Research on the Stability and Water Isolation of Waterproof Coal Pillars between Adjacent Working Faces under the Influence of Water Ponding Goaf—A Case Study

Abstract

:1. Introduction

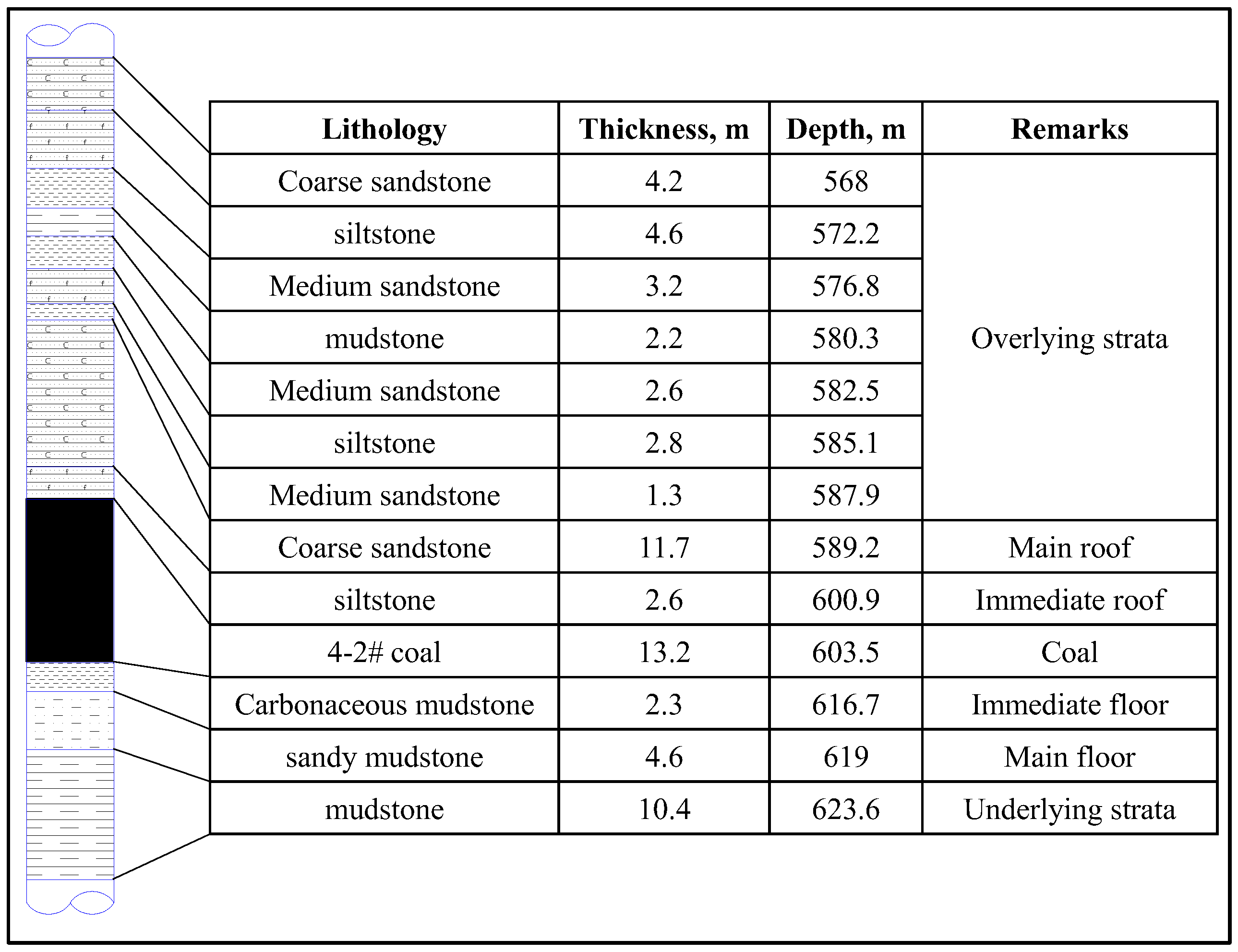

2. Geological Condition

2.1. Geological Conditions of the Working Face

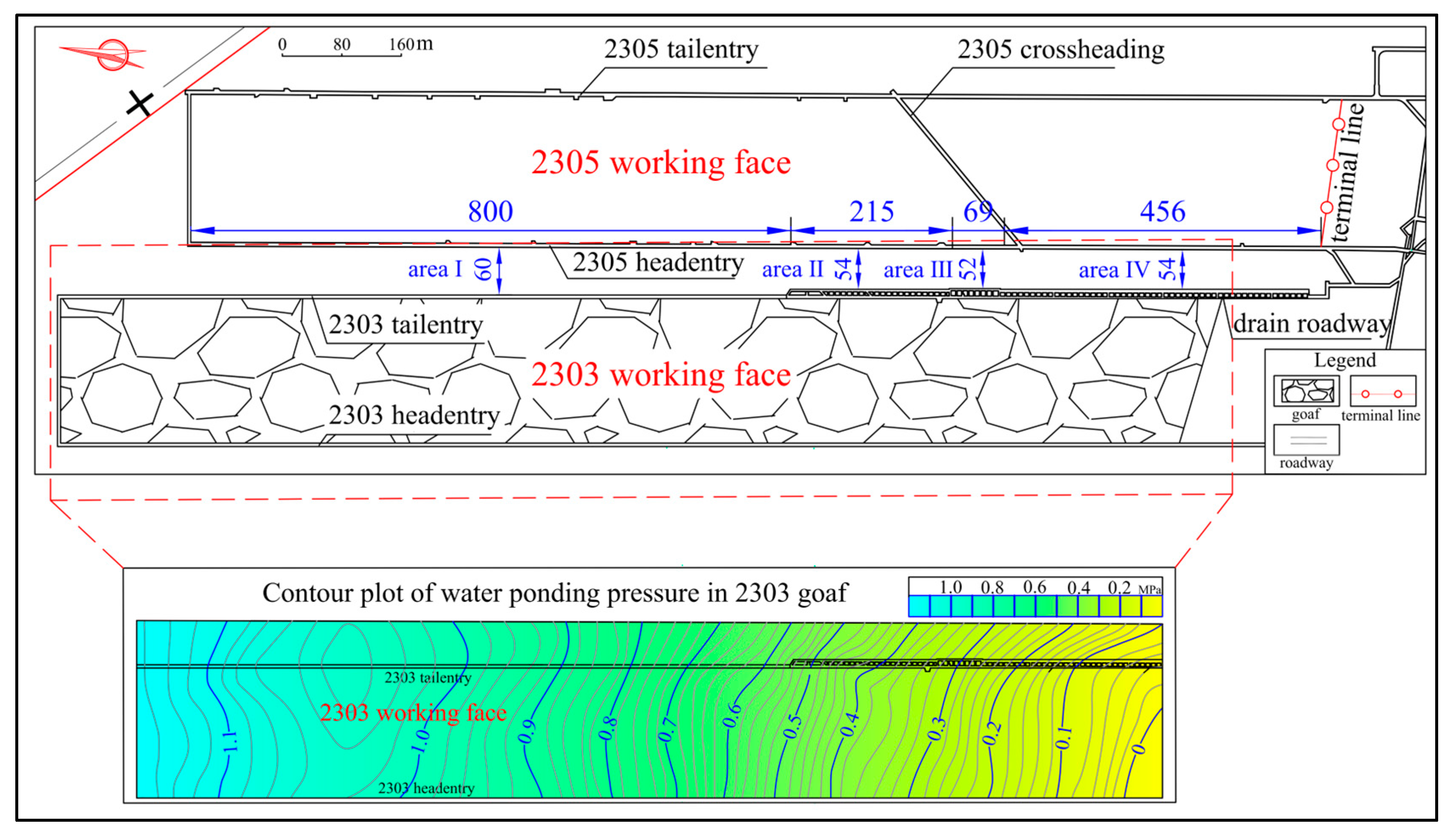

2.2. Water Accumulation Condition in Working Faces

3. Analysis of the Coal Pillar Width under the Influence of the Water-Logged Goaf

3.1. Theoretical Calculation of the Width of Waterproof Coal Pillars

3.2. Calculation of the Width of the Plastic Zone of Waterproof Coal Pillars

- (1)

- The properties of the coal body are continuous, homogeneous, isotropic, and perfectly elastic.

- (2)

- Plastic damage occurs when the coal pillar is subjected to shear stress, and the damaged surface is parallel to the coal seam level.

- (3)

- The coal body undergoes plastic deformation, and the deformation is negligible.

- (4)

- The force on the coal pillar only considers the gravity of the overlying rock and does not consider the influence of its tectonic stress.

- (5)

- The stresses above the coal body are symmetrical about the neutral plane.

- (6)

- The influence of coal body force is not considered.

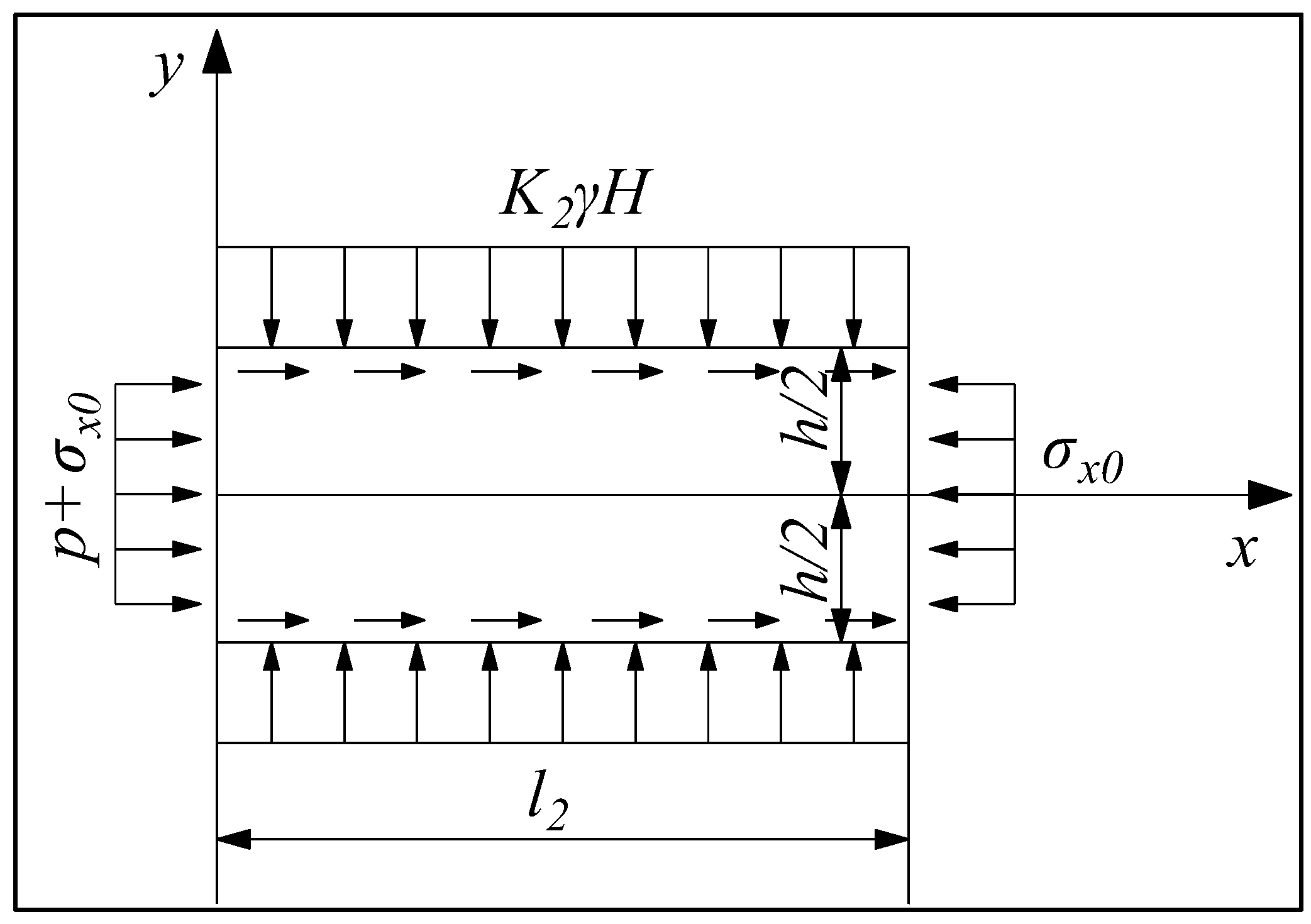

3.3. Calculation of the Width of the Elastic Zone of the Waterproof Coal Pillar

- (1)

- The coal pillar is a uniform, continuous, and isotropic elastomer.

- (2)

- The stress σx0 on both sides of the coal body in the elastic area is symmetric and uniformly distributed.

- (3)

- The stress K2γH above the coal body in the elastic area is uniformly distributed and symmetric about the x-axis.

- (4)

- The lateral water pressure p suffered by the coal body in the elastic area is uniformly distributed, ignoring the blocking effect of the plastic zone on the water pressure, and the size of the water pressure is calculated in accordance with the maximum value measured in the field.

3.4. Calculation of the Width of the Water Pressure Damage Zone of Waterproof Coal Pillars

3.5. Determination of Width of Waterproof Coal Pillar

4. Safety Analysis of Waterproof Coal Pillar Width in the Working Faces

4.1. Analysis of the Development of the Water Conducting Fracture Zone in the Working Face

4.2. Calculation of the Development Height of the Water Conducting Fracture Zone

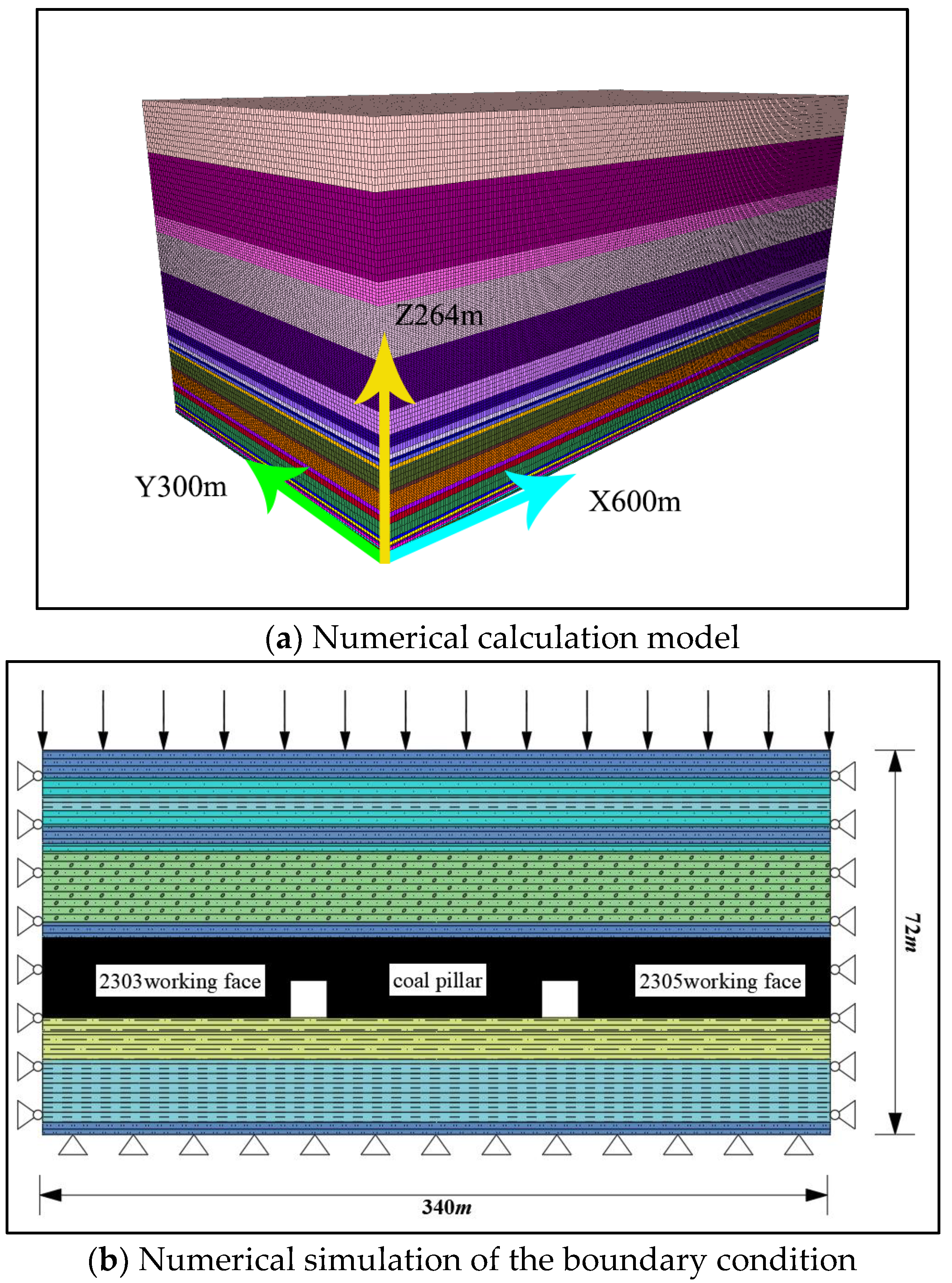

4.3. Numerical Simulation of the Developmental Height of the Water-Conducting Fracture Zone

4.3.1. Modeling of Numerical Calculations

4.3.2. Numerical Simulation Scheme

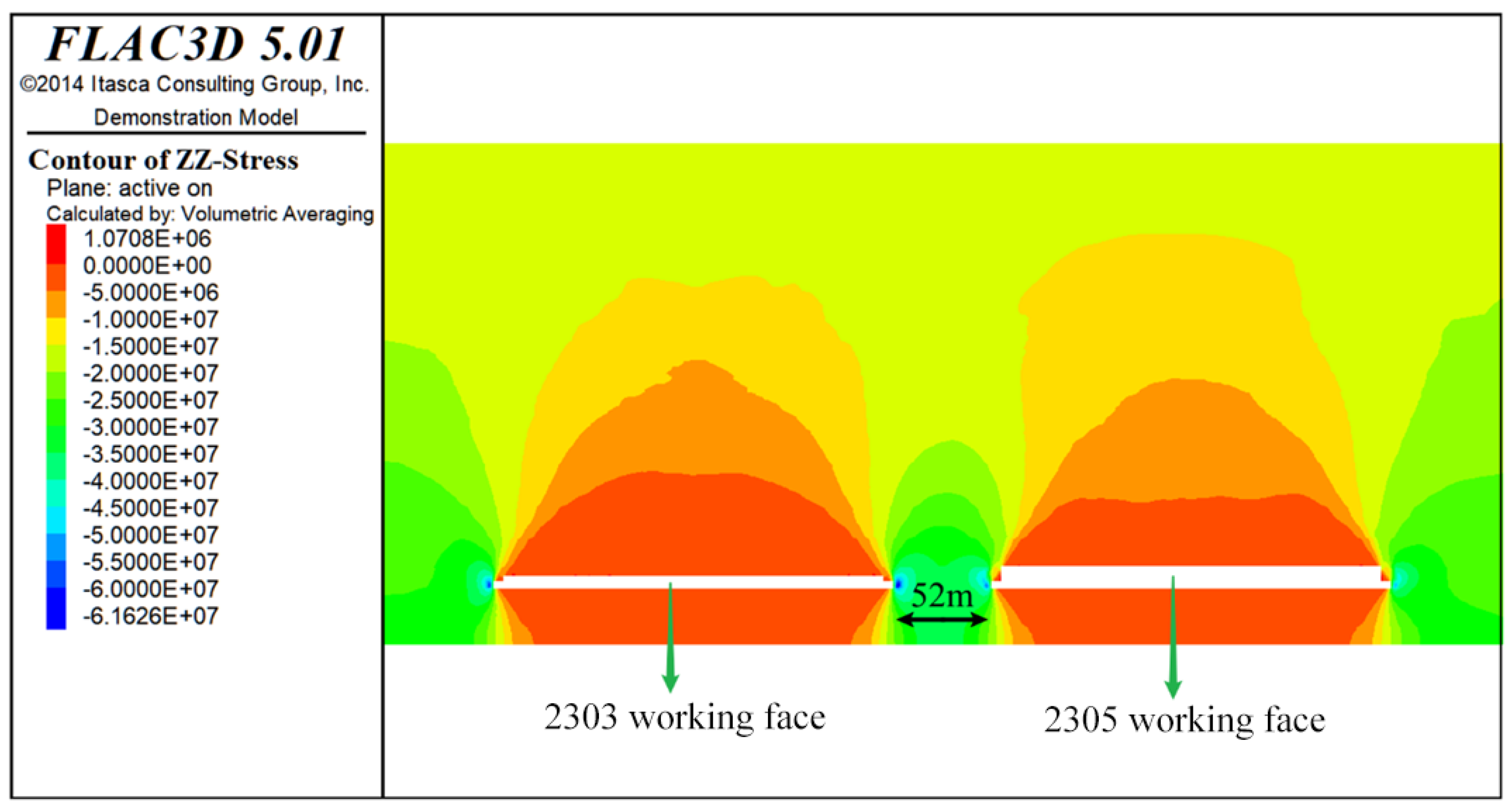

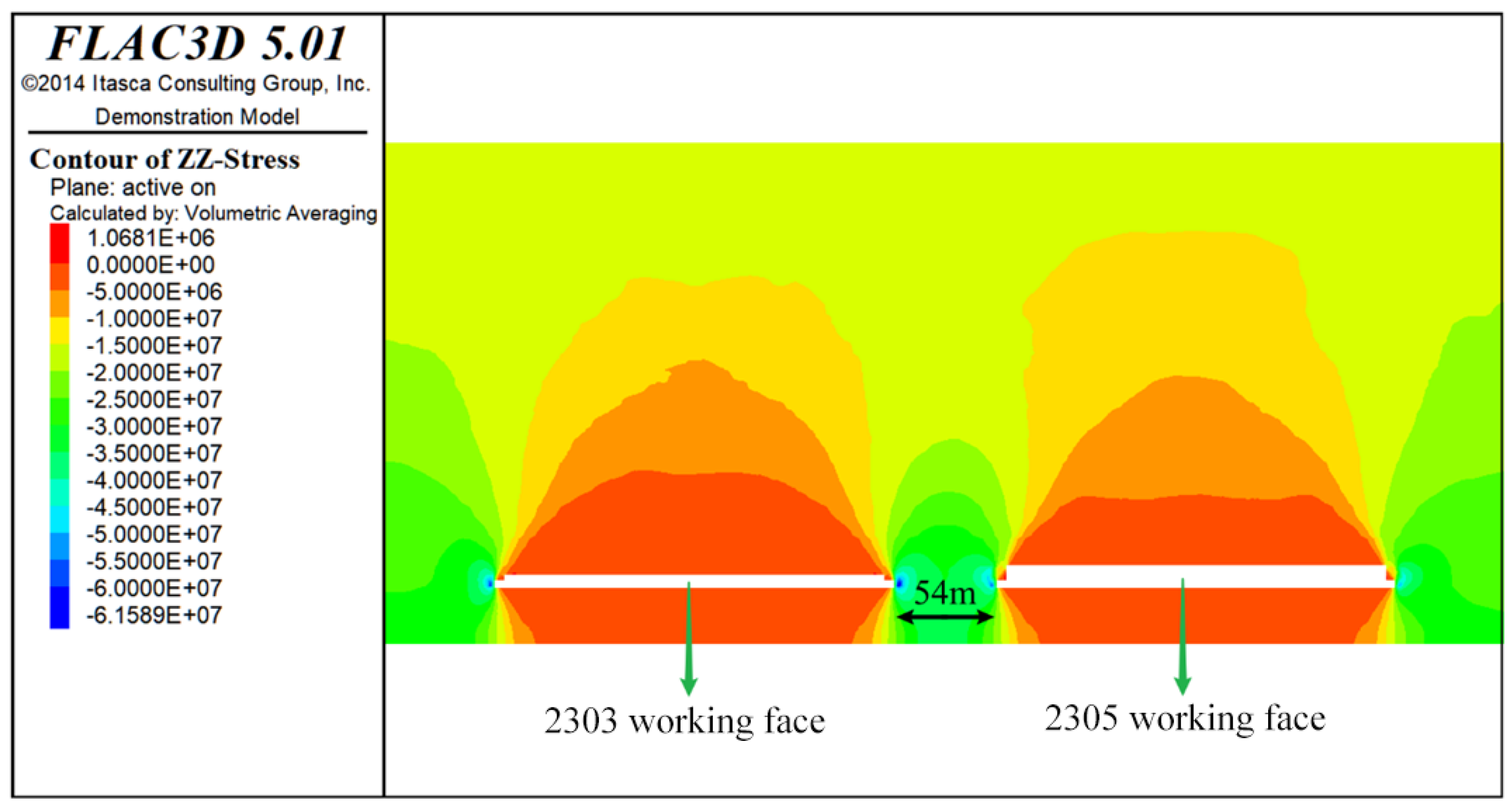

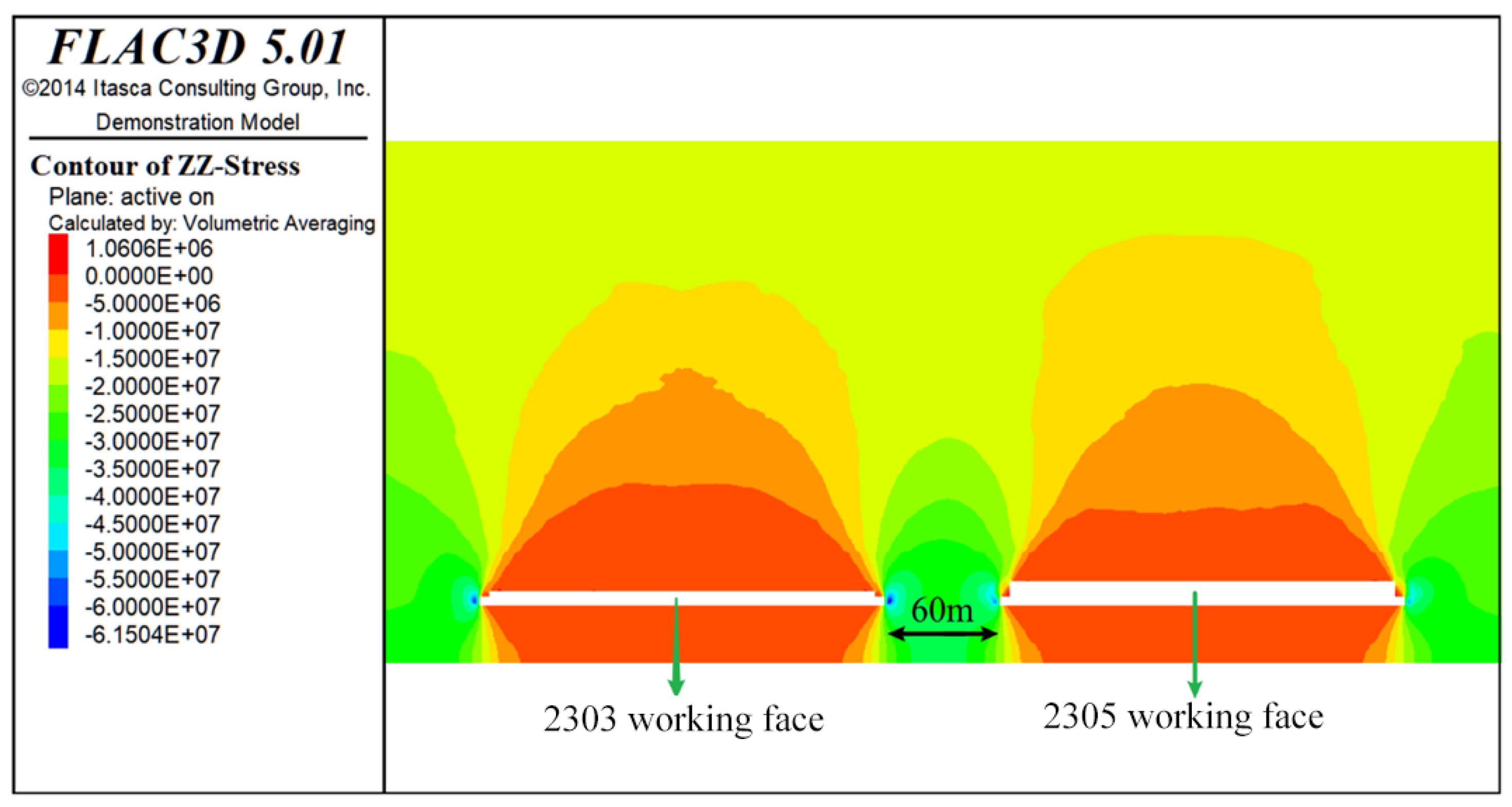

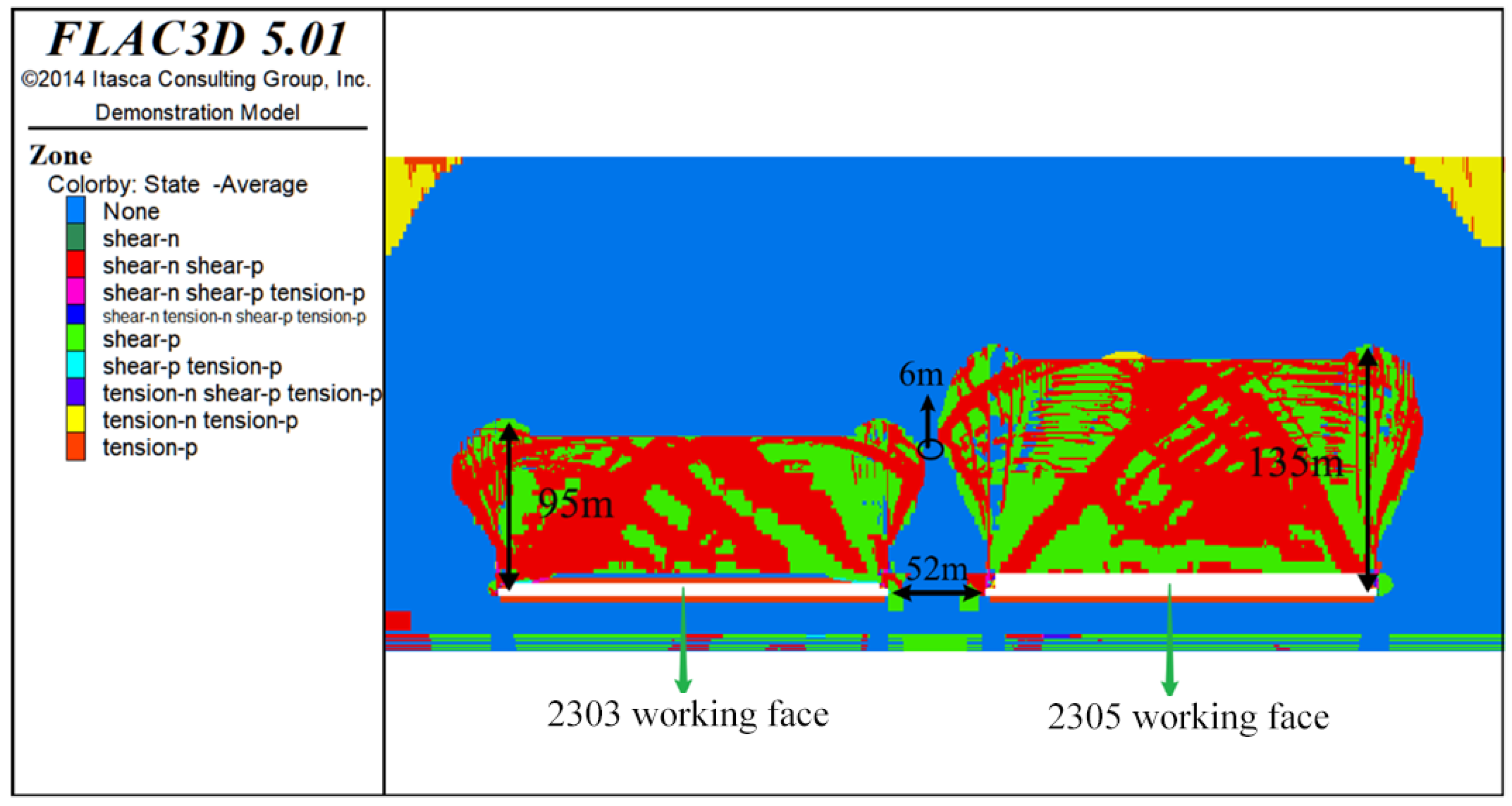

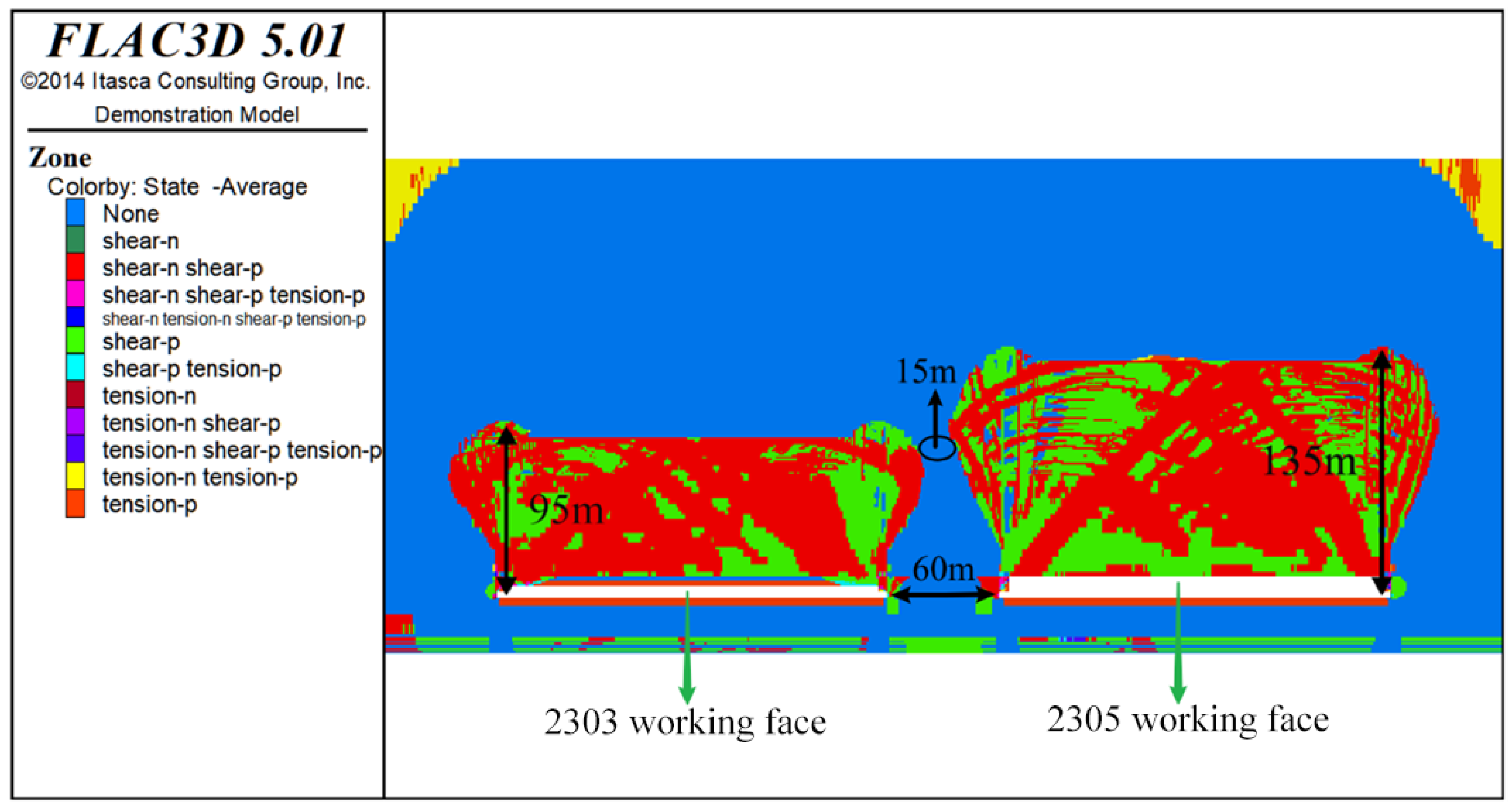

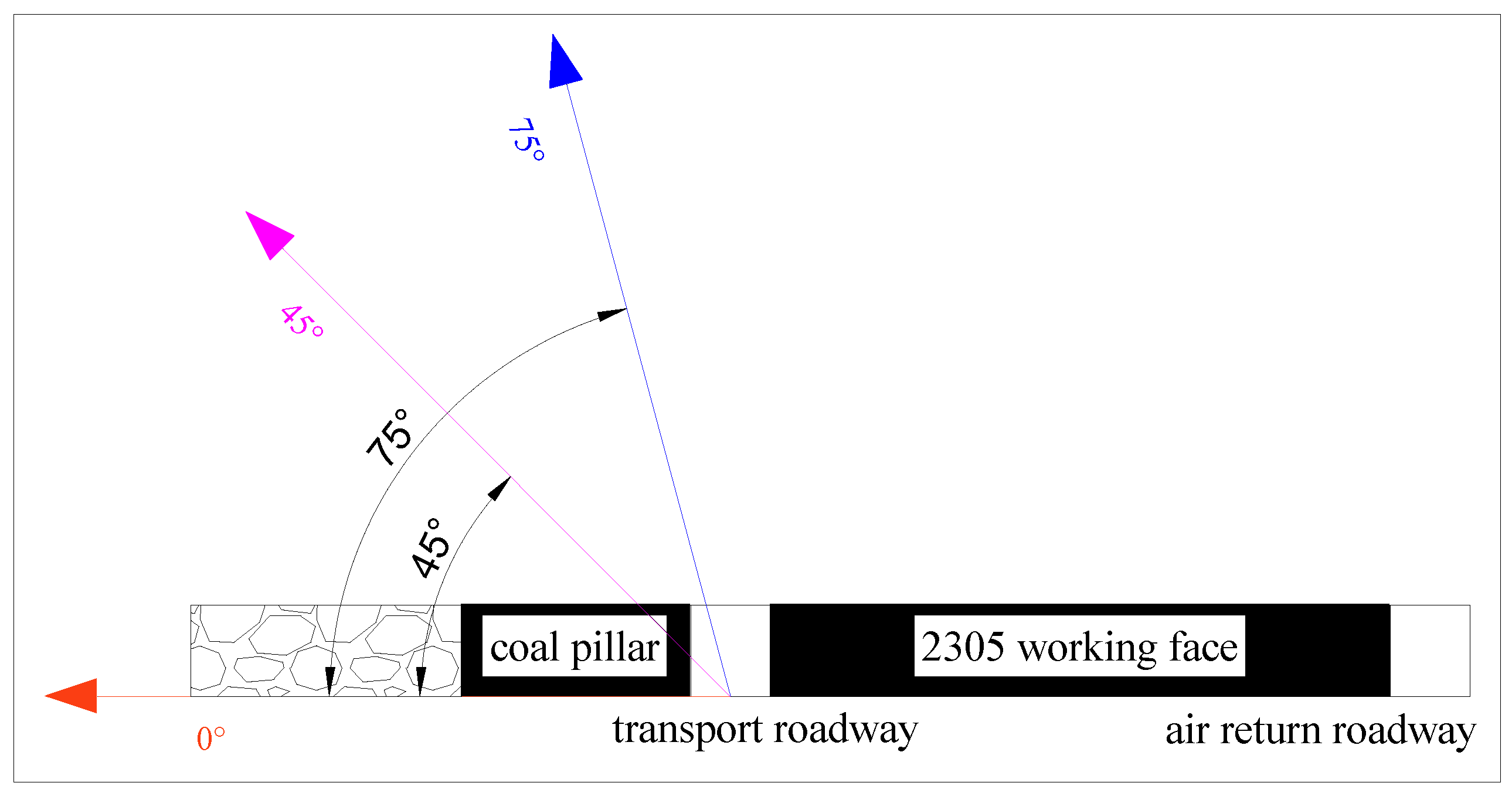

4.3.3. Numerical Simulation Results

- (1)

- (2)

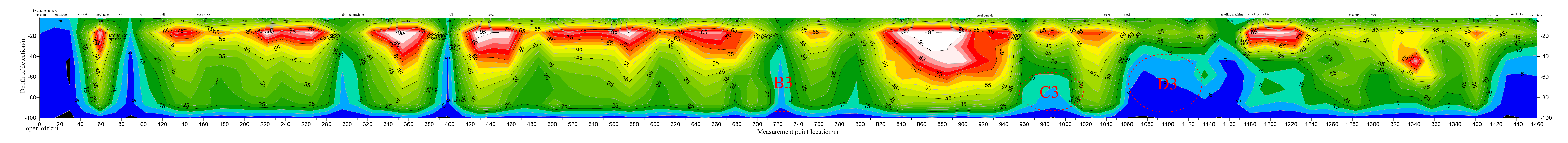

5. Analysis of the Geophysical Survey of the Working Face

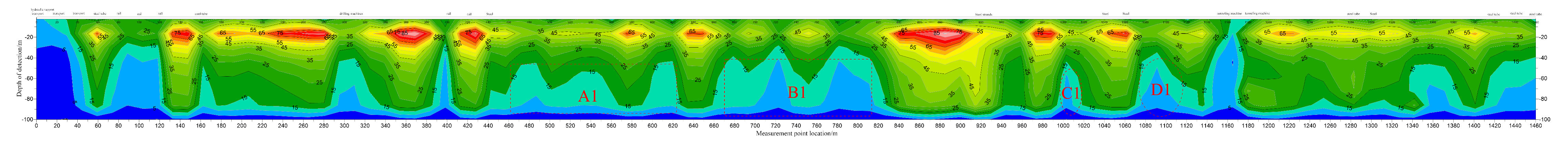

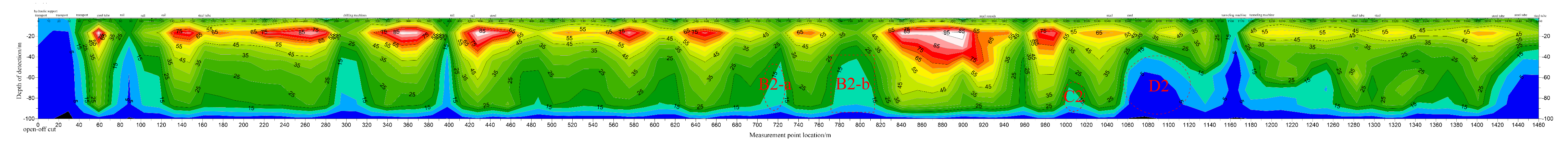

5.1. Transient Electromagnetic Detection Technology Program

5.2. Interpretation and Analysis of Transient Electromagnetic Detection Results

6. Conclusions

- (1)

- According to the mechanical failure characteristics of the coal pillar under the conditions of water accumulation in the goaf, the waterproof coal pillar was divided into a water pressure damage zone, an elastic zone, and a plastic zone. The mechanical model of the coal pillar in different zones was established and the calculation formula of the width of the waterproof coal pillar was obtained. The parameters of the 2303 and 2305 working faces were included in the calculations to obtain the width of the coal pillar corresponding to the plastic zone, elastic area, and water pressure damage zone of the waterproof coal pillar, which were 14.26 m, 4.89 m, and 24.68 m, respectively. The theoretical width of the waterproof coal pillar was 44 m.

- (2)

- The numerical simulation method was used to analyze the development height of the water conducting fracture zone in the overlying rock strata when the actual coal pillar width between the working faces is 52 m, 54 m, and 60 m. The simulation results indicated that the development height of the water-conducting fracture zone of the 2303 and 2305 working faces is 95 m and 135 m, and there are elastic zones of 6 m, 9 m, and 15 m above the coal pillars in the middle of the goaf of the two working faces.

- (3)

- The transient electromagnetic method was used to detect the water richness of the actual coal pillar width between the 2303 and 2305 working faces, and the relatively low resistance areas in the sections of 0~120 m, 290~320 m, 390~400 m, 1140~1180 m, and 1410~1460 m at the measurement points were speculated to be caused by on-site metal interference. The 460~620 m, 670~820 m, 960~1020 m, and 1060~1180 m sections of the measuring points are divided into relatively low-resistance anomaly areas, which are inferred to be caused by the influence of water accumulation in the goaf. The depth of the influence of water accumulation in the goaf on the coal pillar is between 5~15 m, and the overall integrity of the coal pillar is good.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wang, C.; Wang, F.; Ye, Y.; Zhang, X.; Su, Y.; Jiang, L.; Li, Z.; Zhang, H. Evolutionary characteristics of coal consumption in China and its driving mechanism based on supply and demand perspectives. J. Nat. Resour. 2020, 35, 2708–2723. [Google Scholar]

- Chu, S.; Majumdar, A. Opportunities and challenges for a sustainable energy future. Nature 2012, 488, 294–303. [Google Scholar] [CrossRef] [PubMed]

- Yang, Y.; Liu, Y. Progress of world energy geography research and prospect of discipline development. Prog. Geosci. 2013, 32, 818–830. [Google Scholar]

- Dyczko, A. Real-time forecasting of key coking coal quality parameters using neural networks and artificial intelligence. Rud.-Geološko-Naft. Zb. 2023, 38, 105–117. [Google Scholar] [CrossRef]

- He, Z.; Zhou, Y.; Liu, Y. System dynamics simulation of China’s energy consumption structure in 2050: A transition scenario based on key industries. J. Nat. Resour. 2020, 35, 2696–2707. [Google Scholar]

- Li, Z. Research on the situation of coal industry and coal supply and demand in the 14th Five-Year Plan period. Coal Econ. Res. 2021, 41, 9–14. [Google Scholar]

- Miao, Q.; Meng, G.; Chen, M.; Ge, W.; Qu, J.; Wang, T. Coal resource availability analysis and guarantee study in China. Energy Environ. 2020, 6–8, 23. [Google Scholar] [CrossRef]

- Iordanov, I.; Buleha, I.; Bachurina, Y.; Boichenko, H.; Dovgal, V.; Kayun, O.; Kohtieva, O.; Podkopayev, Y. Experimental research on the haulage drifts stability in steeply dipping seams. Min Min. Depos. 2021, 15, 56–67. [Google Scholar] [CrossRef]

- Dychkovskyi, R.; Shavarskyi, I.; Saik, P.; Lozynskyi, V.; Falshtynskyi, V.; Cabana, E. Research into stress-strain state of the rock mass condition in the process of the operation of double-unit longwalls. Min Min. Depos. 2020, 14, 85–94. [Google Scholar] [CrossRef]

- Lu, C. Opening a New Era of Major Changes in China’s Energy System and Innovative Development of Clean and Renewable Energy—A Deep Understanding of the Great Historical Significance of Peak Carbon and Carbon Neutral Targets. People’s Forum-Acad. Front. 2021, 1, 28–41. [Google Scholar] [CrossRef]

- Sakhno, I.; Sakhno, S.; Skyrda, A. Field investigations of deformations in soft surrounding rocks of roadway with roof-bolting support by auger mining of thin coal seams. Rud.-Geološko-Naft. Zb. 2022, 37, 23–38. [Google Scholar] [CrossRef]

- Tian, Y.; Zhang, P.; Wu, R.; Liu, C. Current analysis and prospect of fault activation research under coal mining conditions. Coalf. Geol. Explor. 2021, 49, 60–70. [Google Scholar] [CrossRef]

- Zhienbayev, A.; Balpanova, M.; Asanova, Z.; Zharaspaev, M.; Nurkasyn, R.; Zhakupov, B. Analysis of the roof span stability in terms of room-and-pillar system of ore deposit mining. Min Min. Depos. 2023, 17, 129–137. [Google Scholar] [CrossRef]

- Lozynskyi, V.; Medianyk, V.; Saik, P.; Rysbekov, K.; Demydov, M. Multivariance solutions for designing new levels of coal mines. Rud.-Geološko-Naft. Zb. 2020, 35, 23–31. [Google Scholar] [CrossRef]

- Ren, X. Research on Characteristics and Prevention and Control of Coal Mine Geological Hazards. Contemp. Chem. Res. 2019, 17, 65–66. [Google Scholar] [CrossRef]

- Chen, P.P.; Liu, H.Q.; Zhang, G.Y. Determination of waterproof rock pillar height with the top coal caving under sea. Meitan Xuebao/J. China Coal Soc. 2009, 34, 875–880. [Google Scholar]

- Nguyen, L.Q.; Le, T.T.T.; Nguyen, T.G.; Tran, D.T. Prediction of underground mining-induced subsidence: Artificial neural network based approach. Min Min. Depos. 2023, 17, 45–52. [Google Scholar] [CrossRef]

- Qing, L. Reasonable Width of Waterproof Coal Pillar under the Condition of Different Fault Dip Angles. J. Min. Saf. Eng. 2009, 26, 179–183. [Google Scholar]

- Babets, D.; Sdvyzhkova, O.; Hapieiev, S.; Shashenko, O.; Vasyl, V. Multifactorial analysis of a gateroad stability at goaf interface during longwall coal mining—A case study. Min Min. Depos. 2023, 17, 9–19. [Google Scholar] [CrossRef]

- Smoliński, A.; Malashkevych, D.; Petlovanyi, M.; Rysbekov, K.; Lozynskyi, V.; Sai, K. Research into Impact of Leaving Waste Rocks in the Mined-Out Space on the Geomechanical State of the Rock Mass Surrounding the Longwall Face. Energies 2022, 15, 9522. [Google Scholar] [CrossRef]

- Sharipov, A.; Adoko, A. An approach to estimate coal pillar strength. IOP Conf. Ser. Earth Environ. Sci. 2021, 833, 12136. [Google Scholar] [CrossRef]

- Shavarskyi, I.; Falshtynskyi, V.; Dychkovskyi, R.; Akimov, O.; Sala, D.; Buketov, V. Management of the longwall face advance on the stress-strain state of rock mass. Min Min. Depos. 2022, 16, 78–85. [Google Scholar] [CrossRef]

- Hejmanowski, R.; Witkowski, W.T. Suitability assessment of artificial neural network to approximate surface subsidence due to rock mass drainage. J. Sustain. Min. 2015, 14, 101–107. [Google Scholar] [CrossRef]

- Tan, X.; Song, B.; Bo, H.; Li, Y.; Wang, M.; Lu, G. Extraction of Irregularly Shaped Coal Mining Area Induced Ground Subsidence Prediction Based on Probability Integral Method. Appl. Sci. 2020, 10, 6623. [Google Scholar] [CrossRef]

- Deng, X.; Han, M.; Meng, B. Discussion on the principle and calculation method of retaining waterproof coal rock pillars. Coal Technol. 2001, 20, 30–33, 34. [Google Scholar] [CrossRef]

- Liu, Y.; Chai, X.; Li, J. Optimization of waterproof coal rock columns in adjacent working faces. J. Coal Sci. 2009, 34, 239–242. [Google Scholar] [CrossRef]

- Liu, Y.; Wu, Y.P.; Wang, Y.S. Study on the reasonable width of waterproof coal pillar in the upper disk of fault. J. Xi’an Univ. Sci. Technol. 2010, 30, 523–530. [Google Scholar] [CrossRef]

- Liu, C.; Ding, K. On the critical size of underground watertight coal column for pressure damage. J. Coal 2001, 26, 632–636. [Google Scholar] [CrossRef]

- Yao, Z. Exploration on setting waterproof coal pillar in 14-coal mining face of Shengli coal mine. Sci. Technol. Wind. 2021, 133–134. [Google Scholar] [CrossRef]

- Xie, H. Retention of waterproof coal pillar for mining thick coal seam outcrop area under giant thick red seam. Coal Mine Saf. 2020, 51, 201–204. [Google Scholar]

- Wan, Z.; Xing, W. Research on Optimization Design of Waterproof Coal Pillar in Mine. Inn. Mong. Coal Econ. 2018, 3, 126–127. [Google Scholar] [CrossRef]

- Du, S.; Lian, F.; Zhang, Y.T. Research on waterproof coal (rock) pillar retention for mining under thick loose layer in Liuzhuang coal mine. Coal Sci. Technol. 2018, 46, 30–33. [Google Scholar]

- Wang, R.; Meng, Z.; Xie, X.; Jia, L.; Wang, Y. Rational placement and numerical simulation of waterproof coal pillars under huge-thick loose beds. Coalf. Geol. Explor. 2011, 39, 31–35. [Google Scholar] [CrossRef]

- Wang, G.-C.; An, X. Waterproof Coal Pillar Retention Methods under Thick Loose Alluvial Seam. In Proceedings of the 7th Coal Science and Technology Conference, Beijing, China, 17 April 2011; p. 8. [Google Scholar]

- An, X. Retention method of waterproof coal pillars in thick loose alluvium. Hydraul. Coal Min. Pipeline Transp. 2010, 2, 67–69. [Google Scholar] [CrossRef]

- Jiang, W. Coal body damage characteristics and control mechanism of shallow buried hard coal roadway. Coal Mine Saf. 2021, 52, 207–213. [Google Scholar] [CrossRef]

- Fang, G.; Liu, Y.; Li, A. Stability evaluation of coal pillar in working face of shallow buried coal seam in Shenfu mine. Coal Min. 2019, 24, 56–61. [Google Scholar] [CrossRef]

| Area Number | 1 | 2 | 3 | 4 |

|---|---|---|---|---|

| 2305 Length of working face/m | 0~800 | 800~1015 | 1015~1084 | 1084~1540 |

| Width of coal pillar/m | 60 | 54 | 52 | 54 |

| Ponding pressure/MPa | 1.06~0.6 | 0.6~0.36 | 0.36~0.3 | 0.3~0 |

| Sector Number | Sector I | Sector II | Sector III | Sector IV |

|---|---|---|---|---|

| K | 4 | 4 | 4 | 4 |

| M/m | 12 | 12 | 12 | 12 |

| p/MPa | 1.06 | 0.6 | 0.36 | 0.3 |

| Kp/MPa | 0.94 | 0.94 | 0.94 | 0.94 |

| L/m | 44.1 | 33.2 | 25.7 | 23.5 |

| Actual width/m | 60 | 54 | 52 | 54 |

| Lithology | ρ/kg·m−3 | K/GPa | G/GPa | φ/° | C/MPa | σp/MPa |

|---|---|---|---|---|---|---|

| Mudstone | 2635 | 8.77 | 5.77 | 25.3 | 6.3 | 1.75 |

| Sandy mudstone | 2668 | 8.75 | 4.04 | 28.90 | 8.8 | 1.44 |

| Carbonaceous mudstone | 2660 | 8.65 | 3.5 | 26.90 | 7.8 | 1.4 |

| 4-2# coal | 1418 | 6.27 | 2.41 | 30 | 3.0 | 0.94 |

| Siltstone | 2693 | 6.48 | 5.09 | 31.5 | 1.5 | 7.53 |

| Coarse-grained sandstone | 2673 | 7.13 | 4.64 | 31.7 | 9.7 | 4.75 |

| Medium-grained sandstone | 2673 | 7.13 | 4.64 | 31.7 | 7.7 | 5.26 |

| Number | Low Resistance Area | Interpretation for Results |

|---|---|---|

| 1 | 0~120 m | The apparent resistivity is very low, analyzed as an effect of the transports and rails, and not interpreted as a water anomaly. |

| 2 | 290~320 m | The low apparent resistivity is an effect of the drilling machine and is not interpreted as a water-bearing anomaly. |

| 3 | 390~400 m | The low apparent resistivity is an effect of the rails in the field and is not interpreted as a water anomaly. |

| 4 | 460~620 m (Probing depth: 45~100 m) | Presumed to be a relatively low resistance area. |

| 5 | 670~820 m (Probing depth: 40~100 m) | Presumed to be a relatively low resistance area. |

| 6 | 1000~1020 m (Probing depth: 50~100 m) | Presumed to be a relatively low resistance area. |

| 7 | 1070~1120 m (Probing depth: 40~100 m) | Presumed to be a relatively low resistance area. |

| 8 | 1140~1180 m | The apparent resistivity is very low, analyzed as an effect of the tunneling machine, and not interpreted as a water anomaly. |

| 9 | 1410~1460 m | The apparent resistivity is very low, analyzed as an effect of the steel tube, and not interpreted as a water anomaly. |

| Number | Low Resistance Area | Explanation for Results |

|---|---|---|

| 1 | 0~120 m | The apparent resistivity is very low, analyzed as an effect of the transports and rails, and not interpreted as a water anomaly. |

| 2 | 290~320 m | The low apparent resistivity is an effect of the drilling machine and is not interpreted as a water-bearing anomaly. |

| 3 | 390~400 m | The low apparent resistivity is an effect of the rails in the field and is not interpreted as a water anomaly. |

| 4 | 710~730 m (Probing depth: 50~100 m) | Presumed to be a relatively low resistance area. |

| 5 | 770~810 m (Probing depth: 40~100 m) | Presumed to be a relatively low resistance area. |

| 6 | 1000~1020 m (Probing depth: 65~100 m) | Presumed to be a relatively low resistance area. |

| 7 | 1060~1120 m (Probing depth: 40~100 m) | Presumed to be a relatively low resistance area. |

| 8 | 1140~1180 m | The apparent resistivity is very low, analyzed as an effect of the tunneling machine, and not interpreted as a water anomaly. |

| 9 | 1410~1460 m | The apparent resistivity is very low, analyzed as an effect of the steel tube, and not interpreted as a water anomaly. |

| Number | Low Resistance Area | Explanation for Results |

|---|---|---|

| 1 | 0~120 m | The apparent resistivity is very low, analyzed as an effect of the transports and rails, and not interpreted as a water anomaly. |

| 2 | 290~320 m | The low apparent resistivity is an effect of the drilling machine and is not interpreted as a water-bearing anomaly. |

| 3 | 390~400 m | The low apparent resistivity is an effect of the rails in the field and is not interpreted as a water anomaly. |

| 4 | 710~730 m (Probing depth: 40~100 m) | Presumed to be a relatively low resistance area. |

| 5 | 960~1010 m (Probing depth: 55~100 m) | Presumed to be a relatively low resistance area. |

| 6 | 1060~1130 m (Probing depth: 40~100 m) | Presumed to be a relatively low resistance area. |

| 7 | 1140~1180 m | The apparent resistivity is very low, analyzed as an effect of the tunneling machine, and not interpreted as a water anomaly. |

| 8 | 1410~1460 m | The apparent resistivity is very low, analyzed as an effect of the steel tube, and not interpreted as a water anomaly. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gu, W.; Xu, D.; Wang, Y.; Miao, K.; Yao, S.; Zhang, H.; Han, Z. Research on the Stability and Water Isolation of Waterproof Coal Pillars between Adjacent Working Faces under the Influence of Water Ponding Goaf—A Case Study. Appl. Sci. 2024, 14, 884. https://doi.org/10.3390/app14020884

Gu W, Xu D, Wang Y, Miao K, Yao S, Zhang H, Han Z. Research on the Stability and Water Isolation of Waterproof Coal Pillars between Adjacent Working Faces under the Influence of Water Ponding Goaf—A Case Study. Applied Sciences. 2024; 14(2):884. https://doi.org/10.3390/app14020884

Chicago/Turabian StyleGu, Wei, Dalong Xu, Yunqing Wang, Kuo Miao, Sumeng Yao, Hao Zhang, and Zhenfei Han. 2024. "Research on the Stability and Water Isolation of Waterproof Coal Pillars between Adjacent Working Faces under the Influence of Water Ponding Goaf—A Case Study" Applied Sciences 14, no. 2: 884. https://doi.org/10.3390/app14020884