Bearing Capacity Model of Corroded RC Eccentric Compression Columns Based on Hermite Interpolation and Fourier Fitting

Abstract

:1. Introduction

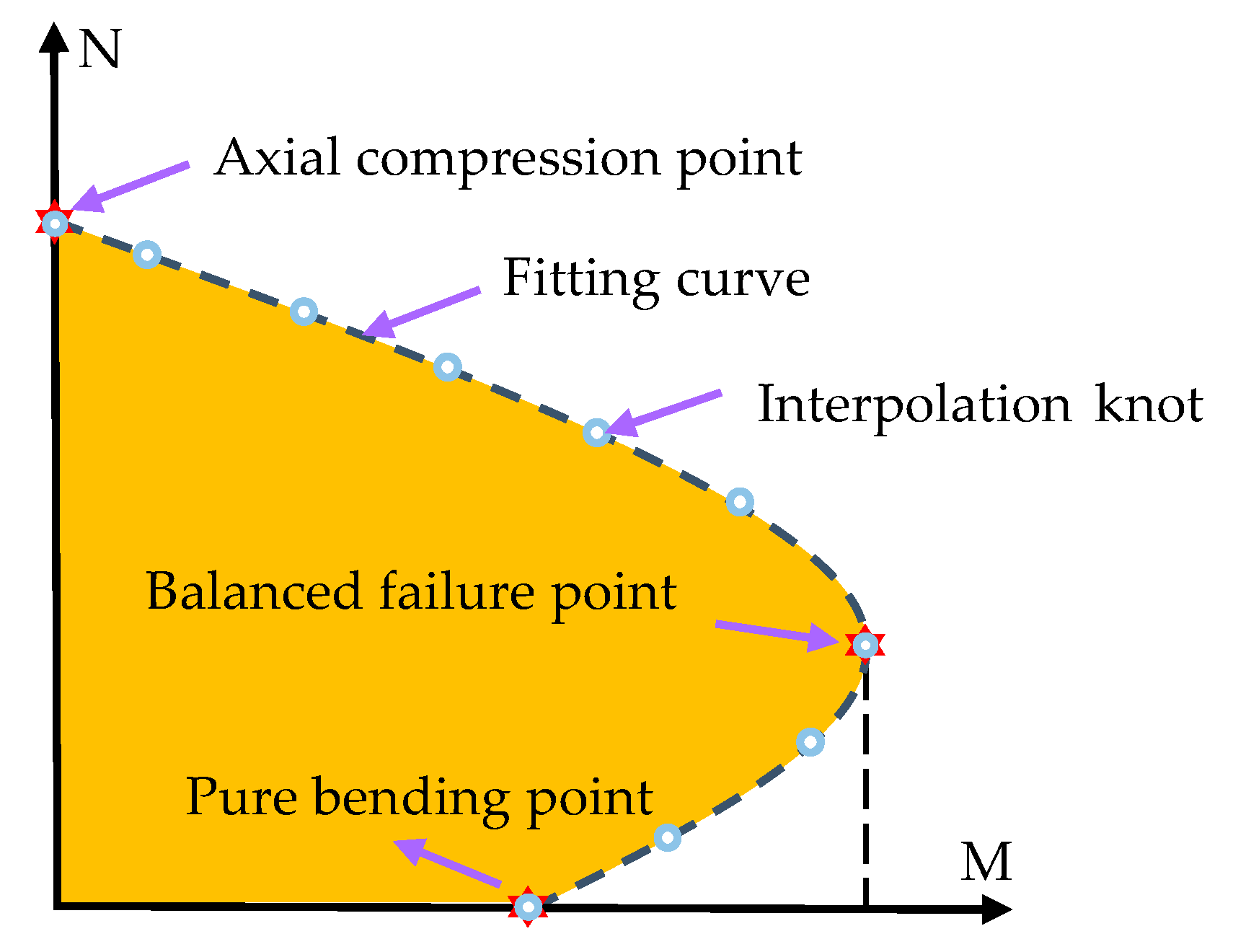

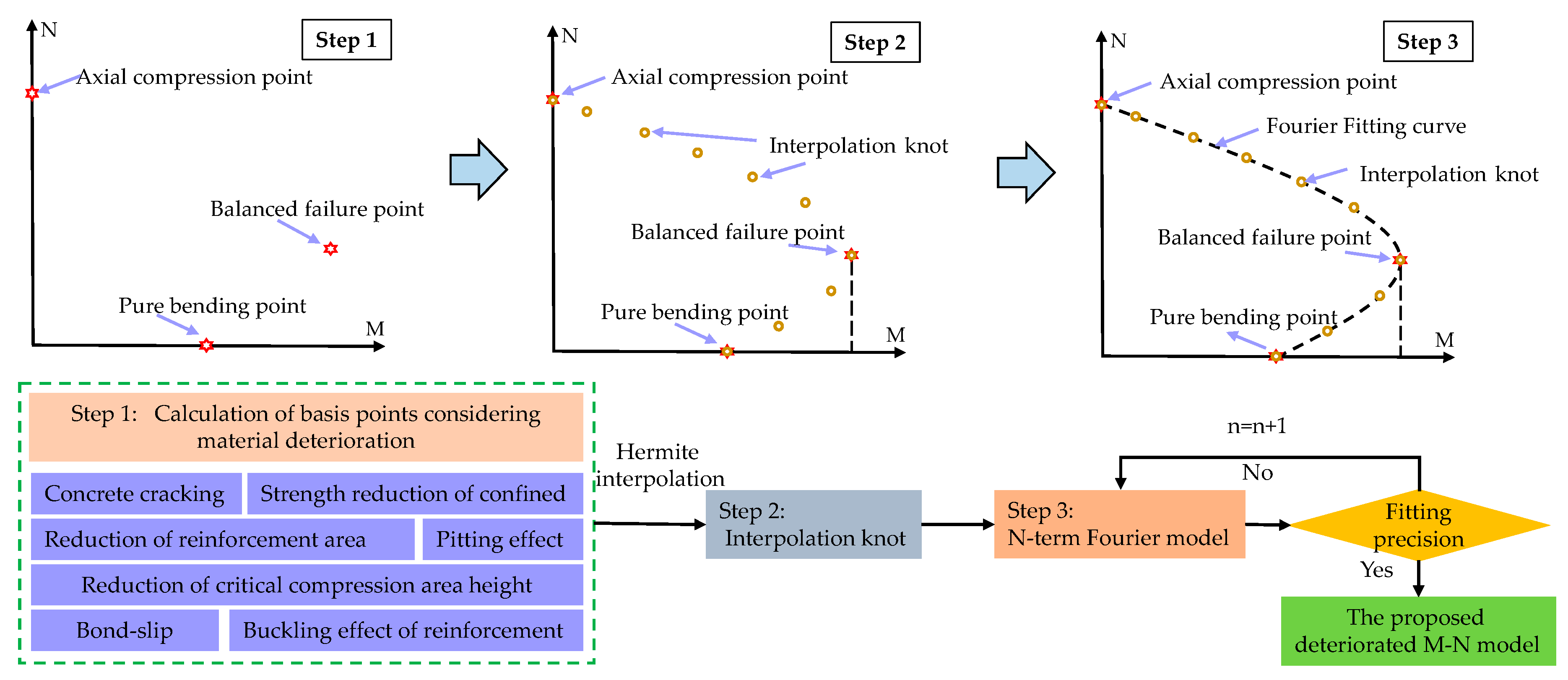

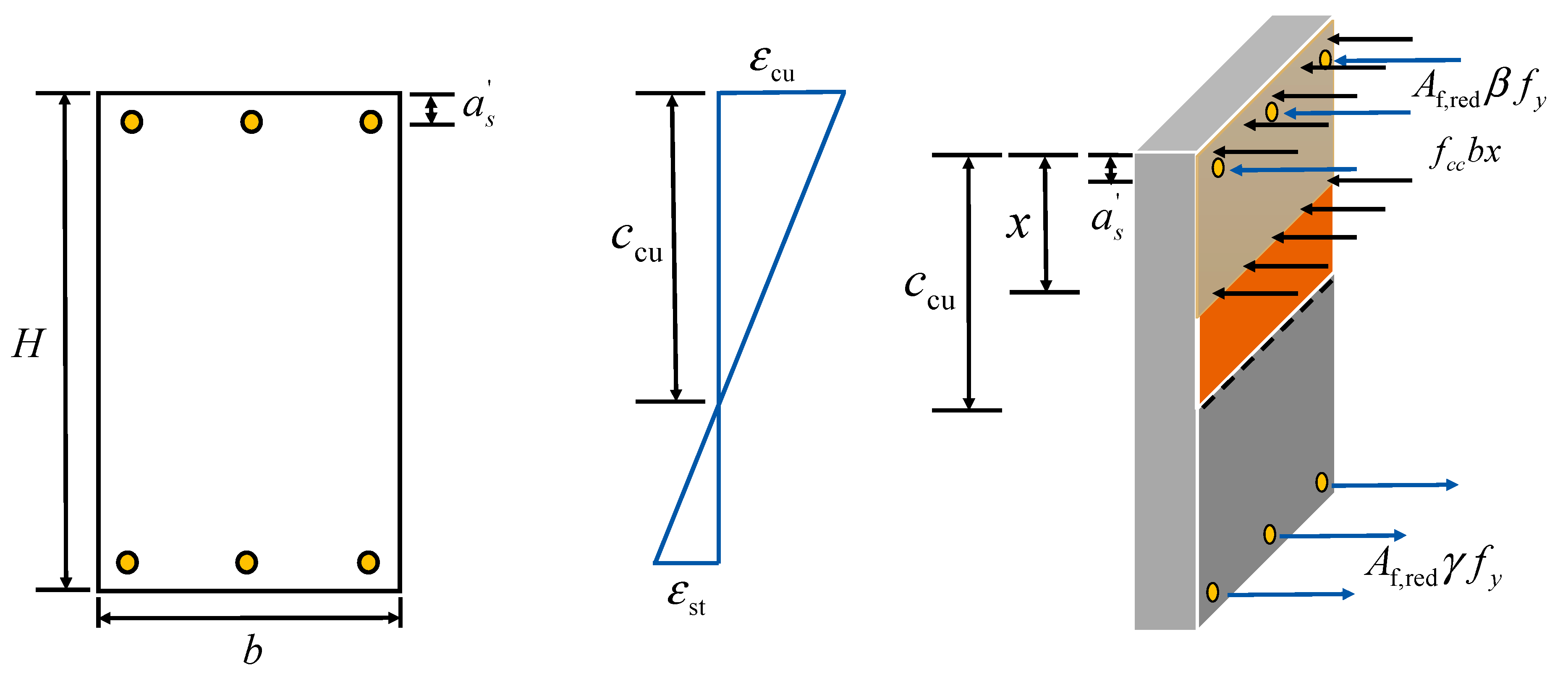

2. The Proposed Model

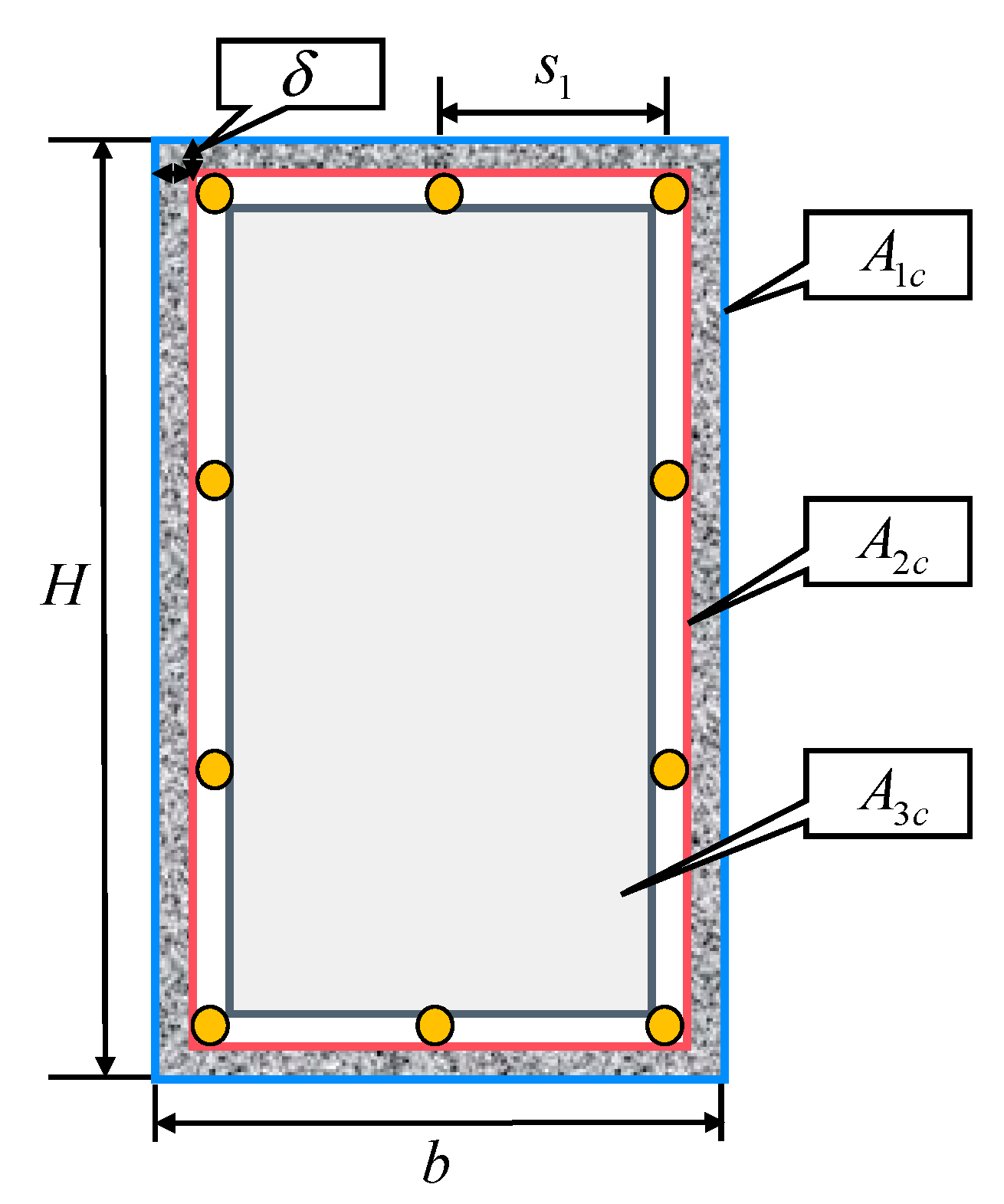

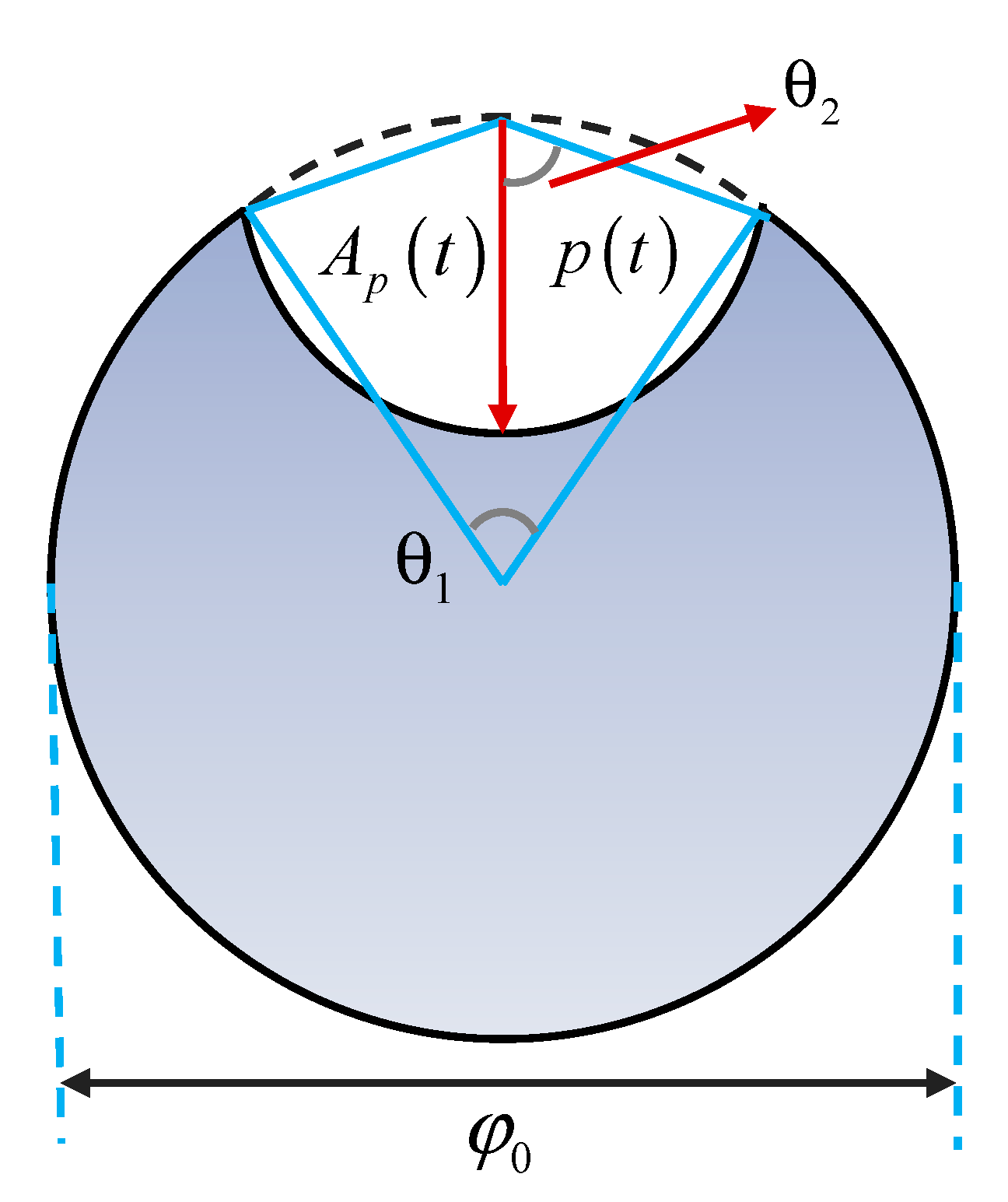

2.1. Axial Compression Point

2.2. Pure bending point

2.3. Balanced Failure Point

2.4. Hermite Interpolation

2.5. Fourier Fitting

3. Model Validation

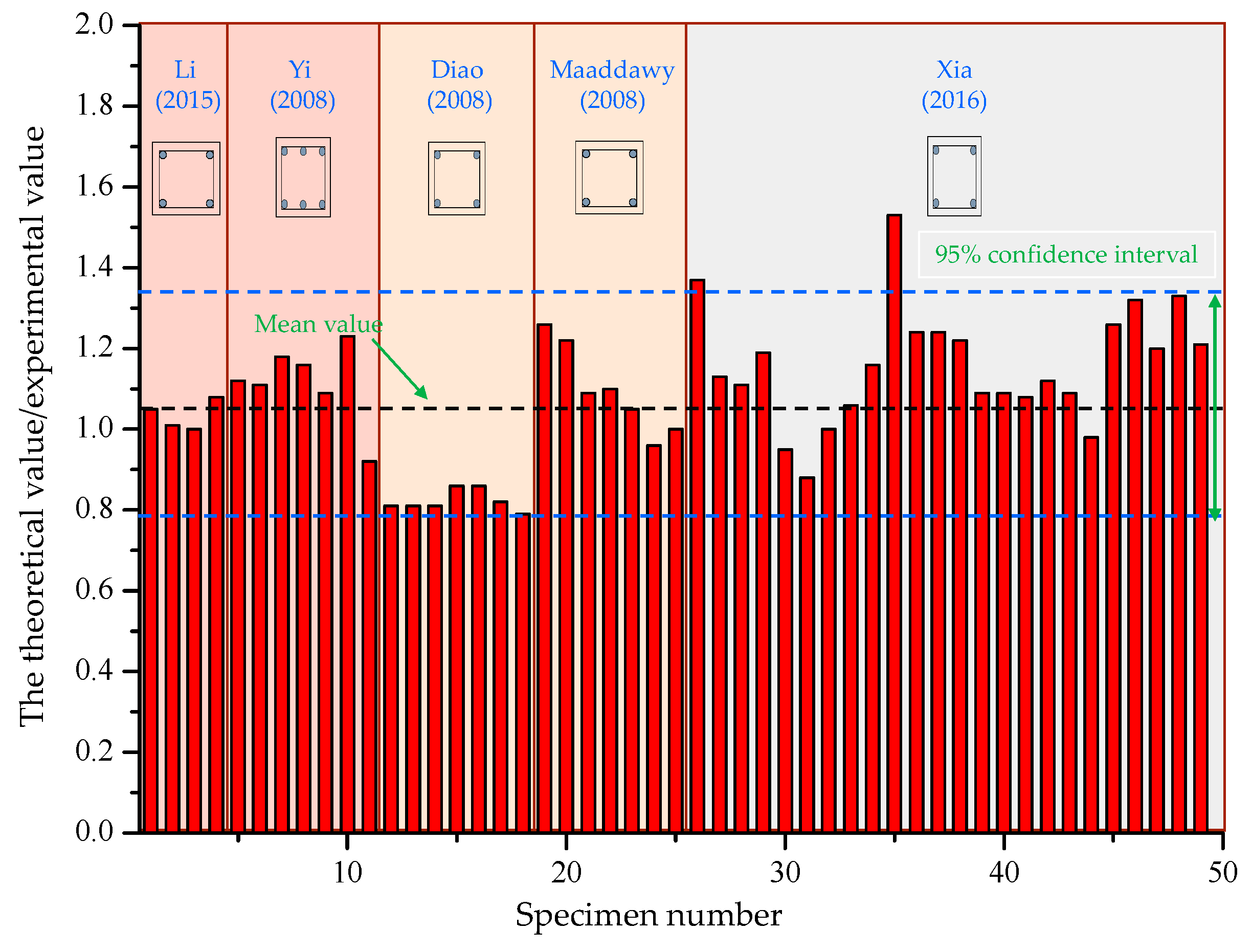

3.1. Validation by Experimental Data

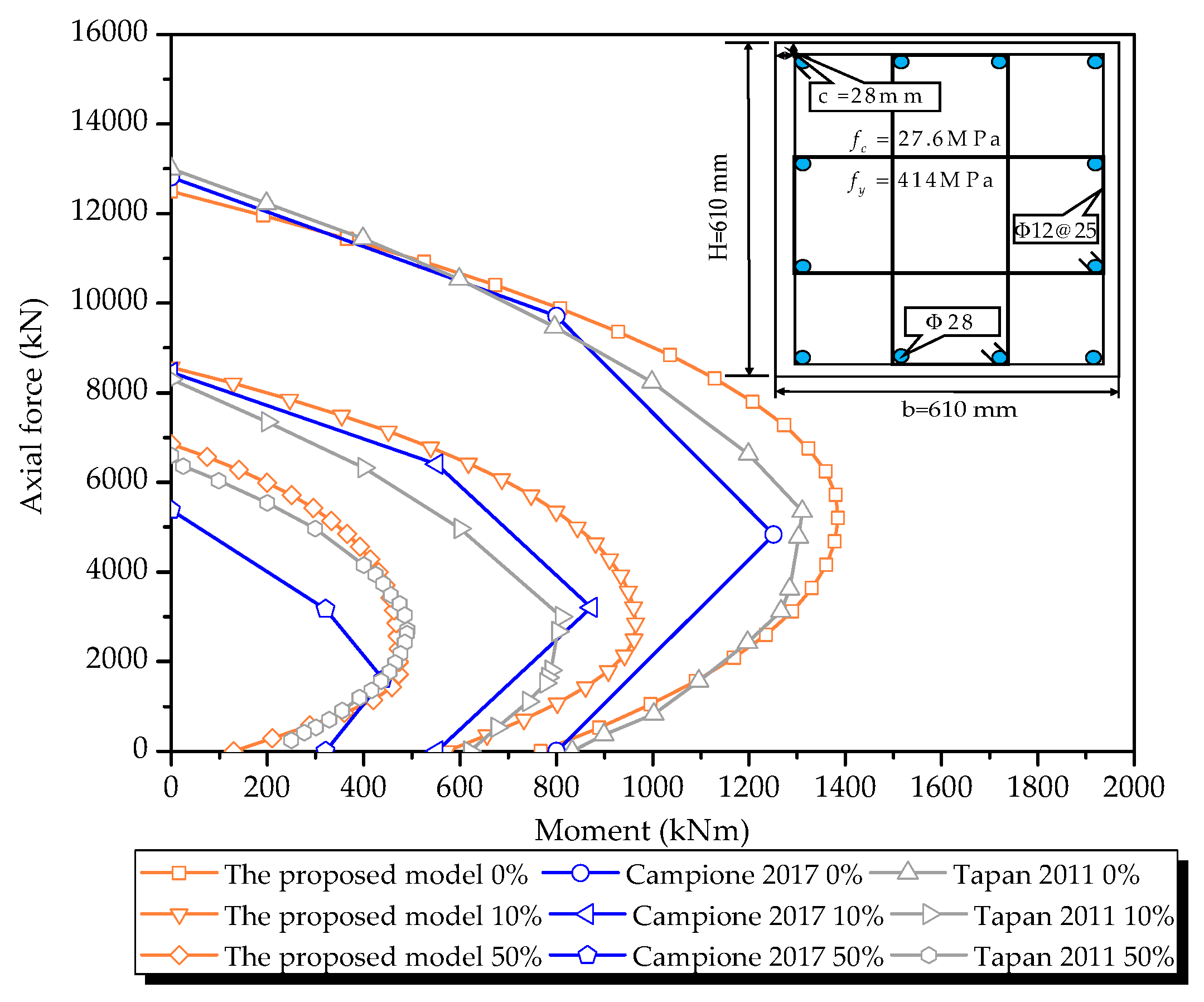

3.2. Validation by Existing Models

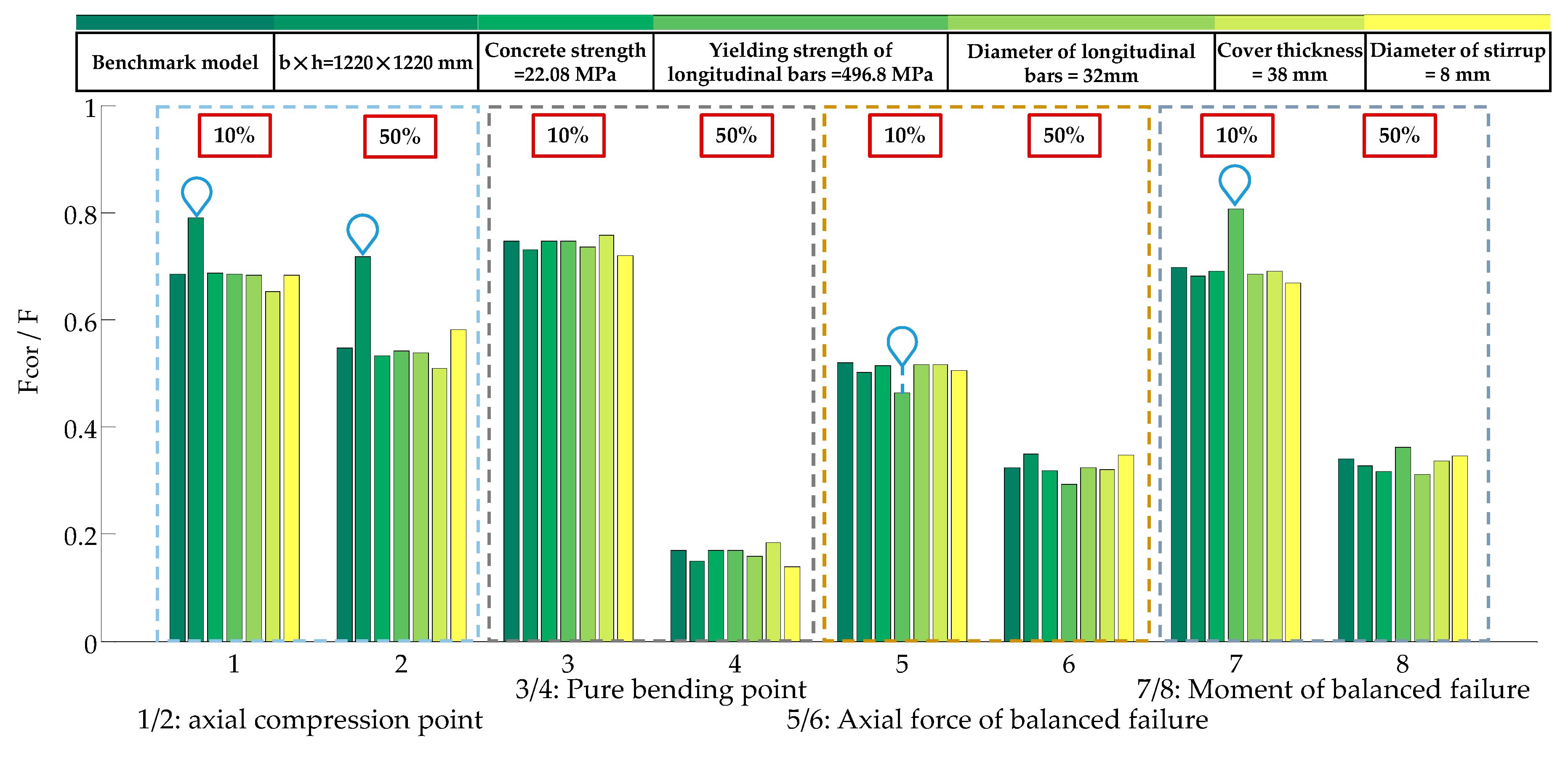

4. Structural Parameters Sensitivity Analysis of Influence on Corrosion Damage

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

Appendix A. AASHTO 2011 (American Code)

Appendix B. JTG/T J21-2011 (Chinese Code)

Appendix C. Sample Data Details

| No. | Data Sources | Column Designation | b × h (mm) | Eccentricity (mm) | Diameter of Longitudinal Reinforcement (mm) | Corrosion Rate of Longitudinal Reinforcement (%) | Diameter of Stirrup (mm) | Corrosion rate of Stirrups (%) | Concrete Strength (MPa) | Yield Strength of Steel bar (MPa) | Cover Thickness (mm) | Stirrup Spacing (mm) | Experimentatal Value (kN) | Predicted Value (kN) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | [19] | Z0 | 100 × 100 | 0 | 9.2 | 0 | 6 | 0 | 57.8 | 354.44 | 15 | 60 | 710 | 748 |

| 2 | Z5 | 0.5 | 4.85 | 665 | 672 | |||||||||

| 3 | Z10 | 0.8 | 9.6 | 632 | 633 | |||||||||

| 4 | Z20 | 1.2 | 13.0 | 545 | 588 | |||||||||

| 5 | [41] | Z1 | 250 × 350 | 40 | 18 | 0 | 8 | 0 | 47.5 | 432 | 25 | 200 | 3530 | 3950 |

| 6 | Z2 | 70 | 0 | 0 | 46.8 | 432 | 2850 | 3150 | ||||||

| 7 | Z3 | 150 | 0 | 0 | 43.3 | 432 | 1420 | 1670 | ||||||

| 8 | Z4 | 40 | 0.98 | 0.98 | 47.8 | 424 | 3020 | 3500 | ||||||

| 9 | Z5 | 70 | 1.56 | 1.56 | 49.0 | 420 | 2620 | 2850 | ||||||

| 10 | Z6 | 150 | 1.34 | 1.34 | 53.7 | 428 | 1310 | 1610 | ||||||

| 11 | Z7 | 40 | 3.51 | 3.51 | 42.5 | 416 | 2940 | 2710 | ||||||

| 12 | [42] | Z0 | 100 × 200 | 130 | 10 | 0 | 6 | 0 | 45.8 | 360 | 25 | 100 | 260 | 210 |

| 13 | Z1 | 1.8 | / | 34.2 | 248 | 200 | ||||||||

| 14 | Z2 | 2.3 | / | 245 | 199 | |||||||||

| 15 | Z3 | 2.5 | / | 230 | 198 | |||||||||

| 16 | Z4 | 4.3 | / | 30.7 | 221 | 190 | ||||||||

| 17 | Z5 | 8.7 | / | 207 | 170 | |||||||||

| 18 | Z6 | 12.2 | / | 190 | 150 | |||||||||

| 19 | [43] | NUW-e1 | 125 × 125 | 47 | 10 | 0 | 6 | 0 | 28.5 | 550 | 15 | 125 | 215 | 270 |

| 20 | NUW-e2 | 64.63 | 165 | 202 | ||||||||||

| 21 | NUW-e3 | 81.25 | 145 | 158 | ||||||||||

| 22 | NUW-e4 | 116.88 | 92 | 101 | ||||||||||

| 23 | CUW-e1 | 37.5 | 4.25 | 4.25 | − | − | ||||||||

| 24 | CUW-e2 | 62.93 | 167 | 176 | ||||||||||

| 25 | CUW-e3 | 80.14 | 145 | 139 | ||||||||||

| 26 | CUW-e4 | 115.82 | 91 | 91 | ||||||||||

| 27 | [18] | AS-0 | 200 × 240 | 50 | 20 | 0 | 6 | / | 25.93 | 380.05 | 30 | 200 | 805 | 1100 |

| 28 | AS-1 | 1.73 | / | 795 | 900 | |||||||||

| 29 | AS-2 | 2.66 | / | 740 | 825 | |||||||||

| 30 | AS-3 | 4.61 | / | 628 | 750 | |||||||||

| 31 | AS-4 | 6.13 | / | 739 | 700 | |||||||||

| 32 | AS-5 | 8.82 | / | 728 | 640 | |||||||||

| 33 | AL-0 | 90 | 0 | / | 802 | 800 | ||||||||

| 34 | AL-1 | 1.63 | / | 651 | 690 | |||||||||

| 35 | AL-2 | 3.90 | / | 526 | 610 | |||||||||

| 36 | AL-3 | 4.97 | / | 372 | 570 | |||||||||

| 37 | AL-4 | 6.11 | / | 434 | 540 | |||||||||

| 38 | AL-5 | 8.31 | / | 411 | 510 | |||||||||

| 39 | BS-0 | 50 | 0 | / | 100 | 970 | 1180 | |||||||

| 40 | BS-1 | 1.61 | / | 884 | 960 | |||||||||

| 41 | BS-2 | 2.45 | / | 837 | 915 | |||||||||

| 42 | BS-3 | 4.06 | / | 763 | 827 | |||||||||

| 43 | BS-4 | 5.66 | / | 690 | 770 | |||||||||

| 44 | BS-5 | 7.27 | / | 649 | 705 | |||||||||

| 45 | BL-0 | 90 | 0 | / | 848 | 830 | ||||||||

| 46 | BL-1 | 1.16 | / | 570 | 720 | |||||||||

| 47 | BL-2 | 2.92 | / | 509 | 670 | |||||||||

| 48 | BL-3 | 3.90 | / | 513 | 615 | |||||||||

| 49 | BL-4 | 5.81 | / | 430 | 570 | |||||||||

| 50 | BL-5 | 7.10 | / | 447 | 540 |

References

- Xin, J.Z.; Zhou, J.T.; Yang, S.X.; Li, X.Q.; Wang, Y. Bridge structure deformation prediction based on GNSS data using Kalman-ARIMA-GARCH model. Sensors 2018, 18, 298. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Xie, H.; Yan, M.; Gou, H.; Zhao, G.; Bao, Y. Eccentric compressive behavior of reinforced concrete columns strengthened using steel mesh reinforced resin concrete. Appl. Sci. 2018, 8, 1827. [Google Scholar] [CrossRef]

- Nabizadeh, A.; Tabatabai, H.; Tabatabai, M.A. Survival analysis of bridge superstructures in wisconsin. Appl. Sci. 2018, 8, 2079. [Google Scholar] [CrossRef]

- Moreno-Gomez, A.; Amezquita-Sanchez, J.P.; Valtierra-Rodriguez, M.; Perez-Ramirez, C.A.; Dominguez-Gonzalez, A.; Chavez-Alegria, O. EMD-Shannon entropy-based methodology to detect incipient damages in a truss structure. Appl. Sci. 2018, 8, 2068. [Google Scholar] [CrossRef]

- Federal Highway Administration (FHWA). Deficient Bridges by Highway System 2017. Available online: https://www.fhwa.dot.gov/bridge/nbi/no10/defbr17.cfm (accessed on 28 February 2018).

- Editorial Department of China Journal of Highway and Transport. Review on China’s bridge engineering research: 2014. China J. Highw. Transp. 2014, 27, 1–96. [Google Scholar] [CrossRef]

- Zhou, J.; Qiu, J.; Zhou, Y.; Zhou, Y.; Xia, R. Experimental Study on Residual Bending Strength of Corroded Reinforced Concrete Beam Based on Micromagnetic Sensor. Sensors 2018, 18, 2635. [Google Scholar] [CrossRef]

- Bossio, A.; Monetta, T.; Bellucci, F.; Lignola, G.P.; Prota, A. Modeling of concrete cracking due to corrosion process of reinforcement bars. Cem. Concr. Res. 2015, 71, 78–92. [Google Scholar] [CrossRef]

- Desnerck, P.; Lees, J.M.; Morley, C.T. Bond behaviour of reinforcing bars in cracked concrete. Constr. Build. Mater. 2015, 94, 126–136. [Google Scholar] [CrossRef]

- Mak, M.W.T.; Desnerck, P.; Lees, J.M. Correlation between surface crack width and steel corrosion in reinforced concrete. In Proceedings of the International Conference on Concrete Repair, Rehabilitation and Retrofitting (ICCRRR 2018), Cape Town, South Africa, 19–21 November 2018; Volume 199, p. 04009. [Google Scholar] [CrossRef]

- Bossio, A.; Lignola, G.P.; Fabbrocino, F.; Monetta, T.; Prota, A.; Bellucci, F.; Manfredi, G. Nondestructive assessment of corrosion of reinforcing bars through surface concrete cracks. Struct. Concr. 2017, 18, 104–117. [Google Scholar] [CrossRef]

- Bossio, A.; Fabbrocino, F.; Monetta, T.; Lignola, G.P.; Prota, A.; Manfredi, G.; Bellucci, F. Corrosion effects on seismic capacity of reinforced concrete structures. Corros. Rev. 2018. [Google Scholar] [CrossRef]

- AASHTO. The Manual for Bridge Evaluation, 2nd ed.; American Association of State Highway and Transportation Officials: Washington, DC, USA, 2011. [Google Scholar]

- Research Institute of Highway Ministry of Transport. Specification for Testing and Evaluating the Bearing Capacity of Highway Bridges; China Communications Press: Beijing, China, 2011.

- Wang, X.H.; Liang, F. Performance of RC columns with partial length corrosion. Nucl. Eng. Des. 2008, 238, 3194–3202. [Google Scholar] [CrossRef]

- Yang, S.Y.; Song, X.B.; Jia, H.X.; Chen, X.; Liu, X.L. Experimental research on hysteretic behaviors of corroded reinforced concrete columns with different maximum amounts of corrosion of rebar. Constr. Build. Mater. 2016, 121, 319–327. [Google Scholar] [CrossRef]

- Meda, A.; Mostosi, S.; Rinaldi, Z.; Riva, P. Experimental evaluation of the corrosion influence on the cyclic behaviour of RC columns. Eng. Struct. 2014, 76, 112–123. [Google Scholar] [CrossRef]

- Xia, J.; Jin, W.L.; Li, L.Y. Performance of corroded reinforced concrete columns under the action of eccentric loads. J. Mater. Civ. Eng. 2016, 28, 04015087. [Google Scholar] [CrossRef]

- Li, Q.; Jin, X.Y. Effect of stirrup corrosion on bearing capacity of uniaxial compression short column. J. Zhejiang Univ. (Eng. Sci.) 2015, 49, 1929–1938. [Google Scholar] [CrossRef]

- Zhang, K.; Wei, J.; Xu, G. Assessment of bearing capacity of corroded reinforced concrete little eccentric compressive members. J. Huazhong Univ. Sci. Technol. (Nat. Sci. Ed.) 2008, 36, 107–109. [Google Scholar] [CrossRef]

- Huang, L.; Lu, Y.; Xu, Z. Correctional recommendation of bearing capacity formula of RC eccentric compression members. Eng. Mech. 2012, 29, 169–175. [Google Scholar] [CrossRef]

- Tapan, M.; Aboutaha, R.S. Effect of steel corrosion and loss of concrete cover on strength of deteriorated RC columns. Constr. Build. Mater. 2011, 25, 2596–2603. [Google Scholar] [CrossRef]

- Tapan, M.; Aboutaha, R.S. Strength evaluation of deteriorated RC bridge columns. J. Bridge Eng. 2008, 13, 226–236. [Google Scholar] [CrossRef]

- Guo, A.; Yuan, W.; Li, H.; Li, H. Structural strength deterioration of coastal bridge piers considering non-uniform corrosion in marine environments. Earthq. Eng. Eng. Vib. 2018, 17, 429–444. [Google Scholar] [CrossRef]

- Akiyama, M.; Frangopol, D.M.; Mizuno, K. Performance Analysis of Tohoku-Shinkansen Viaducts Affected by the 2011 Great East Japan Earthquake. Struct. Infrastruct. E 2014, 10, 1228–1247. [Google Scholar] [CrossRef]

- Campione, G.; Cannella, F.; Cavaleri, L.; Ferrotto, M.F. Moment-axial force domain of corroded R.C. columns. Mater. Struct. 2017, 50, 1–14. [Google Scholar] [CrossRef]

- Naser, M.Z. Deriving temperature-dependent material models for structural steel through artificial intelligence. Constr. Build. Mater. 2018, 191, 56–68. [Google Scholar] [CrossRef]

- Vanneschi, L.; Castelli, M.; Scott, K.; Popovič, A. Accurate High performance concrete prediction with an alignment-based genetic programming system. Int. J. Concr. Struct. M. 2018, 12, 72. [Google Scholar] [CrossRef]

- Campione, G.; Cannella, F.; Minafò, G. A simple model for the calculation of the axial load-carrying capacity of corroded RC columns. Mater. Struct. 2016, 49, 1935–1945. [Google Scholar] [CrossRef]

- Coronelli, D.; Gambarova, P. Structural assessment of corroded reinforced concrete beams: Modeling guidelines. J. Struct. Eng. 2004, 130, 1214–1224. [Google Scholar] [CrossRef]

- Val, D.V. Deterioration of strength of RC beams due to corrosion and its influence on beam reliability. J. Struct. Eng-ASCE 2007, 133, 1297–1306. [Google Scholar] [CrossRef]

- Qian, J.; Cheng, L.; Zhou, D. Behavior of axially loaded concrete columns confined with ordinary hoops. J. Tsinghua. Univ. (Sci. Technol.) 2002, 42, 1369–1373. [Google Scholar] [CrossRef]

- Xia, J.; Jin, W.L.; Zhao, Y.X.; Li, L.Y. Mechanical performance of corroded steel bars in concrete. Proc. Inst. Civ. Eng.-Struct. Build. 2013, 166, 235–246. [Google Scholar] [CrossRef]

- Giamundo, V.; Lignola, G.P.; Prota, A.; Manfredi, G. Analytical evaluation of FRP wrapping effectiveness in restraining reinforcement bar buckling. J. Struct. Eng. 2014, 140, 04014043. [Google Scholar] [CrossRef]

- Lin, H.; Zhao, Y. Effects of confinements on the bond strength between concrete and corroded steel bars. Constr. Build. Mater. 2016, 118, 127–138. [Google Scholar] [CrossRef]

- Zhang, K.B.; Hu, J.; Zhang, J.R.; Peng, H. On the experiment and bearing capacity calculation of eccentrically compressed component made of corroded reinforced concrete. J. Exp. Mech. 2010, 25, 625–632. [Google Scholar]

- Tao, T.Y.; Wang, H.; Kareem, A. Reduced-Hermite bifold-interpolation assisted schemes for the simulation of random wind field. Probab. Eng. Mech. 2018, 53, 126–142. [Google Scholar] [CrossRef]

- Allen, R.C.; Rutan, S.C. Investigation of interpolation techniques for the reconstruction of the first dimension of comprehensive two-dimensional liquid chromatography–diode array detector data. Anal. Chim. Acta 2011, 705, 253–260. [Google Scholar] [CrossRef] [Green Version]

- Gao, Y.; Chen, T.; Wu, Y.; Ling, C.Y.; Han, M. Temperature modeling and simulation of a proton exchange membrane fuel cell based on Fourier fitting. Acta Energiae Sol. Sin. 2018, 39, 679–685. [Google Scholar]

- Xin, J.Z.; Zhou, J.T.; Xiao, Y.J.; Li, X.Q.; Su, X. Research on parameters identification algorithm for concrete nonlinearity constitutive model. Mater. Rev. 2018, 32, 2743–2749. [Google Scholar] [CrossRef]

- Yi, W.J.; Lei, G.Q. Experimental research on the bearing capacity of corroded reinforced concrete columns. J. Hunan Univ. (Nat. Sci.) 2008, 35, 6–10. [Google Scholar] [CrossRef]

- Diao, Y.; Sun, Y. Experiments of reinforced concrete columns with eccentric compressive persistent loading under alternative actions of a mixed aggressive solution and freeze-thaw cycles. J. Build. Struct. 2009, S2, 292–297. [Google Scholar] [CrossRef]

- Maaddawy, T.E. Behavior of corrosion-damaged RC columns wrapped with FRP under combined flexural and axial loading. Cem. Concr. Compos. 2008, 30, 524–534. [Google Scholar] [CrossRef]

| The Proposed Method | General Model Fourier3: | Goodness of Fit by | |||||||

|---|---|---|---|---|---|---|---|---|---|

| 0% | −407.2 | 986.9 | 1833 | 225.9 | −246.7 | −39.12 | −37.11 | 0.0002071 | 1 |

| 10% | 6.43 × 1013 | −9.64 × 1013 | −1.92 × 1012 | 3.86 × 1013 | 1.54 × 1012 | −6.42 × 1012 | −3.84 × 1011 | 4.48 × 10-6 | 0.9999 |

| 50% | 300 | −146 | 168.6 | −23.34 | 67.82 | −3.868 | 15.87 | 0.0007697 | 0.9995 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xin, J.; Zhou, J.; Zhou, F.; Yang, S.X.; Zhou, Y. Bearing Capacity Model of Corroded RC Eccentric Compression Columns Based on Hermite Interpolation and Fourier Fitting. Appl. Sci. 2019, 9, 24. https://doi.org/10.3390/app9010024

Xin J, Zhou J, Zhou F, Yang SX, Zhou Y. Bearing Capacity Model of Corroded RC Eccentric Compression Columns Based on Hermite Interpolation and Fourier Fitting. Applied Sciences. 2019; 9(1):24. https://doi.org/10.3390/app9010024

Chicago/Turabian StyleXin, Jingzhou, Jianting Zhou, Fengbin Zhou, Simon X. Yang, and Yi Zhou. 2019. "Bearing Capacity Model of Corroded RC Eccentric Compression Columns Based on Hermite Interpolation and Fourier Fitting" Applied Sciences 9, no. 1: 24. https://doi.org/10.3390/app9010024