Performance Improvement of Microchannel Heat Exchangers with Modified Louver Fins under Frosting Conditions

Abstract

:1. Introduction

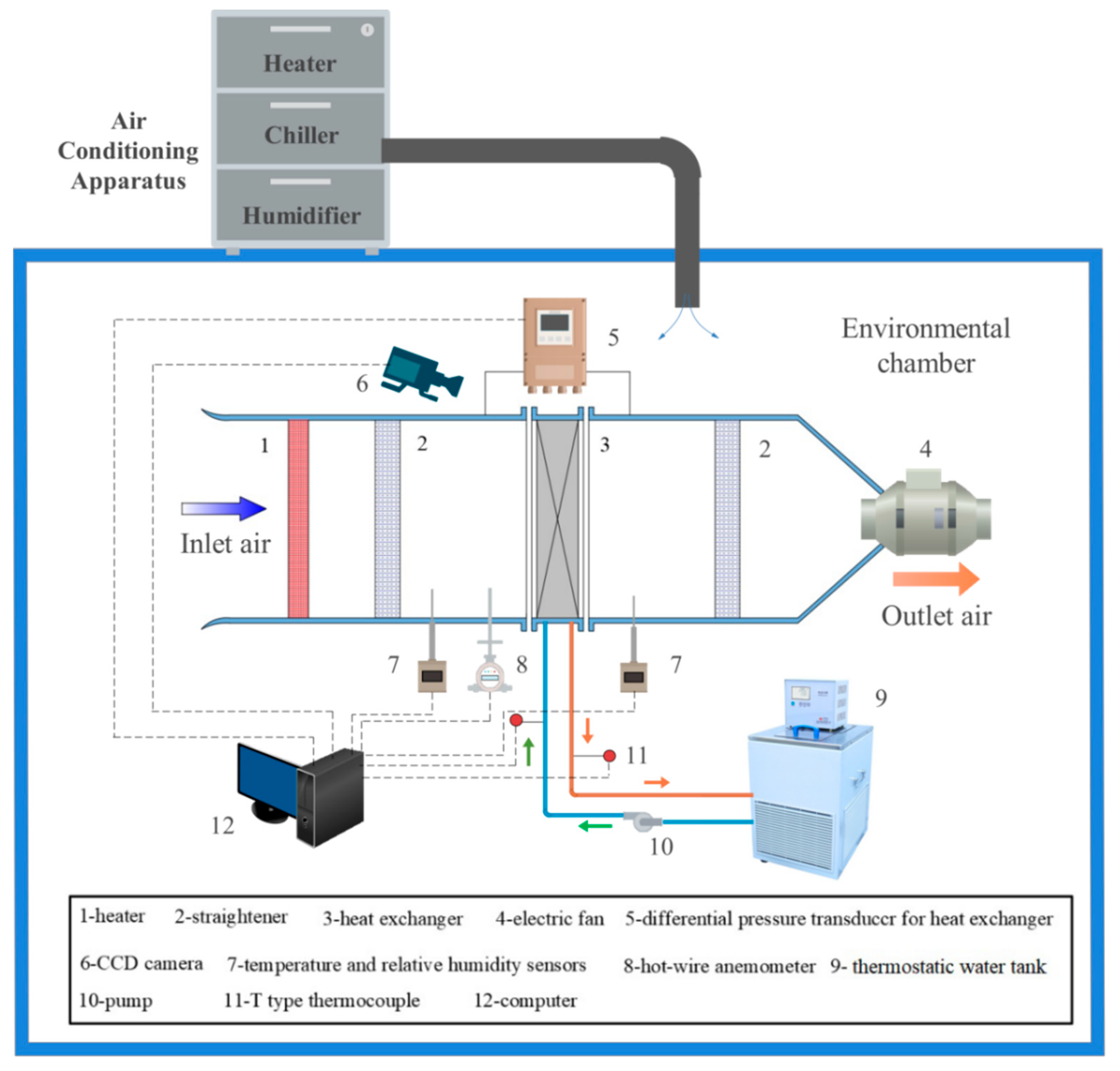

2. Experimental Setup and Measurement

2.1. Testing Setup Description

2.2. Data Reduction

2.3. Uncertainty Analysis

3. Results and Discussion

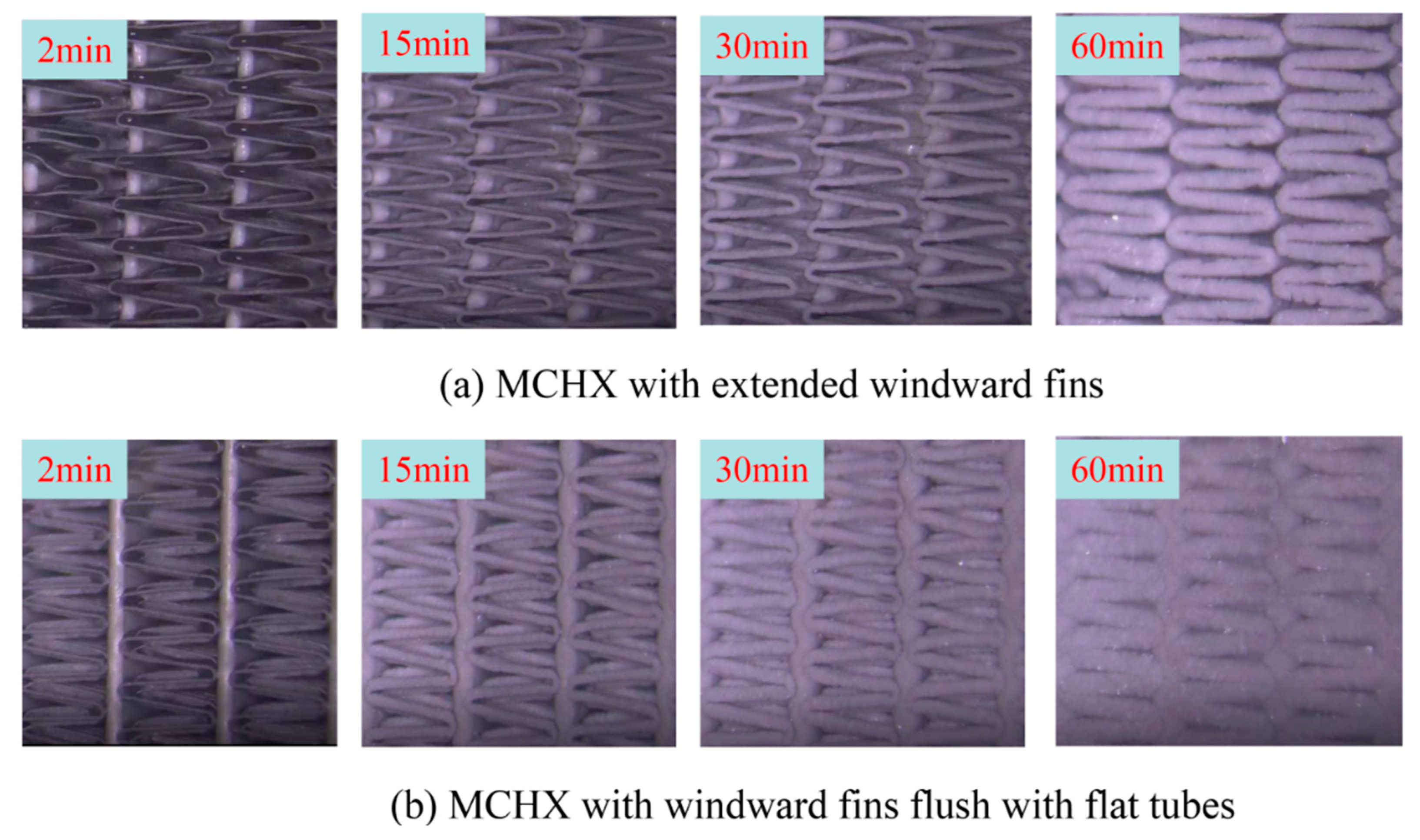

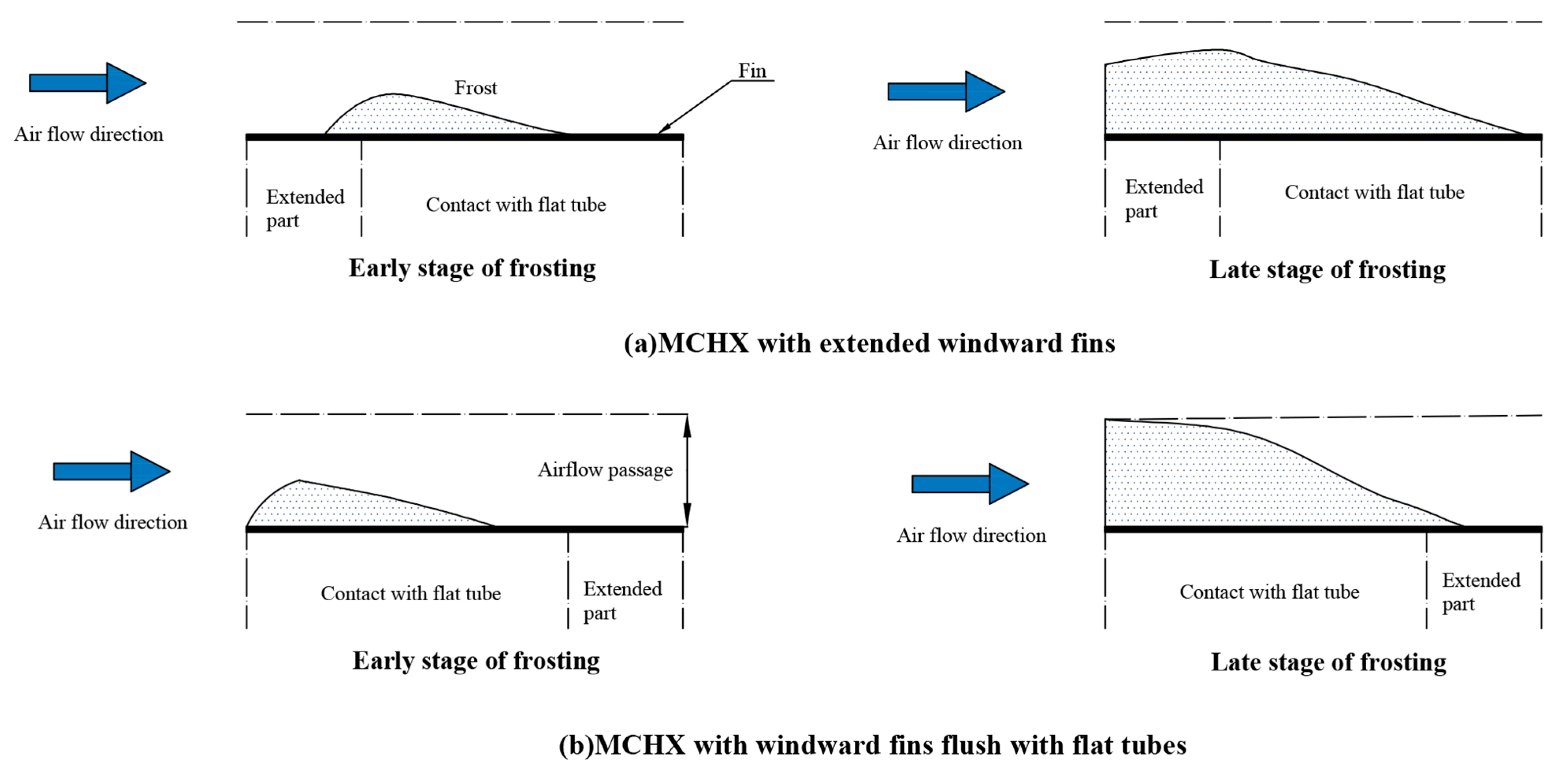

3.1. Frost Growth Behavior Analysis

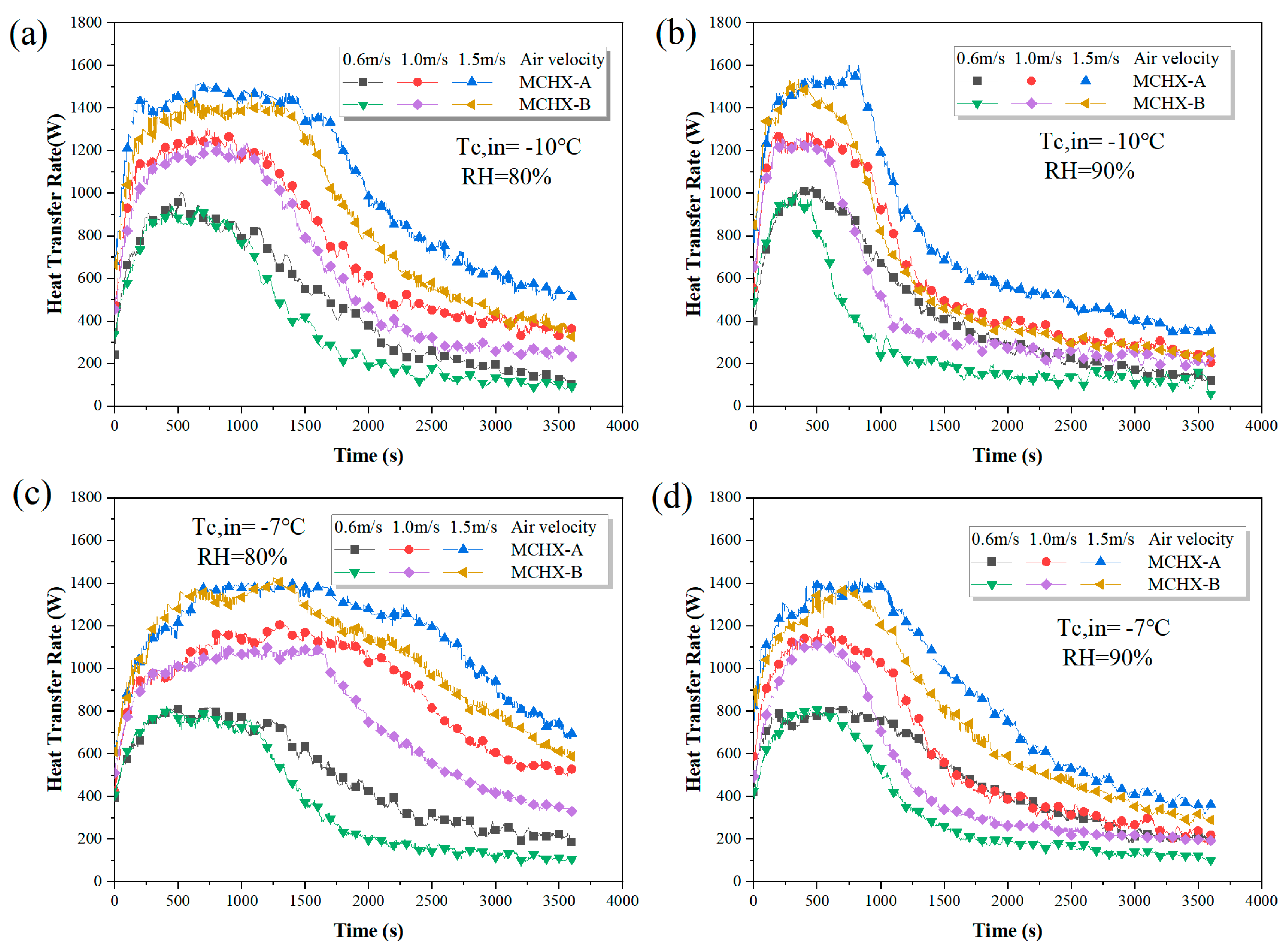

3.2. Heat Transfer Analysis

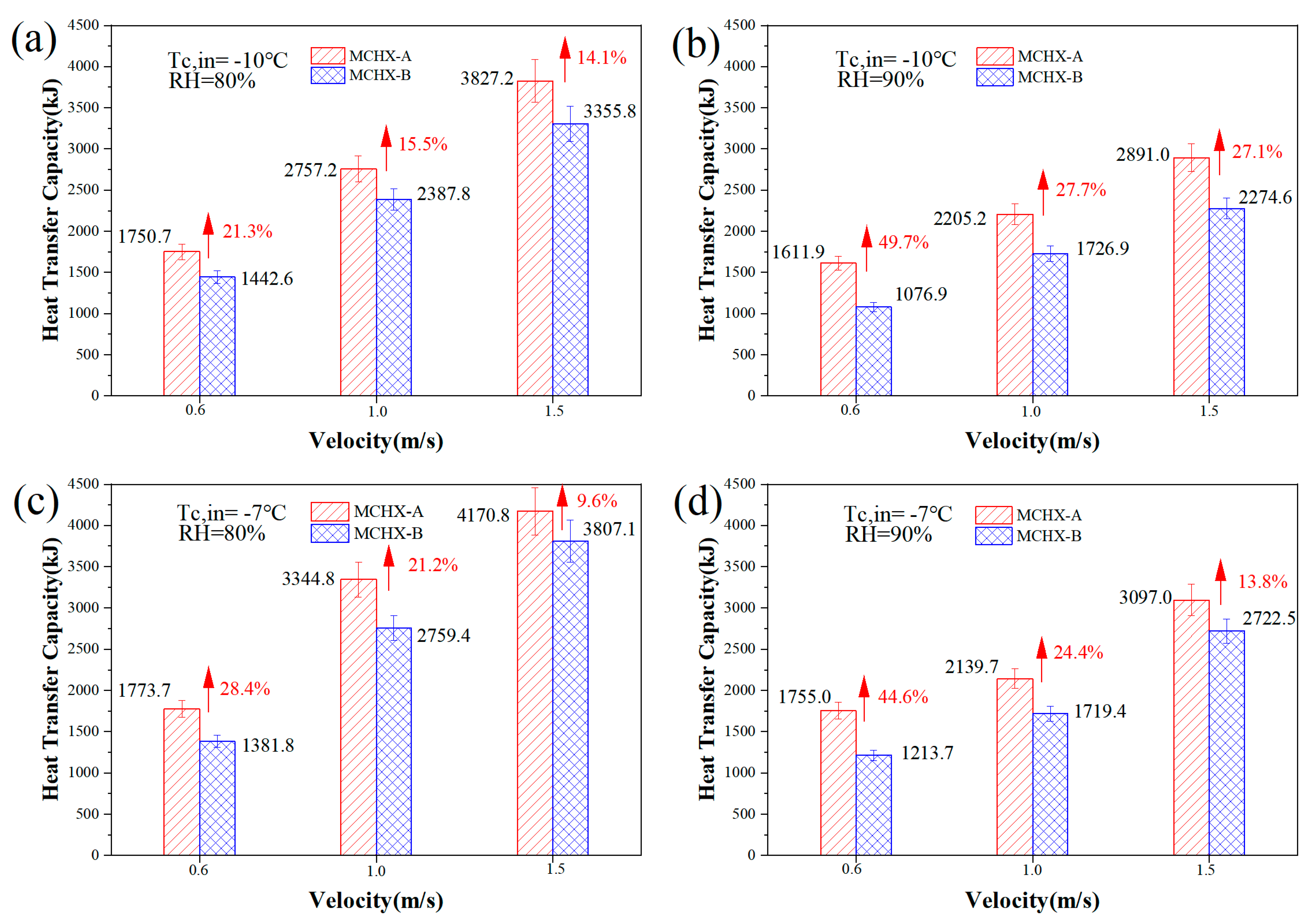

3.3. Analysis of Frost Growth Rate

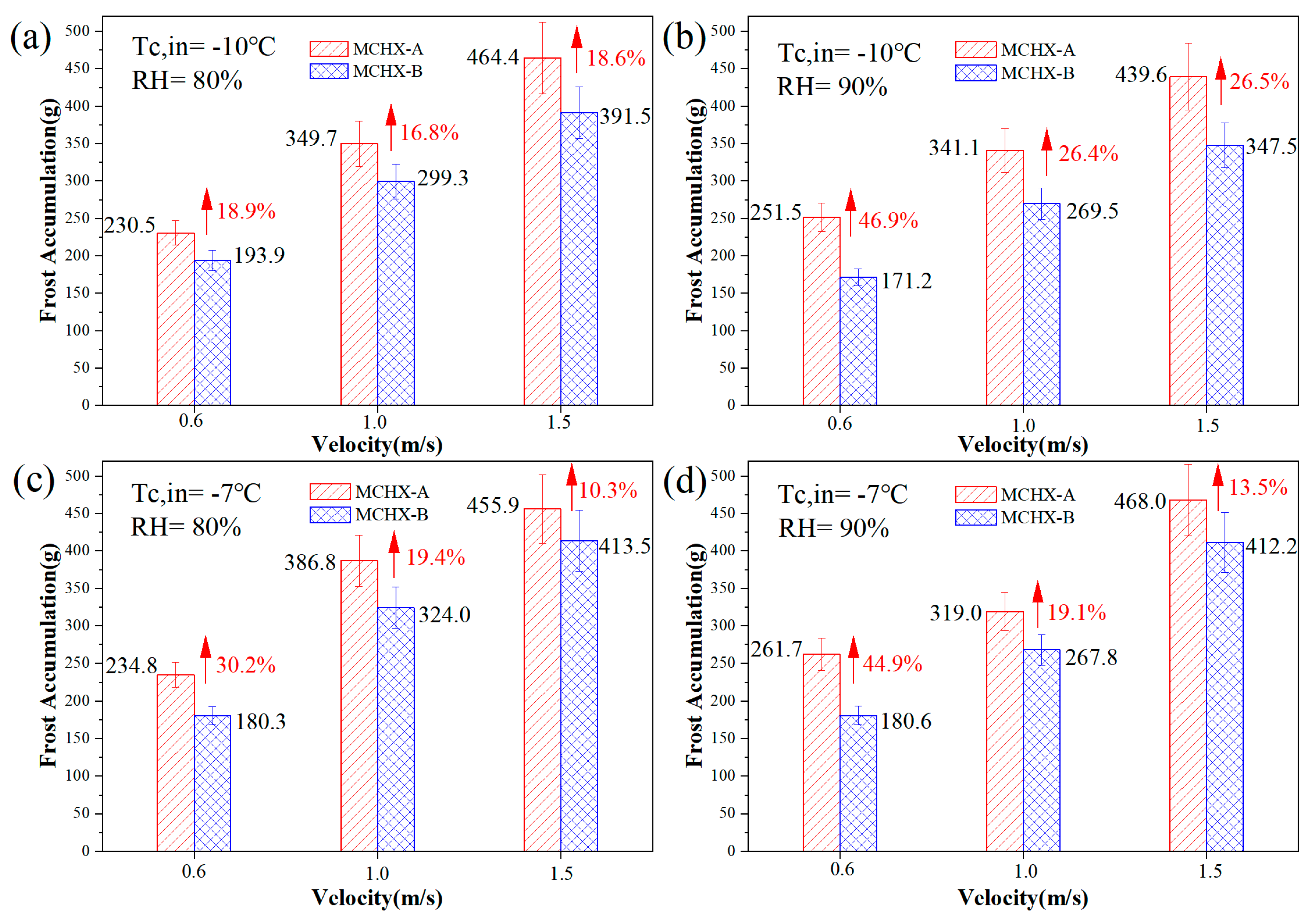

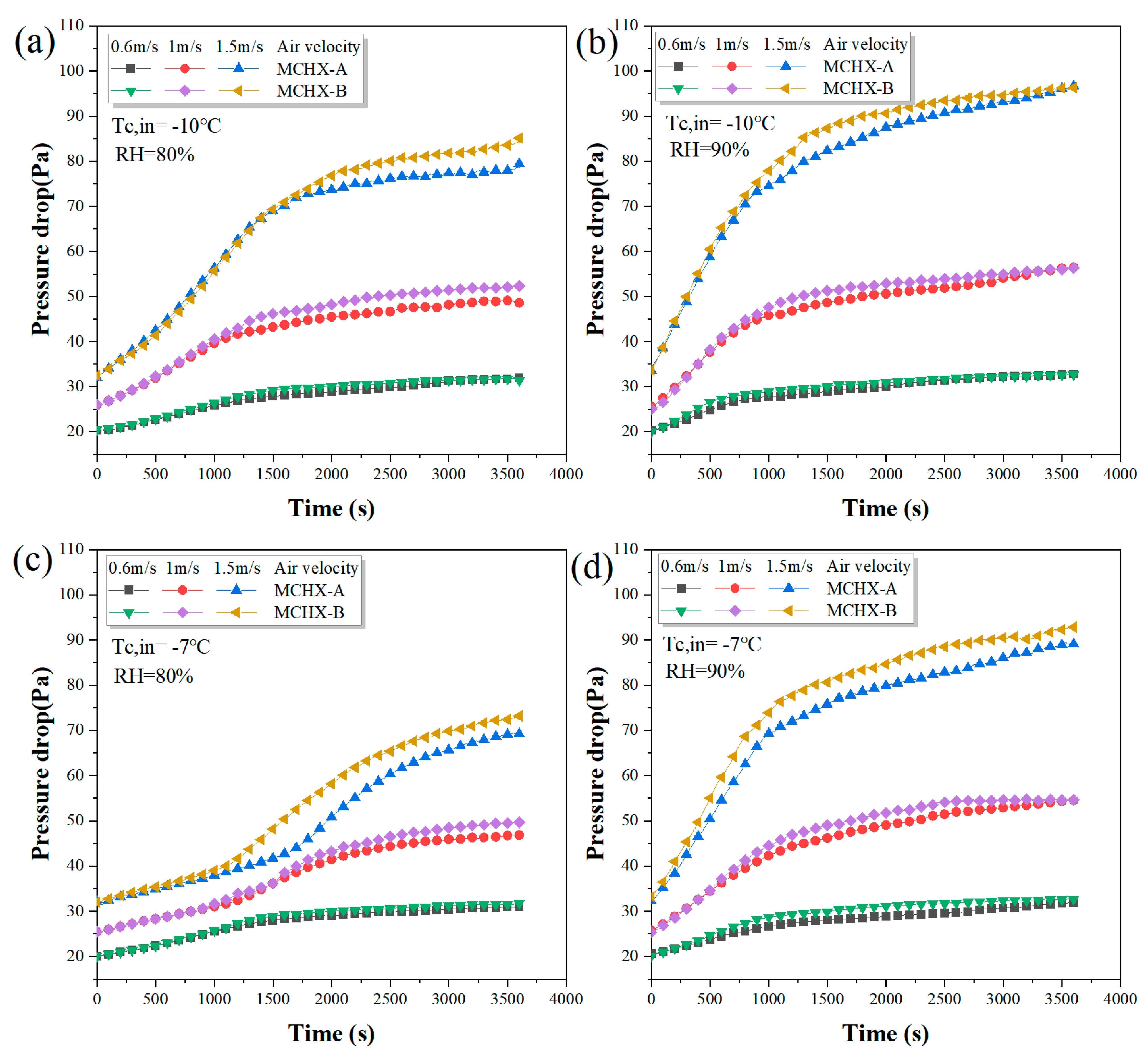

3.4. Pressure Drop Analysis

4. Conclusions

- (1)

- Frost is mainly deposited on the windward side of the heat exchanger. Extending the length of windward fins can effectively capture a large amount of frost and make the frost distribution more uniform, thus inhibiting rapid frost blocking on the front side.

- (2)

- In the early stage of frosting, frost mainly grows in the area where the fin and the flat tube are in contact because of the lower surface temperature. As the frost progresses, the extended fins on the windward side begin to capture the frost. Therefore, the heat transfer rate of the MCHX-A is nearly the same as that of the MCHX-B at the early frosting stage, and the former shows better heat transfer performance than the latter as the frost progresses.

- (3)

- During the 60 min frosting cycle, the total heat transfer capacity and the mass of frost of the MCHX-A are 9.6–49.7% and 10.3–46.9% higher than the MCHX-B, respectively. In addition, the pressure drop of MCHX-B is larger than that of MCHX-A under all frosting conditions. This is mainly because the extended fins on the windward side capture a large amount of frost, which reduces the airflow attenuation rate and increases the heat transfer rate and frost accumulation rate of the heat exchanger.

- (4)

- The MCHX-A has greater potential to improve the thermal-hydraulic performance of MCHX at lower air velocity (0.6 m/s), where the frost layer distribution is more uneven. With the increase of air velocity, the frost layer uniformity is improved, and the proportion of MCHX-A improving heat transfer performance decreases gradually. In addition, as the inlet coolant temperature and RH change to promote frost layer growth, the potential of MCHX-A to improve heat transfer capacity increases. In conclusion, the more uneven the frost layer distribution, the greater the potential of MCHX-A to improve the heat transfer performance.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Khan, M.G.; Fartaj, A. A review on microchannel heat exchangers and potential applications. Int. J. Energy Res. 2011, 35, 553–582. [Google Scholar] [CrossRef]

- Dash, B.; Nanda, J.; Rout, S.K. The role of microchannel geometry selection on heat transfer enhancement in heat sinks: A review. Heat Transf. 2021, 51, 1406–1424. [Google Scholar] [CrossRef]

- Wang, Y.; Zong, S.; Song, Y.; Cao, F.; He, Y.; Gao, Q. Experimental and techno-economic analysis of transcritical CO2 heat pump water heater with fin-and-tube and microchannel heat exchanger. Appl. Therm. Eng. 2021, 199, 117606. [Google Scholar] [CrossRef]

- Shen, B.; Fricke, B. Development of high efficiency window air conditioner using propane under limited charge. Appl. Therm. Eng. 2020, 166, 114662. [Google Scholar] [CrossRef]

- Illán-Gómez, F.; García-Cascales, J.R.; Hidalgo-Mompeán, F.; López-Belchí, A. Experimental assessment of the replacement of a conventional fin-and-tube condenser by a minichannel heat exchanger in an air/water chiller for residential air conditioning. Energy Build. 2017, 144, 104–116. [Google Scholar] [CrossRef]

- Padhmanabhan, S.; Cremaschi, L.; Fisher, D. Comparison of Frost and Defrost Performance between Microchannel Coil and Fin-and-Tube Coil for Heat Pump Systems. Int. J. Air-Cond. Refrig. 2012, 19, 273–284. [Google Scholar] [CrossRef]

- Shao, L.-L.; Yang, L.; Zhang, C.-L. Comparison of heat pump performance using fin-and-tube and microchannel heat exchangers under frost conditions. Appl. Energy 2010, 87, 1187–1197. [Google Scholar] [CrossRef]

- Brignoli, R.; Cecchinato, L.; Zilio, C. Experimental analysis of an air–water heat pump with micro-channel heat exchanger. Appl. Therm. Eng. 2013, 50, 1119–1130. [Google Scholar] [CrossRef]

- Song, M.; Deng, S.; Dang, C.; Mao, N.; Wang, Z. Review on improvement for air source heat pump units during frosting and defrosting. Appl. Energy 2018, 211, 1150–1170. [Google Scholar] [CrossRef]

- Zhou, C.; Ye, S.; Ni, L.; Yao, Y. A review of heat pump research in China using bibliometric methods. J. Renew. Sustain. Energy 2022, 14, 012701. [Google Scholar] [CrossRef]

- Yang, S.; Wu, C.; Zhao, G.; Sun, J.; Yao, X.; Ma, X.; Wang, Z. Condensation frosting and passive anti-frosting. Cell Rep. Phys. Sci. 2021, 2, 100474. [Google Scholar] [CrossRef]

- Sheng, W.; Li, X.; Wang, R.; Dang, C.; Song, M. Condensate drainage on slit or louvered fins in microchannel heat exchangers for anti-frosting. Energy Build. 2020, 223, 110215. [Google Scholar] [CrossRef]

- Li, K.; Xia, D.; Luo, S.; Zhao, Y.; Tu, R.; Zhou, X.; Zhang, H.; Su, L. An experimental investigation on the frosting and defrosting process of an outdoor heat exchanger in an air conditioning heat pump system for electric vehicles. Appl. Therm. Eng. 2022, 201, 117766. [Google Scholar] [CrossRef]

- Moallem, E.; Hong, T.; Cremaschi, L.; Fisher, D.E. Experimental investigation of adverse effect of frost formation on microchannel evaporators, part 1: Effect of fin geometry and environmental effects. Int. J. Refrig. 2013, 36, 1762–1775. [Google Scholar] [CrossRef]

- Hu, Y.; Yuill, D.P.; Ebrahimifakhar, A. The effects of outdoor air-side fouling on frost growth and heat transfer characteristics of a microchannel heat exchanger: An experimental study. Int. J. Heat Mass Transf. 2020, 151, 119423. [Google Scholar] [CrossRef]

- Xia, Y.; Zhong, Y.; Hrnjak, P.S.; Jacobi, A.M. Frost, defrost, and refrost and its impact on the air-side thermal-hydraulic performance of louvered-fin, flat-tube heat exchangers. Int. J. Refrig. 2006, 29, 1066–1079. [Google Scholar] [CrossRef]

- Xiong, T.; Ying, Y.; Han, B.; Yan, G.; Yu, J. Comparison of energy supplies and consumptions in heat pump systems using finned tube and microchannel heat exchangers during defrosting. Int. J. Refrig. 2021, 132, 222–232. [Google Scholar] [CrossRef]

- Hrnjak, P.; Zhang, P.; Rennels, C. Effect of louver angle on performance of heat exchanger with serpentine fins and flat tubes in frosting: Importance of experiments in periodic frosting. Int. J. Refrig. 2017, 84, 321–335. [Google Scholar] [CrossRef]

- Xu, B.; Han, Q.; Chen, J.; Li, F.; Wang, N.; Li, D.; Pan, X. Experimental investigation of frost and defrost performance of microchannel heat exchangers for heat pump systems. Appl. Energy 2013, 103, 180–188. [Google Scholar] [CrossRef]

- Zhang, P.; Hrnjak, P.S. Effect of some geometric parameters on performance of PF2 heat exchangers in periodic frosting. Int. J. Refrig. 2010, 33, 334–346. [Google Scholar] [CrossRef]

- Kim, M.-H.; Kim, H.; Kim, D.R.; Lee, K.-S. A novel louvered fin design to enhance thermal and drainage performances during periodic frosting/defrosting conditions. Energy Convers. Manag. 2016, 110, 494–500. [Google Scholar] [CrossRef]

- Xu, B.; Zhang, C.; Wang, Y.; Chen, J.; Xu, K.; Li, F.; Wang, N. Experimental investigation of the performance of microchannel heat exchangers with a new type of fin under wet and frosting conditions. Appl. Therm. Eng. 2015, 89, 444–458. [Google Scholar] [CrossRef]

- Park, J.-S.; Kim, D.R.; Lee, K.-S. Frosting behaviors and thermal performance of louvered fins with unequal louver pitch. Int. J. Heat Mass Transf. 2016, 95, 499–505. [Google Scholar] [CrossRef]

- Hu, W.; Fan, J.; Song, M.; Jia, P.; Gao, Y. An experimental study on the frosting characteristic and performance of a micro-channel evaporator in an air source heat pump unit. Energy Build. 2020, 224, 110254. [Google Scholar] [CrossRef]

- Hong, S.H.; Jang, D.S.; Yun, S.; Baek, J.H.; Kim, Y. Performance improvement of heat pumps using novel microchannel heat exchangers with plain-louver fins during periodic frosting and defrosting cycles in electric vehicles. Energy Convers. Manag. 2020, 223, 113306. [Google Scholar] [CrossRef]

- Zhang, L.; Jiang, Y.; Dong, J.; Yao, Y.; Deng, S. An experimental study of frost distribution and growth on finned tube heat exchangers used in air source heat pump units. Appl. Therm. Eng. 2018, 132, 38–51. [Google Scholar] [CrossRef]

- Kim, K.; Kim, D.R.; Lee, K.-S. Local frosting behavior of a plated-fin and tube heat exchanger according to the refrigerant flow direction and surface treatment. Int. J. Heat Mass Transf. 2013, 64, 751–758. [Google Scholar] [CrossRef]

- Park, J.-S.; Kim, D.R.; Lee, K.-S. Local frost behaviors of a scaled-up louvered fin heat exchanger. Int. J. Heat Mass Transf. 2015, 89, 1127–1134. [Google Scholar] [CrossRef]

- Park, J.-S.; Byun, S.; Kim, D.R.; Lee, K.-S. Frost behavior of a louvered fin heat exchanger with vortex-generating fins. Int. J. Heat Mass Transf. 2017, 114, 590–596. [Google Scholar] [CrossRef]

- Kim, K.; Kim, M.-H.; Kim, D.R.; Lee, K.-S. Thermal performance of microchannel heat exchangers according to the design parameters under the frosting conditions. Int. J. Heat Mass Transf. 2014, 71, 626–632. [Google Scholar] [CrossRef]

- Qasem, N.A.A.; Zubair, S.M. Compact and microchannel heat exchangers: A comprehensive review of air-side friction factor and heat transfer correlations. Energy Convers. Manag. 2018, 173, 555–601. [Google Scholar] [CrossRef]

- Pu, L.; Liu, R.; Huang, H.; Zhang, S.; Qi, Z.; Xu, W.; Zhou, J. Experimental study of cyclic frosting and defrosting on microchannel heat exchangers with different coatings. Energy Build. 2020, 226, 110382. [Google Scholar] [CrossRef]

- Moffat, R.J. Describing the Uncertainties in Experimental Results. Exp. Therm. Fluid Sci. 1988, 1, 3–17. [Google Scholar] [CrossRef]

| Component | Specifications | |

|---|---|---|

| MCHX | Vertical height (H): 437 mm | Horizontal length (L): 408 mm |

| Fin height (S): 8.1 mm | Fin thickness: 0.1 mm | |

| Flat tube width (W): 20.6 mm | Louver angle (): 40° | |

| Louver pitch ():1.8 mm | Flat tube thickness: 1.3 mm | |

| Louver number: 10 | Fin pitch (): 1.7 mm | |

| Number of flat tubes: 34 Fin depth (): 25.4 mm | Extension length (P): 4 mm | |

| Parameters | Range |

|---|---|

| Ambient air temperature | 2 °C |

| RH | 80% and 90% |

| Inlet coolant temperature | −7 °C and −10 °C |

| Frontal air velocity | 0.6 m/s, 1 m/s, and 1.5 m/s |

| Instrument Name | Rang | Accuracy |

|---|---|---|

| T type thermocouple | −200–350 °C | ±0.5 °C |

| Hot-wire anemometer | 0–99 | ±0.1 |

| Air pressure transmitter | 0–200 Pa | ±0.4 Pa |

| Air temperature sensor | −40–80 °C | ±0.5 °C |

| Humidity transmitter | 0%~100% RH | ±2% RH |

| Parameter | Relative Uncertainty |

|---|---|

| Pressure drops | ±0.4%–±1.3% |

| Frost formation rate | ±6.6%–±9.8% |

| Heat transfer rate | ±5.2%–±6.9% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xiong, T.; Liu, G.; Yan, G. Performance Improvement of Microchannel Heat Exchangers with Modified Louver Fins under Frosting Conditions. Appl. Sci. 2023, 13, 6378. https://doi.org/10.3390/app13116378

Xiong T, Liu G, Yan G. Performance Improvement of Microchannel Heat Exchangers with Modified Louver Fins under Frosting Conditions. Applied Sciences. 2023; 13(11):6378. https://doi.org/10.3390/app13116378

Chicago/Turabian StyleXiong, Tong, Guoqiang Liu, and Gang Yan. 2023. "Performance Improvement of Microchannel Heat Exchangers with Modified Louver Fins under Frosting Conditions" Applied Sciences 13, no. 11: 6378. https://doi.org/10.3390/app13116378