Effects of Freeze-Thaw and Wet-Dry Cycles on Tension Stiffening Behavior of Reinforced RAC Elements

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.1.1. Raw Materials

2.1.2. Natural and Recycled Aggregate Concrete

2.1.3. Steel Bars

2.2. Methods

2.2.1. Production of Reinforced Elements

2.2.2. Freeze-Thaw and Wet-Dry Aging Procedures

- Freeze-thaw cycles (FTC): the samples were submitted to 0, 150 and 300 accelerated freezing and thawing cycles, based on ASTM C666 [38], in a climatic chamber with an automatic temperature control system. The total time of one cycle was 5 h, with a temperature reduction from 4 °C to −18 °C in 2.5 h and then reheating for 2.5 h until reaching 4 °C again;

- Wet-dry cycles (WDC): the samples were submitted to 0, 25 and 50 accelerated wetting and drying cycles, based on NBR 13554 [39] and ASTM D559 [40], and it was performed manually with the use of a water tank and a laboratory oven. The total time of one cycle was 24 h, which consisted of immersion in water at 20 °C for 3 h, superficial drying at 21 °C for 1 h and oven-drying at 60 °C for 20 h.

- In addition, non-degraded samples were kept in a wet chamber and tested as reference at the same age as the degraded samples.

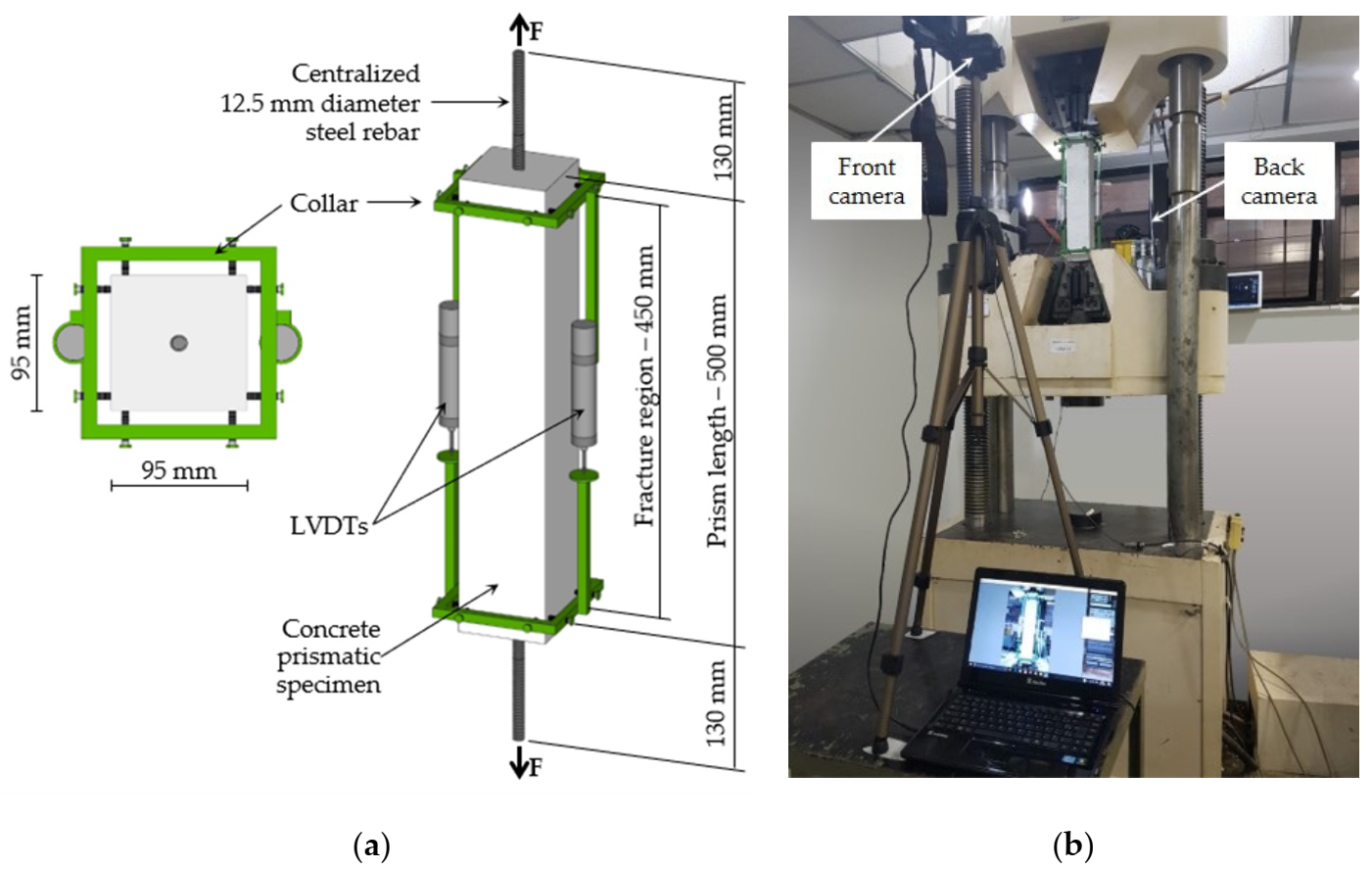

2.2.3. Tension Stiffening Test

2.2.4. Crack Analysis Method

2.2.5. Tension Stiffening Modeling

3. Results and Discussion

3.1. Effects of Freeze-Thaw and Wet-Dry Aging on Main Properties of Reinforced RAC Elements

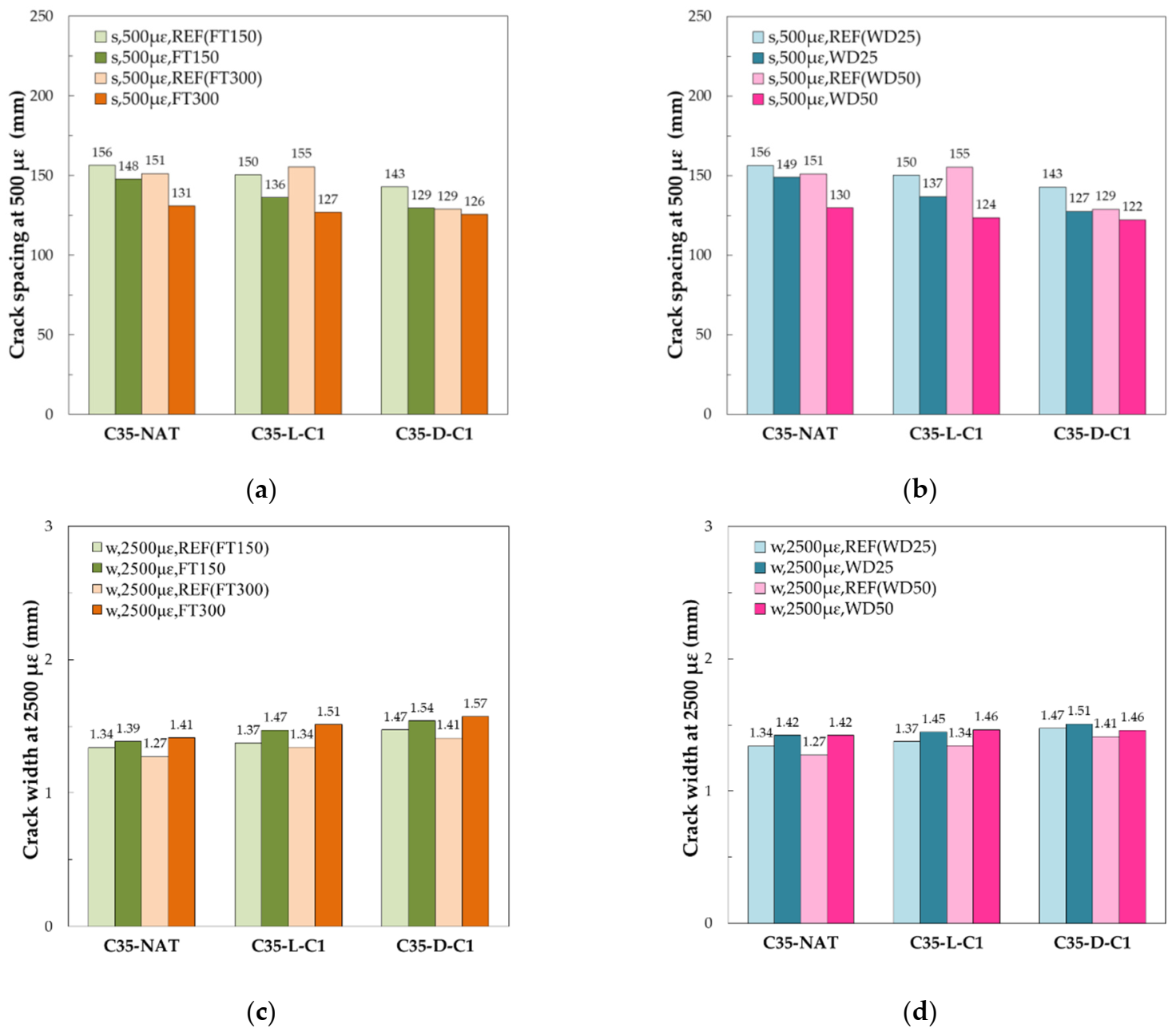

3.2. Effects of Freeze-Thaw and Wet-Dry Aging on Cracking Process of Reinforced RAC Elements

3.3. Effects of Freeze-Thaw and Wet-Dry Aging on Bond Behavior of Reinforced RAC Elements

4. Freeze-Thaw and Wet-Dry Degradation-Law for Reinforced RAC

5. Conclusions

- The degraded elements’ curves presented lower values of strength for both the multiple cracking phase and post cracking phase than the curves of the non-degraded elements. However, after degradation, all composites still present the standard behavior of the tension stiffening test, with the four well-defined phases;

- In the elastic phase, the results show that the presence of RCAs did not significantly influence the elastic modulus of non-degraded samples;

- Both elastic modulus and first crack strength were more impacted by the degradation processes in the concrete with the highest amount of attached mortar in its aggregate. This impact is caused by the greater flow of water and aggressive agents inside the concrete, provided by its greater porosity;

- All mixtures showed a reduction in the stress-strain performance of insulated concrete after degradation. Specifically, the attached mortar content also directly impacted the maximum strength of the concrete matrix;

- The presence of RCAs does not interfere with the cracking pattern of concrete submitted to the aging processes of this study. The spacing behavior was similar for reference and degraded samples. In general, the largest crack openings throughout the test were verified for samples subjected to higher levels of degradation;

- A degradation law relating the aging effect to the open porosity of concrete was developed for both degradation processes—freeze-thaw and wet-dry cycles. Regardless of the aggregate origin, for higher degradation degrees, the total mortar volume in the concrete is the main property for understanding the cycles effects on structural performance. The higher total mortar volume in the concrete composition (and, consequently, the higher concrete water absorption), the higher the impact that degradation will have on the following structural properties: pre-cracking elastic modulus, first crack composite strength, first crack matrix strength, final post-cracking matrix strength and, finally, steel-concrete bond strength;

- The feasibility of using recycled aggregates in structural elements exposed to aggressive external agents can be guaranteed as long as the open porosity is properly considered in the concrete mix-design: this is, certainly, possible if a fundamental characterization of the raw materials is performed (e.g., evaluation of the Attached Mortar content in RCA) and, moreover, a specific mixture proportioning method is used for the RAC (e.g., using the Compressible Packing Method proposed herein).

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Fiol, F.; Thomas, C.; Manso, J.M.; López, I. Influence of Recycled Precast Concrete Aggregate on Durability of Concrete’s Physical Processes. Appl. Sci. 2020, 10, 7348. [Google Scholar] [CrossRef]

- Barroqueiro, T.; da Silva, P.R.; de Brito, J. High-Performance Self-Compacting Concrete with Recycled Aggregates from the Precast Industry: Durability Assessment. Buildings 2020, 10, 113. [Google Scholar] [CrossRef]

- Liu, H.; Hua, M.; Zhu, P.; Chen, C.; Wang, X.; Qian, Z.; Dong, Y. Effect of Freeze–Thaw Cycles on Carbonation Behavior of Three Generations of Repeatedly Recycled Aggregate Concrete. Appl. Sci. 2021, 11, 2643. [Google Scholar] [CrossRef]

- Verian, K.P.; Ashraf, W.; Cao, Y. Properties of recycled concrete aggregate and their influence in new concrete production. Resour. Conserv. Recycl. 2018, 133, 30–49. [Google Scholar] [CrossRef]

- Ouyang, K.; Shi, C.; Chu, H.; Guo, H.; Song, B.; Ding, Y.; Guan, X.; Zhu, J.; Zhang, H.; Wang, Y.; et al. An overview on the efficiency of different pretreatment techniques for recycled concrete aggregate. J. Clean. Prod. 2020, 263. [Google Scholar] [CrossRef]

- Pani, L.; Francesconi, L.; Rombi, J.; Mistretta, F.; Sassu, M.; Stochino, F. Effect of Parent Concrete on the Performance of Recycled Aggregate Concrete. Sustainability 2020, 12, 9399. [Google Scholar] [CrossRef]

- Amario, M.; Rangel, C.S.; Pepe, M.; Toledo Filho, R.D. Optimization of normal and high strength recycled aggregate concrete mixtures by using packing model. Cem. Concr. Compos. 2017, 84, 83–92. [Google Scholar] [CrossRef]

- Muduli, R.; Mukharjee, B.B. Performance assessment of concrete incorporating recycled coarse aggregates and metakaolin: A systematic approach. Constr. Build. Mater. 2020, 233, 117223. [Google Scholar] [CrossRef]

- Sadati, S.; Khayat, K.H. Can Concrete Containing High-Volume Recycled Concrete Aggregate Be Durable? ACI Mater. J. 2018, 115, 471–480. [Google Scholar] [CrossRef]

- Shang, H.; Song, Y.; Ou, J. Behavior of air-entrained concrete after freeze-thaw cycles. Acta Mech. Solida Sin. 2009, 22, 261–266. [Google Scholar] [CrossRef]

- Liu, Y.; Chen, Y.F.; Wang, W.; Li, Z. Bond performance of thermal insulation concrete under freeze–thaw cycles. Constr. Build. Mater. 2016, 104, 116–125. [Google Scholar] [CrossRef]

- Liu, K.; Yan, J.; Meng, X.; Zou, C. Bond behavior between deformed steel bars and recycled aggregate concrete after freeze-thaw cycles. Constr. Build. Mater. 2020, 232, 117236. [Google Scholar] [CrossRef]

- Thomas, R.J.; Fellows, A.J.; Sorensen, A.D. Durability analysis of recycled asphalt pavement as partial coarse aggregate replacement in a high-strength concrete mixture. J. Mater. Civ. Eng. 2018, 30, 04018061. [Google Scholar] [CrossRef]

- Bassani, M.; Tefa, L. Compaction and freeze-thaw degradation assessment of recycled aggregates from unseparated construction and demolition waste. Constr. Build. Mater. 2018, 160, 180–195. [Google Scholar] [CrossRef]

- Kazmi, S.M.S.; Munir, M.J.; Wu, Y.F.; Patnaikuni, I.; Zhou, Y.; Xing, F. Effect of different aggregate treatment techniques on the freeze-thaw and sulfate resistance of recycled aggregate concrete. Cold Reg. Sci. Technol. 2020, 178, 103126. [Google Scholar] [CrossRef]

- Lu, C.; Zhou, Q.; Wang, W.; Wei, S.; Wang, C. Freeze-thaw resistance of recycled aggregate concrete damaged by simulated acid rain. J. Clean. Prod. 2021, 280, 124396. [Google Scholar] [CrossRef]

- Rangel, C.S.; Amario, M.; Pepe, M.; Martinelli, E.; Toledo Filho, R.D. Durability of Structural Recycled Aggregate Concrete Subjected to Freeze-Thaw Cycles. Sustainability 2020, 12, 6475. [Google Scholar] [CrossRef]

- Ren, G.; Shang, H.; Zhang, P.; Zhao, T. Bond behaviour of reinforced recycled concrete after rapid freezing-thawing cycles. Cold. Reg. Sci. Technol. 2019, 157, 133–138. [Google Scholar] [CrossRef]

- Shang, H.S.; Zhao, T.J.; Cao, W.Q. Bond behavior between steel bar and recycled aggregate concrete after freeze–thaw cycles. Cold. Reg. Sci. Technol. 2015, 118, 38–44. [Google Scholar] [CrossRef]

- Huaishuai, S.; Zhiheng, W.; Peng, Z.; Tiejun, Z.; Guoxi, F.; Guosheng, R. Bond behavior of steel bar in air-entrained RCAC in fresh water and sea water after fast freeze-thaw cycles. Cold. Reg. Sci. Technol. 2017, 135, 90–96. [Google Scholar] [CrossRef]

- Wu, Z.; Wong, H.S.; Buenfeld, N.R. Transport properties of concrete after drying-wetting regimes to elucidate the effects of moisture content, hysteresis and microcracking. Cem. Concr. Res. 2017, 98, 136–154. [Google Scholar] [CrossRef]

- Rangel, C.S.; Amario, M.; Pepe, M.; Martinelli, E.; Toledo Filho, R.D. Influence of Wetting and Drying Cycles on Physical and Mechanical Behavior of Recycled Aggregate Concrete. Materials 2020, 13, 5675. [Google Scholar] [CrossRef] [PubMed]

- Rangel, C.S.; Toledo Filho, R.D.; Amario, M.; Pepe, M.; de Castro Polisseni, G.; de Andrade, G.P. Generalized quality control parameter for heterogenous recycled concrete aggregates: A pilot scale case study. J. Clean. Prod. 2019, 208, 589–601. [Google Scholar] [CrossRef]

- ABNT NBR 16916. Fine Aggregate—Determination of Density and Water Absorption; Associação Brasileira de Normas Técnicas: Rio de Janeiro, Brazil, 2021. [Google Scholar]

- ABNT NBR NM 53. Coarse Aggregate—Determination of the Bulk Specific Gravity, Apparent Specific Gravity and Water Absorption; Associação Brasileira de Normas Técnicas: Rio de Janeiro, Brazil, 2009. [Google Scholar]

- ABNT NBR NM 51. Small-Size Coarse Aggregate—Test Method for Resistance to Degradation by Los Angeles Machine; Associação Brasileira de Normas Técnicas: Rio de Janeiro, Brazil, 2001. [Google Scholar]

- ABNT NBR 16697. Portland Cement—Requirements; Associação Brasileira de Normas Técnicas: Rio de Janeiro, Brazil, 2018. [Google Scholar]

- de Larrard, F. Concrete Mixture Proportioning: A Scientific Approach; Series: Modern Concrete Technology; CRC Press: London, UK, 1999. [Google Scholar]

- Pepe, M.; Toledo Filho, R.D.; Koenders, E.A.; Martinelli, E. A novel mix design methodology for Recycled Aggregate Concrete. Constr. Build. Mater. 2016, 122, 362–372. [Google Scholar] [CrossRef]

- Pepe, M.; Toledo Filho, R.D.; Koenders, E.A.; Martinelli, E. Alternative processing procedures for recycled aggregates in structural concrete. Constr. Build. Mater. 2014, 69, 124–132. [Google Scholar] [CrossRef]

- ABNT NBR 9778. Hardened Mortar and Concrete—Determination of Absorption, Voids and Specific Gravity; Associação Brasileira de Normas Técnicas: Rio de Janeiro, Brazil, 2009. [Google Scholar]

- ABNT NBR 5739. Concrete-Compression Test of Cylindrical Specimens; Associação Brasileira de Normas Técnicas: Rio de Janeiro, Brazil, 2018. [Google Scholar]

- ABNT NBR 8522. Concrete-Determination of Static Modulus of Elasticity and Deformation by Compression; Associação Brasileira de Normas Técnicas: Rio de Janeiro, Brazil, 2017. [Google Scholar]

- ABNT NBR 7222. Concrete and Mortar—Determination of the Tension Strength by Diametrical Compression of Cylindrical Test Specimens; Associação Brasileira de Normas Técnicas: Rio de Janeiro, Brazil, 2011. [Google Scholar]

- ABNT NBR 6892-1. Metallic Materials-Tensile Testing Part 1: Method of Test at Room Temperature; Associação Brasileira de Normas Técnicas: Rio de Janeiro, Brazil, 2018. [Google Scholar]

- Tam, V.W.; Gao, X.F.; Tam, C.M. Microstructural analysis of recycled aggregate concrete produced from two-stage mixing approach. Cem. Concr. Res. 2005, 35, 1195–1203. [Google Scholar] [CrossRef] [Green Version]

- Tam, V.W.; Tam, C.M. Assessment of durability of recycled aggregate concrete produced by two-stage mixing approach. J. Mater. Sci. 2007, 42, 3592–3602. [Google Scholar] [CrossRef] [Green Version]

- ASTM C666. Resistance of Concrete to Rapid Freezing and Thawing; American Society for Testing and Materials: West Conshohocken, PA, USA, 2008. [Google Scholar]

- ABNT NBR 13554. Soil-Cement—Durability Test by Wetting and Drying-Test Method; Associação Brasileira de Normas Técnicas: Rio de Janeiro, Brazil, 2012. [Google Scholar]

- ASTM D559. Standard Test Methods for Wetting and Drying Compacted Soil-Cement Mixtures; American Society for Testing and Material: West Conshohocken, PA, USA, 2015. [Google Scholar]

- ABNT NBR 7477. Determinação do Coeficiente de Conformação Superficial de Barras e Fios de aço Destinados à Armadura de Concreto Armado; Associação Brasileira de Normas Técnicas: São Paulo, Brazil, 1982. (In Portuguese) [Google Scholar]

- Rangel, C.S.; Amario, M.; Pepe, M.; Yao, Y.; Mobasher, B.; Toledo Filho, R.D. Tension stiffening approach for interface characterization in recycled aggregate concrete. Cem. Concr. Compos. 2017, 82, 176–189. [Google Scholar] [CrossRef]

- Soranakom, C.; Mobasher, B. Modeling of tension stiffening in reinforced cement composites: Part I. Theoretical modeling. Mater. Struct. 2010, 43, 1217–1230. [Google Scholar] [CrossRef]

- Aveston, J.; Cooper, G.A.; Kelly, A. The properties of fibre composites. In Conference Proceedings, National Physical Laboratory; IPC Science and Technology Press: Surrey, England, 1971; pp. 15–26. [Google Scholar]

| Properties | NFA | NCA_C0 | NCA_C1 | RCA_L_C1 | RCA_D_C1 |

|---|---|---|---|---|---|

| Dmax (mm) | 4.75 | 9.5 | 19.0 | 19.0 | 19.0 |

| Specific gravity (kg/m3) [24,25] | 2447 | 2662 | 2636 | 2105 | 2255 |

| Water absorption (%) [24,25] | 0.5 | 1.5 | 1.3 | 8.2 | 6.1 |

| Attached Mortar—VAM (%) [23] | - | - | - | 64.8 | 35.1 |

| Abrasion wear (%) [26] | - | 39.5 | 36.1 | 46.7 | 46.3 |

| Mixtures | C35-NAT | C35-L-C1 | C35-D-C1 | |

|---|---|---|---|---|

| Materials (kg/m3) | NCA_C1 | 452 | 0 | 0 |

| RCA_L_C1 | 0 | 361 | 0 | |

| RCA_D_C1 | 0 | 0 | 384 | |

| NCA_C0 | 457 | 456 | 453 | |

| NFA | 868 | 867 | 862 | |

| Cement | 325 | 336 | 341 | |

| SP | 1.86 | 1.92 | 1.95 | |

| Effective water | 196 | 191 | 194 | |

| Total water | 212 | 216 | 216 | |

| Mixture parameters | Effective w/c | 0.60 | 0.57 | 0.57 |

| Total mortar volume (%)—VM,tot | 65.5 | 77.6 | 73.1 | |

| 28-days properties | Water absorption (%) [31]—wopen | 3.0 | 3.9 | 3.5 |

| fc,28 (MPa) [32] | 34.2 | 35.3 | 33.5 | |

| Ec,28 (GPa) [33] | 21.3 | 21.2 | 20.9 | |

| ft,28 (MPa) [34] | 2.7 | 2.9 | 2.6 |

| Mixtures | ID | Pre-Cracking Phase | Post-Cracking Phase | Isolated Matrix | ||||

|---|---|---|---|---|---|---|---|---|

| Epre (GPa) | f1st (MPa) | ε1st (με) | εfinal (με) | Epost (GPa) | fm,1st (MPa) | fm,final (MPa) | ||

| C35-NAT | REF(FT150) | 25.8 (2.0) | 2.54 (1.6) | 89 (1.0) | 486 (11.0) | 2.71 (1.6) | 2.34 (1.8) | 1.40 (1.7) |

| FT150 | 24.2 (1.1) | 2.41 (0.6) | 90 (0.6) | 432 (4.5) | 2.65 (4.1) | 2.20 (0.8) | 1.24 (2.0) | |

| REF(FT300) | 26.3 (1.0) | 2.70 (1.7) | 93 (2.3) | 467 (6.2) | 2.67 (1.8) | 2.48 (1.7) | 1.40 (4.2) | |

| FT300 | 22.2 (4.4) | 2.34 (0.8) | 96 (4.4) | 491 (6.3) | 2.72 (3.0) | 2.11 (0.9) | 1.13 (6.9) | |

| C35-L-C1 | REF(FT150) | 26.1 (0.3) | 2.88 (0.9) | 99 (1.1) | 469 (12.3) | 2.48 (4.2) | 2.65 (0.9) | 1.57 (6.4) |

| FT150 | 24.6 (1.0) | 2.69 (0.9) | 99 (1.9) | 470 (4.2) | 2.65 (3.6) | 2.46 (0.6) | 1.29 (2.9) | |

| REF(FT300) | 26.7 (2.4) | 2.98 (0.4) | 101 (2.9) | 517 (6.1) | 2.67 (1.8) | 2.76 (0.4) | 1.59 (2.4) | |

| FT300 | 20.8 (2.4) | 2.44 (0.8) | 106 (2.3) | 540 (9.5) | 2.54 (3.5) | 2.19 (0.9) | 1.07 (8.5) | |

| C35-D-C1 | REF(FT150) | 25.5 (2.7) | 2.71 (2.2) | 96 (0.7) | 480 (4.7) | 2.49 (4.0) | 2.49 (2.4) | 1.54 (2.0) |

| FT150 | 24.1 (1.1) | 2.58 (1.6) | 97 (0.9) | 458 (3.7) | 2.81 (1.7) | 2.35 (1.7) | 1.29 (2.1) | |

| REF(FT300) | 26.5 (4.0) | 2.80 (0.7) | 95 (3.5) | 507 (11.7) | 2.63 (5.6) | 2.58 (1.0) | 1.61 (6.9) | |

| FT300 | 21.7 (2.8) | 2.36 (1.8) | 98 (3.7) | 456 (10.9) | 2.67 (1.6) | 2.12 (1.8) | 1.13 (2.1) | |

| Mixtures | ID | Pre-Cracking Phase | Post-Cracking Phase | Isolated Matrix | ||||

|---|---|---|---|---|---|---|---|---|

| Epre (GPa) | f1st (MPa) | ε1st (με) | εfinal (με) | Epost (GPa) | fm,1st (MPa) | fm,final (MPa) | ||

| C35-NAT | REF(WD25) | 25.8 (2.0) | 2.54 (1.6) | 89 (1.0) | 486 (11.0) | 2.71 (1.6) | 2.34 (1.8) | 1.40 (1.7) |

| WD25 | 25.0 (1.4) | 2.49 (1.3) | 90 (2.6) | 466 (6.8) | 2.59 (2.9) | 2.28 (1.2) | 1.31 (3.2) | |

| REF(WD50) | 26.3 (1.0) | 2.70 (1.7) | 93 (2.3) | 467 (6.2) | 2.67 (1.8) | 2.48 (1.7) | 1.40 (4.2) | |

| WD50 | 23.5 (2.5) | 2.44 (2.7) | 94 (0.6) | 479 (7.7) | 2.69 (5.2) | 2.22 (2.9) | 1.23 (3.9) | |

| C35-L-C1 | REF(WD25) | 26.1 (0.3) | 2.88 (0.9) | 99 (1.1) | 469 (12.3) | 2.48 (4.2) | 2.65 (0.9) | 1.57 (6.4) |

| WD25 | 24.7 (0.7) | 2.74 (0.6) | 100 (1.2) | 507 (8.0) | 2.76 (3.7) | 2.51 (0.6) | 1.37 (7.6) | |

| REF(WD50) | 26.7 (2.4) | 2.98 (0.4) | 101 (2.9) | 517 (6.1) | 2.67 (1.8) | 2.76 (0.4) | 1.59 (2.4) | |

| WD50 | 22.3 (2.6) | 2.54 (3.9) | 103 (6.0) | 481 (4.1) | 2.62 (8.1) | 2.30 (4.3) | 1.19 (2.5) | |

| C35-D-C1 | REF(WD25) | 25.5 (2.7) | 2.71 (2.2) | 96 (0.7) | 480 (4.7) | 2.49 (4.0) | 2.49 (2.4) | 1.54 (2.0) |

| WD25 | 24.4 (1.8) | 2.62 (2.7) | 97 (4.5) | 494 (5.2) | 2.67 (2.5) | 2.40 (2.6) | 1.37 (7.5) | |

| REF(WD50) | 26.5 (4.0) | 2.80 (0.7) | 95 (3.5) | 507 (11.7) | 2.63 (5.6) | 2.58 (1.0) | 1.61 (6.9) | |

| WD50 | 23.1 (0.5) | 2.48 (1.7) | 97 (2.2) | 454 (3.4) | 2.83 (3.1) | 2.25 (1.6) | 1.26 (2.8) | |

| Mixtures | ID | τb (MPa) | ID | τb (MPa) |

|---|---|---|---|---|

| C35-NAT | REF(FT150) | 17.4 | REF(WD25) | 17.4 |

| FT150 | 16.5 | WD25 | 16.7 | |

| REF(FT300) | 17.9 | REF(WD50) | 17.9 | |

| FT300 | 16.0 | WD50 | 16.5 | |

| C35-L-C1 | REF(FT150) | 16.1 | REF(WD25) | 16.1 |

| FT150 | 15.2 | WD25 | 15.3 | |

| REF(FT300) | 16.6 | REF(WD50) | 16.6 | |

| FT300 | 14.1 | WD50 | 14.7 | |

| C35-D-C1 | REF(FT150) | 16.7 | REF(WD25) | 16.7 |

| FT150 | 15.7 | WD25 | 16.0 | |

| REF(FT300) | 17.1 | REF(WD50) | 17.1 | |

| FT300 | 14.7 | WD50 | 15.2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Santana Rangel, C.; Pepe, M.; Amario, M.; Menegatti, L.C.; Martinelli, E.; Toledo Filho, R.D. Effects of Freeze-Thaw and Wet-Dry Cycles on Tension Stiffening Behavior of Reinforced RAC Elements. Appl. Sci. 2021, 11, 10063. https://doi.org/10.3390/app112110063

Santana Rangel C, Pepe M, Amario M, Menegatti LC, Martinelli E, Toledo Filho RD. Effects of Freeze-Thaw and Wet-Dry Cycles on Tension Stiffening Behavior of Reinforced RAC Elements. Applied Sciences. 2021; 11(21):10063. https://doi.org/10.3390/app112110063

Chicago/Turabian StyleSantana Rangel, Caroline, Marco Pepe, Mayara Amario, Lucas Caon Menegatti, Enzo Martinelli, and Romildo Dias Toledo Filho. 2021. "Effects of Freeze-Thaw and Wet-Dry Cycles on Tension Stiffening Behavior of Reinforced RAC Elements" Applied Sciences 11, no. 21: 10063. https://doi.org/10.3390/app112110063