. Analysis of power demand calculation for freeze prevention methods of counter-flow heat exchangers used in energy recovery from exhaust air. Int. J. Heat Mass Transf. 2019, 133, 842–860. [Google Scholar] [CrossRef]

- Canales, F.A.; Gwoździej-Mazur, J.; Jadwiszczak, P.; Struk-Sokołowska, J.; Wartalska, K.; Wdowikowski, M.; Kaźmierczak, B. Long-term trends in 20-day cumulative precipitation for residential rainwater harvesting in Poland. Water 2020, 12, 1932. [Google Scholar] [CrossRef]

| Type | Sensible Heat, kW | Latent Heat, kW |

|---|---|---|

| Plants | −9.9 | 29.2 |

| LED lights | 66.8 | - |

| Month | Performance, % | Performance, m3 | ||||

|---|---|---|---|---|---|---|

| Min | Mean | Max | Min | Mean | Max | |

| I–XII | 61.08 | 67.12 | 69.48 | 229.62 | 252.50 | 261.91 |

| I | 100.00 | 100.00 | 100.00 | 31.93 | 31.93 | 31.93 |

| II | 100.00 | 100.00 | 100.00 | 28.84 | 29.10 | 29.87 |

| III | 100.00 | 100.00 | 100.00 | 31.93 | 31.93 | 31.93 |

| IV | 63.58 | 89.24 | 100.00 | 19.64 | 27.58 | 30.90 |

| V | 24.18 | 53.82 | 75.17 | 7.72 | 17.18 | 24.00 |

| VI | 3.45 | 19.03 | 28.26 | 1.07 | 5.88 | 8.73 |

| VII | 4.52 | 8.24 | 10.45 | 1.44 | 2.63 | 3.34 |

| VIII | 6.03 | 11.73 | 18.63 | 1.93 | 3.75 | 5.95 |

| IX | 31.51 | 42.55 | 60.39 | 9.74 | 13.15 | 18.66 |

| X | 68.24 | 83.55 | 94.25 | 21.79 | 26.68 | 30.09 |

| XI | 97.56 | 99.57 | 100.00 | 30.15 | 30.77 | 30.90 |

| XII | 100.00 | 100.00 | 100.00 | 31.93 | 31.93 | 31.93 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pacak, A.; Jurga, A.; Drąg, P.; Pandelidis, D.; Kaźmierczak, B. A Long-Term Analysis of the Possibility of Water Recovery for Hydroponic Lettuce Irrigation in Indoor Vertical Farm. Part 1: Water Recovery from Exhaust Air. Appl. Sci. 2020, 10, 8907. https://doi.org/10.3390/app10248907

Pacak A, Jurga A, Drąg P, Pandelidis D, Kaźmierczak B. A Long-Term Analysis of the Possibility of Water Recovery for Hydroponic Lettuce Irrigation in Indoor Vertical Farm. Part 1: Water Recovery from Exhaust Air. Applied Sciences. 2020; 10(24):8907. https://doi.org/10.3390/app10248907

Chicago/Turabian StylePacak, Anna, Anna Jurga, Paweł Drąg, Demis Pandelidis, and Bartosz Kaźmierczak. 2020. "A Long-Term Analysis of the Possibility of Water Recovery for Hydroponic Lettuce Irrigation in Indoor Vertical Farm. Part 1: Water Recovery from Exhaust Air" Applied Sciences 10, no. 24: 8907. https://doi.org/10.3390/app10248907