Variability in Mechanical Properties and Cracking Behavior of Frozen Sandstone Containing En Echelon Flaws under Compression

Abstract

:1. Introduction

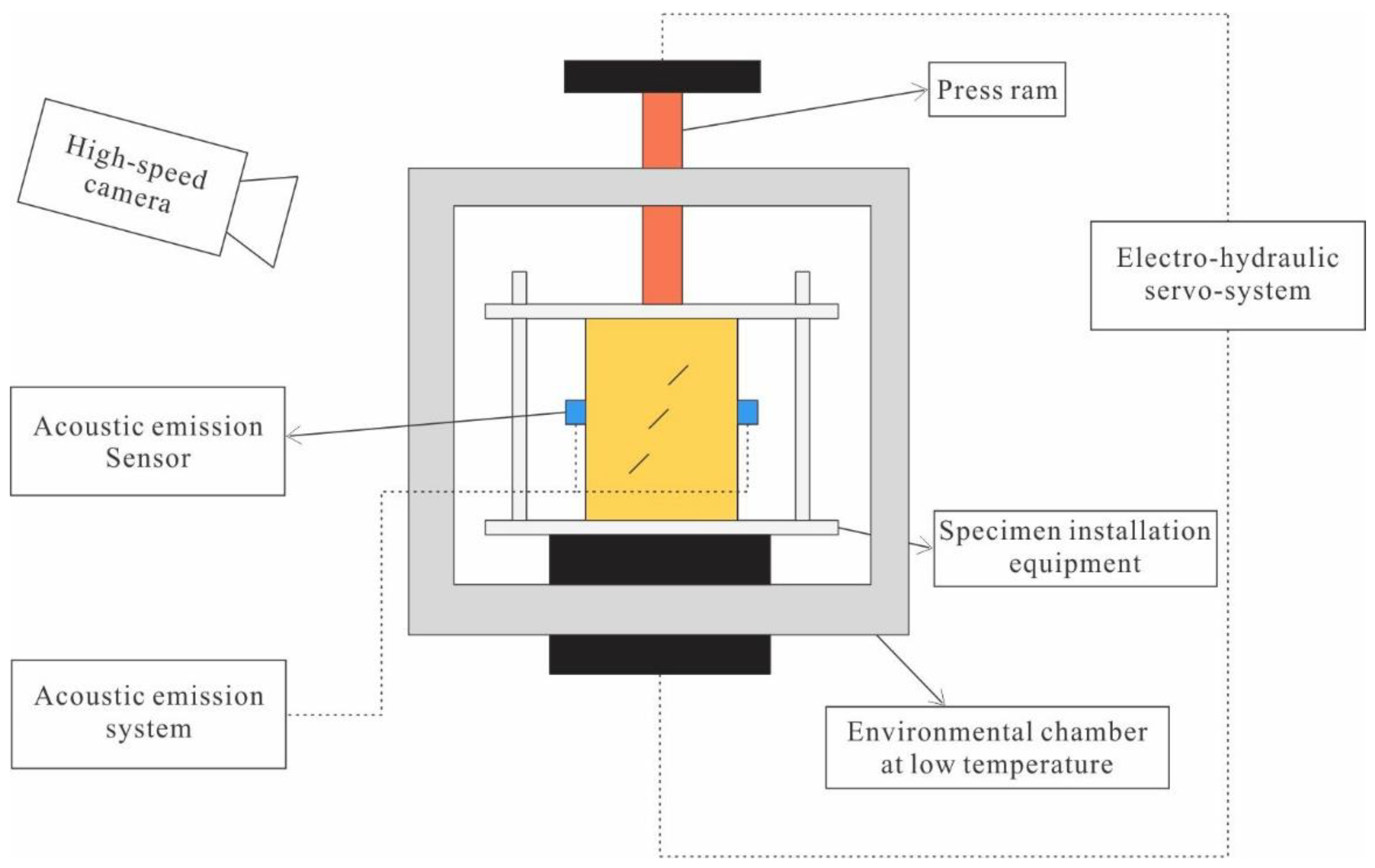

2. Methodology

2.1. Specimens and Equipment

2.2. Experimental Design

- Place the specimens in a drying oven set at 105 °C for a duration of 24 h.

- Subject the specimens to a vacuum chamber with a negative pressure of −1 atmosphere for a period of 2 h, followed by immersion in water until their mass stabilizes.

- Transfer the specimens to a cryogenic freezing box maintained at −20 °C for 6 h.

- Introduce the specimens into an environmental chamber and maintain them at −20 °C for 2 h.

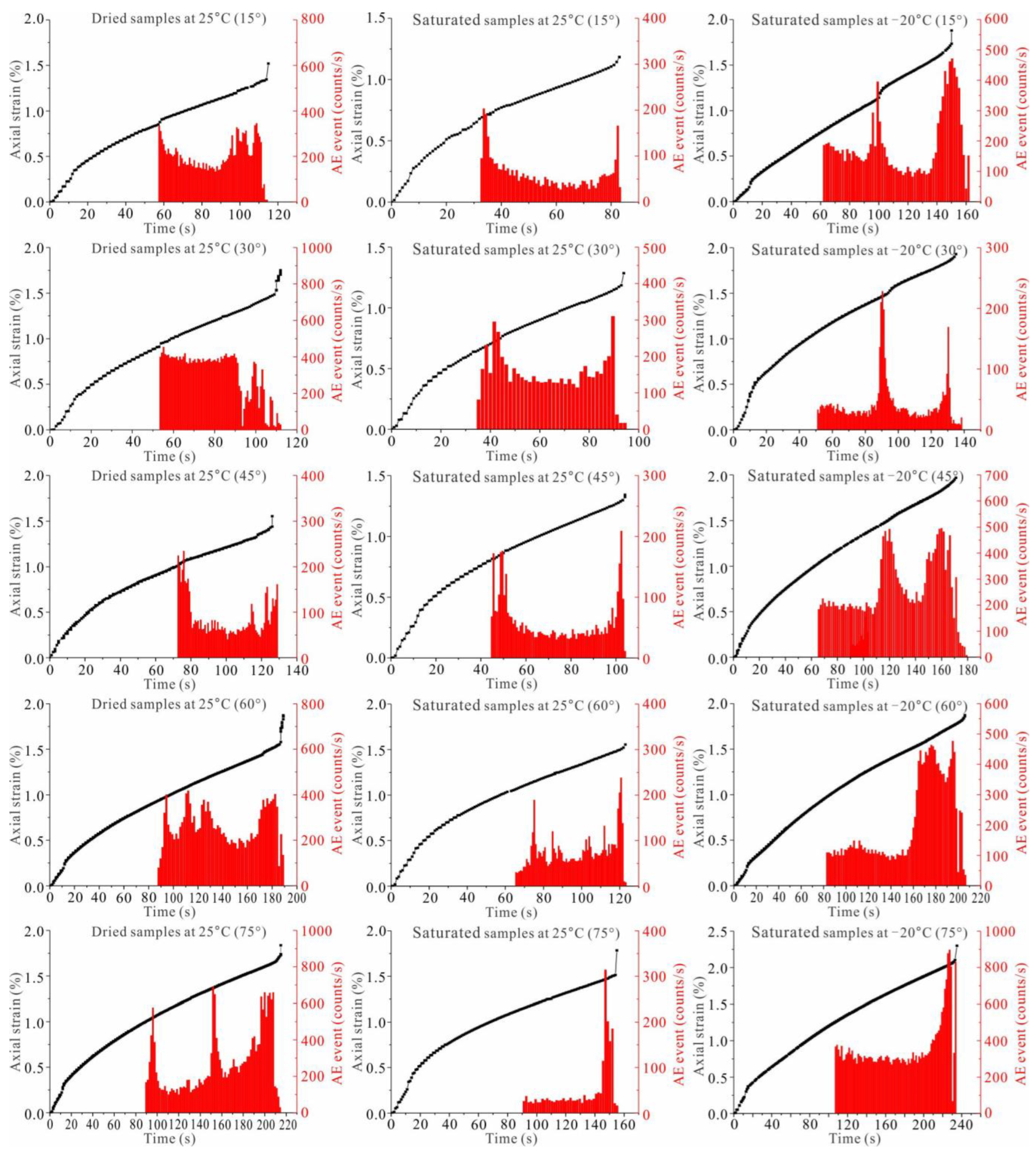

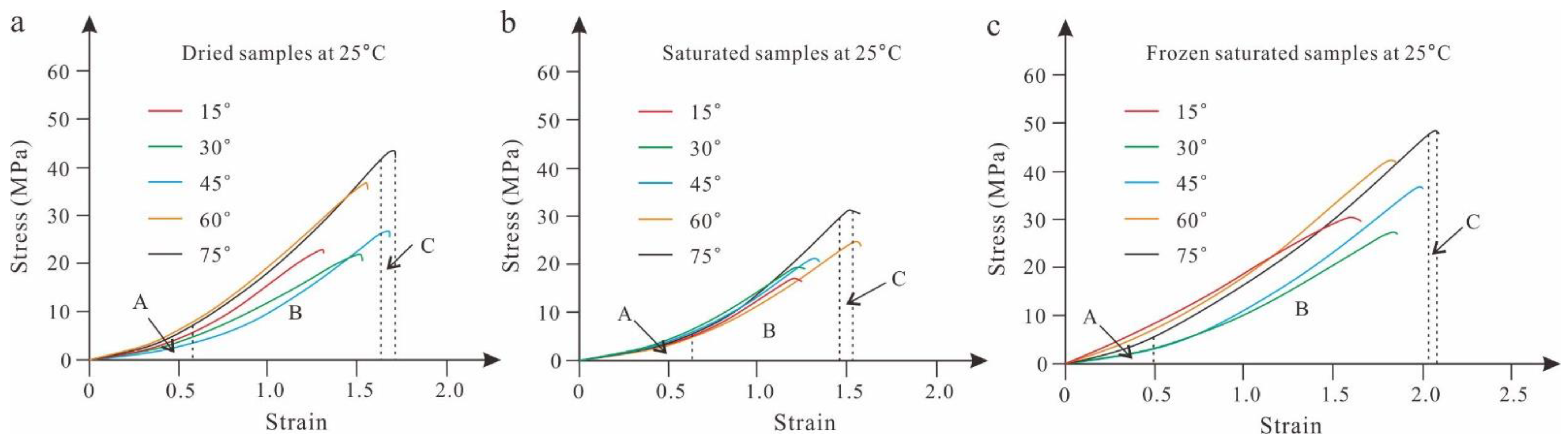

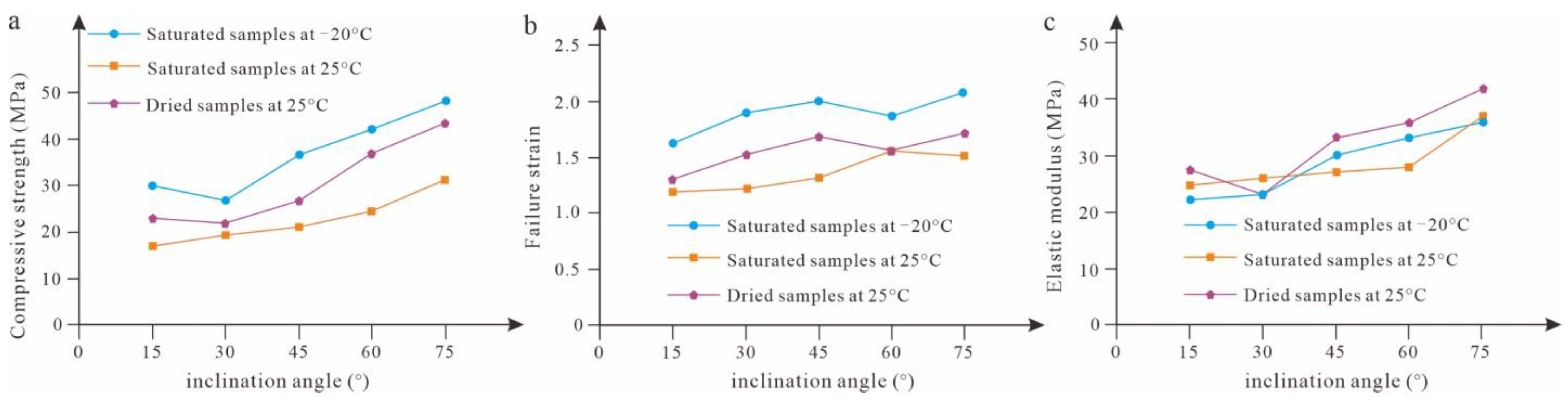

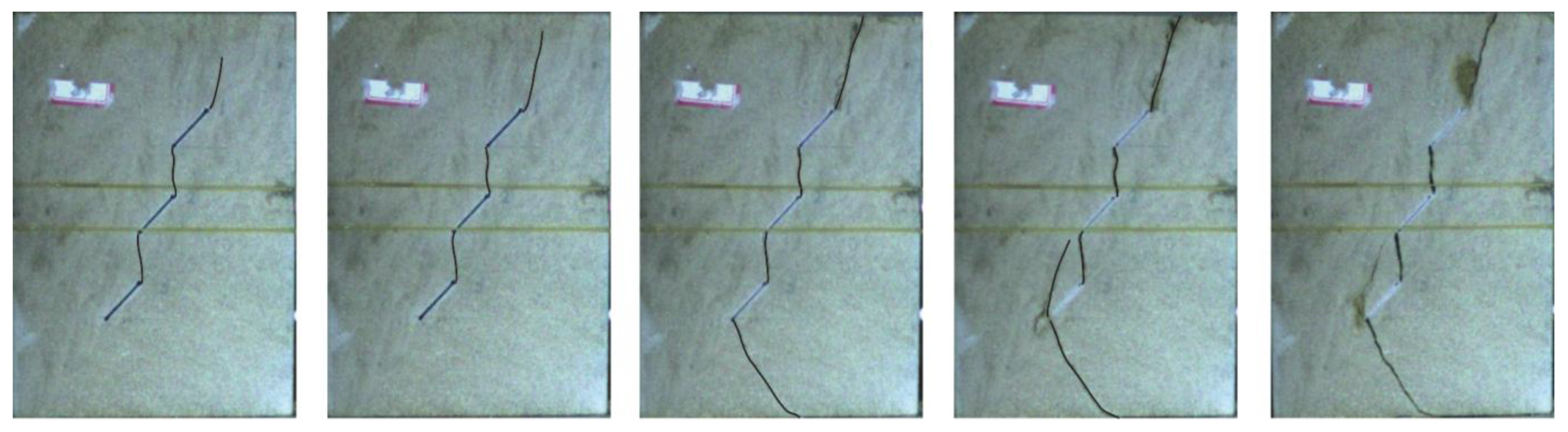

- Begin the uniaxial compression experiment and observe the process using high-speed photography and acoustic emission monitoring. During this process, record the load and deformation using an electro-hydraulic servo-system, and then calculate the data for each specimen, presented as a stress–strain curve in Figure 3. The peak strength and strain values from Figure 3 are collected and displayed in Figure 4, along with the calculation of elastic modulus. The acoustic characteristics of specimens during the failure process are recorded using an acoustic emission device, with both acoustic emission events and axial strain exhibited in Figure 7. The cracking process of each specimen is captured by a high-speed camera, with initial cracks shown in Figure 10, while the failure process of three states is illustrated in Figures 11–13. The entire experiment is divided into two parts: pre-pressure (1 kN) stage and formal experiment (loading rate = 30 kN/min) stage; an environmental chamber is utilized to maintain a constant temperature for the specimens.

3. Uniaxial Compression Strength Characteristics of Fissured Sandstone

3.1. Stress-Stain Curves

3.2. Strength Characteristics with Fissures of Five Different Inclinations

- Enhanced support from ice under compression: the sandstone pores tend to close when subjected to uniaxial compression, and the presence of pore ice imparts a supporting force that elevates the strength and modulus of the frozen sandstone.

- Microcrack-filling effect of ice: the microcracks induced by uniaxial compression are filled with the ice, thereby reducing stress concentrations at the crack tips and enhancing the strength of the rock.

- Cementing effect of unfrozen water film under tension or under shearing load: the unfrozen water film adheres to the pores, thereby enhancing their resistance against tensile and shear forces.

- Frost damage effect: the freezing process leads to an expansion in the volume of pore water, which is attributed to the frost heave force exerted on the pores, resulting in the formation of new microcracks among the grains. In other words, the rock matrix undergoes damage due to the frost heave force, leading to a reduction in the strength of the frozen sandstone.

4. Acoustic Emissions (AEs) of Fissured Sandstone during the Compression Process

4.1. AE Events

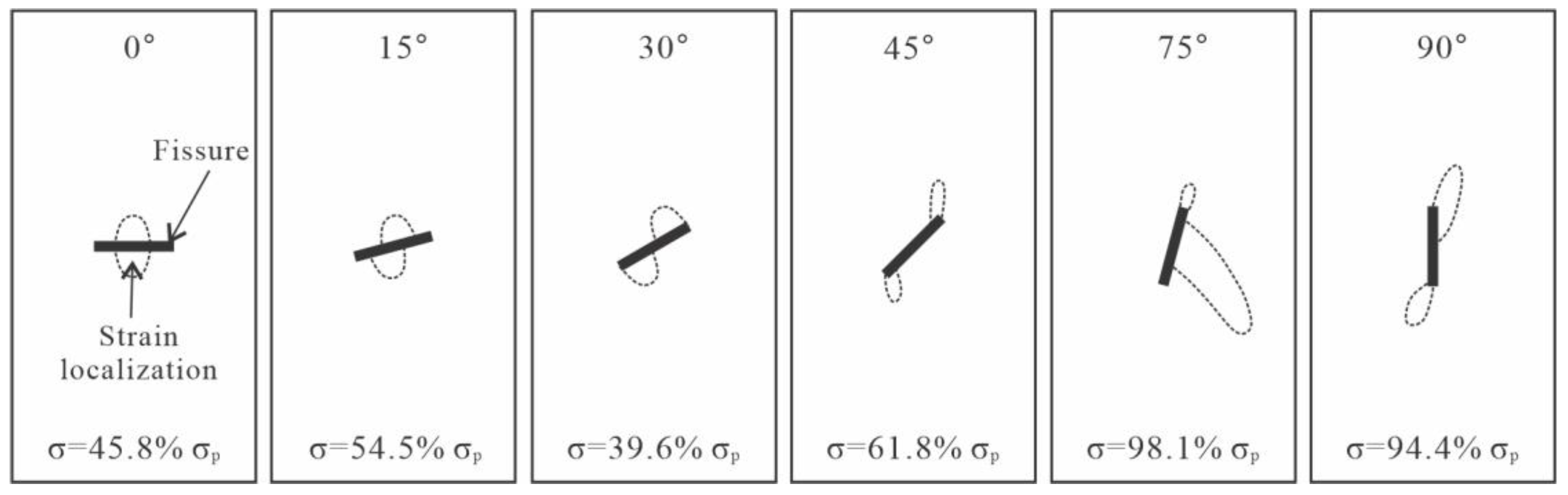

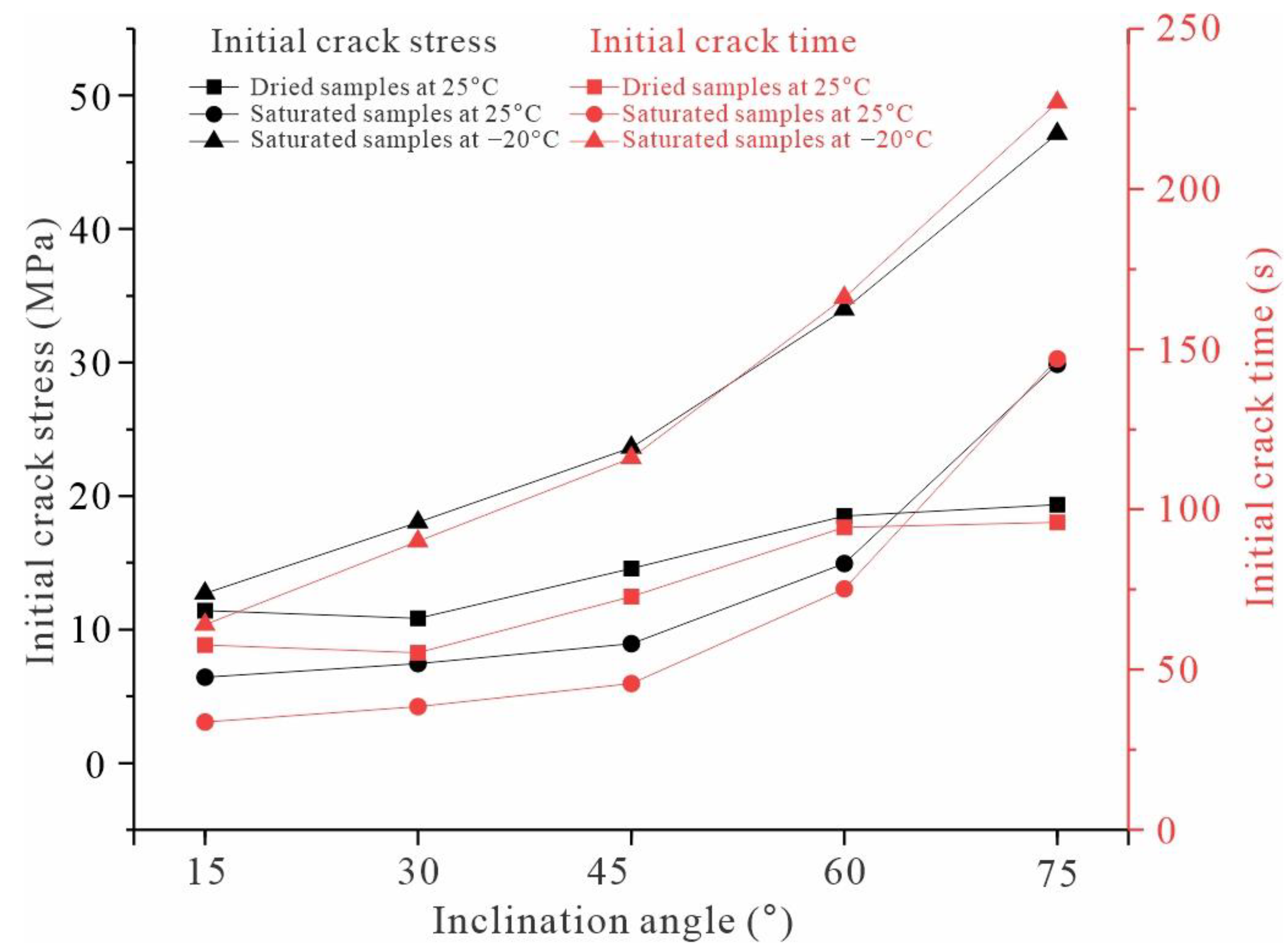

4.2. Initial Cracking during the Compression Process

5. Failure Process of Fissured Sandstone under Uniaxial Compression

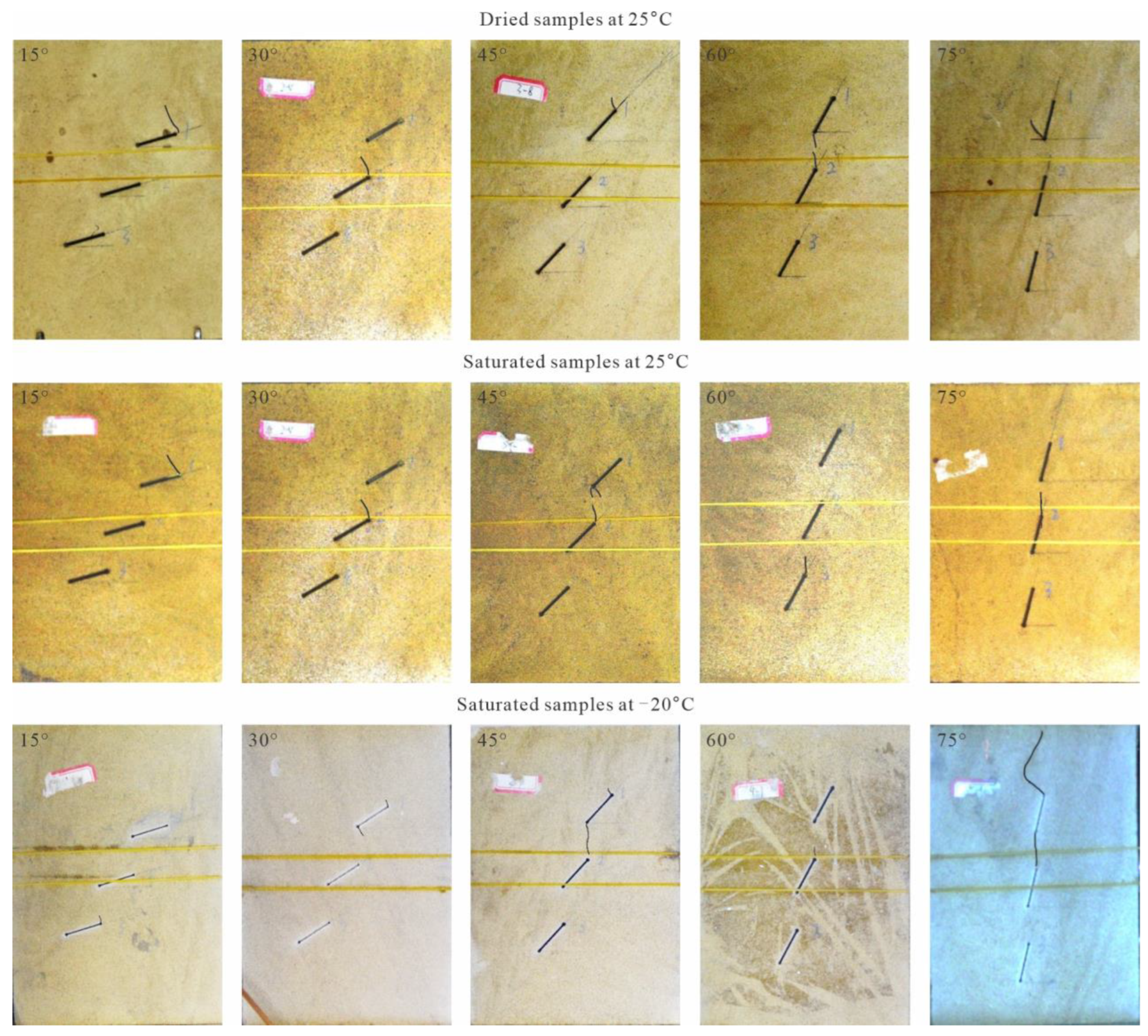

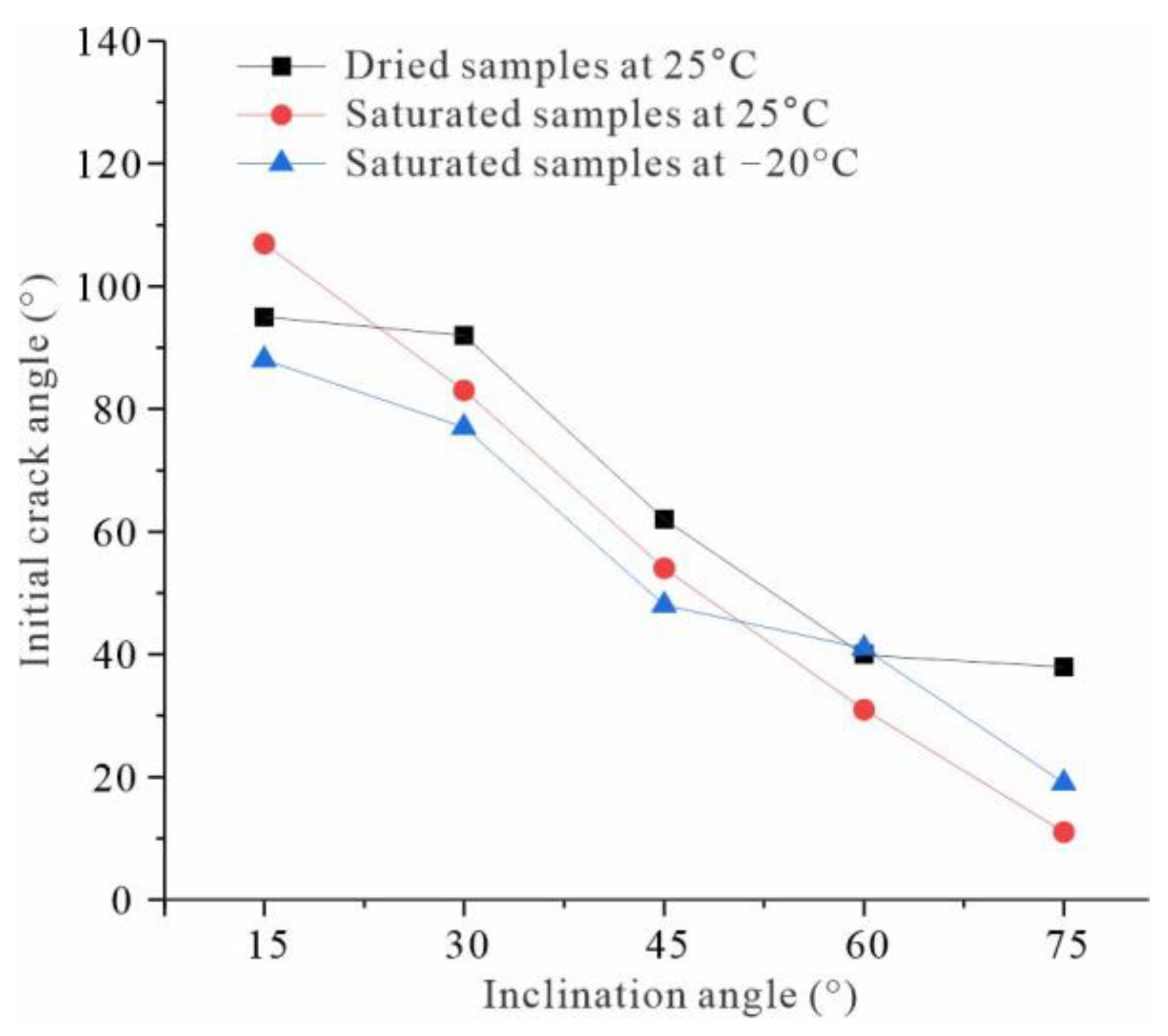

5.1. Initial Crack Angle

5.2. Failure Process

- (1)

- Dried state

- (2)

- Saturated state

- (3)

- Frozen-saturated state

6. Conclusions

- The mechanical properties are influenced by the inclination angle of fissures, saturation, and temperature. In the frozen-saturated and dried states, the UCS curve decreases first and then increases with an increase in inclination angle, reaching its minimum value at 30°. However, in the saturated state, the UCS shows a continuous increase. The ranking of UCS can be stated as follows: frozen-saturated state > dried state > saturated state.

- The AE events in the dried and frozen-saturated states exhibit three peaks during the compression process. The first peak corresponds to the initiation of cracking and propagation between the three fissures, while the second peak corresponds to initial cracking and propagation at the outer tip within fissures 1 and 3; the third corresponds to specimen failure. However, in the saturated state, there are only two peaks observed during the compression process. The first peak represents initial cracking and propagation between all three fissures, whereas the second peak indicates specimen failure.

- The initial crack angles decrease with a rise in fissure inclination, while temperature and saturation have no influence on the initial crack angle. However, the initial crack stress and time increase with fissure inclination in all three states. Furthermore, the ranking of the initial crack stress and time at a given inclination is as follows: frozen-saturated state > dried state > saturated state.

- The strength of saturated sandstone increases when subjected to freezing, and this phenomenon can be attributed to four underlying mechanisms: (1) ice provides braced force under compression, (2) ice fills microcracks, and (3) an unfrozen water film provides a cementing effect under tension or shearing load, while (4) the frost damage effect causes softening. The first three mechanisms counteract the softening effect, resulting in an increase in the UCS of saturated fissured sandstone during freezing.

- The mechanical properties and crack behavior of frozen fissured rock containing a single pre-existing flaw, as well as the influence of ice within the flaw on stress distributions at the fissure tip, remain unclear. These aspects require further investigation in future studies.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Sammis, C.; Biegel, R. Mechanics of strengthening in crystalline rock at low temperatures: A preliminary assessment. In Proceedings of the 26th Seismic Research Review: Trends in Nuclear Explosion Monitoring, Orlando, FL, USA, 21–23 September 2004; pp. 475–484. [Google Scholar]

- Jia, H.; Ding, S.; Zi, F.; Dong, Y.; Shen, Y. Evolution in sandstone pore structures with freeze-thaw cycling and interpretation of damage mechanisms in saturated porous rocks. CATENA 2020, 195, 104915. [Google Scholar] [CrossRef]

- Ma, L.; Qi, J.; Yu, F.; Yao, X. Experimental study on variability in mechanical properties of a frozen sand as determined in triaxial compression tests. Acta Geotech. 2016, 11, 61–70. [Google Scholar] [CrossRef]

- Xu, X.; Li, Q.; Xu, G. Investigation on the behavior of frozen silty clay subjected to monotonic and cyclic triaxial loading. Acta Geotech. 2019, 15, 1289–1302. [Google Scholar] [CrossRef]

- Liu, L.; Li, H.; Li, X.; Wu, D.; Zhang, G. Underlying mechanisms of crack initiation for granitic rocks containing a single pre-existing flaw: Insights from digital image correlation (Dic) analysis. Rock Mech. Rock Eng. 2020, 54, 857–873. [Google Scholar] [CrossRef]

- Liu, L.; Li, H.; Li, X.; Wu, R. Full-field strain evolution and characteristic stress levels of rocks containing a single pre-existing flaw under uniaxial compression. Bull. Eng. Geol. Environ. 2020, 79, 3145–3161. [Google Scholar] [CrossRef]

- Park, C.; Bobet, A. Crack initiation, propagation and coalescence from frictional flaws in uniaxial compression. Eng. Fract. Mech. 2010, 77, 2727–2748. [Google Scholar] [CrossRef]

- Wong, L.N.Y.; Xiong, Q. A method for multiscale interpretation of fracture processes in carrara marble specimen containing a single flaw under uniaxial compression. J. Geophys. Res. Solid Earth 2018, 123, 6459–6490. [Google Scholar] [CrossRef]

- Morgan, S.P.; Johnson, C.A.; Einstein, H.H. Cracking processes in Barre granite: Fracture process zones and crack coalescence. Int. J. Fract. 2013, 180, 177–204. [Google Scholar] [CrossRef]

- Vásárhelyi, B.; Bobet, A. Modeling of crack initiation, propagation and coalescence in uniaxial compression. Rock Mech. Rock Eng. 2000, 33, 119–139. [Google Scholar] [CrossRef]

- Liu, T.; Lin, B.; Zheng, C.; Zou, Q.; Zhu, C.; Yan, F. Influence of coupled effect among flaw parameters on strength characteristic of precracked specimen: Application of response surface methodology and fractal method. J. Nat. Gas Sci. Eng. 2015, 26, 857–866. [Google Scholar] [CrossRef]

- Sagong, M.; Bobet, A. Coalescence of multiple flaws in a rock-model material in uniaxial compression. Int. J. Rock Mech. Min. 2002, 39, 229–241. [Google Scholar] [CrossRef]

- Zhao, Y.; Gao, Y.; Wu, S.; Chen, L.; Zhang, C. Experimental and numerical study of failure characteristics of brittle rocks with single internal 3D open-type flaw. Acta Geotech. 2021, 16, 3087–3113. [Google Scholar] [CrossRef]

- Yang, S.-Q.; Jing, H.-W. Strength failure and crack coalescence behavior of brittle sandstone samples containing a single fissure under uniaxial compression. Int. J. Fract. 2011, 168, 227–250. [Google Scholar] [CrossRef]

- Li, H.; Wong, L.N.Y. Influence of flaw inclination angle and loading condition on crack initiation and propagation. Int. J. Solids Struct. 2012, 49, 2482–2499. [Google Scholar] [CrossRef]

- Wong, R.H.; Chau, K. Crack coalescence in a rock-like material containing two cracks. Int. J. Rock Mech. Min. Sci. 1998, 35, 147–164. [Google Scholar] [CrossRef]

- Yang, S.Q.; Yang, D.S.; Jing, H.W.; Li, Y.H.; Wang, S.Y. An experimental study of the fracture coalescence behaviour of brittle sandstone specimens containing three fissures. Rock Mech. Rock Eng. 2012, 45, 563–582. [Google Scholar] [CrossRef]

- Zhang, X.-P.; Liu, Q.; Wu, S.; Tang, X. Crack coalescence between two non-parallel flaws in rock-like material under uniaxial compression. Eng Geol. 2015, 199, 74–90. [Google Scholar] [CrossRef]

- Xu, G.; Hu, X.; Tang, R.; Hou, Z. Fracture evolution of transversely isotropic rocks with a pre-existing flaw under compression tests based on moment tensor analysis. Acta Geotech. 2021, 17, 169–203. [Google Scholar] [CrossRef]

- Wong, L.; Einstein, H. Systematic evaluation of cracking behavior in specimens containing single flaws under uniaxial compression. Int. J. Rock Mech. Min. Sci. 2009, 46, 239–249. [Google Scholar] [CrossRef]

- Wong, L.N.Y.; Einstein, H.H. Crack coalescence in molded gypsum and carrara marble: Part 1. macroscopic observations and interpretation. Rock Mech. Rock Eng. 2009, 42, 475–511. [Google Scholar] [CrossRef]

- Zhang, K.; Cao, P.; Ma, G.; Wang, W.; Fan, W.; Li, K. Strength, fragmentation and fractal properties of mixed flaws. Acta Geotech. 2016, 11, 901–912. [Google Scholar] [CrossRef]

- Liu, G.; Sun, W.; Lowinger, S.M.; Zhang, Z.; Huang, M.; Peng, J. Coupled flow network and discrete element modeling of injection-induced crack propagation and coalescence in brittle rock. Acta Geotech. 2019, 14, 843–868. [Google Scholar] [CrossRef]

- Sun, W.B.; Du, H.Q.; Zhou, F.; Shao, J.L. Experimental study of crack propagation of rock-like specimens containing conjugate fractures. Geomech. Eng. 2019, 17, 323–331. [Google Scholar] [CrossRef]

- Maji, A.K.; Shah, S.P. Application of acoustic emission and laser holographyto study microfracture in concrete. ACI Symp. Publ. 1989, 112, 83–110. [Google Scholar]

- Janeiro, R.P.; Einstein, H.H. Experimental study of the cracking behavior of specimens containing inclusions (under uniaxial compression). Int. J. Fract. 2010, 164, 83–102. [Google Scholar] [CrossRef]

- Liu, B.; Sun, Y.; Wang, B.; Han, Y.; Zhang, R.; Wang, J. Effect of water content on mechanical and electrical characteristics of the water-rich sandstone during freezing. Environ. Earth Sci. 2020, 79, 236–249. [Google Scholar] [CrossRef]

- Jia, H.; Zi, F.; Yang, G.; Li, G.; Shen, Y.; Sun, Q.; Yang, P. Influence of pore water (ice) content on the strength and deformability of frozen argillaceous siltstone. Rock Mech. Rock Eng. 2020, 53, 967–974. [Google Scholar] [CrossRef]

- Jia, H.; Ding, S.; Wang, Y.; Zi, F.; Sun, Q.; Yang, G. An NMR-based investigation of pore water freezing process in sandstone. Cold Reg. Sci. Technol. 2019, 168, 102893. [Google Scholar] [CrossRef]

- Sun, Q.; Dong, Z.; Jia, H. Decay of sandstone subjected to a combined action of repeated freezing–thawing and salt crystallization. Bull. Eng. Geol. Environ. 2019, 78, 5951–5964. [Google Scholar] [CrossRef]

- Jia, H.; Xiang, W.; Krautblatter, M. Quantifying rock fatigue and decreasing compressive and tensile strength after repeated freeze-thaw cycles. Permafr. Periglac. Process. 2015, 26, 368–377. [Google Scholar] [CrossRef]

- Jia, H.; Leith, K.; Krautblatter, M. Path-dependent frost-wedging experiments in fractured, low-permeability granite. Permafr. Periglac. Process. 2017, 28, 698–709. [Google Scholar] [CrossRef]

- Ruedrich, J.; Kirchner, D.; Siegesmund, S. Physical weathering of building stones induced by freeze–thaw action: A laboratory long-term study. Environ. Earth Sci. 2011, 63, 1573–1586. [Google Scholar] [CrossRef]

- Yang, L.; Jia, H.; Han, L.; Zhang, H.; Tang, L. Hysteresis in the ultrasonic parameters of saturated sandstone during freezing and thawing and correlations with unfrozen water content. J. Rock Mech. Geotech. 2021, 13, 1078–1092. [Google Scholar] [CrossRef]

- Jia, H.; Han, L.; Zhao, T.; Sun, Q.; Tan, X. Strength and the cracking behavior of frozen sandstone containing ice-filled flaws under uniaxial compression. Permafr. Periglac. Process. 2022, 33, 160–175. [Google Scholar] [CrossRef]

- Wang, T.; Sun, Q.; Jia, H.; Ren, J.; Luo, T. Linking the mechanical properties of frozen sandstone to phase composition of pore water measured by LF-NMR at subzero temperatures. Bull. Eng. Geol. Environ. 2021, 80, 4501–4513. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, W.; Han, L.; Wu, D.; Jia, H.; Tang, L. Variability in Mechanical Properties and Cracking Behavior of Frozen Sandstone Containing En Echelon Flaws under Compression. Appl. Sci. 2024, 14, 3427. https://doi.org/10.3390/app14083427

Liu W, Han L, Wu D, Jia H, Tang L. Variability in Mechanical Properties and Cracking Behavior of Frozen Sandstone Containing En Echelon Flaws under Compression. Applied Sciences. 2024; 14(8):3427. https://doi.org/10.3390/app14083427

Chicago/Turabian StyleLiu, Weimin, Li Han, Di Wu, Hailiang Jia, and Liyun Tang. 2024. "Variability in Mechanical Properties and Cracking Behavior of Frozen Sandstone Containing En Echelon Flaws under Compression" Applied Sciences 14, no. 8: 3427. https://doi.org/10.3390/app14083427