1. Introduction

As one of the most important animal foods on the dining table, pork is rich in protein, fat, carbohydrate, calcium, iron, phosphorus, and other ingredients. China is the world’s largest producer and consumer of pork, accounting for about half of the world’s total output. The total viable bacteria count (TVC) is a key indicator to reflect the quality and safety of pork, and meat which TVC exceeds the standard value (6 log CFU/g in China) [

1] would greatly endanger consumers’ healthy. TVC can be not only used to predict the shelf life or to judge whether the meat is rotten or not, but also regard as a means of evaluating the processing environment and the degree of contamination of the pork.

The typical detection method of TVC is plate count method (ISO, 2003) [

2], which is also the national standard method of China, but it is too time-consuming and destructive, with tedious steps and delayed result. Some improved rapid methods for industrial online monitoring are in great request for modern control of the quality and safety of meat. The dry sheet culture method is a widely-used method in recent years with the advantages of simplicity, practicality, and low-cost with strong operation, but still needs a long time to obtain the results [

3]. Bio-electrochemistry is a method of determining the production or consumption of a microorganism by an electrode, thereby providing a signal for analysis [

4]. Although this method can greatly reduce the time consumption, which is still much longer and sensitive to temperature. Some biological methods, such as polymerase chain reaction (PCR) and enzyme linked immunosorbent assay (ELISA) have also been developed and applied for microbial identification and determination [

5,

6]. Although the results are relatively accurate and reliable, they are also accompanied with strong technicality and high cost.

As a new technology that has developed swiftly, near-infrared (NIR) spectroscopy technology has been used widely in the quality and safety detection of various types of agricultural products. Because it has the advantages of being rapid, nondestructive, and inexpensive, NIR spectroscopy has also been applied to detect safety and quality parameters of pork meat by many researchers from all over the world. However, NIR cannot reflect the detailed information of the pork samples, and only gives the average results of the quality parameters. Hyperspectral technology is newly developed from the 1980s, which combines optics, electronics, information processing, and computer science and technology. The advantage of hyperspectral technology lies in its ability to obtain spatial information and spectral information of the object simultaneously. In recent years, the spatially scattering feasibility of hyperspectral imaging for total viable count (TVC) has been investigated [

7,

8,

9,

10,

11,

12,

13,

14]. Peng et al (2011) [

8] applied hyperspectral scattering imaging for the determination of TVC of beef, and a very good result with R

2 = 0.95 and SEP(standard error of prediction set) = 0.30 log CFU/g was obtained by the established partial least square regression (PLSR) model based on three combinations of scattering parameters (i.e., a, b, and a × b). Huang, Zhao, Chen, and Zhang [

10] applied a hyperspectral imaging system working in the 430–960 nm region combined with a back-propagation artificial neural network (BP-ANN) model for TVC evaluation in pork meat, obtaining good results with R

2P of 0.83 and SEP of 0.24 log CFU/g. However, there are some problems with the stability and efficiency of real-time detection. Barbin, ElMasry, Sun, Allen, and Morsy [

11] adopted NIR (900–1700 nm) reflectance hyperspectral imaging combined with PLS algorithm to evaluate the TVC degree of chilled pork meat. The PLS model developed with the full NIR spectra gave the result of R

2P of 0.93 and SEP of 0.70 log CFU/g, which was better than with selected wavelengths. However, the cost of the detection device is higher than the former.

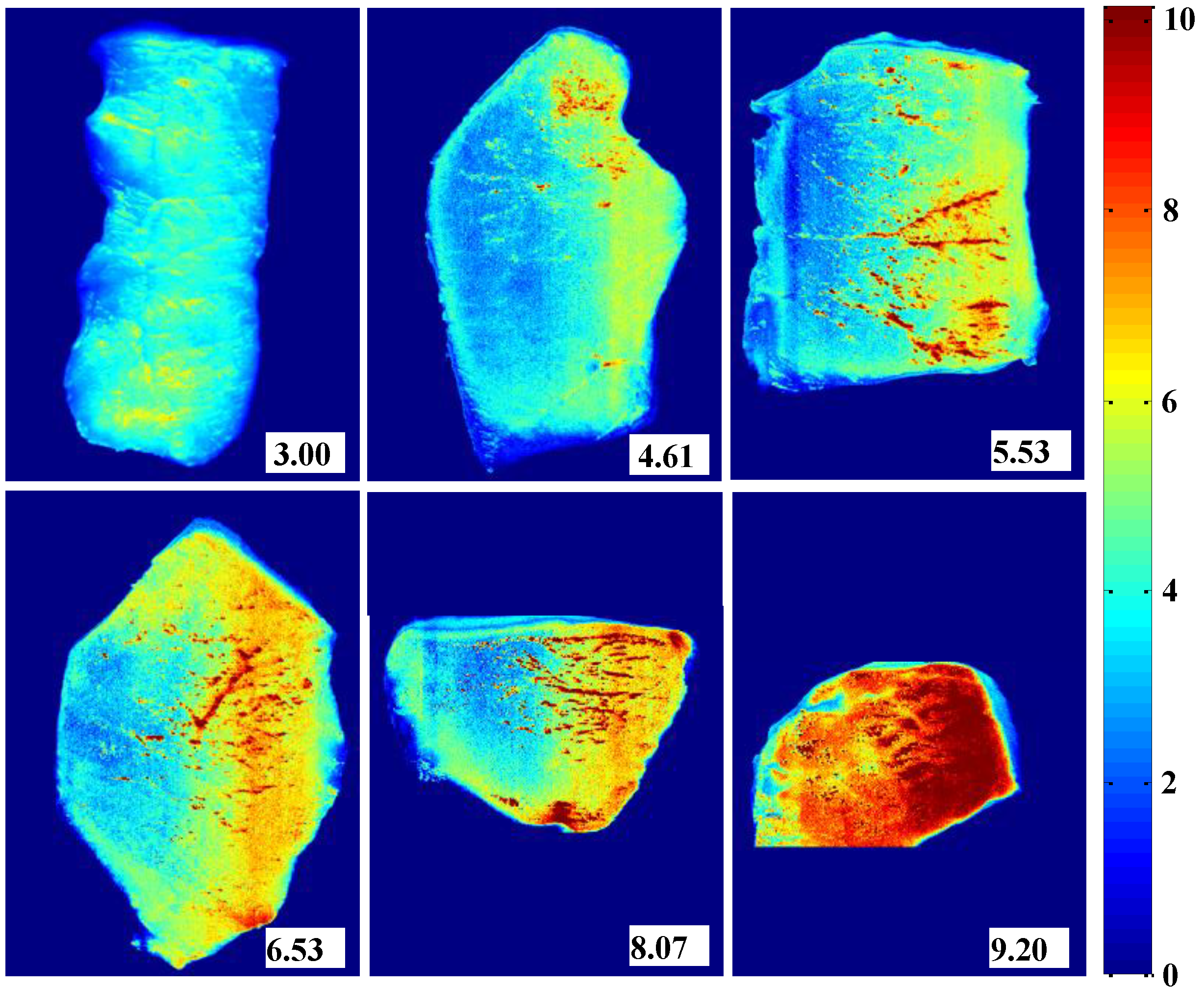

Despite the encouraging findings above, a higher precision and simpler model based on a detection device with low cost should be encouraged. A method for nondestructive, rapid, and real-time detection of total viable count in pork by hyperspectral imaging technique was developed in this study. The hyperspectral reflectance spectra in the range of 400 nm to 1100 nm were collected to build the TVC prediction model for 50 pieces of chilled pork samples. Then, the visual display map of TVC was realized by transferring the prediction model to every pixel of the image to predict TVC in all spots of the sample.

2. Materials and Methods

2.1. Preparation of Pork Samples

Pork tenderloin samples were purchased from a local supermarket (Merry Mart, Beijing, China) and immediately transported to the lab. The pork meat was then sliced into 50 pieces of 80 × 50 × 25 mm3 (length × width × thickness) chops on a sterilized chopping board and placed in PVC (polyvinyl chloride) boxes separately. The samples were then stored in a refrigerator at 4 °C and covered by plastic film. The whole experimental period lasted 15 days, and two to four randomly-selected samples were taken out from the refrigerator on each sampling day for hyperspectral imaging and microbiological analysis. Sample analysis of the first day was conducted immediately before storage.

2.2. Hyperspectral Acquisition

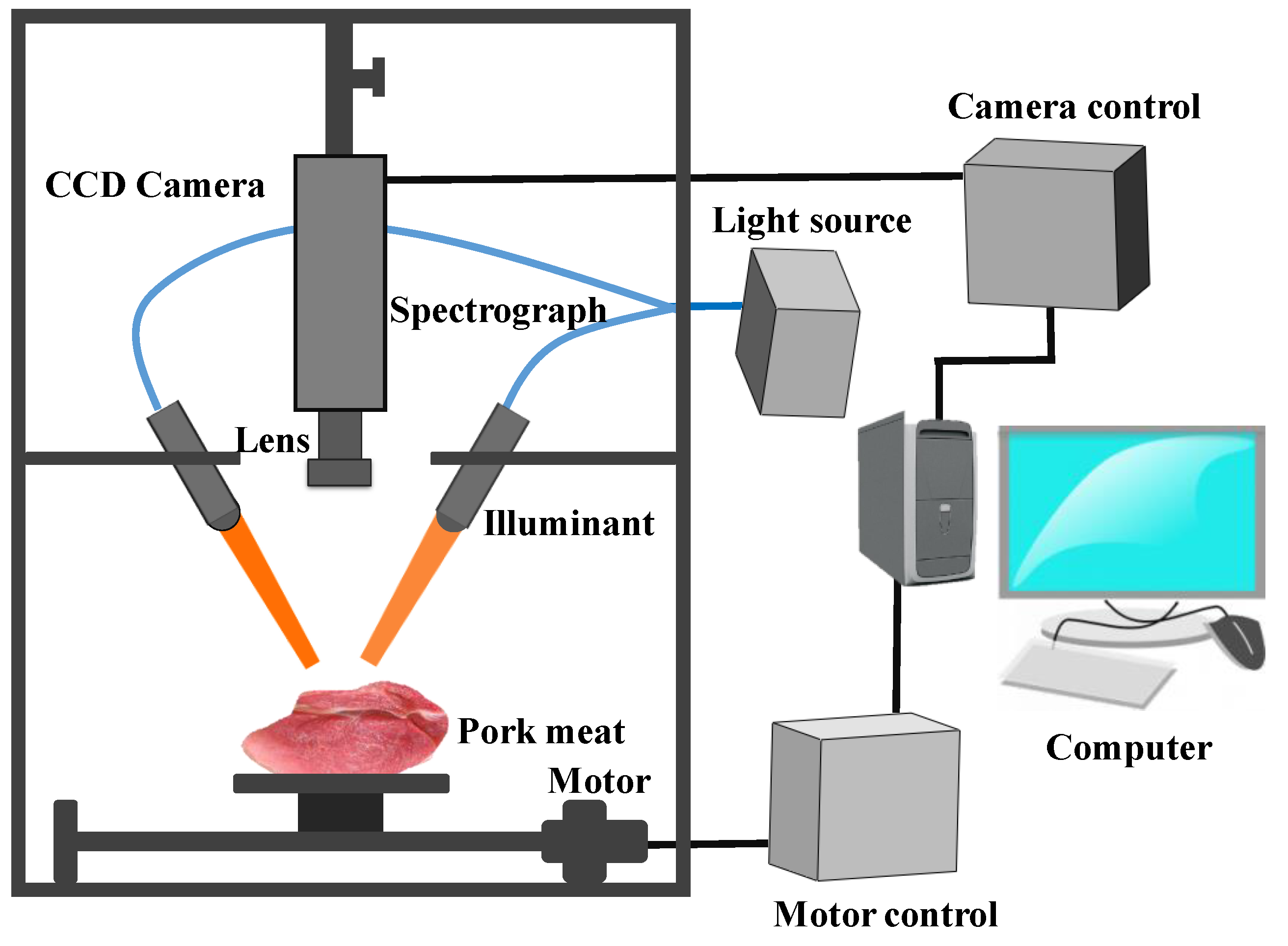

A visible/near-infrared (VIS/NIR) hyperspectral imaging system (

Figure 1) in the spectral range of 400–1100 nm was used in this study. A line illumination source with fiber bundle structure was equipped for better imaging. The hyperspectral imaging system was mainly composed of a high-performance back-illuminated 12-bit charge coupled device (CCD, charge coupled device) camera (Sensicam QE, PCO AG, Kelheim, Germany), an imaging spectrograph (ImSpector V10E, Spectral Imaging Ltd., Oulu, Finland), an illumination unit (Oriel Instruments, Stratford, CT, USA) equipped with a quartz tungsten halogen lamp and optical fiber, a laser displacement sensor (CD33-120N-422, OPTEX, Rancho Dominguez, CA, USA), a computer supported with a data acquisition and control software (Camera Control Kit V2.19, PCO AG, Kelheim, Germany), Microsoft Visual Studio 2010 (Microsoft Corporation, Redmond, WA, USA) and OpenCV 2.4.10 (Willow Garage, Inc., Palo Alto, CA, USA), and a translation stage (horizontal and vertical) operated by stepper motor (AH-STA03300, NEWLABS CO, LTD, Beijing, China). The optical fiber was used to transform the light and form a line of light on the surface of the sample. The whole system was maintained in a dark sealed container to avoid the effects of external light. The resolution of the system was 2.8 nm spectrally and 150 μm spatially. The image generated by this system was of 1376 × 1040 (spatial × spectral) pixels originally, and 2 × 2 binning was performed on the final images of 688 × 520 to improve the signal-to-noise ratio of the images.

Then, pork meat samples were tiled on the black board at room temperature for 30 min. With the system described above, the samples were placed on the translation stage, and the vertical height of the camera from the sample was adjusted according to the preset height. Then, each sample was scanned line by line with 80 ms exposure time according the total length of the pork meat sample to build a hypercube. The scan speed of the system was about 50 mm/s, considering the exposure time and data processing. A hypercube with three dimensions (x, y, λ) was achieved for every sample, which the x-dimension of the cube stands for the length of one line (688 pixels in this study), the y-dimension of the cube stands for the line number which reflects the scanning length of the sample, and the λ-dimension stands for the 520 bands in the range of 400–1100 nm. In this way, each pixel of the hyperspectral image represents a spectrum.

2.3. Measurement of TVC

The number of viable bacteria on the pork meat sample was measured immediately after hyperspectral image acquisition by using the national standard method of China (GB/T 4789.2, 2010). Meat (25 g) was cut and weighed from the middle area of the sample with a sterilized knife, and then transferred into a homogeneous cup with 225 mL phosphate buffer solution. Then, a 1:10 dilution was obtained. Serial dilutions were prepared with the 1:10 dilution and phosphate buffer solution. Two or three suitable diluents were selected for bacteria culture according to estimation of the pollution status of the sample. One milliliter of specimen was drawn into a sterile plate with a duplicate plate. At the same time, 1 mL blank phosphate buffer solution was drawn into a plate for blank control, with a duplicate plate as well. Then, 15–20 mL culture medium that was cooled to 46 °C was quickly deposited into the plate timely. All the plates were rotated to mix evenly, and were then cultured for 48 ± 2 h at 36 ± 1 °C after the medium was cooled and solidified. After cultivation, the plate with TVC count in range of 30 to 300 was counted and calculated in terms of colony-forming units (CFU) per gram.

2.4. Spectral Data Extraction and Analysis

All the spectral images were processed through the following procedures using MATLAB 8.3 and ENVI 5.1. Dark correction and white correction were carried out on the raw sample images. The dark image was acquired by covering a dark cap with very low reflectance to the lens of the CCD camera. The white reference image was acquired with a white Teflon board. Then, the corrected reflectance images were calculated by the following Equation 1:

where

R is the corrected reflectance image of the sample,

I0 is the raw spectral image of the samples,

Br is the dark reference image, and

Ir is the white reference image. Then, the region of interest (ROI) and segmentation of the images were implemented at the same time to extract the spectra of the samples by setting three thresholds in the reflectance image—two of them were set for all pixels at 651 nm as 0.50 for maximum value and 0.25 for minimum value, the last one was set with the ratio value of 651 nm and 550 nm and 1.20 for minimum value.

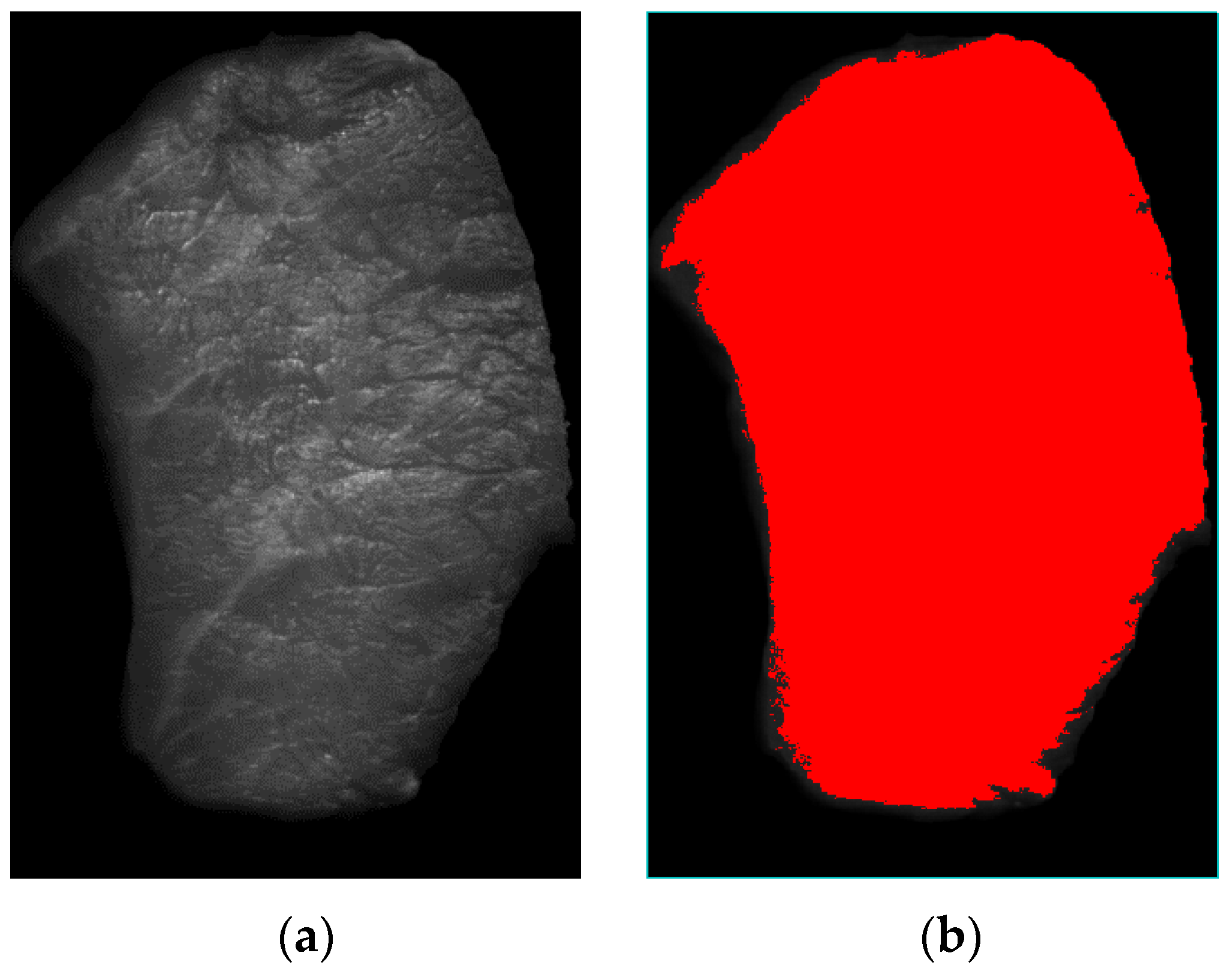

Figure 2a shows a grayscale image at band 651 nm, and the segmentation was confirmed relatively well as shown in

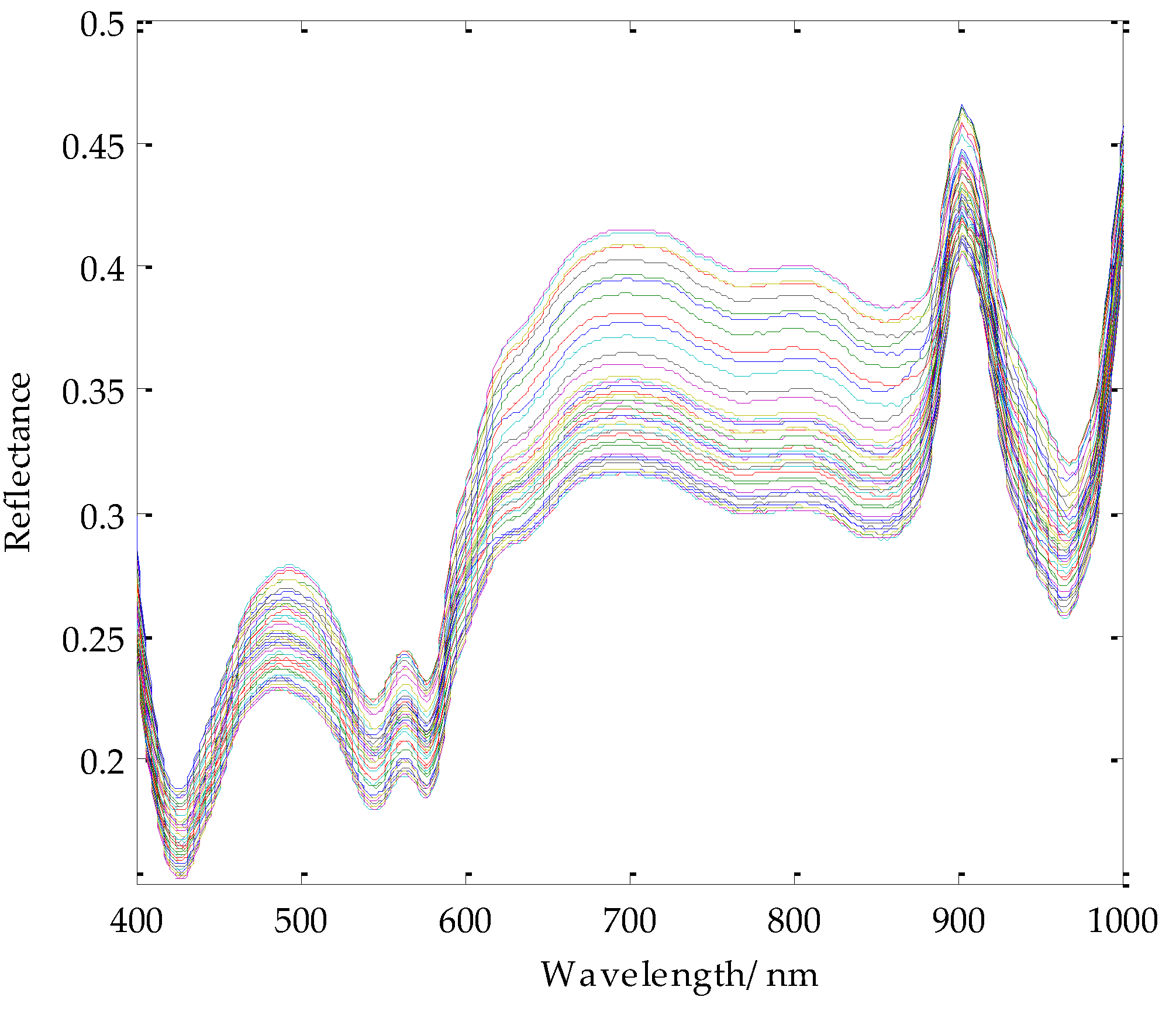

Figure 2b, which was chosen to be the ROI at the same time. Then, the mean reflectance spectrum of the ROI was extracted to be the spectrum of the sample. The reflectance spectra of all samples were finally obtained by the above procedures.

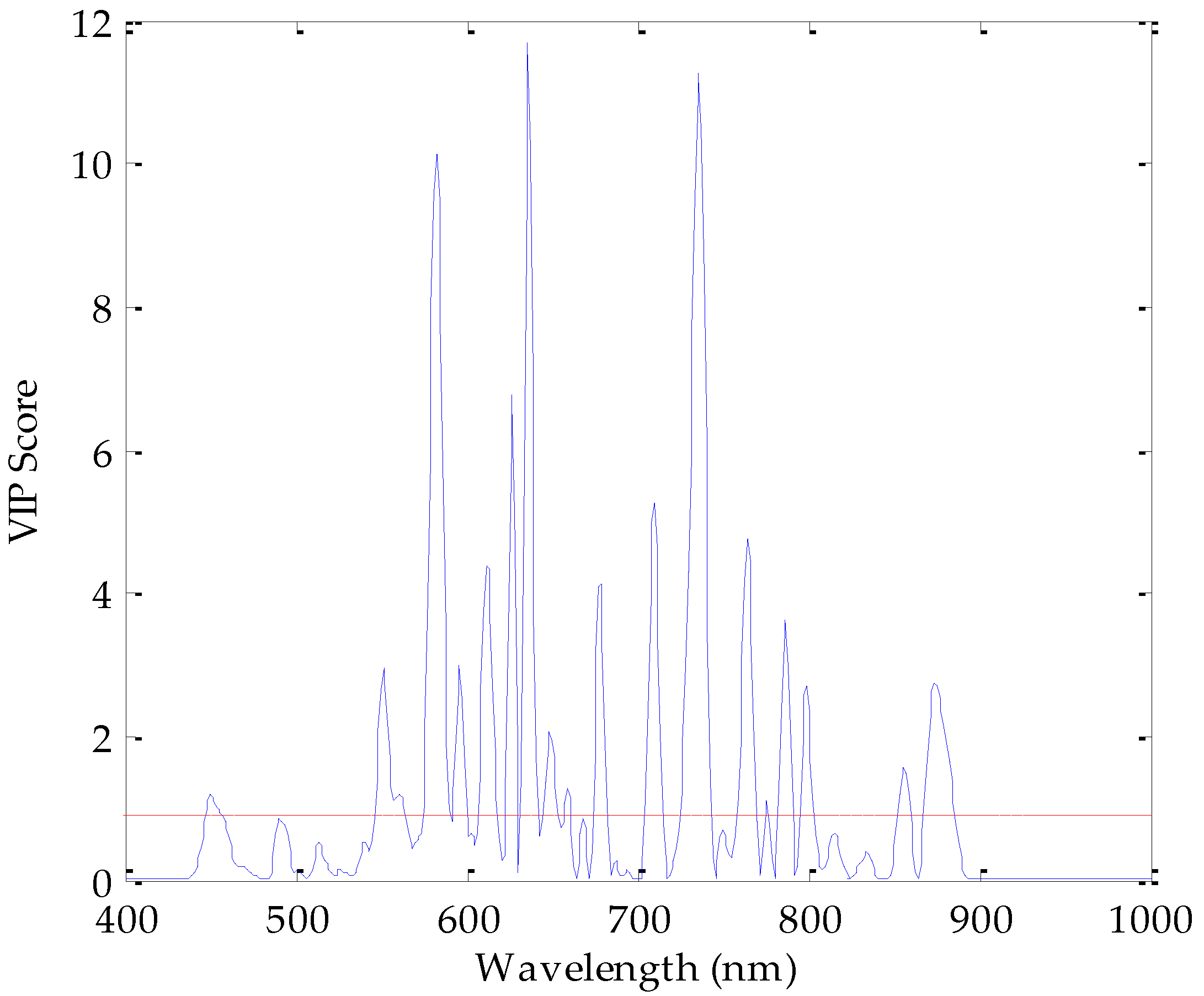

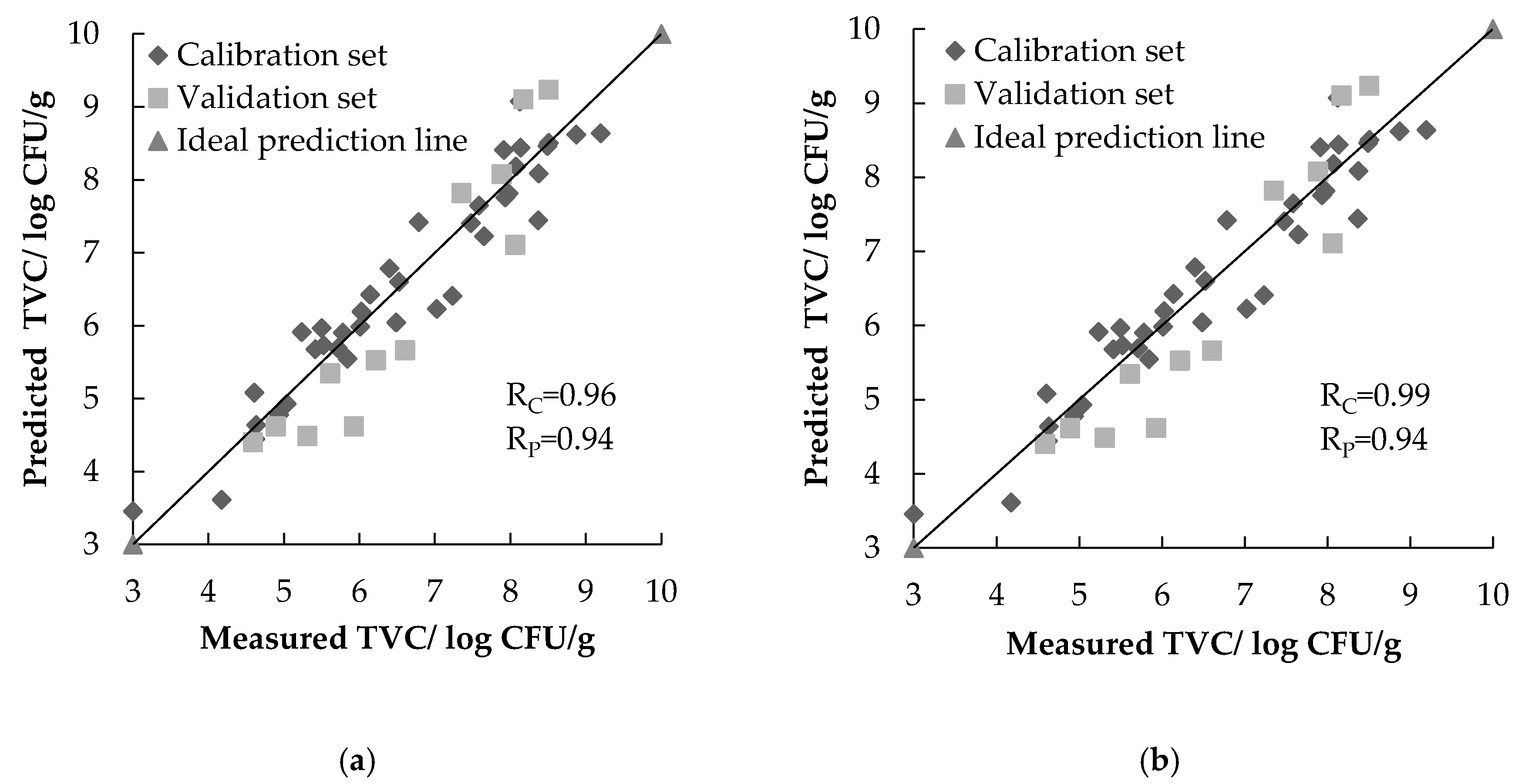

In this study, two methods were used to establish the prediction model of total bacterial count. Support vector machine regression (SVR) [

15] could make the regression problem simpler by mapping the low dimensional nonlinear problem into a high dimensional linear problem based on kernel function. At the same time, SVR can account for both the training accuracy and generalization ability by the maximum distance method based on structural risk minimization principle. The method has been widely used in many fields, such as classification, regression, and face recognition, etc. Partial least squares regression (PLSR) [

16] is a linear and supervised multivariate calibration method that attempts to find fewer factors that can predict the microbial counts from the reflectance values at various wavelengths. PLSR is particularly suited when the matrix of predictors has more variables than number of samples, and when there is a high correlation among the original predictors. Therefore, these two mathematical approaches were adopted as modeling methods for comparison. The better one was used to predict the microbial contamination in pork samples and for spatial visualization of the results within the sample.