Hybrid Rocket Engine Noise: Measurements and Predictions of Acoustic Environments from Horizontal Static Fire

Abstract

:1. Introduction

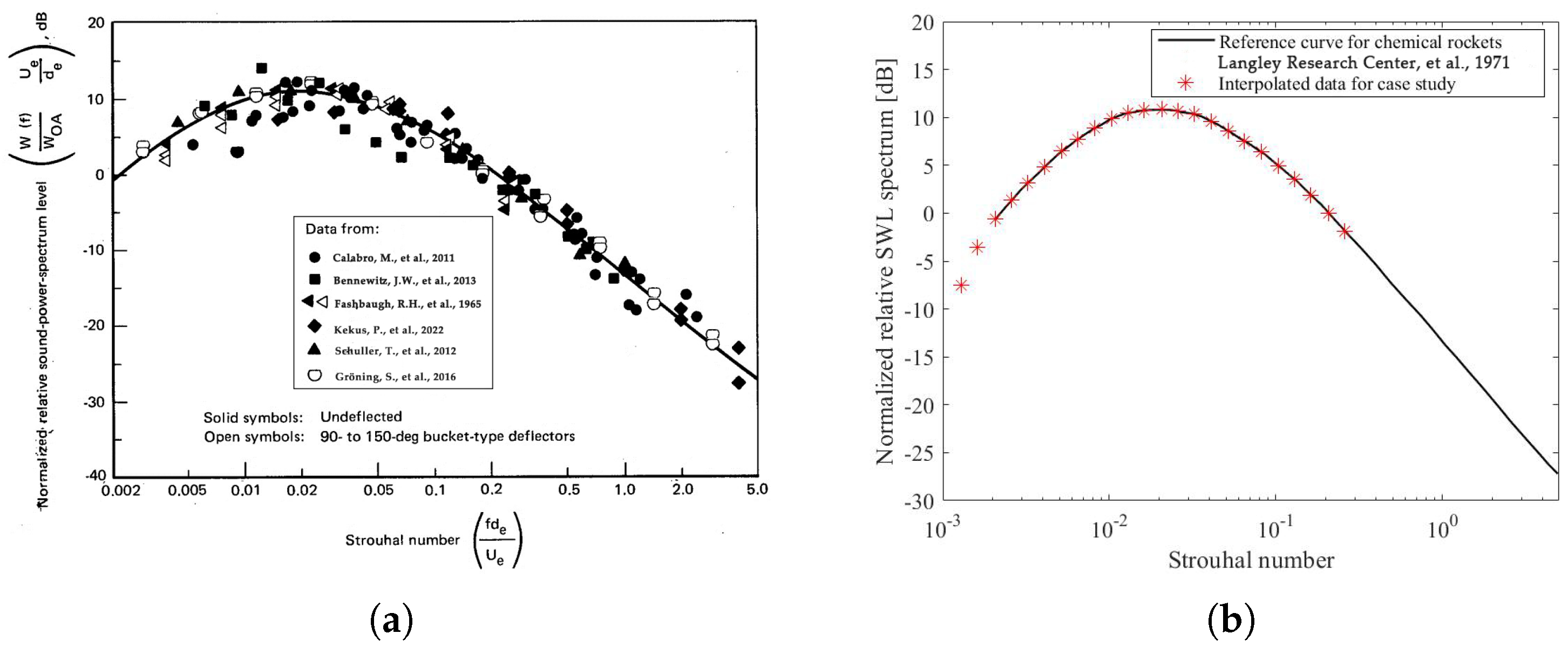

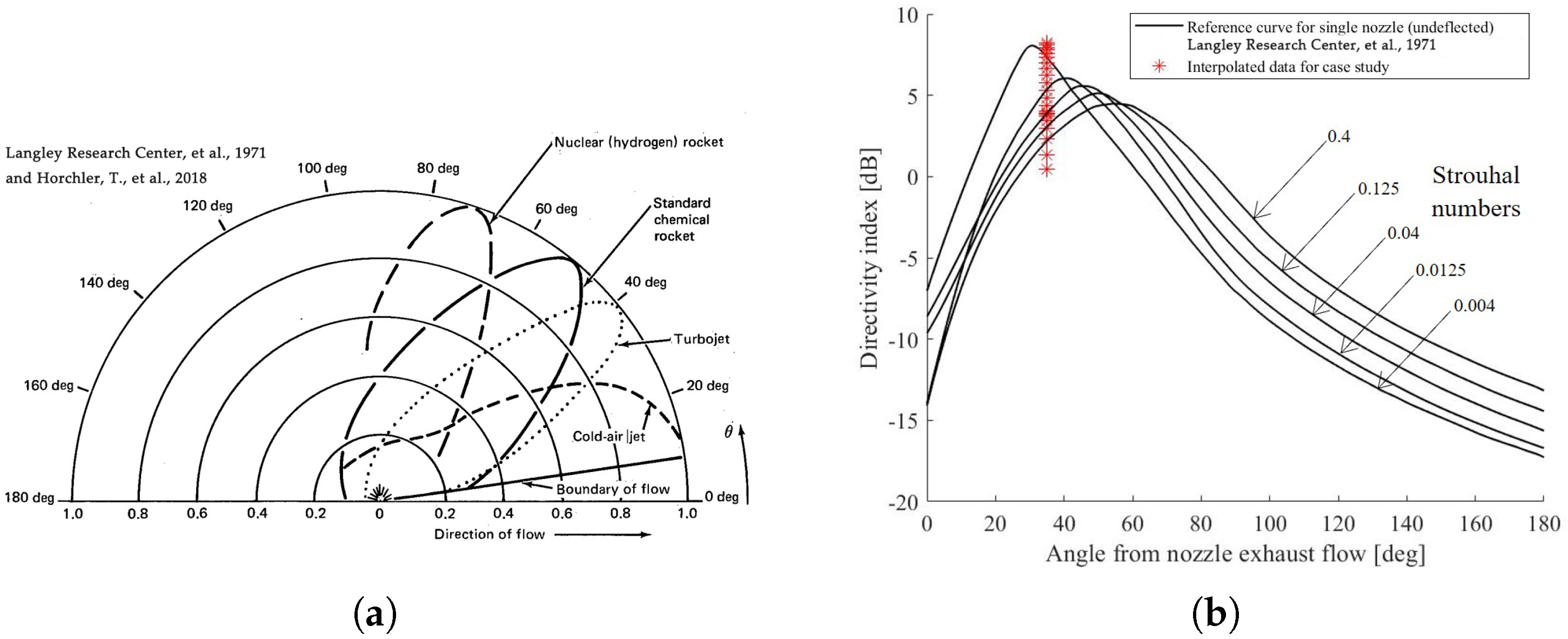

2. Jet Noise Prediction Model

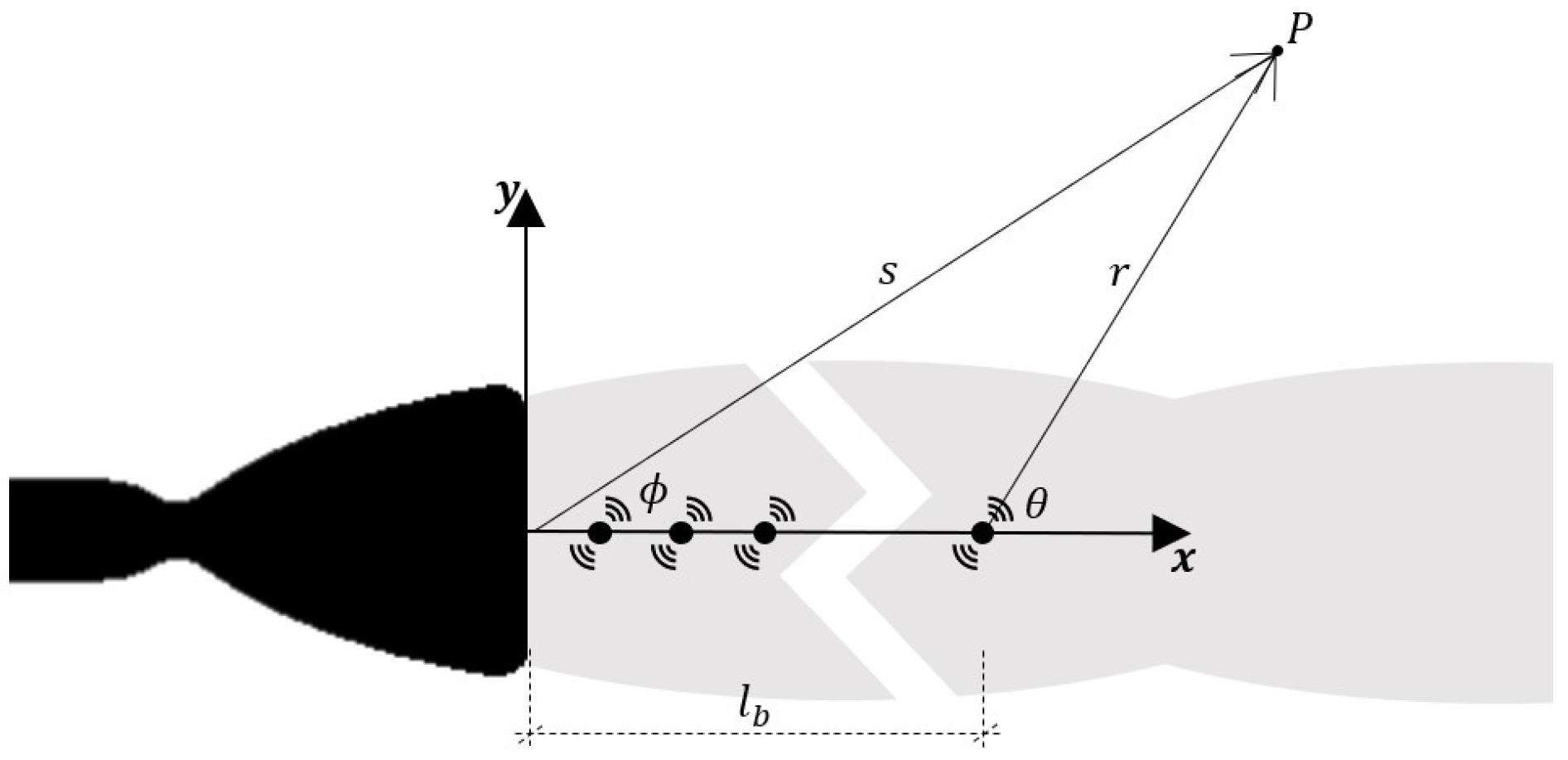

Distribution Source Method

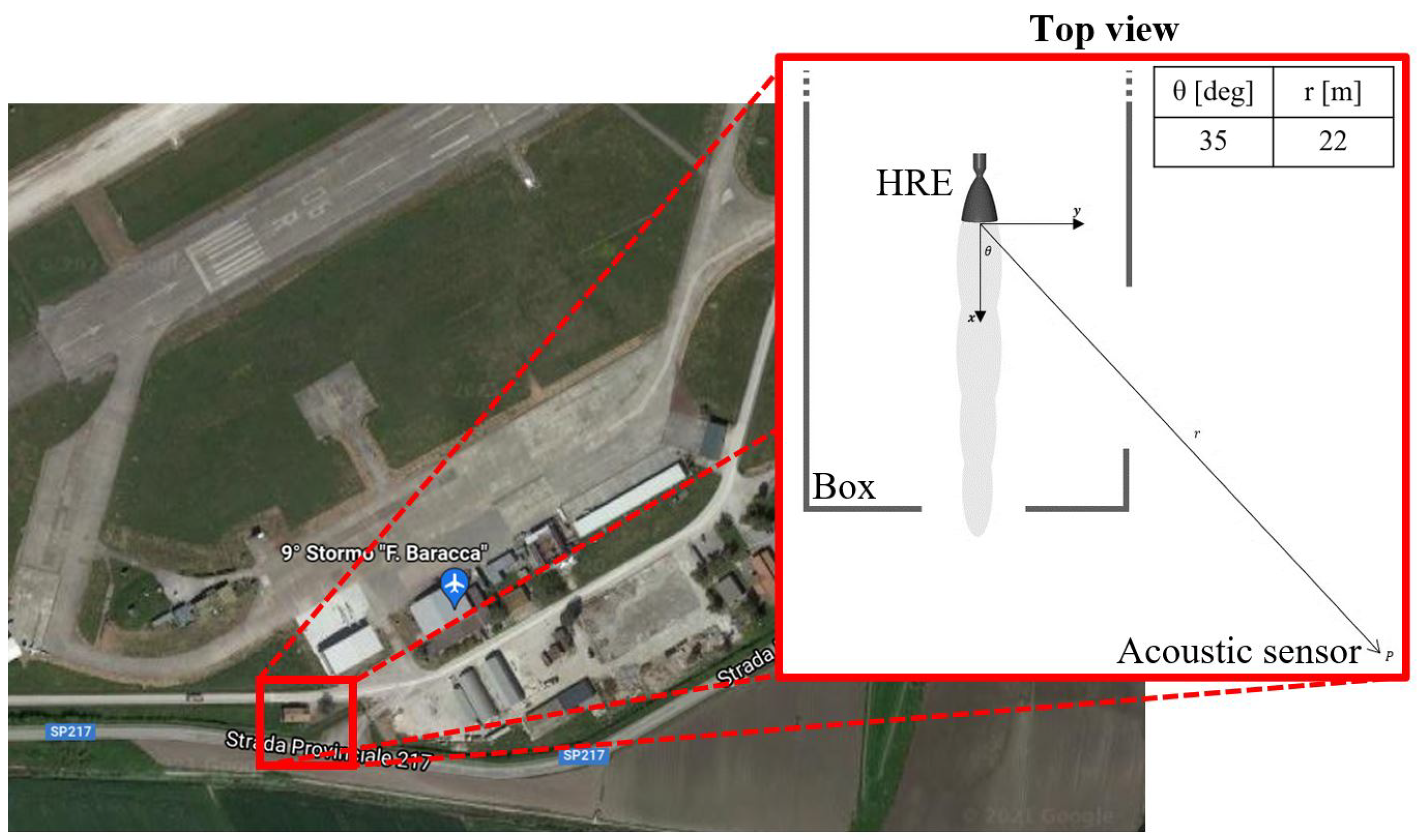

3. Experimental Activity and Results

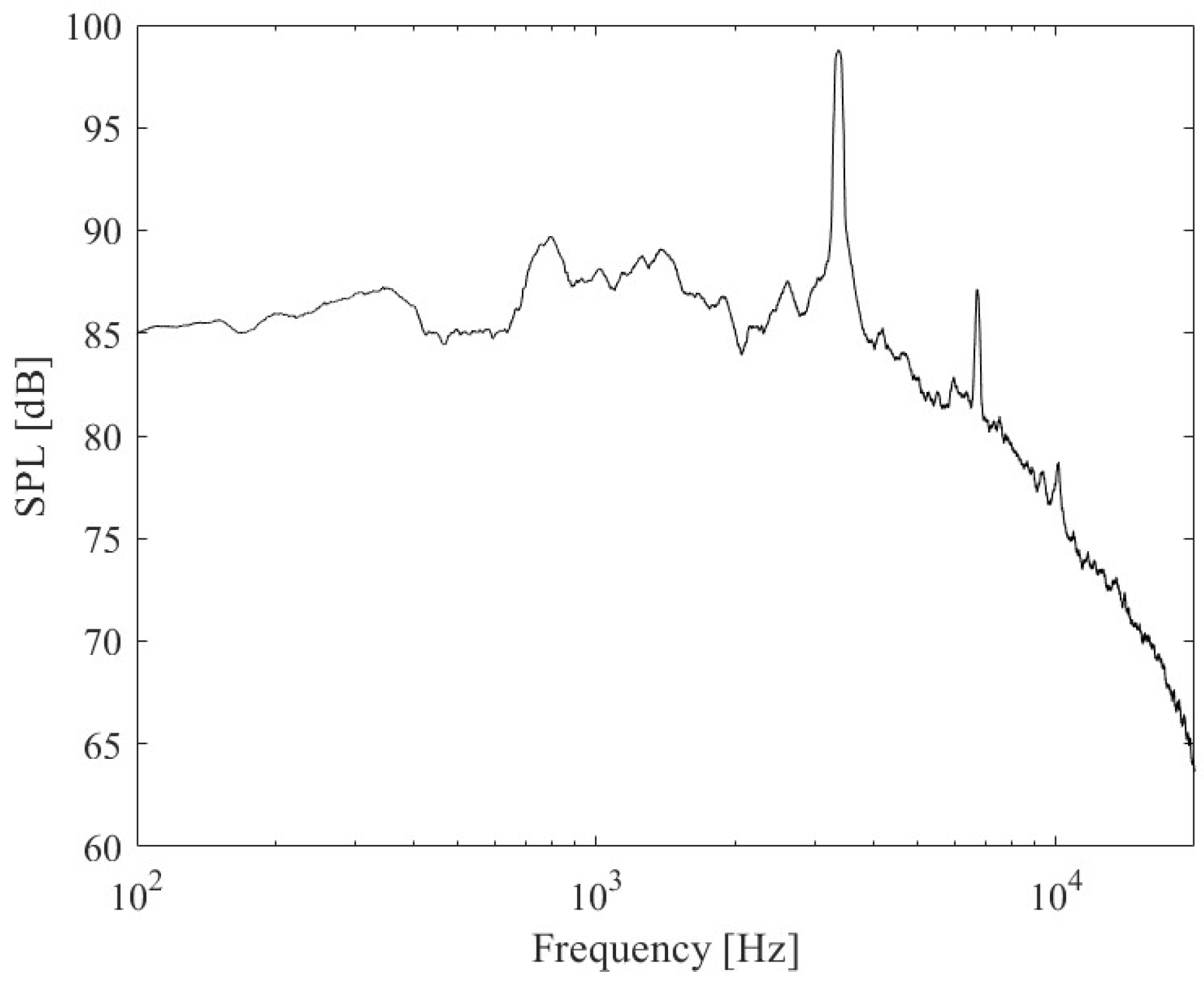

3.1. Analytical Acoustic Analysis of Combustion and Post-Combustion Chambers

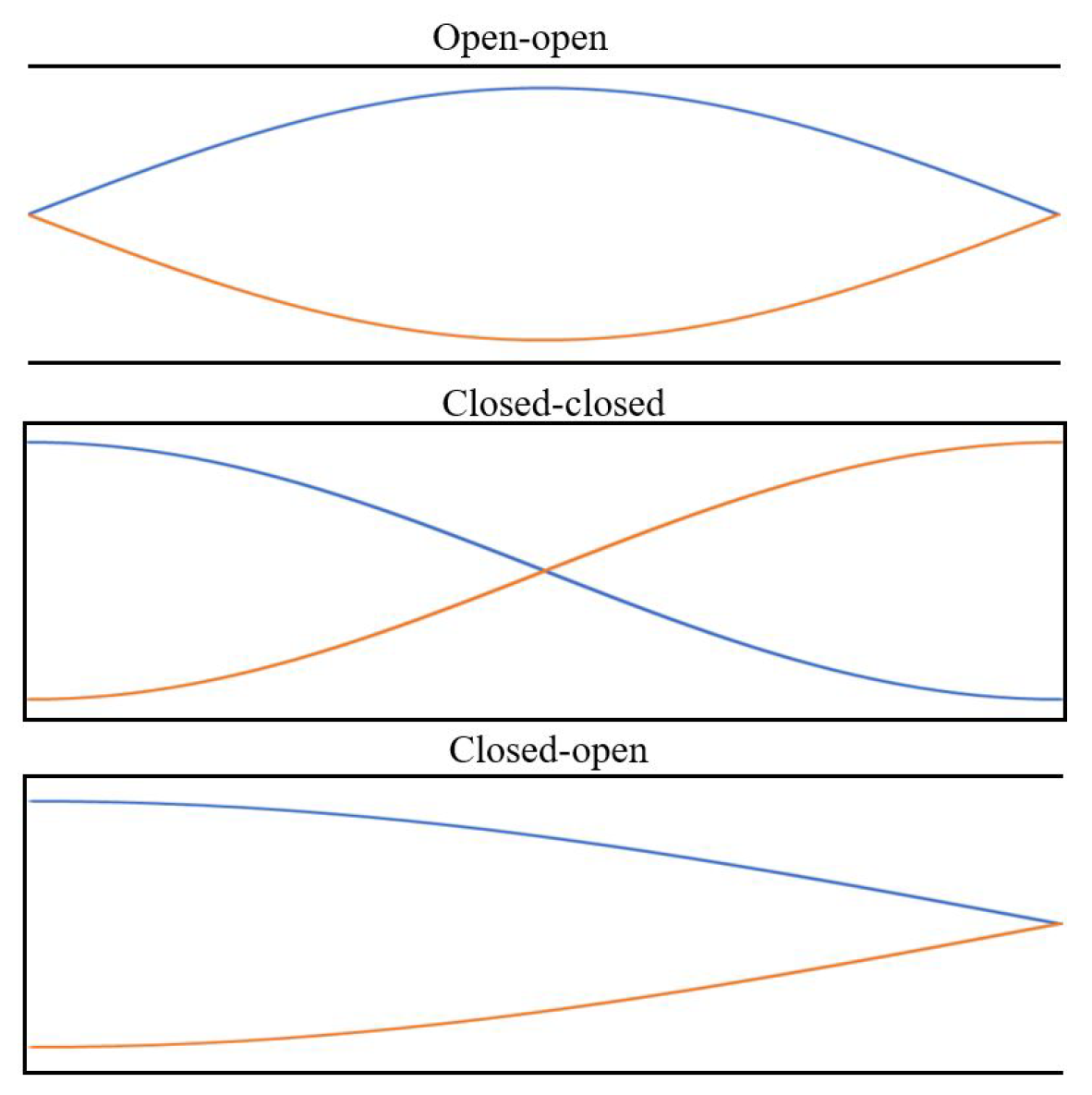

- The first post-combustion chamber longitudinal mode closed–open with the third combustion chamber longitudinal mode closed–open;

- The first post-combustion chamber longitudinal mode closed–closed with the fifth combustion chamber longitudinal mode open–open;

- The second post-combustion chamber longitudinal mode closed–open with the eighth combustion chamber longitudinal mode closed–open;

- The second post-combustion chamber longitudinal mode closed–closed with the tenth combustion chamber longitudinal mode open–open.

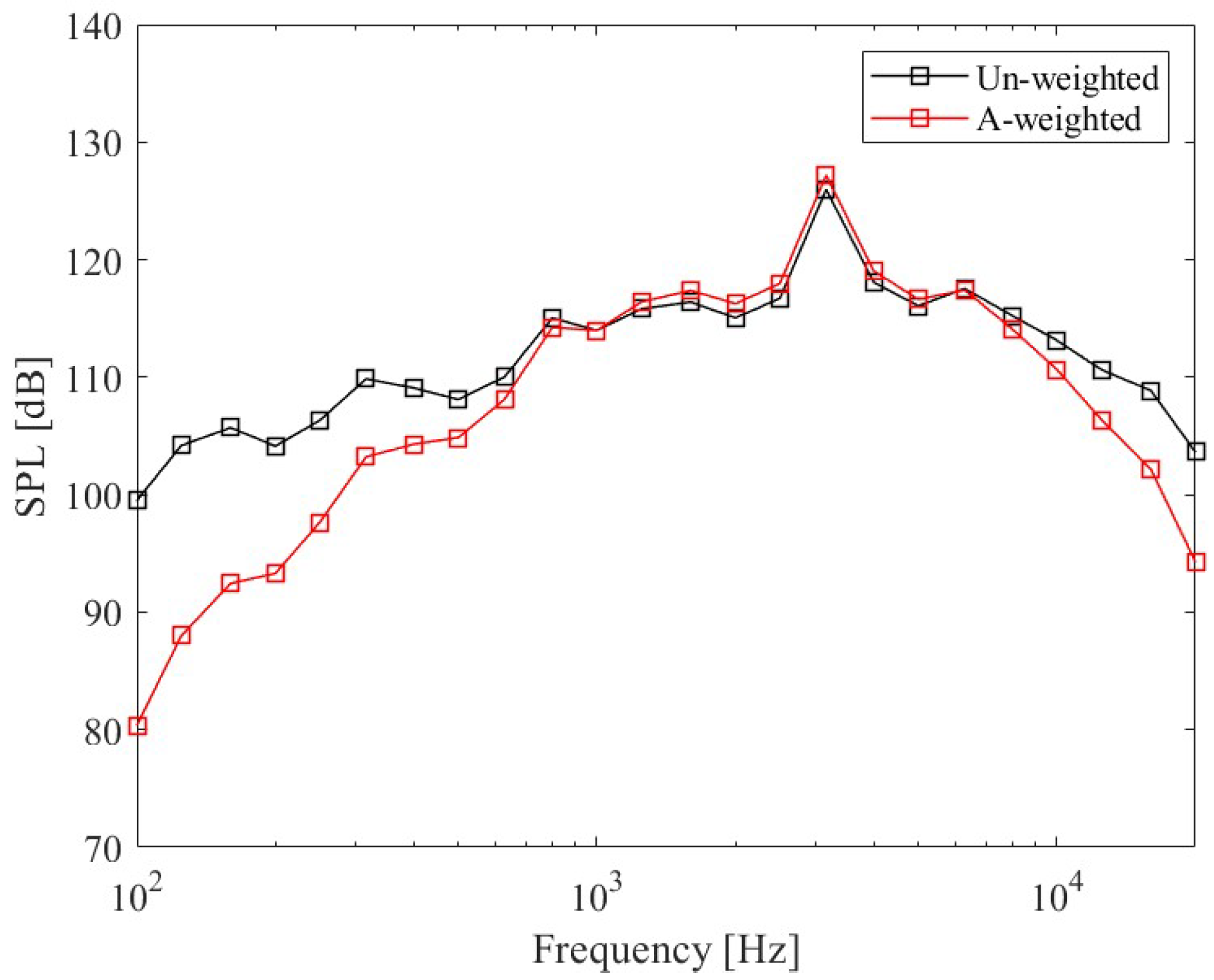

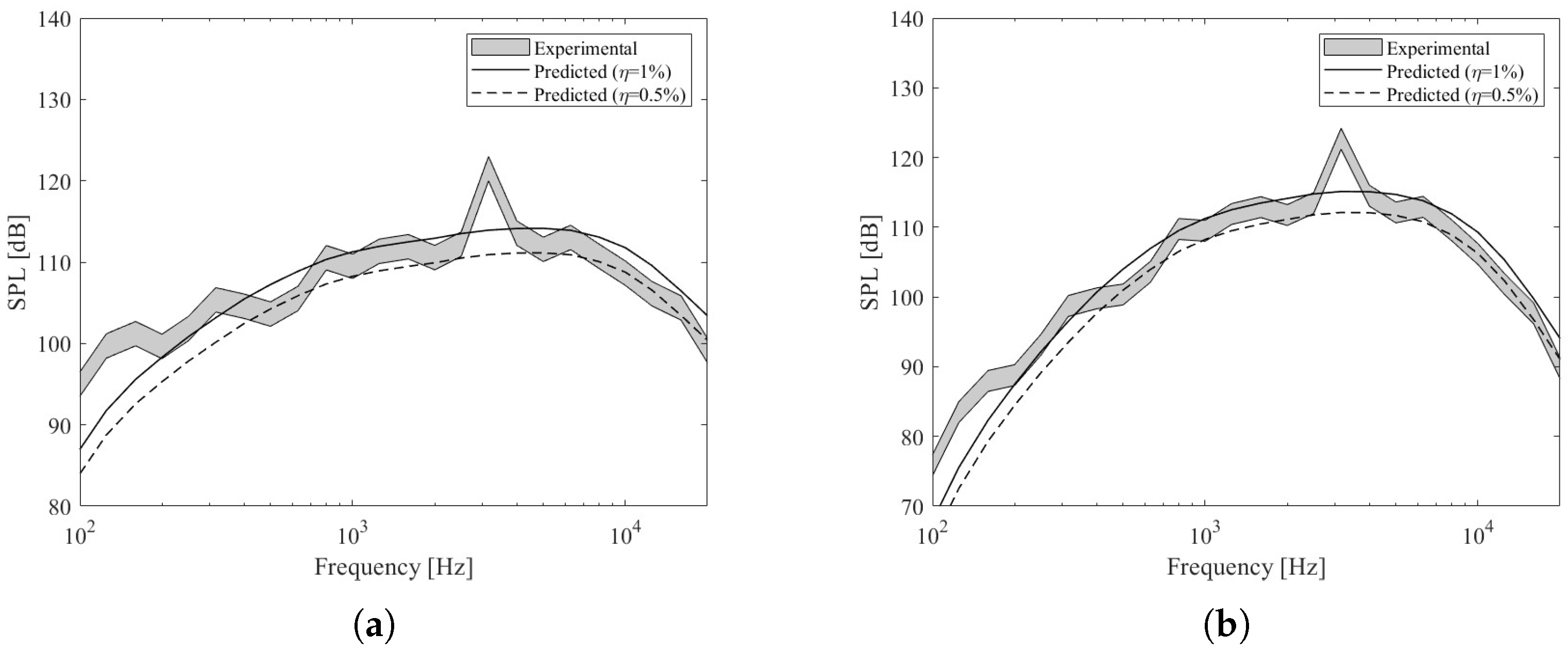

3.2. Eldred Model Results

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| DNS | Direct Navier–Stokes |

| LES | Large Eddy Simulation |

| RANS | Reynolds Averaged Navier–Stokes |

| CFD | Computational Fluid dynamics |

| CIRA | Italian Aerospace Research Centre |

| HRE | Hybrid Rocket Engine |

| DSM | Distribution Source Method |

| SPL | Sound Pressure Level |

| OASPL | Overall Sound Pressure Level |

| DI | Directivity Index |

| FEM | Finite Element Method |

References

- Tam, C.K. Supersonic jet noise. Annu. Rev. Fluid Mech. 1995, 27, 17–43. [Google Scholar] [CrossRef]

- Tam, C.; Golebiowski, M.; Seiner, J. On the two components of turbulent mixing noise from supersonic jets. In Proceedings of the Aeroacoustics Conference, State College, PA, USA, 6–8 May 1996. [Google Scholar]

- Bianco, D.; Adamo, F.P.; Barbarino, M.; Vitiello, P.; Bartoccini, D.; Federico, L.; Citarella, R. Integrated Aero–Vibroacoustics: The Design Verification Process of Vega-C Launcher. Appl. Sci. 2018, 8, 88. [Google Scholar] [CrossRef] [Green Version]

- Citarella, R.; Federico, L. Advances in Vibroacoustics and Aeroacustics of Aerospace and Automotive Systems. Appl. Sci. 2018, 8, 366. [Google Scholar] [CrossRef] [Green Version]

- Citarella, R.; Federico, L.; Barbarino, M. Aeroacustic and vibroacoustic advancement in aerospace and automotive systems. Appl. Sci. 2020, 10, 3853. [Google Scholar] [CrossRef]

- Zoppellari, E.; Juve, D. Reduction of jet noise by water injection. In Proceedings of the 3rd AIAA/CEAS Aeroacoustics Conference, Atlanta, GA, USA, 12–14 May 1997. [Google Scholar]

- Barbarino, M.; Ilsami, M.; Tuccillo, R.; Federico, L. Combined CFD-Stochastic Analysis of an Active Fluidic Injection System for Jet Noise Reduction. Appl. Sci. 2017, 7, 623. [Google Scholar] [CrossRef] [Green Version]

- Barbarino, M.; Ilsami, M.; Tuccillo, R.; Federico, L. Design Of Active Fluidic Injection Systems For Jet-Noise Reduction Through Stochastic Reconstruction Of Turbulent Flow Fields. In Proceedings of the International Congress on Sound and Vibration in Aeroacoustics Conference, London, UK, 23–27 July 2017. [Google Scholar]

- Brès, G.A.; Lele, S.K. Modelling of jet noise: A perspective from large-eddy simulations. Philos. Trans. R. Soc. 2019, 377, 2159. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Goldstein, M. A hybrid RANS/LES approach for predicting jet noise. In Proceedings of the 12th AIAA/CEAS Aeroacoustics Conference, Cambridge, MA, USA, 8–10 May 2006. [Google Scholar]

- Langley Research Center; Eldred, K.M. Acoustic Loads Generated by the Propulsion System; National Aeronautics and Space Administration: Washington, DC, UDA, 1971.

- Lubert, C.P.; Gee, K.L.; Tsutsumi, S. Supersonic jet noise from launch vehicles: 50 years since NASA SP-8072. J. Acoust. Soc. Am. 2022, 151, 752–791. [Google Scholar] [CrossRef] [PubMed]

- Battista, F.; Cardillo, D.; Fragiacomo, M.; Di Martino, G.D.; Mungiguerra, S.; Savino, R. Design and Testing of a Paraffin-Based 1000 N HRE Breadboard. Aerospace 2019, 6, 89. [Google Scholar] [CrossRef] [Green Version]

- Venugopal, S.; Rajesh, K.K.; Ramanujachari, V. Hybrid rocket technology. Def. Sci. J. 2011, 61, 193. [Google Scholar] [CrossRef] [Green Version]

- Calabro, M. Overview on hybrid propulsion. Prog. Prop. Phys. 2011, 2, 353–374. [Google Scholar]

- Bennewitz, J.W.; Frederick, R.A. Overview of combustion instabilities in liquid rocket engines-coupling mechanisms & control techniques. In Proceedings of the 49th AIAA/ASME/SAE/ASEE Joint PropulsionConference, San Jose, CA, USA, 14–17 July 2013. [Google Scholar]

- Fashbaugh, R.H.; Streeter, V.L. Resonance in liquid rocket engine systems. J. Basic Eng. 1965, 87, 1011–1017. [Google Scholar] [CrossRef]

- Kekus, P. Acoustic Analysis of a Liquid-Propellant Rocket Engine: Optimisation of the Meshing Strategy. In Proceedings of the 2nd International Conference on Flight Vehicles, Aerothermodynamics and Re-Entry Missions & Engineering, Heilbronn, Germany, 19–23 June 2022. [Google Scholar]

- Horchler, T. Selection Rules for Resonant Longitudinal Injector-Coupling in Experimental Rocket Combustors. Aerospace 2022, 9, 669. [Google Scholar] [CrossRef]

- Schuller, T.; Durox, D.; Palies, P.; Candel, S. Acoustic decoupling of longitudinal modes in generic combustion systems. Combust. Flame 2012, 159, 1921–1931. [Google Scholar] [CrossRef]

- Gröning, S.; Hardi, J.S.; Suslov, D.; Oschwald, M. Injector-driven combustion instabilities in a hydrogen/oxygen rocket combustor. J. Propuls. Power 2016, 32, 560–573. [Google Scholar] [CrossRef]

- Horchler, T.; Armbruster, W.; Hardi, J.; Karl, S.; Hannemann, K.; Gernoth, A.; De Rosa, M. Modeling combustion chamber acoustics using the DLR TAU code. In Proceedings of the Space Propulsion Conference, Seville, Spain, 14–18 May 2018. [Google Scholar]

- Pirk, R.; Souto, C.D.A.; Silveira, D.D.D.; Souza, C.M.D.; Góes, L.C.S. Liquid rocket combustion chamber acoustic characterization. J. Aerosp. Technol. Manag. 2010, 2, 269–278. [Google Scholar] [CrossRef]

- Yu, Y.; Koeglmeier, S.; Sisco, J.; Anderson, W. Combustion instability of gaseous fuels in a continuously variable resonance chamber (CVRC). In Proceedings of the 44th AIAA/ASME/SAE/ASEE Joint Propulsion Conference & Exhibit, Hartford, CT, USA, 21–23 July 2008. [Google Scholar]

| Equipment | Model | Frequency Range | Dynamic Range |

|---|---|---|---|

| Microphone | PCB 377B02 | ±2 dB (3.15 Hz to 20 kHz) | 147 dB (3% distortion limit) |

| Microphone preamplifier | PCB 426A30 | ±0.1 dB (10 Hz to 126 kHz) | - |

| Preamplifier power supply | Larson Davis 2221 | ±0.2 dB (10 Hz to 100 kHz) | - |

| # Coupling Frequency | Experimental Frequencies (Hz) | Analytical Frequencies (Hz) | Error (%) |

|---|---|---|---|

| 1st | 3364 | 3360 | 0.12 |

| 2nd | 6725 | 6721 | 0.06 |

| 3rd | 10,127 | 10,081 | 0.45 |

| 4th | 13,528 | 13,442 | 0.64 |

| Frequency Weighting | Predicted OASPL (dB) | Experimental OASPL (dB) | OASPL (dB) |

|---|---|---|---|

| Un-weighted | 124.35 | 126.55 | 2.20 |

| A-weighted | 124.39 | 127.07 | 2.68 |

| Frequency Weighting | Predicted OASPL (dB) | Experimental OASPL (dB) | OASPL (dB) |

|---|---|---|---|

| Un-weighted | 121.35 | 123.55 | 2.20 |

| A-weighted | 121.39 | 124.07 | 2.68 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fasulo, G.; Federico, L.; Sollazzo, A.; De Vivo, L.; Citarella, R. Hybrid Rocket Engine Noise: Measurements and Predictions of Acoustic Environments from Horizontal Static Fire. Appl. Sci. 2023, 13, 9041. https://doi.org/10.3390/app13159041

Fasulo G, Federico L, Sollazzo A, De Vivo L, Citarella R. Hybrid Rocket Engine Noise: Measurements and Predictions of Acoustic Environments from Horizontal Static Fire. Applied Sciences. 2023; 13(15):9041. https://doi.org/10.3390/app13159041

Chicago/Turabian StyleFasulo, Giovanni, Luigi Federico, Adolfo Sollazzo, Luciano De Vivo, and Roberto Citarella. 2023. "Hybrid Rocket Engine Noise: Measurements and Predictions of Acoustic Environments from Horizontal Static Fire" Applied Sciences 13, no. 15: 9041. https://doi.org/10.3390/app13159041