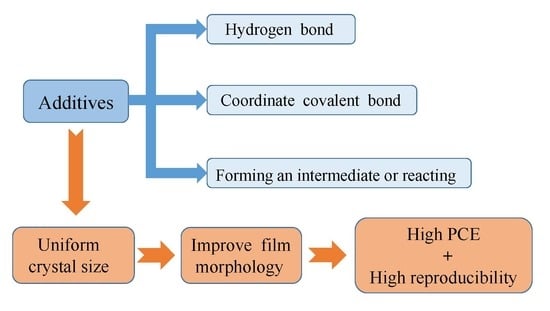

2.1. Hydrogen Bonds

A hydrogen bond is a relatively weak bond that hydrogen atoms interaction with the electronegative atoms nitrogen, oxygen or fluorine. Hydrogen bond is usually weaker than ionic, covalent and metallic bonds, but plays an important role in formation of perovskite film. In a typical perovskite precursor solution, hydrogen bond formed between the hydrogen atom and the other atoms (e.g., N, O atoms), which will affect the growth of perovskite crystals and the quality of the films in finally.

Chang et al. [

23] first discovered that the addition of 1 wt.% poly (ethylene glycol) (PEG) to a CH

3NH

3PbI

3−xCl

x perovskite precursor solution can solve the problem of poor coverage of the perovskite film on TiO

2 as shown in

Figure 1. The higher coverage of the perovskite layer reduces the possibility of direct contact between the TiO

2 and the 2,2′,7,7′-Tetrakis[

N,N-di(4-methoxyphenyl)amino]-9,9′-spirobifluorene(spiro-OMeTAD) layer, which leads to a higher open-circuit voltage (

Voc) in a device. However, when the PEG content exceeds 1 wt.%, the performance of a device would decrease in all aspects. This is because once the amount of PEG additive is overloaded, the charge cannot efficiently be transferred to the TiO

2 nanoparticles or spiro-OMeTAD layer and will accumulate or recombine in the perovskite layer. Zhao et al. [

24] reported a PEG polymer scaffold PSCs, and subsequently, the PCE exceeded 16%. The long-chain insulating polymer dissolved in the precursor solution will be assembled into a three-dimensional (3D) scaffold when the precursor solution is spin-coated on the substrate. The formed scaffold can guarantee a uniform thickness and homogeneous morphology of the perovskite films. Therefore, the performance of the solar cell is greatly improved.

As we known, PEG is a hygroscopic polymer containing O atoms. There is a strong interaction with perovskite by hydrogen bonds with H atoms in CH

3NH

3+.

Figure 2a–d show the Scanning electron microscopy (SEM) images of perovskite films without polymer scaffolds and with polymer scaffolds. This is consistent with the report from Chang. They speculated that PEG molecules are anchored on the surface of the perovskite crystallites by a hydrogen bond, as shown in

Figure 2e. Another interesting finding is that PEG has a strong hygroscopicity and a binding effect with methylammonium iodide (MAI), which can protect perovskite from being decomposed. The enhancement of device stability is mainly due to the forces of hydrogen bond between MAI and PEG. The MAI molecule is anchored by a nearby PEG molecule. After annealing, MAPbI

3 phase will be generated by the reacts of PbI

2 and MAI. The instantaneous decomposition regeneration mechanism in

Figure 2g explains the rapid self-healing process in perovskite films with PEG scaffolds. They further tried PEG and [6,6]-phenyl-C

61-methylbutyrate (PC

61BM) dual additives in the perovskite solution [

25]. Among them, PEG still plays a role in ameliorating the film morphology and device stability.

Similarly, polyvinylpyrrolidone (PVP) can also serve as an additive for enhancing the stability of the PSCs by forming hydrogen bonds. Nakamura et al. [

26] proposed that doping PVP in the perovskite precursor solution can produce a perovskite film with a smoother surface morphology and minimum crystallite size in ambient air. The production of translucent perovskite films also requires smaller grain sizes [

27]. Translucent perovskite film (50–100 nm) is a key device for window applications in zero-energy building technology [

28,

29]. The mechanism of PVP as an additive to control the crystal size and enhance device stability is shown in

Figure 3a–e. The hydrogen bonds formed between O atoms in PVP and H atoms of CH

3NH

3+ in the perovskite can protect the minimum perovskite crystals. As a result, the stability of the PVP-doped device further increases.

In addition, the polymer can be used as an additive to stabilize the perovskite crystals to prevent moisture degradation. Recently, Kim et al. [

30] selected non-electroactive polymer polyethylene oxide (PEO) as an additive to make flexible devices and optimized the concentration of PEO. PEO additive acts as a crystallization inhibitor by physically interfering with crystallization and improving processability, thereby producing a large-area defect-free perovskite film. The oxygen atom in the PEO molecule can form a hydrogen bond with the methylammonium cation (MA

+) in the perovskite component, hindering the formation of hydrate under hydration conditions. As shown in

Figure 4a, in a dry environment, equipment with PEO additives exhibited similar performance to equipment without the added polymer. However, it is apparent from

Figure 4b that the difference between the equipment with and without the PEO additive becomes superficial on wet days. To investigate the origin of these differences, we analyzed these films using SEM. As expected, there was no significant difference in the grain size of the film deposited at low humidity, and the difference in grain size of high humidity was more pronounced. This is because PEO is capable of forming stable coordination bonds with positive ions and generating a stable five-membered ring structure. The hydrophobic ethylene group on the surface of the film also prevents the penetration of water molecules, again reducing the negative effects of humidity.

It is interesting that bifunctional molecules have also been used as templates to direct nucleation or crystal growth. Mei et al. [

31] reported that (5-AVA)

x(MA)

1−xPbI

3 perovskite can be obtained by using 5-ammoniumvaleric acid (5-AVA) additive. The doped perovskite film has a better morphology on the TiO

2 surface and a lower defect concentration, resulting in improved conversion efficiency. Before that, Mercier et al. reported the effect of 4-ammonium-butyric acid (4-ABA) additive on the crystal structure of perovskite; that is, the ABA molecules form linear hydrogen bond chains [

32]. 5-AVA affects the crystal growth of (5-AVA)

x(MA)

1−xPbI

3 by the hydrogen bond between COOH groups and NH

3+ groups. The COOH groups of 5-AVA anchors monolayers of amino acids to the surface of mesoporous TiO

2 and ZrO

2 films by cooperative binding with exposed Ti or Zr ions. In this state, the terminal -NH

3+ group of 5-AVA faces the perovskite and thus serves as a nucleation site. The optimized device showed the PCE of 11.6% with short-circuit current density (

Jsc),

Voc and fill factor (

FF)of 21.1 mA cm

−2, 843 mV and 0.65, respectively (

Figure 5b). For 5-AVA-doped PSCs, the slope of the

JV curve at the open circuit voltage is steeper than for MAPbI

3, indicating that the resistance of the doped device is reduced. In brief, the better surface contact had been ensured between perovskite and TiO

2 by the hydrogen bonds between the COOH groups and -NH

3+ groups (

Figure 5c,d). Recently, Lin et al. [

33] also explored the role of 5-AVA as a perovskite precursor solution additive. They found that unpackaged devices with AVA-MAPbI

3 showed a 40-fold longer life than devices with MAPbI

3 in ambient air. This is because AVA-MAPbI

3 also has the effect of inactivating surface defect sites.

One additive that has the effect of cross-linking adjacent perovskite crystals is PbAc

2. Tang et al. [

34] found that PbAc

2 can act as a cross-linking agent to stabilize the perovskite mesophase by forming strong hydrogen bonds. In addition, PbAc

2 can produce PbI

2 in the perovskite film, which will passivate defects at the grain boundaries. Although PbAc

2 has been used as a lead source for the manufacture of pinhole-free and ultra-smooth perovskite films, it has never previously been reported as an additive for enhancing the crystallization of perovskite films. The efficiency of adding only 3% of PbAc

2 is relatively improved by about 10%, and the device stability is also greatly improved. As shown in

Figure 6b, the stable output PCE of the two devices with and without PbAc

2 was 18.50% and 16.13%, respectively. This is because PbAc

2 is introduced into the precursor solution to form a strong hydrogen bond. As shown in

Figure 6f, hydrogen bonding can be formed by the interaction between MA

+ and O in PbAc

2. This hydrogen bonding causes PbAc

2 to act as a crosslinking agent in the mesophase to enhance its stability. As shown in

Figure 6g, the absorption peak having a wave number of 1580 cm

−1 belongs to the N-H bond of the MA

+ group. For perovskite films containing 3% PbAc

2, the N-H bond was red shifted to 1571 cm

−1, demonstrating that hydrogen bonding affects adjacent N-H bonds by reducing its vibration frequency.

Recently, Zhu et al. [

35] found that ethylamine alcohol chloride (EA·HCl) was introduced into the perovskite film to effectively passivate the defect state. As shown in

Figure 7a, EA·HCl has two groups: a hydroxyl group (-OH) and an ammonium group (-NH

3), which interact with the halogen in MAPbI

xCl

3-x to form a hydrogen bond that inhibits ion migration. Bifunctional groups can passivate defects by generating hydrogen bonding interactions or by coordinating with under-coordinated iodide ions to immobilize the halide anions of the perovskite. The perovskite grain size and film coverage were improved, and

Figure 7d,e shows a top-view SEM image of the perovskite film without and on the Poly (3,4-ethylenedioxythiophene)/poly (styrenesulfonate) (PEDOT:PSS) coated Indium Tin Oxide(ITO) glass substrate. The final device performance also demonstrates that the EA⋅HCl additive can be introduced into the perovskite film by a simple one-step solution process, which increases the open circuit voltage from 0.87 V to 0.92 V and increases the device efficiency from 14.52% to 16.97%. (

Figure 7c).

2.2. Coordinate Covalent Bond

The coordinate covalent bond, also known as a dative bond or coordinate bond, is pervasive. In all metal aquo-complexes, the bonding between water and the metal cation is described as a coordinate covalent bond. Metal-ligand interactions in most organometallic compounds and most coordination compounds are described similarly.

Tripathi et al. [

36] used amine-based polymer poly[9,9-bis (30-(

N,

N-dimethylaminol-propyl)-2,7-fluorene)-alt-2,7-(9,9-dioctylfluorene)] (PFN-P1) as a surfactant to product PSCs take excellent performance and stability. The authors used a cationic derivative (PFN-P2) on the cathode side, while the neutral form PFN-P1 served as an additive for the perovskite layer (

Figure 8b–d). The ability of cationic or halogenated PFN derivatives to improve the electron selectivity at the cathode interface has been demonstrated [

37,

38] The PFN-P1 is spin coated onto PEDOT:PSS firstly, and PbI

2 solution is spin-coated on top, subsequently. Since PFN-P1 is soluble in

N,N-Dimethylformamide(DMF), it can dissolve in the PbI

2 solution immediately. The coordinate covalent bond is formed between the nitrogen lone electron pair in PFN-P1 and Pb

2+, and makes PFN-P1 act as a surfactant. From

Figure 8e–h, it can be seen that the grain size of perovskite on PEDOT:PSS varies from 100 to 480 nm, while the PFN-P1-doped film has an almost uniform grain size over the entire surface. The PFN-P1 layer flattens the surface and suppresses irregular crystallization of the PbI

2 layer, thereby promoting more uniform crystallization.

Figure 8i depicts the J-V characteristics of both devices. The device without PFN-P1 had a PCE of 12.0%, while the device with PFN-P1 had a superior PCE of 13.2%. The efficiency improvement of PFN-P1 based devices is mainly due to the higher

Voc and shunt resistance (

Rsh), while

Jsc and the

FF of devices remained mostly unchanged. The increase in

Voc is attributable to the reduction of charge carrier recombination at the interface, and the high

Rsh means that charge recombination is suppressed effectively. Moreover, owing to the passivation effect of the separation and accumulation of PFN-P1 molecules at the grain boundary [

39], the stability of the device also greatly improved.

Methyl formate (MAF) had been employed to produce higher quality crystalline perovskite films, resulting from HCOO-interacts with Pb

2+ and then slows the crystal growth of perovskite. Seo et al. proposed an ionic liquid (IL)-driven crystallization mechanism as a new strategy for the preparation of high-efficiency perovskite solar cells. If a small amount of ionic liquid (IL) is added to the precursor solution, it remains in the perovskite structure after the annealing process [

40].

Figure 9a shows the chemical structure of MAF and MAI. They have the same cation (methylammonium) and a different counter anion formate (HCOO

−) or iodide (I

−). The mechanism is depicted in

Figure 9b: (1) HCOO

− and Pb

2+ are coordinate in solution and in the early stages of crystal growth; (2) when annealing to 100 °C, HCOO

− and Pb

2+ is replaced by Pb

2+ and I

− gradually; (3) the HCOO

− and Pb

2+ coordination is replaced by Pb

2+ and I- completely, and the MAF is located on the surface of the perovskite crystal. Therefore, crystal growth is slowed down with the presence of MAF, while slower crystal growth results in the larger grain size.

Figure 9b are SEM images of a perovskite structure with MAF and without MAF having average grain sizes of 325 and 170 nm, respectively. Large grains can pass through the entire thickness of the perovskite structure to form a local single crystal device. Charge transfer through a single crystal is much faster than that in polycrystalline semiconductor. [

41,

42]

Figure 9d shows a

J-V curve with and without MAF. MAF-doped PSCs demonstrated an excellent

Jsc = 23 mA/cm

2, which corresponds well with the above hypothesis.

Metal ions play important roles in improving the quality of perovskite films as precursor solution additives. Chu et al. incorporated a series of alkali metal halide (NaCl, KCl, LiCl) into the PbI

2 precursor solution to adjust the morphology of the PbI

2 film [

43]. These halogenated additives can chelate with Pb

2+ during film formation, facilitating the growth of the crystals. A significant improvement in perovskite film crystallinity has been obtained by adopting the two-step processing to adjust the morphology of PbI

2 film. The large crystal size be formed with the presence of the alkali metal halide additives results in greatly improved PCE and device stability of the planar heterojunction PSCs.

Figure 10a–d show the SEM images of spin-coated PbI

2 films with and without additives;

Figure 10e–h show the perovskite films with and without additives. In the two-step processing, the quality of the perovskite film depends on the quality of the precursor PbI

2 film greatly. The optimized film formation process can not only improve device efficiency, but also significantly reduce photocurrent hysteresis (

Figure 10j). As shown in

Figure 10i, the highest PCE (15.08%) was achieved with a device doped with 0.75% KCl,

Jsc = 19.42 mA/cm

2,

Voc = 1.04 V,

FF = 0.74. Devices fabricated using 1% NaCl as an additive also exhibited improved device performance: PCE = 12.77%. The additive of LiCl reduces the performance of the device at all concentrations. This is due to the high sensitivity for oxygen and moisture of Li

+. In summary, devices fabricated using KCl as an additive provide the best performance. These alkali metal halide additives act as electrically active impurities can passivate the grain boundary and interface states, thereby creating and disassociating the effective charge in the perovskite film [

44].

Potassium iodide (KI) and potassium triiodide complex (KI

3) are useful inorganic additives for the perovskite solution. Zhang et al. prepared a KI

3 additive solution by dissolving equimolar amounts of KI and I

2 in dimethyl sulfoxide (DMSO) [

45]. They fabricated the PSCs using the KI

3 additive with the method of gas-quenching. Due to the halide exchange and defect passivation caused by I

2 provided by the KI

3 complex, the surface morphology of the deposited perovskite film was changed significantly shown in the SEM of

Figure 11a–c. As shown in

Figure 11d, the (220) peak of the KI sample shifted towards lower angle compared to the control sample, indicating that iodine occupied the interstitial position resulting in lower angle shift. The KI

3 sample showed a larger shift than the KI sample, indicating an even larger lattice constant resultant in the film. Due to the reduced non-radiative recombination, samples with a mixture of KI

3 additives or KI and KI

3 additives exhibited slower decay and longer life than KI and control samples. (

Figure 11e) The study also found that KI and KI

3 additives can significantly enhance device stability. This is due to the hydrolysis of DMF that occurs during the aging process, which consumes MA

+ during the formation of dimethyl formate, so the amount of MA

+ used after aging is reduced. However, when the KI

3 complex is present in the precursor, MA

+ does not decrease due to I3-bonding with the MA

+ cation, and it is possible to form a MAI

3 complex that stabilizes the precursor solution. Finally, the best performing device with KI:KI

3 = 7:3 additive achieved 21.3% PCE in reverse scan, 21.0% in forward scan, showing negligible current density—voltage (

JV) The hysteresis of the characteristic is shown in

Figure 11f.

Recently, many studies have passed through additive engineering to passivate grain boundaries (GBs) to produce high quality perovskite film. Fu et al. [

46] prepared a high performance PSC incorporating a lead salt of pyridine-2-carboxylate (PbPyA

2). Pyridine and carboxyl groups on PbPyA

2 not only control crystallization, but also passivate GBs to form high quality perovskite film with larger grains and fewer defects. As shown in

Figure 12a, during the film formation process, the carboxyl group of PbPyA

2 has a strong interaction with Pb

2+ and MA

+ ions, thereby controlling the crystallization of the perovskite to suppress the formation of morphological defects. After crystallization, PbPyA

2 molecules are mainly distributed around GBs, not only by organic acid ions interacting with GBs, but also excess Pb

2+ ions near GBs can also cover volatile components, thereby reducing deep defects, inhibiting ion migration, and inhibiting the components to volatilize and inhibit external damage. In order to test the effect of PbPyA

2 on the crystal structure of perovskite film, the authors conducted X-ray diffraction(XRD) tests on films with different doping concentrations, and the results of those tests are shown in

Figure 12b. At different concentrations, the diffraction pattern of the tetragonal crystal showed the same, while the doped film showed a peak of PbPyA

2 at 9.18, indicating that PbPyA

2 was not embedded in the perovskite crystal lattice and was only distributed around GB. A device having the structure shown in

Figure 12c was then fabricated, and the J-V curve is indicated in

Figure 12d. Clearly, after the introduction of PbPyA

2, the device exhibited lower hysteresis and increased

Voc, indicating that the additive PbPyA

2 minimized trap density and inhibited ion migration. The result was a

Voc of 1.12 V, a

Jsc of 22.99 mA cm

−2, an

FF of 77.51% and a PCE of 19.96%.

Various additives engineering reports are based on Pb-based perovskites. However, in recent years, Sn-based perovskites, which are non-toxic and have a suitable band gap, have also become promising candidates for the preparation of perovskite solar cells. However, the preparation of highly stable and highly efficient tin-based PSCs is challenging, because Sn

2+ in perovskites is readily oxidized to Sn

4+ upon exposure to air. Tai et al. [

47] reported the production of air-stable FASnI

3 solar cells by adding hydroxy benzene sulfonic acid or a salt as an antioxidant to the perovskite precursor solution and excess SnCl

2.

Figure 13a shows the molecular structure of three representative additives used in their work, including phenomenally acid (PSA), 2-aminophenol-4-sulfonic acid (APSA) and hydroquinone sulfonate potassium salt (KHQSA). The interaction between the sulfonate group and the Sn

2+ ion causes the perovskite particles and the SnCl

2 additive composite layer to be encapsulated in situ, thereby greatly enhancing the oxidative stability of the perovskite film. Compared with the former two, KHQSA containing two hydroxyl (-OH) groups has higher antioxidant activity.

Figure 13b appears in a scanning transmission electron microscope (STEM) image showing the distribution of KHQSA on the surface of the perovskite particles.

Figure 13c shows a XRD pattern of a FASnI

3 film with different additives. The additive did not cause a significant change in the pattern, indicating that the additive molecules were not incorporated into the perovskite crystal lattice. As shown in

Figure 13d, PCE was observed to have a similar dose dependency for PSA, APSA and KHQSA, which can be attributed to a certain amount of additive to prevent phase separation of SnCl

2 and oxidation of perovskite. Excessive additives can significantly reduce photocurrent, because the conductivity of the complex located at the grain boundary and surface of the perovskite is poor. After optimization, the champion PCEs of PSA, APSA and KHQSA was 5.58%, 5.16% and 6.76%, respectively.

Figure 13e shows the J-V curves for the best performing raw and KHQSA modified PSCs. The hysteresis of KHQSA-PSC is negligible compared to the apparent JV hysteresis shown in the original PSC, which may be linked to the lower trap density of the perovskite film.

The synergy between different additives has also been explored. Kim et al. [

48] reported that the perovskite solar cell of (FA

0.65MA

0.2Cs

0.15)Pb(I

0.8Br

0.2)

3 was highly efficient by the two complementary additives Phenethylammonium Iodide(PEAI) and Pb (SCN)

2. The coupling of PEA

+ and Thiocyanate ion (SCN

−) provides a synergistic effect, reduces the formation of excess PbI

2, enhances crystallinity and enhances the quality of the perovskite film finally.

Figure 14a compares SEM images of perovskite films prepared without and with additives, with 2% Pb(SCN)

2 resulting in significant growth of apparent grains compared to the original film. However, use of 1% of PEAI reduces the apparent grain size due to the larger size of the PEA, which limits or alters the growth of the 3D perovskite.

Figure 14b compares the XRD patterns of the same sample as shown in

Figure 14a. Use of PEAI and Pb(SCN)

2 increased the main XRD perovskite peak by nearly 14 times compared to the original sample. One potential problem with the Pb(SCN)

2 additives is the formation of excess PbI

2. A slight excess of PbI

2 is generally advantageous over a short period of time. However, excessive PbI

2 is generally not conducive to PSC performance. It can also be observed from

Figure 14b that the formation of such PbI

2 is markedly suppressed when PEAI and Pb(SCN)

2 are simultaneously added. Strong molecular interaction between PEAI and PbX

2 (X = I or SCN) is a good explanation for this. At the same time, as shown in

Figure 14d, defects associated with insufficient lead coordination or halide vacancies may be passivized by SCN located at or near the GB.

Figure 14c shows the J-V curve for the various devices mentioned above. The synergistic effect of using both PEAI and Pb(SCN)

2 is evident in dramatically improved device characteristics, with PCE increasing from 16.3% to 18.7%, an increase of more than 2%.

2.3. Forming an Intermediate or Reacting

While the alkali halide salt additives offer monovalent cations and anions, bivalent or trivalent metal ions have not yet been widely explored as additives. Jahandar et al. [

49] used the CuBr

2 additive in the perovskite precursor solution to produce devices with a highly efficient. By replacing a part of PbI

2 to CuBr

2, they fabricated high-efficiency PSCs (ITO/PEDOT: PSS/CH

3NH

3I(PbI

2)

1-X(CuBr

2)X/PCBM/LiF/Al), and there is no significant

J-V hysteresis. The PbI

2-DMSO

2 intermediate cannot be flowed due to the melting and resolving process conduct at the same time during the heat treatment, while the CuBr

2-DMSO

2 intermediate is flowable [

50]. Thus, the CH

3NH

3I(PbI

2)

1−X(CuBr

2)

X perovskite can form larger grains more reproducibly than the MAPbI

3 film (

Figure 15a–j). Furthermore, the weak bond between DMSO and MAI∙PbI2 may accelerate the crystallization of MAPbI

3 [

51].

Figure 15k shows the JV curves of CH

3NH

3I(PbI

2)

1-X(CuBr

2)

X perovskite solar cells with various CuBr

2 concentration (x = 0, 0.025, 0.050, 0.075 and 0.100). The control device had a

Voc of 0.945 V,

Jsc of 17.96 mA/cm

2,

FF of 0.77, and PCE of 13.18%. For devices doped with CuBr

2, when x = 0.05,

Voc = 0.961 V,

Jsc = 21.51 mA/cm

2,

FF = 0.82, and PCE = 17.09%. Angelis et al. reported the same result, confirming again that Br plays the role as well as iodine in the organometallic halide perovskite [

52]. In addition, Mojtaba et al. [

53] introduced monovalent cations Na

+ and Ag

+ with similar radii of Pb

2+ Studies have shown that those additives can minimize the boundaries between the adjacent crystallites and increase charge transport properties and optimize the device performance.

Xiao et al. [

54] reported on the important role of H

3PO

2 in controlling the morphology of perovskite films, which has been largely ignored. H

3PO

2 has been used as a stabilizer in HI, and therefore, introduces MAH

2PO

2 impurities into the synthesized MAI (unpurified MAI). Pb(H

2PO

2)

2 mesophase is formed and slows the crystallization processing. Both the MAH

2PO

2 impurity and the Pb(H

2PO

2)

2 mesophase all impede the rapid reaction of PbI

2 and MAI, resulting in a highly uniform and smooth perovskite film with larger grain size. The authors used non-purified MAI and purified MAI precursor solutions to fabricate the perovskite film by a two-step processing. The perovskite film is formed on the ITO/PEDOT:PSS substrate, non-purified MAI with a mirror-like surface, as shown in

Figure 16a. The grain size of perovskite film made with purified MAI is not uniform and has many white spots, as shown in

Figure 16b. Therefore, MAH

2PO

2 will lead to differences morphology of the film. It is worth noting that the conversion from Pb(H

2PO

2)

2 to perovskite by thermal annealing is much slower than the direct reaction of PbI

2 and MAI. Therefore, the mesophases of Pb(H

2PO

2)

2 and MAH

2PO

2 would coexist. The similar phenomenon has also been explored in existence of HPbI

3 [

55]. As shown in

Figure 16, the performance of the device with 2 wt.% MAH

2PO

2 and the device performance of the non-purified MAI are better than those of the device after purification. In summary, the reaction of MAH

2PO

2 and PbI

2 is reversible; thus, Pb(H

2PO

2)

2 can be slowly converted to perovskite in the presence of excess MAI during thermal annealing. Based on this finding, the authors controlled the crystallization rate of perovskite by adjusting the proportion of MAH

2PO

2 in the MAI precursor to obtain the optimal film morphology.

Phosphorous acid (HPA) is also a stabilizer that has been used in PSCs to optimizing film morphology. Zhang et al. [

56] showed that the strong reducing agent HPA can act as an additive of a perovskite precursor solution, which is usually added to the HI solution as a stabilizer to prevent the oxidation [

57]. By reducing the non-radiative recombination center, the performance of the PSCs is greatly improved. It is well known that a semiconductor device with high performance usually requires high purity and low defect materials. However, due to the obvious non-uniformity of the polycrystalline material and little knowledge of the defect components [

58], there is still a good prospect for further improvement [

59]. MAI has strongly hygroscopicity and is not stable in air and light, especially after long-term storage. The SEM image of perovskite film is shown in

Figure 17a,b; both samples show complete coverage without pinholes on the substrate. The perovskite grain size is significantly increased by added HPA, increasing from an average of 168 to 769 nm. As shown in

Figure 17c, the photoluminescence (PL) spectra of the perovskite films was found that the HPA-modified perovskite films showed a PL quantum efficiency (PLQE) improvement of 11.6 ± 0.7%, compared with 0.84 ± 0.15% in the control group. It is worth noting that because the HPA additive can reduce the oxidized I

2 (

Figure 17d) and reduced the density of metal lead in the perovskite crystals result in a PCE improvement from 13.2% to 16.2%.

Recently, Bae et al. [

60] proposed a dual additive method in which the morphology of the perovskite film was improved by the simultaneous addition of dimethyl sulfoxide (DMSO) and methoxy ammonium salt (MeO) (

Figure 18a). They show that an appropriate amount of MeO additive can help the precursor form a stable intermediate PbI

2-DMSO adduct during film formation and expand the perovskite grains by preventing the kinetics of adduct conversion to perovskite. As shown in the film plane of SEM of

Figure 18b, when the amount of the MeO additive was increased from 0 to 5 and 10%, the grain size was observed to increase from approximately 150 nm to 380 nm and 120 nm, respectively. This may be due to the delayed conversion of the adduct of the perovskite caused by the lesser influence of the MeO additive, resulting in grain growth. However, higher amounts of MeO did not result in a further increase in grain size. The author attributes this phenomenon to the decomposition of MAI (

Figure 18c). Since non-stoichiometric conditions result in a decrease in MAI content, grain growth of perovskites is limited and access PbI

2 precipitates in the grain boundaries. As shown in the XRD pattern of

Figure 18d, all films exhibited similar diffraction patterns, which mean that MeO does not affect lattice parameters and crystal structure by substituting the position of the MA cation. The J-V curve of the PSC prepared by various doping amounts of MeO is illustrated in

Figure 18e. When a small amount of MeO (MeO5 and MeO10) was added, all equipment parameters were enhanced, especially for MeO10 devices with 16.86% PCE (

VOC = 1.10 V,

JSC = 21.59 mA cm

−2 and

FF = 0.71).

The method of reducing the crystallization rate by forming an intermediate phase continues being explored. Yang et al. [

61] found that ammonium besylate (ABS) can form a mesophase with the precursor material to reduce the crystallization rate. As shown in

Figure 19a, the steric hindrance of ABS and DMSO hindered the conversion of layered PbI

2 to tetragonal phase perovskites. Thereafter, the chlorobenzene accelerated the nucleation and crystallization of the perovskite by rapidly extracting the DMSO solvent, and then formed the MAI-PbI

2-ABS phase. During the annealing process, the mesophase MAI-PbI

2-ABS was gradually converted into crystalline MAPbI

3, and finally, large-grain and uniform film formed. The decrease in trap density was qualitatively demonstrated by PL (

Figure 19b) and time-resolved photoluminescence (TRPL) (

Figure 19c) maps, indicating that the surface defects of the film were small. As shown in

Figure 19d, the perovskite solar cell has the structure of FTO/compact titanium dioxide (cTiO

2)/meso-titanium dioxide (mTiO

2)/MAPbI

3 (with or without ABS)/spiral—OMeTAD/Au.

Figure 19e shows photovoltaic performance of various PSCs. In the ABS-based device, the crystallinity is good, the series resistance is small, and the FF is significantly increased from 75.68% to 78.62%. As a result, the overall PCE has increased dramatically from 17.29% to an impressive 19.64%.

The principle of chemical interaction between Lewis acid and Lewis base is also applied to the performance optimization of PSC. Kim et al. [

62] used the principle that melamine can interact with Lewis acids such as PbI

2, using melaminium dodide (M) as a solution for the perovskite precursor solution.

Figure 20a shows the chemical structure of melamine based on 1,3,5-triazine. Since the triamine contains three primary amines, it can interact with a Lewis acid such as PbI

2. The bifunctionality of Lewis bases and hydrogen bond acceptors is expected to interact with Lewis acids and organic cations in organic-inorganic halide perovskites to minimize unreacted PbI

2. In

Figure 20b, the steady state PL intensity increases after the addition of M, indicating that the additive M enhances the radiation recombination without changing the optical band gap. In

Figure 20c, the PL is exponentially attenuated by two processes of a fast decay component associated with non-radiative recombination and a slow decay component associated with radiation recombination. The carrier lifetime increased from 460.38 ns to 706.28 ns. The energy level diagram of the material is shown in

Figure 20d, with the valence band moving slightly upward by about 0.07 eV. In terms of hole injection, the valence band of spiro-MeOTAD is better matched than the control perovskite film. In addition, the upshifted conduction band also facilitates electron injection into the TiO

2. Steady-state photoluminescence (PL) and time-resolved photoluminescence (TRPL) were measured to investigate the effect of M additives on the reorganization and carrier lifetime of the perovskite film. Compared to the original perovskite, the optimized device improved V

OC and FF, with an average PCE approaching a maximum of 17.32%, an increase of about 9.2% compared to the PCE of 15.86% of the original perovskite without additive treatment.

Although many chemical additive projects produce high quality film, inherent insulating properties of chemical additives prevent the efficient transport and extraction of charge carriers. Thus, semiconductor additives have been noted. Urea and/or thiourea can be integrated as a core functional part into newly designed semiconductor chemical additives to increase the size and uniformity of the perovskite grains. However, the incorporation of urea or thiourea moieties into organic semiconductors requires a large amount of synthetic effort and often leads to a significant decrease in charge carrier mobility. Therefore, Yu et al. [

63] used Rhodamine as a core operative part of semiconductor chemical additives. Furthermore, the effect of the conjugated organic molecule (SA-1, SA-2), which has a rhodamine moiety, as shown in

Figure 21a, as a semiconductor chemical additive on the perovskite film formation was further explored.

Figure 21b shows a SEM image of the resulting perovskite film. It is noteworthy that a significant increase in the perovskite grain size based on MAPbI

3 and FA

0.8 MA

0.2Pb(I

0.8Br

0.2)

3 was observed in the film treated with SA-1.This may be due to the Lewis acid-base interaction between the rhodamine fraction of SA-1 and the perovskite precursor, which may increase the free energy of the critical Gibbs nucleation. Therefore, relatively few nuclei are formed, which leads to a considerable increase in the size of the perovskite grains. The SEM image of the perovskite with SA-2 also showed an increase in the size of the grains, indicating that the tertiary amine moiety did not significantly affect the Lewis acid-base interaction between the rhodamine moiety and the perovskite precursor.

Figure 21c shows the J–V curve for the best performance device using SA material. Among them, the PCE with SA-2 was the highest, at 20.3%.