Novel Microscopic Approach to Particle Size Evaluation in Colloidal Systems

Abstract

:1. Introduction

2. Experimental Section

2.1. Materials

2.2. Bitumen Aging Process

2.3. Atomic Force Microscopy (AFM)

2.3.1. Intermittent-Contact (IC) Mode (Tapping)

2.3.2. AFM Sample Preparation

- -

- A laboratory grade oven was set to a temperature of 100 °C. When the oven reached the desired temperature, the sample was introduced. Using a spatula, a small scoop of solid bitumen was taken and smeared on the AFM sample disk.

- -

- The sample disk was put in the oven for 10 min.

- -

- After 10 min, the oven was turned off and left open in order to enable the bitumen sample to cool gradually.

- -

- When the oven temperature had cooled down to room temperature, the sample was taken out.

- -

- The sample was analyzed using the AFM instrument and images were captured.

2.4. Optical Microscopy (OM)

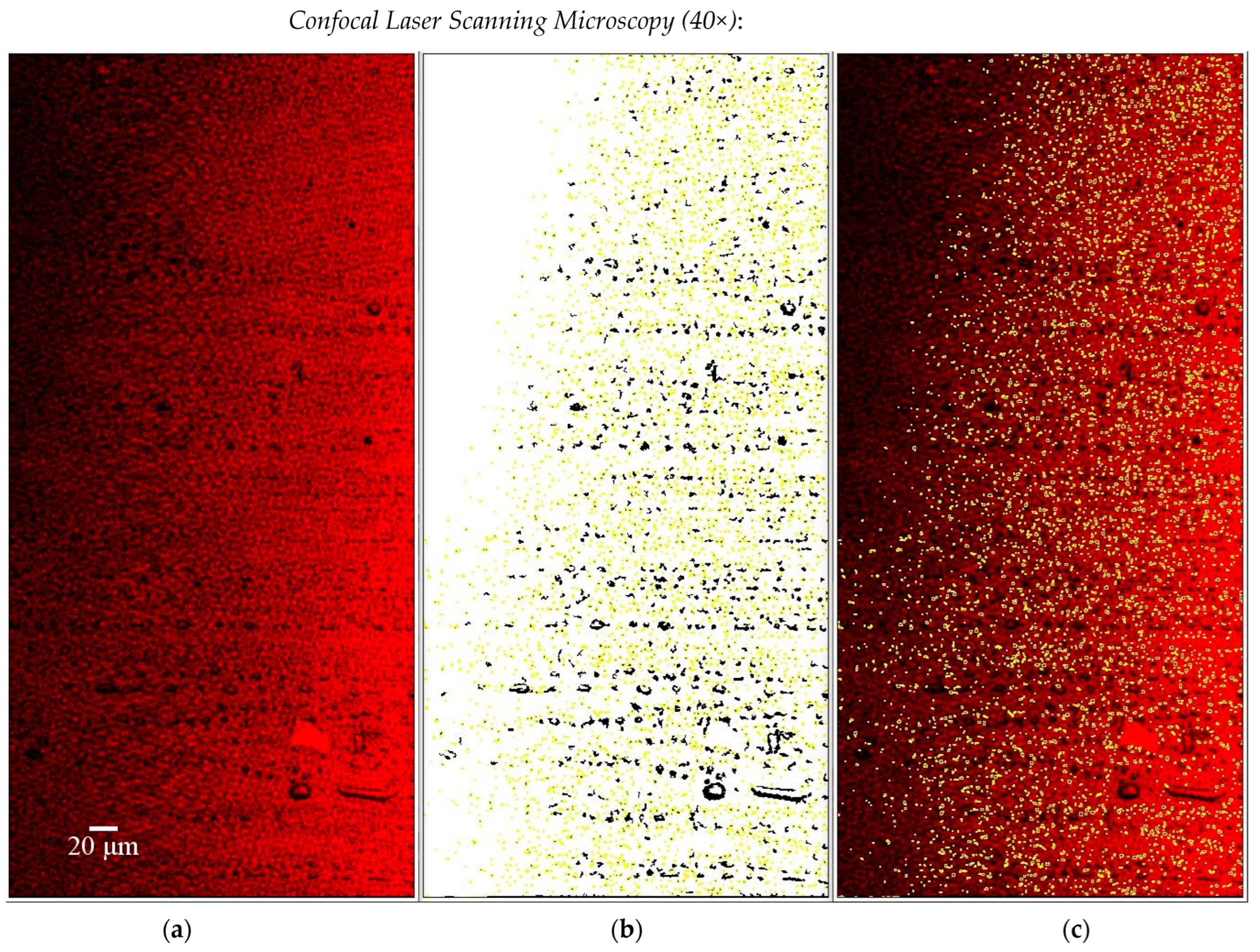

2.5. Confocal Laser Scanning Microscopy (CM)

Preparation of Glass Slides for Optical (OM) and Confocal Microscopy

- -

- A glass slide was placed on an electric heating plate which was set to between 150 and 200 °C.

- -

- Using a spatula, a small scoop of solid bitumen was taken and smeared on the hot glass slide.

- -

- After a few seconds, a glass cover slip was placed on the part of the glass slide covering the smeared bitumen.

- -

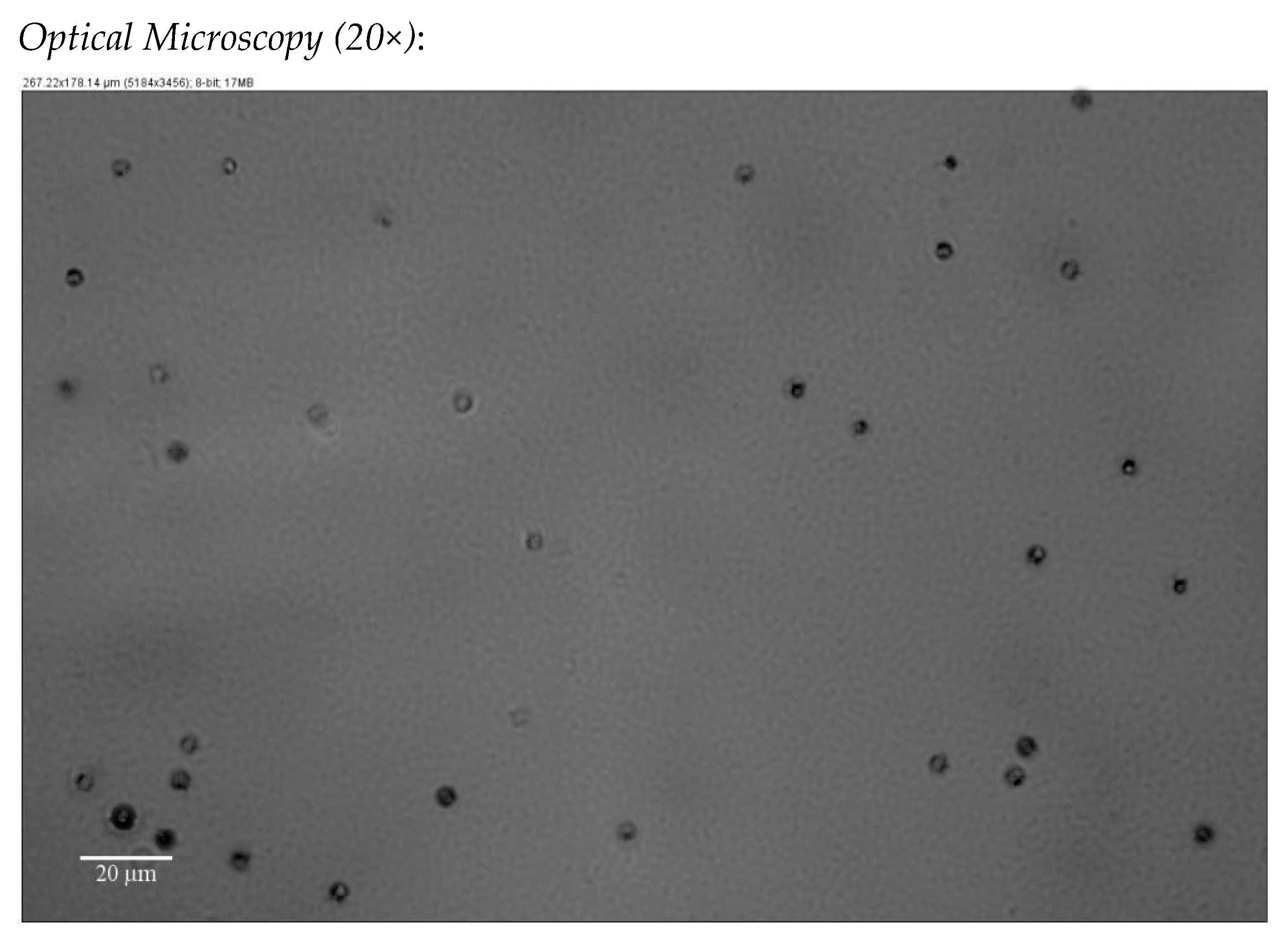

- The glass slide was removed from the heating plate and the cover slip was gently moved in a circular motion to continuously smear the bitumen sample until it became so thin in that light could pass through it; see Figure 1.

- -

- The glass slide was allowed to cool, and then microscopic analysis was carried out.

2.6. Data Elaboration

3. Results and Discussion

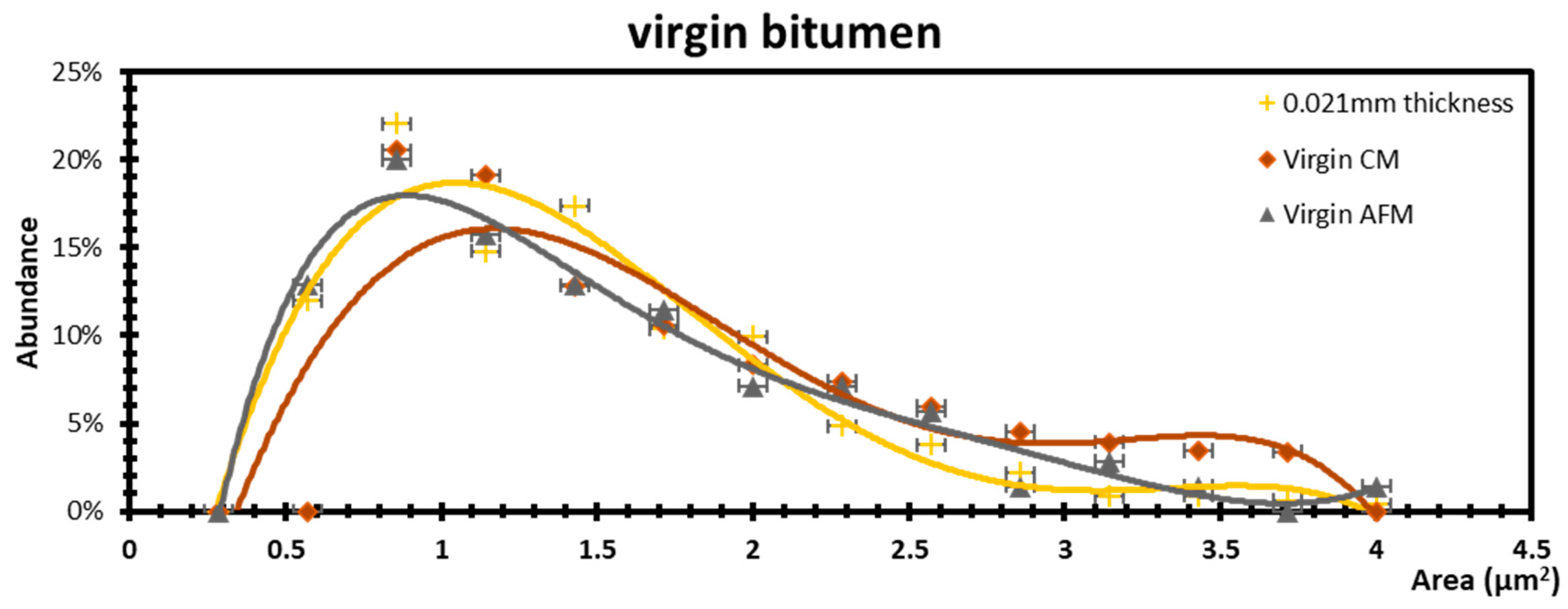

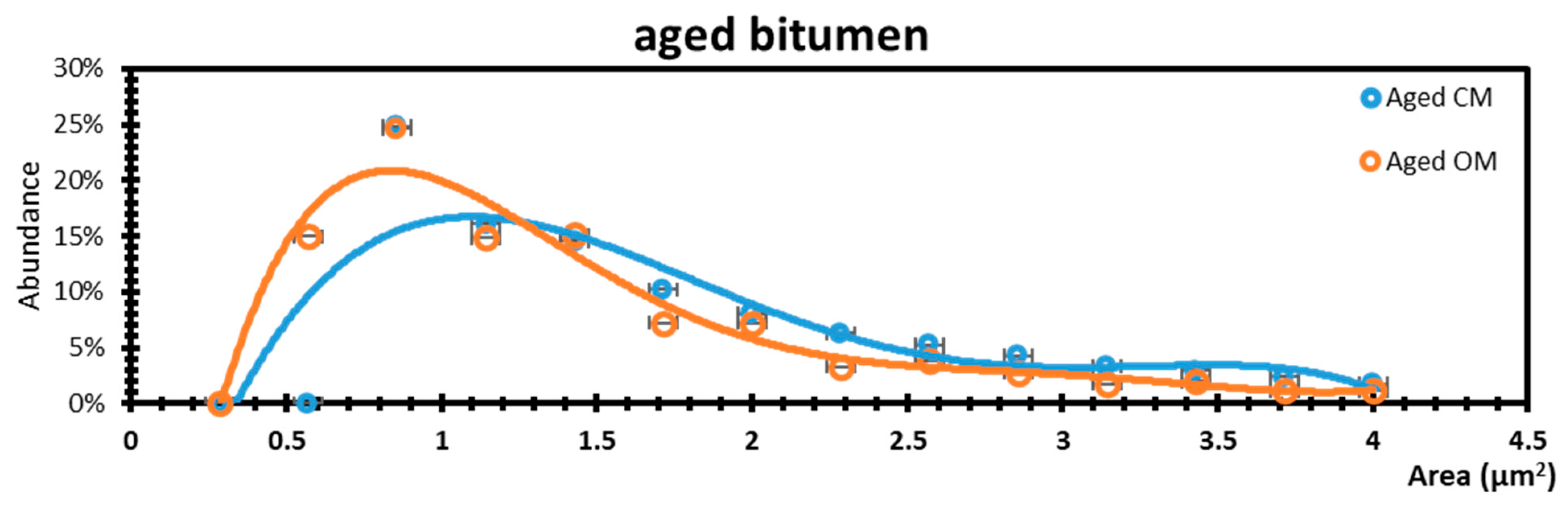

- Confocal microscopy: Confocal microscope photos have a photo resolution of 0.3 µm2/pixel, therefore, we opted to group the particle count into 14 classes (this is a low resolution for a line graph, and is due to the poor resolution of the photos) thanks to the data software provided by our collaborator (Professor Ranieri who is duly acknowledged in the footnotes).

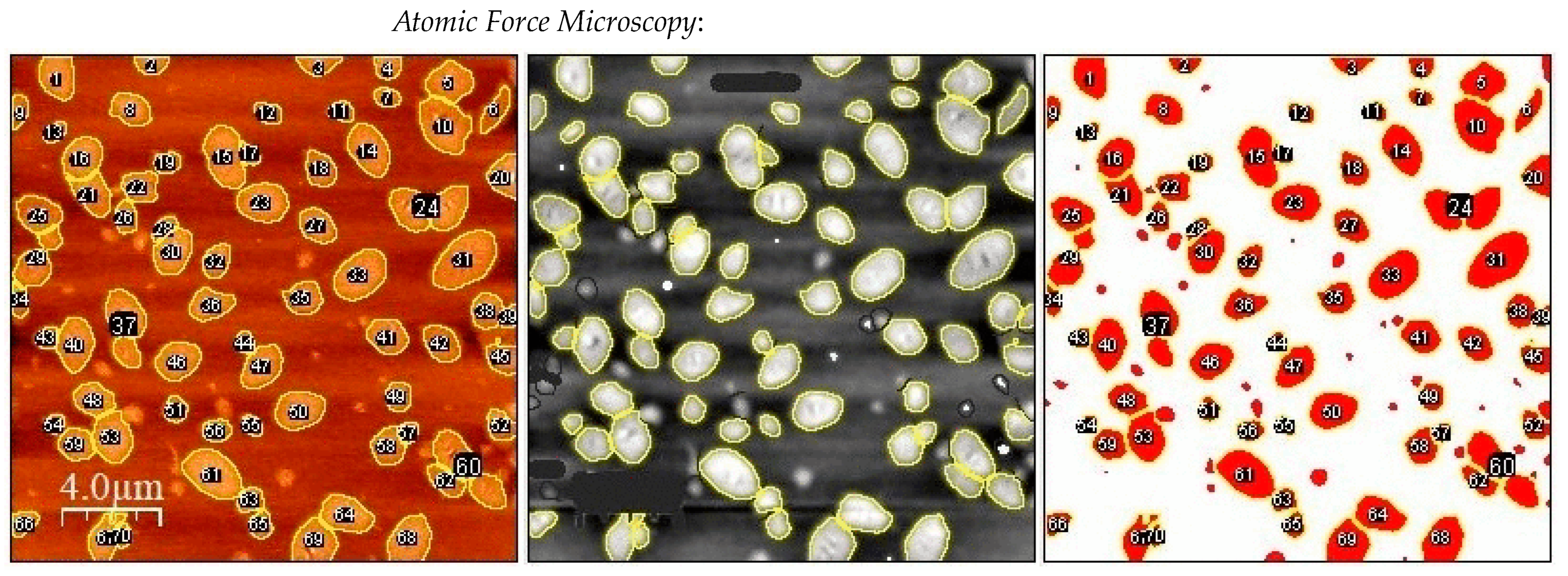

- Atomic Force Microscopy: The procedure is the same, but since this technique has a high resolution, we did not consider the particles which are undetectable on the optical microscope (being the technique with the lowest resolution); for the same reason, the total number of particles per photo is very low (about a hundred).

“Generally, if we have n data points, there is exactly one polynomial of degree at most n−1 going through all the data points. The interpolation error is proportional to the distance between the data points to the power n. Furthermore, the interpolant is a polynomial and thus infinitely differentiable. So we see that polynomial interpolation overcomes most of the problems of linear interpolation”.[38]

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lenggoro, W.; Xia, B.; Okuyama, K. Sizing of Colloidal Nanoparticles by Electrospray and Differential Mobility Analyzer Methods. Langmuir 2002, 18, 4584–4591. [Google Scholar] [CrossRef]

- Kuchibhatla, S.; Karakoti, A.; Seal, S. Colloidal stability by surface modification. JOM 2005, 57, 52–56. [Google Scholar] [CrossRef]

- Pileni, M.P. Nanosized Particles Made in Colloidal Assemblies. Langmuir 1997, 13, 3266–3276. [Google Scholar] [CrossRef]

- Calandra, P.; Longo, A.; Liveri, V.T. Preparation and Characterisation of Na2S and ZnSO4 Nanoparticles in Water/AOT/n-Heptane Microemulsions. Colloid Polym. Sci. 2001, 279, 1112–1117. [Google Scholar] [CrossRef]

- Tuoriniemi, J.; Johnsson, A.C.J.H.; Holmberg, J.P.; Gustafsson, S.; Gallego-Urrea, J.A.; Olsson, E.; Pettersson, J.B.C.; Hassellöv, M. Intermethod comparison of the particle size distributions of colloidal silica nanoparticles. Sci. Technol. Adv. Mater. 2014, 15, 035009. [Google Scholar] [CrossRef] [PubMed]

- Joudeh, N.; Linke, D. Nanoparticle classification, physicochemical properties, characterization, and applications: A comprehensive review for biologists. J. Nanobiotechnol. 2022, 20, 262. [Google Scholar] [CrossRef]

- Stone, V.; Nowack, B.; Baun, A.; Van den Brink, N.; Von der Kammer, F.; Dusinska, M.; Handy, R.; Hankin, S.; Hassellöv, M.; Joner, E.; et al. Nanomaterials for environmental studies: Classification, reference material issues, and strategies for physico-chemical characterisation. Sci. Total Environ. 2010, 408, 1745–1754. [Google Scholar] [CrossRef]

- Rossi, C.O.; Caputo, P.; Loise, V.; Ashimova, S.; Teltayev, B.; Sangiorgi, C. A New Green Rejuvenator: Evaluation of Structural Changes of Aged and Recycled Bitumens by Means of Rheology and NMR. In Proceedings of the RILEM 252-CMB-Symposium on Chemo Mechanical Characterization of Bituminous Materials, Braunschweig, Germany, 17–18 September 2018; Poulikakos, L.D., Falchetto, A.C., Wistuba, M.P., Hofko, B., Porot, L., Di Benedetto, H., Eds.; RILEM Bookseries. Springer: Berlin/Heidelberg, Germany, 2019; Volume 20, pp. 177–182. [Google Scholar] [CrossRef]

- Tauste, R.; Moreno-Navarro, F.; Sol-Sánchez, M.; Rubio-Gámez, M.C. Understanding the bitumen ageing phenomenon: A review. Constr. Build. Mater. 2018, 192, 593–609. [Google Scholar] [CrossRef]

- Loise, V.; Calandra, P.; Abe, A.A.; Porto, M.; Rossi, C.O.; Davoli, M.; Caputo, P. Additives on aged bitumens: What probe to distinguish between rejuvenating and fluxing effects? J. Mol. Liq. 2021, 339, 116742. [Google Scholar] [CrossRef]

- Abe, A.A.; Rossi, C.O.; Eskandarsefat, S.; Porto, M.; Loise, V.; Venturini, L.; Caputo, P. Reclaimed asphalt recycling agents: Looking into the blueprint of their mechanisms of action. Constr. Build. Mater. 2023, 363, 129843. [Google Scholar] [CrossRef]

- Porto, M.; Caputo, P.; Loise, V.; Teltayev, B.; Angelico, R.; Calandra, P.; Rossi, C.O. New Experimental Approaches to Analyse the Supramolecular Structure of Rejuvenated Aged Bitumens. Ser. Geol. Tech. Sci. 2019, 6, 295–301. [Google Scholar] [CrossRef]

- Farshad, F.; Fardin, K.; Yong-Rak, K.; Reddy, K.S.; Hamzeh, F.H. Molecular dynamics modeling and simulation of bituminous binder chemical aging due to variation of oxidation level and saturate-aromatic-resin-asphaltene fraction. Fuel 2019, 237, 71–80. [Google Scholar] [CrossRef]

- Yu, X.; Burnham, N.A.; Tao, M. Surface microstructure of bitumen characterized by atomic force microscopy. Adv. Colloid Interface Sci. 2015, 218, 17–33. [Google Scholar] [CrossRef] [PubMed]

- Xing, C.; Jiang, W.; Li, M.; Wang, M.; Xiao, J.; Xu, Z. Application of atomic force microscopy in bitumen materials at the nanoscale: A review. Constr. Build. Mater. 2022, 342 Pt B, 128059. [Google Scholar] [CrossRef]

- Masson, J.F.; Leblond, V.; Margeson, J. Bitumen morphologies by phase-detection atomic force microscopy. J. Microsc. 2006, 221, 17–29. [Google Scholar] [CrossRef] [PubMed]

- Mirwald, J.; Hofko, B.; Pipintakos, G.; Blom, J.; Soenen, H. Comparison of microscopic techniques to study the diversity of the bitumen microstructure. Micron 2022, 159, 103294. [Google Scholar] [CrossRef] [PubMed]

- Amin, J.S.; Nikooee, E.; Ghatee, M.H.; Ayatollahi, S.; Alamdari, A.; Sedghamiz, T. Investigating the effect of different asphaltene structures on surface topography and wettability alteration. Appl. Surf. Sci. 2011, 257, 8341–8349. [Google Scholar] [CrossRef]

- Sabbaghi, S.; Shariaty-Niassar, M.; Ayatollahi, S.H.; Jahanmiri, A. Characterization of asphaltene structure using atomic force microscopy. J. Microsc. 2008, 231, 364–373. [Google Scholar] [CrossRef] [PubMed]

- Udupa, G.; Singaperumal, M.; Sirohi, R.S.; Kothiyal, M.P. Characterization of surface topography by confocal microscopy: I. Principles and the measurement system. Meas. Sci. Technol. 2000, 11, 305. [Google Scholar] [CrossRef]

- Ramm, A.; Sakib, N.; Bhasin, A.; Downer, M.C. Optical characterization of temperature- and composition-dependent microstructure in asphalt binders. J. Microsc. 2016, 262, 216–225. [Google Scholar] [CrossRef]

- Loebera, L.; Mullera, G.; Morelb, J.; Sutton, O. Bitumen in colloid science: A chemical, structural and rheological approach. Fuel 1998, 77, 1443–1450. [Google Scholar] [CrossRef]

- Pipintakos, G.; Hasheminejad, N.; Lommaert, C.; Bocharova, A.; Blom, J. Application of Atomic Force (AFM), Environmental Scanning Electron (ESEM) and Confocal Laser Scanning Microscopy (CLSM) in bitumen: A review of the ageing effect. Micron 2021, 147, 103083. [Google Scholar] [CrossRef] [PubMed]

- ASTM D2872-22; Standard Test Method for Effect of Heat and Air on a Moving Film of Asphalt (Rolling Thin-Film Oven Test). ASTM International: West Conshohocken, PA, USA, 2020; ASTM Book of Standards Volume 04.03. pp. 1–4. [CrossRef]

- Hu, Z.; Zhang, H.; Wang, S.; Xu, T. Thermal-oxidative aging mechanism of asphalt binder based on isothermal thermal analysis at the SARA level. Constr. Build. Mater. 2020, 255, 119349. [Google Scholar] [CrossRef]

- Saoula, S.; Soudani, K.; Haddadi, S.; Munoz, M.E.; Santamaria, A. Analysis of the Rheological Behavior of Aging Bitumen and Predicting the Risk of Permanent Deformation of Asphalt. Mater. Sci. Appl. 2013, 4, 312–318. [Google Scholar] [CrossRef]

- Rossi, C.O.; Caputo, P.; De Luca, G.; Maiuolo, L.; Eskandarsefat, S.; Sangiorgi, C. 1H-NMR Spectroscopy: A Possible Approach to Advanced Bitumen Characterization for Industrial and Paving Applications. Appl. Sci. 2018, 8, 229. [Google Scholar] [CrossRef]

- Bevan, M.A.; Eichmann, S.L. Optical microscopy measurements of kT-scale colloidal interactions. Colloid Interface Sci. 2011, 16, 149–157. [Google Scholar] [CrossRef]

- Lu, P.J. Confocal scanning optical microscopy and nanotechnology. In Handbook of Microscopy for Nanotechnology; Springer: Boston, MA, USA, 2005; pp. 3–24. [Google Scholar]

- Kino, G.S.; Corle, R.T. Confocal Scanning Optical Microscopy and Related Imaging Systems; Academic Press: Cambridge, MA, USA, 1996. [Google Scholar]

- Shaw, P.J. Introduction to confocal microscopy. In Light Microscopy in Biology; Oxford Academic: New York, NY, USA, 1999; pp. 45–71. [Google Scholar]

- Hasanvand, M.Z.; Behbahani, R.M.; Feyzi, F.; Mousavi-Dehghani, S. Asphaltene particles size and size distribution change at high pressure high temperature conditions: Experimental study on a heavy oil sample. High Temp. High Press. 2017, 46, 85–99. [Google Scholar]

- Duran, J.A.; Casas, Y.A.; Xiang, L.; Zhang, L.; Zeng, H.; Yarranton, H.W. Nature of Asphaltene Aggregates. Energy Fuels 2019, 33, 3694–3710. [Google Scholar] [CrossRef]

- Li, X.; Lu, S.; Niu, M.; Cheng, R.; Gong, Y.; Xu, J. Asphaltene Inhibition and Flow Improvement of Crude Oil with a High Content of Asphaltene and Wax by Polymers Bearing Ultra-Long Side Chain. Energies 2021, 14, 8243. [Google Scholar] [CrossRef]

- Takashimizu, Y.; Iiyoshi, M. New parameter of roundness R: Circularity corrected by aspect ratio. Prog. Earth Planet. Sci. 2016, 3, 2. [Google Scholar] [CrossRef]

- Walsh, S.; Diamond, D. Non-linear curve fitting using Microsoft Excel Solver. Talanta 1995, 42, 561–572. [Google Scholar] [CrossRef] [PubMed]

- Murphy, S. The Art of Polynomial Interpolation; Pennsylvania State University: University Park, PA, USA, 2022; Available online: https://psu.pb.unizin.org/polynomialinterpretation/ (accessed on 4 April 2024).

- Steffensen, J.F. Interpolation, 2nd ed.; Dover Publications Inc.: Mineola, NY, USA, 2006; ISBN 978-0-486-15483-1. [Google Scholar]

- Calandra, P.; Caputo, P.; De Santo, M.P.; Todaro, L.; Liveri, V.T.; Rossi, C.O. Effect of additives on the structural organization of asphaltene aggregates in bitumen. Constr. Build. Mater. 2019, 199, 288–297. [Google Scholar] [CrossRef]

- Kotlyar, L.S.; Sparks, B.D.; Woods, J.R.; Chung, K.H. Solids Associated with the Asphaltene Fraction of Oil Sands Bitumen. Energy Fuels 1999, 13, 346–350. [Google Scholar] [CrossRef]

- Tanaka, R.; Sato, E.; Hunt, J.E.; Winans, R.E.; Sato, S.; Takanohashi, T. Characterization of asphaltene aggregates using X-ray diffraction and smallangle X-ray Scattering. Energy Fuels 2004, 18, 1118–1125. [Google Scholar] [CrossRef]

- Tanaka, R.; Hunt, J.E.; Winans, R.E.; Thiyagarajan, P.; Sato, S.; Takanohashi, T. Aggregates structure analysis of petroleum asphaltenes with small-angle neutron scattering. Energy Fuels 2003, 17, 127–134. [Google Scholar] [CrossRef]

- Prosperi, E.; Bocci, E. A Review on Bitumen Aging and Rejuvenation Chemistry: Processes, Materials and Analyses. Sustainability 2021, 13, 6523. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Calandra, P.; Abe, A.A.; Scavo, A.; Bruno, L.; Rossi, C.O.; Caputo, P. Novel Microscopic Approach to Particle Size Evaluation in Colloidal Systems. Appl. Sci. 2024, 14, 3567. https://doi.org/10.3390/app14093567

Calandra P, Abe AA, Scavo A, Bruno L, Rossi CO, Caputo P. Novel Microscopic Approach to Particle Size Evaluation in Colloidal Systems. Applied Sciences. 2024; 14(9):3567. https://doi.org/10.3390/app14093567

Chicago/Turabian StyleCalandra, Pietro, Abraham A. Abe, Antonio Scavo, Leonardo Bruno, Cesare Oliviero Rossi, and Paolino Caputo. 2024. "Novel Microscopic Approach to Particle Size Evaluation in Colloidal Systems" Applied Sciences 14, no. 9: 3567. https://doi.org/10.3390/app14093567