Coupling and Trapping of Light in Thin-Film Solar Cells Using Modulated Interface Textures

Abstract

:Featured Application

Abstract

1. Introduction

2. Materials and Methods

2.1. ZnO:Al Front Contacts

2.2. Texture Etched ZnO:Al

2.3. Solar Cells

3. Results

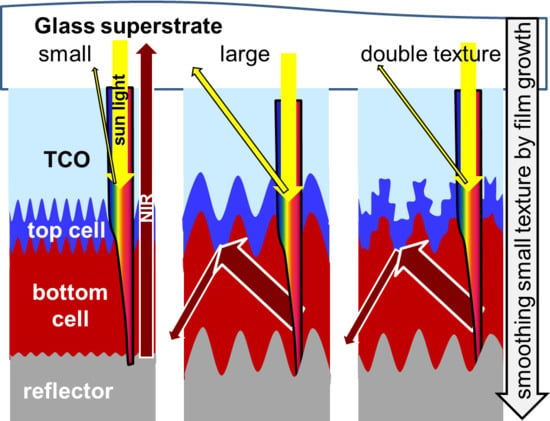

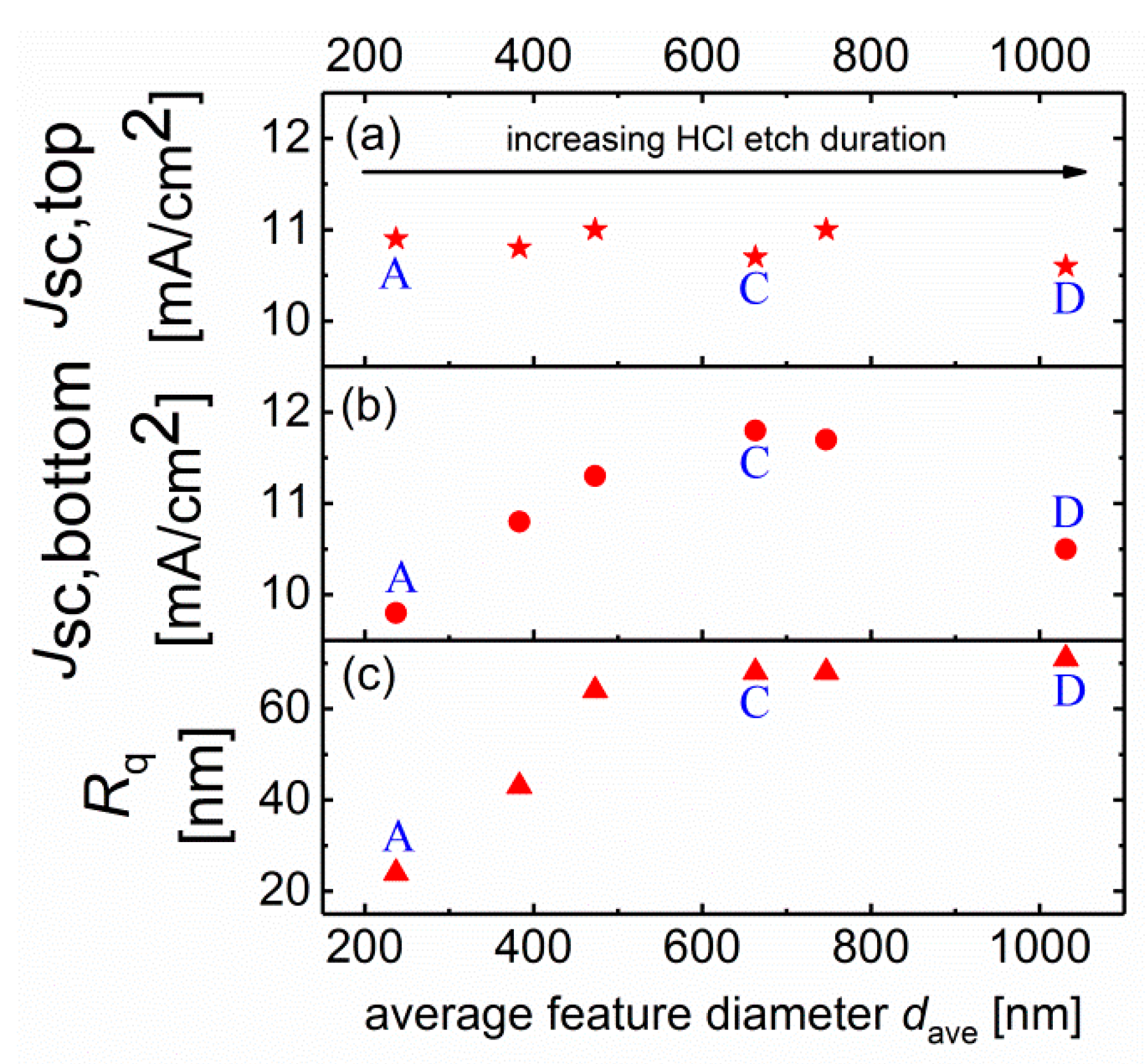

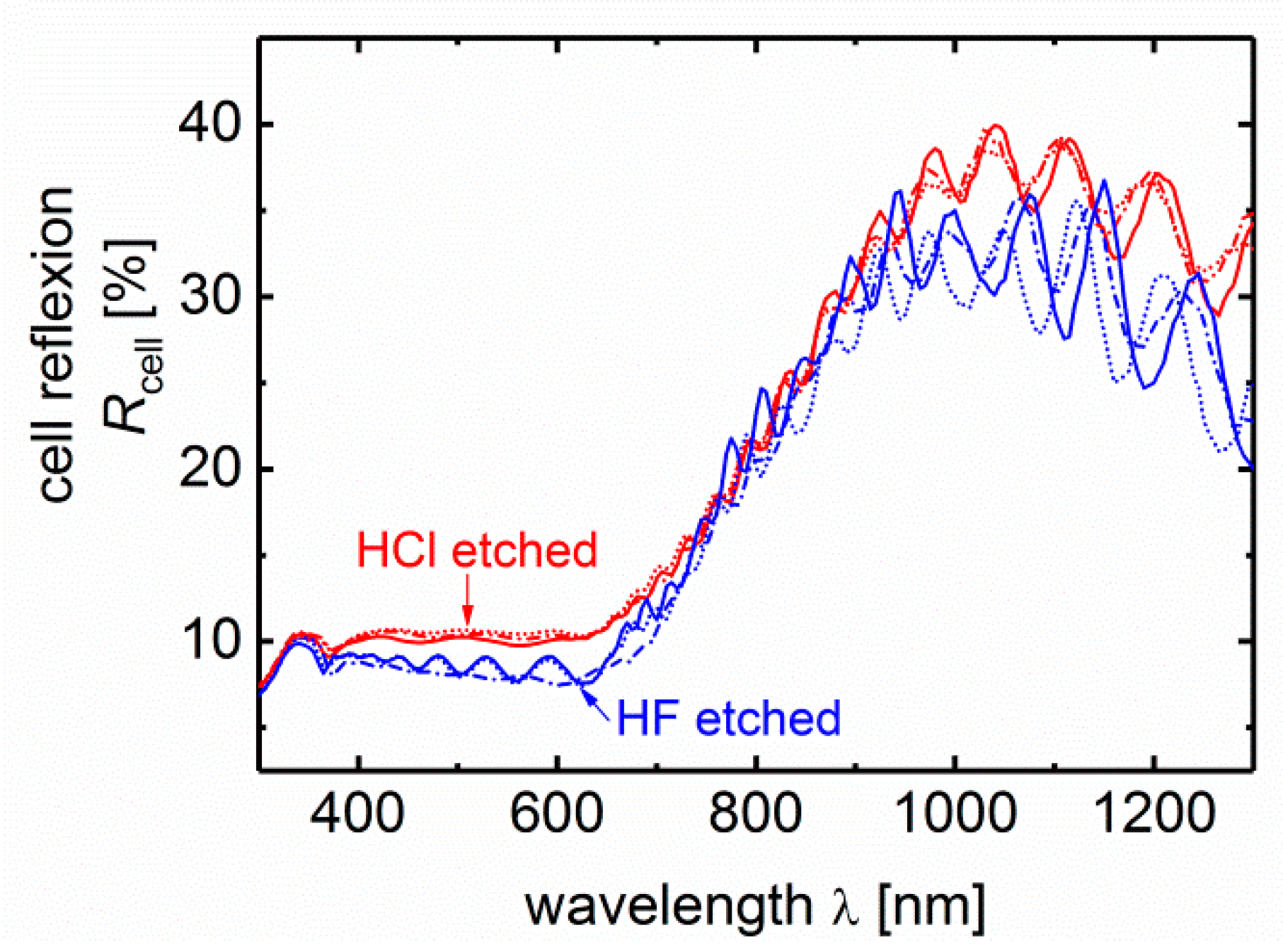

3.1. Solar Cells on Single Textured ZnO:Al with Different Feature Size

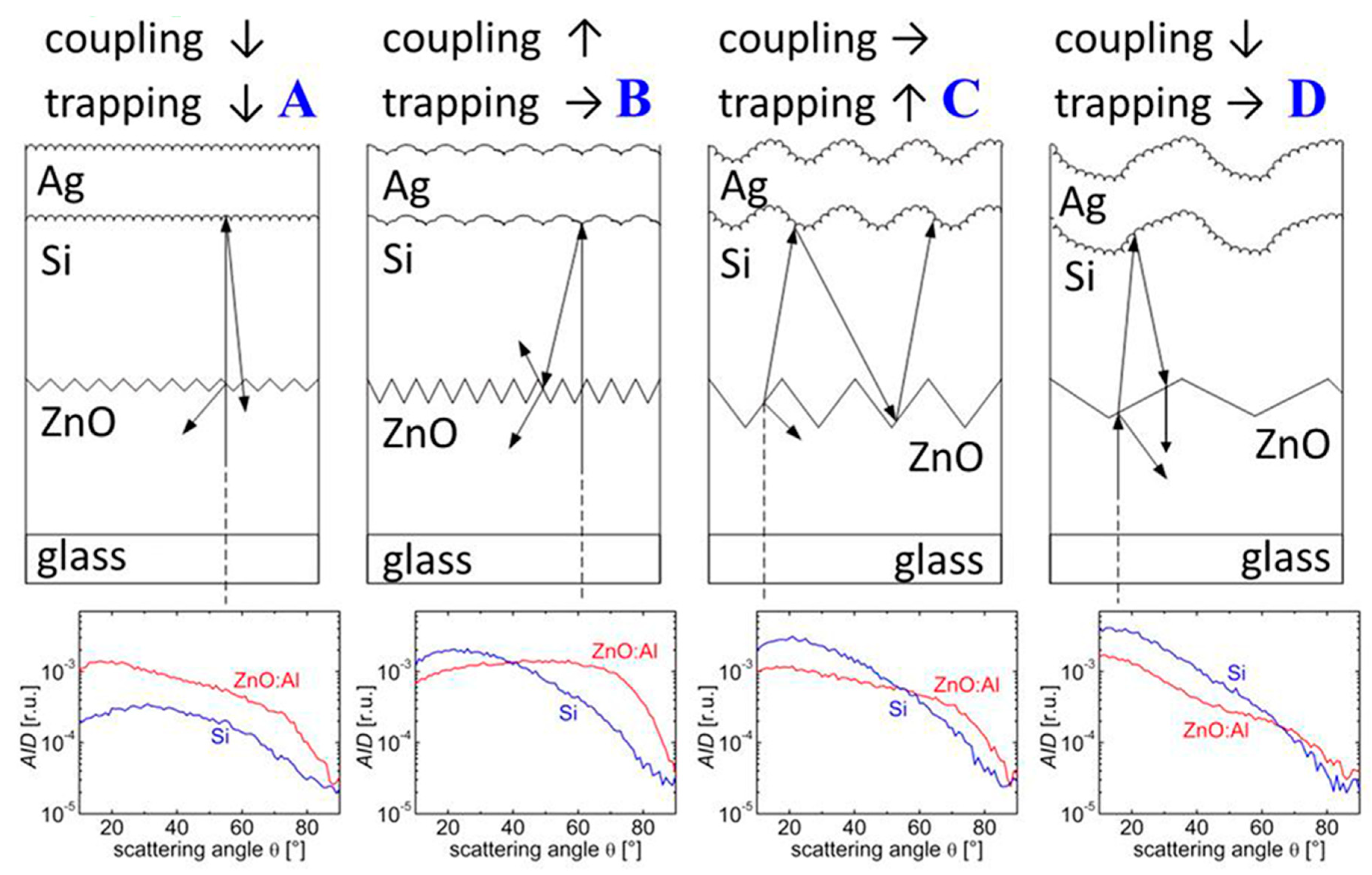

3.2. Light Trapping Model

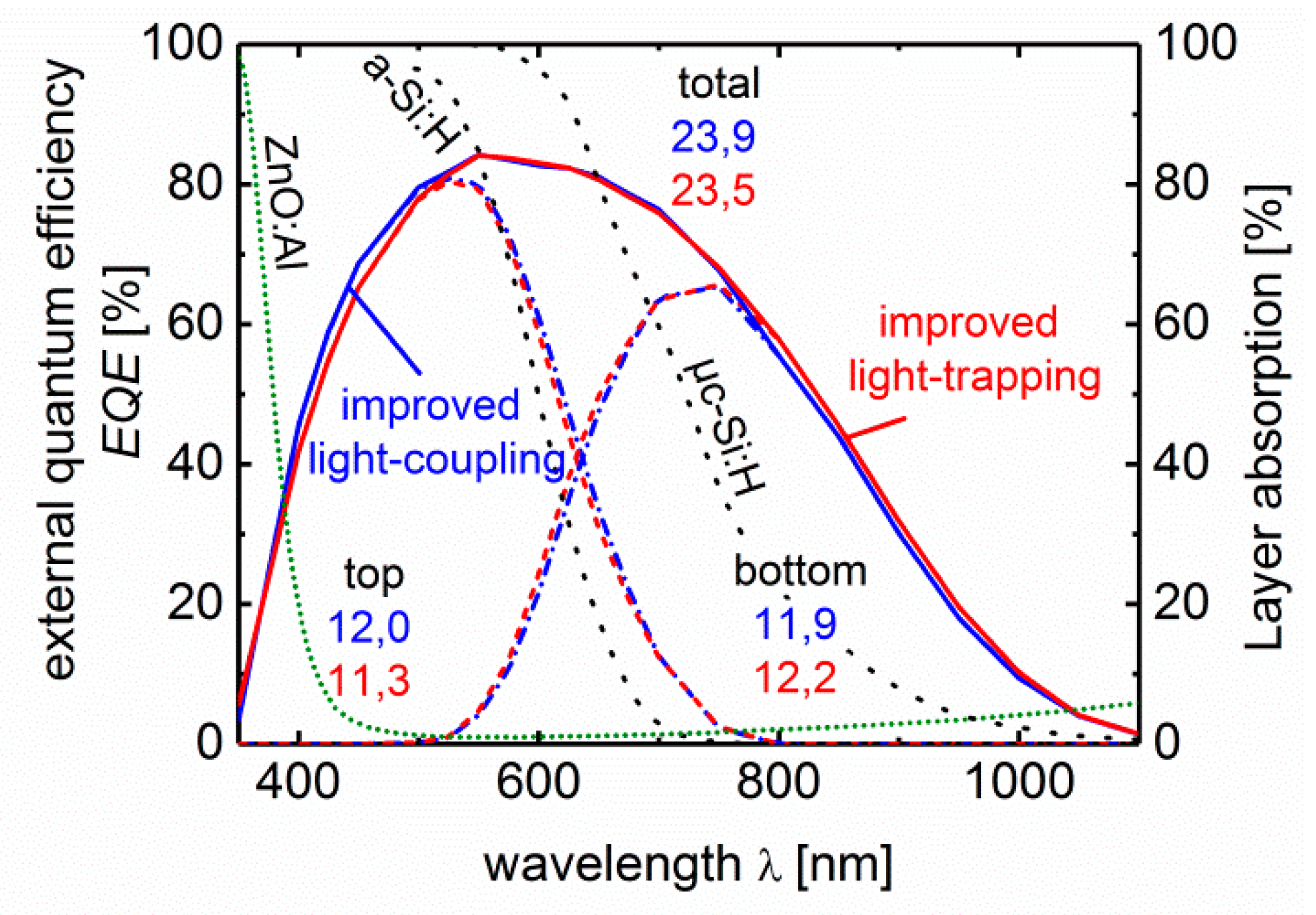

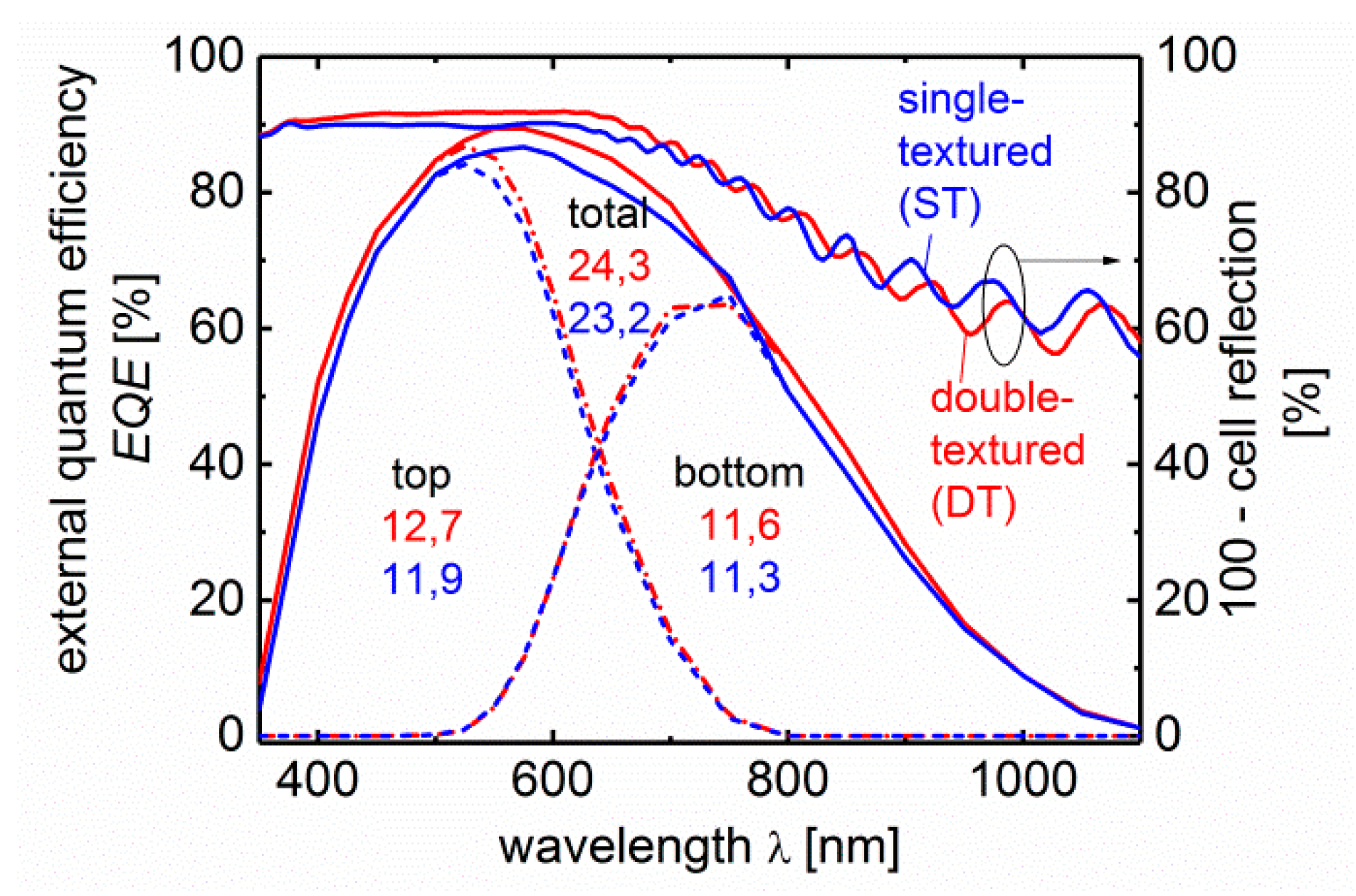

3.3. Good Coupling and Scattering Using Double Textured ZnO:Al

4. Conclusions and Outlook

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Goetzberger, A.; Hebling, C.; Schock, H.-W. Photovoltaic materials, history, status and outlook. Mater. Sci. Eng. R Rep. 2003, 40, 1–46. [Google Scholar] [CrossRef]

- Chopra, K.L.; Paulson, P.D.; Dutta, V. Thin-film solar cells: An overview. Prog. Photovolt. Res. Appl. 2004, 12, 69–92. [Google Scholar] [CrossRef]

- Springer, J.; Poruba, A.; Vanecek, M. Improved three-dimensional optical model for thin-film silicon solar cells. J. Appl. Phys. 2004, 96, 5329–5337. [Google Scholar] [CrossRef]

- Boccard, M.; Söderström, T.; Cuony, P.; Battaglia, C.; Hänni, S.; Nicolay, S.; Ding, L.; Benkhaira, M.; Bugnon, G.; Billet, A.; et al. Optimization of ZnO front electrodes for high-efficiency micromorph thin-film si solar cells. IEEE J. Photovolt. 2012, 2, 229–235. [Google Scholar] [CrossRef]

- Berginski, M.; Hüpkes, J.; Reetz, W.; Rech, B.; Wuttig, M. Recent development on surface-textured ZnO:Al films prepared by sputtering for thin-film solar cell application. Thin Solid Films 2008, 516, 5836–5841. [Google Scholar] [CrossRef]

- Quiroz, C.O.R.; Shen, Y.; Salvador, M.; Forberich, K.; Schrenker, N.; Spyropoulos, G.D.; Heumuller, T.; Wilkinson, B.; Kirchartz, T.; Spiecker, E.; et al. Balancing electrical and optical losses for efficient 4-terminal Si-perovskite solar cells with solution processed percolation electrodes. J. Mater. Chem. A 2018, 6, 3583–3592. [Google Scholar] [CrossRef]

- Sai, H.; Jia, H.; Kondo, M. Impact of front and rear texture of thin-film microcrystalline silicon solar cells on their light trapping properties. J. Appl. Phys. 2010, 108, 044505. [Google Scholar]

- Ferry, V.E.; Verschuuren, M.A.; Li, H.B.T.; Verhagen, E.; Walters, R.J.; Schropp, R.E.I.; Atwater, H.A.; Polman, A. Light trapping in ultrathin plasmonic solar cells. Opt. Express 2010, 18, A237–A245. [Google Scholar] [CrossRef] [Green Version]

- Zhu, H.; Hüpkes, J.; Bunte, E.; Huang, S.M. Study of ZnO:Al films for silicon thin film solar cells. Appl. Surf. Sci. 2012, 261, 268–275. [Google Scholar] [CrossRef]

- Faÿ, S.; Steinhauser, J.; Nicolay, S.; Ballif, C. Polycrystalline ZnO:B grown by lpcvd as tco for thin film silicon solar cells. Thin Solid Films 2010, 518, 2961–2966. [Google Scholar] [CrossRef]

- Moulin, E.; Bittkau, K.; Ghosh, M.; Bugnon, G.; Stuckelberger, M.; Meier, M.; Haug, F.J.; Hüpkes, J.; Ballif, C. Comparison of lpcvd and sputter-etched ZnO layers applied as front electrodes in tandem thin-film silicon solar cells. Sol. Energy Mater. Sol. Cells 2016, 145, 185–192. [Google Scholar] [CrossRef]

- Schade, H.; Lechner, P.; Geyer, R.; Stiebig, H.; Rech, B.; Kluth, O. Texture Properties of tco uniquely determining light trapping in thin-film silicon solar cells. In Proceedings of the Thirty-first IEEE Photovoltaic Specialists Conference, Lake Buena Vista, FL, USA, 3–7 January 2005; pp. 1436–1439. [Google Scholar]

- Schneider, B.W.; Lal, N.N.; Baker-Finch, S.; White, T.P. Pyramidal surface textures for light trapping and antireflection in perovskite-on-silicon tandem solar cells. Opt. Express 2014, 22, A1422–A1430. [Google Scholar] [CrossRef] [PubMed]

- Shi, D.; Zeng, Y.; Shen, W. Perovskite/c-Si tandem solar cell with inverted nanopyramids: Realizing high efficiency by controllable light trapping. Sci. Rep. 2015, 5, 16504. [Google Scholar] [CrossRef] [PubMed]

- Goffard, J.; Colin, C.; Mollica, F.; Cattoni, A.; Sauvan, C.; Lalanne, P.; Guillemoles, J.; Naghavi, N.; Collin, S. Light trapping in ultrathin CIGS solar cells with nanostructured back mirrors. IEEE J. Photovolt. 2017, 7, 1433–1441. [Google Scholar] [CrossRef]

- Li, J.F.; Hao, H.Y.; Hao, J.B.; Shi, L.; Dong, J.J.; Liu, H.; Xing, J. Light trapping effect of textured FTO in perovskite solar cells. IOP Conf. Ser. Mater. Sci. Eng. 2019, 479, 012046. [Google Scholar] [CrossRef]

- Bittkau, K.; Beckers, T. Near-field study of light scattering at rough interfaces of a-Si:H/µc-Si:H tandem solar cells. Phys. Status Solidi (a) 2010, 207, 661–666. [Google Scholar] [CrossRef]

- Deckman, H.W.; Wronski, C.R.; Witzke, H.; Yablonovitch, E. Optically enhanced amorphous silicon solar cells. Appl. Phys. Lett. 1983, 42, 968–970. [Google Scholar] [CrossRef]

- Schulte, M.; Bittkau, K.; Jäger, K.; Ermes, M.; Zeman, M.; Pieters, B.E. Angular resolved scattering by a nano-textured ZnO/silicon interface. Appl. Phys. Lett. 2011, 99, 111107. [Google Scholar] [CrossRef] [Green Version]

- Dominé, D.; Haug, F.-J.; Battaglia, C.; Ballif, C. Modeling of light scattering from micro- and nanotextured surfaces. J. Appl. Phys. 2010, 107, 044504. [Google Scholar] [CrossRef]

- Sever, M.; Lipovšek, B.; Krč, J.; Čampa, A.; Sánchez Plaza, G.; Haug, F.-J.; Duchamp, M.; Soppe, W.; Topič, M. Combined model of non-conformal layer growth for accurate optical simulation of thin-film silicon solar cells. Sol. Energy Mater. Sol. Cells 2013, 119, 59–66. [Google Scholar] [CrossRef] [Green Version]

- Wang, K.X.; Yu, Z.; Liu, V.; Cui, Y.; Fan, S. Absorption enhancement in ultrathin crystalline silicon solar cells with antireflection and light-trapping nanocone gratings. Nano Lett. 2012, 12, 1616–1619. [Google Scholar] [CrossRef] [PubMed]

- Haug, F.-J.; Naqavi, A.; Ballif, C. Diffraction and absorption enhancement from textured back reflectors of thin film solar cells. J. Appl. Phys. 2012, 112, 024516. [Google Scholar] [CrossRef] [Green Version]

- Bittkau, K.; Böttler, W.; Ermes, M.; Smirnov, V.; Finger, F. Light scattering at textured back contacts for n-i-p thin-film silicon solar cells. J. Appl. Phys. 2012, 111, 083101. [Google Scholar] [CrossRef] [Green Version]

- Moulin, E.; Paetzold, U.W.; Bittkau, K.; Owen, J.; Kirchhoff, J.; Bauer, A.; Carius, R. Investigation of the impact of the rear-dielectric/silver back reflector design on the optical performance of thin-film silicon solar cells by means of detached reflectors. Prog. Photovolt. Res. Appl. 2013, 21, 1236–1247. [Google Scholar] [CrossRef]

- Tamang, A.; Hongsingthong, A.; Jovanov, V.; Sichanugrist, P.; Khan, B.A.; Dewan, R.; Konagai, M.; Knipp, D. Enhanced photon management in silicon thin film solar cells with different front and back interface texture. Sci. Rep. 2016, 6, 29639. [Google Scholar] [CrossRef]

- Fujibayashi, T.; Matsui, T.; Kondo, M. Improvement in quantum efficiency of thin film si solar cells due to the suppression of optical reflectance at transparent conducting oxide/Si interface by TiO2/ZnO antireflection coating. Appl. Phys. Lett. 2006, 88, 183508. [Google Scholar] [CrossRef]

- Bruggeman, D.A.G. Berechnung verschiedener physikalischer Konstanten von heterogenen Substanzen (calculation of different physical constants of heterogen substances). Ann. Phys. 1935, 24, 636–664. [Google Scholar] [CrossRef]

- Boccard, M.; Cuony, P.; Battaglia, C.; Hänni, S.; Nicolay, S.; Ding, L.; Benkhaira, M.; Bugnon, G.; Billet, A.; Charrière, M.; et al. Nanometer- and micrometer-scale texturing for high-efficiency micromorph thin-film silicon solar cells. IEEE J. Photovolt. 2012, 2, 83–87. [Google Scholar] [CrossRef]

- Kambe, M.; Takahashi, A.; Taneda, N.; Masumo, K.; Oyama, T.; Sato, K. Fabrication of a-Si:H solar cells on high haze SnO2:F thin films. In Proceedings of the 33rd IEEE Photovoltaic Specialists Conference, San Diego, CA, USA, 11–16 May 2008; pp. 1–4. [Google Scholar]

- Jiang, Q.J.; Lu, J.G.; Yuan, Y.L.; Cai, H.; Zhang, J.; Deng, N.; Ye, Z.Z. Enhancement of the light trapping by double-layered surface texture of ito/azo and azo/azo transparent conductive films. Mater. Lett. 2014, 123, 14–18. [Google Scholar] [CrossRef]

- Owen, J.I.; Hüpkes, J.; Bunte, E.; Pust, S.E.; Gordijn, A. Etching modulated surface textures into sputtered ZnO:Al films. In Proceedings of the 25th European Photovoltaic Solar Energy Conference and Exhibition/5th World Conference on Photovoltaic Energy Conversion, Valencia, Spain, 6–10 September 2010; pp. 2951–2955. [Google Scholar]

- Meier, M.; Paetzold, U.W.; Ghosh, M.; Zhang, W.; Merdzhanova, T.; Jost, G.; Sommer, N.; Michard, S.; Gordijn, A. Fabrication of light-scattering multiscale textures by nanoimprinting for the application to thin-film silicon solar cells. IEEE J. Photovolt. 2014, 4, 772–777. [Google Scholar] [CrossRef]

- Wang, Y.; Hu, D.; Jia, H.; Wang, Q. Efficient enhancement of light trapping in the double-textured al doped ZnO films with nanorod and crater structures. Phys. B Condens. Matter 2019, 565, 9–13. [Google Scholar] [CrossRef]

- Bai, L.; Liu, B.; Chen, Z.; Huang, Q.; Li, B.; Zhang, D.; Sun, J.; Wei, C.; Zhao, Y.; Zhang, X. Theoretical insights into highly transparent multi-sized conducting films with high-haze and wide-angular scattering for thin film solar cells. J. Power Sour. 2015, 297, 68–74. [Google Scholar] [CrossRef]

- Boccard, M.; Battaglia, C.; Hänni, S.; Söderström, K.; Escarré, J.; Nicolay, S.; Meillaud, F.; Despeisse, M.; Ballif, C. Multiscale transparent electrode architecture for efficient light management and carrier collection in solar cells. Nano Lett. 2012, 12, 1344–1348. [Google Scholar] [CrossRef] [PubMed]

- Isabella, O.; Moll, F.; Krč, J.; Zeman, M. Modulated surface textures using zinc-oxide films for solar cells applications. Phys. Status Solidi (a) 2010, 207, 642–646. [Google Scholar] [CrossRef]

- Hussain, S.Q.; Le, A.H.T.; Mallem, K.; Park, H.; Ju, M.; Lee, S.; Cho, J.; Lee, Y.; Park, J.; Cho, E.-C.; et al. Efficient light trapping for maskless large area randomly textured glass structures with various haze ratios in silicon thin film solar cells. Sol. Energy 2018, 173, 1173–1180. [Google Scholar] [CrossRef]

- Venkataraj, S.; Wang, J.; Vayalakkara, P.; Aberle, A.G. Light scattering enhancement by double scattering technique for multijunction thin-film silicon solar cells. IEEE J. Photovolt. 2013, 3, 605–612. [Google Scholar] [CrossRef]

- Lee, Y.-C.; Huang, C.-F.; Chang, J.-Y.; Wu, M.-L. Enhanced light trapping based on guided mode resonance effect for thin-film silicon solar cells with two filling-factor gratings. Opt. Express 2008, 16, 7969–7975. [Google Scholar] [CrossRef]

- Kanata, T.; Takakura, H.; Hamakawa, Y. Preparation of composition-controlled silicon oxynitride films by sputtering; deposition mechanism, and optical and surface properties. Appl. Phys. A 1989, 49, 305–311. [Google Scholar] [CrossRef]

- Ruske, M.; Bräuer, G.; Pistner, J.; Szczyrbowski, J.; Weigert, M. Properties of SiO2 and Si3N4 layers deposited by mf twin magnetron sputtering using different target materials. Thin Solid Films 1999, 351, 158–163. [Google Scholar] [CrossRef]

- Rebib, F.; Tomasella, E.; Dubois, M.; Cellier, J.; Sauvage, T.; Jacquet, M. SiOxNy thin films deposited by reactive sputtering: Process study and structural characterisation. Thin Solid Films 2007, 515, 3480–3487. [Google Scholar] [CrossRef]

- Hüpkes, J.; Zhu, H.; Owen, J.I.; Jost, G.; Bunte, E. Instabilities in reactive sputtering of ZnO:Al and reliable texture-etching solution for light trapping in silicon thin film solar cells. Thin Solid Films 2012, 520, 1913–1917. [Google Scholar] [CrossRef]

- Owen, J.I.; Pust, S.E.; Bunte, E.; Hüpkes, J. ZnO etch-feature control via concentration and temperature of various acids. Ecs J. Solid State Sci. Technol. 2012, 1, 11–17. [Google Scholar] [CrossRef]

- Bunte, E.; Zhu, H.; Hüpkes, J.; Owen, J. Novel texturing method for sputtered zinc oxide films prepared at high deposition rate from ceramic tube targets. EPJ Photovolt. 2011, 2, 20602. [Google Scholar] [CrossRef] [Green Version]

- Zhu, H.; Hüpkes, J.; Bunte, E.; Owen, J.; Huang, S.M. Novel etching method on high rate ZnO:Al thin films reactively sputtered from dual tube metallic targets for silicon-based solar cells. Sol. Energy Mater. Sol. Cells 2011, 95, 964–968. [Google Scholar] [CrossRef]

- Owen, J.I.; Hüpkes, J.; Zhu, H.B.; Bunte, E.; Pust, S.E. Novel etch process to tune crater size on magnetron sputtered ZnO:Al. Phys. Status Solidi a-Appl. Mater. Sci. 2011, 208, 109–113. [Google Scholar] [CrossRef]

- Hüpkes, J.; Owen, J.I.; Zhu, H.; Pust, S.; Worbs, J.; Jost, G. New texture etching of zinc oxide: Tunable light trapping for silicon thin film solar cells. In Proceedings of the 25th European Photovoltaic Solar Energy Conference and Exhibition/5th World Conference on Photovoltaic Energy Conversion, Valencia, Spain, 6–10 September 2010; pp. 3224–3227. [Google Scholar]

- Bittkau, K.; Schulte, M.; Beckers, T.; Carius, R. Fourier analysis for the study of light scattering properties of randomly textured ZnO films. In Spie Photonics Europe; SPIE: Brussels, Belgium, 2010; Volume 7725, pp. 77250–77258. [Google Scholar] [CrossRef]

- Schulte, M.; Bittkau, K.; Pieters, B.E.; Jorke, S.; Stiebig, H.; Hüpkes, J.; Rau, U. Ray tracing for the optics at nano-textured ZnO-air and ZnO-silicon interfaces. Prog. Photovolt. 2011, 19, 724–732. [Google Scholar] [CrossRef]

- Hüpkes, J.; Müller, J.; Rech, B. Transparent Conductive Zinc Oxide; Ellmer, K., Klein, A., Rech, B., Eds.; Texture Etched ZnO:Al for Silicon Thin Film Solar Cells; Springer: Berlin/Heidelberg, Germany, 2008; Volume 104, pp. 359–413. [Google Scholar]

- Merdzhanova, T.; Zimmermann, T.; Zastrow, U.; Gordijn, A.; Beyer, W. A-si:H/μc-si:H solar cells prepared by the single-chamber processes—minimization of phosphorus and boron cross contamination. Thin Solid Films 2013, 540, 251–255. [Google Scholar] [CrossRef]

- Jovanov, V.; Xu, X.; Shrestha, S.; Schulte, M.; Hüpkes, J.; Zeman, M.; Knipp, D. Influence of interface morphologies on amorphous silicon thin film solar cells prepared on randomly textured substrates. Sol. Energy Mater. Sol. Cells 2013, 112, 182–189. [Google Scholar] [CrossRef]

- Ku, S.; Haas, S.; Pieters, B.E.; Zastrow, U.; Besmehn, A.; Ye, Q.; Rau, U. Investigation of laser scribing of a-Si:H from the film side for solar modules using a UV laser with ns pulses. Appl. Phys. A 2011, 105, 355–362. [Google Scholar] [CrossRef]

- Houben, L.; Luysberg, M.; Hapke, P.; Carius, R.; Finger, F.; Wagner, H. Structural properties of microcrystalline silicon in the transition from highly crystalline to amorphous growth. Philos. Mag. A 1998, 77, 1447–1460. [Google Scholar] [CrossRef]

- Smirnov, V.; Böttler, W.; Hüpkes, J.; Finger, F. ZnO based back reflectors with a wide range of surface morphologies for light trapping in n-i-p microcrystalline silicon solar cells. In Proceedings of the E-MRS Spring Meeting 2013 Symposium d Advanced Inorganic Materials and Structures for Photovoltaics, Strasbourg, France, 27–31 May 2013; Topic, M., Conibeer, G., Kondo, M., Poortmans, J., Sites, J.R., Slaoui, A., Eds.; Elsevier: Amsterdam, The Netherlands, 2014; Volume 44, pp. 223–228. [Google Scholar]

- Bailat, J.; Vallat-Sauvain, E.; Vallat, A.; Shah, A. Simulation of the growth dynamics of amorphous and microcrystalline silicon. J. Non-Cryst. Solids 2004, 338, 32–36. [Google Scholar] [CrossRef]

- Jovanov, V.; Xu, X.; Shrestha, S.; Schulte, M.; Hüpkes, J.; Knipp, D. Predicting the interface morphologies of silicon films on arbitrary substrates: Application in solar cells. Acs Appl. Mater. Interfaces 2013, 5, 7109–7116. [Google Scholar] [CrossRef] [PubMed]

- Hertel, K.; Huepkes, J.; Pflaum, C. An image processing approach to approximating interface textures of microcrystalline silicon layers grown on existing aluminum-doped zinc oxide textures. Opt. Express 2013, 21, A977–A990. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Vetterl, O.; Hapke, P.; Finger, F.; Houben, L.; Luysberg, M.; Wagner, H. Growth of microcrystalline silicon using the layer-by-layer technique at various plasma excitation frequencies. J. Non-Cryst. Solids 1998, 227, 866–870. [Google Scholar] [CrossRef]

- Jost, G.; Merdzhanova, T.; Zimmermann, T.; Kirchhoff, J.; Hüpkes, J. Angular resolved scattering measurements as quality control tool for texture-etched ZnO:Al front contacts. In Proceedings of the 27th European Photovoltaic Conference, Frankfurt, Germany, 24–28 September 2012. [Google Scholar]

- Sommer, N.; Goetzendoerfer, S.; Koehler, F.; Ziegner, M.; Huepkes, J. Influence of deposition conditions and substrate morphology on the electrical properties of sputtered zno: Al grown on texture-etched glass. Thin Solid Films 2014, 568, 25–30. [Google Scholar] [CrossRef]

- Čampa, A.; Meier, M.; Boccard, M.; Mercaldo, L.V.; Ghosh, M.; Zhang, C.; Merdzhanova, T.; Krč, J.; Haug, F.J.; Topič, M. Micromorph silicon solar cell optical performance: Influence of intermediate reflector and front electrode surface texture. Sol. Energy Mater. Sol. Cells 2014, 130, 401–409. [Google Scholar] [CrossRef]

- Kirner, S.; Hammerschmidt, M.; Schwanke, C.; Lockau, D.; Calnan, S.; Frijnts, T.; Neubert, S.; Schöpke, A.; Schmidt, F.; Zollondz, J.; et al. Implications of tco topography on intermediate reflector design for a-Si/μc-Si tandem solar cells—experiments and rigorous optical simulations. IEEE J. Photovolt. 2014, 4, 10–15. [Google Scholar] [CrossRef]

- Fahr, S.; Rockstuhl, C.; Lederer, F. The interplay of intermediate reflectors and randomly textured surfaces in tandem solar cells. Appl. Phys. Lett. 2010, 97, 173510. [Google Scholar] [CrossRef]

- Brammer, T.; Hüpkes, J.; Krause, M.; Kluth, O.; Müller, J.; Stiebig, H.; Rech, B. Locally contacted thin-film solar cells. In Proceedings of the 3rd World Conference on Photovoltaic Energy Conversion, Osaka, Japan, 11–18 May 2003; pp. 176–179. [Google Scholar]

- Python, M.; Madani, O.; Dominé, D.; Meillaud, F.; Vallat-Sauvain, E.; Ballif, C. Influence of the substrate geometrical parameters on microcrystalline silicon growth for thin-film solar cells. Sol. Energy Mater. Sol. Cells 2009, 93, 1714–1720. [Google Scholar] [CrossRef]

- Jost, G.; Merdzhanova, T.; Zimmermann, T.; Hüpkes, J. Process monitoring of texture-etched high-rate ZnO:Al front contacts for silicon thin-film solar cells. Thin Solid Films 2013, 532, 66–72. [Google Scholar] [CrossRef]

- Zhang, C.; Meier, M.; Lambertz, A.; Smirnov, V.; Holländer, B.; Gordijn, A.; Merdzhanova, T. Optical and electrical effects of p-type μc-SiOx:H in thin-film silicon solar cells on various front textures. Int. J. Photoenergy 2014, 2014, 10. [Google Scholar] [CrossRef]

- Lambertz, A.; Smirnov, V.; Merdzhanova, T.; Ding, K.; Haas, S.; Jost, G.; Schropp, R.E.I.; Finger, F.; Rau, U. Microcrystalline silicon–oxygen alloys for application in silicon solar cells and modules. Sol. Energy Mater. Sol. Cells 2013, 119, 134–143. [Google Scholar] [CrossRef]

| Layer | Power Output | Process Pressure | Heater Temperature | Argon Flow | Oxygen Flow | Nitrogen Flow | vcarrier | No. of Passes |

|---|---|---|---|---|---|---|---|---|

| [kW] | [Pa] | [°C] | [sccm] | [sccm] | [sccm] | [mm/s] | ||

| SiOxNy | 4 | 0.3 | 25 | 200 | 18 | 100 | 3 | 2 |

| ZnO:Al | 10 | 0.3–1 | 430–500 | 200 | - | - | 8 | 7–10 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hüpkes, J.; Jost, G.C.E.; Merdzhanova, T.; Owen, J.I.; Zimmermann, T. Coupling and Trapping of Light in Thin-Film Solar Cells Using Modulated Interface Textures. Appl. Sci. 2019, 9, 4648. https://doi.org/10.3390/app9214648

Hüpkes J, Jost GCE, Merdzhanova T, Owen JI, Zimmermann T. Coupling and Trapping of Light in Thin-Film Solar Cells Using Modulated Interface Textures. Applied Sciences. 2019; 9(21):4648. https://doi.org/10.3390/app9214648

Chicago/Turabian StyleHüpkes, Jürgen, Gabrielle C. E. Jost, Tsvetelina Merdzhanova, Jorj I. Owen, and Thomas Zimmermann. 2019. "Coupling and Trapping of Light in Thin-Film Solar Cells Using Modulated Interface Textures" Applied Sciences 9, no. 21: 4648. https://doi.org/10.3390/app9214648