Design and Research of a Color Discrimination Method for Polycrystalline Silicon Cells Based on Laser Detection System

Abstract

:Featured Application

Abstract

1. Introduction

1.1. Origin and Development of Color Discrimination

1.2. Current Color Discrimination System

1.3. Brief of the Existing Technology and This Work

2. Method for Color Analysis of Objects with Complex Surface Conditions

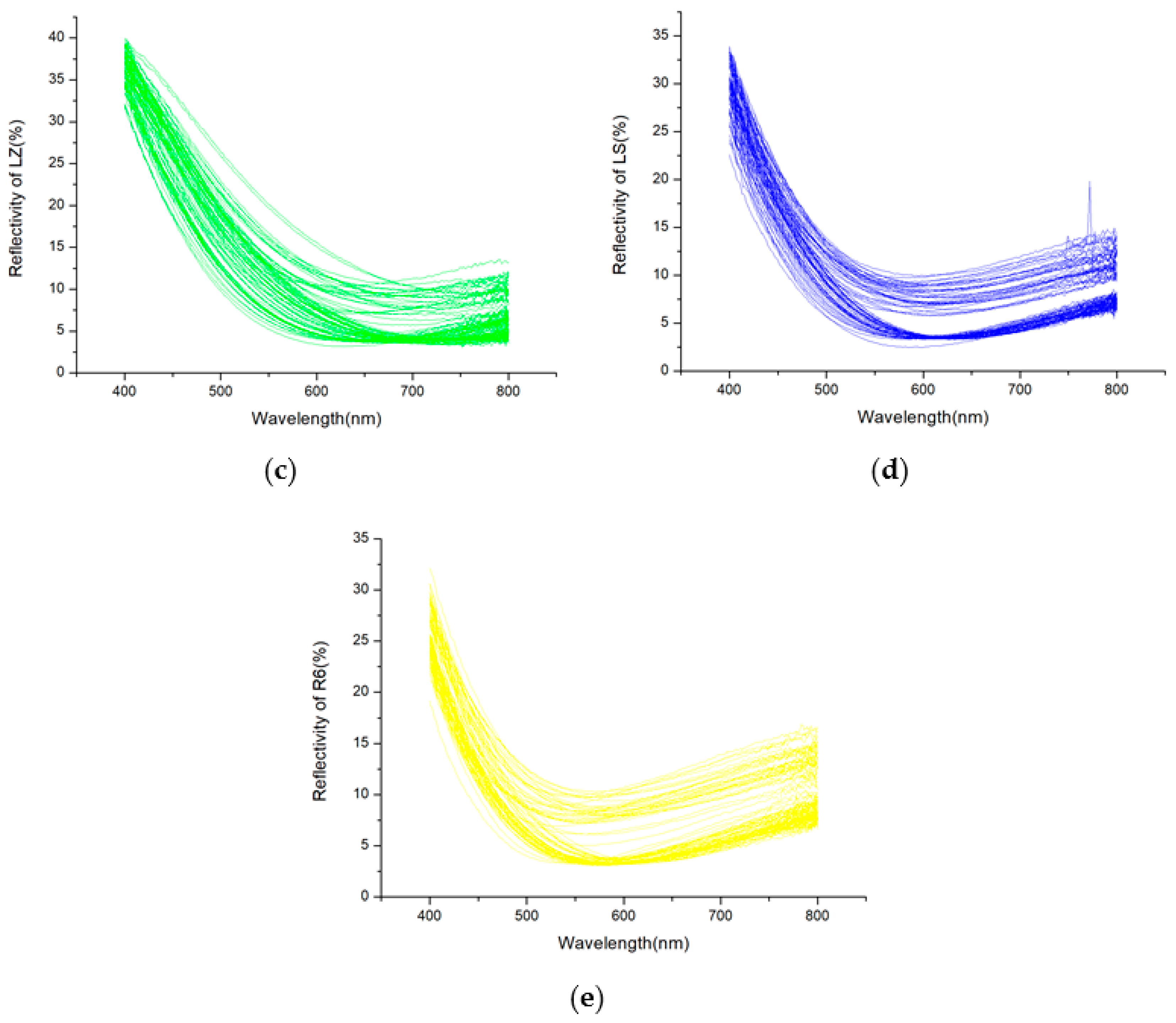

2.1. The Selection of Samples and Their Conditions

2.2. Method of Samples Color Discrimination

2.3. Concrete Analysis of the Polycrystalline Silicon Cells

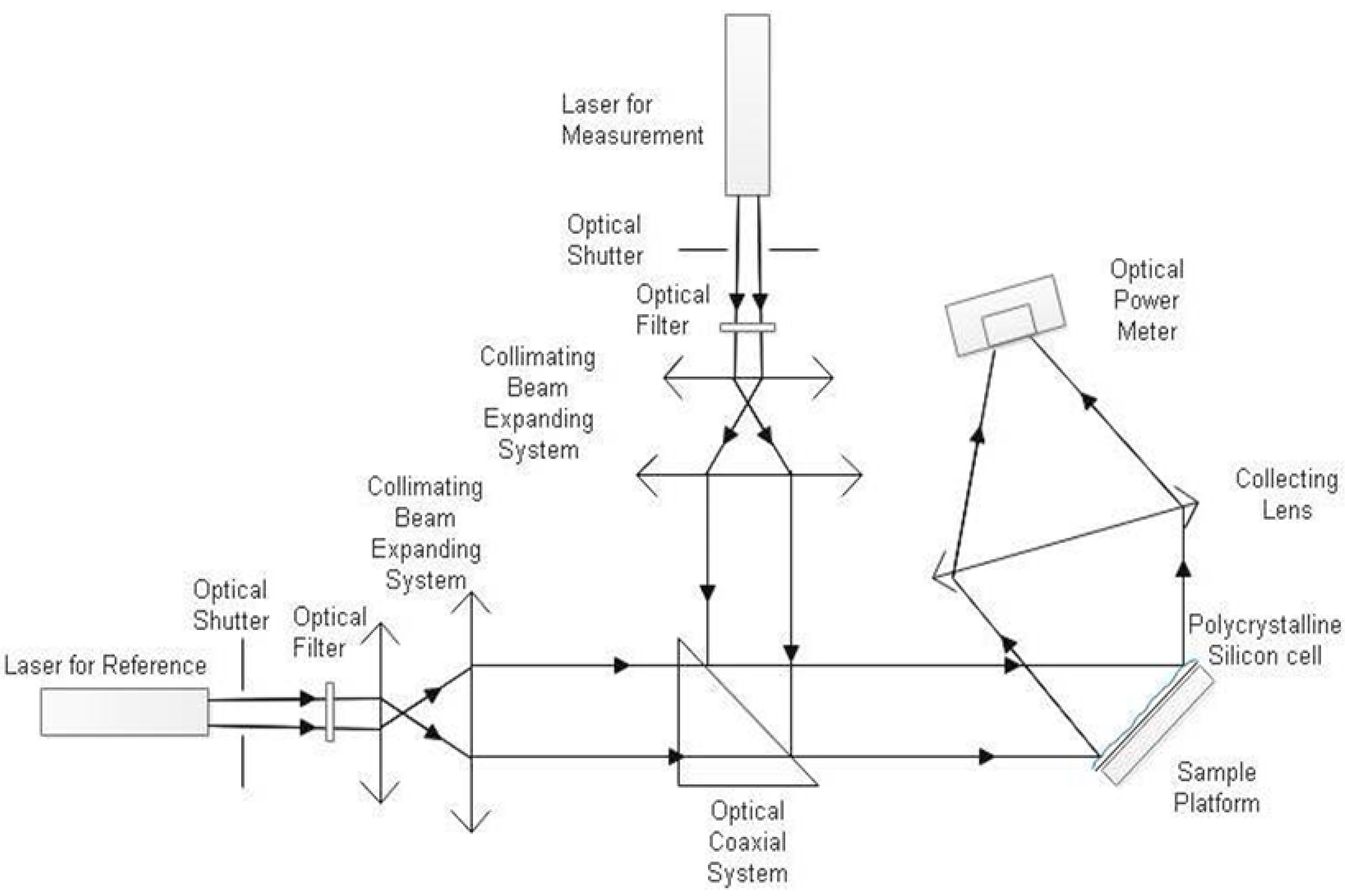

3. Design and Construction of Laser Detection System

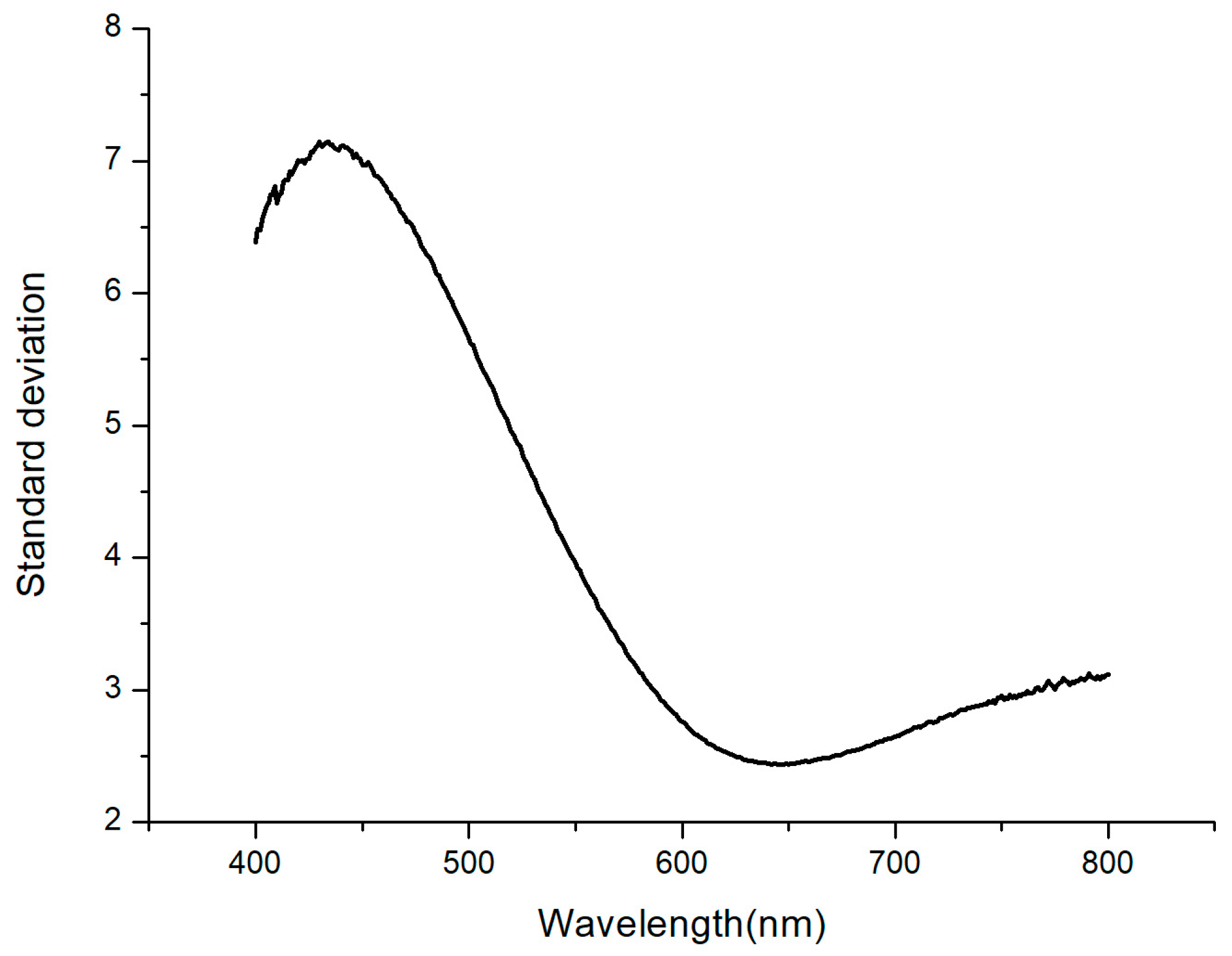

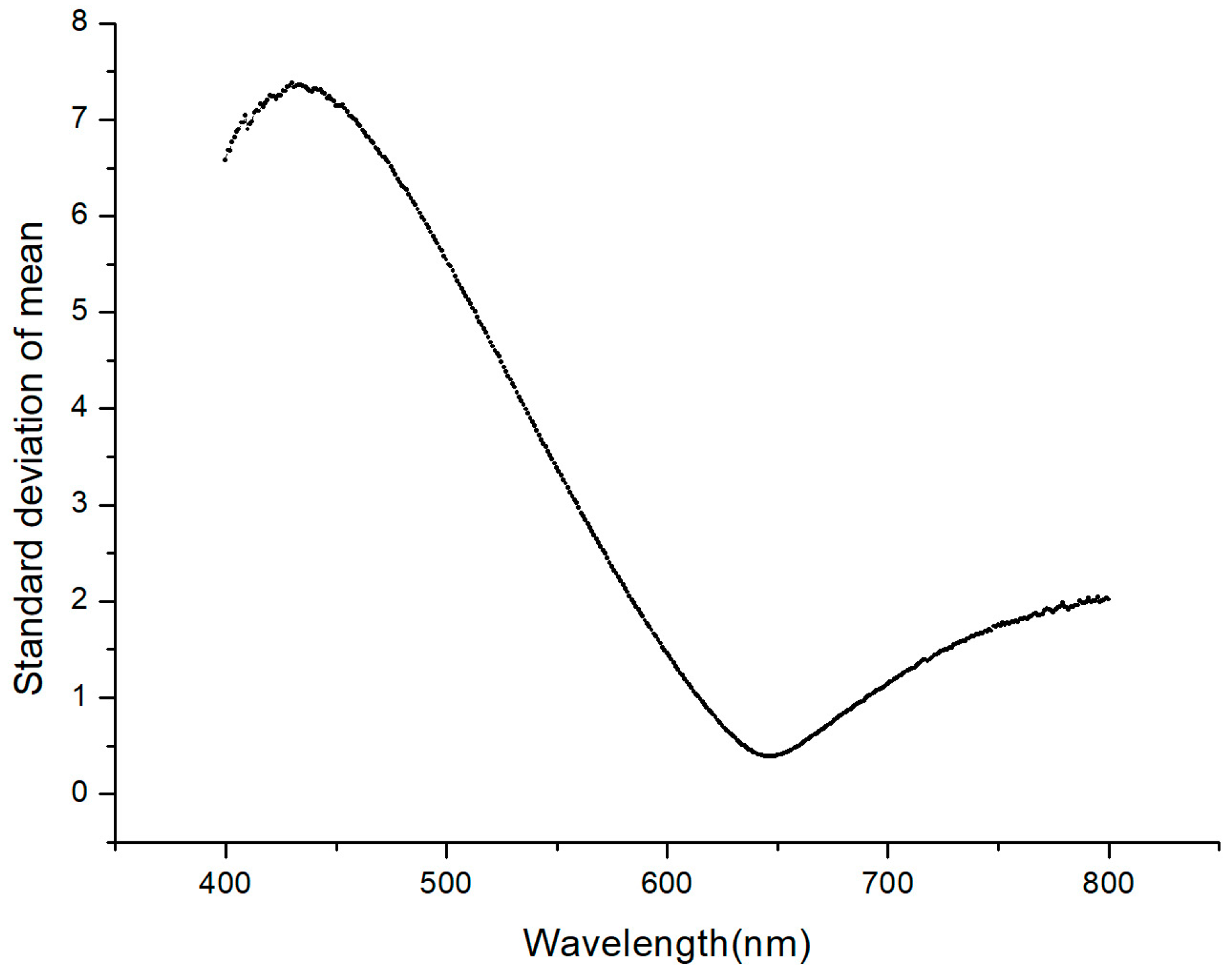

4. Results Prediction, Measurement, Analysis and Determination of Color Interval

4.1. Results Prediction

4.2. Results Measurement, Analysis and Determination of Color Interval

5. Discussion

6. Conclusions

7. Patents

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Newton, I. Opticks, 4th ed.; Royal Society: London, UK, 1704. [Google Scholar]

- Foss, C.E.; Nickerson, D.; Granville, W.C. Analysis of the Ostwald Color System. J. Opt. Soc. Am. 1944, 34, 361–381. [Google Scholar] [CrossRef]

- Fairman, H.S.; Brill, M.H.; Hemmendinger, H. How the CIE 1931 color-matching functions were derived from Wright-Guild data. Color Res. Appl. 1997, 22, 11–23. [Google Scholar] [CrossRef]

- Gray, C.G.; Pawley, J.S. Sorting Machine using Dual Frequency Optical Detectors. U.S. Patent 5,631,460, 20 May 1997. [Google Scholar]

- Saranathan, V.; Leggett, A. Structure, function, and self-assembly of single network gyroid (I4132) photonic crystals in butterfly wing scales. Proc. Natl. Acad. Sci. USA 2010, 107, 11676–11681. [Google Scholar] [CrossRef] [PubMed]

- Mirghasemi, S.; Yazdi, H.S.; Lotfizad, M.A. Target-based color space for sea target detection. Appl. Intell. 2012, 36, 960–978. [Google Scholar] [CrossRef]

- Tsai, S.H.; Tseng, Y.H. A novel color detection method based on HSL color space for robotic soccer competition. Comput. Math. Appl. 2012, 64, 1291–1300. [Google Scholar] [CrossRef] [Green Version]

- Perales, E.; Linhares, J.M.; Masuda, O.; Martínez-Verdú, F.M.; Nascimento, S.M. Effects of high-color-discrimination capability spectra on color-deficient vision. J. Opt. Soc. Am. A Opt. Image Sci. Vis. 2013, 30, 1780–1786. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Martínez-harms, J.; Márquez, N.; Menzel, R.; Vorobyev, M. Visual generalization in honeybees: Evidence of peak shift in color discrimination. J. Comp. Physiol. A 2014, 200, 317–325. [Google Scholar] [CrossRef] [PubMed]

- Souza, G.S.; Malone, F.L.; Crawford, T.L.; Miquilini, L.; Salomão, R.C.; Guimarães, D.L.; Ventura, D.F.; Fitzgerald, M.E.; Silveira, L.C. Low number of luminance levels in the luminance noise increases color discrimination thresholds estimated with pseudoisochromatic stimuli. Front. Psychol. 2014, 5, 1291. [Google Scholar] [CrossRef] [PubMed]

- Jurasevska, K.; Ozolinsh, M.; Fomins, S.; Gutmane, A.; Zutere, B.; Pausus, A.; Karitans, V. Color-discrimination threshold determination using pseudoisochromatic test plates. Front. Psychol. 2014, 5, 1376. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Madani, A.; Yusof, R. Traffic sign recognition based on color, shape, and pictogram classification using support vector machines. Neural Comput. Appl. 2018, 30, 2807–2817. [Google Scholar] [CrossRef]

- Jansen-Van Vuuren, R.D.; Armin, A.; Pandey, A.K.; Burn, P.L.; Meredith, P. Organic Photodiodes: The Future of Full Color Detection and Image Sensing. Adv. Mater. 2016, 28, 4766–4802. [Google Scholar] [CrossRef] [PubMed]

- Zhang, L.; Yang, L.; Luo, T. Unified Saliency Detection Model Using Color and Texture Features. PLoS ONE 2016, 11, e0149328. [Google Scholar] [CrossRef] [PubMed]

- Pujol, F.A.; Pujol, M.; Jimeno-Morenilla, A.; Pujol, M.J. Face Detection based on Skin Color Segmentation using Fuzzy Entropy. Entropy 2017, 19, 26. [Google Scholar] [CrossRef]

- Hoshino, E.; Hayashi, K.; Suzuki, M.; Obatake, M.; Urayama, K.Y.; Nakano, S.; Taura, Y.; Nio, M.; Takahashi, O. An iPhone application using a novel stool color detection algorithm for biliary atresia screening. Pediatr. Surg. Int. 2017, 33, 1115–1121. [Google Scholar] [CrossRef] [PubMed]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, Z.; Wang, S.; Zhang, L.; Ma, Z. Design and Research of a Color Discrimination Method for Polycrystalline Silicon Cells Based on Laser Detection System. Appl. Sci. 2019, 9, 4468. https://doi.org/10.3390/app9204468

Chen Z, Wang S, Zhang L, Ma Z. Design and Research of a Color Discrimination Method for Polycrystalline Silicon Cells Based on Laser Detection System. Applied Sciences. 2019; 9(20):4468. https://doi.org/10.3390/app9204468

Chicago/Turabian StyleChen, Zijian, Shiyu Wang, Lian Zhang, and Zenghong Ma. 2019. "Design and Research of a Color Discrimination Method for Polycrystalline Silicon Cells Based on Laser Detection System" Applied Sciences 9, no. 20: 4468. https://doi.org/10.3390/app9204468