Experimental Study on Anti-Icing Performance of NS-DBD Plasma Actuator

Abstract

:1. Introduction

2. Experimental Setup

3. Experimental Results

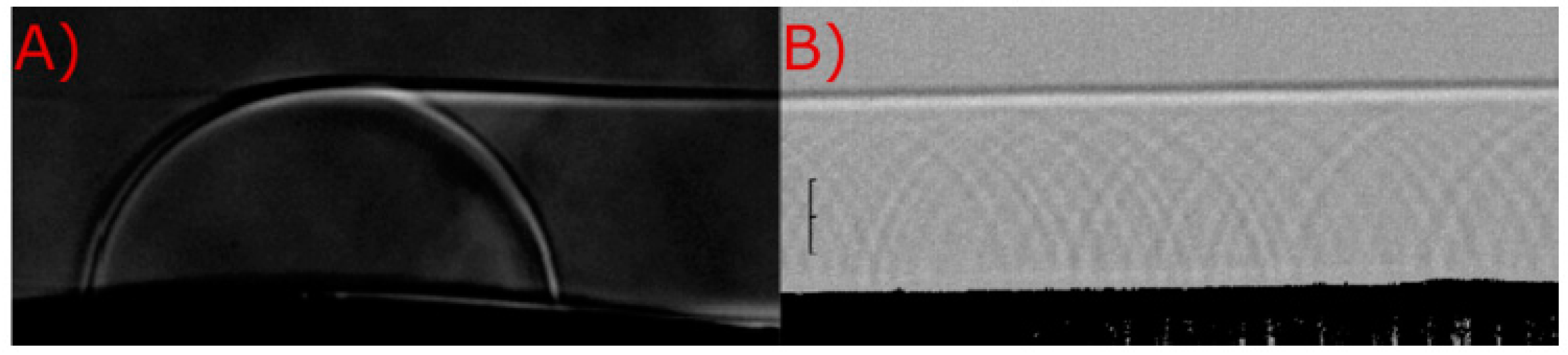

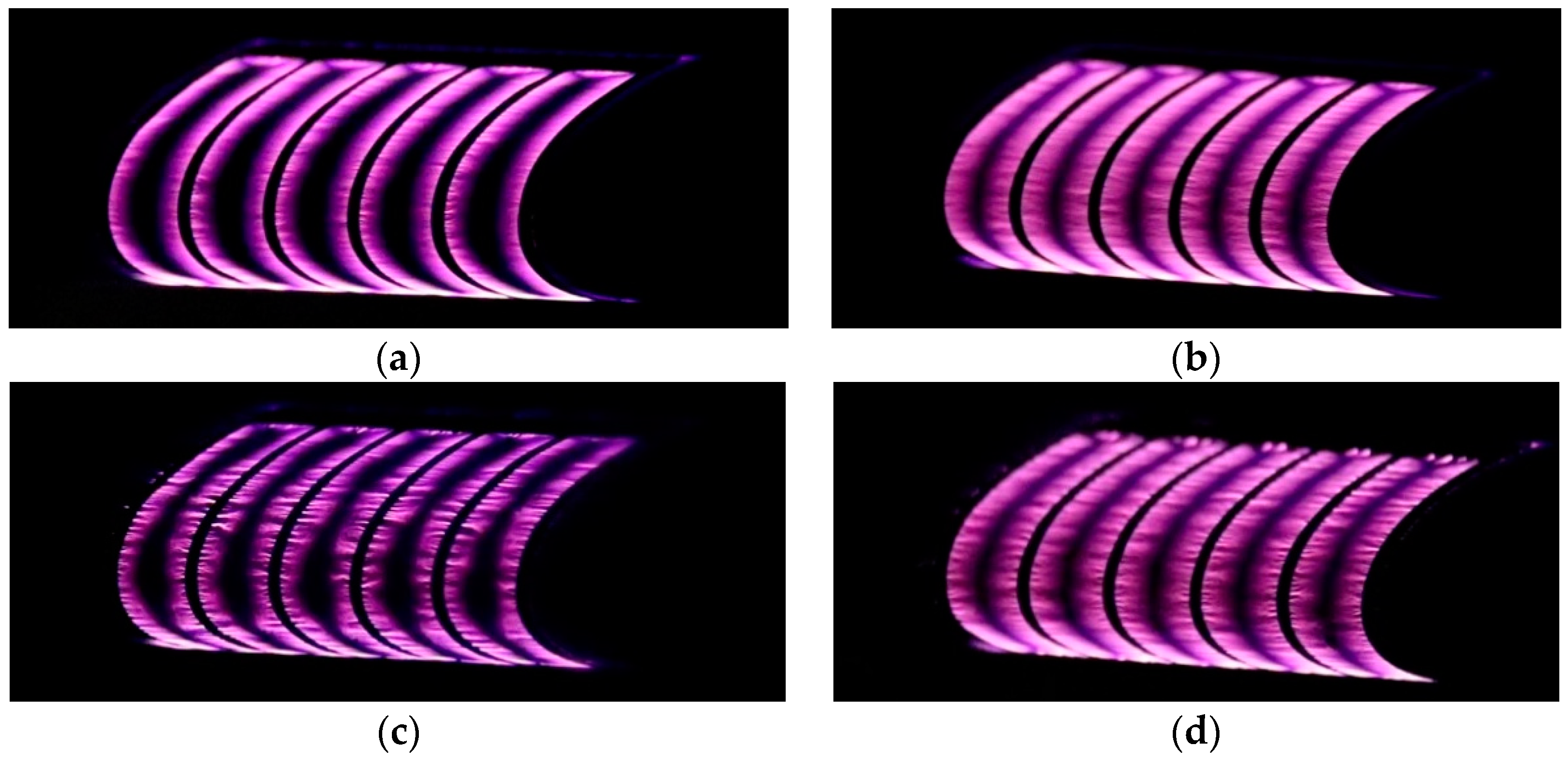

3.1. Electrical Diagnostics

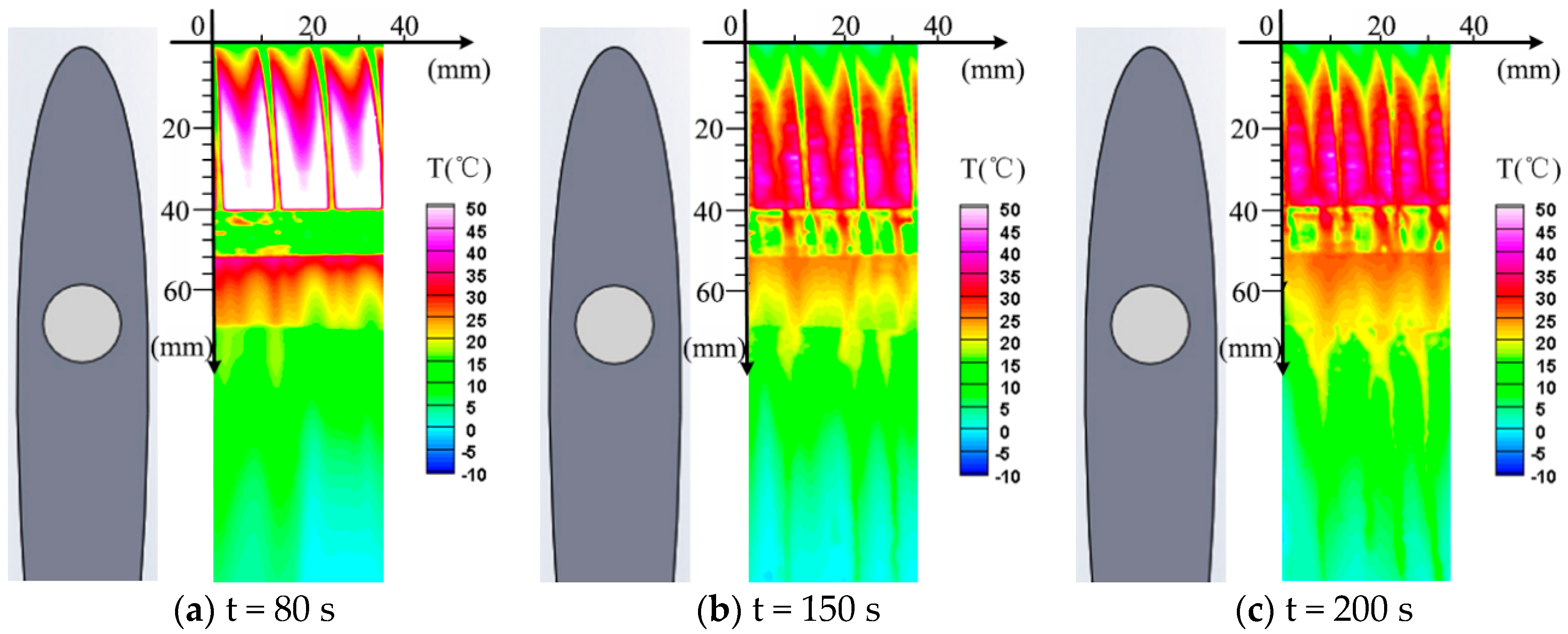

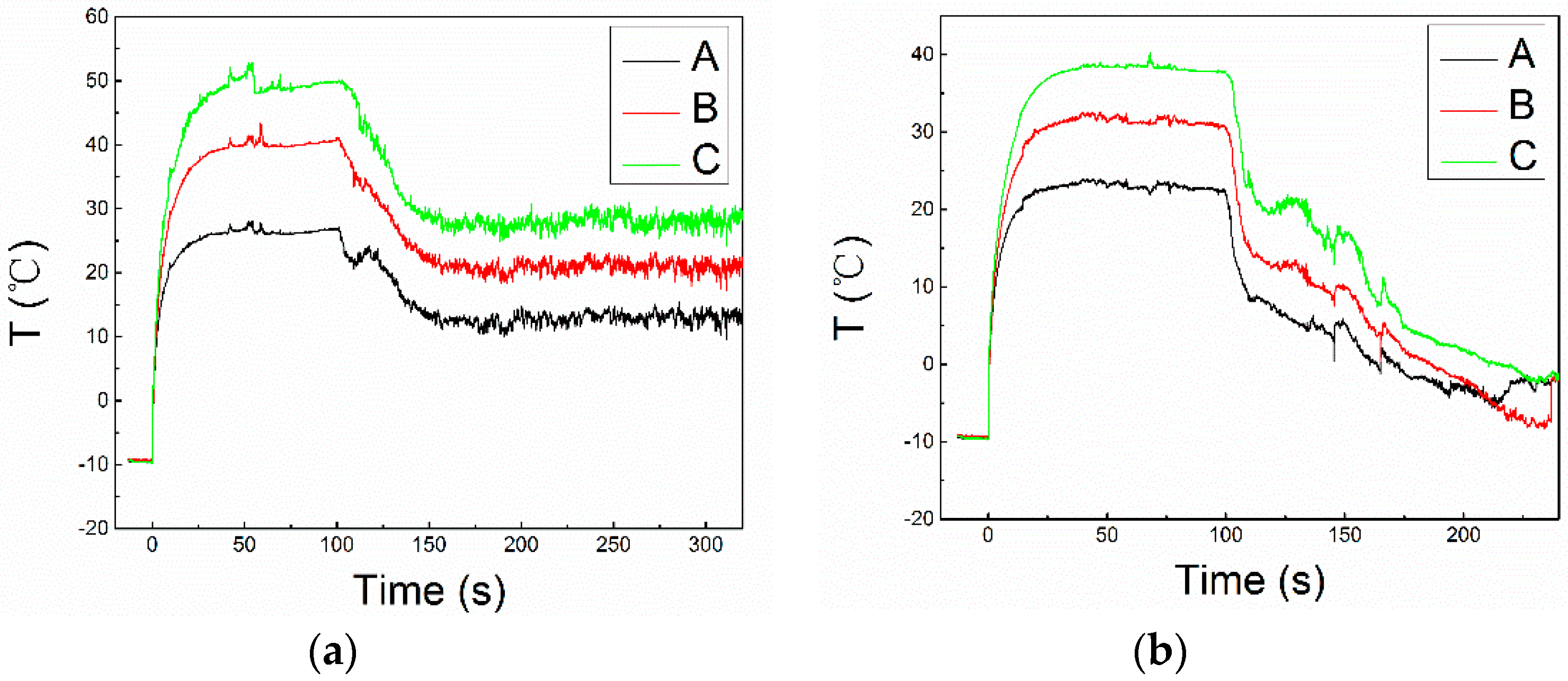

3.2. Thermal Properties

3.3. Anti-Icing Performance

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Lynch, F.; Khodadoust, A. Erratum to “Effects of ice accretions on aircraft aerodynamics”: [Prog. Aerosp. Sci. 37 (2001) 669–767]. Prog. Aerosp. Sci. 2002, 38, 273–274. [Google Scholar] [CrossRef]

- Calay, R.K.; Holdoacute, A.E.; Mayman, P.; Lun, I. Experimental Simulation of Runback Ice. J. Aircr. 2015, 34, 206–212. [Google Scholar] [CrossRef]

- Aircraft Icing. AOPA Air Satety Foundation [EB/OL]. Available online: http://www.asf.org (accessed on 4 September 2009).

- Thomas, S.K.; Cassoni, R.P.; Macarthur, C.D. Aircraft anti-icing and de-icing techniques and modeling. J. Aircr. 1996, 33, 841–854. [Google Scholar] [CrossRef]

- Kind, R.J.; Potapczuk, M.G.; Feo, A.; Golia, C.; Shah, A.D. Experimental and computational simulation of in-flight icing phenomena. Prog. Aerosp. Sci. 1998, 34, 257–345. [Google Scholar] [CrossRef]

- Zumwalt, G.W.; Schrag, R.L.; Bernhart, W.D.; Friedberg, R.A. Electro-Impulse De-Icing Testing Analysis and Design; NASA-CR-4175, E-4279, NAS 1.26:4175; NASA: Washington, DC, USA, 1988.

- Papadakis, M.; Wong, S.H.; Yeong, H.W.; Wong, S.C.; Vu, G. Icing Tunnel Experiments with a Hot Air Anti-Icing System. In Proceedings of the 46th AIAA Aerospace Sciences Meeting and Exhibit, Reno, NV, USA, 7–10 January 2008. [Google Scholar]

- D’Avirro, J.; Chaput, M. Optimizing the Use of Aircraft Deicing and Anti-Icing Fluids. ACRP Rep. 2011. [Google Scholar] [CrossRef]

- Pauw, D.D.; Dolatabadi, A. Effect of Superhydrophobic Coating on the Anti-Icing and Deicing of an Airfoil. J. Aircr. 2016, 54, 1–10. [Google Scholar]

- Zumwalt, G. Icing tunnel tests of Electro-Impulse De-Icing of an Engine Inlet and High-speed Wings. AIAA J. 2013, 85, 466. [Google Scholar]

- Zhao, Z.; Chen, H.; Liu, X.; Liu, H.; Zhang, D. Development of High-efficient Synthetic Electric Heating Coating for Anti-icing/de-icing. Surf. Coat. Technol. 2018, 349, 340–346. [Google Scholar] [CrossRef]

- Pourbagian, M.; Habashi, W.G. Surrogate-Based Optimization of Electrothermal Wing Anti-Icing Systems. J. Aircr. 2013, 50, 1555–1563. [Google Scholar] [CrossRef]

- Broeren, A.P.; Riley, J.T. Scaling of Lift Degradation Due to Anti-Icing Fluids. J. Aircr. 2013, 50, 1886–1895. [Google Scholar] [CrossRef]

- Zhao, Y.; Chang, S.; Yang, B.; Zhang, W.; Leng, M. Experimental study on the thermal performance of loop heat pipe for the aircraft anti-icing system. Int. J. Heat Mass Trans. 2017, 111, 795–803. [Google Scholar] [CrossRef]

- Moreau, E. Airflow control by non-thermal plasma actuators. J. Phys. D Appl. Phys. 2007, 40, 605–636. [Google Scholar] [CrossRef]

- Corke, T.C.; Enloe, C.L.; Wilkinson, S.P. Dielectric Barrier Discharge Plasma Actuators for Flow Control. Annu. Rev. Fluid Mech. 2009, 42, 505–529. [Google Scholar] [CrossRef]

- Zhao, G.Y.; Li, Y.H.; Liang, H.; Han, M.H.; Hua, W.Z. Control of vortex on a non-slender delta wing by a nanosecond pulse surface dielectric barrier discharge. Exp. Fluids 2015, 56, 1864. [Google Scholar] [CrossRef]

- Little, J.; Takshima, K.; Nishihara, M.; Adamovich, I.; Mo, S. Separation Control with Nanosecond-Pulse-Driven Dielectric Barrier Discharge Plasma Actuators. AIAA J. 2012, 50, 350–365. [Google Scholar] [CrossRef] [Green Version]

- Starikovskii, A.Y.; Nikipelov, A.A.; Nudnova, M.M.; Roupassov, D.V. SDBD plasma actuator with nanosecond pulse-periodic discharge. Plasma Sour. Sci. Technol. 2009, 18, 034015. [Google Scholar] [CrossRef]

- Takashima, K.; Zuzeek, Y.; Lempert, W.; Adamovich, I. Characterization of Surface Dielectric Barrier Discharge Plasma Sustained by Repetitive Nanosecond Pulses. Plasma Sour. Sci. Technol. 2011, 20, 055009. [Google Scholar] [CrossRef]

- Correale, G.; Michelis, T.; Ragni, D.; Kotsonis, M.; Scarano, F. Nanosecond-pulsed plasma actuation in quiescent air and laminar boundary layer. J. Phys. D Appl. Phys. 2014, 47, 105201. [Google Scholar] [CrossRef]

- Benard, N.; Zouzou, N.; Claverie, A.; Sotton, J.; Moreau, E. Optical visualization and electrical characterization of fast-rising pulsed dielectric barrier discharge for airflow control applications. J. Appl. Phys. 2012, 111, 47. [Google Scholar] [CrossRef]

- Unfer, T.; Boeuf, J.P. Modelling of a nanosecond surface discharge actuator. J. Phys. D Appl. Phys. 2009, 42, 194017. [Google Scholar] [CrossRef]

- Zhu, Y.; Wu, Y.; Cui, W.; Li, Y.; Jia, M. Modelling of plasma aerodynamic actuation driven by nanosecond SDBD discharge. J. Phys. D Appl. Phys. 2013, 46, 355205. [Google Scholar] [CrossRef]

- Wu, Y.; Li, Y.; Jia, M.; Song, H.; Liang, H. Optical emission characteristics of surface nanosecond pulsed dielectric barrier discharge plasma. J. Appl. Phys. 2013, 113, 505. [Google Scholar] [CrossRef]

- Jiang, H.; Shao, T.; Zhang, C.; Li, W.; Yan, P. Experimental study of Q-V Lissajous figures in nanosecond-pulse surface discharges. IEEE Trans. Dielectr. Electr. Insul. 2013, 20, 1101–1111. [Google Scholar] [CrossRef]

- Cai, J.; Tian, Y.; Meng, X.; Han, X.; Zhang, D. An experimental study of icing control using DBD plasma actuator. Exp. Fluids 2017, 58, 102. [Google Scholar] [CrossRef]

- Liu, Y.; Kolbakir, C.; Hu, H. A comparison study on the thermal effects in DBD plasma actuation and electrical heating for aircraft icing mitigation. Int. J. Heat Mass Trans. 2018, 124, 319–330. [Google Scholar] [CrossRef]

- Jia, Y.; Sang, W.; Cai, Y. Numerical Analysis of Anti-Icing Property of NSDBD Plasma Actuator on Airfoil. In Proceedings of the AIAA Atmospheric and Space Environments Conference, Denver, CO, USA, 5–9 June 2017. [Google Scholar]

- Van Den, B.J. De-Icing Using ns-DBD Plasma Actuators. Master’s Thesis, Delft University of Technology, Delft, The Netherlands, 2016. [Google Scholar]

- Bian, D.L.; Wu, Y.; Jia, M. Characterization of surface dielectric barrier discharge (SDBD) based on PI/Al2O3 nanocomposite. Plasma Process. Polym. 2018, e1700236. [Google Scholar] [CrossRef]

- Wicks, M.; Thomas, F.O. Effect of Relative Humidity on Dielectric Barrier Discharge Plasma Actuator Body Force. AIAA J. 2015, 53, 1–4. [Google Scholar] [CrossRef]

- Rodrigues, F.; Pascoa, J.; Trancossi, M. Heat generation mechanisms of DBD plasma actuators. Exp. Therm. Fluid Sci. 2018, 90, 55–65. [Google Scholar] [CrossRef]

- Popov, N.A. Fast gas heating in a nitrogen-oxygen discharge plasma: I. Kinetic mechanism. J. Phys. D Appl. Phys. 2011, 44, 285201. [Google Scholar] [CrossRef]

- Poggie, J.; Bisek, N.; Adamovich, I.; Nishihara, M. Numerical Simulation of Nanosecond-Pulse Electrical Discharges. Plasma Sour. Sci. Technol. 2012, 22, 015001. [Google Scholar] [CrossRef]

- Tirumala, R.; Benard, N.; Moreau, E.; Fenot, M.; Lalizel, G. Temperature characterization of dielectric barrier discharge actuators: Influence of electrical and geometric parameters. J. Phys. D Appl. Phys. 2014, 47, 255203. [Google Scholar] [CrossRef]

- Liu, Y.; Hu, H. An Experimental Investigation on the Convective Heat Transfer Process over an Ice Roughened Airfoil. In Proceedings of the 53rd AIAA Aerospace Sciences Meeting, Kissimmee, FL, USA, 5–9 January 2015. [Google Scholar]

- Zheng, J.G.; Li, J.; Zhao, Z.J.; Cui, Y.D.; Khoo, B.C. Numerical Study of Nanosecond Pulsed Plasma Actuator in Laminar Flat Plate Boundary Layer. Commun. Comput. Phys. 2016, 20, 1424–1442. [Google Scholar] [CrossRef]

- Thomas, G.O. On the Conditions Required for Explosion Mitigation by Water Sprays. Process Saf. Environ. Protect. 2000, 78, 339–354. [Google Scholar] [CrossRef] [Green Version]

- Goossens, H.W.J.; Cleijne, J.W.; Smolders, H.J.; Dongen, M.E.H.V. Shock wave induced evaporation of water droplets in a gas-droplet mixture. Exp. Fluids 1988, 6, 561–568. [Google Scholar] [CrossRef]

- Wei, Q.F. Surface characterization of plasma-treated polypropylene fibers. Mater. Charact. 2004, 52, 231–235. [Google Scholar] [CrossRef]

- Wei, Q.; Li, Q.; Wang, X.; Huang, F.; Gao, W. Dynamic water adsorption behaviour of plasma-treated polypropylene nonwovens. Polym. Test. 2006, 25, 717–722. [Google Scholar] [CrossRef]

- Starostin, A.; Valtsifer, V.; Barkay, Z.; Legchenkova, I.; Danchuk, V.; Bormashenko, E. Drop-Wise and Film-Wise Water Condensation Processes Occurring on Metallic Micro-Scaled Surfaces. Appl. Surf. Sci. 2018, 444, 604–609. [Google Scholar] [CrossRef]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, J.; Liang, H.; Wu, Y.; Wei, B.; Zhao, G.; Tian, M.; Xie, L. Experimental Study on Anti-Icing Performance of NS-DBD Plasma Actuator. Appl. Sci. 2018, 8, 1889. https://doi.org/10.3390/app8101889

Chen J, Liang H, Wu Y, Wei B, Zhao G, Tian M, Xie L. Experimental Study on Anti-Icing Performance of NS-DBD Plasma Actuator. Applied Sciences. 2018; 8(10):1889. https://doi.org/10.3390/app8101889

Chicago/Turabian StyleChen, Jie, Hua Liang, Yun Wu, Biao Wei, Guangyin Zhao, Miao Tian, and Like Xie. 2018. "Experimental Study on Anti-Icing Performance of NS-DBD Plasma Actuator" Applied Sciences 8, no. 10: 1889. https://doi.org/10.3390/app8101889

APA StyleChen, J., Liang, H., Wu, Y., Wei, B., Zhao, G., Tian, M., & Xie, L. (2018). Experimental Study on Anti-Icing Performance of NS-DBD Plasma Actuator. Applied Sciences, 8(10), 1889. https://doi.org/10.3390/app8101889