Dynamic Shear Degradation of Geosynthetic–Soil Interface in Waste Landfill Sites

Abstract

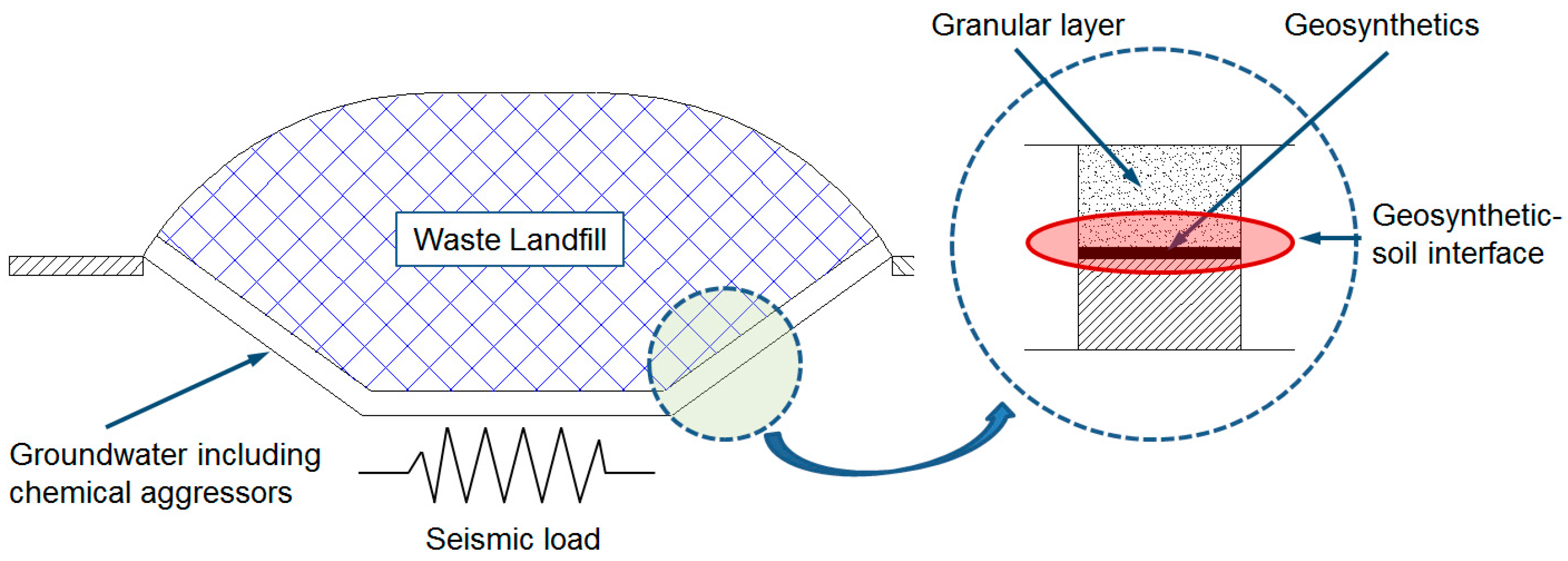

:1. Introduction

2. Chemical Characteristics of Leachate

3. Disturbed State Concept (DSC)

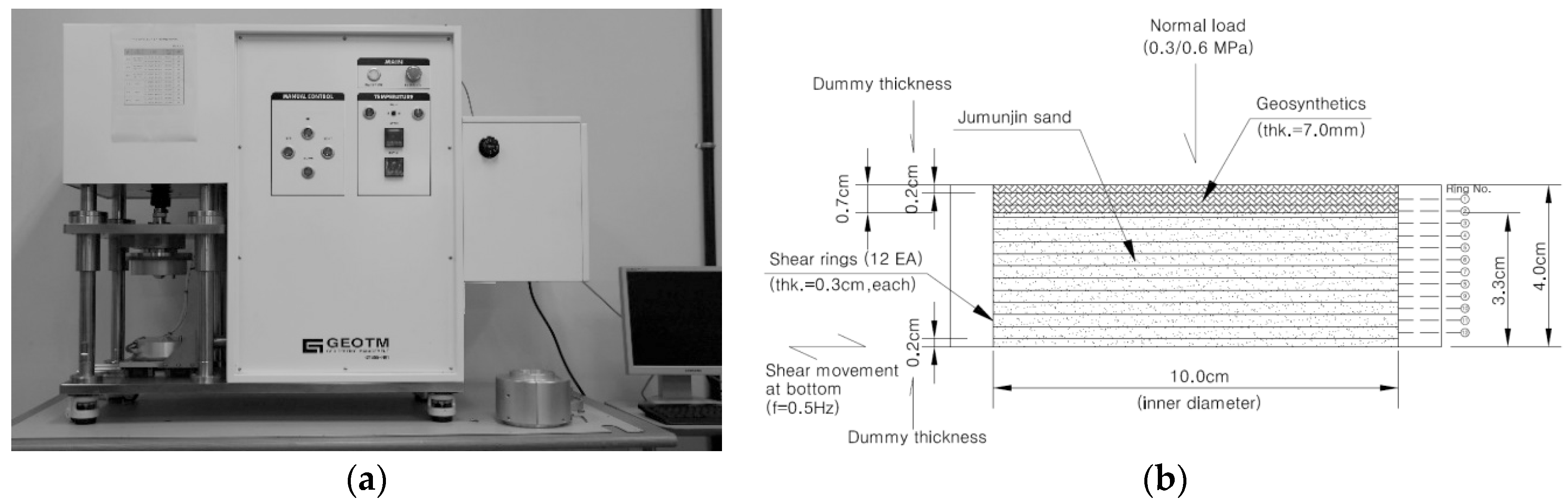

4. Laboratory Test

4.1. Test Apparatus and Conditions

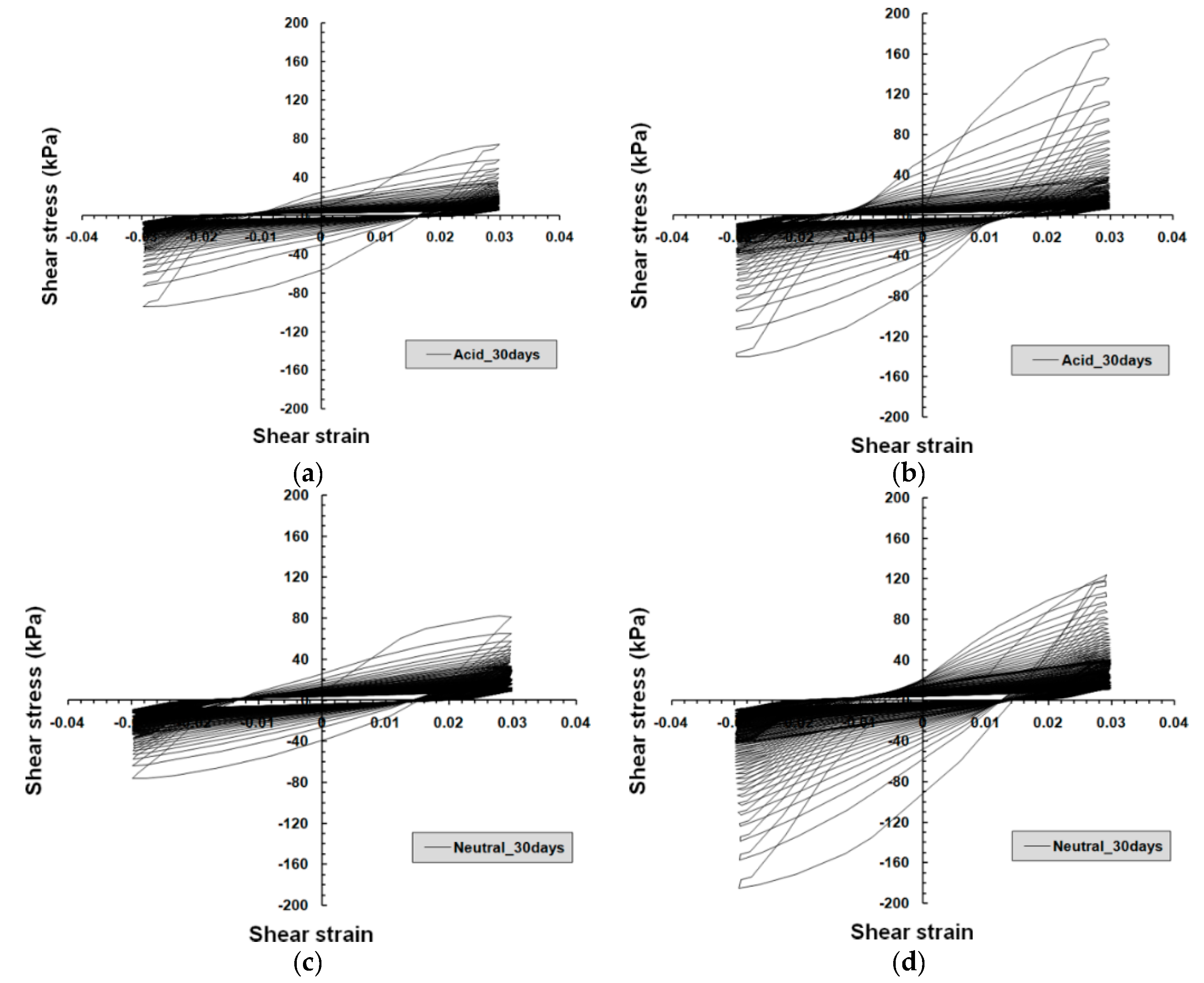

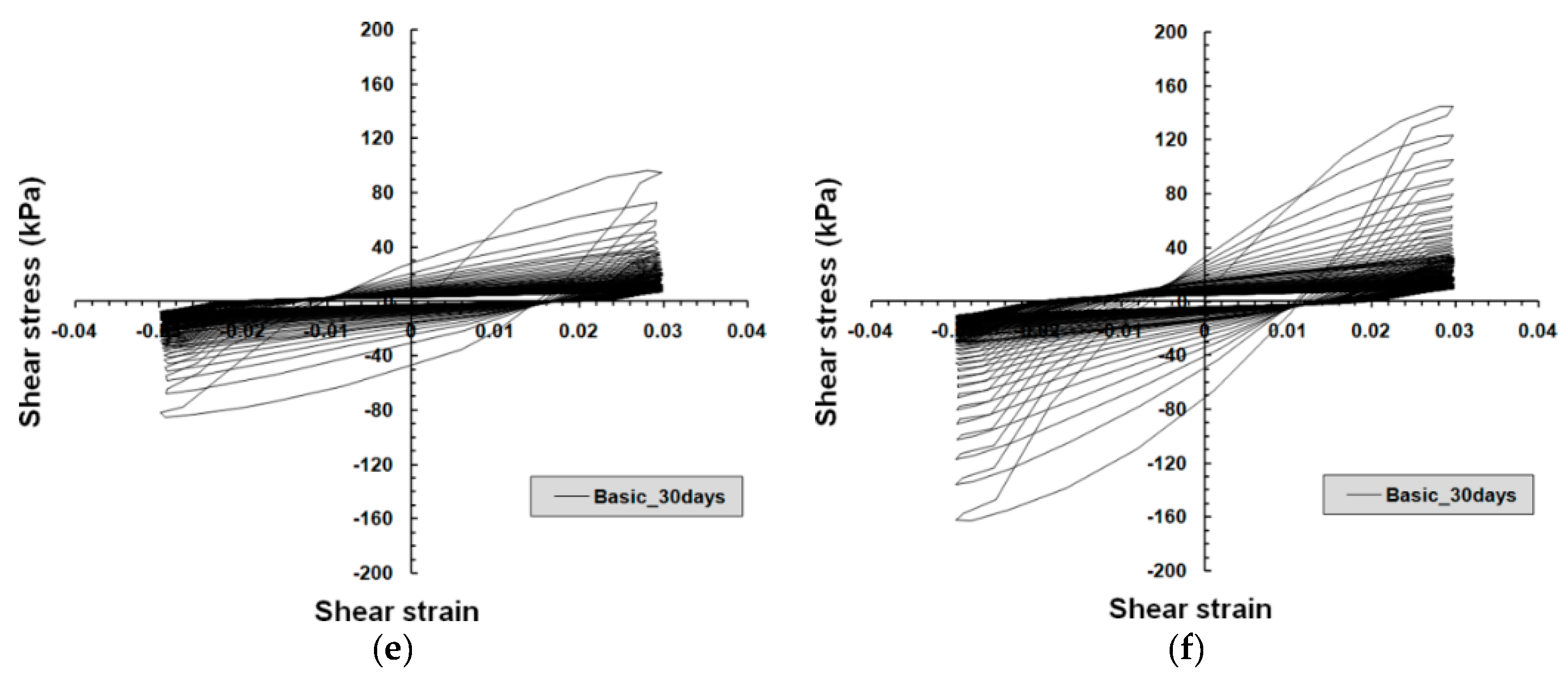

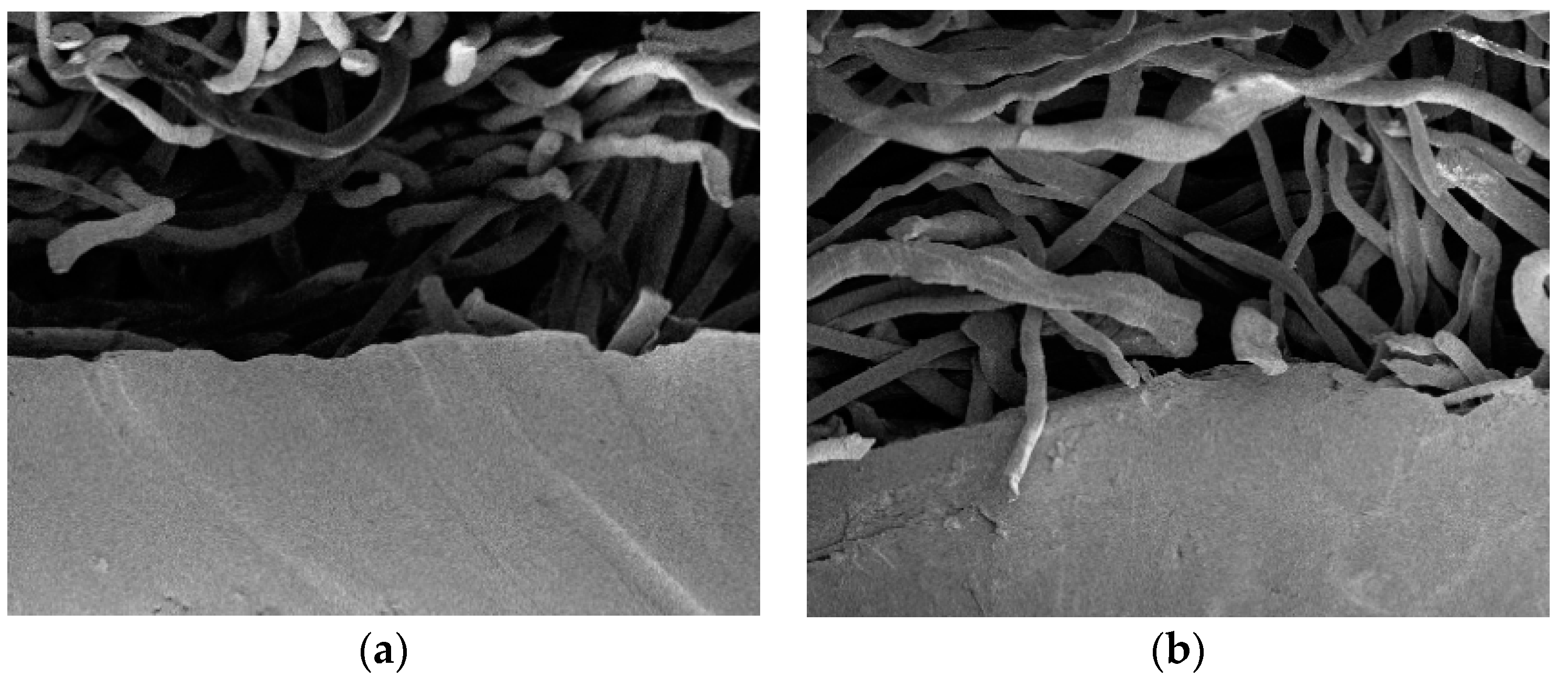

4.2. Test Results

4.3. Evaluation of Disturbance Function and Parameters

5. Numerical Back-Prediction of Test Results

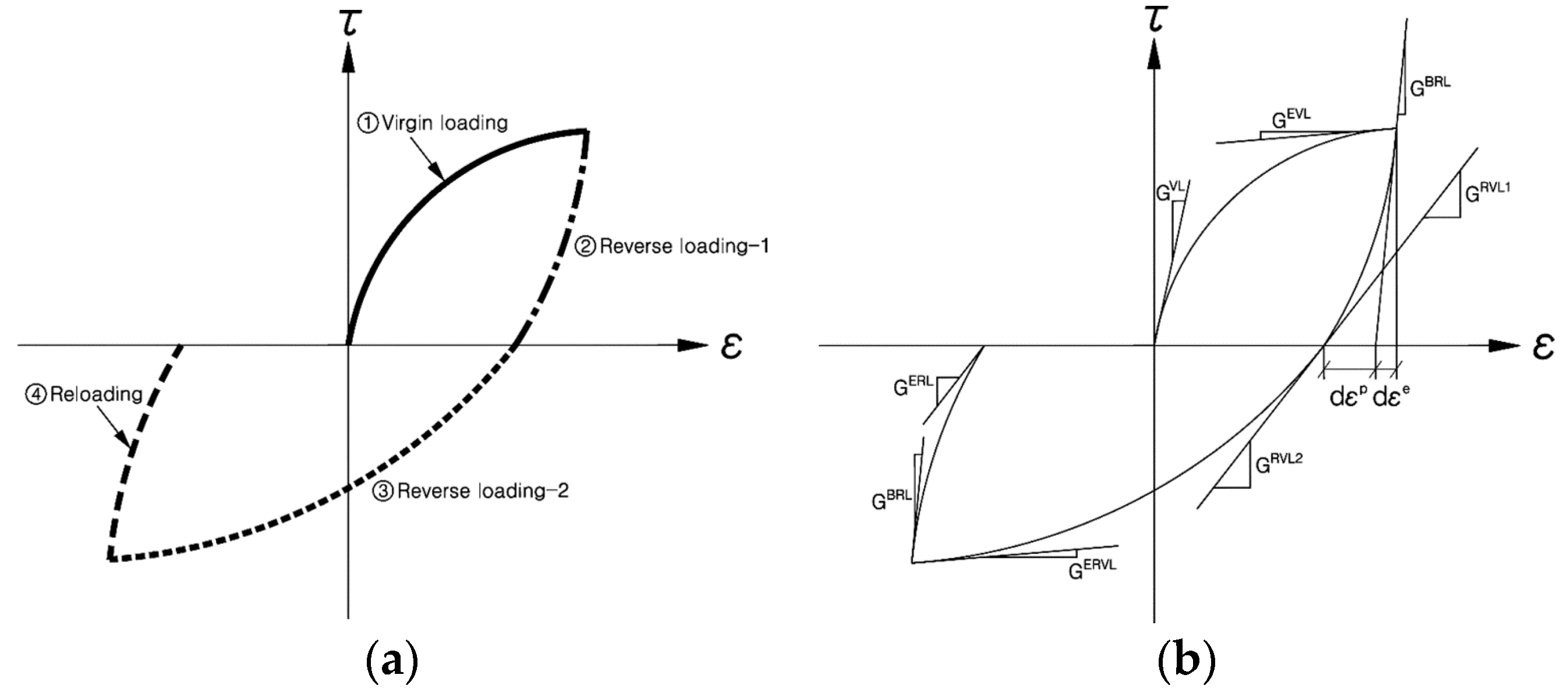

5.1. Methodology

- (1)

- Obtain the DSC parameters and from the experimental test results.

- (2)

- (3)

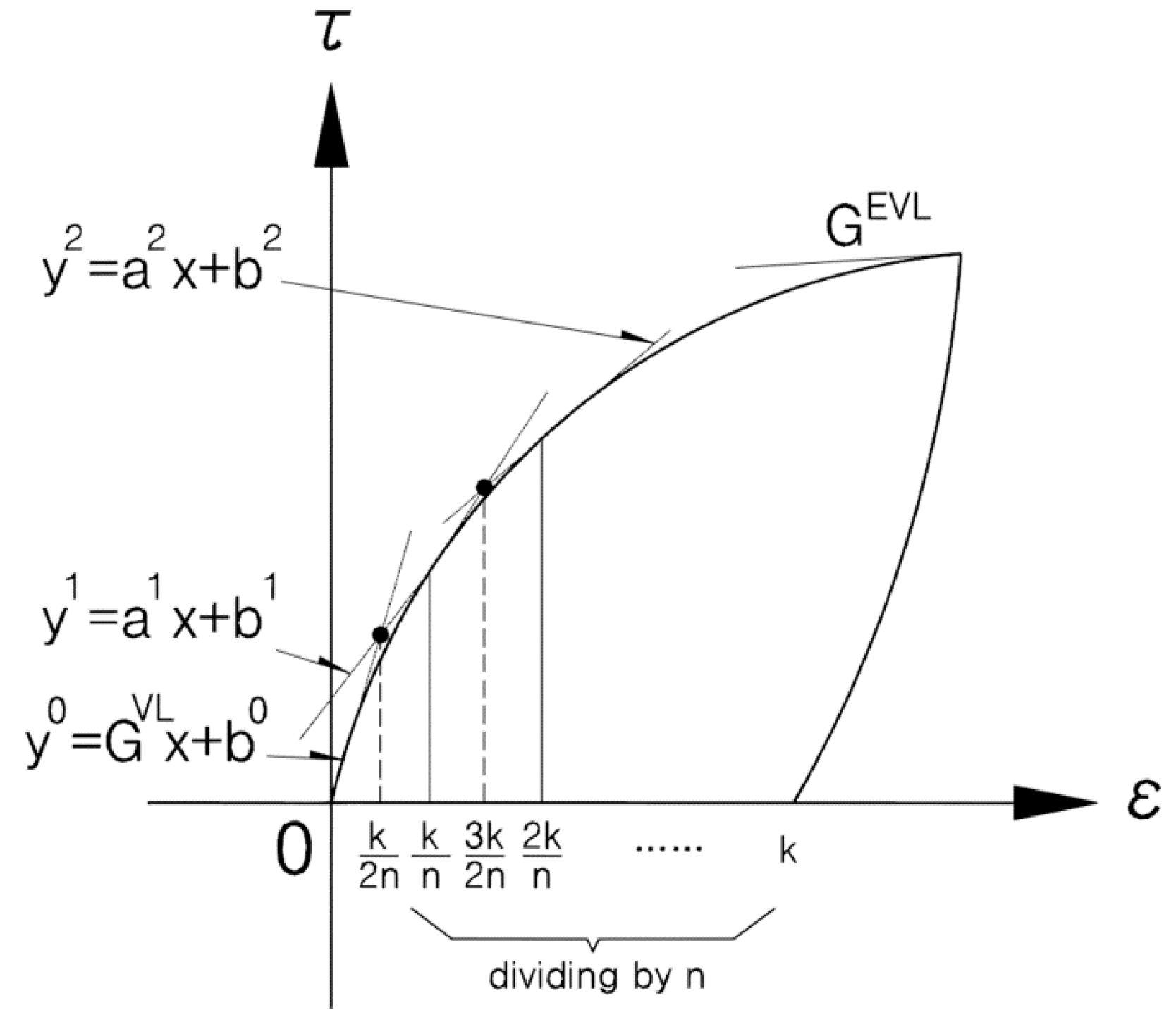

- Numerical interpolation: Equally divide each phase by “n” segments, and obtain the average tangential gradient by dividing the difference between the initial tangential gradient (GVL) and the final tangential gradient (GEVL), as demonstrated in Figure 13. Then, the linear equations at each dividing point (k/n, 2k/n, …) can be generated, as shown in Figure 13. The total number of the linear equations is (n + 1), and n = 10 was applied in the present study. Therefore, the equation of the initial tangential line can be expressed using Equation (5), and the general equations are expressed using Equations (6)–(8) in the virgin loading phase.

- (4)

- Obtain by combining the yields of Equations (3), (4) and (9). The updated shear stress at each cycle can be obtained using Equation (6).

- (5)

- Obtain the average strain increment: Based on the variation of the shear strain between the RI and FA conditions, the average plastic strain incremental can be calculated. In the present study, the number of cycles that begin to approach the FA state is considered as 50.

- (6)

- Update : Based on the result of Equation (9) and the average strain increment from the procedure of Equation (7), the cyclic shear stress at any cycle can be calculated.

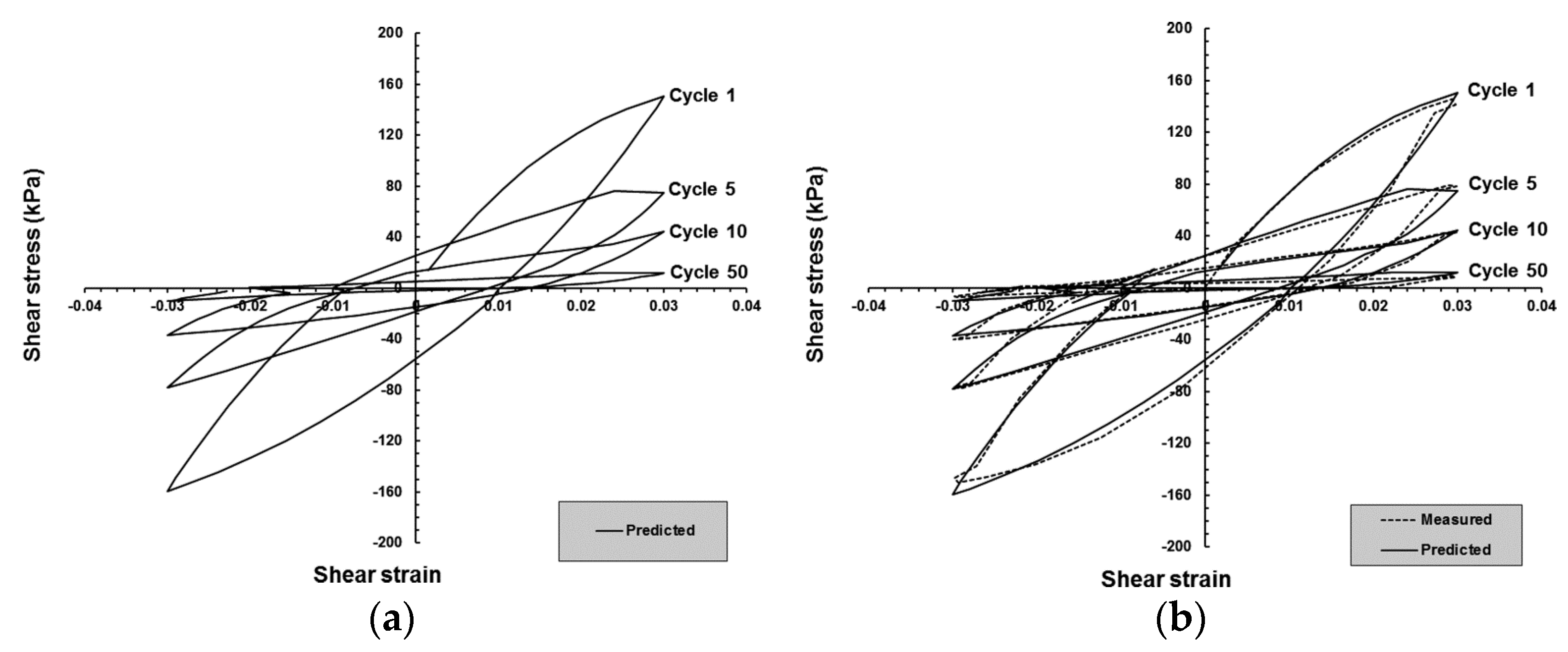

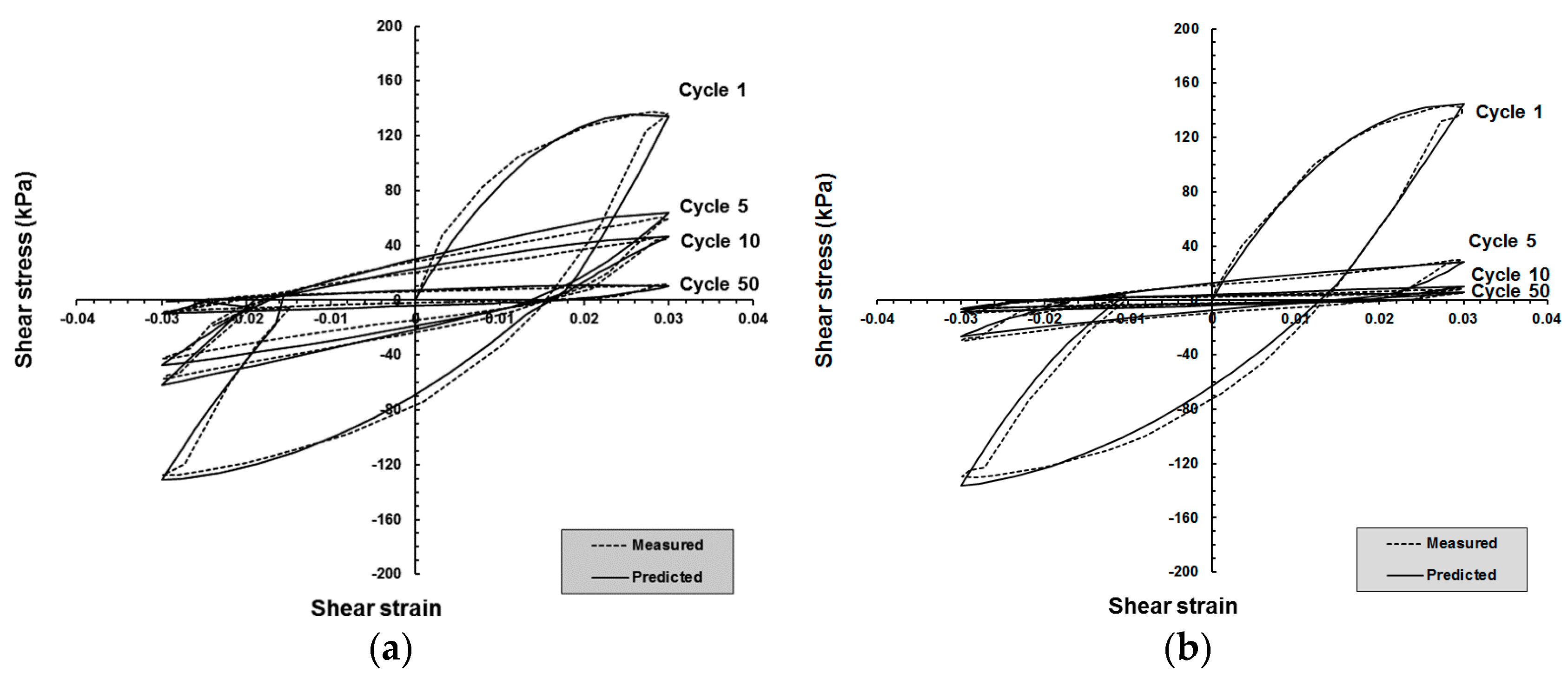

5.2. Back-Prediction Results

6. Conclusions

- (1)

- The new disturbance function parameters, and , were estimated using a linear regression technique. Parameter increased with the increase of the submersion period under the same chemical and normal stress conditions. On the contrary, parameter decreased with the increase of the normal stress under the same chemical and submersion conditions. Parameter increased with the increase of the submersion period and the normal stress under the same chemical conditions.

- (2)

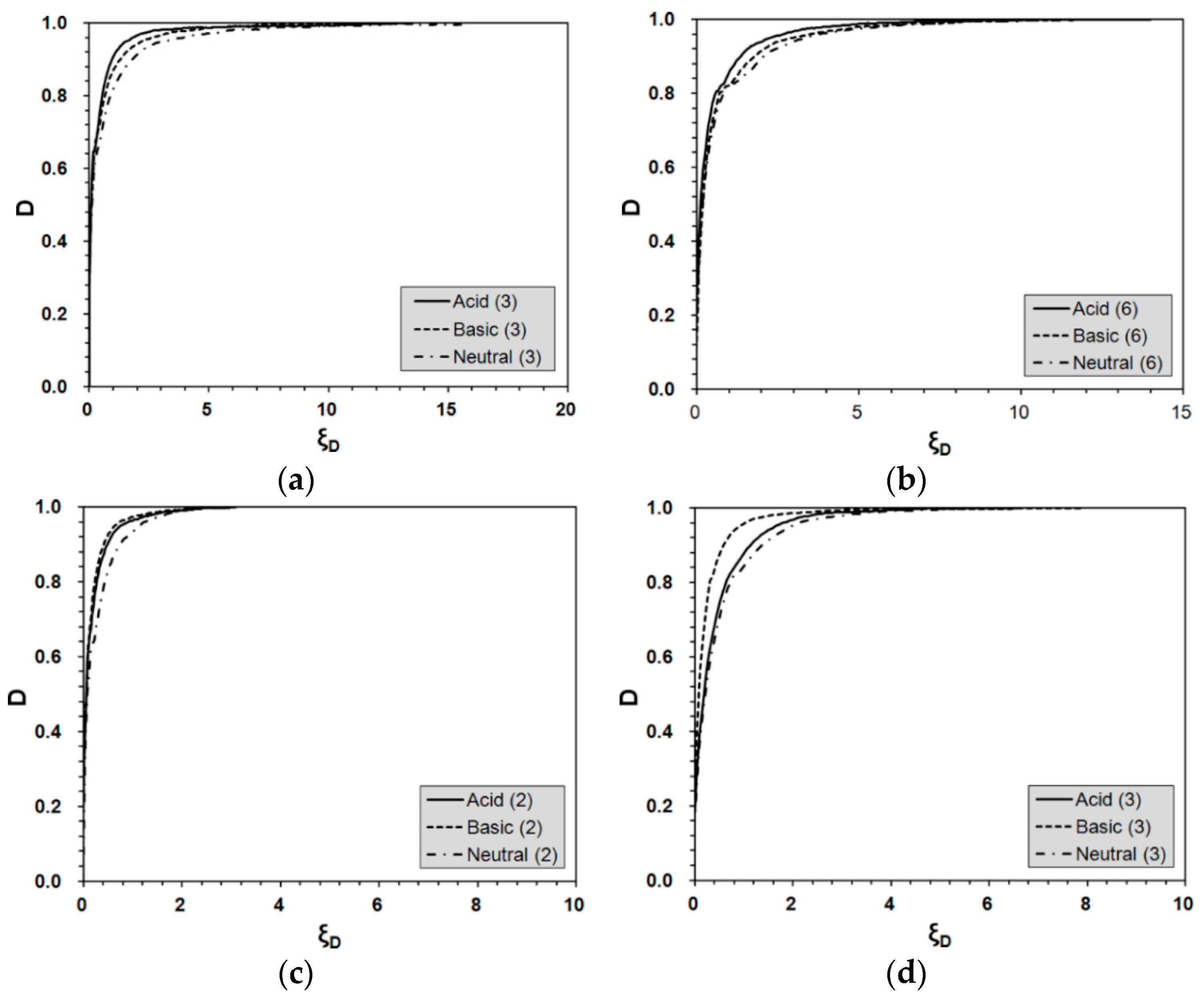

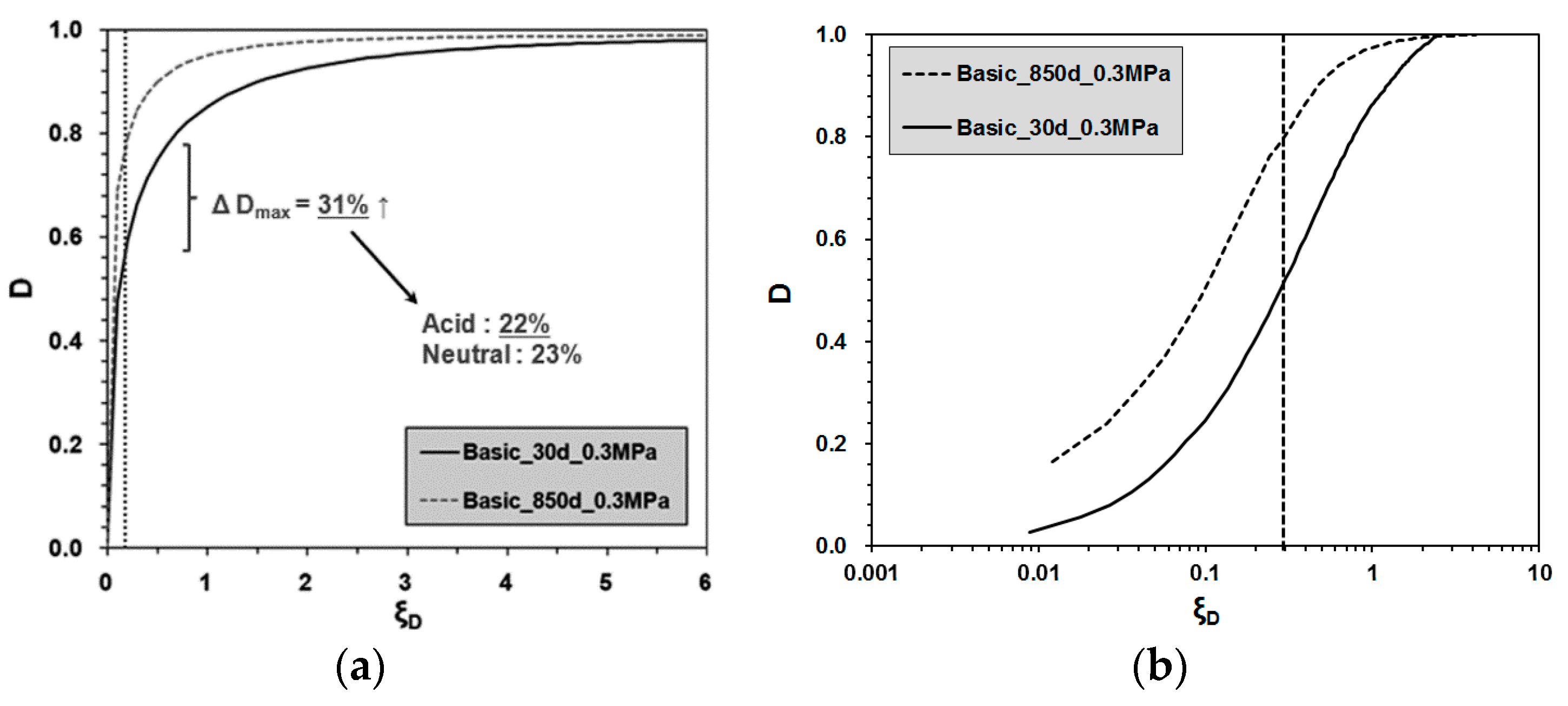

- Based on the test results and the new disturbance function parameters, the new disturbance function curves that correspond to the chemical conditions were evaluated. For the short-term submersion (30 days), the acid condition causes more vulnerability. For the long-term submersion, the difference in the disturbance function value at a certain deviatoric plastic strain trajectory, , was more distinct than that of the value after short-term submersion. In all of cases, acidic conditions caused the most vulnerability for the geosynthetic–soil interface for short-term submersion, and the basic conditions caused the most vulnerable for long-term submersion.

- (3)

- The variation between the disturbance curves for each submersion period was significant, and the largest variation was under the basic conditions in which 0.3 MPa of normal stress was applied. The variation between the disturbance curves under each normal stress condition was also remarkable, and the largest variation was for the acidic conditions for the 850-day submersion period.

- (4)

- The performance of the numerical back-prediction of the cyclic shear stress–strain relationship is based on the numerical interpolation procedures that are suggested in the present study. Based on the experiment data, the DSC parameters were utilized to reproduce the cyclic shear stress according to the loading cycle. The back-prediction result was also verified by a comparison between the predicted data and the measured data, and sound agreements were demonstrated. Furthermore, the compatibility and accuracy of the DSC parameters, and were ensured.

- (5)

- The proposed methodology can be used in seismic design procedures of a waste landfill. First of all, only a few seismic simple shear tests need to be performed for representative disturbance functions and parameters to be obtained. Then, those parameters can be verified by numerical back-prediction in order to reduce a large number of laboratory tests. If a considerable number of laboratory tests are performed, the guideline of critical shear strain under dynamic conditions shall be suggested in a further study.

- (6)

- In the future, it is expected that the numerical back-prediction of the geosynthetic–soil interface will serve as the basis of a fully numerical analysis. The numerical back-prediction is capable of considering the shear stress degradation with a sufficient accuracy to reducing a large number of laboratory tests. Based on the representative parameters which are verified by numerical back-prediction, the estimated shear strain can be used as a criterion under seismic conditions. Test are performed with limited number of factors (such as normal stress, material, chemical aggressors, etc.), therefore, it is still difficult to suggest typical back-bone curves. Relevant research will be performed in a further study.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Orloff, K.; Falk, H. An international perspective on hazardous waste practices. Int. J. Hyg. Environ. Health 2003, 206, 291–302. [Google Scholar] [CrossRef] [PubMed]

- Mor, S.; Ravindra, K.; Dahiya, R.P.; Chandra, A. Leachate characterization and assessment of groundwater pollution near municipal solid waste landfill site. Environ. Monit. Assess. 2006, 118, 435–456. [Google Scholar] [CrossRef] [PubMed]

- Bouazza, A.; Zornberg, J.G.; Adam, D. Geosynthetics in waste containment facilities: Recent advances. In Proceedings of the 7th International Conference on Geosynthetics, Nice, France, 22–27 September 2007; Volume 90, pp. 445–507. [Google Scholar]

- Kwak, C.W. Cyclic Shear Behaviors of Geosynthetic-Soil Interface Considering Chemical Effects. Ph.D. Thesis, Department of Civil and Environmental Engineering, Seoul National University, Seoul, Korea, 2014. [Google Scholar]

- Stark, T.D.; Williamson, T.A.; Eid, H.T. HDPE geomembrane/geotextile interface shear strength. J. Geotech. Eng. 1996, 122, 197–203. [Google Scholar] [CrossRef]

- Nguyen, Q.V.; Fatahi, B.; Hokmabadi, A.S. Influence of Size and Load-Bearing Mechanism of Piles on Seismic Performance of Buildings Considering Soil-Pile-Structure Interaction. Int. J. Geomech. 2017, 17, 04017007. [Google Scholar] [CrossRef]

- Seo, M.W.; Park, I.J.; Park, J.B. Development of displacement-softening model for interface shear behavior between geosynthetics. Soils Found. 2004, 44, 27–38. [Google Scholar] [CrossRef]

- Seo, M.W.; Park, J.B.; Park, I.J. Evaluation of interface shear strength between geosynthetics under wet condition. Soils Found. 2007, 47, 845–856. [Google Scholar] [CrossRef]

- De, A.; Zimmie, T.F. Landfill Stability: Static and Dynamic Geosynthetic Interface Friction Value; Geosynthetic Asia’97; Brookfield: Bangalore, India, 1997; pp. 271–278. [Google Scholar]

- Fishman, K.L.; Pal, S. Further study of geomembrane/cohesive soil interface shear behavior. Geotext. Geomembr. 1994, 13, 571–590. [Google Scholar] [CrossRef]

- Ghosh, B.; Fatahi, B.; Khabbaz, H.; Yin, J.H. Analytical study for double-layer geosynthetic reinforced load transfer platform on column improved soft soil. Geotext. Geomembr. 2017, 45, 508–536. [Google Scholar] [CrossRef]

- Ghosh, B.; Fatahi, B.; Khabbaz, H. Analytical Solution to Analyze LTP on Column-Improved Soft Soil Considering Soil Nonlinearity. Int. J. Geomech. 2017, 17, 04016082-1–04016082-24. [Google Scholar] [CrossRef]

- Hokmabadi, A.S.; Fatahi, B. Influence of Foundation Type on Seismic Performance of Buildings Considering Soil-Structure Interaction. Int. J. Struct. Stab. Dyn. 2016, 16, 1550043. [Google Scholar] [CrossRef]

- Armaleh, S.H.; Desai, C.S. Modeling Include Testing of Cohesionless Soils under Disturbed State Concept; Department of Civil Engineering and Engineering Mechanics, University of Arizona: Tuscon, AZ, USA, 1990. [Google Scholar]

- Ma, Y. Disturbed State Concept for Rock Joints; Department of Civil Engineering and Engineering Mechanics, University of Arizona: Tuscon, AZ, USA, 1990. [Google Scholar]

- Rigby, D.B.; Desai, C.S. Testing, Modeling, and Application of Saturated Interfaces in Dynamic Soil-Structure Interaction; Department of Civil Engineering and Engineering Mechanics, University of Arizona: Tuscon, AZ, USA, 1995. [Google Scholar]

- Park, I.J.; Yoo, J.H.; Kim, S.I. Disturbed state modeling for dynamic analysis of soil-structure interface. J. KGS 2000, 16, 5–13. [Google Scholar]

- Kjeldsen, P.; Barlaz, M.A.; Rooker, A.P.; Baun, A.; Ledin, A.; Christensen, T.H. Present and long-term composition of MSW landfill leachate: A review. Crit. Rev. Environ. Sci. Technol. 2002, 32, 297–336. [Google Scholar] [CrossRef]

- Oweis, I.S.; Khera, R.P. Geotechnology of Waste Management, 2nd ed.; PWS Publishing Company: Boston, MA, USA, 1998; pp. 1–24 & 295–299. [Google Scholar]

- Bilgili, M.S.; Demir, A.; Ince, M.; Ozkaya, B. Metal concentrations of simulated aerobic and anaerobic pilot scale landfill reactors. J. Hazard. Mater. 2007, 145, 186–194. [Google Scholar] [CrossRef] [PubMed]

- Kwak, C.W.; Park, I.J.; Park, J.B. Evaluation of disturbance function for geosynthetic–soil interface considering chemical reactions based on cyclic direct shear tests. Soils Found. 2013, 53, 720–734. [Google Scholar] [CrossRef]

- Rafizul, I.M.; Alamgir, M. Characterization and tropical seasonal variation of leachate: Results from landfill lysimeter studied. Waste Manag. 2012, 32, 2080–2095. [Google Scholar] [CrossRef] [PubMed]

- Desai, C.S. A consistent finite element technique for work-softening behavior. In Proceedings of the International Conference on Computer Mechanics in Nonlinear Mechanics; University of Texas Press: Austin, TX, USA, 1974. [Google Scholar]

- Desai, C.S.; Ma, Y. Modeling of joints and interfaces using the disturbed state concept. Int. J. Numer. Anal. Methods Geomech. 1992, 16, 623–653. [Google Scholar] [CrossRef]

- Kwak, C.W.; Park, I.J.; Park, J.B. Modified cyclic shear test for evaluating disturbance function and numerical formulation of geosynthetic-soil interface considering chemical effect. Geotech. Test. J. 2013, 36, 553–567. [Google Scholar] [CrossRef]

- Park, I.J. Disturbed State Modeling for Dynamic and Liquefaction Analysis; Department of Civil Engineering and Engineering Mechanics, University of Arizona: Tuscon, AZ, USA, 1997. [Google Scholar]

- Kwak, C.W.; Park, I.J.; Park, J.B. Development of Modified Interface apparatus and prototype cyclic simple shear test considering chemical and thermal effects. Geotech. Test. J. 2016, 39, 20–34. [Google Scholar] [CrossRef]

- ASTM D5035-11. Standard Test Method for Breaking Force and Elongation of Textile Fabrics (Strip Method); ASTM International: West Conshohocken, PA, USA, 2015. [Google Scholar]

- Ling, H.I.; Wang, J.P.; Leshchinsky, D. Cyclic behavior of soil-structure interfaces associated with modular-block reinforced soil-retaining walls. Geosynth. Int. 2008, 15, 14–21. [Google Scholar] [CrossRef]

- Masada, T.; Mithell, G.F.; Sargand, S.M.; Shashikumar, B. Modified direct shear study of clay liner-geomembrane interfaces exposed to landfill leachate. Geotext. Geomembr. 1994, 13, 165–179. [Google Scholar] [CrossRef]

- Stessel, R.I.; Hodge, J.S. Chemical resistance testing of geomembrane liners. J. Hazard. Mater. 1995, 42, 265–287. [Google Scholar] [CrossRef]

- Ehrig, H.J. Water and element balances of landfills. In The Landfill; Baccini, P., Ed.; Springer: Berlin, Germany, 1988; pp. 83–115. [Google Scholar]

- Shibuya, S.; Mitachi, T.; Fukuda, F.; Degoshi, T. Strain-rate effects on shear modulus and damping of normally consolidated clay. Geotech. Test. J. 1995, 18, 365–375. [Google Scholar]

- Araei, A.A.; Razeghi, H.R.; Tabatabaei, S.H.; Ghalandarzadeh, A.; Tabatabaei, S.H. Effects of loading rate and initial stress state on stress-strain behavior of rock fill materials under monotonic and cyclic loading conditions. Sci. Iran. A 2012, 19, 1220–1235. [Google Scholar] [CrossRef]

- ASTM D3999. Standard Test Methods for the Determination of the Modulus and Damping Properties of Soils Using the Cyclic Triaxial Apparatus; ASTM International: West Conshohocken, PA, USA, 1996. [Google Scholar]

- Koerner, R.M. Designing with Geosynthetics, 6th ed.; Xlibris Corporation: Lexington, KY, USA, 2013; Volume 1, pp. 165–173. [Google Scholar]

- Rowe, R.K.; Sangam, H.P. Durability of HDPE Geomembranes. Geotext. Geomembr. 2002, 20, 77–95. [Google Scholar] [CrossRef]

- Thurairajah, A. Shear behavior of sand under stress reversal. In Proceedings of the 8th International Conference on Soil Mechanics and Foundation Engineering, Moscow, Russia, 6–11 August 1973; Volume 1, pp. 439–445. [Google Scholar]

| Gs | Max. Dry Density (kN/m3) | Min. Dry Density (kN/m3) | Max. Void Ratio | Min. Void Ratio | Relative Density (%) | Moist Content (%) |

|---|---|---|---|---|---|---|

| 2.63 | 16.70 | 13.85 | 0.915 | 0.535 | 60 | 33.0 |

| Type | Geocomposite (Geonet + Nonwoven Fabric) |

|---|---|

| Manufacturer | GOLDENPOW, Korea |

| Ingredients | Geonet (High Density Polyethylene, HDPE), nonwoven fabric (Polyethylene Terephthalate(PET) + polypropylene (PP)), Carbon black (antioxidant; 2.2%) |

| Thickness | 7.0 mm |

| Tensile strength (kN/m) | 18.1 (longitudinal)/7.6 (transversal) |

| Unit weight (kN/m3) | 4.62 |

| Density (kN/m3) | 9.29 |

| Tensile strength (N/cm) | 141.4 (ASTM D5035-11 [28]) |

| Submersion Period (Days) | Normal Stress (MPa) | Chemical Condition | Parameters | Avg. |

|---|---|---|---|---|

| 30 | 0.3 | Acid | 1.9269 | |

| 0.4536 | ||||

| Neutral | 1.7287 | |||

| 0.4859 | ||||

| Basic | 1.9723 | |||

| 0.4768 | ||||

| 0.6 | Acid | 1.8193 | ||

| 0.5260 | ||||

| Neutral | 1.5810 | |||

| 0.4972 | ||||

| Basic | 1.7989 | |||

| 0.5179 | ||||

| 850 | 0.3 | Acid | 2.9476 | |

| 0.4852 | ||||

| Neutral | 2.7061 | |||

| 0.5286 | ||||

| Basic | 3.2338 | |||

| 0.4329 | ||||

| 0.6 | Acid | 2.3057 | ||

| 0.6040 | ||||

| Neutral | 2.0655 | |||

| 0.6179 | ||||

| Basic | 2.9057 | |||

| 0.4885 |

| Chemical Conditions | Max. Decreases of Disturbance (Δ Dmax) (between the Results of 30 and 850 Days of Submersion) | ||

|---|---|---|---|

| Basic | Neutral | Acid | |

| 0.3 MPa of normal stress | 31 % | 23 % | 22 % |

| 0.6 MPa of normal stress | 26 % | 10 % | 8 % |

| Cycle | Index | Gradient | |

|---|---|---|---|

| Measured | Predicted | ||

| 1 | GVL | 9184.71 | 8882.43 |

| GEVL | 2120.37 | 1668.50 | |

| GBRL | 9560.71 | 9280.93 | |

| GRVL1 | 5778.57 | 5653.48 | |

| GRVL2 | 5778.57 | 5254.98 | |

| GERVL | 1216.63 | 2465.50 | |

| GBRL | 10,306.53 | 9280.93 | |

| GERL | 5403.29 | 5653.48 | |

| Chemical Conditions | DSC Parameters | Normal Stress (MPa) | ||

|---|---|---|---|---|

| 0.30 | 0.45 (New) | 0.60 | ||

| Basic | 1.5529 | 1.7171 (predicted) | 1.8814 | |

| 0.5287 | 0.5804 (predicted) | 0.6320 | ||

| Acid | 3.3713 | 3.4440 (predicted) | 3.5166 | |

| 0.5175 | 0.6231 (predicted) | 0.7287 | ||

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kwak, C.; Park, J.; Jang, D.; Park, I. Dynamic Shear Degradation of Geosynthetic–Soil Interface in Waste Landfill Sites. Appl. Sci. 2017, 7, 1225. https://doi.org/10.3390/app7121225

Kwak C, Park J, Jang D, Park I. Dynamic Shear Degradation of Geosynthetic–Soil Interface in Waste Landfill Sites. Applied Sciences. 2017; 7(12):1225. https://doi.org/10.3390/app7121225

Chicago/Turabian StyleKwak, Changwon, Junboum Park, Dongin Jang, and Innjoon Park. 2017. "Dynamic Shear Degradation of Geosynthetic–Soil Interface in Waste Landfill Sites" Applied Sciences 7, no. 12: 1225. https://doi.org/10.3390/app7121225