Optimization of Grinding Parameters for Minimum Grinding Time When Grinding Tablet Punches by CBN Wheel on CNC Milling Machine

Abstract

:1. Introduction

2. Methodology

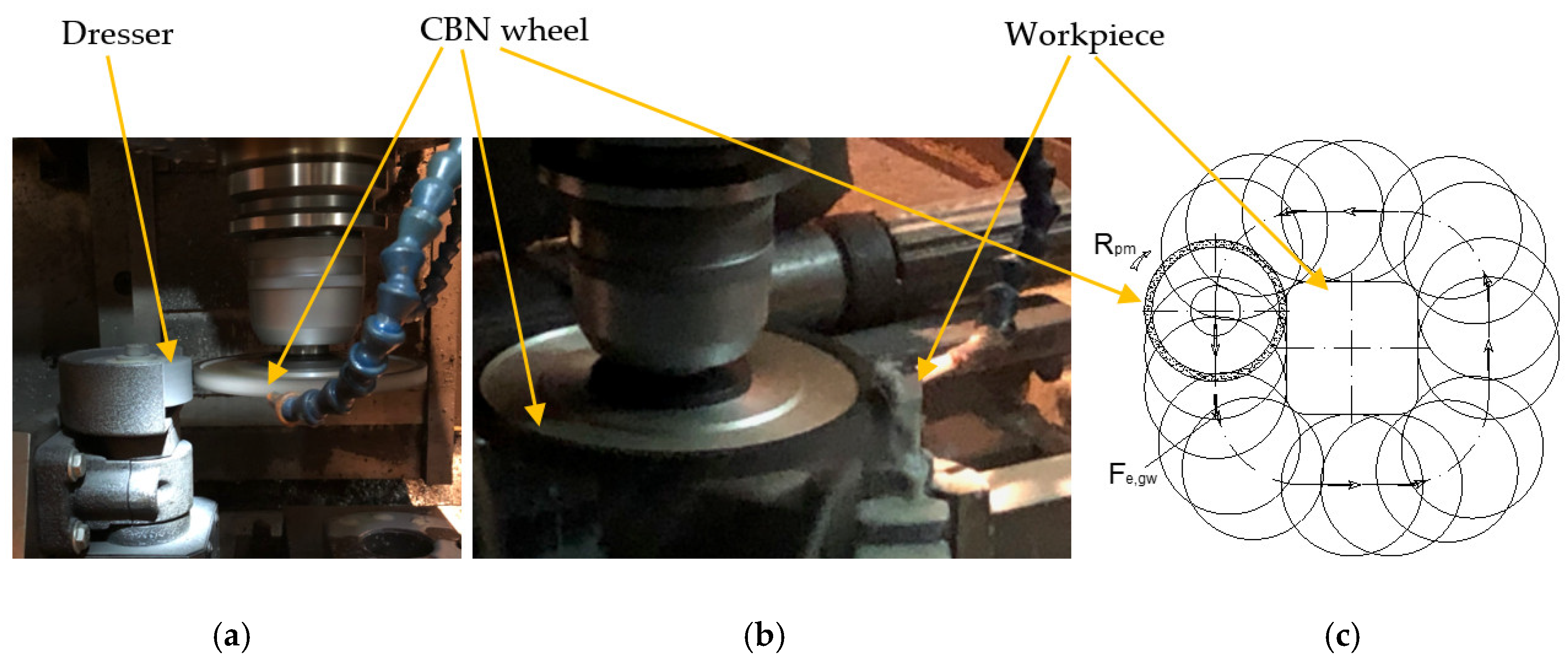

2.1. Experimental Setup

2.2. Design of Experiment

3. Results and Discussion

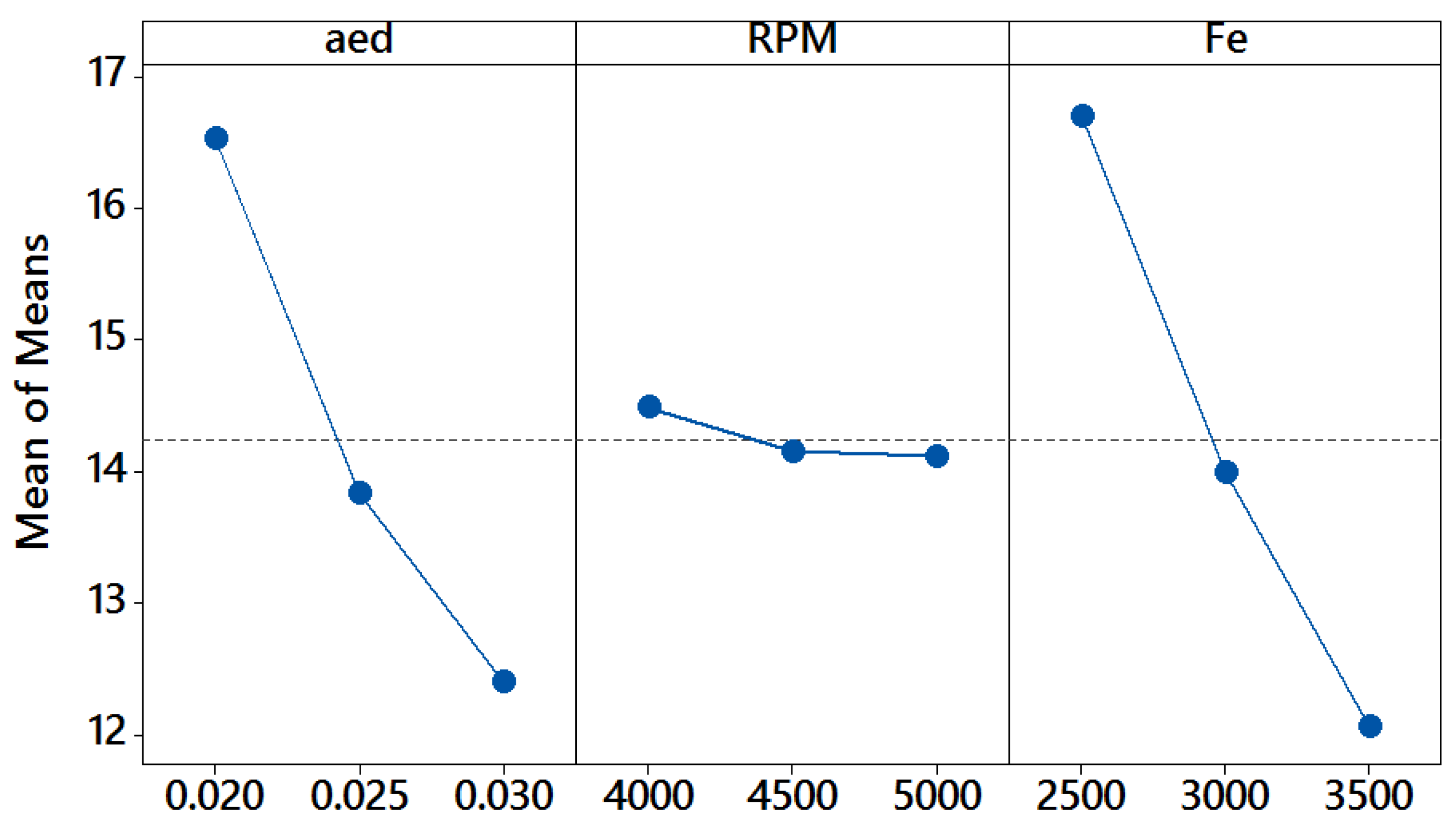

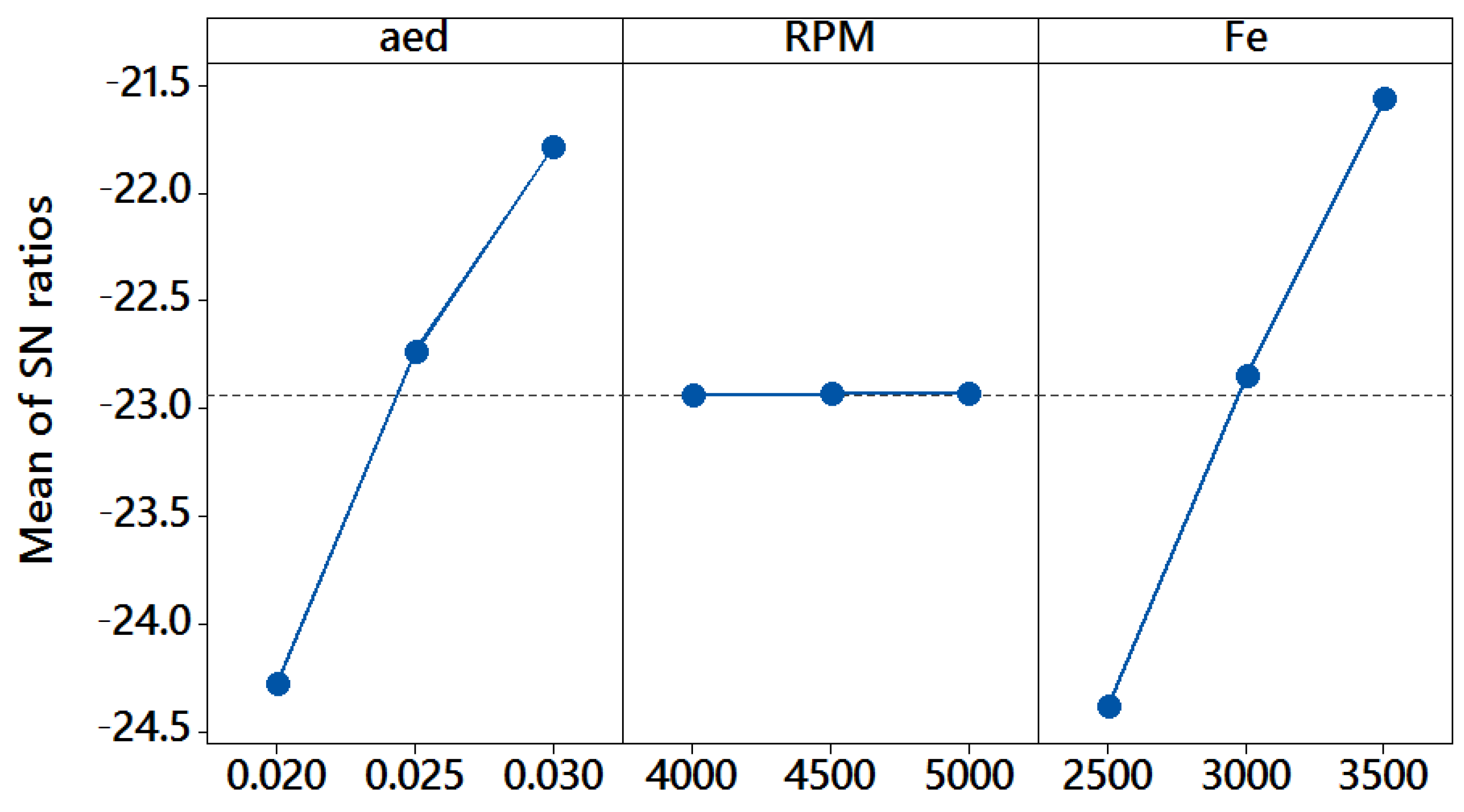

3.1. Determining the Influence of Cutting Parameters

3.2. Determining the Optimum Cutting Parameters

3.3. Determining the Optimum Surface Roughness Value

3.4. Determining Confidence Interval

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Chatterjee, S.; Rudrapati, R.; pal, P.K.; Nand, G. Experiments, analysis and parametric optimization of cylindrical traverse cut grinding of aluminum bronze. Mater. Today Proc. 2018, 5, 5272–5280. [Google Scholar] [CrossRef]

- Gupta, R.; Shishodia, K.S.; Sekhon, G.S. Optimization of grinding process parameters using enumeration method. J. Mater. Process. Technol. 2001, 112, 63–67. [Google Scholar] [CrossRef]

- Li, G.F.; Wang, L.S.; Yang, L.B. Multi-parameter optimization and control of the cylindrical grinding process. J. Mater. Process. Technol. 2002, 129, 232–236. [Google Scholar] [CrossRef]

- Pereverzev, P.P.; Akintseva, A.V. Automatic Cycles Multiparametric Optimization of Internal Grinding. Procedia Eng. 2015, 129, 121–126. [Google Scholar] [CrossRef]

- Lin, B.; Zhou, K.; Guo, J.; Liu, Q.Y.; Wang, W.J. Influence of grinding parameters on surface temperature and burn behaviors of grinding rail. Tribol. Int. 2018, 122, 151–162. [Google Scholar] [CrossRef]

- Vidal, G.; Ortega, N.; Bravo, H.; Dubar, M.; González, H. An Analysis of Electroplated cBN Grinding Wheel Wear and Conditioning during Creep Feed Grinding of Aeronautical Alloys. Metals 2018, 8, 350. [Google Scholar] [CrossRef]

- Pandiyan, V.; Caesarendra, W.; Tjahjowidodo, T.; Praveen, G. Predictive Modelling and Analysis of Process Parameters on Material Removal Characteristics in Abrasive Belt Grinding Process. Appl. Sci. 2017, 7, 363. [Google Scholar] [CrossRef]

- Ky, L.H.; Hong, T.T.; Dung, H.T.; Tuan, N.A.; van Tung, N.; Tung, L.A.; Pi, V.N. Optimization of dressing parameters for grinding table shape punches by CBN wheel on CNC milling machine. Int. J. Mech. Eng. Technol. 2019, 10, 960–967. [Google Scholar]

- Du, S.; Chen, M.; Xie, L.; Zhu, Z.; Wan, X. Optimization of process parameters in the high-speed milling of titanium alloy TB17 for surface integrity by the Taguchi-Grey relational analysis method. Adv. Mech. Eng. 2016, 8, 1–12. [Google Scholar] [CrossRef]

- Thi-Bich, M.; Van-Chien, D.; Tien-Long, B.; Duc-Toan, N. Cutting Force Model for Thermal-Assisted Machining of Tool Steel Based on the Taguchi Method. Metals 2018, 8, 992. [Google Scholar] [CrossRef]

- Nguyen, H.; Hsu, Q. Surface Roughness Analysis in the Hard Milling of JIS SKD61 Alloy Steel. Appl. Sci. 2016, 6, 172. [Google Scholar] [CrossRef]

- Do, T.; Hsu, Q. Optimization of Minimum Quantity Lubricant Conditions and Cutting Parameters in Hard Milling of AISI H13 Steel. Appl. Sci. 2017, 6, 83. [Google Scholar] [CrossRef]

- Niu, W.; Mo, R.; Chang, Z.; Wan, N. Investigating the Effect of Cutting Parameters of Ti–6Al–4V on Surface Roughness Based on a SPH Cutting Model. Appl. Sci. 2019, 9, 654. [Google Scholar] [CrossRef]

- Kim, N.; Bhalerao, I.; Han, D.; Yang, C.; Lee, H. Improving Surface Roughness of Additively Manufactured Parts Using a Photopolymerization Model and Multi-Objective Particle Swarm Optimization. Appl. Sci. 2019, 9, 151. [Google Scholar] [CrossRef]

| Machine and Equipment | Specifications |

|---|---|

| Grinding machine | CNC milling machine of Mitsubishi, Model M-V50C (made in Japan) |

| Abrasive of the grinding wheel | Cubic boron nitride with JIS code of S2556-CBN 325-N75B53-3.0 (made in Japan) |

| Work-piece material | 90CrSi |

| Work-piece dimensions | 13 mm × 13 mm × 30 mm |

| Cooling modes | Caltex Aquatex 3180 |

| Environment | Flood |

| Input Parameters | Label | Unit | Experimental Levels | ||

|---|---|---|---|---|---|

| Low Level (1) | Base Level (2) | High Level (3) | |||

| Cutting depth | aed | mm | 0.02 | 0.025 | 0.03 |

| Wheel speed | Rpm | rpm | 4000 | 4500 | 5000 |

| Feed rate | Fe | mm/min | 2500 | 3000 | 3500 |

| Experiment Number | Factors | ||

|---|---|---|---|

| aed (mm) | RPM (rpm) | Fe (mm/min) | |

| 1 | 0.02 | 4000 | 2500 |

| 2 | 0.02 | 4500 | 3000 |

| 3 | 0.02 | 5000 | 3500 |

| 4 | 0.025 | 4000 | 3000 |

| 5 | 0.025 | 4500 | 3500 |

| 6 | 0.025 | 5000 | 2500 |

| 7 | 0.03 | 4000 | 3500 |

| 8 | 0.03 | 4500 | 2500 |

| 9 | 0.03 | 5000 | 3000 |

| Experiment Number | Factors and Their Levels | Response: The Grinding Time (tw) | S/N | |||||

|---|---|---|---|---|---|---|---|---|

| aed (mm) | RPM (rpm) | Fe (mm/min) | tw1 (min) | tw2 (min) | tw3 (min) | twmean (min) | ||

| 1 | 0.02 | 4000 | 2500 | 19.31 | 19.38 | 19.40 | 19.36 | −25.74 |

| 2 | 0.02 | 4500 | 3000 | 16.20 | 16.22 | 16.25 | 16.22 | −24.20 |

| 3 | 0.02 | 5000 | 3500 | 13.92 | 13.97 | 14.02 | 13.97 | −22.90 |

| 4 | 0.025 | 4000 | 3000 | 13.54 | 13.58 | 13.61 | 13.58 | −22.66 |

| 5 | 0.025 | 4500 | 3500 | 11.69 | 11.72 | 11.68 | 11.70 | −21.36 |

| 6 | 0.025 | 5000 | 2500 | 16.18 | 16.22 | 16.20 | 16.20 | −24.19 |

| 7 | 0.03 | 4000 | 3500 | 10.48 | 10.52 | 10.50 | 10.50 | −20.42 |

| 8 | 0.03 | 4500 | 2500 | 14.50 | 14.53 | 14.52 | 14.52 | −23.24 |

| 9 | 0.03 | 5000 | 3000 | 12.16 | 12.18 | 12.15 | 12.16 | −21.70 |

| Analysis of Variance for Means | Model Summary | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Source | DF | Seq SS | Adj SS | Adj MS | F | P | S | R-Sq | R-Sq (adj) |

| aed | 2 | 26.3201 | 26.3201 | 13.1600 | 109.15 | 0.009 | 0.3472 | 99.59% | 98.38% |

| RPM | 2 | 0.2502 | 0.2502 | 0.1251 | 1.04 | 0.491 | |||

| Fe | 2 | 32.5820 | 32.5820 | 16.2910 | 135.12 | 0.007 | |||

| Residual Error | 2 | 0.2411 | 0.2411 | 0.1206 | |||||

| Total | 8 | 59.3934 | |||||||

| Level | aed | RPM | Fe |

|---|---|---|---|

| 1 | 16.52 | 14.48 | 16.69 |

| 2 | 13.82 | 14.15 | 13.99 |

| 3 | 12.39 | 14.11 | 12.05 |

| Delta | 4.12 | 0.37 | 4.64 |

| Rank | 2 | 3 | 1 |

| Analysis of Variance for SN Retios | Model Summary | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Source | DF | Seq SS | Adj SS | Adj MS | F | P | S | R-Sq | R-Sq (adj) |

| aed | 2 | 9.5112 | 9.5112 | 4.75561 | 185818.41 | 0.000 | 0.0051 | 100.00% | 100.00% |

| RPM | 2 | 0.0001 | 0.0001 | 0.00006 | 2.18 | 0.314 | |||

| Fe | 2 | 12.0185 | 12.0185 | 6.00924 | 234802.40 | 0.000 | |||

| Residual Error | 2 | 0.0001 | 0.0001 | 0.00003 | |||||

| Total | 8 | 21.5299 | |||||||

| Output Factors | Optimum Parameters | ||

|---|---|---|---|

| Prediction Value | Experimental Value | Error (%) | |

| aed3, RPM3, Fe3 | aed3, RPM3, Fe3 | ||

| Grinding time-t (min) | 10.06 | 9.4 | 6.6 |

| S/N ratio | −20.05 | −19.46 | |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vu, N.-P.; Nguyen, Q.-T.; Tran, T.-H.; Le, H.-K.; Nguyen, A.-T.; Luu, A.-T.; Nguyen, V.-T.; Le, X.-H. Optimization of Grinding Parameters for Minimum Grinding Time When Grinding Tablet Punches by CBN Wheel on CNC Milling Machine. Appl. Sci. 2019, 9, 957. https://doi.org/10.3390/app9050957

Vu N-P, Nguyen Q-T, Tran T-H, Le H-K, Nguyen A-T, Luu A-T, Nguyen V-T, Le X-H. Optimization of Grinding Parameters for Minimum Grinding Time When Grinding Tablet Punches by CBN Wheel on CNC Milling Machine. Applied Sciences. 2019; 9(5):957. https://doi.org/10.3390/app9050957

Chicago/Turabian StyleVu, Ngoc-Pi, Quoc-Tuan Nguyen, Thi-Hong Tran, Hong-Ky Le, Anh-Tuan Nguyen, Anh-Tung Luu, Van-Tung Nguyen, and Xuan-Hung Le. 2019. "Optimization of Grinding Parameters for Minimum Grinding Time When Grinding Tablet Punches by CBN Wheel on CNC Milling Machine" Applied Sciences 9, no. 5: 957. https://doi.org/10.3390/app9050957

APA StyleVu, N.-P., Nguyen, Q.-T., Tran, T.-H., Le, H.-K., Nguyen, A.-T., Luu, A.-T., Nguyen, V.-T., & Le, X.-H. (2019). Optimization of Grinding Parameters for Minimum Grinding Time When Grinding Tablet Punches by CBN Wheel on CNC Milling Machine. Applied Sciences, 9(5), 957. https://doi.org/10.3390/app9050957