Prediction of Viscosity Values of Nanofluids at Different pH Values by Alternating Decision Tree and Multilayer Perceptron Methods

Abstract

:1. Introduction

2. Materials and Methods

2.1. CuO Nanofluids Production

Scanning Electron Microscope Analysis

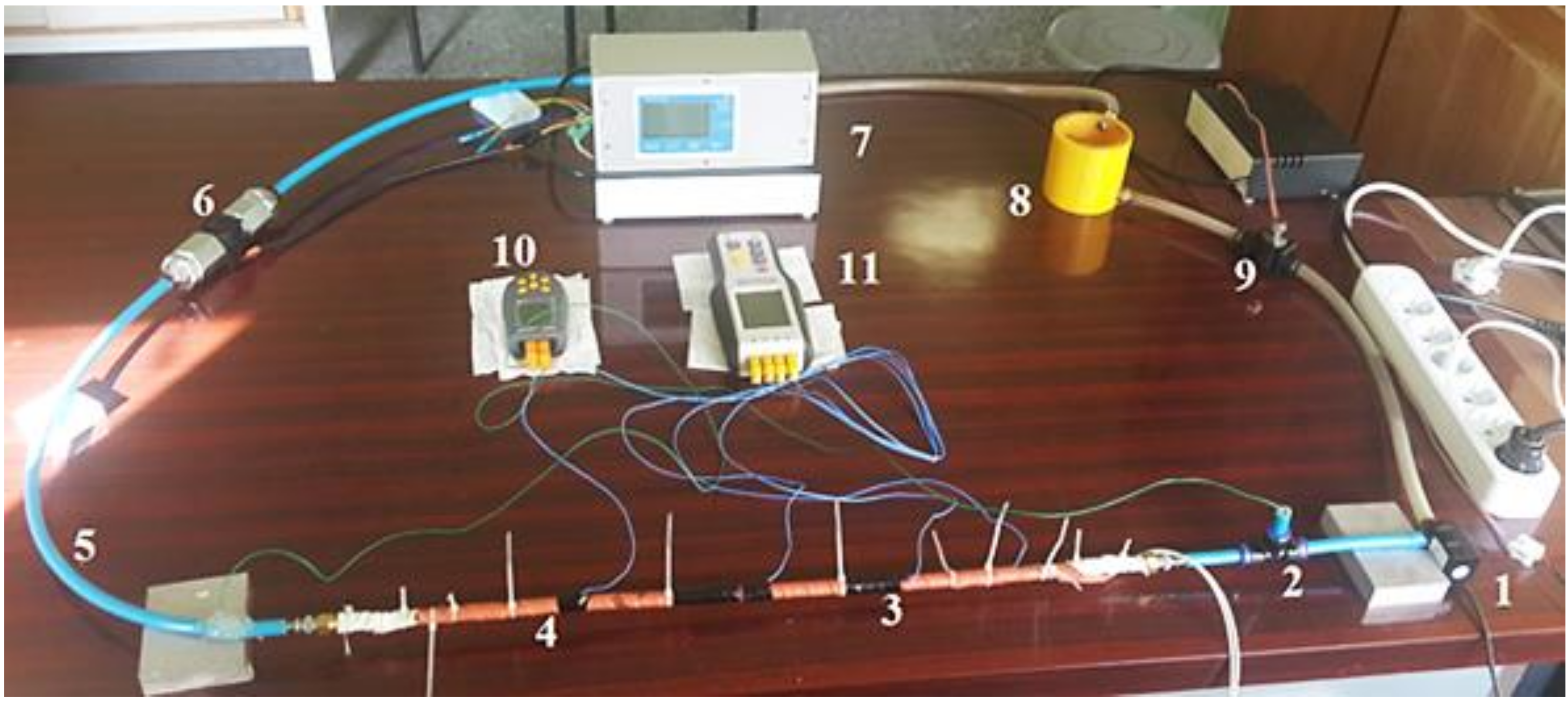

2.2. Viscosity Measurement, the Average Speed (Vavr) and Reynolds Calculations of Nanofluids

2.3. Computational Intelligence Methods

2.3.1. Alternating Decision Tree

2.3.2. Multilayer Perceptron

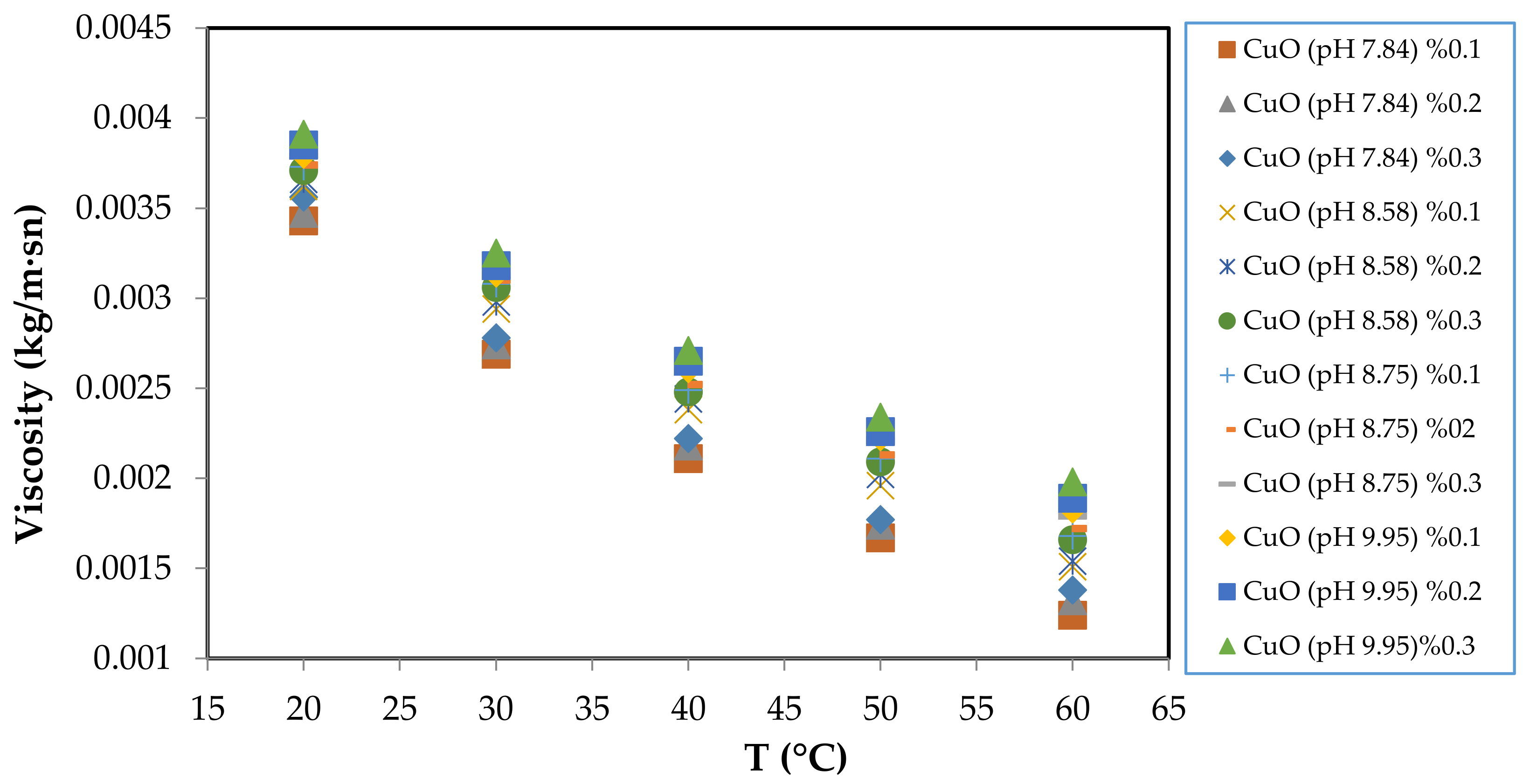

3. Results

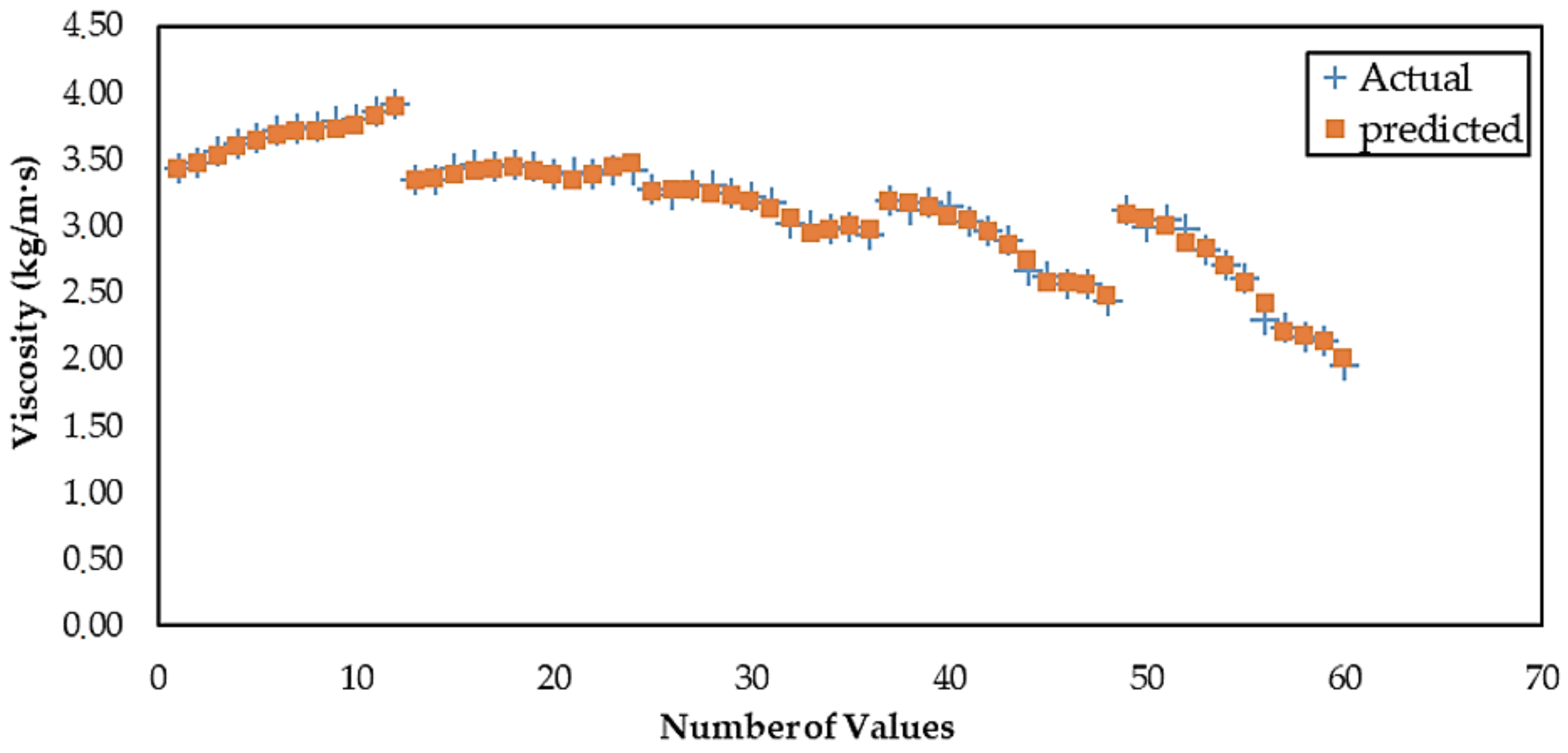

Creating Predictive Models for Viscosity Values with ADTree and MLP

4. Conclusions

Author Contributions

Conflicts of Interest

References

- Elcioglu, E.B.; Yazicioglu, A.G.; Kakac, S. A Comparative Evaluation on Nanofluid Viscosity. J. Therm. Sci. Technol. 2014, 34, 137–151. [Google Scholar]

- Xie, H.; Li, L.; Sun, Y.; Wang, Y.; Gao, S.; Tian, Y.; Ma, X.; Guo, C.; Bo, F.; Zhang, L. An Available Strategy for Nasal Brain Transport of Nanocomposite Based on PAMAM Dendrimers via In Situ Gel. Nanomaterials 2019, 9, 147. [Google Scholar] [CrossRef] [PubMed]

- Vigani, B.; Rossi, S.; Milanesi, G.; Bonferoni, M.C.; Sandri, G.; Bruni, G.; Ferrari, F. Electrospun Alginate Fibers: Mixing of Two Different Poly (ethylene oxide) Grades to Improve Fiber Functional Properties. Nanomaterials 2018, 8, 971. [Google Scholar] [CrossRef]

- Mishra, P.C.; Mukherjee, S.; Nayak, S.K.; Panda, A. A brief review on viscosity of nanofluids. Int. Nano Lett. 2014, 4, 109–120. [Google Scholar] [CrossRef] [Green Version]

- Einstein, A. Eineneuebestimmung der molekuldimensionen. Ann. Phys. 1906, 324, 289–306. [Google Scholar] [CrossRef]

- Phuoc, T.X.; Massoudi, M. Experimental observations of the effects of shear rates and particle concentration on the viscosity of Fe2O3–deionized water nanofluids. Int. J. Therm. Sci. 2009, 48, 1294–1301. [Google Scholar] [CrossRef]

- Dybowska-Sarapuk, L.; Kielbasinski, K.; Arazna, A.; Futera, K.; Skalski, A.; Janczak, D.; Sloma, M.; Jakubowska, M. Efficient Inkjet Printing of Graphene-Based Elements: Influence of Dispersing Agent on Ink Viscosity. Nanomaterials 2018, 8, 602. [Google Scholar] [CrossRef] [PubMed]

- Tavman, I.; Turgut, A. An ınvestigation on thermal conductivity and viscosity of water based nanofluids. Microfluid. Based Microsyst. NATO Sci. Peace Secur. Ser. A Chem. Biol. 2010, 23, 139–162. [Google Scholar]

- Nguyen, C.T.; Desgranges, F.; Gilles, R.; Nicolas, G.; Thierry, M.; Boucher, S. Temperature and particle-size dependent viscosity data for water-based nanofluids–hysteresis phenomenon. Int. J. Heat Fluid Flow 2007, 28, 1492–1506. [Google Scholar] [CrossRef]

- Weerapun, D.; Somchai, W. Measurement of temperature dependent thermal conductivity and viscosity of TiO2 water nanofluids. Exp. Therm. Fluid Sci. 2009, 33, 706–714. [Google Scholar]

- Zhao, J.-F.; Luo, Z.-Y.; Ni, M.-J.; Cen, K.-F. Dependence of nanofluid viscosity on particle size and pH value. Chin. Phys. Lett. 2009, 26, 066202. [Google Scholar]

- Miastkowska, M.; Lasoń, E.; Sikora, E.; Wolińska-Kennard, K. Preparation and Characterization of Water-Based Nano-Perfumes. Nanomaterials 2018, 8, 981. [Google Scholar] [CrossRef]

- Hemmati-Sarapardeh, A.; Varamesh, A.; Husein, M.M.; Karan, K. On the evaluation of the viscosity of nanofluid systems: Modeling and data assessment. Renew. Sustain. Energy Rev. 2018, 81, 313–329. [Google Scholar] [CrossRef]

- Afrand, M.; Nadooshan, A.A.; Hassani, M.; Yarmand, H.; Dahari, M. Predicting the viscosity of multi-walled carbon nanotubes/water nanofluid by developing an optimal artificial neural network based on experimental data. Int. Commun. Heat Mass Transf. 2016, 77, 49–53. [Google Scholar] [CrossRef]

- Meybodi, M.K.; Naseri, S.; Shokrollahi, A.; Daryasafar, A. Prediction of viscosity of water-based Al2O3, TiO2, SiO2, and CuO nanofluids using a reliable approach. Chemom. Intell. Lab. Syst. 2015, 149, 60–69. [Google Scholar] [CrossRef]

- Karimi, H.; Yousefi, F.; Rahimi, M.R. Correlation of viscosity in nanofluids using genetic algorithm-neural network (GA-NN). Heat Mass Transf. 2011, 47, 1417–1425. [Google Scholar] [CrossRef]

- Ansari, H.R.; Zarei, M.J.; Sabbaghi, S.; Keshavarz, P. A new comprehensive model for relative viscosity of various nanofluids using feed-forward back-propagation MLP neural networks. Int. Commun. Heat Mass Transf. 2018, 91, 158–164. [Google Scholar] [CrossRef]

- Esfe, M.H.; Tatar, A.; Ahangar, M.R.H.; Rostamian, H. A comparison of performance of several artificial intelligence methods for predicting the dynamic viscosity of TiO2/SAE 50 nano-lubricant. Phys. E Low Dimens. Syst. Nanostruct. 2018, 96, 85–93. [Google Scholar] [CrossRef]

- Gil, E.; Cortés, J.; Iturriza, I.; Ordás, N. XPS and SEM analysis of the surface of gas atomized powder precursor of ODS ferritic steels obtained through the STARS route. Appl. Surf. Sci. 2018, 427, 182–191. [Google Scholar] [CrossRef]

- Miller, J.C.; Serrato, R.; Represas-Cardenas, J.M.; Kundahl, G. The Handbook of Nanotechnology; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2004. [Google Scholar]

- Çengel Yunus, A. Practical Approach to Heat and Mass Transfer, 3rd ed.; McGraw Hill: New York, NY, USA, 2010; pp. 467–468. [Google Scholar]

- Sikandar, A.; Anwar, W.; Bajwa, U.I.; Wang, X.; Sikandar, M.; Yao, L.; Jiang, Z.L.; Chunkai, Z. Decision Tree Based Approaches for Detecting Protein Complex in Protein Protein Interaction Network (PPI) via Link and Sequence Analysis. IEEE Access 2018, 6, 22108–22120. [Google Scholar] [CrossRef]

- Shirzadi, A.; Soliamani, K.; Habibnejhad, M.; Kavian, A.; Chapi, K.; Shahabi, H.; Chen, W.; Khosravi, K.; Thai Pham, B.; Pradhan, B.; et al. Novel GIS Based Machine Learning Algorithms for Shallow Landslide Susceptibility Mapping. Sensors 2018, 18, 3777. [Google Scholar] [CrossRef] [PubMed]

- Pal, M.; Mather, P.M. An assessment of the effectiveness of decision tree methods for land cover classification. Remote Sens. Environ. 2003, 86, 554–565. [Google Scholar] [CrossRef]

- Freund, Y.; Mason, L. The Alternating Decision Tree Learning Algorithm; ICML Academic Press: San Francisco, CA, USA, 1999; Volume 99, pp. 124–133. [Google Scholar]

- Frank, E.; Mayo, M.; ve Kramer, S. Alternating model trees. In Proceedings of the 30th Annual ACM Symposium on Applied Computing, Salamanca, Spain, 13–17 April 2015; pp. 871–878. [Google Scholar]

- Zhai, X.; Ali, A.A.S.; Amira, A.; Bensaali, F. MLP neural network based gas classification system on Zynq SoC. IEEE Access 2016, 4, 8138–8146. [Google Scholar] [CrossRef]

- Rehman, I.U.; Nasralla, M.M.; Philip, N.Y. Multilayer Perceptron Neural Network-Based QoS-Aware, Content-Aware and Device-Aware QoE Prediction Model: A Proposed Prediction Model for Medical Ultrasound Streaming Over Small Cell Networks. Electronics 2019, 8, 194. [Google Scholar] [CrossRef]

- Das, M.; Akpinar, E.K. Investigation of Pear Drying Performance by Different Methods and Regression of Convective Heat Transfer Coefficient with Support Vector Machine. Appl. Sci. 2018, 8, 215. [Google Scholar] [CrossRef]

| Number of Layers | 3 |

| Number of Neurons in Layers | 6-6-1 |

| Weight Ratings | Random |

| Activation Function | Logsig |

| Transfer Function | Tangent Sigmoid Transfer |

| Learning Function | Backpropagation |

| Accuracy Criteria | Formulas | Parameters |

|---|---|---|

| MSE | P: Predicted Value A: Actual Value n: Total Estimated Value | |

| RMSE | P: Predicted Value A: Actual Value n: Total Estimated Value | |

| MAPE | d: Predicted Value z: Actual Value P: Total Estimated Value |

| Kernel Models | MSE | RMSE | MAPE |

|---|---|---|---|

| Alternating Decision Tree | 0.056 | 0.1436 | 0.0384 |

| Multilayer Perceptron | 0.023 | 0.0745 | 0.0204 |

| Nanofluids | Number of Values | Method | Error Analysis | Error Analysis Result | Reference |

|---|---|---|---|---|---|

| Al2O3, TiO2, SiO2 and CuO-water nanofluids | 3144 | MLP | RMSE | 0.1 | Hemmati-Sarapardeh et al. [13] |

| Multi-walled Carbon Nanotubes MWCNTs/water Nanofluids | 268 | ANN | MSE | 0.28 | Afrand et al. [14] |

| Al2O3, CuO, TiO2 and SiO2 Nanofluids | 801 | LS-SVM | RMSE | 37.084 | Meybodi et al. [15] |

| Al2O3–H2O, CuO–H2O, TiO2–H2O, TiO2–EG, SiO2–H2O, SiO2–EtOH | 381 | GA-ANN | MSE | 2.48 | Karimi et al. [16] |

| Different Nanofluids | 1620 | MLP | MSE | 0.09 | Ansari et al. [17] |

| TiO2/SAE 50 Nano-lubricant | 251 | LS-SWM | RMSE | 0.58 | Esfe et al. [18] |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Demirpolat, A.B.; Das, M. Prediction of Viscosity Values of Nanofluids at Different pH Values by Alternating Decision Tree and Multilayer Perceptron Methods. Appl. Sci. 2019, 9, 1288. https://doi.org/10.3390/app9071288

Demirpolat AB, Das M. Prediction of Viscosity Values of Nanofluids at Different pH Values by Alternating Decision Tree and Multilayer Perceptron Methods. Applied Sciences. 2019; 9(7):1288. https://doi.org/10.3390/app9071288

Chicago/Turabian StyleDemirpolat, Ahmet Beyzade, and Mehmet Das. 2019. "Prediction of Viscosity Values of Nanofluids at Different pH Values by Alternating Decision Tree and Multilayer Perceptron Methods" Applied Sciences 9, no. 7: 1288. https://doi.org/10.3390/app9071288