1. Introduction

The use of synthetic antioxidants is discouraged due to their potential adverse effects on human health, and the poultry meat industry is actively seeking natural antioxidants to replace the synthetic ones. Several natural antioxidants from plants showed positive effects in improving meat quality and extending shelf life [

1,

2,

3,

4].

Meat color and odor are important attributes for the consumer evaluation on meat quality [

5,

6]. Usually, fresh meat is characterized by a cherry-red color due to the formation of oxymyoglobin (OxyMb). However, oxidation of the heme pigment will convert the red color to brown [

7]. Lipid oxidation is considered as the major problem affecting meat quality [

8] because it changes color, generates off-odor [

9], and impairs protein functionality [

10]. Protein functionality such as solubility, emulsification, water binding capacity, and texture are also affected by lipid oxidation and their interactions with protein oxidation products [

10,

11].

The progress of oxidation in fresh meat depends on many internal factors such as catalyst (Iron Fe, Cu,

etc.), antioxidant capacity, pH, fatty acid composition, and free radical formation. However, many external factors such as high storage temperature, oxygen availability, meat processing method, and additives also can influence lipid and protein oxidation in meat [

12]. Therefore, finding new natural antioxidants to resolve these problems in meat and other foods is important.

Herbs and plant extracts such as rosemary [

13], oregano [

14], grape seed and bearberry extracts [

15,

16], plum extract [

17], and garlic and onion oleoresins [

8] have been tested to prevent lipid oxidation in meat because they contained high levels of antioxidants [

4]. Plants produce a wide variety of “secondary compounds” including alkaloids, terpenes, and phenolics in their cells to protect themselves from external herbivores and diseases [

18]. Among these compounds, tannins have metal-chelating, antioxidant, and protein precipitating activities [

19], and show positive effects on meat color stability and extend their self-life [

20].

The tannins are defined as water-soluble phenolic compounds with molecular weights between 500 and 3000 Da, and have special properties such as precipitating alkaloids, gelatin, and other proteins [

21]. These properties of tannins are based on their chemical structures, which have two or three phenolic hydroxyl groups on the phenyl ring (polyphenol). Tannins are classified into two different main groups—hydrolysable and condensed tannins. The hydrolyzable type of tannins contains polyhydric alcohol and hydroxyl groups, which are esterified by gallic acid (gallotannins) or to hexahydroxy diphenic acid (ellagitannins) [

22]. Condensed tannins are more complex in their structure compared to hydrolysable tannins, and are mainly produced by two main polymerized products of flavan-3-ols and flavan-3,4-diols, or a mixture of both [

23].

Tannic acid is a yellowish-white to light-brown powder, and is soluble in water and alcohol (hydrolysable tannins). The antioxidant activity of tannic acid was explained by several researchers through their ability to prevent hydroxyl radical formation [

24], metal-chelating activity [

22], and radical-scavenging activity [

25]. These activities make the tannic acid a possible replacement for synthetic antioxidants [

26,

27]. Tannic acid can be obtained in two different ways: (1) solvent extraction of nutgalls or excrescences from young twigs of Quercus infectoria Oliver, and (2) solvent extraction of the seed pod of Tara (Caesalpinia spinosa), or the nutgalls of various sumac species, including Rhus semialata, R. coriaria, R. galabra, and R. typhia [

28]. The commercial formula for tannic acid is given as C

76H

52O

46 and is composed of a mixture of polygalloyl glucose and polygalloyl quinnic acid ester depending on the plant extract sources and purification methods used [

18,

19]. Tannic acid is classified as generally recognized as safe (GRAS) by the Food and Drug Administration (FDA), and up to 10 ppm of tannic acid is allowed to be used in meat products [

28]. However, little work has been done to determine their effect on the storage stability and quality characteristics of ground chicken meat.

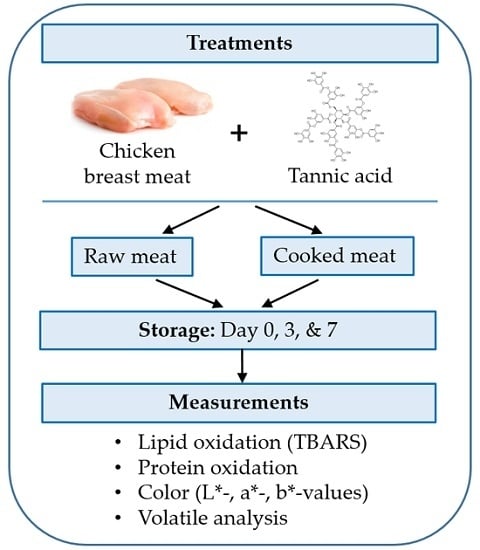

The objective of this study was to investigate the effect of adding tannic acid on the stability and quality of ground chicken meat (raw and cooked meat) during storage.

2. Materials and Methods

Tannic acid powder containing 90% tannin was obtained from Sigma-Aldrich (St. Louis, MO, USA). The tannic acid contained gallic acid, monogalloyl glucose, digalloyl glucose, trigalloyl glucose, tetragalloyl glucose, pentagalloyl glucose, ESA galloyl glucose, EPTA galloyl glucose, and octagalloyl glucose. The product is hydrolyzable tannin obtained from oak gall nuts from Quercus infectoria.

2.1. Sample Preparation

One hundred and twenty, 6-week-old broilers raised on a corn-soybean meal diet were slaughtered using the USDA guidelines [

29]. The chicken carcasses were chilled in ice water for 2 h and drained in a cold room, and the breast muscles were separated from the carcasses 24 h after slaughter. The breast muscles were ground twice a through a 10-mm and a 3-mm plates (Kitchen Aid, Inc., St. Joseph, MI, USA) after removing skins before use. Five treatments including (1) control (none added), (2) 2.5 ppm tannic acid, (3) 5 ppm tannic acid, (4) 10 ppm tannic acid, and (5) 5 ppm butylated hydroxyanisole (BHA) were prepared. Tannic acid (0.1 g) was dissolved in 50 mL of de-ionized distilled water (DDW) and stored in a dark area to prevent exposure to light. BHA powder (0.1 g) was dissolved in 10 mL of 100% ethanol, and then mixed with 50 mL mineral oil to make a stock solution. The ethanol added was removed using a rotary evaporator (BUCH Rotavapor, Model R-200, BUCHI Co., New Castle, DE, USA) at (70 °C, 175 mbar vacuum pressure) before adding the stock solution to meat samples. Each additive treatment was added to the ground breast meat and then mixed for 2 min in a bowl mixer (Model KSM 90; Kitchen Aid Inc., St. Joseph, MI, USA). All treatments were added with the same amounts of mineral oil to provide the same conditions.

For raw-meat study, the prepared meat samples (approximately 100 g each) were individually packaged in oxygen-permeable bags (polyethylene, 4” × 6”, 2 mil, Associated Bag Co., Milwaukee, WI, USA), stored at 4 ℃ for 7 days, and analyzed for lipid and protein oxidation, and color at 0, 3, and 7 days of storage.

The same preparation method was used for cooked meat study, but the raw meat samples were vacuum packaged in oxygen-impermeable vacuum bags (O2 permeability, 9.3 mL O2/m2/24 h at 0 °C, Koch, Kansas City, MO, USA), and the meats were cooked in-bag in a 90 °C water bath (Isotemp®, Fisher Scientific Inc., Pittsburgh, PA, USA) until the internal temperature of the meat reached to 75 °C. After cooling to room temperature, the cooked meat was individually re-packaged in oxygen-permeable bag (polyethylene, 4” × 6”, 2 mil, Associated Bag Co., Milwaukee, WI, USA), stored at 4 °C for 7 days, and analyzed for lipid and protein oxidation and volatiles at 0, 3, and 7 days of storage.

2.2. 2-Thiobarbituric Acid-Reactive Substances (TBARS) Measurement

Lipid oxidation was determined using a TBARS method [

30]. Five grams of ground chicken meat were weighed into a 50-mL test tube, added with 50 μL BHT (7.2%) and 15 mL of deionized distilled water (DDW), and homogenized using a Polytron (Type PT 10/35, Brinkman Instruments Inc., Westbury, NY, USA) for 15 s at high speed. One milliliter of the meat homogenate was transferred to a disposable test tube (13 × 100 mm), and thiobarbituric acid/trichloroacetic acid solution (15 mM TBA/15% TCA, 2 mL) was added. The mixture was vortex-mixed and incubated in a boiling water bath for 15 min to develop color. Then, samples were cooled in ice-water for 10 min, mixed again, and centrifuged for 15 min at 2500×

g at 4 °C. The absorbance of the resulting supernatant solution was determined at 532 nm against a blank containing 1 mL of DDW and 2 mL of TBA/TCA solution. The amounts of TBARS were expressed as mg of malondialdehyde (MDA) per kg of meat.

2.3. Color Measurement

The color of meat was measured on the surface of meat samples using a Konica Minolta Color Meter (CR-410, Konioka Minolta, Osaka, Japan). The color meter was calibrated using an illuminant source C (average daylight) on a standard white ceramic tile covered with the same packaging film as the ones used for meat samples to negate the color and light reflectance properties of the packaging material. The color was expressed as CIE L*- (lightness), a*- (redness), and b*- (yellowness) values [

31]. The areas selected for color measurement were free from obvious defects that may affect the uniform color readings. An average of two random readings on the top of the sample surface was used for statistical analysis.

2.4. Volatile Analysis

Volatiles of samples were analyzed using a Solatek-72 Multimatrix-Vial Auto-sampler/Sample Concentrator 3100 (Tekmar-Dohrmann, Cincinnati, OH, USA) connected to a GC/MS (Model 6890/5973; Hewlett-Packard Co., Wilmington, DE, USA) according to the method of Ahn

et al. [

32]. Sample (3 g for raw meat and 2 g for cooked meat) was placed in a 40-mL sample vial, flushed with helium gas (40 psi) for 3 s, and then capped airtight with a Teflon-fluorocarbon resin/silicone septum (I-Chem Co., New Castle, DE, USA). Samples from different treatments were randomly organized on the refrigerated (4 °C) holding trying to minimize the oxidative changes among treatments during analysis. The meat sample was purged with helium (40 mL/min) for 14 min at 20 °C. Volatiles were trapped using a Tenax/charcoal/silica column (Tekmar-Dohrmann) and desorbed for 2 min at 225 °C, focused in a cryofocusing module (−70 °C), and then thermally desorbed into a capillary column for 2 min at 225 °C. An HP-624 column (7.5 m, 0.25 mm i.d., 1.4 μm nominal), an HP-1 column (52.5 m, 0.25 mm i.d., 0.25 μm nominal), and an HP-Wax column (7.5 m, 0.250 mm i.d., 0.25 μm nominal) were connected using zero dead-volume column connectors (J &W Scientific, Folsom, CA, USA). Ramped oven temperature was used to improve volatile separation. The initial oven temperature of 25 °C was held for 5 min. After that, the oven temperature was increased to 85 °C at 40 °C per min, increased to 165 °C at 20 °C per min, and then increased to 230 °C at 5 °C per min and held for 2.5 min at the temperature. Constant column pressure at 22.5 psi was maintained. The ionization potential of MS was 70 eV, and the scan range was 20.1–350 m/z. The identification of volatiles was achieved by the Wiley Library (Hewlett-Packard Co., Wilmington, DE, USA). The area of each peak was integrated using ChemStation™ software (Hewlett-Packard Co., Wilmington, DE, USA), and the total peak area (total ion counts × 10

4) was reported as an indicator of volatiles generated from the samples.

2.5. Protein Oxidation (Total Carbonyl)

Protein oxidation was determined by the method by Lund

et al. [

33] with minor modifications. One gram of meat sample was added to 10 mL of pyrophosphate buffer (2.0 mM Na

4P

2O

7, 10 mM Trizma-maleate), 100 mM KCL, 2.0 mM MgCl

2, and 2.0 mM ethylene glycol tetraacetic acid, pH 7.4) and homogenized using a Brinkman Polytron (Type PT 10/35). Two equal amounts of meat homogenate (2 mL) were taken from a sample, precipitated with 2 mL of 20% trichloroacetic acid, and centrifuged at 12,000×

g for 5 min at room temperature. After centrifugation, one of the pellets was dissolved with 2 mL of 10 mM 2,4-dinitrophenylhydrazine in 2 M HCl and the other one was dissolved with 2 M HCl (blank), and were incubated for 30 min in the dark. During the incubation, the samples were vortex-mixed for 10 s every 3 min. The protein was further precipitated with 2 mL of 20% trichloroacetic acid and centrifuged at 12,000×

g for 5 min. The 2,4-dinitrophenylhydrazine was removed by washing the pellets 3 times with 4 mL of 10 mM HCl in 1:1 (vol/vol) ethanol:ethyl acetate, followed by centrifuging at 12,000×

g for 5 min. The pellets were finally solubilized in 2 mL of 6.0 mM guanidine hydrochloride dissolved in 20 mM potassium dihydrogen phosphate (pH = 2.3). The samples were kept at 5 °C overnight and centrifuged to remove insoluble materials. The absorbance of supernatants was read at 370 nm and the value of blank sample was subtracted from their corresponding sample value. The protein concentration of meat samples was measured using Protein Assay Kit (Bio-Rad Laboratories, Hercules, CA, USA) following Microplate Assay protocol at 280 nm (BioTek-Gen5 Microplate data collection & analysis software/BioTek Instruments, Inc., Model S4MLFPTA, Winooski, VT, USA). The carbonyl content was calculated as nmol/mg protein using absorption coefficient of 22,000/M/cm as described by Levine

et al. [

34].

2.6. Statistical Analysis

Data were analyzed using the procedures of the generalized linear model (Proc. GLM, SAS program, version 9.3, 2012, SAS Institute Inc., Cary, NC, USA) [

35]. Mean values and standard error of the means (SEM) were reported. The significance was defined at

p < 0.05 and Tukey or Tukey’s Multiple Range tests were used to determine whether there is a significant difference between the mean values.