Modeling kV X-ray-Induced Coloration in Radiochromic Films

Abstract

:1. Introduction

2. Materials and Methods

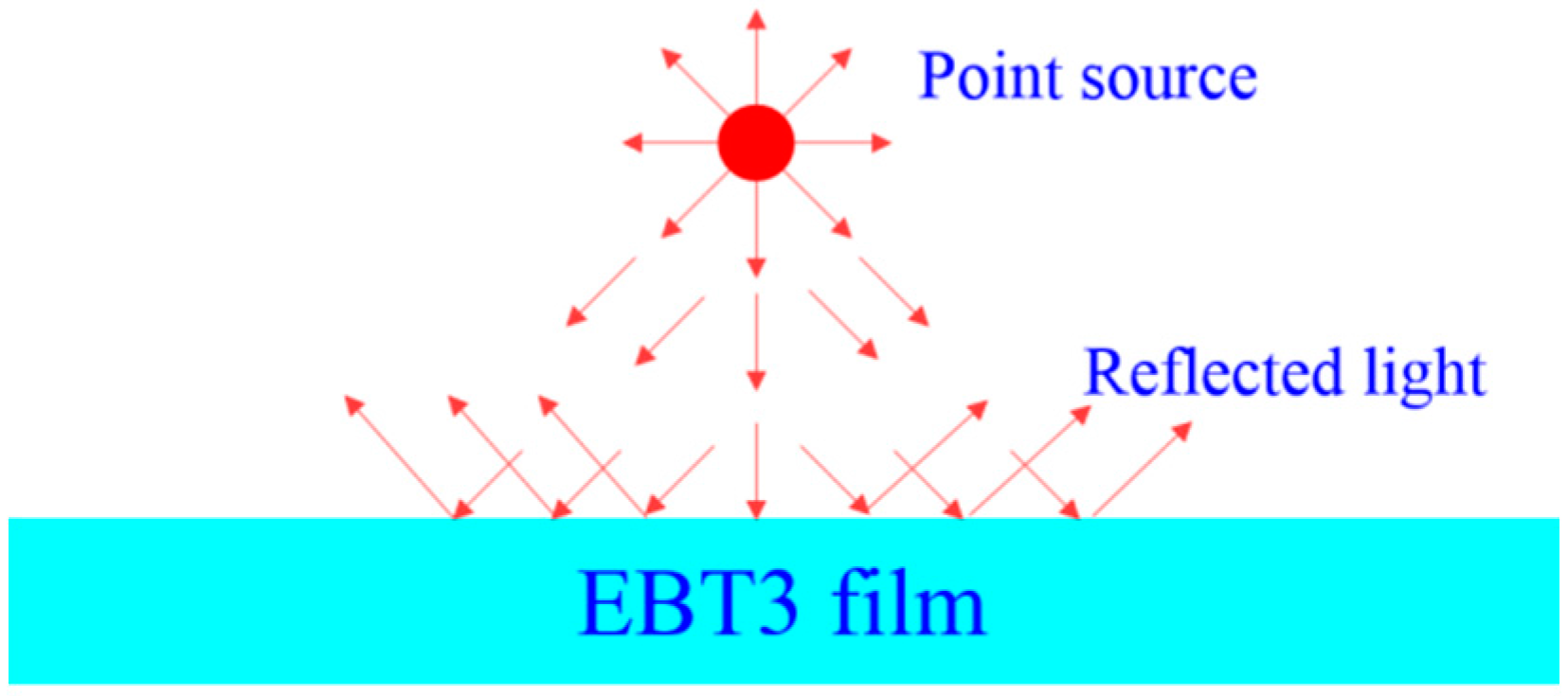

2.1. Monte Carlo Model

2.2. Finite Element Method (FEM)

2.3. Computation Scheme

3. Results and Discussions

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Butson, M.J.; Yu, P.K.N.; Cheung, T.; Metcalfe, P. Radiochromic film for medical radiation dosimetry. Mater. Sci. Eng. R Rep. 2003, 41, 61–120. [Google Scholar] [CrossRef]

- McLaughlin, W.L.; Al-Sheikhly, M.; Lewis, D.F.; Kovács, A.; Wojnárovits, L. Radiochromic Solid-State Polymerization Reaction. In Irradiation of Polymers, Chapter 11; ACS Symposium Series; American Chemical Society: Washington, DC, USA, 1996; Volume 620, pp. 152–166. [Google Scholar]

- Shahmohammadi Beni, M.; Krstic, D.; Nikezic, D.; Yu, K.N. Modeling Coloration of a Radiochromic Film with Molecular Dynamics-Coupled Finite Element Method. Appl. Sci. 2017, 7, 1031. [Google Scholar] [CrossRef]

- X-5 Monte Carlo Team. MCNP—A General Monte Carlo N-Particle Transport Code, Version 5, Vol. I: Overview and Theory; LA-UR-03-1987; Los Alamos National Laboratory: Los Alamos, NM, USA, 2003.

- Shahmohammadi Beni, M.; Ng, C.Y.P.; Krstic, D.; Nikezic, D.; Yu, K.N. Conversion coefficients for determination of dispersed photon dose during radiotherapy: NRUrad input code for MCNP. PLoS ONE 2017, 12, e0174836. [Google Scholar] [CrossRef] [PubMed]

- Shahmohammadi Beni, M.; Krstic, D.; Nikezic, D.; Yu, K.N. A calibration method for realistic neutron dosimetry in radiobiological experiments assisted by MCNP simulation. J. Radiat. Res. 2016, 57, 492–498. [Google Scholar] [CrossRef] [PubMed]

- Shahmohammadi Beni, M.; Krstic, D.; Nikezic, D.; Yu, K.N. Realistic dosimetry for studies on biological responses to X-rays and γ-rays. J. Radiat. Res. 2017, 58, 729–736. [Google Scholar] [CrossRef] [PubMed]

- MUMPS Solver. Available online: http://mumps.enseeiht.fr/ (accessed on 14 November 2017).

- Girard, F.; Bouchard, H.; Lacroix, F. Reference dosimetry using radiochromic film. J. Appl. Clin. Med. Phys. 2012, 13, 339–353. [Google Scholar] [CrossRef] [PubMed]

- Chan, P.M.; Ng, C.Y.P.; Shahmohammadi Beni, M.; Law, S.S.; Yu, K.N. Auto-development issue in quality assurance of biological X-ray irradiator using Gafchromic EBT3 film. Results Phys. 2017, 7, 444–445. [Google Scholar] [CrossRef]

- V 20 Committee. Standard for Verification and Validation in Computational Fluid Dynamics and Heat Transfer; American Society of Mechanical Engineers: New York, NY, USA, 2009. [Google Scholar]

- Shahmohammadi Beni, M.; Yu, K.N. Computational Fluid Dynamics Analysis of Cold Plasma Plume Mixing with Blood Using Level Set Method Coupled with Heat Transfer. Appl. Sci. 2017, 7, 578. [Google Scholar] [CrossRef]

- Shahmohammadi Beni, M.; Yu, K.N. Computational fluid dynamics analysis of cold plasma carrier gas injected into a fluid using level set method. Biointerphases 2015, 10, 041003. [Google Scholar] [CrossRef] [PubMed]

- Shahmohammadi Beni, M.; Zhao, J.; Yu, K.N. Investigation of droplet behaviors for spray cooling using level set method. Ann. Nucl. Energy 2018, 113, 162–170. [Google Scholar] [CrossRef]

- Shahmohammadi Beni, M.; Hau, T.C.; Krstic, D.; Nikezic, D.; Yu, K.N. Monte Carlo studies on neutron interactions in radiobiological experiments. PLoS ONE 2017, 12, e0181281. [Google Scholar] [CrossRef] [PubMed]

- Chance, R.R.; Patel, G.N. Solid-state polymerization of a diacetylene crystal: Thermal, ultraviolet, and γ-ray polymerization of 2, 4-hexadiyne-1, 6-diol bis-(p-toluene sulfonate). J. Polym. Sci. Part B Polym. Phys. 1978, 16, 859–881. [Google Scholar] [CrossRef]

- Kim, T.Y.; Lofgren, E.A.; Jabarin, S.A. Solid-state polymerization of poly(ethylene terephthalate). I. Experimental study of the reaction kinetics and properties. J. Appl. Polym. Sci. 2003, 89, 197–212. [Google Scholar] [CrossRef]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shahmohammadi Beni, M.; Krstic, D.; Nikezic, D.; Yu, K.N. Modeling kV X-ray-Induced Coloration in Radiochromic Films. Appl. Sci. 2018, 8, 106. https://doi.org/10.3390/app8010106

Shahmohammadi Beni M, Krstic D, Nikezic D, Yu KN. Modeling kV X-ray-Induced Coloration in Radiochromic Films. Applied Sciences. 2018; 8(1):106. https://doi.org/10.3390/app8010106

Chicago/Turabian StyleShahmohammadi Beni, Mehrdad, Dragana Krstic, Dragoslav Nikezic, and Kwan Ngok Yu. 2018. "Modeling kV X-ray-Induced Coloration in Radiochromic Films" Applied Sciences 8, no. 1: 106. https://doi.org/10.3390/app8010106