Needle-Bonded Electromagnetic Shielding Thermally Insulating Nonwoven Composite Boards: Property Evaluations

Abstract

:1. Introduction

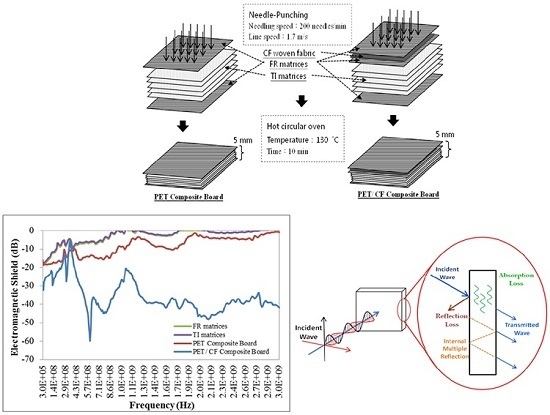

2. Materials and Methods

2.1. Materials and Manufacturing

2.2. Testing Methods

2.2.1. Tensile Force

2.2.2. Tearing Force

2.2.3. Bursting Force

2.2.4. LOI (Limiting Oxygen Index)

2.2.5. Thermal Conductivity

2.2.6. Air Permeability

2.2.7. Electromagnetic Shielding Effectiveness (EMSE)

3. Results and Discussion

3.1. Mechanical Properties of Matrices

3.2. Tensile Force and Tearing Force of the PET/CF Composite Board

3.3. The EMSE of the PET/CF Composite Boards

3.4. The LOI of the PET/CF Composite Boards

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Braune, S.; Wrocklage, C.; Raczek, J.; Gailus, T.; Lücking, C.H. Resting blood pressure increase during exposure to a radiofrequency electromagnetic field. Lancet 1998, 351, 1857–1858. [Google Scholar] [CrossRef]

- Eulitz, C.; Ullsperger, P.; Freude, G.; Elbert, T. Mobile phones modulate response patterns of human brain activity. Neuroreport 1998, 9, 3229–3232. [Google Scholar] [CrossRef] [PubMed]

- Das, A.; Krishnasamy, J.; Alagirusamy, R.; Basu, A. Analysis of the Electromagnetic Shielding Behavior of Stainless Steel Filament and PET/SS Hybrid Yarn Incorporated Conductive Woven Fabrics. Fiber Polym. 2014, 15, 2423–2427. [Google Scholar] [CrossRef]

- Jagatheesan, K.; Ramasamy, A.; Das, A.; Basu, A. Electromagnetic shielding behaviour of conductive filler composites and conductive fabrics—A review. Indian J. Fibre Text. 2014, 39, 329–342. [Google Scholar]

- Šafářová, V.; Militký, J. Electromagnetic shielding properties of woven fabrics made from high-performance fibers. Text. Res. J. 2014, 84, 1255–1267. [Google Scholar]

- Cao, M.S.; Lu, M.M.; Bi, S.; Wang, C.Y.; Liu, J.; Yuan, J.; Fan, L.Z. Flexible graphene/polymer composite films in sandwich structures for effective electromagnetic interference shielding. Carbon 2014, 66, 67–76. [Google Scholar]

- Mann, K.; Röschke, J. Effects of pulsed high-frequency electromagnetic fields on human sleep. Neuropsychobiology 1996, 33, 41–47. [Google Scholar] [CrossRef] [PubMed]

- Borbély, A.A.; Huber, R.; Graf, T.; Fuchs, B.; Gallmann, E.; Achermann, P. Pulsed high-frequency electromagnetic field affects human sleep and sleep electroencephalogram. Neurosci. Lett. 1999, 275, 207–210. [Google Scholar] [CrossRef]

- Wang, B.; Lai, H. Acute exposure to pulsed 2450-MHz microwaves affects water-maze performance of rats. Bioelectromagnetics 2000, 21, 52–56. [Google Scholar] [CrossRef]

- Yamashita, K. The Effects of the Far-Infrared Ray (FIR) Energy Radiation on Living Body. In Blood Cell—An Overview of Studies in Hematology; Moschandreou, T.E., Ed.; InTech: Rijeka, Croatia, 2012; Volume 14, pp. 271–299. [Google Scholar]

- Li, T.T.; Pan, Y.J.; Hsieh, C.T.; Lou, C.W.; Chuang, Y.C.; Huang, Y.T.; Lin, J.H. Comfort and Functional Properties of Far-Infrared/Anion-ReleasingWarp-Knitted Elastic Composite Fabrics Using Bamboo Charcoal, Copper, and Phase Change Materials. Appl. Sci. 2016, 6, 62. [Google Scholar] [CrossRef]

- Huang, C.L.; Lou, C.W.; Liu, C.F.; Hung, H.C.; Song, X.M.; Lin, J.H. Polypropylene/Graphene and Polypropylene/Carbon Fiber Conductive Composites: Mechanical, Crystallization and Electromagnetic Properties. Appl. Sci. (Basel) 2015, 5, 1196–1210. [Google Scholar] [CrossRef]

- Lin, J.H.; Lin, Z.I.; Pan, Y.J.; Huang, C.L.; Chen, C.K.; Lou, C.W. Polymer composites made of multi-walled carbon nanotubes and graphene nano-sheets: Effects of sandwich structures on their electromagnetic interference shielding effectiveness. Compos. Part B Eng. 2016, 89, 424–431. [Google Scholar] [CrossRef]

- Lin, C.W.; Lin, Z.Y.; Lou, C.W.; Kuo, T.L.; Lin, J.H. Wood Plastic Composites: Using Carbon Fiber to Create Electromagnetic Shielding Effectiveness. J. Thermoplast. Compos. 2015, 28, 1047–1057. [Google Scholar] [CrossRef]

- Al-Homoud, M.S. Performance characteristics and practical applications of common building thermal insulation materials. Build. Environ. 2005, 40, 353–366. [Google Scholar] [CrossRef]

- Sarier, N.; Onder, E. Thermal insulation capability of PEG-containing polyurethane foams. Thermochim. Acta 2008, 475, 15–21. [Google Scholar] [CrossRef]

- Lou, C.W.; Lin, C.M.; Hsing, W.H.; Chen, A.P.; Lin, J.H. Manufacturing Techniques and Electrical Properties of Conductive Fabrics with Recycled Polypropylene Nonwoven Selvage. Text. Res. J. 2011, 81, 1331–1343. [Google Scholar]

- Lin, J.H.; Huang, Y.T.; Li, T.T.; Lin, C.M.; Lou, C.W. Manufacture technique and performance evaluation of electromagnetic-shielding/far-infrared elastic warp-knitted composite fabrics. J. Text. Inst. 2016, 107, 493–503. [Google Scholar] [CrossRef]

- Huang, C.L.; Huang, Y.T.; Li, T.T.; Chiang, C.H.; Lou, C.W.; Lin, J.H. Composite processing and propertyevaluation of far-infrared/electromagnetic shielding bamboo charcoal/phase-change material/stainless steel elastic composite fabrics. J. Polym. Eng. 2016, 36, 211–220. [Google Scholar] [CrossRef]

- Yu, Z.C.; He, H.L.; Lu, Y.H.; Zhang, J.F.; Lou, C.W.; Chen, A.P.; Lin, J.H. Functional properties andelectromagnetic shielding behaviour of elastic warp-knitted fabrics. Fibres Text. East. Eur. 2015, 23, 78–83. [Google Scholar] [CrossRef]

- Hwang, P.W.; Chen, A.P.; Lou, C.W.; Lin, J.H. Electromagnetic Shielding Effectiveness and Functions of StainlessSteel/Bamboo Charcoal Conductive Fibrics. J. Ind. Text. 2014, 44, 477–494. [Google Scholar] [CrossRef]

| Matrices | Blending Ratio | Fiber Orientation | Tensile Force | Tearing Force | Bursting Force | LOI | Thermal Conductivity | Air Permeability |

|---|---|---|---|---|---|---|---|---|

| - | N | N | N | - | W/m·K | cm3/cm2/s | ||

| FR Matrices (FR/LM) | 100/0 | CD | 143.4 ± 7.93 | 249.1 ± 19.92 | 463.5 ± 26.24 | 32 | - | - |

| MD | 40.2 ± 4.15 | 141.2 ± 12.01 | ||||||

| 90/10 | CD | 149.7 ± 14.9 | 226.3 ± 21.36 | 507.3 ± 24.23 | 30 | - | - | |

| MD | 35.1 ± 4.89 | 124.5 ± 13.78 | ||||||

| 80/20 | CD | 133.3 ± 8.20 | 219.7 ± 27.73 | 498.6 ± 33.79 | 29 | - | - | |

| MD | 36.3 ± 2.26 | 124.5 ± 9.59 | ||||||

| TI Matrices (FI/LM) | 100/0 | CD | 64.0 ± 6.32 | 95.8 ± 7.85 | 232.3 ± 21.44 | - | 0.033 ± 0.0081 | 164.2 ± 7.38 |

| MD | 26.5 ± 3.26 | 76.3 ± 9.32 | ||||||

| 90/10 | CD | 65.9 ± 6.55 | 97.45 ± 8.47 | 230.6 ± 24.34 | - | 0.047 ± 0.0078 | 152.9 ± 9.31 | |

| MD | 20.3 ± 1.68 | 81.5 ± 9.62 | ||||||

| 80/20 | CD | 70.8 ± 5.20 | 121.6 ± 10.91 | 241.5 ± 23.73 | - | 0.045 ± 0.0166 | 146.7 ± 13.74 | |

| MD | 23.1 ± 2.16 | 94.5 ± 6.42 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lin, J.-H.; Chuang, Y.-C.; Huang, C.-H.; Li, T.-T.; Huang, C.-L.; Chen, Y.-S.; Lou, C.-W. Needle-Bonded Electromagnetic Shielding Thermally Insulating Nonwoven Composite Boards: Property Evaluations. Appl. Sci. 2016, 6, 303. https://doi.org/10.3390/app6100303

Lin J-H, Chuang Y-C, Huang C-H, Li T-T, Huang C-L, Chen Y-S, Lou C-W. Needle-Bonded Electromagnetic Shielding Thermally Insulating Nonwoven Composite Boards: Property Evaluations. Applied Sciences. 2016; 6(10):303. https://doi.org/10.3390/app6100303

Chicago/Turabian StyleLin, Jia-Horng, Yu-Chun Chuang, Chen-Hung Huang, Ting-Ting Li, Chien-Lin Huang, Yueh-Sheng Chen, and Ching-Wen Lou. 2016. "Needle-Bonded Electromagnetic Shielding Thermally Insulating Nonwoven Composite Boards: Property Evaluations" Applied Sciences 6, no. 10: 303. https://doi.org/10.3390/app6100303