How to Find Disruptions in Logistics Processes in the Cold Chain and Avoid Waste of Products?

Abstract

:1. Introduction

2. State of the Art

3. Methodology

| • Outer dim. in mm (L × D × H): | 800 × 1000 × 1900 mm |

| • Inner dim. in mm (L × D × H): | 610 × 820 × 1535 mm |

| • Inner volume: | 768 L |

| • K value: | 0.33 W/m2·K |

| • Unloaded weight: | 130 kg |

| • Insulating material: | Polyurethane foam |

| • Wall material: | Food grade polyethylene |

- Measurement and data collection: Sensors placed inside containers regularly measure and collect data regarding temperature and other environmental conditions;

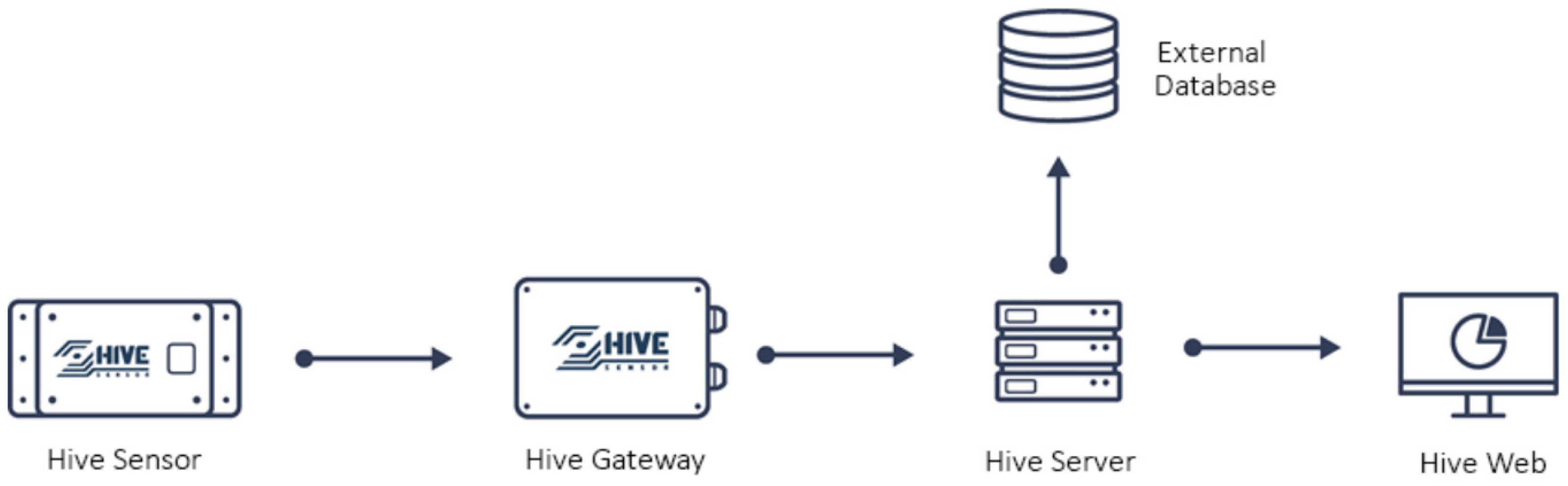

- Data transmission to the Gateway: When the measurement devices are within the range of gateway receivers, they transmit the gathered data to these receivers. These receivers are part of the SKK Gateway system;

- Data transmission to the cloud: Data received by the gateway receivers are sent to the cloud, enabling storage and further analysis;

- Data viewing via Hive Web: System users can use the Hive Web interface to view the collected data. They can monitor current conditions and measurement history;

- Generating reports using analytical tools: Data stored in the cloud can be processed and analyzed using analytical tools such as Tableau. This allows for report generation and analysis of the effects of any disruptions impacting storage and transportation processes.

- Temperature: For monitoring temperature, the system gathers data from sensors placed inside containers. These data are crucial for monitoring and controlling the storage conditions of temperature-sensitive goods;

- Other environmental conditions: In addition to temperature, the system can collect data related to other conditions, such as humidity, light levels, vibrations, etc. This information may be relevant depending on the type of goods stored in the containers.

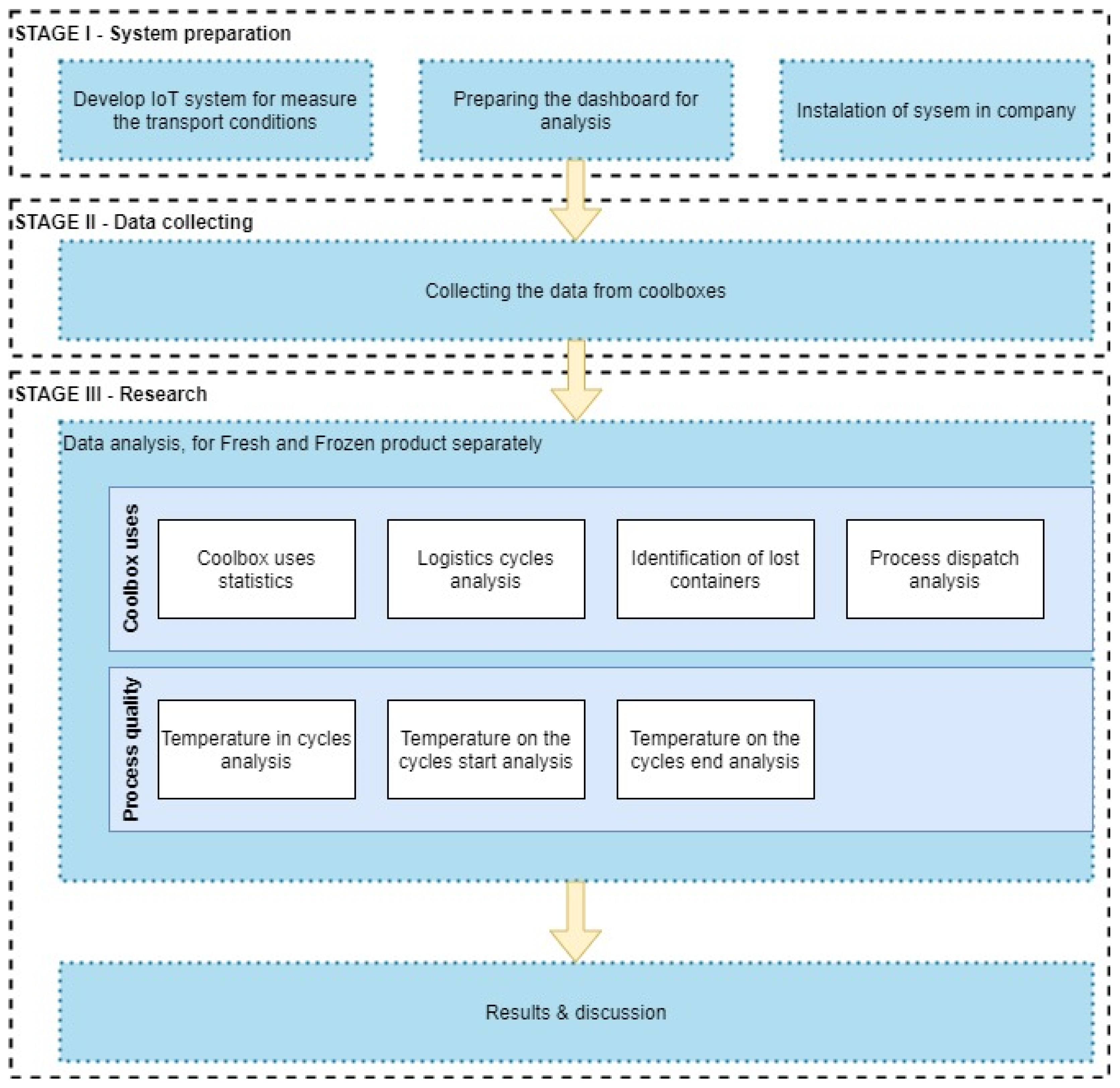

- STATGE I—A monitoring technology for storage and transportation conditions of goods based on the BLE (Bluetooth Low Energy) standard was developed—presented in Appendix A;

- STAGE II—A data acquisition system and data storage in the cloud (MS Azure) were developed;

- STAGE III—Disturbances in the process affecting the quality of implemented processes were analyzed using Tableau dashboards.

4. Case Study—Analysis of Disruptions

- Number of containers/sensors: 40 units;

- Measurements: Temperature, light;

- Measurement interval: 10 min;

- Device memory: Up to 8 days of measurements;

- Number of gateway devices: 3 units;

- Analysis period: From 6 May 2022 to 6 July 2022 (2 months);

- Basis for data analysis: Logistic cycle detection algorithm;

- Transported goods:

- ○

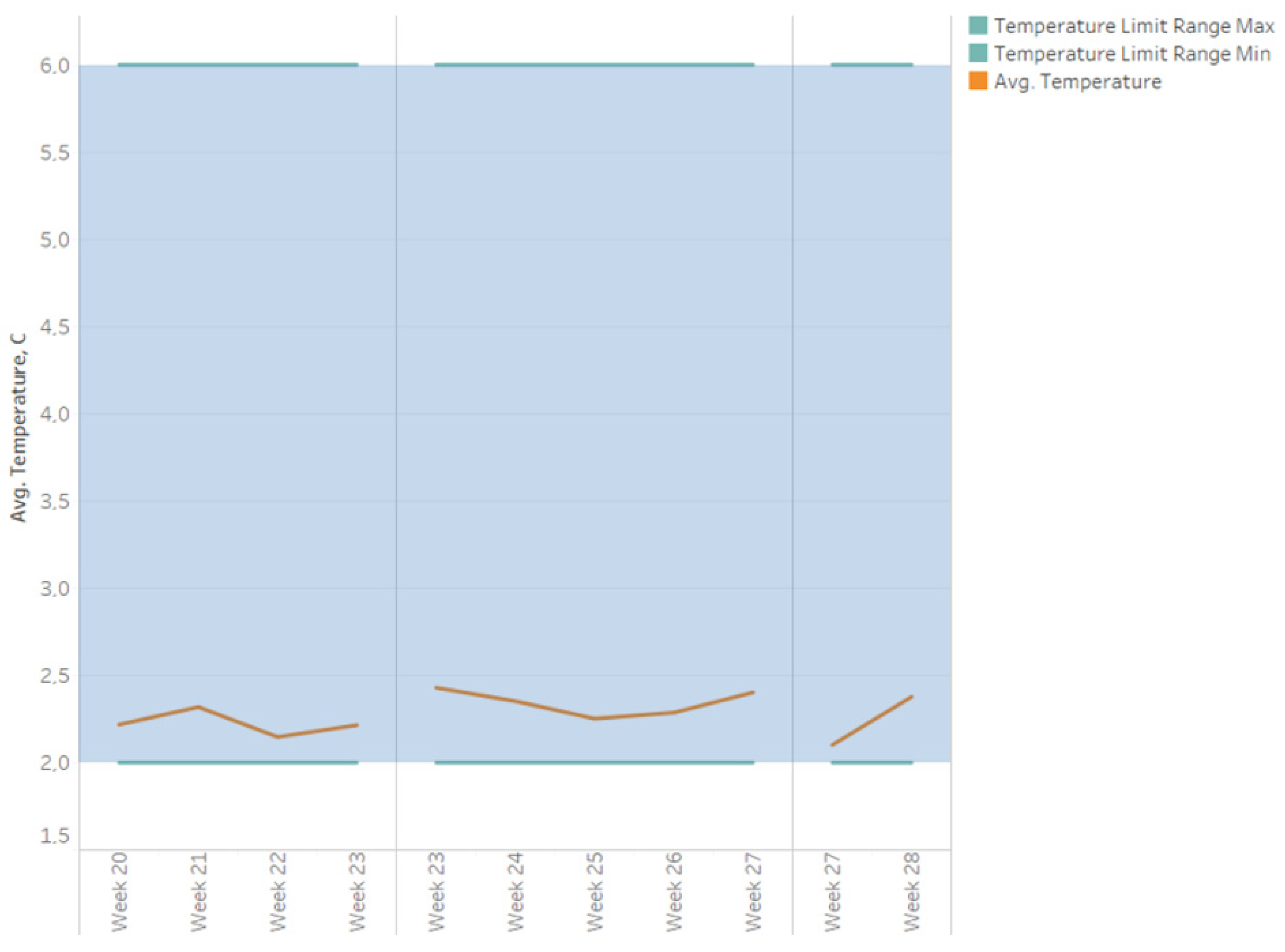

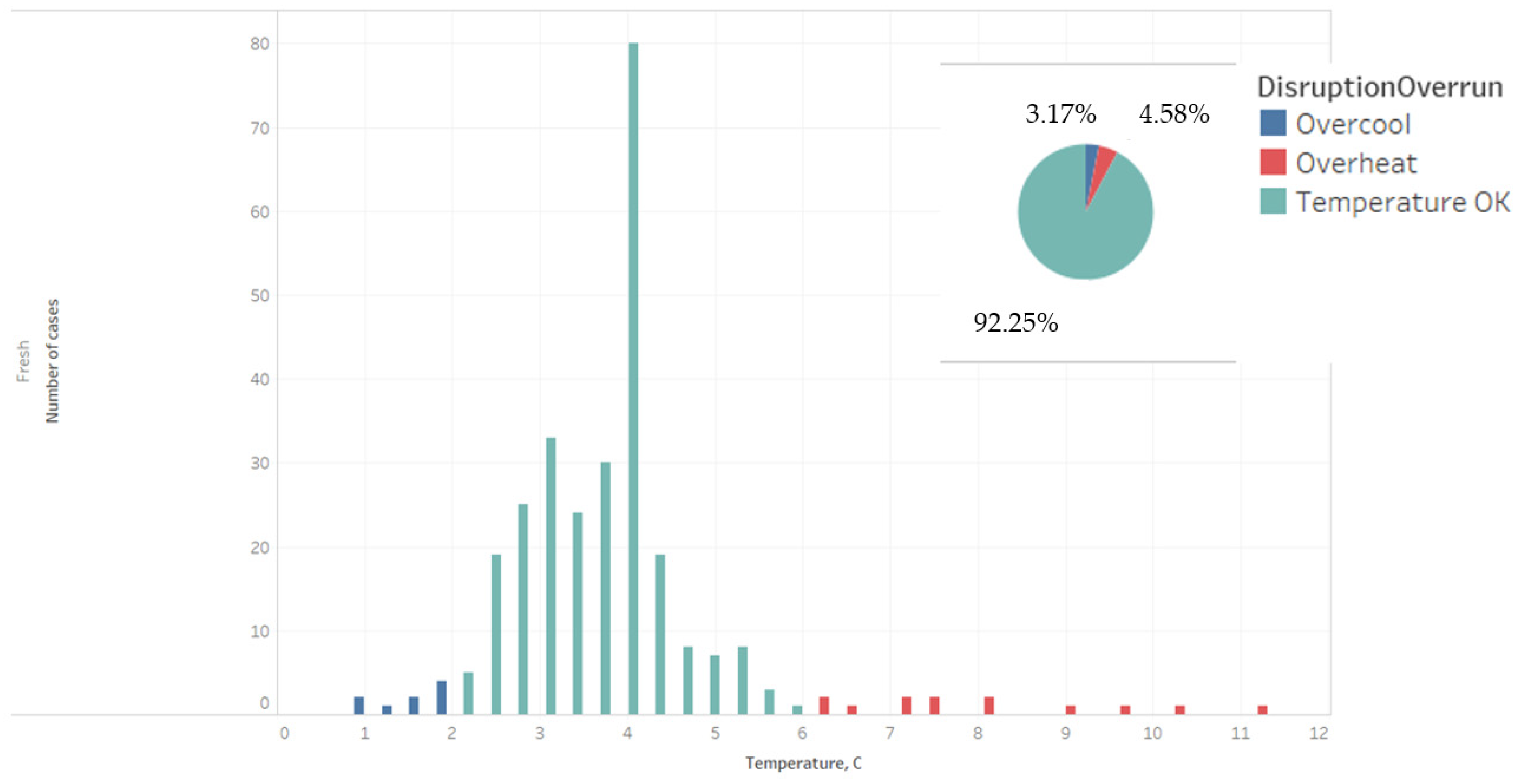

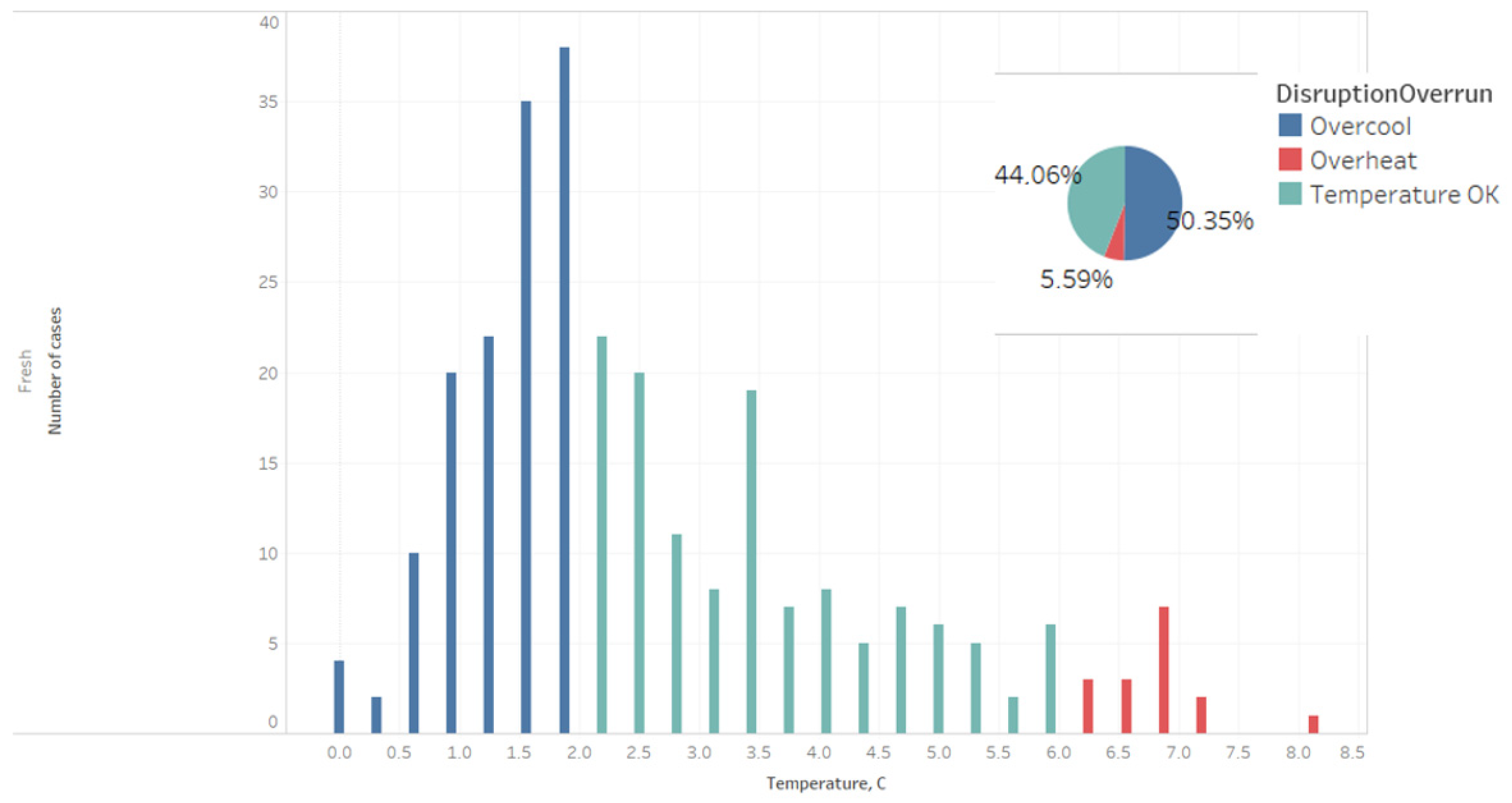

- Fresh (from 2 °C to 6 °C);

- ○

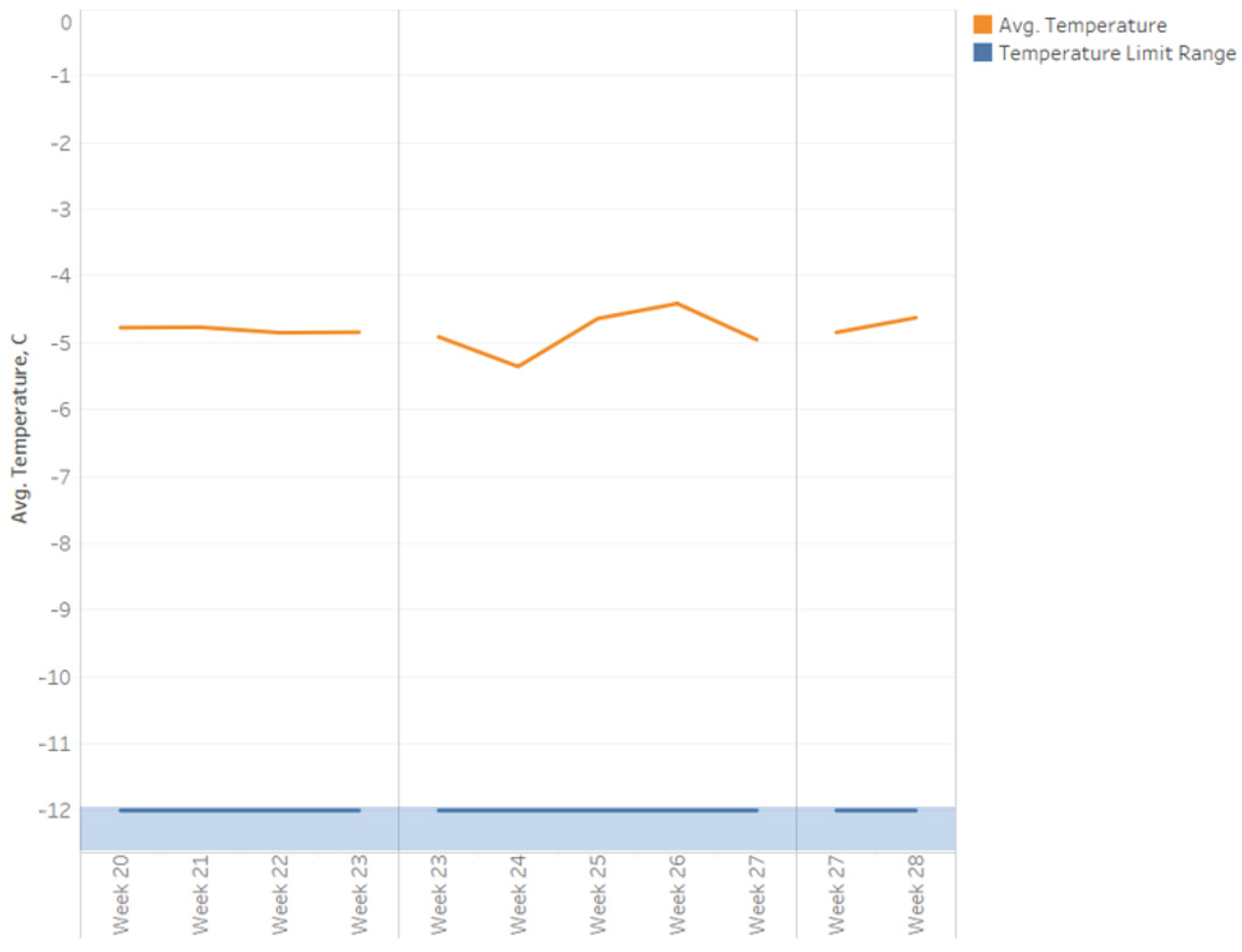

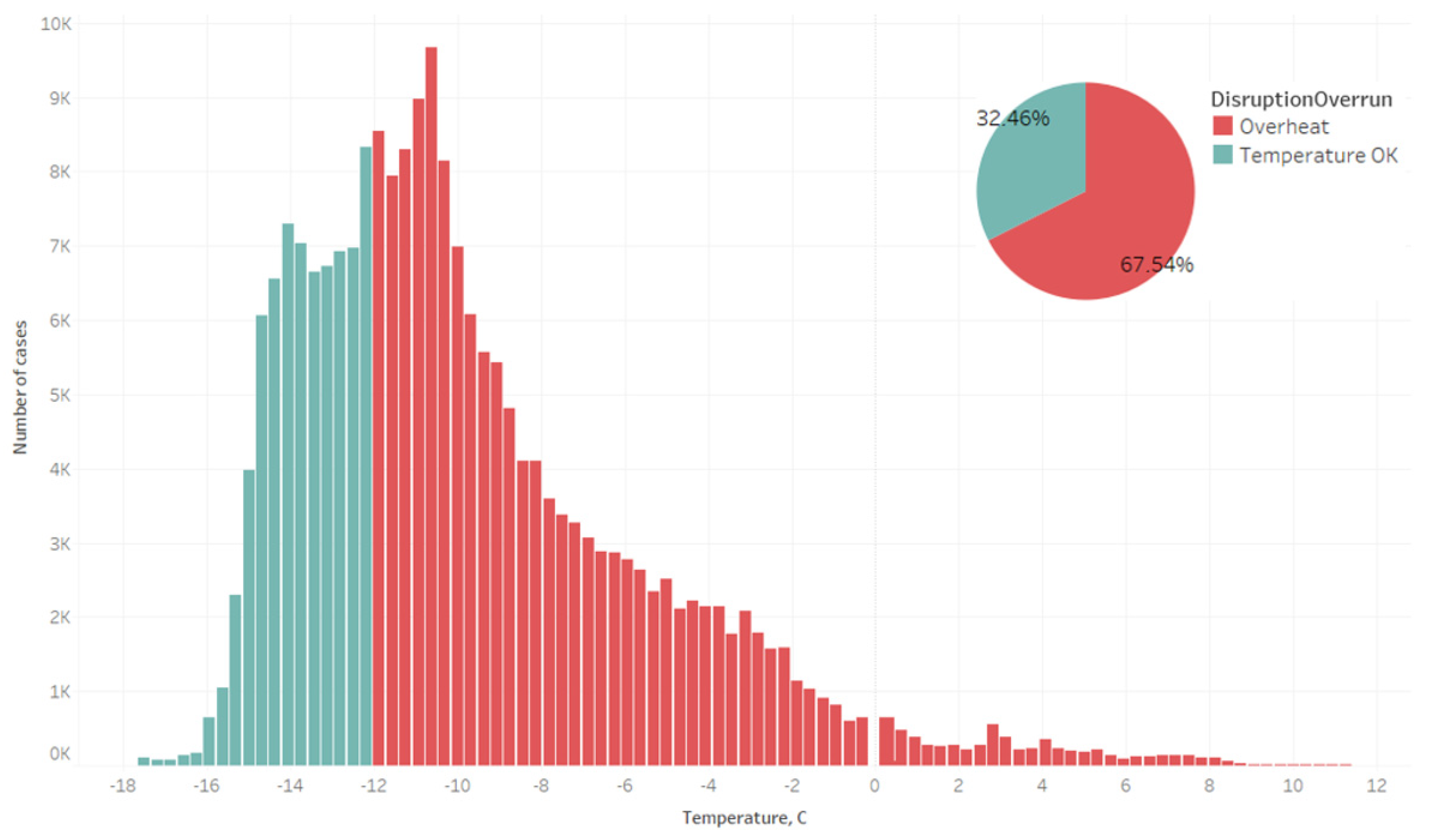

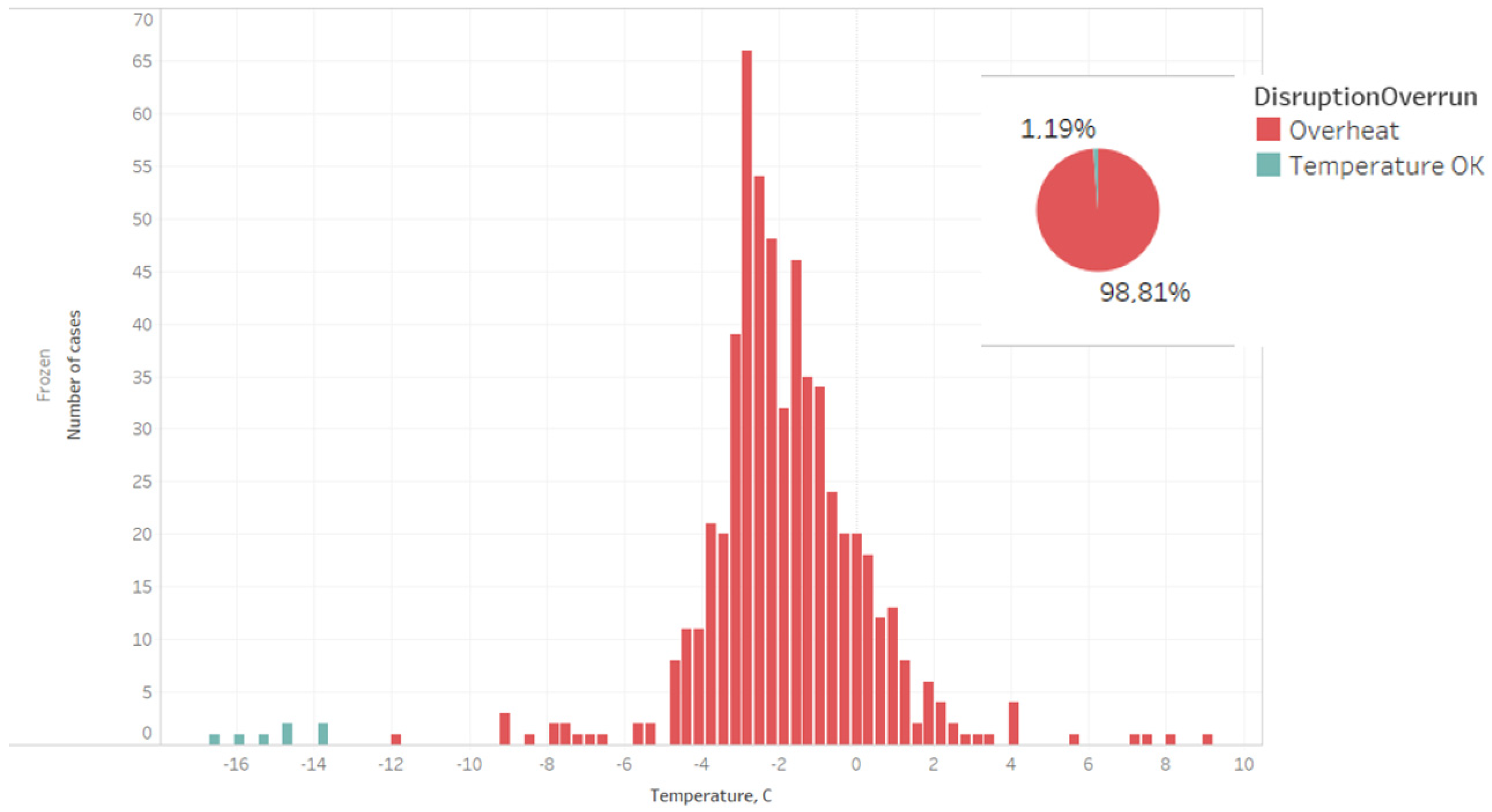

- Frozen (below −12 °C)

- Range: Distribution center (DC) plus approximately 150 km.

4.1. Analysis Objectives

- Identification of lost/delayed containers;

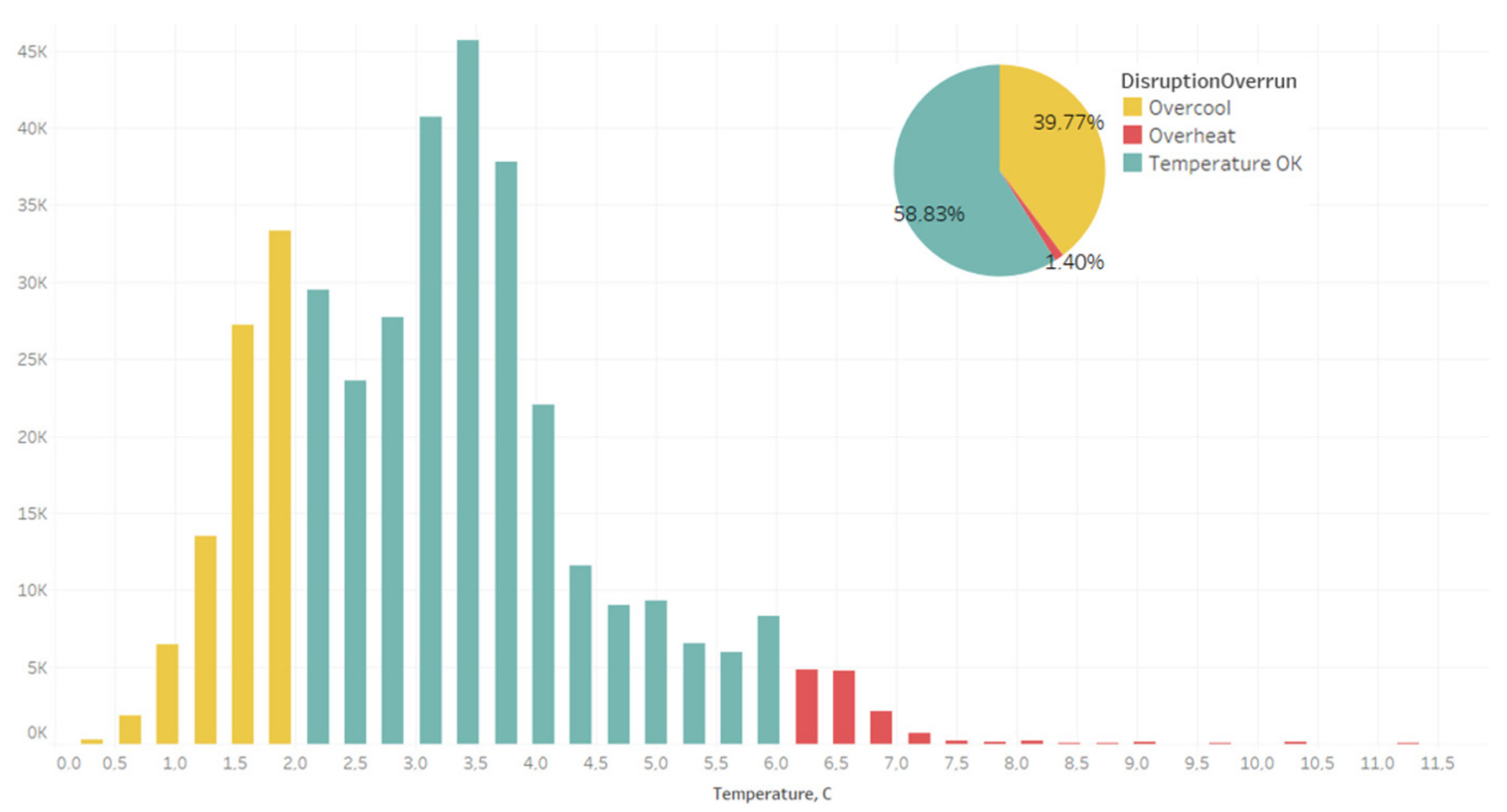

- Identification of temperature exceedances during transportation:

- ○

- At the beginning;

- ○

- During transportation;

- ○

- At the end of the cycle.

- Identification of container utilization.

- Dry: Products stored at room temperature, dry, without the need for temperature control, mainly products with a long shelf life;

- Fresh: Products stored at controlled temperatures, i.e., from 2 °C to 6 °C, referred to as fresh products;

- Frozen: Products stored at controlled temperatures, i.e., below −12 °C (frozen) or −20 °C (deep-frozen).

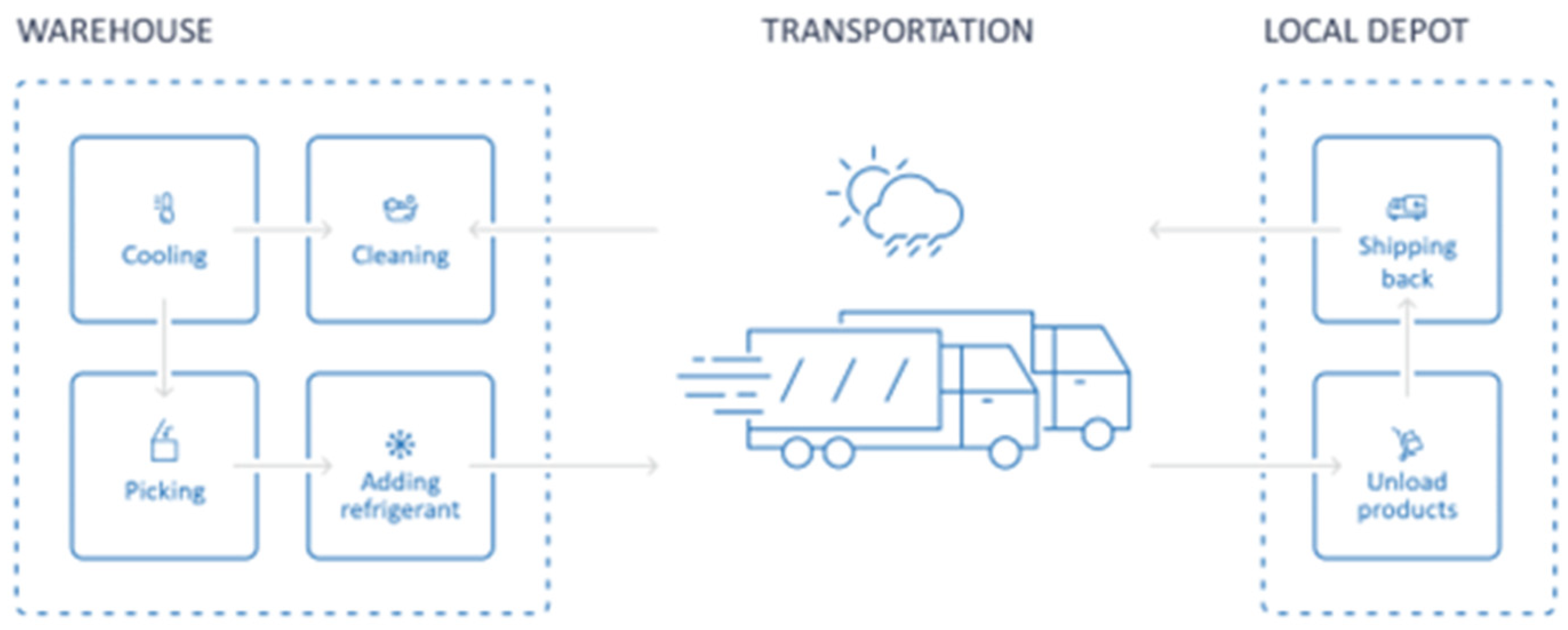

4.2. Logistics Process of Container Circulation in the Cold Supply Chain

- Drying in a zone (room) with forced air circulation at a higher temperature than the rest of the distribution center;

- Drying in a zone without raising the temperature and without forced air circulation.

- Loading/Unloading Zone: This is where goods received from suppliers are unloaded, and products destined for customers are loaded. It may have a direct connection to the warehouse through entry gates or an indirect connection via intermediate ramps and sluices, depending on the nature of the stored goods and desired conditions inside the warehouse;

- Receiving Zone: This is where goods are received, and processes include order quantity and quality control, cargo sorting, product labeling, determining storage locations, and possibly subdividing into smaller units. The receiving zone is usually separated from other areas to avoid interference. It may also be connected to the shipping area.

- Storage Zone: This is the primary warehouse area where products are stored. The size and layout depend on factors like the type of stored products, turnover rate, available technological solutions (e.g., shelf type and height, machinery, automation systems), storage method (on the floor, on shelves, in racks, etc.), and other factors. Various equipment and tools, such as forklifts, lifting devices, and cranes, are used in this area;

- Container Cooling Zone: This is where containers are cooled after cleaning and drying. Properly cooled containers are essential for maintaining the required temperature during product transportation;

- Picking Zone: This zone might not exist in every facility but is used for assembling orders. It’s typically found in warehouses serving small distributors or retail customers with diverse orders;

- Shipping Zone: In this area, completed orders are packed, labeled, and then sent to the loading area. Efficient operations in the shipping zone require equipment that aids in packing and labeling cargo and ensures a smooth flow of goods between this zone and the picking and loading areas;

- Service Areas: Every warehouse typically includes service areas such as restrooms, offices, changing rooms, customer service desks, and quality control departments. These areas may also include battery charging stations for electric equipment.

- Cleaning Zone: This is where containers are cleaned;

- Drying Zone: Containers are dried in this area;

- Cooling Zone: Containers are cooled here.

- The Receiving/Dispatch Zone may also serve as the Loading/Unloading Zone;

- The Storage Zone may also serve as the Picking Zone.

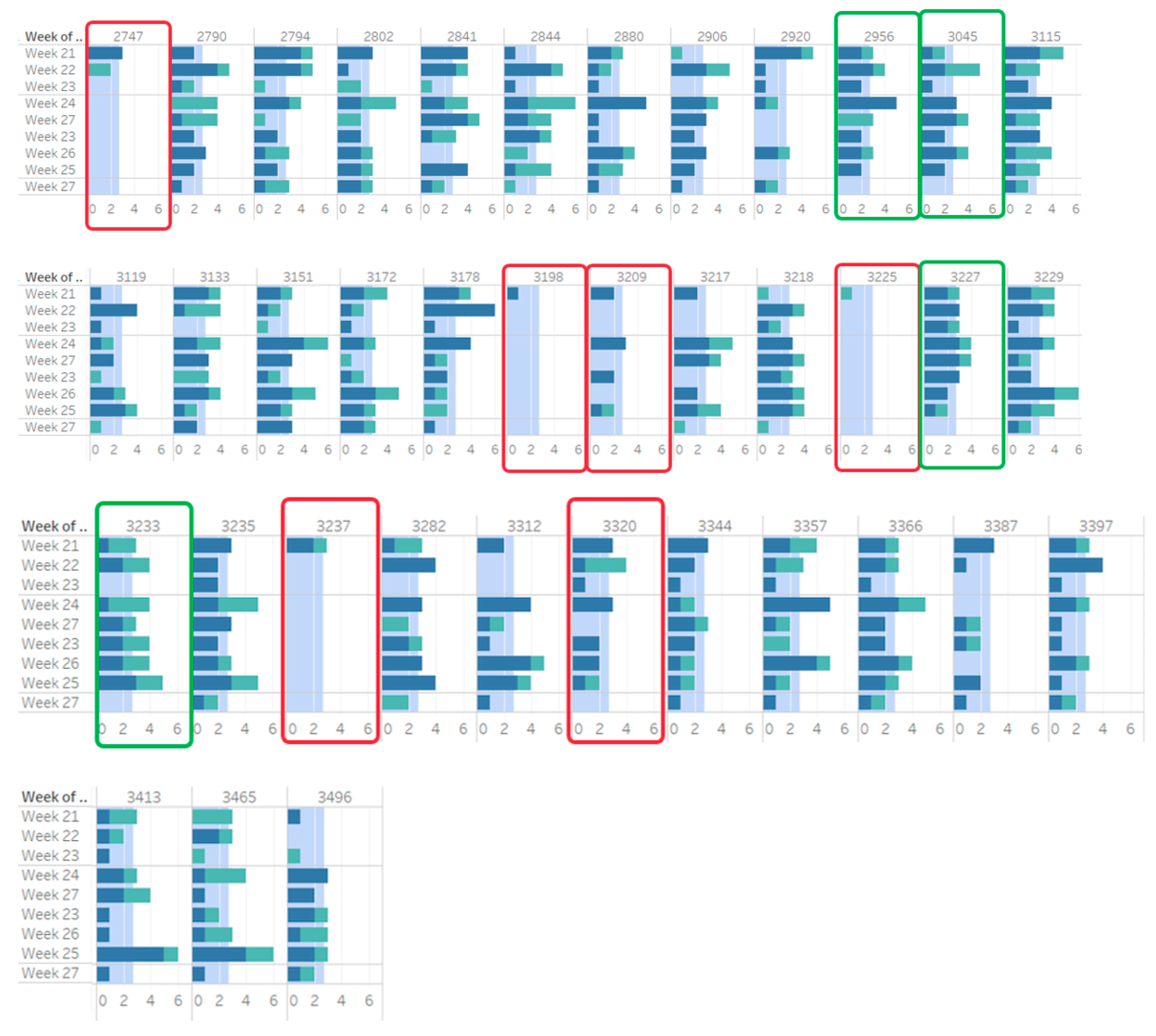

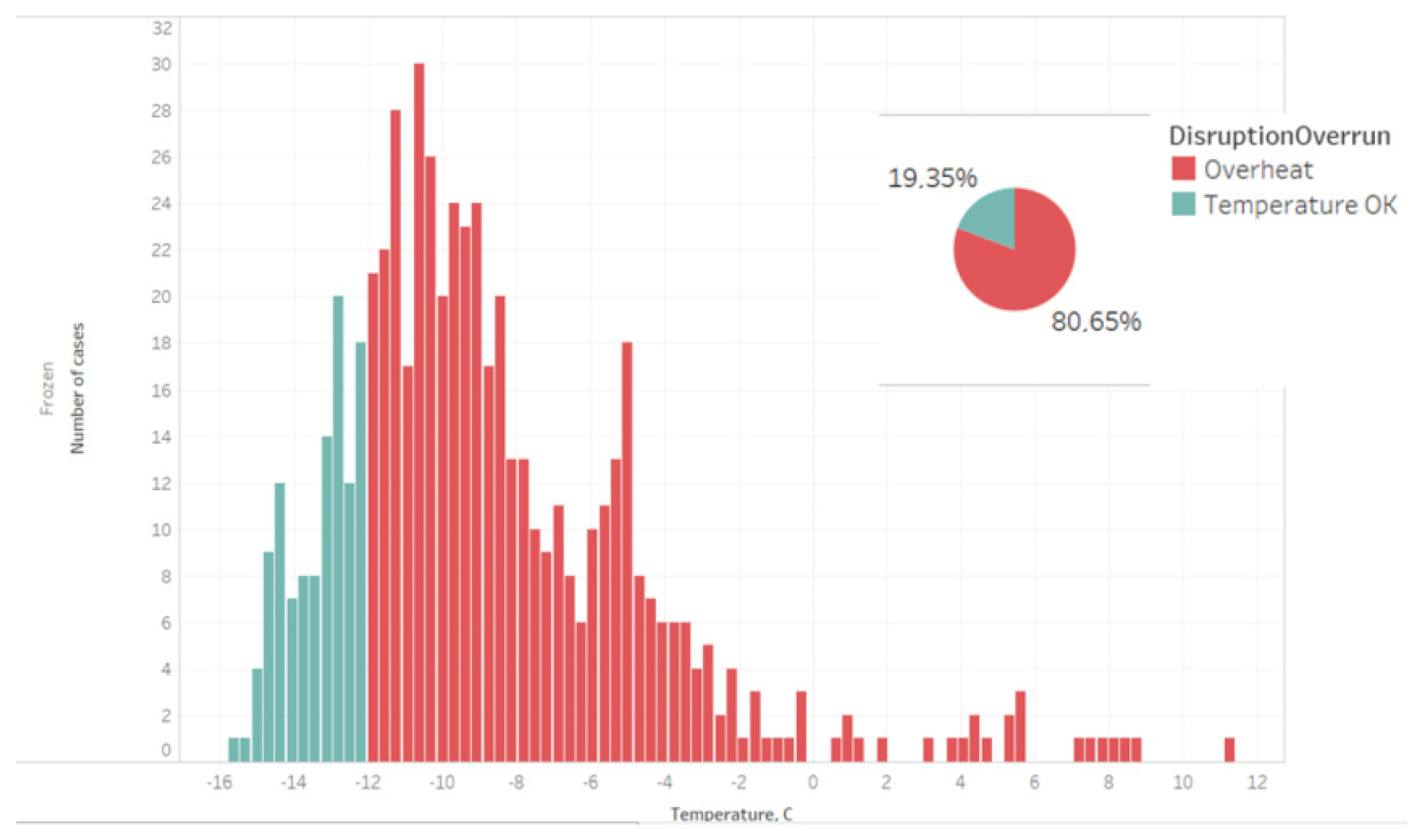

4.3. Results Analysis, Conclusions, and Recommendations

- 26 containers are used correctly (above 70% utilization);

- 6 containers have low rotation rates, with utilization between 30% and 70%, and among them, 2 containers are considered lost;

- 8 containers are considered lost or have malfunctioning sensors (no data collected for over 10 days).

- Temperature requirements of the products: Different food products or other goods may require different temperature ranges to stay fresh, chilled, or frozen. Therefore, the amount of dry ice used should be adjusted to the specific temperature requirements of the stored products;

- Size of the thermally insulated container: Thermally insulated containers vary in size, affecting the amount of space available for placing dry ice. Dosage must be adapted to the container’s capacity to maintain a balance between cooling and the occupied space;

- Duration of transport or storage: The length of the journey or storage period is crucial. Depending on whether it is a short trip or an extended storage period, it may be necessary to adjust the amount of dry ice to maintain the desired temperature throughout the entire journey or storage period;

- Insulation of the container: The quality of insulation in thermally insulated containers affects the efficiency of cooling or freezing. Better insulation requires less dry ice to maintain a stable temperature inside;

- Weather conditions: Ambient temperature and weather conditions, such as sunlight, can influence the rate of dry ice sublimation. In higher temperatures or intense sunlight, it may be necessary to increase the amount of dry ice;

- Type of products: Products with different densities, structures, or initial temperatures may require adjusting the amount of dry ice. Products that are already chilled may require less dry ice than those at room temperature.

5. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

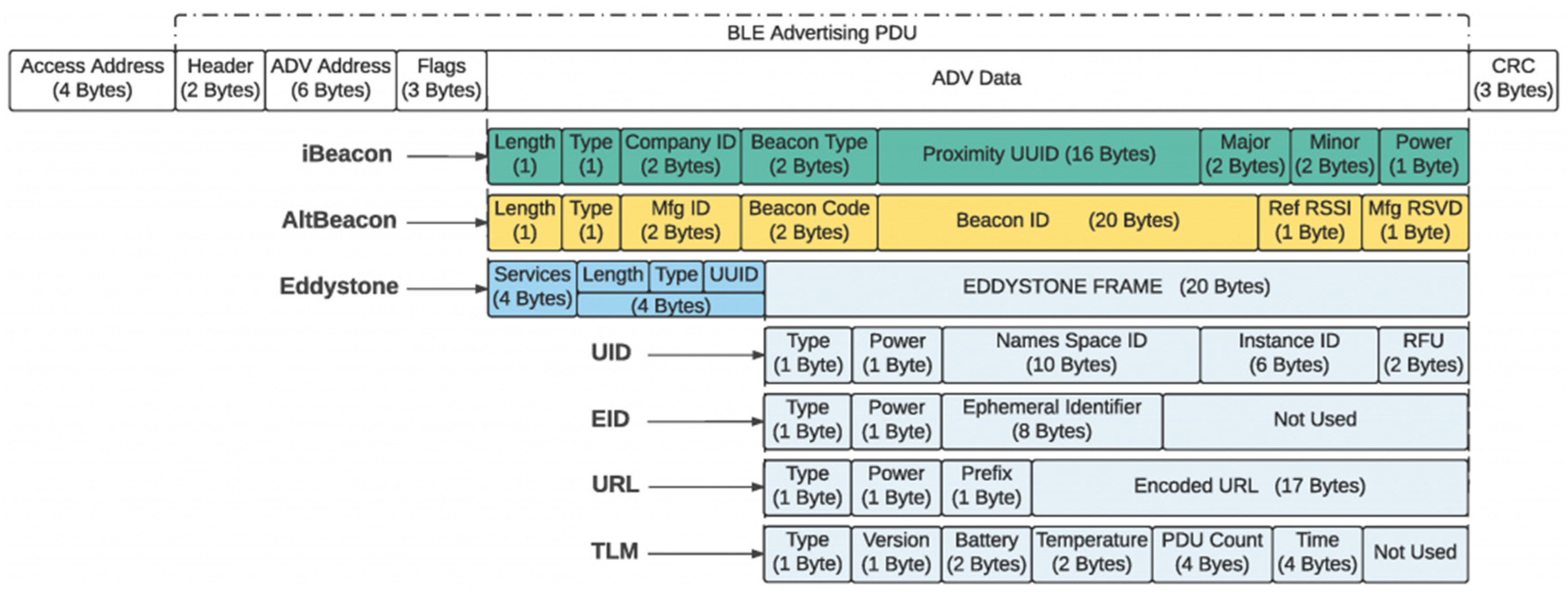

Appendix A. System Components

- Gateway

| Parameter | Value |

|---|---|

| Radio System Frequency | 2.4 [GHz] |

| Maximum Operating Range | 15 [m] |

| Temperature Range | 0–40 [°C] |

| Humidity Range | 10–90 [%] |

| IP (Ingress Protection) Rating | IP54 |

| Wi-Fi Interface | 802 b/g/n 150 Mbps |

| Network Interface | Port Ethernet 10/100 Mbps |

| Power Supply | 230 [V], PoE |

| Operating System | Linux |

- Sensor

| Parameter | Value |

|---|---|

| Operating Temperature | −40 ÷ 85 [°C] |

| Operating Voltage | 2.4 ÷ 3.6 [V] |

| Memory | 1000 ÷ 5000 cells of memory on the sensor |

| Radio Power | −12 ÷ 3 [dBm] |

| Measurement Interval | 1 ÷ 1800 [s] |

- Changing sensor operation parameters (activating sensors, changing measurement intervals);

- Controlling the transmission of sensor measurement data;

- Managing the transmission of the current sensor configuration.

- Data collections—Server

- Saving measurement data in real-time;

- Access to historical data;

- Tracking Hive Sensor location;

- Measurement and technical data visualization;

- the possibility of creating designated dashboards;

- Management of the Hive Sensor;

- Access and management of Hive Gateway devices;

- Configuration of system actions (e.g., an alert) after meeting defined conditions;

- Exporting measurement data to an external database or other data source;

- Provide data for external software to integrate with other Big Data solutions.

- Hive Web

- The possibility to create customizable dashboards;

- Visualization of temperature, light, humidity, and acceleration measurements in graph and table form for the selected Hive Sensor for the last 7 days with information about the minimum, maximum and average value for a given time range;

- Real-time value for selected sensors;

- Information about the last known location of the Hive Sensor;

- Information about the number of sensors within the range of a given Hive Gateway device;

- List of Hive Sensors with the date of adding to the system and the date of the last update.

Appendix B. ATP Agreement

- Deep-frozen or frozen foodstuffs;

- Foodstuffs, even if they are not deep-frozen or frozen.

- Frozen or deep-frozen cream and fruit juice concentrates: −20 °C;

- Frozen and deep-frozen fish, fish products, mollusks, and crustaceans, as well as all other frozen and deep-frozen foodstuffs: −18 °C;

- Any other deep-frozen foodstuffs: −18 °C;

- Frozen butter and other fats: −14 °C;

- Frozen offal, egg yolks, poultry, and game: −12 °C;

- Frozen meat: −10 °C;

- Ice cream: −20 °C;

- Butter: −10 °C;

- All other frozen foodstuffs (except butter): −12 °C.

- Butter: +6 °C;

- Milk in tankers (raw or pasteurized) for direct consumption: +4 °C;

- Industrial milk: +6 °C;

- Dairy products (yogurt yoghurt, kefirs, cream, and curd cheese): +4 °C;

- Fish (should always be transported on ice): +2 °C;

- Ready meat products: +6 °C;

- Meat (excluding offal): +7 °C;

- Poultry and rabbits: +4 °C.

References

- Keener, L.; Jerry, R. The Squeaky Wheel: Is Transportation the Watershed for Food Safety and Food Defense? Available online: https://www.food-safety.com/articles/4426-the-squeaky-wheel-is-transporation-the-watershed-for-food-safety-and-food-defense (accessed on 16 October 2023).

- Maksimović, M.; Vujović, V.; Omanović-Mikličanin, E. A Low Cost Internet of Things Solution for Traceability and Monitoring Food Safety During Transportation. In Proceedings of the 7th International Conference on Information and Communication Technologies in Agriculture, Food and Environment, Kavala, Greece, 17–20 September 2015. [Google Scholar]

- Zhang, H.; Sun, X.; Liu, Y. Food Safety and Technological Implications of Food Traceability Systems. In IFIP Advances in Information and Communication Technology, Proceedings of the CCTA 2010: Computer and Computing Technologies in Agriculture IV, Nanchang, China, 22–25 October 2010; Springer: Berlin/Heidelberg, Germany, 2011; Volume 345, pp. 1–10. [Google Scholar]

- Zhang, Y.; Chen, B.; Lu, X. Intelligent Monitoring System on Refrigerator Trucks Based on the Internet of Things. In Lecture Notes of the Institute for Computer Sciences, Social Informatics and Telecommunications Engineering, Proceedings of the ICWCA 2011: Wireless Communications and Applications, Sanya, China, 1–3 August 2011; Springer: Berlin/Heidelberg, Germany, 2012; Volume 72, pp. 201–206. [Google Scholar]

- Vinodini Ramesh, M.; Narayanadas, R. A Public Transport System Based Sensor Network for Fake Alcohol Detection. In Lecture Notes of the Institute for Computer Sciences, Social Informatics and Telecommunications Engineering, Proceedings of the ICWCA 2011: Wireless Communications and Applications, Sanya, China, 1–3 August 2011; Springer: Berlin/Heidelberg, Germany, 2012; Volume 72. [Google Scholar]

- Fangchun, Y.; Wang, S.; Li, J.; Liu, Z.; Sun, Q. An Overview of Internet of Vehicles. Commun. China 2014, 11, 1–15. [Google Scholar] [CrossRef]

- Hopper, L.; Womble, P.; Moore, R.; Paschal, J.; Payne, F.; Thompson, C.; Crist, W.; Luck, B.; Tabayehnejab, N.; Stombaugh, T.; et al. A Wireless Electronic Monitoring System for Securing Milk from Farm to Processor. In Proceedings of the 2008 IEEE Conference on Technologies for Homeland Security, Waltham, MA, USA, 12–13 May 2008; pp. 525–529. [Google Scholar]

- Martins, F.; Lopes, L.; Paulino, H. Sensor Systems and Software: Third International ICST Conference, S-Cube 2012, Lisbon, Portugal, June 4–5, 2012, Revised Selected Papers; Springer: Berlin/Heidelberg, Germany, 2012; ISBN 978-3-642-32777-3. [Google Scholar]

- Taj, S.; Imran, A.S.; Kastrati, Z.; Daudpota, S.M.; Memon, R.A.; Ahmed, J. IoT-Based Supply Chain Management: A Systematic Literature Review. Internet Things 2023, 24, 100982. [Google Scholar] [CrossRef]

- Ryan, J.M. Guide to Food Safety and Quality during Transportation; Elsevier: Amsterdam, The Netherlands, 2017. [Google Scholar]

- Badia-Melis, R.; Mc Carthy, U.; Ruiz-Garcia, L.; Garcia-Hierro, J.; Robla Villalba, J.I. New Trends in Cold Chain Monitoring Applications—A Review. Food Control 2018, 86, 170–182. [Google Scholar] [CrossRef]

- Ndraha, N.; Hsiao, H.-I.; Vlajic, J.; Yang, M.-F.; Lin, H.-T.V. Time-Temperature Abuse in the Food Cold Chain: Review of Issues, Challenges, and Recommendations. Food Control 2018, 89, 12–21. [Google Scholar] [CrossRef]

- Wang, J.; Yue, H. Food Safety Pre-Warning System Based on Data Mining for a Sustainable Food Supply Chain. Food Control 2017, 73, 223–229. [Google Scholar] [CrossRef]

- Pratap, S.; Jauhar, S.K.; Gunasekaran, A.; Kamble, S.S. Optimizing the IoT and Big Data Embedded Smart Supply Chains for Sustainable Performance. Comput. Ind. Eng. 2024, 187, 109828. [Google Scholar] [CrossRef]

- Gajewska, T.; Grigoroudis, E. Estimating the Performance of the Logistics Services Attributes Influencing Customer Satisfaction in the Field of Refrigerated Transport. Int. J. Shipp. Transp. Logist. 2017, 9, 540–561. [Google Scholar] [CrossRef]

- Gajewska, T.; Lorenc, A. The Impact of Trailer Conditions on the Quality of Refrigerated Food Transport Services—A Case Study. Transp. Probl. 2019, 14, 97–107. [Google Scholar] [CrossRef]

- Jamme, H.-T.; Connor, D.S. Diffusion of the Internet-of-Things (IoT): A Framework Based on Smart Retail Technology. Appl. Geogr. 2023, 161, 103122. [Google Scholar] [CrossRef]

- Xia, J.; Huang, W.; Wang, X.; Zhu, Z.; Zhang, M.; Zhang, X. Flexible Sensing Technology for Fruit Quality Control in the Cold Chain: Characterization, Application, and Improvement. Food Control 2023, 154, 109976. [Google Scholar] [CrossRef]

- Zhang, L.; Zhang, M.; Law, C.L.; Ma, Y. Effect of Vibration and Broken Cold Chain on the Evolution of Cell Wall Polysaccharides during Fruit Cucumber (Cucumis sativus L.) Shriveling Under Simulated Transportation. Food Packag. Shelf Life 2023, 38, 101126. [Google Scholar] [CrossRef]

- Xiang, B.; Zhang, X. Advancements in the Development of Field Precooling of Fruits and Vegetables with/without Phase Change Materials. J. Energy Storage 2023, 73, 109007. [Google Scholar] [CrossRef]

- Liu, Z.; Guo, H.; Zhao, Y.; Hu, B.; Shi, L.; Lang, L.; Huang, B. Research on the Optimized Route of Cold Chain Logistics Transportation of Fresh Products in Context of Energy-Saving and Emission Reduction. Math. Biosci. Eng. 2021, 18, 1926–1940. [Google Scholar] [CrossRef] [PubMed]

- Patel, A.S.; Brahmbhatt, M.N.; Bariya, A.R.; Nayak, J.B.; Singh, V.K. Blockchain Technology in Food Safety and Traceability Concern to Livestock Products. Heliyon 2023, 9, e16526. [Google Scholar] [CrossRef] [PubMed]

- Bai, Y.; Wu, H.; Huang, M.; Luo, J.; Yang, Z. How to Build a Cold Chain Supply Chain System for Fresh Agricultural Products through Blockchain Technology—A Study of Tripartite Evolutionary Game Theory Based on Prospect Theory. PLoS ONE 2023, 18, e0294520. [Google Scholar] [CrossRef] [PubMed]

- Liu, S.; Yu, Z. Modeling and Efficiency Analysis of Blockchain Agriculture Products E-Commerce Cold Chain Traceability System Based on Petri Net. Heliyon 2023, 9, e21302. [Google Scholar] [CrossRef] [PubMed]

- Liu, C.; Hou, P. Dynamic Modelling of Cold Chain Logistics Services under Budget Constraints for the Delivery of Fresh Products in an Urban Area. Appl. Math. Model. 2024, 125, 809–835. [Google Scholar] [CrossRef]

- Wu, W.; Shen, L.; Zhao, Z.; Harish, A.R.; Zhong, R.Y.; Huang, G.Q. Internet of Everything and Digital Twin Enabled Service Platform for Cold Chain Logistics. J. Ind. Inf. Integr. 2023, 33, 100443. [Google Scholar] [CrossRef]

- Hernandez-Cuellar, D. An Stochastic Cold Food Supply Chain (CFSC) Design. In Proceedings of Cyber-Physical Systems and Internet of Things Week 2023; ACM: New York, NY, USA, 2023; pp. 391–394. [Google Scholar]

- Xu, B.; Sun, J.; Zhang, Z.; Gu, R. Research on Cold Chain Logistics Transportation Scheme under Complex Conditional Constraints. Sustainability 2023, 15, 8431. [Google Scholar] [CrossRef]

- Yin, X.; Gu, C.; Fan, Z.; Huang, H. Routing Optimization in Distribution of Cold Chain Logistics. In Proceedings of the 2017 10th International Symposium on Computational Intelligence and Design (ISCID), Hangzhou, China, 9–10 December 2017; pp. 171–176. [Google Scholar]

- REN, X.Y. Path Optimization of Cold Chain Distribution with Multiple Distribution Centers Considering Carbon Emissions. Appl. Ecol. Environ. Res. 2019, 17, 9437–9453. [Google Scholar] [CrossRef]

- Xiong, H. Research on Cold Chain Logistics Distribution Route Based on Ant Colony Optimization Algorithm. Discret. Dyn. Nat. Soc. 2021, 2021, 6623563. [Google Scholar] [CrossRef]

- Liu, Y. Design of Dynamic Programming Model for Multi-Objective Cold Chain Logistics Deployment Path Based on Meme Algorithm. Iran. J. Sci. Technol. Trans. Civil. Eng. 2022, 46, 2553–2560. [Google Scholar] [CrossRef]

- Adding an IoT Protocol to Beacons. Available online: https://www.beaconzone.co.uk/blog/adding-an-iot-protocol-to-beacons (accessed on 15 October 2023).

| Process | Obligatory | Zone | Scanning | Frequency per Cycle | The Environmental Temperature of the Coolbox | Notes |

|---|---|---|---|---|---|---|

| Arrival at DC | Yes | Receiving/Dispatch | Yes | 1 | 2 °C ÷ +20 °C | |

| Container eashing | Yes | Receiving/Dispatch | No | In every cycle or every few cycles | 60 °C | High-pressure cleaning, chemicals, high temperature > 60 °C |

| Drying | No | Cleaning Zone/Storage Zone CB | Recommended | As often as washing | 2 °C ÷ +50 °C | Natural drying or with forced air circulation and higher temperature |

| Cooling | Recommended | Receiving/Dispatch | Recommended—in the absence of an automatic system, such as the Hive Sensor | Always, with the exception being the need for a timed dispatch or cancellation of the shipment (skipping cooling) | −20 °C ÷ +6 °C | Cooling to a specified temperature (fresh or frozen) |

| Loading of products/goods | Yes | Drying Zone/Storage Zone CB | Recommended | 1 | 2 °C ÷ +6 °C | In the fresh zone |

| Placement of the coolant | Yes | Storage | No | 1 | 2 °C ÷ +6 °C | Loading dry ice or eutectic coolant |

| Coolbox transit to the gate | Yes | Receiving/Dispatch | Recommended | 1 | 2 °C ÷ +6 °C | |

| Loading onto the trailer | Yes | Receiving/Dispatch | Yes | 1 | 2 °C ÷ +6 °C | |

| Transport to the store | Yes | Receiving/Dispatch | Yes | 1 | Atmospheric | Trailer temperature or atmospheric, depending on the season |

| Delivery to the store | Yes | Transport | Yes | |||

| Unloading of the coolbox at the store | Yes | Transport | No | 1 | Atmospheric or fresh | Duration usually ranges from a few minutes to several hours from delivery |

| Waiting for transport | Yes | Shop | No | 1 | Atmospheric | During the next delivery, approximately 24 h. |

| Loading onto the trailer | Yes | Shop | Yes | 1 | Atmospheric | |

| Transport to the DC (distribution center) | Yes | Transport | No | 1 | Atmospheric |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lorenc, A. How to Find Disruptions in Logistics Processes in the Cold Chain and Avoid Waste of Products? Appl. Sci. 2024, 14, 255. https://doi.org/10.3390/app14010255

Lorenc A. How to Find Disruptions in Logistics Processes in the Cold Chain and Avoid Waste of Products? Applied Sciences. 2024; 14(1):255. https://doi.org/10.3390/app14010255

Chicago/Turabian StyleLorenc, Augustyn. 2024. "How to Find Disruptions in Logistics Processes in the Cold Chain and Avoid Waste of Products?" Applied Sciences 14, no. 1: 255. https://doi.org/10.3390/app14010255