Agricultural Greenhouses: Resource Management Technologies and Perspectives for Zero Greenhouse Gas Emissions

Abstract

:1. Introduction

- i.

- To provide a background on the current levels of energy consumption in agricultural production with a particular focus on greenhouses.

- ii.

- To provide an overview of the literature on the energy-saving techniques used in greenhouse agricultural production.

- iii.

- To map the literature on the efficient energy storage systems that can be used in greenhouse agricultural production.

- iv.

- To provide an overview of promising sustainable and environmentally friendly prospects for the development of agriculture greenhouses to reduce their energy consumption and associated greenhouse gas emissions.

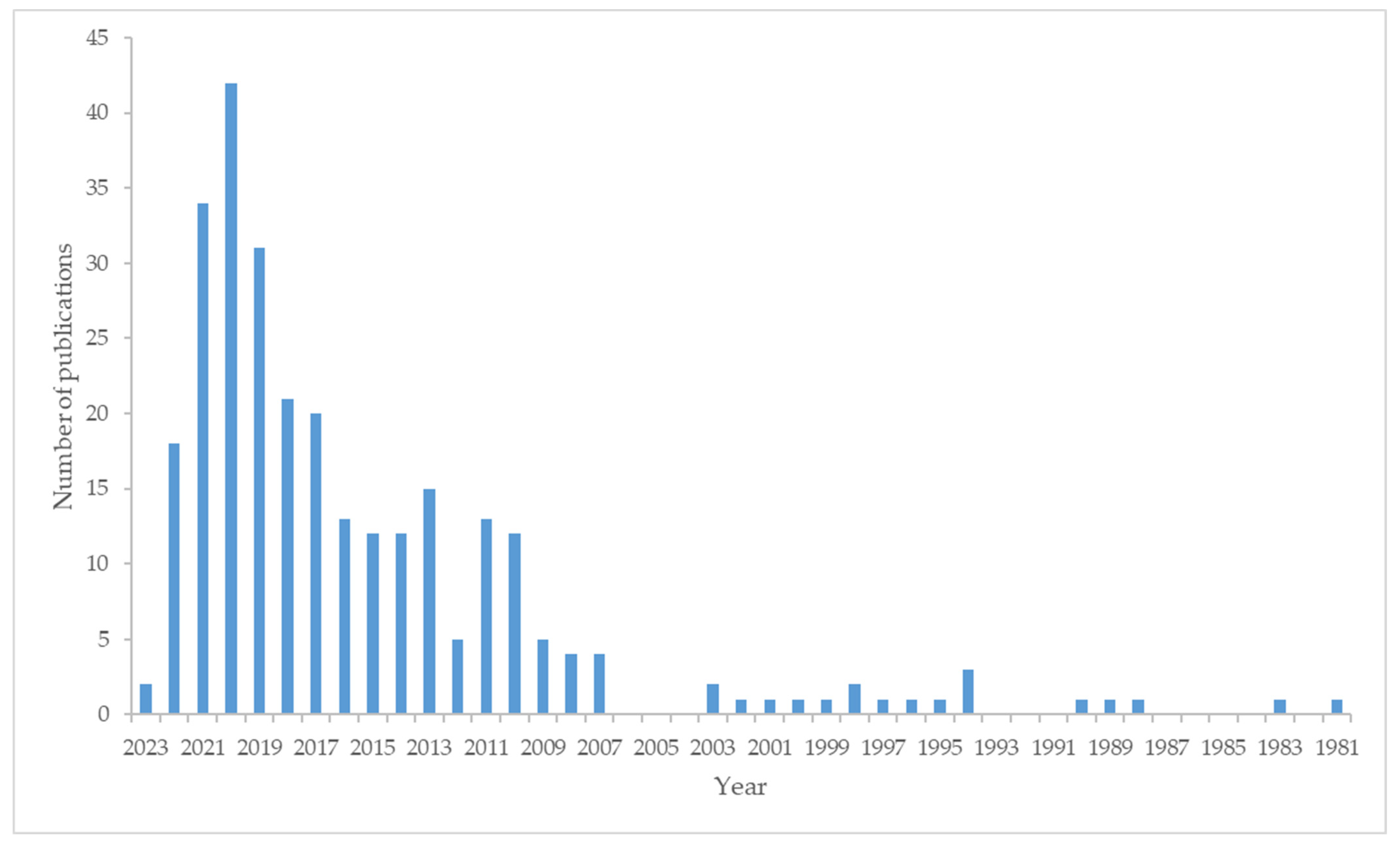

2. Methods

2.1. Eligibility Criteria

2.2. Information Sources

2.3. Search Strategy

2.4. Selection Process

2.5. Data Collection Process

2.6. Data Items

2.7. Synthesis Methods

2.8. Study Selection

3. Greenhouses

3.1. Conventional Greenhouses

3.2. Energy Consumption of Conventional Greenhouses

3.3. Interaction between Greenhouses and the Environment

3.4. Zero-Energy Greenhouses and Energy Conservation

4. Energy-Saving Techniques for Greenhouses

4.1. Conventional Saving Techniques

4.2. Control Systems in Greenhouses

5. Renewable Energy Systems and Energy Storage Systems in Agricultural Greenhouses

5.1. Renewable Energy Systems in Agricultural Greenhouses

5.2. Energy Storage Systems in Agricultural Greenhouses

5.3. Economic and Environmental Impact

6. Developments and Prospects

6.1. Intelligent Shading Systems

6.2. IoT Systems for the Optimization of Greenhouse Structures

6.3. Sensors and AI Systems for the Optimization of Greenhouse Covers

6.4. Smart Glass Systems

7. Reduction of CO2 Emissions through Carbon Sequestration (Carbon Capture and Storage)

7.1. The Optimized Environment in Greenhouses and Achievement of Zero CO2 Emissions

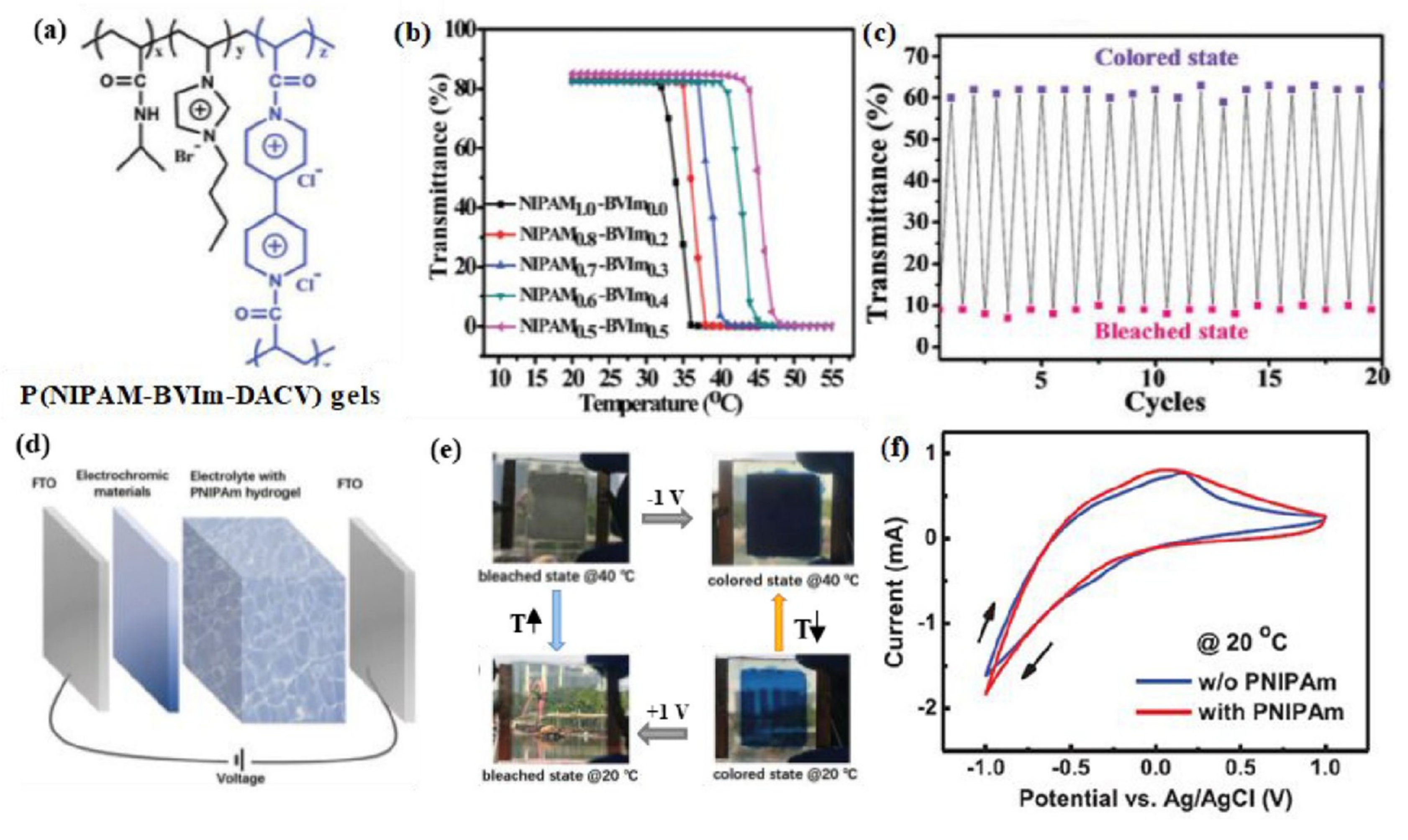

7.2. Graphene–Oxide (GO) Hydrogels

7.3. Integrated Interventions: Plant-Based CO2 Reduction Using Biofuels, and IT Tools

8. Discussion

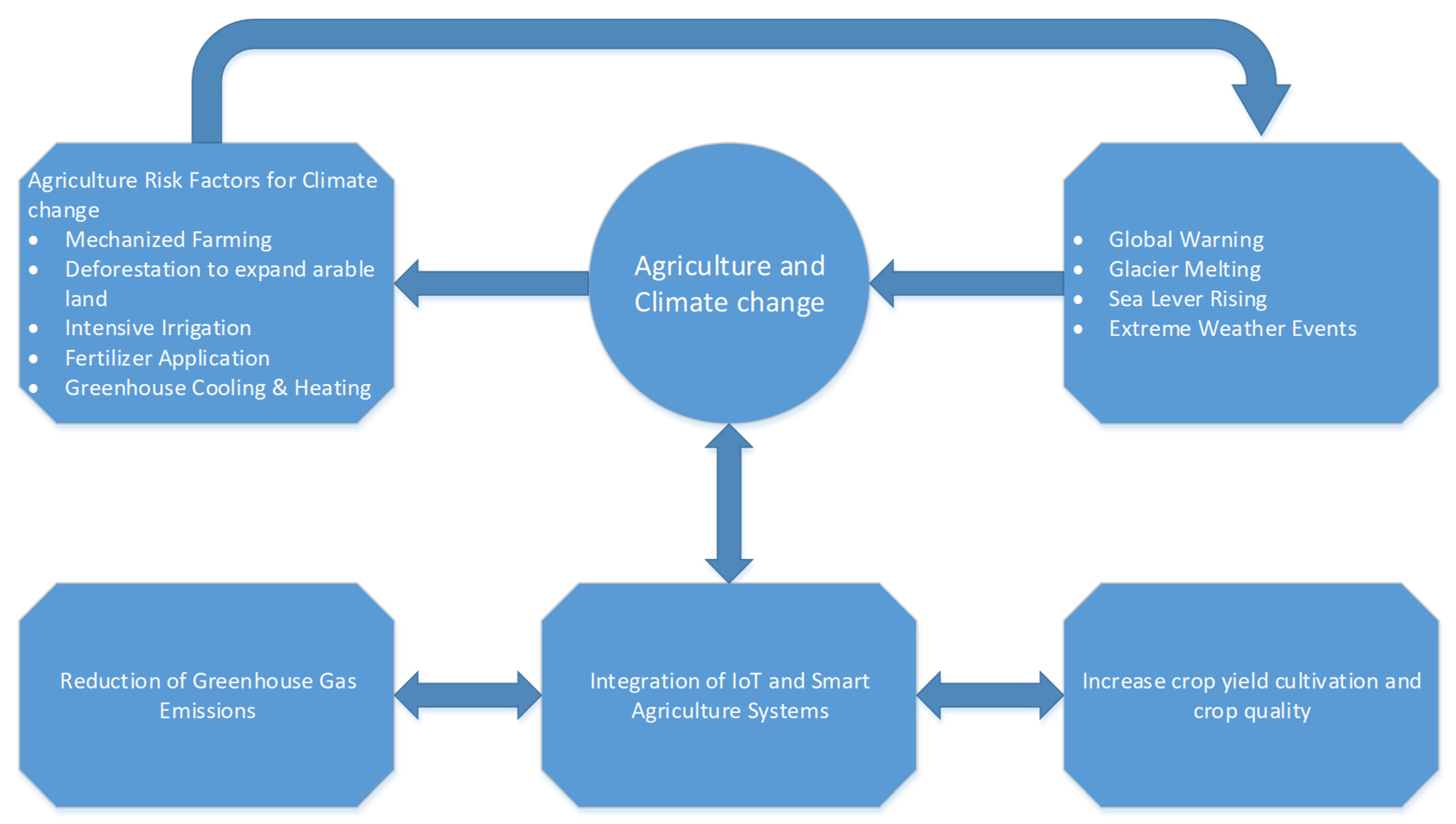

8.1. Environmental Benefits and Climate Change’s Effects on Agriculture

8.2. Future Research Agenda

9. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Khudoyberdiev, A.; Ullah, I.; Kim, D. Optimization-assisted water supplement mechanism with energy efficiency in IoT based greenhouse. J. Intell. Fuzzy Syst. 2021, 40, 10163–10182. [Google Scholar] [CrossRef]

- Bersani, C.; Ouammi, A.; Sacile, R.; Zero, E. Model predictive control of smart greenhouses as the path towards near zero energy consumption. Energies 2020, 13, 3647. [Google Scholar] [CrossRef]

- Baudoin, W.; Nono-Womdim, R.; Lutaladio, N.; Hodder, A.; Castilla, N.; Leonardi, C.; De Pascale, S.; Qaryouti, M.; Duffy, R. Good Agricultural Practices for Greenhouse Vegetable Crops: Principles for Mediterranean Climate Areas; FAO Plant Production and Protection Paper (FAO) No 217; Food and Agriculture Organization: Rome, Italy, 2013; Available online: https://www.fao.org/3/i3284e/i3284e.pdf (accessed on 21 January 2023).

- Gołasa, P.; Wysokiński, M.; Bieńkowska-Gołasa, W.; Gradziuk, P.; Golonko, M.; Gradziuk, B.; Siedlecka, A.; Gromada, A. Sources of greenhouse gas emissions in agriculture, with particular emphasis on emissions from energy used. Energies 2021, 14, 3784. [Google Scholar] [CrossRef]

- Muñoz-Liesa, J.; Royapoor, M.; Cuerva, E.; Gassó-Domingo, S.; Gabarrell, X.; Josa, A. Building-integrated greenhouses raise energy co-benefits through active ventilation systems. Build. Environ. 2022, 208, 108585. [Google Scholar] [CrossRef]

- Morci, H.A.; Elmulthum, N.; Hadid, M. The role of greenhouses in filling trade gap of tomato crop in Saudi Arabia. Egypt. J. Agron. 2020, 42, 197–207. [Google Scholar] [CrossRef]

- Ruijs, M.; Benninga, J. Market Potential and Investment Opportunities of High-Tech Greenhouse Vegetable Production in the USA: An Exploratory Study for Midwest and East Coast Regions and the State of California; Wageningen University & Research: Wageningen, The Netherlands, 2020. [Google Scholar]

- Xue, J. Economic assessment of photovoltaic greenhouses in China. J. Renew. Sustain. Energy 2017, 9, 033502. [Google Scholar] [CrossRef]

- Araghi, Y.; Dijkema, G.P. Alternative Energy Sources and Energy Infrastructure for Dutch Greenhouses—Investigating Growers’ Preferences. In Proceedings of the 2014 International Symposium for Next Generation Infrastructure Conference, Vienna, Austria, 30 September–1 October 2014. [Google Scholar]

- Wells, L.; Rismanchi, B.; Aye, L. A review of Net Zero Energy Buildings with reflections on the Australian context. Energy Build. 2018, 158, 616–628. [Google Scholar] [CrossRef]

- Wiik, M.K.; Fufa, S.M.; Kristjansdottir, T.; Andresen, I. Lessons learnt from embodied GHG emission calculations in zero emission buildings (ZEBs) from the Norwegian ZEB research centre. Energy Build. 2018, 165, 25–34. [Google Scholar] [CrossRef]

- Feng, W.; Zhang, Q.; Ji, H.; Wang, R.; Zhou, N.; Ye, Q.; Hao, B.; Li, Y.; Luo, D.; Lau, S.S.Y. A review of net zero energy buildings in hot and humid climates: Experience learned from 34 case study buildings. Renew. Sustain. Energy Rev. 2019, 114, 109303. [Google Scholar] [CrossRef]

- Zulauf, C.; Brown, B. Cover crops, 2017 US census of agriculture. Farmdoc Dly. 2019, 9, 135. [Google Scholar]

- Canakci, M.; Emekli, N.Y.; Bilgin, S.; Caglayan, N. Heating requirement and its costs in greenhouse structures: A case study for Mediterranean region of Turkey. Renew. Sustain. Energy Rev. 2013, 24, 483–490. [Google Scholar] [CrossRef]

- Hossard, L.; Philibert, A.; Bertrand, M.; Colnenne-David, C.; Debaeke, P.; Munier-Jolain, N.; Jeuffroy, M.H.; Richard, G.; Makowski, D. Effects of halving pesticide use on wheat production. Sci. Rep. 2014, 4, 4405. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Chauhan, Y.K.; Ratan, R. Study on placement of sensors for readings accuracy level enhancement in greenhouse. In Applications of Computing, Automation and Wireless Systems in Electrical Engineering; Lecture Notes in Electrical Engineering; Springer: Singapore, 2019; pp. 245–254. [Google Scholar]

- Zhao, C.; Chavan, S.; He, X.; Zhou, M.; Cazzonelli, C.I.; Chen, Z.-H.; Tissue, D.T.; Ghannoum, O. Smart glass impacts stomatal sensitivity of greenhouse Capsicum through altered light. J. Exp. Bot. 2021, 72, 3235–3248. [Google Scholar] [CrossRef]

- Hunt, J.D.; Byers, E. Reducing sea level rise with submerged barriers and dams in Greenland. Mitig. Adapt. Strateg. Glob. Change 2019, 24, 779–794. [Google Scholar] [CrossRef] [Green Version]

- Breyer, C.; Fasihi, M.; Aghahosseini, A. Carbon dioxide direct air capture for effective climate change mitigation based on renewable electricity: A new type of energy system sector coupling. Mitig. Adapt. Strateg. Glob. Change 2020, 25, 43–65. [Google Scholar] [CrossRef] [Green Version]

- Pomarici, E.; Sardone, R. EU wine policy in the framework of the CAP: Post-2020 challenges. Agric. Food Econ. 2020, 8, 17. [Google Scholar] [CrossRef]

- García-Mañas, F.; Rodríguez, F.; Berenguel, M. Leaf area index soft sensor for tomato crops in greenhouses. IFAC-PapersOnLine 2020, 53, 15796–15803. [Google Scholar] [CrossRef]

- DeLay, N.D.; Thompson, N.M.; Mintert, J.R. Precision agriculture technology adoption and technical efficiency. J. Agric. Econ. 2022, 73, 195–219. [Google Scholar] [CrossRef]

- Acosta-Silva, Y.d.J.; Torres-Pacheco, I.; Matsumoto, Y.; Toledano-Ayala, M.; Soto-Zarazúa, G.M.; Zelaya-Ángel, O.; Méndez-López, A. Applications of solar and wind renewable energy in agriculture: A review. Sci. Prog. 2019, 102, 127–140. [Google Scholar] [CrossRef]

- Ahamed, M.S.; Guo, H.; Tanino, K. Energy saving techniques for reducing the heating cost of conventional greenhouses. Biosyst. Eng. 2019, 178, 9–33. [Google Scholar] [CrossRef]

- Cuce, E.; Harjunowibowo, D.; Cuce, P.M. Renewable and sustainable energy saving strategies for greenhouse systems: A comprehensive review. Renew. Sustain. Energy Rev. 2016, 64, 34–59. [Google Scholar] [CrossRef]

- Bibbiani, C.; Fantozzi, F.; Gargari, C.; Campiotti, C.A.; Schettini, E.; Vox, G. Wood biomass as sustainable energy for greenhouses heating in Italy. Agric. Agric. Sci. Procedia 2016, 8, 637–645. [Google Scholar] [CrossRef]

- Taki, M.; Ajabshirchi, Y.; Mobtaker, H.G.; Abdi, R. Energy consumption, input-output relationship and cost analysis for greenhouse productions in Esfahan province of Iran. Am. J. Exp. Agric. 2012, 2, 485–501. [Google Scholar] [CrossRef]

- Djevic, M.; Dimitrijevic, A. Energy consumption for different greenhouse constructions. Energy 2009, 34, 1325–1331. [Google Scholar] [CrossRef]

- Vadiee, A.; Martin, V. Energy management strategies for commercial greenhouses. Appl. Energy 2014, 114, 880–888. [Google Scholar] [CrossRef]

- Pahlavan, R.; Omid, M.; Akram, A. The relationship between energy inputs and crop yield in greenhouse basil production. J. Agric. Sci. Technol. 2012, 14, 1243–1253. [Google Scholar]

- Maraveas, C. Environmental sustainability of greenhouse covering materials. Sustainability 2019, 11, 6129. [Google Scholar] [CrossRef] [Green Version]

- Maraveas, C.; Bartzanas, T. Application of Internet of Things (IoT) for optimized greenhouse environments. AgriEngineering 2021, 3, 954–970. [Google Scholar] [CrossRef]

- Ihoume, I.; Tadili, R.; Arbaoui, N.; Bazgaou, A.; Idrissi, A.; Benchrifa, M.; Fatnassi, H. Performance study of a sustainable solar heating system based on a copper coil water to air heat exchanger for greenhouse heating. Sol. Energy 2022, 232, 128–138. [Google Scholar] [CrossRef]

- Wall, W.P.; Khalid, B.; Urbański, M.; Kot, M. Factors influencing consumer’s adoption of renewable energy. Energies 2021, 14, 5420. [Google Scholar] [CrossRef]

- Fiorito, F.; Sauchelli, M.; Arroyo, D.; Pesenti, M.; Imperadori, M.; Masera, G.; Ranzi, G. Shape morphing solar shadings: A review. Renew. Sustain. Energy Rev. 2016, 55, 863–884. [Google Scholar] [CrossRef] [Green Version]

- Alves, M.; Pérez-Rodríguez, A.; Dale, P.J.; Domínguez, C.; Sadewasser, S. Thin-film micro-concentrator solar cells. J. Phys. Energy 2019, 2, 012001. [Google Scholar] [CrossRef]

- Chen, C.-J.; Huang, Y.-Y.; Li, Y.-S.; Chang, C.-Y.; Huang, Y.-M. An AIoT based smart agricultural system for pests detection. IEEE Access 2020, 8, 180750–180761. [Google Scholar] [CrossRef]

- Zhou, Y.; Dong, X.; Mi, Y.; Fan, F.; Xu, Q.; Zhao, H.; Wang, S.; Long, Y. Hydrogel smart windows. J. Mater. Chem. A 2020, 8, 10007–10025. [Google Scholar] [CrossRef]

- Lee, K.; Um, H.-D.; Choi, D.; Park, J.; Kim, N.; Kim, H.; Seo, K. The development of transparent photovoltaics. Cell Rep. Phys. Sci. 2020, 1, 100143. [Google Scholar] [CrossRef]

- Latimer, J.G. Dealing with the High Cost of Energy for Greenhouse Operations; Publication 430-101; Virginia Tech University: Blacksburg, VA, USA, 2009; Available online: https://www.pubs.ext.vt.edu/content/dam/pubs_ext_vt_edu/430/430-101/HORT-284.pdf (accessed on 29 January 2023).

- Fowler, P.; Bucklin, R.; Baird, C.; Chapman, F.; Watson, C. Comparison of Energy Needed to Heat Greenhouses and Insulated Frame Buildings Used in Aquaculture; University of Florida, Institute of Food and Agricultural Sciences: Gainesville, FL, USA, 2021; Available online: https://edis.ifas.ufl.edu/publication/AA212 (accessed on 27 January 2023).

- Sonneveld, P.; Swinkels, G.; Campen, J.; Van Tuijl, B.; Janssen, H.; Bot, G. Performance results of a solar greenhouse combining electrical and thermal energy production. Biosyst. Eng. 2010, 106, 48–57. [Google Scholar] [CrossRef]

- Bontsema, J.; Van Henten, E.; Gieling, T.H.; Swinkels, G. The effect of sensor errors on production and energy consumption in greenhouse horticulture. Comput. Electron. Agric. 2011, 79, 63–66. [Google Scholar] [CrossRef]

- Wu, G.; Yang, Q.; Zhang, Y.; Fang, H.; Feng, C.; Zheng, H. Energy and optical analysis of photovoltaic thermal integrated with rotary linear curved Fresnel lens inside a Chinese solar greenhouse. Energy 2020, 197, 117215. [Google Scholar] [CrossRef]

- Anjali, J.; Jose, V.K.; Lee, J.-M. Carbon-based hydrogels: Synthesis and their recent energy applications. J. Mater. Chem. A 2019, 7, 15491–15518. [Google Scholar] [CrossRef]

- Latter, B.; Capstick, S. Climate emergency: UK universities’ declarations and their role in responding to climate change. Front. Sustain. 2021, 2, 660596. [Google Scholar] [CrossRef]

- Gassner, A.; Coe, R.; Sinclair, F. Improving food security through increasing the precision of agricultural development. In Precision Agriculture for Sustainability and Environmental Protection; Taylor & Francis: Abingdon, UK, 2013. [Google Scholar]

- Hall, R.; Scoones, I.; Tsikata, D. Plantations, outgrowers and commercial farming in Africa: Agricultural commercialisation and implications for agrarian change. J. Peasant. Stud. 2017, 44, 515–537. [Google Scholar] [CrossRef] [Green Version]

- Withers, P.J.A.; Hodgkinson, R.A.; Rollett, A.; Dyer, C.; Dils, R.; Collins, A.L.; Bilsborrow, P.E.; Bailey, G.; Sylvester-Bradley, R. Reducing soil phosphorus fertility brings potential long-term environmental gains: A UK analysis. Environ. Res. Lett. 2017, 12, 063001. [Google Scholar] [CrossRef] [Green Version]

- World Bank. Climate-Smart Agriculture (CSA). 2020. Available online: https://www.worldbank.org/en/topic/climate-smart-agriculture (accessed on 27 January 2023).

- Chastas, P.; Theodosiou, T.; Kontoleon, K.J.; Bikas, D. Normalising and assessing carbon emissions in the building sector: A review on the embodied CO2 emissions of residential buildings. Build. Environ. 2018, 130, 212–226. [Google Scholar] [CrossRef]

- Chi, Y.; Yang, P.; Ren, S.; Ma, N.; Yang, J.; Xu, Y. Effects of fertilizer types and water quality on carbon dioxide emissions from soil in wheat-maize rotations. Sci. Total Environ. 2020, 698, 134010. [Google Scholar] [CrossRef]

- Radicetti, E.; Campiglia, E.; Langeroodi, A.S.; Zsembeli, J.; Mendler-Drienyovszki, N.; Mancinelli, R. Soil carbon dioxide emissions in eggplants based on cover crop residue management. Nutr. Cycl. Agroecosyst. 2020, 118, 39–55. [Google Scholar] [CrossRef]

- Della Lunga, D.; Brye, K.R.; Slayden, J.M.; Henry, C.G.; Wood, L.S. Relationships among soil factors and greenhouse gas emissions from furrow-irrigated rice in the mid-southern, USA. Geoderma Reg. 2021, 24, e00365. [Google Scholar] [CrossRef]

- Sanz-Pérez, E.S.; Murdock, C.R.; Didas, S.A.; Jones, C.W. Direct capture of CO2 from ambient air. Chem. Rev. 2016, 116, 11840–11876. [Google Scholar] [CrossRef]

- Bao, J.; Lu, W.-H.; Zhao, J.; Bi, X.T. Greenhouses for CO2 sequestration from atmosphere. Carbon Resour. Convers. 2018, 1, 183–190. [Google Scholar] [CrossRef]

- US Environmental Protection Agency. Sources of Greenhouse Gas Emissions. 2018. Available online: https://www.epa.gov/ghgemissions/sources-greenhouse-gas-emissions (accessed on 17 January 2023).

- Sivasankari, A.; Gandhimathi, S. Wireless sensor based crop monitoring system for agriculture using Wi-Fi network dissertation. Int. J. Comput. Sci. Inf. Technol. Res. 2014, 2, 293–303. [Google Scholar]

- Pellegrini, P.; Fernández, R.J. Crop intensification, land use, and on-farm energy-use efficiency during the worldwide spread of the green revolution. Proc. Natl. Acad. Sci. USA 2018, 115, 2335–2340. [Google Scholar] [CrossRef] [Green Version]

- Villa-Henriksen, A.; Edwards, G.T.; Pesonen, L.A.; Green, O.; Sørensen, C.A.G. Internet of Things in arable farming: Implementation, applications, challenges and potential. Biosyst. Eng. 2020, 191, 60–84. [Google Scholar] [CrossRef]

- López-Valdez, F.; Fernández-Luqueño, F.; Pérez-Morales, C.; Miranda-Arámbula, M. Greenhouse Gases Production from Some Crops Growing Under Greenhouse Conditions. In Greenhouse Gases; IntechOpen: London, UK, 2016. [Google Scholar]

- Yamaka, W.; Phadkantha, R.; Rakpho, P. Economic and energy impacts on greenhouse gas emissions: A case study of China and the USA. Energy Rep. 2021, 7, 240–247. [Google Scholar] [CrossRef]

- US Energy Information Administration. EIA Projects Nearly 50% Increase in World Energy Usage by 2050, Led by Growth in Asia. 2018. Available online: https://www.eia.gov/todayinenergy/detail.php?id=41433 (accessed on 29 January 2023).

- Fitton, N.; Alexander, P.; Arnell, N.; Bajzelj, B.; Calvin, K.; Doelman, J.; Gerber, J.S.; Havlik, P.; Hasegawa, T.; Herrero, M.; et al. The vulnerabilities of agricultural land and food production to future water scarcity. Glob. Environ. Change 2019, 58, 101944. [Google Scholar] [CrossRef]

- US Energy Information Administration. How Much Carbon Dioxide Is Produced when Different Fuels Are Burned. 2013. Available online: https://www.eia.gov/tools/faqs/faq.php?id=73&t=11 (accessed on 27 January 2023).

- Katanbafnasab, M.; Abu-Hijleh, B. Assessment of the energy impact of using building integrated photovoltaic and electrochromic glazing in office building in UAE. Engineering 2013, 5, 56. [Google Scholar] [CrossRef]

- Eurostats. Renewable Energy Statistics. 2018. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php?title=Renewable_energy_statistics (accessed on 17 January 2023).

- Gornall, J.; Betts, R.; Burke, E.; Clark, R.; Camp, J.; Willett, K.; Wiltshire, A. Implications of climate change for agricultural productivity in the early twenty-first century. Philos. Trans. R. Soc. B Biol. Sci. 2010, 365, 2973–2989. [Google Scholar] [CrossRef] [PubMed]

- Nagargade, M.; Tyagi, V.; Kumar, M. Climate smart agriculture: An option for changing climatic situation. In Plant Engineering; Jurić, S., Ed.; IntechOpen: London, UK, 2017; pp. 143–165. [Google Scholar] [CrossRef] [Green Version]

- Bayer, P.; Aklin, M. The European Union emissions trading system reduced CO2 emissions despite low prices. Proc. Natl. Acad. Sci. USA 2020, 117, 8804–8812. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Z. Crossing the river by feeling the stones: The case of carbon trading in China. Environ. Econ. Policy Stud. 2015, 17, 263–297. [Google Scholar] [CrossRef] [Green Version]

- Carbon Brief. How Much Flooding Is in the UK’s Future? A Look at the IPCC Report. 2014. Available online: https://www.carbonbrief.org/how-much-flooding-is-in-the-uks-future-a-look-at-the-ipcc-report/ (accessed on 27 January 2023).

- Sefton, C.; Muchan, K.; Parry, S.; Matthews, B.; Barker, L.; Turner, S.; Hannaford, J. The 2019/2020 floods in the UK: A hydrological appraisal. Weather 2021, 76, 378–384. [Google Scholar] [CrossRef]

- Wong, J.; Wang, X.; Li, H.; Chan, G. A review of cloud-based BIM technology in the construction sector. J. Inf. Technol. Constr. 2014, 19, 281–291. [Google Scholar]

- Antony, A.P.; Leith, K.; Jolley, C.; Lu, J.; Sweeney, D.J. A review of practice and implementation of the internet of things (IoT) for smallholder agriculture. Sustainability 2020, 12, 3750. [Google Scholar] [CrossRef]

- Scottish Government. NHS Scotland Climate Emergency and Sustainability Strategy 2022 to 2026—Draft: Consultation. 2022. Available online: https://www.gov.scot/publications/nhs-scotland-draft-climate-emergency-sustainability-strategy/ (accessed on 29 January 2023).

- Sivakumar, M.V.K. Interactions between climate and desertification. Agric. For. Meteorol. 2007, 142, 143–155. [Google Scholar] [CrossRef]

- Panwar, N.; Kaushik, S.; Kothari, S. Solar greenhouse an option for renewable and sustainable farming. Renew. Sustain. Energy Rev. 2011, 15, 3934–3945. [Google Scholar] [CrossRef]

- Sanford, S. Reducing Greenhouse Energy Consumption—An Overview. Available online: https://cdn.shopify.com/s/files/1/0145/8808/4272/files/A3907-01.pdf (accessed on 27 January 2023).

- Sahdev, R.K.; Kumar, M.; Dhingra, A.K. A comprehensive review of greenhouse shapes and its applications. Front. Energy 2019, 13, 427–438. [Google Scholar] [CrossRef]

- Ahamed, M.S.; Guo, H.; Tanino, K. Energy-efficient design of greenhouse for Canadian Prairies using a heating simulation model. Int. J. Energy Res. 2018, 42, 2263–2272. [Google Scholar] [CrossRef]

- Sethi, V.P. On the selection of shape and orientation of a greenhouse: Thermal modeling and experimental validation. Sol. Energy 2009, 83, 21–38. [Google Scholar] [CrossRef]

- Singh, R.; Tiwari, G. Energy conservation in the greenhouse system: A steady state analysis. Energy 2010, 35, 2367–2373. [Google Scholar] [CrossRef]

- Çakır, U.; Şahin, E. Using solar greenhouses in cold climates and evaluating optimum type according to sizing, position and location: A case study. Comput. Electron. Agric. 2015, 117, 245–257. [Google Scholar] [CrossRef]

- Mobtaker, H.G.; Ajabshirchi, Y.; Ranjbar, S.F.; Matloobi, M. Simulation of thermal performance of solar greenhouse in north-west of Iran: An experimental validation. Renew. Energy 2019, 135, 88–97. [Google Scholar] [CrossRef]

- Gupta, A.; Tiwari, G. Computer model and its validation for prediction of storage effect of water mass in a greenhouse: A transient analysis. Energy Convers. Manag. 2002, 43, 2625–2640. [Google Scholar] [CrossRef]

- Papadakis, G.; Manolakos, D.; Kyritsis, S. Solar radiation transmissivity of a single-span greenhouse through measurements on scale models. J. Agric. Eng. Res. 1998, 71, 331–338. [Google Scholar] [CrossRef]

- Roberts, W.J. Glazing materials, structural design, and other factors affecting light transmission in greenhouses. In Proceedings of the GreenHouse Glazing and Solar Radiation Transmission Workshop, New Brunswick, NJ, USA, October 1998. [Google Scholar]

- Short, T.H.; Duyne, G. Naturally ventilated greenhouses for Mediterranean climates. In Strategies for Market Oriented Greenhouse Production; International Society for Horticultural Science: Leuven, Belgium, 1995; Volume 434, pp. 229–236. [Google Scholar] [CrossRef]

- Papadakis, G.; Briassoulis, D.; Scarascia Mugnozza, G.; Vox, G.; Feuilloley, P.; Stoffers, J.A. Review Paper (SE—Structures and Environment): Radiometric and Thermal Properties of, and Testing Methods for, Greenhouse Covering Materials. J. Agric. Eng. Res. 2000, 77, 7–38. [Google Scholar] [CrossRef]

- Dieleman, J.; Hemming, S. Energy saving: From engineering to crop management. In Proceedings of the International Symposium on High Technology for Greenhouse Systems: GreenSys2009, Quebec, QC, Canada, 14–19 June 2009; pp. 65–73. [Google Scholar]

- Kempkes, F.; Janse, J.; Hemming, S. Greenhouse concept with high insulating double glass with coatings and new climate control strategies; from design to results from tomato experiments. In Proceedings of the International Symposium on New Technologies for Environment Control, Energy-Saving and Crop Production in Greenhouse and Plant, Jeju, Republic of Korea, 6–11 October 2013; pp. 83–92. [Google Scholar]

- Hemming, S.; Kempkes, F.; Janse, J. New greenhouse concept with high insulating double glass and new climate control strategies-Modelling and first results from a cucumber experiment. In Proceedings of the International Symposium on Advanced Technologies and Management Towards Sustainable Greenhouse Ecosystems: Greensys2011, Neos Marmaras, Greece, 5–10 June 2011; pp. 231–239. [Google Scholar]

- Rasheed, A.; Na, W.H.; Lee, J.W.; Kim, H.T.; Lee, H.W. Optimization of greenhouse thermal screens for maximized energy conservation. Energies 2019, 12, 3592. [Google Scholar] [CrossRef] [Green Version]

- Andersson, N. Properties of thermal screens used for energy saving in greenhouses. In Proceedings of the International Conference on Agricultural Engineering—AgEng 2010: Towards Environmental Technologies, Clermont-Ferrand, France, 6–8 September 2010. [Google Scholar]

- Short, T.H.; Shah, S.A. A portable polystyrene-pellet insulation system for greenhouses. Trans. ASAE 1981, 24, 1291–1295. [Google Scholar] [CrossRef]

- Hepbasli, A. A comparative investigation of various greenhouse heating options using exergy analysis method. Appl. Energy 2011, 88, 4411–4423. [Google Scholar] [CrossRef]

- Sanford, S. Greenhouse unit heaters—Types, placement, & efficiency. Energy 2008, 3907, 2. [Google Scholar]

- Yang, S.-H.; Lee, C.G.; Ashtiani-Araghi, A.; Kim, J.Y.; Rhee, J.Y. Heat gain and contribution to heating from supplemental lighting in greenhouse. Eng. Agric. Environ. Food 2015, 8, 67–71. [Google Scholar] [CrossRef]

- Ahamed, M.S.; Guo, H.; Tanino, K. A quasi-steady state model for predicting the heating requirements of conventional greenhouses in cold regions. Inf. Process. Agric. 2018, 5, 33–46. [Google Scholar] [CrossRef]

- Brault, D.; Gueymard, C.; Boily, R.; Gosselin, A. Contribution of HPS Lighting to the Heating Requirements of a Greenhouse; American Society of Agricultural Engineers (USA): St. Joseph, MI, USA, 1989. [Google Scholar]

- Zakaria, F.; Radwan, M.; Sadek, M.; Elazab, H.A. Insulating material based on shredded used tires and inexpensive polymers for different roofs. Int. J. Eng. Technol. (UAE) 2018, 7, 1983–1988. [Google Scholar] [CrossRef]

- Abu-Jdayil, B.; Mourad, A.-H.; Hittini, W.; Hassan, M.; Hameedi, S. Traditional, state-of-the-art and renewable thermal building insulation materials: An overview. Constr. Build. Mater. 2019, 214, 709–735. [Google Scholar] [CrossRef]

- Rabbat, C.; Awad, S.; Villot, A.; Rollet, D.; Andrès, Y. Sustainability of biomass-based insulation materials in buildings: Current status in France, end-of-life projections and energy recovery potentials. Renew. Sustain. Energy Rev. 2022, 156, 111962. [Google Scholar] [CrossRef]

- Akpenpuun, T.D.; Na, W.H.; Ogunlowo, Q.O.; Rabiu, A.; Adesanya, M.A.; Addae, K.S.; Kim, H.T.; Lee, H.W. Effect of glazing configuration as an energy-saving strategy in naturally ventilated greenhouses for strawberry (Seolhyang sp.) cultivation. J. Agric. Eng. 2021, 52, 2. [Google Scholar] [CrossRef]

- Max, J.F.; Reisinger, G.; Hofmann, T.; Hinken, J.; Tantau, H.-J.; Ulbrich, A.; Lambrecht, S.; von Elsner, B.; Schurr, U. Glass–film-combination: Opto-physical properties and energy saving potential of a novel greenhouse glazing system. Energy Build. 2012, 50, 298–307. [Google Scholar] [CrossRef]

- Lu, L.; Ya’acob, M.E.; Anuar, M.S.; Mohtar, M.N. Comprehensive review on the application of inorganic and organic photovoltaics as greenhouse shading materials. Sustain. Energy Technol. Assess. 2022, 52, 102077. [Google Scholar] [CrossRef]

- Abdel-Ghany, A.M.; Al-Helal, I.M.; Alzahrani, S.M.; Alsadon, A.A.; Ali, I.M.; Elleithy, R.M. Covering materials incorporating radiation-preventing techniques to meet greenhouse cooling challenges in arid regions: A review. Sci. World J. 2012, 2012, 906360. [Google Scholar] [CrossRef] [PubMed]

- Ghani, S.; Bakochristou, F.; ElBialy, E.M.A.A.; Gamaledin, S.M.A.; Rashwan, M.M.; Abdelhalim, A.M.; Ismail, S.M. Design challenges of agricultural greenhouses in hot and arid environments—A review. Eng. Agric. Environ. Food 2019, 12, 48–70. [Google Scholar] [CrossRef]

- Ganguly, A.; Ghosh, S. A review of ventilation and cooling technologies in agricultural greenhouse application. Iran. J. Energy Environ. 2011, 2, 32–46. [Google Scholar]

- Akrami, M.; Salah, A.H.; Javadi, A.A.; Fath, H.E.; Hassanein, M.J.; Farmani, R.; Dibaj, M.; Negm, A. Towards a sustainable greenhouse: Review of trends and emerging practices in analysing greenhouse ventilation requirements to sustain maximum agricultural yield. Sustainability 2020, 12, 2794. [Google Scholar] [CrossRef] [Green Version]

- Akrami, M.; Javadi, A.A.; Hassanein, M.J.; Farmani, R.; Dibaj, M.; Tabor, G.R.; Negm, A. Study of the effects of vent configuration on mono-span greenhouse ventilation using computational fluid dynamics. Sustainability 2020, 12, 986. [Google Scholar] [CrossRef] [Green Version]

- Bozchalui, M.C.; Canizares, C.A.; Bhattacharya, K. Optimal energy management of greenhouses in smart grids. IEEE Trans. Smart Grid 2014, 6, 827–835. [Google Scholar] [CrossRef]

- Shamshiri, R.R.; Kalantari, F.; Ting, K.; Thorp, K.R.; Hameed, I.A.; Weltzien, C.; Ahmad, D.; Shad, Z.M. Advances in greenhouse automation and controlled environment agriculture: A transition to plant factories and urban agriculture. Int. J. Agric. Biol. Eng. 2018, 11, 1–22. [Google Scholar] [CrossRef]

- Iddio, E.; Wang, L.; Thomas, Y.; McMorrow, G.; Denzer, A. Energy efficient operation and modeling for greenhouses: A literature review. Renew. Sustain. Energy Rev. 2020, 117, 109480. [Google Scholar] [CrossRef]

- Dan, L.; Xin, C.; Chongwei, H.; Liangliang, J. Intelligent agriculture greenhouse environment monitoring system based on IOT technology. In Proceedings of the 2015 IEEE International Conference on Intelligent Transportation, Big Data and Smart City, Halong Bay, Vietnam, 19–20 December 2015; pp. 487–490. [Google Scholar] [CrossRef]

- Maher, A.; Kamel, E.; Enrico, F.; Atif, I.; Abdelkader, M. An intelligent system for the climate control and energy savings in agricultural greenhouses. Energy Effic. 2016, 9, 1241–1255. [Google Scholar] [CrossRef]

- Afzali, S.; Mosharafian, S.; van Iersel, M.W.; Mohammadpour Velni, J. Development and implementation of an IoT-enabled optimal and predictive lighting control strategy in greenhouses. Plants 2021, 10, 2652. [Google Scholar] [CrossRef] [PubMed]

- Weaver, G.; van Iersel, M.W. Longer photoperiods with adaptive lighting control can improve growth of greenhouse-grown ‘Little Gem’ lettuce (Lactuca sativa). HortScience 2020, 55, 573–580. [Google Scholar] [CrossRef] [Green Version]

- Vatistas, C.; Avgoustaki, D.D.; Bartzanas, T. A Systematic Literature Review on Controlled-Environment Agriculture: How Vertical Farms and Greenhouses Can Influence the Sustainability and Footprint of Urban Microclimate with Local Food Production. Atmosphere 2022, 13, 1258. [Google Scholar] [CrossRef]

- Dion, L.-M.; Lefsrud, M.; Orsat, V. Review of CO2 recovery methods from the exhaust gas of biomass heating systems for safe enrichment in greenhouses. Biomass Bioenergy 2011, 35, 3422–3432. [Google Scholar] [CrossRef]

- Bergstrand, K.-J. Organic fertilizers in greenhouse production systems—A review. Sci. Hortic. 2022, 295, 110855. [Google Scholar] [CrossRef]

- Yuan, H.; Li, L.; Wang, J.; Wang, H.; NA, S. Design and test of regulation and control equipment for nutrient solution of water and fertilizer integration in greenhouse. Trans. Chin. Soc. Agric. Eng. 2016, 32, 27–32. [Google Scholar]

- Zhang, S.; Guo, Y.; Zhao, H.; Wang, Y.; Chow, D.; Fang, Y. Methodologies of control strategies for improving energy efficiency in agricultural greenhouses. J. Clean. Prod. 2020, 274, 122695. [Google Scholar] [CrossRef]

- Li, H.; Guo, Y.; Zhao, H.; Wang, Y.; Chow, D. Towards automated greenhouse: A state of the art review on greenhouse monitoring methods and technologies based on internet of things. Comput. Electron. Agric. 2021, 191, 106558. [Google Scholar] [CrossRef]

- Gong, L.; Yu, M.; Jiang, S.; Cutsuridis, V.; Pearson, S. Deep learning based prediction on greenhouse crop yield combined TCN and RNN. Sensors 2021, 21, 4537. [Google Scholar] [CrossRef]

- Ojo, M.O.; Zahid, A. Deep Learning in Controlled Environment Agriculture: A Review of Recent Advancements, Challenges and Prospects. Sensors 2022, 22, 7965. [Google Scholar] [CrossRef]

- Fuentes, A.; Yoon, S.; Kim, S.C.; Park, D.S. A robust deep-learning-based detector for real-time tomato plant diseases and pests recognition. Sensors 2017, 17, 2022. [Google Scholar] [CrossRef] [Green Version]

- Li, L.; Zhang, S.; Wang, B. Plant disease detection and classification by deep learning—A review. IEEE Access 2021, 9, 56683–56698. [Google Scholar] [CrossRef]

- Liu, J.; Wang, X. Plant diseases and pests detection based on deep learning: A review. Plant Methods 2021, 17, 22. [Google Scholar] [CrossRef]

- Eltawil, M.A.; Zhao, Z. Grid-connected photovoltaic power systems: Technical and potential problems—A review. Renew. Sustain. Energy Rev. 2010, 14, 112–129. [Google Scholar] [CrossRef]

- Hammam, M.; El-Mansy, M.; El-Bashir, S.; El-Shaarawy, M. Performance evaluation of thin-film solar concentrators for greenhouse applications. Desalination 2007, 209, 244–250. [Google Scholar] [CrossRef]

- Singh, R.K.; Berkvens, R.; Weyn, M. Energy efficient wireless communication for IoT enabled greenhouses. In Proceedings of the 2020 International Conference on COMmunication Systems & NETworkS (COMSNETS), Bengaluru, India, 7–11 January 2020; pp. 885–887. [Google Scholar] [CrossRef]

- Trypanagnostopoulos, G.; Kavga, A.; Souliotis, Μ.; Tripanagnostopoulos, Y. Greenhouse performance results for roof installed photovoltaics. Renew. Energy 2017, 111, 724–731. [Google Scholar] [CrossRef]

- Tiwari, G.; Mishra, R.; Solanki, S. Photovoltaic modules and their applications: A review on thermal modelling. Appl. Energy 2011, 88, 2287–2304. [Google Scholar] [CrossRef]

- Pérez-Alonso, J.; Pérez-García, M.; Pasamontes-Romera, M.; Callejón-Ferre, A.J. Performance analysis and neural modelling of a greenhouse integrated photovoltaic system. Renew. Sustain. Energy Rev. 2012, 16, 4675–4685. [Google Scholar] [CrossRef]

- Gorjian, S.; Calise, F.; Kant, K.; Ahamed, M.S.; Copertaro, B.; Najafi, G.; Zhang, X.; Aghaei, M.; Shamshiri, R.R. A review on opportunities for implementation of solar energy technologies in agricultural greenhouses. J. Clean. Prod. 2021, 285, 124807. [Google Scholar] [CrossRef]

- Marucci, A.; Monarca, D.; Colantoni, A.; Campiglia, E.; Cappuccini, A. Analysis of the internal shading in a photovoltaic greenhouse tunnel. J. Agric. Eng. 2017, 48, 154–160. [Google Scholar] [CrossRef] [Green Version]

- Cossu, M.; Yano, A.; Li, Z.; Onoe, M.; Nakamura, H.; Matsumoto, T.; Nakata, J. Advances on the semi-transparent modules based on micro solar cells: First integration in a greenhouse system. Appl. Energy 2016, 162, 1042–1051. [Google Scholar] [CrossRef] [Green Version]

- Hassanien, R.H.E.; Ming, L. Influences of greenhouse-integrated semi-transparent photovoltaics on microclimate and lettuce growth. Int. J. Agric. Biol. Eng. 2017, 10, 11–22. [Google Scholar] [CrossRef] [Green Version]

- Yano, A.; Kadowaki, M.; Furue, A.; Tamaki, N.; Tanaka, T.; Hiraki, E.; Kato, Y.; Ishizu, F.; Noda, S. Shading and electrical features of a photovoltaic array mounted inside the roof of an east–west oriented greenhouse. Biosyst. Eng. 2010, 106, 367–377. [Google Scholar] [CrossRef]

- Li, Z.; Yano, A.; Cossu, M.; Yoshioka, H.; Kita, I.; Ibaraki, Y. Electrical energy producing greenhouse shading system with a semi-transparent photovoltaic blind based on micro-spherical solar cells. Energies 2018, 11, 1681. [Google Scholar] [CrossRef] [Green Version]

- Yano, A.; Onoe, M.; Nakata, J. Prototype semi-transparent photovoltaic modules for greenhouse roof applications. Biosyst. Eng. 2014, 122, 62–73. [Google Scholar] [CrossRef] [Green Version]

- Marion, B.; MacAlpine, S.; Deline, C.; Asgharzadeh, A.; Toor, F.; Riley, D.; Stein, J.; Hansen, C. A practical irradiance model for bifacial PV modules. In Proceedings of the 2017 IEEE 44th Photovoltaic Specialist Conference (PVSC), Washington, DC, USA, 25–30 June 2017; pp. 1537–1542. [Google Scholar] [CrossRef]

- Gorjian, S.; Ebadi, H.; Calise, F.; Shukla, A.; Ingrao, C. A review on recent advancements in performance enhancement techniques for low-temperature solar collectors. Energy Convers. Manag. 2020, 222, 113246. [Google Scholar] [CrossRef]

- Semple, L.; Carriveau, R.; Ting, D.S.-K. A techno-economic analysis of seasonal thermal energy storage for greenhouse applications. Energy Build. 2017, 154, 175–187. [Google Scholar] [CrossRef]

- Vourdoubas, J. Overview of heating greenhouses with renewable energy sources a case study in Crete-Greece. J. Agric. Environ. Sci. 2015, 4, 70–76. [Google Scholar] [CrossRef] [Green Version]

- Papasolomontos, A.; Baudoin, W.; Lutaladio, N.; Castilla, N.; Baeza, E.; Montero, J.I.; Teitel, M.; Lopez, J.C.; Kacira, M.; Kittas, C.; et al. Regional Working Group on Greenhouse Crop Production in the Mediterranean Region: History and development. In Good Agricultural Practices for Greenhouse Vegetable Crops: Principles for Mediterranean Climate Areas; FAO Plant Production and Protection Paper (FAO) No 217; Food and Agriculture Organization: Rome, Italy, 2013; Available online: https://www.fao.org/3/i3284e/i3284e.pdf (accessed on 21 January 2023).

- Meinardi, F.; Bruni, F.; Brovelli, S. Luminescent solar concentrators for building-integrated photovoltaics. Nat. Rev. Mater. 2017, 2, 17072. [Google Scholar] [CrossRef]

- Nefedov, E.; Vyatkin, V. Decentralised coordination of intelligent autonomous batteries. In Proceedings of the 7th IFIP WG 5.5/SOCOLNET Advanced Doctoral Conference on Computing, Electrical and Industrial Systems (DoCEIS 2016), Costa de Caparica, Portugal, 11–13 April 2016; pp. 425–433. [Google Scholar]

- Slama, S.B. Prosumer in smart grids based on intelligent edge computing: A review on Artificial Intelligence Scheduling Techniques. Ain Shams Eng. J. 2022, 13, 101504. [Google Scholar] [CrossRef]

- Jawad, H.M.; Nordin, R.; Gharghan, S.K.; Jawad, A.M.; Ismail, M. Energy-efficient wireless sensor networks for precision agriculture: A review. Sensors 2017, 17, 1781. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Nam, M.; Noh, H.Y.; Kang, J.-H.; Cho, J.; Min, B.K.; Shim, J.W.; Ko, D.-H. Semi-transparent quaternary organic blends for advanced photovoltaic applications. Nano Energy 2019, 58, 652–659. [Google Scholar] [CrossRef]

- Ravishankar, E.; Booth, R.E.; Saravitz, C.; Sederoff, H.; Ade, H.W.; O’Connor, B.T. Achieving net zero energy greenhouses by integrating semitransparent organic solar cells. Joule 2020, 4, 490–506. [Google Scholar] [CrossRef]

- Ezzaeri, K.; Fatnassi, H.; Bouharroud, R.; Gourdo, L.; Bazgaou, A.; Wifaya, A.; Demrati, H.; Bekkaoui, A.; Aharoune, A.; Poncet, C.; et al. The effect of photovoltaic panels on the microclimate and on the tomato production under photovoltaic canarian greenhouses. Sol. Energy 2018, 173, 1126–1134. [Google Scholar] [CrossRef]

- Pascuzzi, S.; Anifantis, A.S.; Blanco, I.; Scarascia Mugnozza, G. Electrolyzer performance analysis of an integrated hydrogen power system for greenhouse heating. A case study. Sustainability 2016, 8, 629. [Google Scholar] [CrossRef] [Green Version]

- Bazgaou, A.; Fatnassi, H.; Bouharroud, R.; Elame, F.; Ezzaeri, K.; Gourdo, L.; Wifaya, A.; Demrati, H.; Tiskatine, R.; Bekkaoui, A.; et al. Performance assessment of combining rock-bed thermal energy storage and water filled passive solar sleeves for heating Canarian greenhouse. Sol. Energy 2020, 198, 8–24. [Google Scholar] [CrossRef]

- Ma, J. Direct wind heating greenhouse underground heating system. IOP Conf. Ser. Earth Environ. Sci. 2019, 300, 042056. [Google Scholar] [CrossRef]

- Abdellatif, S.M.; El Ashmawy, N.M.; El-Bakhaswan, M.K.; Tarabye, H.H. Hybird, solar and biomass energy system for heating greenhouse sweet coloured pepper. Adv. Res. 2016, 8, 1–21. [Google Scholar] [CrossRef]

- Gousgouriotis, I.J.; Katsigiannis, Y.A.; Georgilakis, P.S. Economic evaluation of biomass heating systems: A case of greenhouses in northern Greece. Oper. Res. 2007, 7, 83–104. [Google Scholar] [CrossRef]

- Sain, G.; Loboguerrero, A.M.; Corner-Dolloff, C.; Lizarazo, M.; Nowak, A.; Martínez-Barón, D.; Andrieu, N. Costs and benefits of climate-smart agriculture: The case of the Dry Corridor in Guatemala. Agric. Syst. 2017, 151, 163–173. [Google Scholar] [CrossRef]

- Sahraei, N.; Watson, S.; Sofia, S.; Pennes, A.; Buonassisi, T.; Peters, I.M. Persistent and adaptive power system for solar powered sensors of Internet of Things (IoT). Energy Procedia 2017, 143, 739–741. [Google Scholar] [CrossRef]

- Aguacil, S.; Lufkin, S.; Rey, E. Active surfaces selection method for building-integrated photovoltaics (BIPV) in renovation projects based on self-consumption and self-sufficiency. Energy Build. 2019, 193, 15–28. [Google Scholar] [CrossRef] [Green Version]

- Biyik, E.; Araz, M.; Hepbasli, A.; Shahrestani, M.; Yao, R.; Shao, L.; Essah, E.; Oliveira, A.C.; del Caño, T.; Rico, E.; et al. A key review of building integrated photovoltaic (BIPV) systems. Eng. Sci. Technol. Int. J. 2017, 20, 833–858. [Google Scholar] [CrossRef]

- Behzadi, A.; Arabkoohsar, A. Feasibility study of a smart building energy system comprising solar PV/T panels and a heat storage unit. Energy 2020, 210, 118528. [Google Scholar] [CrossRef]

- Han, F.; Chen, C.; Hu, Q.; He, Y.; Wei, S.; Li, C. Modeling method of an active–passive ventilation wall with latent heat storage for evaluating its thermal properties in the solar greenhouse. Energy Build. 2021, 238, 110840. [Google Scholar] [CrossRef]

- Al Dakheel, J.; Del Pero, C.; Aste, N.; Leonforte, F. Smart buildings features and key performance indicators: A review. Sustain. Cities Soc. 2020, 61, 102328. [Google Scholar] [CrossRef]

- Xu, J.; Wang, R.Z.; Li, Y. A review of available technologies for seasonal thermal energy storage. Sol. Energy 2014, 103, 610–638. [Google Scholar] [CrossRef]

- Paksoy, H.Ö.; Beyhan, B. Thermal energy storage (TES) systems for greenhouse technology. In Advances in Thermal Energy Storage Systems; Elsevier: Amsterdam, The Netherlands, 2015; pp. 533–548. [Google Scholar] [CrossRef]

- Piché, P.; Haillot, D.; Gibout, S.; Arrabie, C.; Lamontagne, M.-A.; Gilbert, V.; Bédécarrats, J.-P. Design, construction and analysis of a thermal energy storage system adapted to greenhouse cultivation in isolated northern communities. Sol. Energy 2020, 204, 90–105. [Google Scholar] [CrossRef]

- Bonte, M.; Stuyfzand, P.J.; Hulsmann, A.; Van Beelen, P. Underground thermal energy storage: Environmental risks and policy developments in the Netherlands and European Union. Ecol. Soc. 2011, 16, 22. [Google Scholar] [CrossRef] [Green Version]

- Turgut, B.; Dasgan, H.Y.; Abak, K.; Paksoy, H.; Evliya, H.; Bozdag, S. Aquifer thermal energy storage application in greenhouse climatization. In Proceedings of the International Symposium on Strategies Towards Sustainability of Protected Cultivation in Mild Winter Climate, Antalya, Turkey, 6–11 April 2008; pp. 143–148. [Google Scholar]

- Skarphagen, H.; Banks, D.; Frengstad, B.S.; Gether, H. Design considerations for borehole thermal energy storage (BTES): A review with emphasis on convective heat transfer. Geofluids 2019, 2019, 4961781. [Google Scholar] [CrossRef]

- Gether, K.; Gether, H.; Skarphagen, H.; Gether, J. Principles of saving energy with dynamic thermal storage. In ECEEE 2009 Summer Study on Energy Efficiency: Act! Innovate! Deliver! Reducing Energy Demand Sustainably; European Council for an Energy Efficient Economy: Brussels, Belgium, 2009; pp. 1541–1546. [Google Scholar]

- Vadiee, A.; Martin, V. Thermal energy storage strategies for effective closed greenhouse design. Appl. Energy 2013, 109, 337–343. [Google Scholar] [CrossRef]

- Kürklü, A.; Bilgin, S.; Özkan, B. A study on the solar energy storing rock-bed to heat a polyethylene tunnel type greenhouse. Renew. Energy 2003, 28, 683–697. [Google Scholar] [CrossRef]

- Bazgaou, A.; Fatnassi, H.; Bouhroud, R.; Gourdo, L.; Ezzaeri, K.; Tiskatine, R.; Demrati, H.; Wifaya, A.; Bekkaoui, A.; Aharoune, A.; et al. An experimental study on the effect of a rock-bed heating system on the microclimate and the crop development under canarian greenhouse. Sol. Energy 2018, 176, 42–50. [Google Scholar] [CrossRef]

- Öztürk, H.H.; Başçetinçelik, A. Effect of thermal screens on the microclimate and overall heat loss coefficient in plastic tunnel greenhouses. Turk. J. Agric. For. 2003, 27, 123–134. [Google Scholar]

- Mihalakakou, G.; Santamouris, M.; Asimakopoulos, D.; Papanikolaou, N. Impact of ground cover on the efficiencies of earth-to-air heat exchangers. Appl. Energy 1994, 48, 19–32. [Google Scholar] [CrossRef]

- Mihalakakou, G.; Santamouris, M.; Asimakopoulos, D. Modelling the thermal performance of earth-to-air heat exchangers. Sol. Energy 1994, 53, 301–305. [Google Scholar] [CrossRef]

- Santamouris, M.; Balaras, C.; Dascalaki, E.; Vallindras, M. Passive solar agricultural greenhouses: A worldwide classification and evaluation of technologies and systems used for heating purposes. Sol. Energy 1994, 53, 411–426. [Google Scholar] [CrossRef]

- Santamouris, M.; Mihalakakou, G.; Balaras, C.; Lewis, J.; Vallindras, M.; Argiriou, A. Energy conservation in greenhouses with buried pipes. Energy 1996, 21, 353–360. [Google Scholar] [CrossRef]

- Abhat, A. Low temperature latent heat thermal energy storage: Heat storage materials. Sol. Energy 1983, 30, 313–332. [Google Scholar] [CrossRef]

- Jaffrin, A.; Makhlouf, S. Solar greenhouse with latent heat storage assisted by a dehumidifying heat pump. In Advances In Solar Energy Technology; Elsevier: Amsterdam, The Netherlands, 1988; pp. 3358–3363. [Google Scholar] [CrossRef]

- Boulard, T.; Razafinjohany, E.; Baille, A.; Jaffrin, A.; Fabre, B. Performance of a greenhouse heating system with a phase change material. Agric. For. Meteorol. 1990, 52, 303–318. [Google Scholar] [CrossRef]

- Başçetinçelik, A.; Öztürk, H.H.; Paksoy, H.Ö.; Demirel, Y. Energetic and exergetic efficiency of latent heat storage system for greenhouse heating. Renew. Energy 1999, 16, 691–694. [Google Scholar] [CrossRef]

- Berroug, F.; Lakhal, E.; El Omari, M.; Faraji, M.; El Qarnia, H. Thermal performance of a greenhouse with a phase change material north wall. Energy Build. 2011, 43, 3027–3035. [Google Scholar] [CrossRef]

- Bouadila, S.; Lazaar, M.; Skouri, S.; Kooli, S.; Farhat, A. Assessment of the greenhouse climate with a new packed-bed solar air heater at night, in Tunisia. Renew. Sustain. Energy Rev. 2014, 35, 31–41. [Google Scholar] [CrossRef]

- Yan, S.-R.; Fazilati, M.A.; Samani, N.; Ghasemi, H.R.; Toghraie, D.; Nguyen, Q.; Karimipour, A. Energy efficiency optimization of the waste heat recovery system with embedded phase change materials in greenhouses: A thermo-economic-environmental study. J. Energy Storage 2020, 30, 101445. [Google Scholar] [CrossRef]

- Bouadila, S.; Kooli, S.; Skouri, S.; Lazaar, M.; Farhat, A. Improvement of the greenhouse climate using a solar air heater with latent storage energy. Energy 2014, 64, 663–672. [Google Scholar] [CrossRef]

- Beyhan, B.; Paksoy, H.; Daşgan, Y. Root zone temperature control with thermal energy storage in phase change materials for soilless greenhouse applications. Energy Convers. Manag. 2013, 74, 446–453. [Google Scholar] [CrossRef] [Green Version]

- Llorach-Massana, P.; Peña, J.; Rieradevall, J.; Montero, J.I. Analysis of the technical, environmental and economic potential of phase change materials (PCM) for root zone heating in Mediterranean greenhouses. Renew. Energy 2017, 103, 570–581. [Google Scholar] [CrossRef] [Green Version]

- Ifeanyi, A.; Isherwood, P.; Abdul-Lateef, A.O. A study of copper–tungsten oxide materials for photovoltaic application. World J. Eng. 2021, 19, 822–831. [Google Scholar] [CrossRef]

- Zhong, Y.L.; Tian, Z.; Simon, G.P.; Li, D. Scalable production of graphene via wet chemistry: Progress and challenges. Mater. Today 2015, 18, 73–78. [Google Scholar] [CrossRef]

- Figueiredo, P.; Lintinen, K.; Hirvonen, J.T.; Kostiainen, M.A.; Santos, H.A. Properties and chemical modifications of lignin: Towards lignin-based nanomaterials for biomedical applications. Prog. Mater. Sci. 2018, 93, 233–269. [Google Scholar] [CrossRef]

- Mishra, P.; Stockmal, K.; Ardito, G.; Tao, M.; Van Dessel, S.; Granados-Focil, S. Thermo-optically responsive phase change materials for passive temperature regulation. Sol. Energy 2020, 197, 222–228. [Google Scholar] [CrossRef]

- US Energy Information Administration. Why Do Carbon Dioxide Emissions Weigh More Than the Original Fuel? 2023. Available online: https://www.eia.gov/tools/faqs/faq.php?id=82&t=11 (accessed on 22 February 2023).

- Mostefaoui, Z.; Amara, S. Renewable energy analysis in the agriculture–greenhouse farms: A case study in the mediterranean region (sidi bel abbes, Algeria). Environ. Prog. Sustain. Energy 2019, 38, e13029. [Google Scholar] [CrossRef]

- Lazaar, M.; Bouadila, S.; Kooli, S.; Farhat, A. Conditioning of the tunnel greenhouse in the north of Tunisia using a calcium chloride hexahydrate integrated in polypropylene heat exchanger. Appl. Therm. Eng. 2014, 68, 62–68. [Google Scholar] [CrossRef]

- Demirel, Y. Heat storage by phase changing materials and thermoeconomics. In Thermal Energy Storage for Sustainable Energy Consumption: Fundamentals, Case Studies and Design; Paksoy, H.Ö., Ed.; NATO Science Series; Springer: Dordrecht, The Netherlands, 2007; pp. 133–151. [Google Scholar] [CrossRef]

- Jouhara, H.; Żabnieńska-Góra, A.; Khordehgah, N.; Ahmad, D.; Lipinski, T. Latent thermal energy storage technologies and applications: A review. Int. J. Thermofluids 2020, 5, 100039. [Google Scholar] [CrossRef]

- Dienel, T.; Bauer, C.; Dolamic, I.; Brühwiler, D. Spectral-based analysis of thin film luminescent solar concentrators. Sol. Energy 2010, 84, 1366–1369. [Google Scholar] [CrossRef] [Green Version]

- Krumer, Z.; Pera, S.J.; van Dijk-Moes, R.J.; Zhao, Y.; de Brouwer, A.F.; Groeneveld, E.; van Sark, W.G.; Schropp, R.E.; de Mello Donegá, C. Tackling self-absorption in luminescent solar concentrators with type-II colloidal quantum dots. Sol. Energy Mater. Sol. Cells 2013, 111, 57–65. [Google Scholar] [CrossRef] [Green Version]

- Carbone, I.A.; Frawley, K.R.; McCann, M.K. Flexible, front-facing luminescent solar concentrators fabricated from lumogen F red 305 and polydimethylsiloxane. Int. J. Photoenergy 2019, 2019, 8680931. [Google Scholar] [CrossRef]

- Shayan, S.; Matloub, S.; Rostami, A. Efficiency enhancement in a single bandgap silicon solar cell considering hot-carrier extraction using selective energy contacts. Opt. Express 2021, 29, 5068–5080. [Google Scholar] [CrossRef]

- Torrisi, S.B.; Singh, A.K.; Montoya, J.H.; Biswas, T.; Persson, K.A. Two-dimensional forms of robust CO2 reduction photocatalysts. npj 2D Mater. Appl. 2020, 4, 24. [Google Scholar] [CrossRef]

- Becker-Koch, D.; Albaladejo-Siguan, M.; Lami, V.; Paulus, F.; Xiang, H.; Chen, Z.; Vaynzof, Y. Ligand dependent oxidation dictates the performance evolution of high efficiency PbS quantum dot solar cells. Sustain. Energy Fuels 2020, 4, 108–115. [Google Scholar] [CrossRef] [Green Version]

- Saeidi, S.; Rezaei, B.; Irannejad, N.; Ensafi, A.A. Efficiency improvement of luminescent solar concentrators using upconversion nitrogen-doped graphene quantum dots. J. Power Sources 2020, 476, 228647. [Google Scholar] [CrossRef]

- Eren, G.O.; Sadeghi, S.; Shahzad, M.; Nizamoglu, S. Protocol on synthesis and characterization of copper-doped InP/ZnSe quantum dots as ecofriendly luminescent solar concentrators with high performance and large area. STAR Protoc. 2021, 2, 100664. [Google Scholar] [CrossRef]

- Matsui, T.; Sai, H.; Bidiville, A.; Hsu, H.-J.; Matsubara, K. Progress and limitations of thin-film silicon solar cells. Sol. Energy 2018, 170, 486–498. [Google Scholar] [CrossRef]

- Jumaah, H.J.; Kalantar, B.; Halin, A.A.; Mansor, S.; Ueda, N.; Jumaah, S.J. Development of UAV-based PM2.5 monitoring system. Drones 2021, 5, 60. [Google Scholar] [CrossRef]

- Ullah, Z.; Al-Turjman, F.; Mostarda, L. Cognition in UAV-aided 5G and beyond communications: A survey. IEEE Trans. Cogn. Commun. Netw. 2020, 6, 872–891. [Google Scholar] [CrossRef]

- Aggarwal, S.; Kumar, N.; Tanwar, S. Blockchain-envisioned UAV communication using 6G networks: Open issues, use cases, and future directions. IEEE Internet Things J. 2020, 8, 5416–5441. [Google Scholar] [CrossRef]

- Chaurasia, R.; Mohindru, V. Unmanned aerial vehicle (UAV): A comprehensive survey. In Unmanned Aerial Vehicles for Internet of Things (IoT) Concepts, Techniques, and Applications; Scrivener Publishing: Beverly, MA, USA, 2021; pp. 1–27. [Google Scholar] [CrossRef]

- Mohamed, E.S.; Belal, A.; Abd-Elmabod, S.K.; El-Shirbeny, M.A.; Gad, A.; Zahran, M.B. Smart farming for improving agricultural management. Egypt. J. Remote Sens. Space Sci. 2021, 24, 971–981. [Google Scholar] [CrossRef]

- Rojas, A. Smart agriculture IoT with cloud computing. Rev. Hist. América 2015, 29, 37–66. [Google Scholar]

- Sinha, A.; Shrivastava, G.; Kumar, P. Architecting user-centric internet of things for smart agriculture. Sustain. Comput. Inform. Syst. 2019, 23, 88–102. [Google Scholar] [CrossRef]

- Katamreddy, S.; Walsh, J.; Ward, S.; Riordan, D. Closed loop process control for precision farming: An Agriculture 4.0 perspective. In Proceedings of the 2019 30th Irish Signals and Systems Conference (ISSC), Maynooth, Ireland, 17–18 June 2019; pp. 1–6. [Google Scholar]

- Maraveas, C.; Piromalis, D.; Arvanitis, K.; Bartzanas, T.; Loukatos, D. Applications of IoT for optimized greenhouse environment and resources management. Comput. Electron. Agric. 2022, 198, 106993. [Google Scholar] [CrossRef]

- US Environmental Protection Agency. Climate Impacts on Agriculture and Food Supply; US Environmental Protection Agency: Washington, DC, USA, 2020. [Google Scholar]

- Elijah, O.; Rahman, T.A.; Orikumhi, I.; Leow, C.Y.; Hindia, M.N. An overview of Internet of Things (IoT) and data analytics in agriculture: Benefits and challenges. IEEE Internet Things J. 2018, 5, 3758–3773. [Google Scholar] [CrossRef]

- Thomopoulos, V.; Bitas, D.; Papastavros, K.-N.; Tsipianitis, D.; Kavga, A. Development of an integrated IoT-based greenhouse control three-device robotic system. Agronomy 2021, 11, 405. [Google Scholar] [CrossRef]

- Halligan, S.C.; Murray, K.A.; Vrain, O.; Lyons, J.G.; Geever, L.M. Controlling the Thermosensitivity of Poly (N-vinylcaprolactam) for Smart Glass Applications via Electron Beam Irradiation. Mater. Today Proc. 2019, 10, 430–435. [Google Scholar] [CrossRef]

- Kamalisarvestani, M.; Saidur, R.; Mekhilef, S.; Javadi, F. Performance, materials and coating technologies of thermochromic thin films on smart windows. Renew. Sustain. Energy Rev. 2013, 26, 353–364. [Google Scholar] [CrossRef]

- Korecko, J.; Jirka, V.; Sourek, B.; Cerveny, J. Module greenhouse with high efficiency of transformation of solar energy, utilizing active and passive glass optical rasters. Sol. Energy 2010, 84, 1794–1808. [Google Scholar] [CrossRef]

- Ruan, J.; Jiang, H.; Zhu, C.; Hu, X.; Shi, Y.; Liu, T.; Rao, W.; Chan, F.T.S. Agriculture IoT: Emerging trends, cooperation networks, and outlook. IEEE Wirel. Commun. 2019, 26, 56–63. [Google Scholar] [CrossRef]

- Schimschar, S.; Blok, K.; Boermans, T.; Hermelink, A. Germany’s path towards nearly zero-energy buildings—Enabling the greenhouse gas mitigation potential in the building stock. Energy Policy 2011, 39, 3346–3360. [Google Scholar] [CrossRef]

- Kitaoka, S.; Shinano, T.; Suzuki, T.; Shoji, S.; Hasegawa, Y. Application of a new film for horticultural use to convert UV-light to photosynthetic active radiation. Eurasian J. For. Res. 2022, 22, 73–77. [Google Scholar]

- Chou, H.-T.; Chen, Y.-C.; Lee, C.-Y.; Chang, H.-Y.; Tai, N.-H. Switchable transparency of dual-controlled smart glass prepared with hydrogel-containing graphene oxide for energy efficiency. Sol. Energy Mater. Sol. Cells 2017, 166, 45–51. [Google Scholar] [CrossRef]

- Aynur, T.N. Variable refrigerant flow systems: A review. Energy Build. 2010, 42, 1106–1112. [Google Scholar] [CrossRef]

- Zhang, R.; Sun, K.; Hong, T.; Yura, Y.; Hinokuma, R. A novel Variable Refrigerant Flow (VRF) heat recovery system model: Development and validation. Energy Build. 2018, 168, 399–412. [Google Scholar] [CrossRef] [Green Version]

- Lee, Y.; Kim, W. Development of an Optimal Start Control Strategy for a Variable Refrigerant Flow (VRF) System. Energies 2021, 14, 271. [Google Scholar] [CrossRef]

- Self, S.J.; Reddy, B.V.; Rosen, M.A. Geothermal heat pump systems: Status review and comparison with other heating options. Appl. Energy 2013, 101, 341–348. [Google Scholar] [CrossRef]

- Lamarche, L.; Kajl, S.; Beauchamp, B. A review of methods to evaluate borehole thermal resistances in geothermal heat-pump systems. Geothermics 2010, 39, 187–200. [Google Scholar] [CrossRef]

- Yang, H.; Cui, P.; Fang, Z. Vertical-borehole ground-coupled heat pumps: A review of models and systems. Appl. Energy 2010, 87, 16–27. [Google Scholar] [CrossRef]

- Taheri, S.; Razban, A. Learning-based CO2 concentration prediction: Application to indoor air quality control using demand-controlled ventilation. Build. Environ. 2021, 205, 108164. [Google Scholar] [CrossRef]

- Franco, A.; Miserocchi, L.; Testi, D. HVAC energy saving strategies for public buildings based on heat pumps and demand controlled ventilation. Energies 2021, 14, 5541. [Google Scholar] [CrossRef]

- Han, J.; West, J.; Huber, A. Demonstration of Energy-Saving Dehumidification in Ontario Greenhouses. In Proceedings of the Canadian Greenhouse Conference, Niagara Falls, ON, Canada, 7–8 October 2020; pp. 7–8. [Google Scholar]

- Lundström, L.; Wallin, F. Heat demand profiles of energy conservation measures in buildings and their impact on a district heating system. Appl. Energy 2016, 161, 290–299. [Google Scholar] [CrossRef] [Green Version]

- Gaba, N. Optimization of HVAC Energy Usage with Building Automation and Control Systems in Tropical Climates: A Review. 2022. Available online: https://www.researchsquare.com/article/rs-2388861/v1 (accessed on 2 February 2023).

- Reka, S.S.; Chezian, B.K.; Chandra, S.S. A novel approach of iot-based smart greenhouse farming system. In Green Buildings and Sustainable Engineering; Drück, H., Pillai, R., Tharian, M., Majeed, A., Eds.; Springer: Singapore, 2019; pp. 227–235. [Google Scholar]

- Oh, S.; Baltazar, J.-C.; Haberl, J.S. Assessment of the Impact of Using a Smart Thermostat and Smart Meter Data on a Whole-Building Energy Simulation. Sustainability 2022, 14, 6299. [Google Scholar] [CrossRef]

- Cetin, K.S.; O’Neill, Z. Smart meters and smart devices in buildings: A review of recent progress and influence on electricity use and peak demand. Curr. Sustain./Renew. Energy Rep. 2017, 4, 1–7. [Google Scholar] [CrossRef]

- Yildirim, N.; Bilir, L. Evaluation of a hybrid system for a nearly zero energy greenhouse. Energy Convers. Manag. 2017, 148, 1278–1290. [Google Scholar] [CrossRef]

- Giampieri, A.; Ma, Z.; Smallbone, A.; Roskilly, A.P. Thermodynamics and economics of liquid desiccants for heating, ventilation and air-conditioning—An overview. Appl. Energy 2018, 220, 455–479. [Google Scholar] [CrossRef] [Green Version]

- Ahirwar, M.; Mahia, R.N. An Evaluation of Techniques for Controlling and Monitoring Greenhouse. In Proceedings of the 2023 International Conference for Advancement in Technology (ICONAT), Goa, India, 24–26 January 2023; pp. 1–8. [Google Scholar] [CrossRef]

- Ishimoto, Y.; Sugiyama, M.; Kato, E.; Moriyama, R.; Tsuzuki, K.; Kurosawa, A. Putting Costs of Direct Air Capture in Context; Social Science Research Network: Rochester, NY, USA, 2017. [Google Scholar]

- Lindsey, R.; Dlugokencky, E. Climate Change: Atmospheric Carbon Dioxide. 2020. Available online: https://www.climate.gov/news-features/understanding-climate/climate-change-atmospheric-carbon-dioxide (accessed on 21 December 2022).

- Lindsey, R.; Dahlman, L. Climate Change: Global Temperature. 2020. Available online: https://www.climate.gov/news-features/understanding-climate/climate-change-global-temperature (accessed on 1 January 2023).

- Yan, Q.; Lin, Y.; Wu, P.; Zhao, L.; Cao, L.; Peng, L.; Kong, C.; Chen, L. Designed Synthesis of Functionalized Two-Dimensional Metal–Organic Frameworks with Preferential CO2 Capture. ChemPlusChem 2013, 78, 86–91. [Google Scholar] [CrossRef]

- Terlouw, T.; Treyer, K.; Bauer, C.; Mazzotti, M. Life cycle assessment of direct air carbon capture and storage with low-carbon energy sources. Environ. Sci. Technol. 2021, 55, 11397–11411. [Google Scholar] [CrossRef]

- Fasihi, M.; Efimova, O.; Breyer, C. Techno-economic assessment of CO2 direct air capture plants. J. Clean. Prod. 2019, 224, 957–980. [Google Scholar] [CrossRef]

- Cormos, A.-M.; Simon, A. Dynamic modeling and validation of post-combustion calcium-looping process. In Computer Aided Chemical Engineering; Elsevier: Amsterdam, The Netherlands, 2014; Volume 33, pp. 1645–1650. [Google Scholar] [CrossRef]

- Beuttler, C.; Charles, L.; Wurzbacher, J. The role of direct air capture in mitigation of anthropogenic greenhouse gas emissions. Front. Clim. 2019, 1, 10. [Google Scholar] [CrossRef] [Green Version]

- Ho, N.A.D.; Leo, C. A review on the emerging applications of cellulose, cellulose derivatives and nanocellulose in carbon capture. Environ. Res. 2021, 197, 111100. [Google Scholar] [CrossRef]

- Kapoor, R.T.; Rafatullah, M.; Qamar, M.; Qutob, M.; Alosaimi, A.M.; Alorfi, H.S.; Hussein, M.A. Review on Recent Developments in Bioinspired-Materials for Sustainable Energy and Environmental Applications. Sustainability 2022, 14, 16931. [Google Scholar] [CrossRef]

- Yi, J.; Choe, G.; Park, J.; Lee, J.Y. Graphene oxide-incorporated hydrogels for biomedical applications. Polym. J. 2020, 52, 823–837. [Google Scholar] [CrossRef]

- Cirillo, G.; Pantuso, E.; Curcio, M.; Vittorio, O.; Leggio, A.; Iemma, F.; De Filpo, G.; Nicoletta, F.P. Alginate Bioconjugate and Graphene Oxide in Multifunctional Hydrogels for Versatile Biomedical Applications. Molecules 2021, 26, 1355. [Google Scholar] [CrossRef]

- Liao, G.; Hu, J.; Chen, Z.; Zhang, R.; Wang, G.; Kuang, T. Preparation, properties, and applications of graphene-based hydrogels. Front. Chem. 2018, 6, 450. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Chatterjee, S.G.; Chatterjee, S.; Ray, A.K.; Chakraborty, A.K. Graphene–metal oxide nanohybrids for toxic gas sensor: A review. Sens. Actuators B Chem. 2015, 221, 1170–1181. [Google Scholar] [CrossRef]

- Luchetta, C.; Oliveira Munsignatti, E.C.; Pastore, H.O. CO2 Metallothermal Reduction to Graphene: The Influence of Zn. Front. Chem. Eng. 2021, 3, 707855. [Google Scholar] [CrossRef]

- He, G.; Huang, S.; Villalobos, L.F.; Zhao, J.; Mensi, M.; Oveisi, E.; Rezaei, M.; Agrawal, K.V. High-permeance polymer-functionalized single-layer graphene membranes that surpass the postcombustion carbon capture target. Energy Environ. Sci. 2019, 12, 3305–3312. [Google Scholar] [CrossRef] [Green Version]

- Zhongming, Z.; Linong, L.; Xiaona, Y.; Wangqiang, Z.; Wei, L. Graphene Filter Makes Carbon Capture More Efficient and Cheaper, EPFL, 2021. Available online: https://actu.epfl.ch/news/graphene-filter-makes-carbon-capture-more-efficien/ (accessed on 1 January 2023).

- Najafabadi, A.T. Emerging applications of graphene and its derivatives in carbon capture and conversion: Current status and future prospects. Renew. Sustain. Energy Rev. 2015, 41, 1515–1545. [Google Scholar] [CrossRef]

- Hastings, A.; Clifton-Brown, J.; Wattenbach, M.; Stampfl, P.; Mitchell, C.P.; Smith, P. Potential of Miscanthus grasses to provide energy and hence reduce greenhouse gas emissions. Agron. Sustain. Dev. 2008, 28, 465–472. [Google Scholar] [CrossRef] [Green Version]

- Kaye, J.P.; Quemada, M. Using cover crops to mitigate and adapt to climate change. A review. Agron. Sustain. Dev. 2017, 37, 4. [Google Scholar] [CrossRef] [Green Version]

- Launay, C.; Houot, S.; Frédéric, S.; Girault, R.; Levavasseur, F.; Marsac, S.; Constantin, J. Incorporating energy cover crops for biogas production into agricultural systems: Benefits and environmental impacts. A review. Agron. Sustain. Dev. 2022, 42, 57. [Google Scholar] [CrossRef]

- Meul, M.; Van Passel, S.; Nevens, F.; Dessein, J.; Rogge, E.; Mulier, A.; Van Hauwermeiren, A. MOTIFS: A monitoring tool for integrated farm sustainability. Agron. Sustain. Dev. 2008, 28, 321–332. [Google Scholar] [CrossRef] [Green Version]

- Hercher-Pasteur, J.; Loiseau, E.; Sinfort, C.; Hélias, A. Energetic assessment of the agricultural production system. A review. Agron. Sustain. Dev. 2020, 40, 29. [Google Scholar] [CrossRef]

- Asgedom, H.; Kebreab, E. Beneficial management practices and mitigation of greenhouse gas emissions in the agriculture of the Canadian Prairie: A review. Agron. Sustain. Dev. 2011, 31, 433–451. [Google Scholar] [CrossRef] [Green Version]

- Stavi, I.; Lal, R. Agriculture and greenhouse gases, a common tragedy. A review. Agron. Sustain. Dev. 2013, 33, 275–289. [Google Scholar] [CrossRef]

- Aguilera, E.; Guzmán, G.; Alonso, A. Greenhouse gas emissions from conventional and organic cropping systems in Spain. II. Fruit tree orchards. Agron. Sustain. Dev. 2015, 35, 725–737. [Google Scholar] [CrossRef] [Green Version]

- Greenhouse Gas Working Group. Agriculture’s Role in Greenhouse Gas Emissions and Capture; Greenhouse Gas Working Group: Madison, WI, USA, 2010. [Google Scholar]

- Lal, R. Potential of desertification control to sequester carbon and mitigate the greenhouse effect. Clim. Change 2001, 51, 35–72. [Google Scholar] [CrossRef]

- Townsend, T.J.; Ramsden, S.J.; Wilson, P. How do we cultivate in England? Tillage practices in crop production systems. Soil Use Manag. 2016, 32, 106–117. [Google Scholar] [CrossRef] [Green Version]

- Caffrey, K.R.; Veal, M.W. Conducting an agricultural life cycle assessment: Challenges and perspectives. Sci. World J. 2013, 2013, 472431. [Google Scholar] [CrossRef] [Green Version]

- Ahmad Ludin, N.; Ahmad Affandi, N.A.; Purvis-Roberts, K.; Ahmad, A.; Ibrahim, M.A.; Sopian, K.; Jusoh, S. Environmental impact and levelised cost of energy analysis of solar photovoltaic systems in selected Asia Pacific region: A cradle-to-grave approach. Sustainability 2021, 13, 396. [Google Scholar] [CrossRef]

- Mohtar, R. Financing Climate Action: Equity Challenges and Practical Solutions; Policy Center for the New South: Salé, Morocco, 2023. [Google Scholar]

- Baeza, E.; Van Breugel, A.; Hemming, S.; Stanghellini, C. Smart greenhouse covers: A look into the future. In Proceedings of the XI International Symposium on Protected Cultivation in Mild Winter Climates and I International Symposium on Nettings and Screens in Horticulture, Tenerife, Spain, 27–31 January 2019; pp. 213–224. [Google Scholar]

- Achour, Y.; Ouammi, A.; Zejli, D. Technological progresses in modern sustainable greenhouses cultivation as the path towards precision agriculture. Renew. Sustain. Energy Rev. 2021, 147, 111251. [Google Scholar] [CrossRef]

- Chel, A.; Kaushik, G. Renewable energy for sustainable agriculture. Agron. Sustain. Dev. 2011, 31, 91–118. [Google Scholar] [CrossRef]

- Eichler Inwood, S.E.; Dale, V.H. State of apps targeting management for sustainability of agricultural landscapes. A review. Agron. Sustain. Dev. 2019, 39, 8. [Google Scholar] [CrossRef] [Green Version]

| Technique | Description | Advantages | Disadvantages | Refs. |

|---|---|---|---|---|

| Insulation | Adding insulating materials to reduce heat loss during cold weather. | Reduces heat loss, lowers heating costs. | - May require additional structural support. - Can limit ventilation, leading to increased humidity levels and the risk of disease. | [102,103,104] |

| Double-layer glazing | Installing two layers of glazing with air or gas between them for improved insulation. | - Reduces heat loss, lowers heating costs. - Can be combined with shading to control light levels. | - May require additional structural support. - Requires regular cleaning. | [105,106] |

| Shading | Adding shading materials to reduce solar radiation and heat gain during hot weather. | - Reduces solar radiation and heat gain, lowers cooling costs. - Can improve temperature consistency. | - Can reduce light levels, negatively impacting plant growth. - Requires regular maintenance to prevent shading materials from degrading. | [107,108,109] |

| Ventilation | Controlling airflow to regulate temperature and humidity. | - Reduces need for heating and cooling, lowers energy costs. - Improves temperature and humidity consistency. | - May require additional structural support. - Can increase energy consumption if not properly controlled. | [110,111,112] |

| Control System | Description | Advantages | Disadvantages | Refs. |

|---|---|---|---|---|

| Temperature Control | Monitors and controls the temperature using heaters, fans, and vents. | - Maintains optimal growing conditions for plants. - Prevents damage from temperature extremes. | - Difficult to balance temperature and humidity control. | [115,116] |

| Humidity Control | Monitors and controls the humidity level using humidifiers, dehumidifiers, and ventilation systems. | - Prevents damage from excessive humidity levels. - Prevents water stress in plants due to low humidity. | - Increases energy costs. - Requires constant monitoring for proper humidity control. | [109,117] |

| Lighting Control | Controls the amount and duration of light that plants receive using artificial lighting, shade cloths, and curtains. | - Provides consistent light levels. - Increases crop yield by extending the growing season. | - Increases energy costs due to the electricity usage. - Can produce heat, raising greenhouse temperatures. | [118,119] |

| CO2 Control | Maintains optimal CO2 levels inside the greenhouse using CO2 generators and sensors. | - Increases plant growth and crop yield. - Reduces water use by improving plant water use efficiency. | - Increases energy costs due to the electricity usage. - Can produce heat, raising greenhouse temperatures. - Requires careful monitoring to ensure safety. - Improper operation may produce toxic byproducts. | [120,121] |

| Nutrient Control | Controls the amount and type of nutrients that plants receive using fertilizers and nutrient monitoring systems. | - Increases plant growth and crop yield. - Reduces waste by providing only the necessary nutrients. | - Requires constant monitoring to prevent nutrient imbalances. - Requires additional equipment to monitor and adjust nutrient levels. | [122,123] |

| Study Area | Type of Facility | Main Findings | Refs. |

|---|---|---|---|

| Arizona North Carolina, US | Solar-powered Semitransparent organic solar cells | - Generates enough thermal energy for year-round operation; - Excess energy can be contributed to the grid network; | [154] |

| Agadir, Morocco | Solar-powered Flexible PV modules | - Checkboard pattern of PV modules does not affect product yield inside the greenhouse. | [155] |

| Kunming, China | Solar-powered Semitransparent mono-Si cells | - Combination of semi-transparent PV modules and polyethylene cover reduces solar radiation by 35–40% on clear days, but no significant shading effect. | [140] |

| Viterbo, Italy | Solar-powered Flexible and semitransparent modules, mono Si cells | - Curvilinear greenhouse shape maintains shading percentage below 40% throughout the year. | [138] |

| Matsue, Japan | Solar-powered Semi-transparent, Poly-Si spherical microcells | - These PV modules are suitable for installation on sidewalls and roofs, since they have a low module conversion efficiency variation of only 0.2% over a wide range of incident radiation angles.; - Higher yield ratio due to capturing ground-reflected radiation; - Low module conversion efficiency variation over a wide range of radiation angles; | [139] |

| Bari, Italy | Solar photovoltaic hydrogen system powering a low enthalpy geothermal heat pump | - Alkaline barometric water electrolyzer shows promise in greenhouse-integrated heating system; - Efficiency depends on location, climate, and energy demand; - Includes photovoltaic panels, hydrogen storage, fuel cells, and geothermal heat pump; | [156] |

| Souss-Massa, Morocco | Passive solar and rock-bed thermal energy storage | - Combined heating system improves winter temperatures in the greenhouse (3–5 °C on sunny days and 2–3 °C on cloudy/rainy days); - Reduces air relative humidity and benefits plant growth and health; - Significant increase in tomato yield (49% increase in tomato yield); - Cost-effective and efficient solution for covering heating requirements. | [157] |

| Sanbei area, China | Wind powered underground heating system | - Reduces coal consumption and CO2 emissions significantly; - Provides a substantial amount of thermal energy for the greenhouse (130.27 GJ/quarter); - Effective reduction coal consumption of 8.10 ton/quarter; - Effective at reducing greenhouse gas emissions of 21,222 kg/quarter; | [158] |

| Izmir, Turkey | Solar and biomass energy system | - Hybrid heating system improves greenhouse performance and sustainability; - Contributes to high-quality crop production; - The hybrid configuration provided 88.87% of the total nocturnal heating demands; - The solar and biomass fractions of 30.32% and 58.55%, respectively, indicate that both renewable energy sources are contributing to the system’s performance; | [159] |

| Chalkidiki, Greece | Biomass-powered | - Biomass combustion units applied to greenhouses are a profitable investment; - A subsidy can make the investment even more attractive; - The payback period of 4 years for the 2 MW biomass combustion unit is particularly noteworthy, as it suggests that the initial investment can be recouped relatively quickly; | [160] |

| Location | Type of Facility | PCM | Area (m2) | Findings | Refs. |

|---|---|---|---|---|---|

| Isfahan, Iran | PCM integrated with heater | Hydrated salt of sodium acetate | 1320 | - PCM increased greenhouse temperature by 3 °C - Exhaust gas temperature reduced by 24 °C - Gas consumption reduced by 48% - Payback period of 4 months | [189] |

| Borj Cedria, Tunisia | PCM with solar thermal collector | Capsule AC27 | 14.8 | - PCM stored 56% of the diurnal excess heat inside the greenhouse - The stored heat represents 30% of the total nocturnal heating requirement | [190] |

| Beijing, China | PCM wallboard | Paraffin wax | 400 | - Wall surface temperature increased by 2.2–3.4 °C - Indoor temperature increased by 0.8–1.4 °C | [166] |

| Marrakesh, Morocco | PCM wallboard | Calcium chloride hexahydrate | 24 | - Indoor temperature increased by 6–12 °C | [187] |

| Adana, Turkey | PCM storage container | Oleic Acid (OA) and Capric Acid (CA) | 500 | 2.4 °C higher temperature | [191] |

| Cabrils, Barcelona, Spain | PCM storage container | Rubitherm RT18HC, RT15HC, RT12HC | 230 | Optimum melting temperature 15 °C | [192] |

| Alternatives Attributes | Solar Thermal Energy | Bio-Fuel Energy | Geothermal Energy |

|---|---|---|---|

| Beginning investment (EUR/m2) | 65–80 | 20–25 | 80–200 |

| Amount of natural gas saved [m3 a.e./(m2jr)] | 10–11 | 8–13 | 21–120 |

| Additional electricity required (kWh/m2) | 25–27 | 2–3 | 7–11 |

| Emission savings (gr/m2) | 6–7 | 22–31 | 32–66 |

| Fabrication Method | Material | Size of Individual Micro Solar Cells (μm) | Efficiency under One Sun (%) | Efficiency under Concentrated Illumination | Comments |

|---|---|---|---|---|---|

| Area-selective electrodeposition | CuInSe2 | 200 | 0.26 | No | Patterned SiO2 layer on top of Mo back contact, concentration. |

| By power variation of red laser. | |||||

| Cu(In, Ga)Se2 | 10–500 | 2 | 4.6% (35×) | Patterned SiO2 layer on top of Mo back contact, concentration. | |

| By power variation of red laser. | |||||

| Cu(In, Ga)Se2 | 1000 | 7.64 | No | Patterned Mo back contact, line-shaped cells. | |

| CuInSe2 | 105 | 5.38 | No | Patterned Mo back contact, line-shaped cells. | |

| Cu(In, Ga)Se2 | 200 | 4.8 | No | Patterned SiO2 layer on top of Mo back contact. | |

| LIFT | Cu(In, Ga)Se2 | 50–100 | 0.15 | 0.237% (20×) | No re-patterning of the substrate. Transfer of the donor film in a spatially structured manner |

| Area-selective PVD | CuInSe2 | 50–100 | 1.4 | 3.36% (20×) | Glass patterned by fs-laser, PVD Mo layer. |

| CuInSe2 | 50–100 | 2.9 | 3.06% (3×) | Glass patterned by fs-laser, PVD Mo layer. | |

| PVD | close | 60 | 2.9 | 3.1% (3×) | No re-patterning of the substrate, growth of indium islands. |

| Classification | Material | Luminous Transmittance (Tulum) | Solar Energy Modulation Ability (∆Tsol) | Characteristics | |

|---|---|---|---|---|---|

| Single function hydrogel | PNIPAm | 70.7 | 25.5 | 32 | Conventional thermochromic hydrogel with excellent Tulum, Dtsol, and suitable sc |

| 87.2 | 81.3 | 32 | |||

| HPC | 90 | — | 40 | Hydrogel in liquid state with easy to control sc, which is applicable to a wide range of environmental conditions | |

| 67.4 | 25.7 | 38 | |||

| 80 | — | 30 | |||

| PNVCL | 88 | — | 34 | ||

| Regular the solar | PNIPAm- | 62.6 | 34.7 | — | By enhancing the IR regulating ability, the Dtsol was increased |

| modulation ability | VO2 | ||||

| PNIPAm/ | 38.4 | 62.7 | 40 | ||

| VO2@SiO2 | |||||

| HPC-VO2 | 67.4 | 25.7 | 38 | ||

| CS × WO3/ | 45.3 | 32.9 | — | ||

| PAM- | |||||

| PNIPAm | |||||

| Mechanical | EGP5 | 77.2 | 56.1 | 32.1 | Fabricated host–guest interaction-based hybrid hydrogels to avoid shrinkage |

| properties | Si-Al- | 73.5 | 80.1 | 32.5 | and increase the durability |

| PNIPAm | |||||

| PNIPAm/ | — | — | 32 | ||

| BOMA-16 | |||||

| Photo- | ATO/ | 62.7 | 35.7 | — | High absorbance materials were added to increase the response speed of |

| thermochromic | PNIPAm | thermochromic hydrogels | |||

| HPMC/ | 50.5 | 25.5 | 35 | ||

| AuNCs | |||||

| GO/ | — | 58.2 | — | ||

| PNIPAm | |||||

| Adjusting colors | EGP6 | 64.0 | 66.9 | — | Materials with both thermochromism and cool/warm tone switchability |

| functions | |||||

| Devices | PNIPAm/Ag | 74.6 | 58.2 | 32 | Thermochromic hydrogels were attached to a transparent electrothermal |

| grid | heater to fabricated devices, which are able to change color by adding electricity | ||||

| Si-Al- | 73.5 | 80.1 | 32.5 | ||

| PNIPAm/Ag | |||||

| grid | |||||

| PGVCL/FTO | 88 | — | 34 | ||

| layer | |||||

| HPC/Si solar cell | 95.0 | — | 40 | Material that achieves both the energy (electricity) conservation and generation functionality |