Study on Cost-Effective Performance of Alternative Fuels and Energy Efficiency Measures for Shipping Decarbonization

Abstract

:1. Introduction

1.1. Literature Review

1.2. Research Gaps and Limitations

1.3. Contribution of This Research

2. Methodology

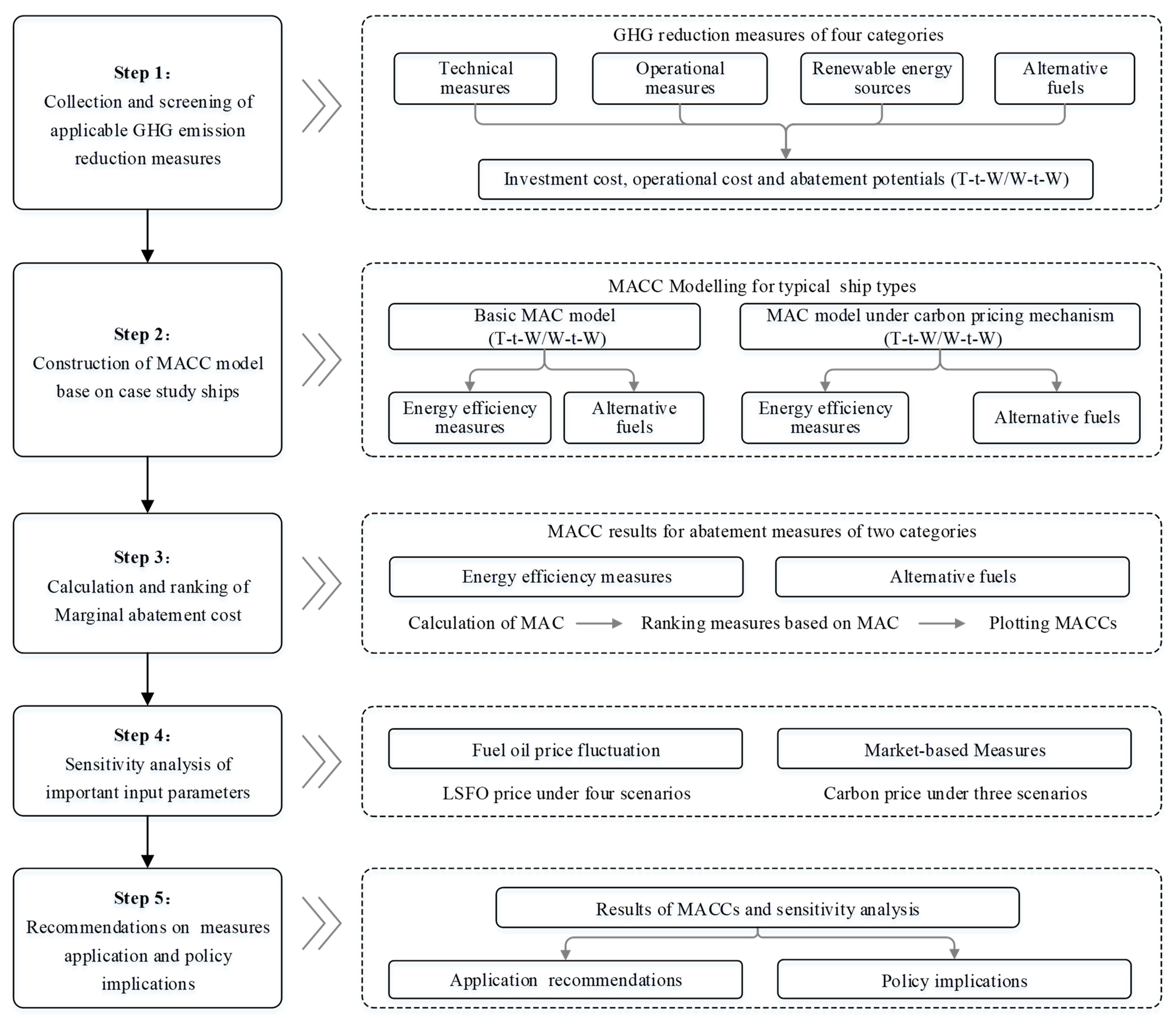

2.1. Research Procedures

- Conduct a comprehensive survey of various representative GHG abatement measures, and screen applicable measures for case study vessels.

- Develop a MAC model based on the survey data, and calculate the MAC of individual abatement measures.

- Rank the measures according to their cost-effectiveness, and construct a MACC based on the relationship between the MAC and the abatement potential of each measure.

- Perform a sensitivity analysis to investigate several input parameters’ influence on the cost-effectiveness.

- Propose recommendations on the abatement measure application and policy development.

2.2. Basic MAC Model

- represents the annual net cost of implementing an abatement measure compared with conventional ships (USD/year);

- represents the annual GHG emission abatement amount (t CO2e/MJ).

2.2.1. Net Cost

- IC is the annualized investment cost of implementing the measure (USD/year);

- OC is the operational cost related to using the measure (USD/year);

- CS is the cost savings obtained by implementing the measure (USD/year).

- TC is the total investment cost of implementing the measure;

- d is the discount rate;

- L is the lifetime of a vessel implementing the measure.

- FPalt is the price of the alternative fuel (USD/t);

- FCLSFO is the annual LSFO fuel consumption of the vessel (t/year);

- LHVLSFO and LHValt represent the lower heating value of LSFO and alternative fuel, respectively (MJ/kg).

2.2.2. Abatement Amount

- GHGTtW is the GHG emission factor of LSFO in the scope of Tank-to-Wake (g CO2e/MJ);

- GHGWtW is the GHG emission factor of LSFO in the scope of Well-to-Wake (g CO2e/MJ);

- APeff is the abatement potential of the energy efficiency measure (%);

- APalt is the abatement potential of the alternative fuel (%).

- eec is the emissions from the extraction or from the cultivation of raw materials, g CO2e/MJ;

- el is the annualized emissions from carbon stock changes caused by land-use change (over 20 years), g CO2e/MJ;

- ep is the emissions from processing, including electricity generation, g CO2e/MJ;

- etd is the emissions from transport and distribution, g CO2e/MJ;

- ec is the emissions credits generated by biomass growth, g CO2e/MJ;

- esca is the emission savings from soil carbon accumulation via improved agricultural management, g CO2e/MJ;

- eccs is the emission savings from CO2 capture and geological storage, g CO2e/MJ;

- eccu is the emission savings from CO2 capture and utilization, g CO2e/MJ.

- Cslip is the coefficient accounting for fuel slip (% of fuel mass);

- is the CO2 emission conversion factor (g CO2/g fuel);

- is the CH4 emission conversion factor (g CH4/g fuel);

- is the N2O emission conversion factor (g N2O/g fuel);

- is the Global Warming Potential of methane (g CO2e/g CH4);

- is the Global Warming Potential of N2O (g CO2e/g N2O);

- eoccs is the emission savings from on-board CO2 capture and geological storage (g CO2e/MJ);

- LHValt is the lower heating value of alternative fuel (MJ/g).

2.3. MAC Model under Carbon Pricing

- MS is the annual carbon price savings achieved by implementing the abatement measure (USD/year);

- CP is the carbon price determined in the market-based mechanism (USD/t CO2e).

2.4. MACC Construction

2.5. Sensitivity Analysis

3. Case Study

3.1. Ship Types

3.2. Abatement Measures

3.3. Emission Factors

3.4. Fuel Prices

4. Results and Discussion

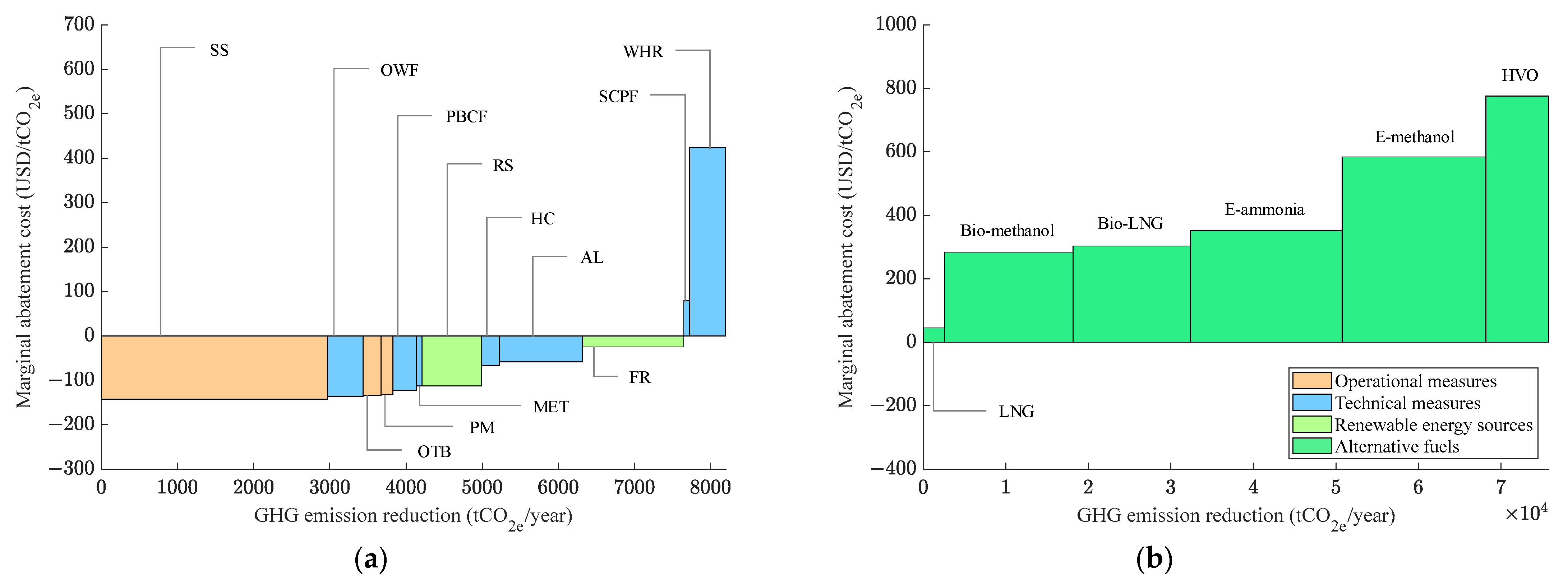

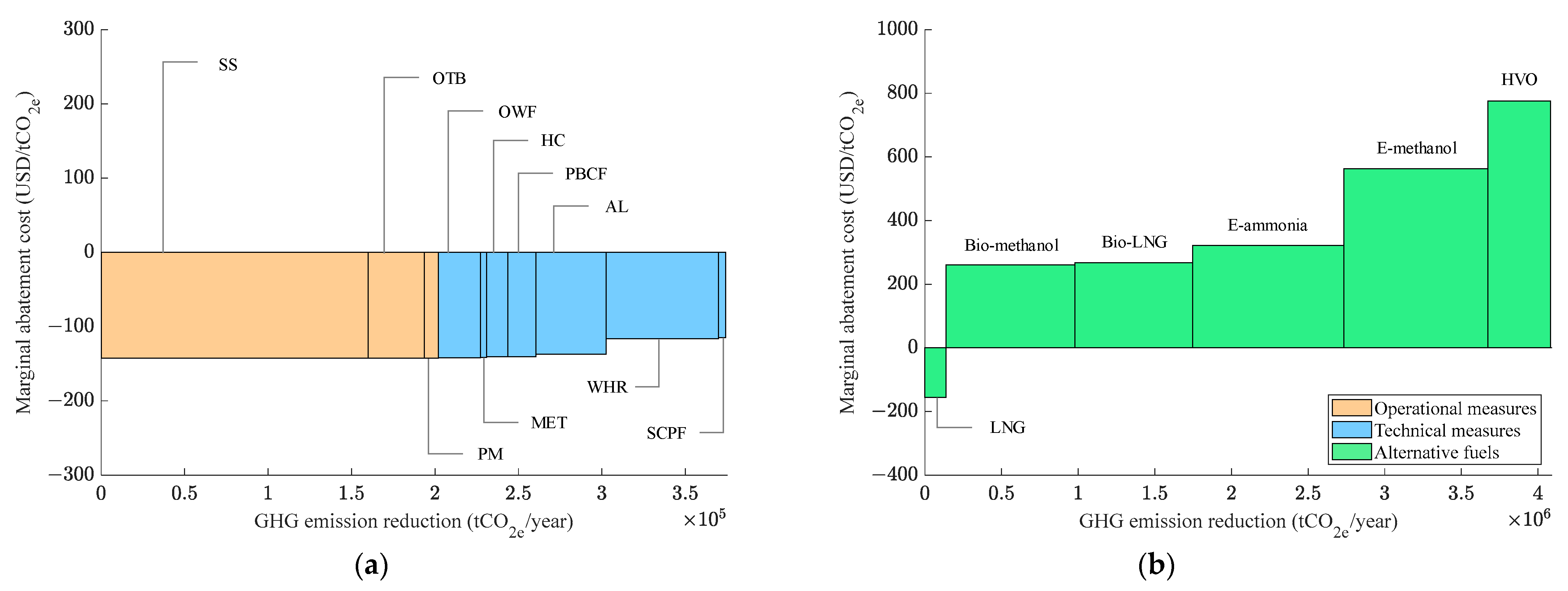

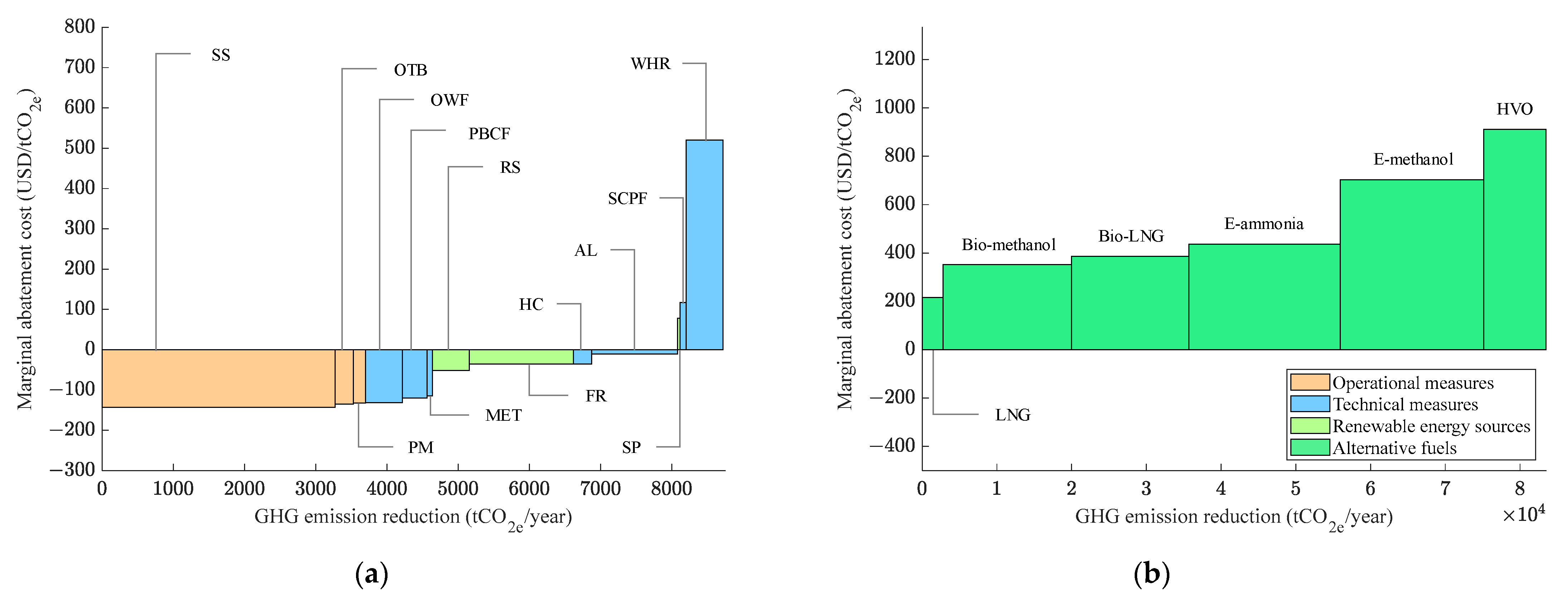

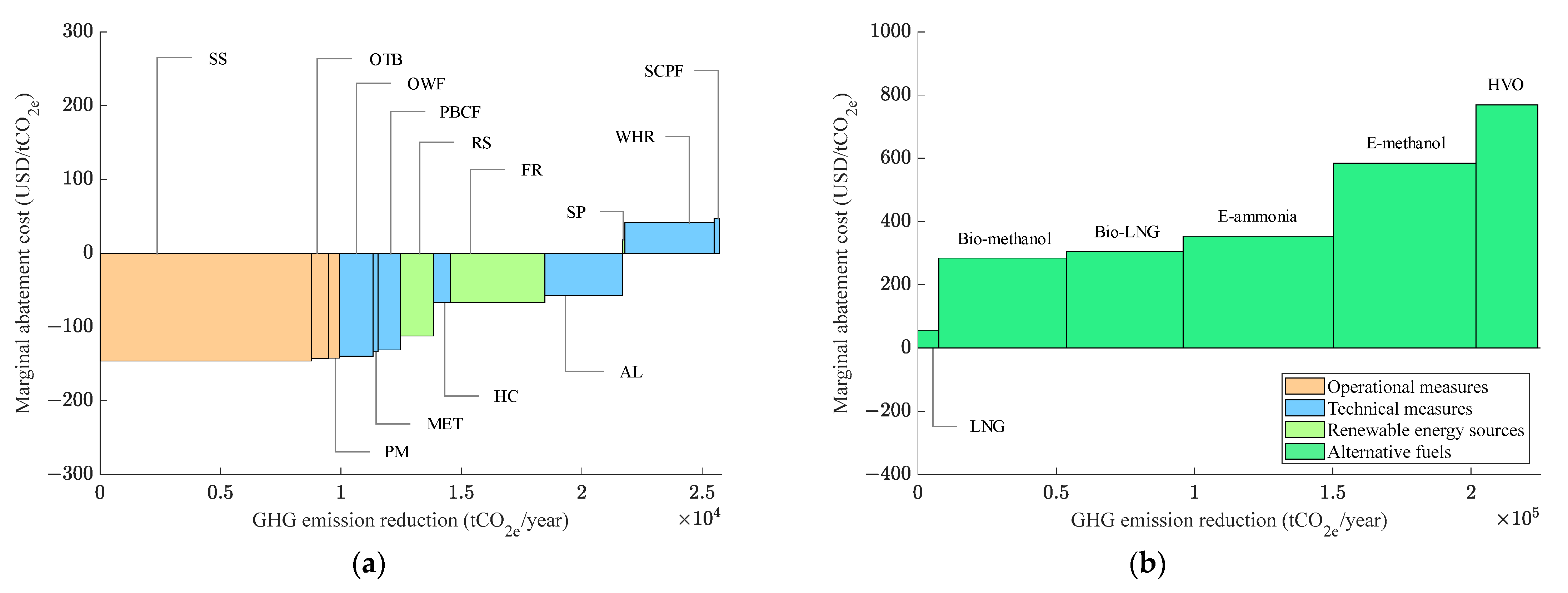

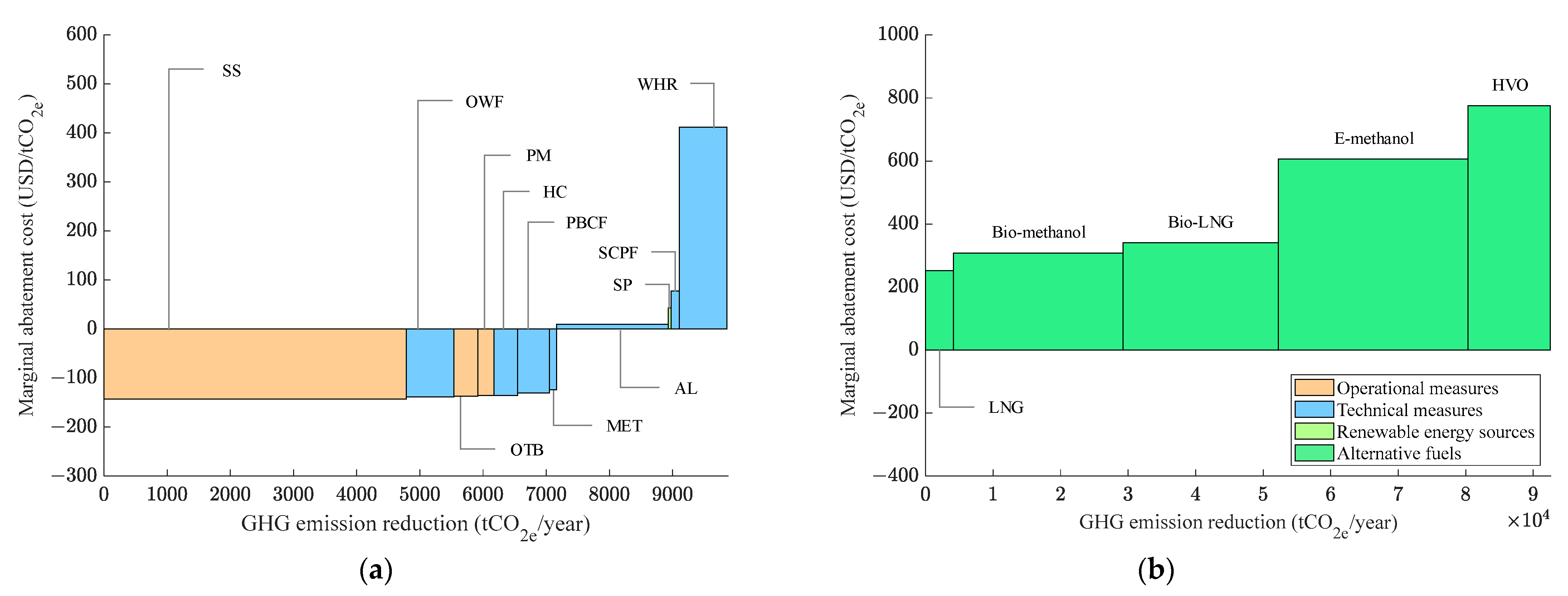

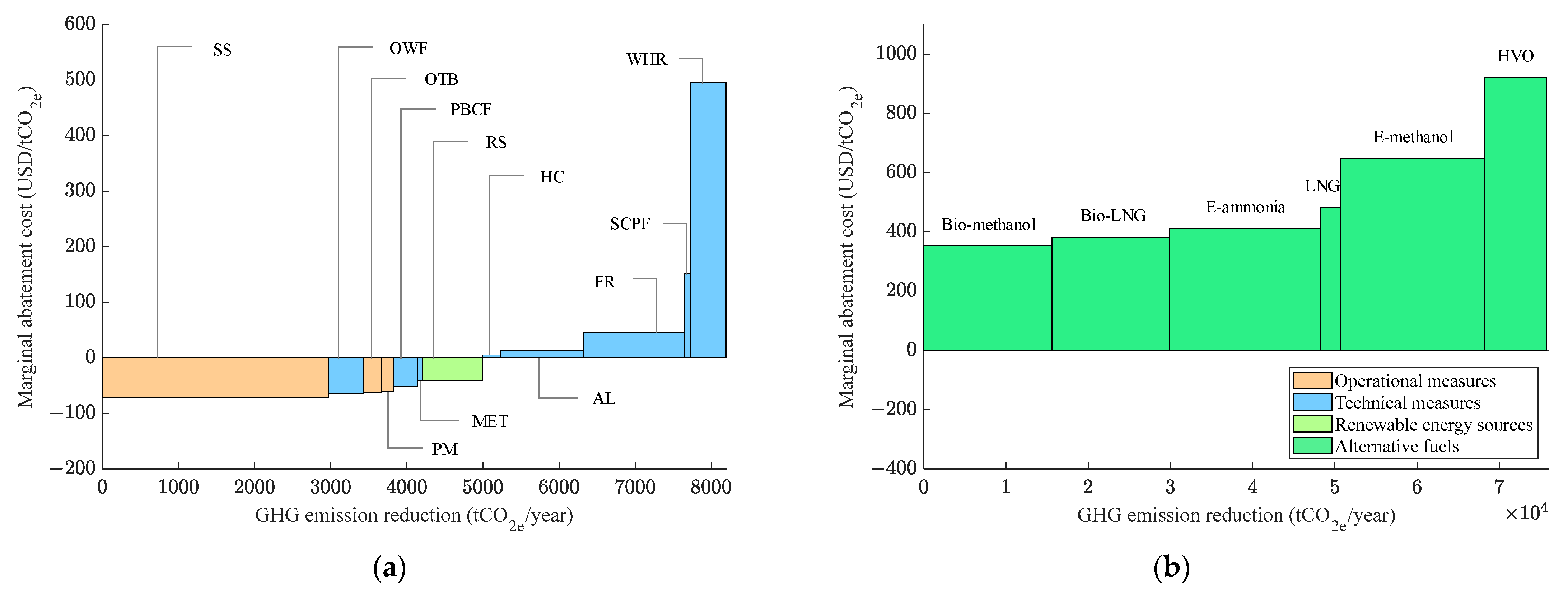

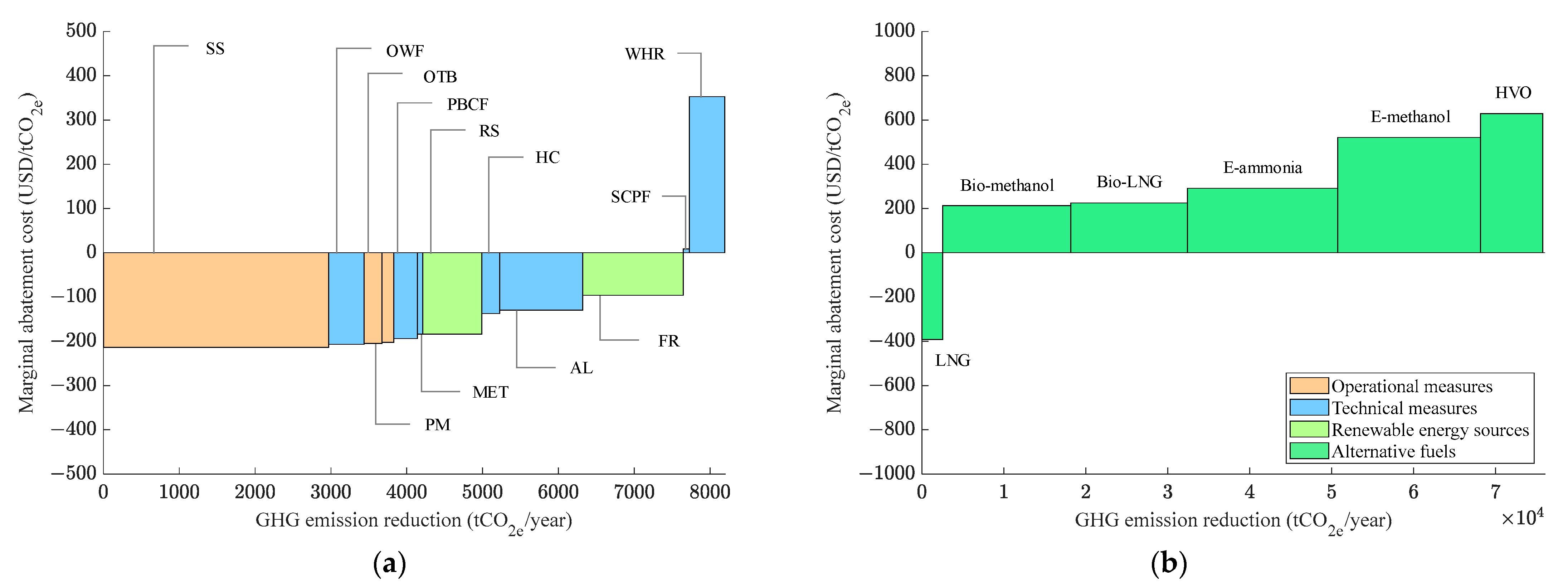

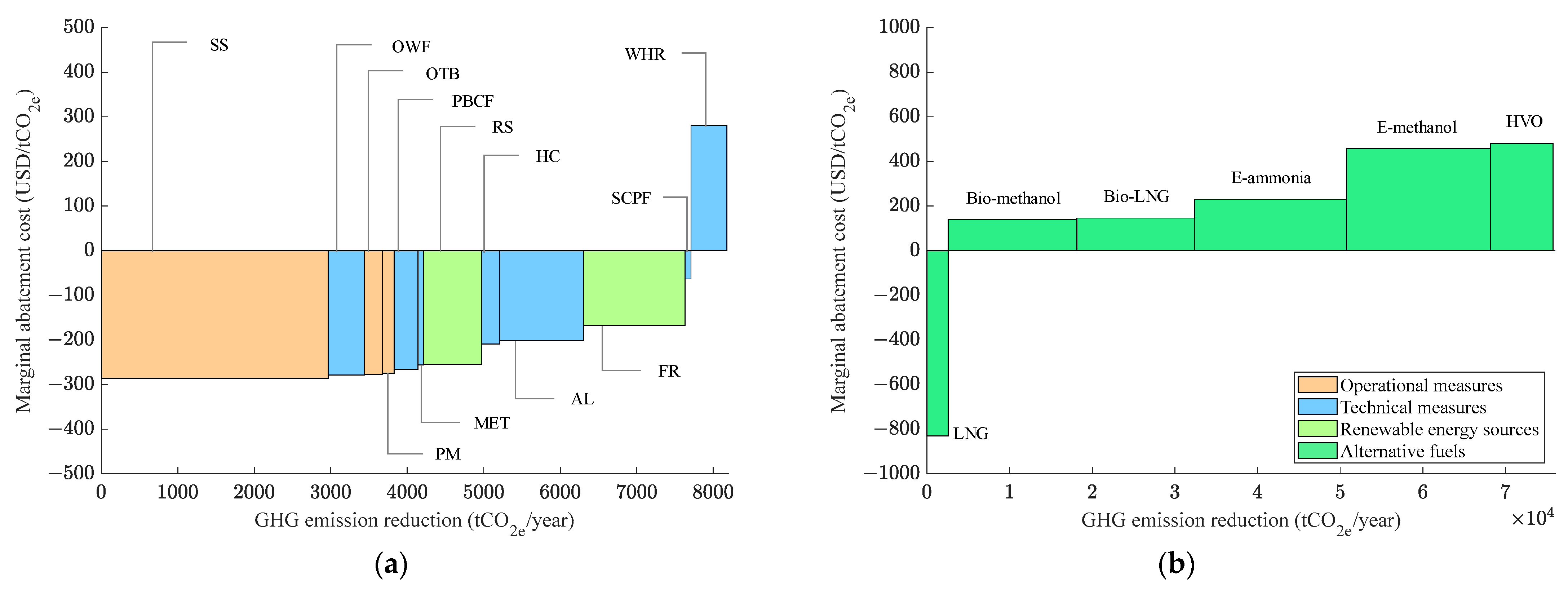

4.1. Results of MACC Basic Model

4.2. Sensitivity Analysis

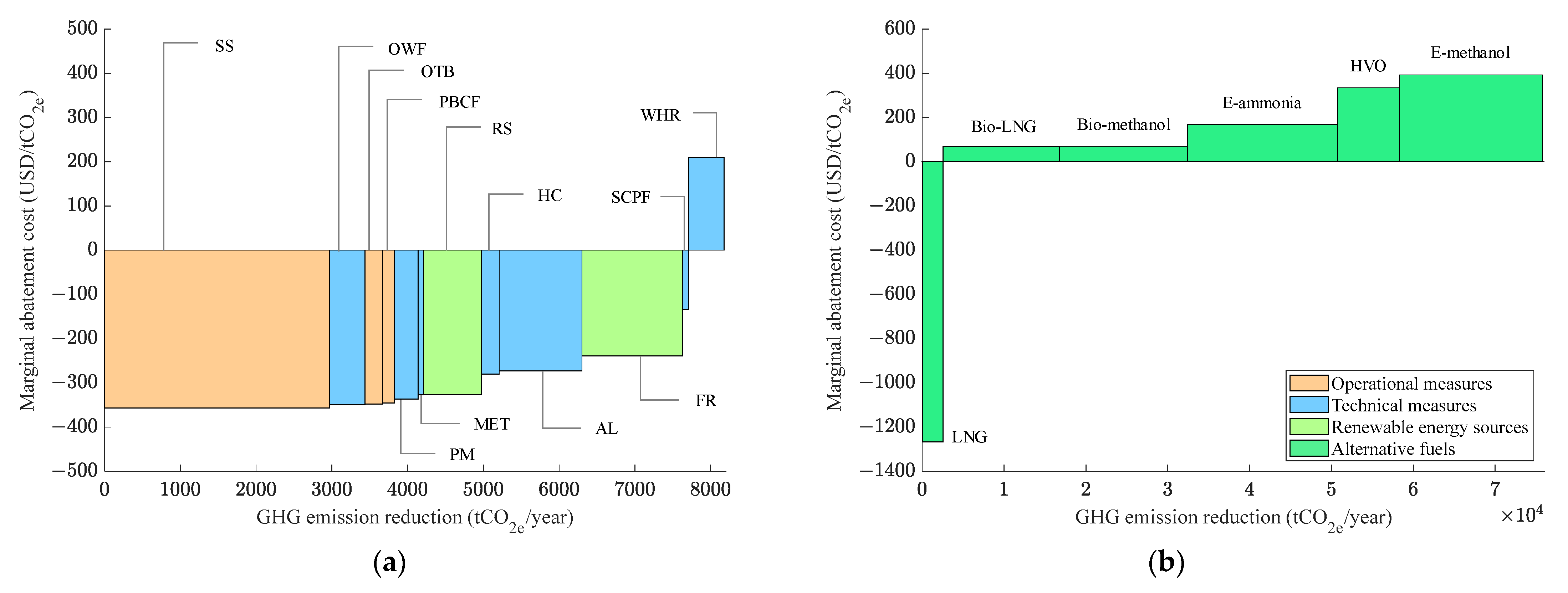

4.2.1. Fuel Oil Price

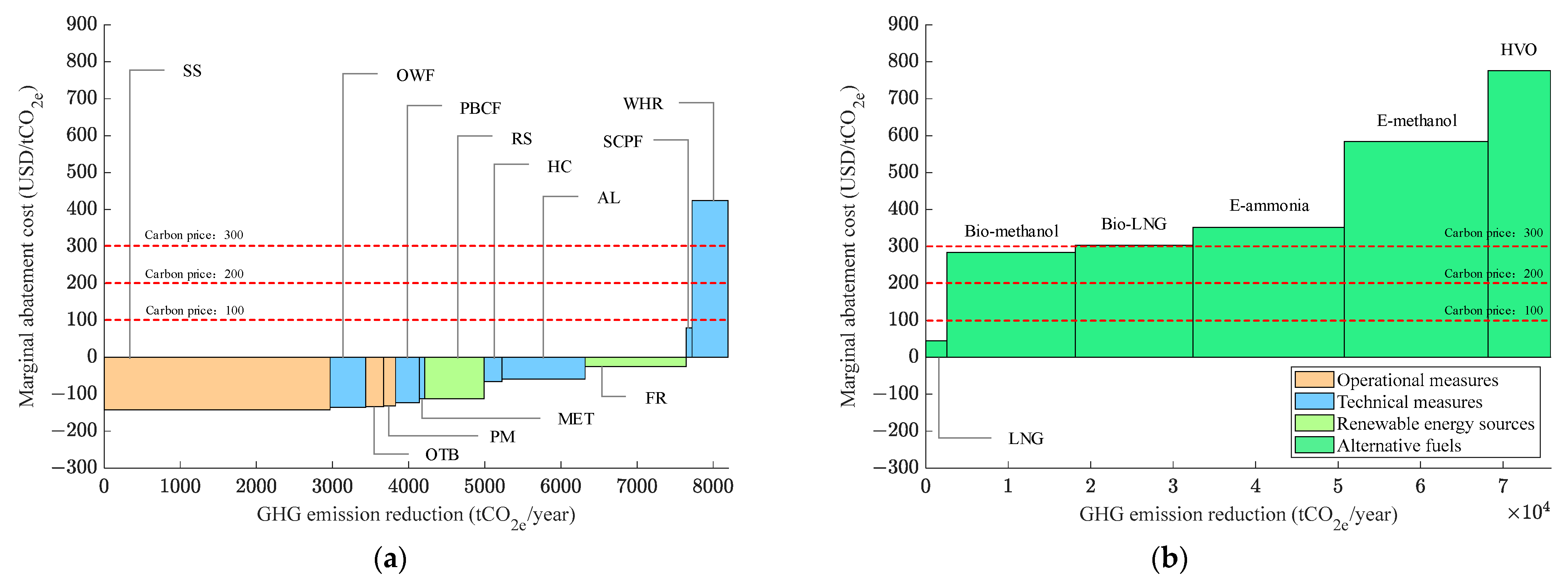

4.2.2. Carbon Price

5. Conclusions

- The energy efficiency measures that are cost-effective when applied to the five investigated ship types mainly include slow steaming, trim and ballast optimization, propeller maintenance, optimized water flow of hull openings, main engine tuning, hull coating, and propeller boss cap with fins. Ship owners can prioritize the adoption of these energy efficiency measures in their decarbonization strategies.

- The cost-effectiveness ranking of various alternative fuels applied to the typical ship types generally remains consistent, namely LNG, bio-methanol, bio-LNG, e-ammonia, e-methanol, and HVO.

- The cost-effective performance of LNG fuel is closely related to the application ship types and its fuel consumption. LNG fuel is a cost-effective option when applied to 8000 TEU container ships with an annual fuel consumption of 264,000 t. However, it becomes a measure with a positive MAC value for the other four investigated ship types with relatively lower fuel consumption.

- The adoption of alternative fuels including bio-methanol, bio-LNG, e-ammonia, e-methanol, and HVO on the investigated five typical ship types are proven to be measures with positive MAC values due to their high fuel costs.

- The cost-effective performance of energy efficiency measures will be influenced to varying degrees in different LSFO price scenarios, but the cost-effectiveness ranking of the various energy efficiency measures remains consistent.

- Fluctuations in fuel oil price significantly affect the cost-effective performance of different alternative fuels. Moreover, when fuel prices increase or decrease to a certain extent, the ranking of the cost-effective performance of different alternative fuels will change accordingly.

- A carbon pricing mechanism does not have a significant effect on most energy efficiency measures, but it has a certain stimulating effect on several cost-positive energy efficiency measures, such as waste heat recovery system, speed control of pumps and fans, and solar panels.

- A carbon pricing mechanism can effectively improve the cost-effective performance of alternative fuels with a high fuel cost. To bridge the fuel cost gap between the conventional fuels and alternative fuels such as bio-methanol, bio-LNG, e-ammonia, e-methanol, and HVO, a carbon price ranging from USD 300 to 800 per ton of CO2e needs to be imposed.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- IMO. 2023 IMO Strategy on Reduction of GHG Emissions from Ships; MEPC: London, UK, 2023. [Google Scholar]

- Paul, B.; James, B.; Chester, L.; Line, S.; Jamie, S.; Adam, H.; Iain, S. How to decarbonise international shipping: Options for fuels, technologies and policies. Energy Convers. Manag. 2019, 182, 72–88. [Google Scholar]

- Zheng, W.; Abdel, E.M.; Yang, C.; Jiayuan, T. Decarbonizing the international shipping industry: Solutions and policy recommendations. Mar. Pollut. Bull. 2018, 126, 428–435. [Google Scholar]

- Yuan, J.; Nian, V.; He, J.; Yan, W. Cost-effectiveness analysis of energy efficiency measures for maritime shipping using a metamodel based approach with different data sources. Energy 2019, 189, 116205. [Google Scholar] [CrossRef]

- Cullinane, K.; Yang, J. Evaluating the Costs of Decarbonizing the Ship Industry: A Review of the Literature. J. Mar. Sci. Eng. 2022, 10, 946. [Google Scholar] [CrossRef]

- Korberg, A.D.; Brynolf, S.; Grahn, M.; Skov, I.R. Techno-economic assessment of advanced fuels and propulsion systems in future fossil-free ships. Renew. Sustain. Energy Rev. 2021, 142, 110861. [Google Scholar] [CrossRef]

- Maurício Aguilar Nepomuceno, D.O.; Alexandre, S.; David Alves Castelo, B. Implementation of Maritime Transport Mitigation Measures according to their marginal abatement costs and their mitigation potentials. Energy Policy 2022, 160, 112699. [Google Scholar] [CrossRef]

- Hu, H.; Yuan, J.; Nian, V. Development of a multi-objective decision-making method to evaluate correlated decarbonization measures under uncertainty—The example of international shipping. Transp. Policy 2019, 82, 148–157. [Google Scholar] [CrossRef]

- Wahl, J.; Kallo, J. Carbon abatement cost of hydrogen based synthetic fuels—A general framework exemplarily applied to the maritime sector. Int. J. Hydrogen Energy 2022, 47, 3515–3531. [Google Scholar] [CrossRef]

- Jinchi, D.; Hui, W.; Lingyun, P.; Bofeng, C.; Hui, L.; Jinnan, W.; Lu, Y.; Chuyu, X.; Yang, C. Marginal abatement cost curves and mitigation technologies for petrochemical and chemical industries in China. Environ. Eng. 2021, 39, 32–40. [Google Scholar]

- Jun, Y.; Szu Hui, N.; Weng Sut, S. Uncertainty quantification of CO2 emission reduction for maritime shipping. Energy Policy 2016, 88, 113–130. [Google Scholar]

- Shihping Kevin, H.; Lopin, K.; Kuei-Lan, C. The applicability of marginal abatement cost approach: A comprehensive review. J. Clean. Prod. 2016, 127, 59–71. [Google Scholar]

- Elkafas, A.G.; Rivarolo, M.; Barberis, S.; Massardo, A.F. Feasibility Assessment of Alternative Clean Power Systems onboard Passenger Short-Distance Ferry. J. Mar. Sci. Eng. 2023, 11, 1735. [Google Scholar] [CrossRef]

- Kyprianidou, I.; Worrell, E.; Charalambides, G.A. The cost-effectiveness of CO2 mitigation measures for the decarbonisation of shipping. The case study of a globally operating ship-management company. J. Clean. Prod. 2021, 316, 128094. [Google Scholar]

- Fabian, K.; Paul, E. Marginal abatement cost curves: A call for caution. Clim. Policy 2012, 12, 219–236. [Google Scholar]

- IMO. Second IMO GHG Study 2009; International Maritime Organization: London, UK, 2009. [Google Scholar]

- Jasper, F. Technical support for European action to reducing Greenhouse Gas Emissions from international maritime transport. Transp. Syst. Logist. 2009, 37, 1198–1209. [Google Scholar]

- IMO. Third IMO GHG Study 2014; International Maritime Organization: London, UK, 2014. [Google Scholar]

- IMO. Fourth IMO GHG Study 2020; International Maritime Organization: London, UK, 2020. [Google Scholar]

- Magnus, S.E.; Tore, L.; Peter, H.; Øyvind, E.; Stig, B.D. Future cost scenarios for reduction of ship CO2 emissions. Marit. Policy Manag. 2011, 38, 11–37. [Google Scholar]

- Maddox Consulting. Analysis of Market Barriers to Cost Effective GHG Emission Reductions in the Maritime Transport Sector; Maddox Consulting, LLC: Atlanta, GA, USA, 2012. [Google Scholar]

- Nadine, H.; Sonja, P. The potential contribution of the shipping sector to an efficient reduction of global carbon dioxide emissions. Environ. Sci. Policy 2014, 42, 56–66. [Google Scholar]

- Magnus, S.E.; Øyvind, E.; Rolf, S.; Tore, L.; Sverre, A. Cost-effectiveness assessment of CO2 reducing measures in shipping. Marit. Policy Manag. 2009, 36, 367–384. [Google Scholar]

- Philippe, C. Greenhouse Gas Emissions Reduction Potential from International Shipping, OECD/ITF Joint Transport Research Centre Discussion Papers; OECD Publishing: Paris, France, 2009. [Google Scholar]

- Pierre, C.S.; Martin, K. CO2 emissions of the container world fleet. Procedia-Soc. Behav. Sci. 2012, 48, 1–11. [Google Scholar]

- Lindstad, H.; Verbeek, R.; Blok, M.; Zyl, S.; Hübscher, A.; Kramer, H.; Purwanto, J.; Ivanova, O.; Boonman, H. GHG Emission Reduction Potential of EU-Related Maritime Transport and on its Impacts; Publications Office of the European Union: Luxembourg, 2015. [Google Scholar]

- Yuan, J.; Ng, S. Emission reduction measures ranking under uncertainty. Appl. Energy 2017, 188, 270–279. [Google Scholar] [CrossRef]

- DNV GL. Low Carbon Shipping Towards 2050; DNV GL: Høvik, Norway, 2017. [Google Scholar]

- Wu, Y.-H.; Hua, J.; Chen, H.-L. Economic feasibility of an alternative fuel for sustainable short sea shipping: Case of cross-taiwan strait transport. In Proceedings of the 4th World Congress on New Technologies, Madrid, Spain, 19–21 August 2018. [Google Scholar]

- Yegnidemir, G. Analysis of the Reduction of Emissions from Ships in Europe. Master Thesis, Czech Technical University, Prague, Prague, 2020. [Google Scholar]

- DNV GL. Ammonia as a Marine Fuel; DNV GL: Høvik, Norway, 2020. [Google Scholar]

- Ejder, E.; Arslanoglu, Y. Evaluation of ammonia fueled engine for a bulk carrier in marine decarbonization pathways. J. Clean. Prod. 2022, 379, 134688. [Google Scholar] [CrossRef]

- Armstrong, V.N.; Banks, C. Integrated approach to vessel energy efficiency. Ocean Eng. 2015, 110, 39–48. [Google Scholar] [CrossRef]

- IMO. Guidelines on Life Cycle GHG Intensity of Marine Fuels; International Maritime Organization: London, UK, 2024. [Google Scholar]

- Liu, N.; Fan, L.; Chen, X. Marginal Abatement Cost Curve of Technology Oriented Under Carbon-Trading Mechanism—Taking Cement, Thermal Power, Coal and Iron and Steel Sectors as an Example. Forum Sci. Technol. China 2017, 7, 57–63. [Google Scholar] [CrossRef]

- Comer, B.; Osipova, L. Accounting for Well-to-Wake Carbon Dioxide Equivalent Emissions in Maritime Transportation Climate Policies; International Council on Clean Transportation: Washington, DC, USA, 2011. [Google Scholar]

- ITF. Carbon Pricing in Shipping. Organisation for Economic Co-operation and Development; OECD Publishing: Paris, France, 2022. [Google Scholar]

- Brynolf, S.; Fridell, E.; Andersson, K. Environmental assessment of marine fuels: Liquefied natural gas, liquefied biogas, methanol and bio-methanol. J. Clean. Prod. 2014, 74, 86–95. [Google Scholar] [CrossRef]

- McKinlay, C.; Turnock, S.; Hudson, D. Route to zero emission shipping: Hydrogen, ammonia or methanol? Int. J. Hydrogen Energy 2021, 46, 28282–28297. [Google Scholar] [CrossRef]

- ABS. Sustainability Whitepaper-Ammonia as a Marine Fuel; American Bureau of Shipping: Houston, TX, USA, 2020. [Google Scholar]

- SGMF. Ammonia as a Marine Fuel-an Introduction; Society for Gas as a marine fuel: London, UK, 2023. [Google Scholar]

- IMarEST. Marginal Abatement Costs and Cost-Effectiveness of Energy-Efficiency Measures; MEPC: London, UK, 2011. [Google Scholar]

- DNV GL. Energy Efficiency Appraisal Tool for IMO.; DNV GL: Høvik, Norway, 2016. [Google Scholar]

- Greenvoyage2050. Available online: https://greenvoyage2050.imo.org/technology/frequency-controlled-electric-motors (accessed on 3 January 2024).

- Clarkson Research. Green Environmental Protection Development and Outlook; Clarkson Research: London, UK, 2022. [Google Scholar]

- MAN Energy Solutions. Shipping en route to Paris Agreement overshoot; MAN Energy Solutions: Copenhagen, Denmark, 2022. [Google Scholar]

- MMM Center for Zero Carbon Shipping. Maritime Decarbonization Strategy 2022; Mærsk Mc-Kinney Møller Center for Zero Carbon Shipping: Copenhagen, Denmark, 2022. [Google Scholar]

- MMM Center for Zero Carbon Shipping. Industry Transition Strategy 2021; Mærsk Mc-Kinney Møller Center for Zero Carbon Shipping: Copenhagen, Denmark, 2021. [Google Scholar]

- Solakivi, T.; Paimander, A.; Ojala, L. Cost competitiveness of alternative maritime fuels in the new regulatory framework. Transp. Res. Part D Transp. Environ. 2022, 113, 103500. [Google Scholar] [CrossRef]

- Jang, H.; Mujeeb-Ahmed, M.P.; Wang, H.; Park, C.; Hwang, I.; Jeong, B.; Zhou, P.; Mickeviciene, R. Regulatory gap analysis for risk assessment of ammonia-fuelled ships. Ocean Eng. 2023, 287, 115751. [Google Scholar] [CrossRef]

| MACC Method | Country/Organization | Year | Application Ships | Abatement Measures | Ref. |

|---|---|---|---|---|---|

| First type: cumulative assessment for cost-effectiveness of integrated application of various abatement measures by a fleet (linear cost-effectiveness trend line) | IMO | 2009 | Global fleet (14 ship types) | 25 energy efficiency measures (10 groups) | [16] |

| Netherlands | 2009 | Global fleet (14 ship types) | 29 energy efficiency measures (12 groups) | [17] | |

| IMO | 2014 | Global fleet (14 ship types) | 22 measures (including LNG and biofuel) | [18] | |

| IMO | 2020 | Global fleet (13 ship types) | 34 energy efficiency measures (3 groups) + 10 alternative fuels | [19] | |

| Norway | 2011 | Global fleet (7 ship types) | 25 energy efficiency measures (3 groups) + LNG | [20] | |

| United States of America | 2012 | Global fleet (14 ship types) | 12 energy efficiency measures (6 operational + 6 technical) | [21] | |

| Germany | 2012 | Global fleet (14 ship types) | 22 energy efficiency measures (15 groups) | [22] | |

| China | 2019 | Global fleet (tankers, containers, and bulk carriers) | 14 energy efficiency measures (5 optional + 9 technical) | [8] | |

| Second type: individual assessment of various abatement measures applied in case ships (step-form cost-effectiveness curves) | Norway | 2009 | 2 Case ships (74,000 DWT bulk carrier, 8000 TEU Container ship) | 12 energy efficiency measures | [23] |

| Organization for Economic Co-operation and Development and the International Transport Forum | 2009 | 8500 TEU Container ship | Slow steaming | [24] | |

| Germany | 2012 | Container ship fleet | 12 energy efficiency measures | [25] | |

| Netherlands | 2015 | 10 Case ships | 18 energy efficiency measures + 2 alternative fuels | [26] | |

| Singapore | 2016 | 3 Case ships (bulk carrier, container ship, tanker) | 14 energy efficiency measures (5 optional + 9 technical) | [27] | |

| Norway | 2017 | 6 Case ships | 8 alternative fuels | [28] | |

| China | 2018 | 2 Case ships (feeder container ship, ferry) | LNG | [29] | |

| Czech | 2020 | 9 Case ships | 12 energy efficiency measures | [30] | |

| Norway | 2020 | 4 Case ships | 8 alternative fuels | [31] | |

| Cyprus | 2021 | 4 Case ships | 18 energy efficiency measures (3 groups) + 2 alternative fuels (LNG, biofuel) | [14] | |

| Germany | 2022 | Not specified | 4 alternative fuels (LNG, methanol, ammonia, and hydrogen) | [9] | |

| Turkey | 2022 | Bulk carrier | Ammonia | [32] |

| Ship Type | Classification | Main Engine Power (kW) | Design Speed (kn) | Fuel Consumption (t/year) | Newbuilding Cost (Million USD) |

|---|---|---|---|---|---|

| Bulk carrier | Handysize (61–63K DWT) | 10,000 | 14.6 | 4900 | 34.5 |

| Container ship | 8000 TEU | 68,000 | 25.0 | 264,000 | 98 |

| Product tanker | LR2 (115K DWT) | 13,000 | 14.8 | 5400 | 63 |

| Crude oil tanker | VLCC (315–320K DWT) | 26,000 | 15.5 | 145,000 | 117.5 |

| Ro-Ro passenger ferry | 3500 DWT | 16,000 | 20.3 | 7900 | 110 |

| Category | Sub-Category | Abatement Measures | Applicability | Abatement Potential | Investment Cost (USD) | Operational Cost (USD) | Ref. |

|---|---|---|---|---|---|---|---|

| Energy efficiency measures | Operational measures | Slow steaming (SS, with 10% reduction) | All ship types except for cruise vessels and ferries | 19% | N/A | N/A | [42] |

| Optimization of Trim and Ballast (OTB) | All ship types | 1.5–4% | 26,700 | N/A | [14] | ||

| Propeller maintenance | All ship types | 1% | 3000–4500 (Maintenance at intervals of 5 years) | N/A | [17] | ||

| Technical measures | Optimized water flow of hull openings (OWF) | All ship types | 3% | 42,000–240,000 | N/A | [14,42] | |

| Air lubrication (AL) |

| 5–7% | Approx. 3% of shipbuilding cost | 11,000 | [14,42] | ||

| Hull coating (HC) | All ship types | 1.5% | Approx. 30 × DWT^(2/3) (Generally recoated at intervals of 5 years) | N/A | [42] | ||

| Propeller boss cap with fins (PBCF) | All ship types | 2% | 79,000–520,000 | N/A | [14] | ||

| Main engine tuning (MET) | All ship types | 0.45% | 27,000–48,000 | N/A | [14,42] | ||

| Waste heat recovery (WHR) | Main engine power ≥ 10,000 kW (slow steaming vessel would not be able to use WHR) | 3–8% | 327 USD/kW (Proportional to main engine power) | 10,000–30,000/year | [43] | ||

| Speed control of pumps and fans (SCPF) | All ship types | 0.5% | 100–200 USD/kW (Auxiliary engine power) | N/A | [44] | ||

| Renewable energy sources | Flettner rotors (FR) | Bulk carriers, crude oil tankers, chemical tankers, and product tankers (above 10,000 DWT) | 8.5% | 2,000,000–4,000,000 | N/A | [17,45] | |

| Rigid sails (RS) | Bulk carriers, crude oil tankers, chemical tankers, and product tankers (above 10,000 DWT) | 3–5% | 300,000–600,000 | N/A | [43,45] | ||

| Solar panels (SP) | Ships have sufficient deck space available (tankers, vehicle carriers, and Ro-Ro vessels) | 0.2% | 3400 USD/kW (Power of SP generally calculated as 1% of the auxiliary engine power) | N/A | [14,17] |

| Category | Sub-Category | Abatement Measures | Applicability | Abatement Potential | Investment Cost (USD) | Operational Cost (USD) | Ref. |

|---|---|---|---|---|---|---|---|

| Alternative fuels | Fossil fuel | LNG | All ship types | 13.9% | Approx. 15–20% higher than conventional vessels | Mainly fuel cost | [34] |

| Biofuels | Bio-LNG | All ship types | 77.7% | Approx. 15–20% higher than conventional vessels | Mainly fuel cost | [34] | |

| Bio-methanol | All ship types | 85.0% | Approx. 14.4% higher than conventional vessels | Mainly fuel cost | [34] | ||

| Hydrotreated vegetable oil (HVO) | All ship types | 82.1% | Equivalent to conventional vessels | Mainly fuel cost | [34] | ||

| Electrofuels | E-methanol | All ship types | 95% | Approx. 14.4% higher than conventional vessels | Mainly fuel cost | [34,46] | |

| E-ammonia | Cargo ships | 100% | Approx. 21.2% higher than conventional vessels | Mainly fuel cost | [47] |

| Fuel Category | Fuel Type | Engine Type | GHG Emission Factors (g CO2e/MJ) | Abatement Potential | ||

|---|---|---|---|---|---|---|

| GHGWtT | GHGTtW | GHGWtW | ||||

| Fossil fuels | LSFO | Diesel | 13.2 | 76.8 | 90 | Baseline |

| LNG | DF Diesel | 18.5 | 59.0 | 77.5 | 13.9% | |

| Methanol | DF Diesel | 31.3 | 71.6 | 100.4 | −14.3% | |

| Ammonia | DF Diesel | 121 | 0 | 121 | −34.4% | |

| Biofuels | Bio-LNG | DF Diesel | −38.9 | 59.0 | 20.1 | 77.7% |

| Bio-methanol | DF Diesel | −58.1 | 71.6 | 11.0 | 85.0% | |

| HVO | Diesel | −20.7 | 71.9 | 51.2 | 41.3% | |

| Electrofuels | E-Methanol | DF Diesel | −67.1 | 71.6 | 4.5 | 95.0% |

| E-Ammonia | DF Diesel | 0 | 0 | 0 | 100% | |

| Fuel Type | LSFO | LNG | Bio-LNG | Bio-Methanol | HVO | E-Methanol | E-Ammonia |

|---|---|---|---|---|---|---|---|

| Average price (USD/t) | 455 | 425 | 1416 | 612 | 1750 | 1174 | 740 |

| Ship Type | Energy Efficiency Measures with Negative MAC Values | ||

|---|---|---|---|

| Ranking Orders | Abatement Potentials | Annual Cost Savings (million USD) | |

| Bulk carrier (61–63K DWT) | SS, OWF, OTB, PM, PBCF, MET, RS, HC, AL | 40% | 0.75 |

| Container ship (8000 TEU) | SS, OTB, PM, OWF, MET, HC, PBCF, AL, SCPF | 36.5% | 43.34 |

| Product tanker (115K DWT) | SS, OTB, PM, OWF, PBCF, MET, RS, HC, AL | 38.5% | 0.69 |

| VLCC (315–320K DWT) | SS, OTB, PM, OWF, MET, PBCF, RS, HC, AL | 38.5% | 21.8 |

| Ro-Ro passenger ferry (3500 DWT) | SS, OWF, OTB, PM, HC, PBCF, MET | 28.5% | 1.0 |

| Category | Ranking (Baseline) | Abatement Measures | LSFO Price (% Change from Baseline) | ||||

|---|---|---|---|---|---|---|---|

| −50% | Baseline (455 USD/t) | +50% | +100% | +150% | |||

| MAC (USD/tCO2e) | |||||||

| Energy efficiency measures | 1 | Slow steaming | −71 | −143 | −214 | −285 | −357 |

| 2 | Optimized water flow of hull openings | −64 | −136 | −207 | −278 | −350 | |

| 3 | Optimization of Trim and Ballast | −62 | −134 | −205 | −277 | −348 | |

| 4 | Propeller maintenance | −60 | −131 | −203 | −274 | −346 | |

| 5 | Propeller boss cap with fins | −52 | −123 | −194 | −266 | −337 | |

| 6 | Main engine tuning | −42 | −113 | −184 | −256 | −327 | |

| 7 | Rigid sails | −41 | −112 | −183 | −255 | −326 | |

| 8 | Hull coating | 5 | −66 | −137 | −209 | −280 | |

| 9 | Air lubrication | 13 | −59 | −130 | −201 | −273 | |

| 10 | Flettner rotors | 46 | −25 | −96 | −167 | −239 | |

| 11 | Speed control of pumps and fans | 151 | 80 | 8 | −63 | −134 | |

| 12 | Waste heat recovery | 495 | 424 | 353 | 281 | 210 | |

| Alternative fuels | 1 | LNG | 482 | 45 | −392 | −829 | −1266 |

| 2 | Bio-methanol | 355 | 284 | 212 | 141 | 68 | |

| 3 | Bio-LNG | 382 | 303 | 225 | 147 | 69 | |

| 4 | E-ammonia | 412 | 352 | 291 | 230 | 169 | |

| 5 | E-methanol | 648 | 584 | 520 | 456 | 334 | |

| 6 | HVO | 922 | 776 | 629 | 482 | 392 | |

| Category | Ranking (Baseline) | Abatement Measures | Carbon Price (USD/t CO2e) | |||

|---|---|---|---|---|---|---|

| Baseline | 100 | 200 | 300 | |||

| MAC (USD/tCO2e) | ||||||

| Energy efficiency measures | 1 | Slow steaming | −143 | −243 | −343 | −443 |

| 2 | Optimized water flow of hull openings | −136 | −236 | −336 | −436 | |

| 3 | Optimization of Trim and Ballast | −134 | −234 | −334 | −434 | |

| 4 | Propeller maintenance | −131 | −231 | −331 | −431 | |

| 5 | Propeller boss cap with fins | −123 | −223 | −323 | −423 | |

| 6 | Main engine tuning | −113 | −213 | −313 | −413 | |

| 7 | Rigid sails | −112 | −212 | −312 | −412 | |

| 8 | Hull coating | −66 | −166 | −266 | −366 | |

| 9 | Air lubrication | −59 | −159 | −259 | −359 | |

| 10 | Flettner rotors | −25 | −125 | −225 | −325 | |

| 11 | Speed control of pumps and fans | 80 | −20 | −120 | −220 | |

| 12 | Waste heat recovery | 424 | 324 | 224 | 124 | |

| Alternative fuels | 1 | LNG | 45 | −55 | −155 | −255 |

| 2 | Bio-methanol | 284 | 174 | 74 | −26 | |

| 3 | Bio-LNG | 303 | 203 | 103 | 3 | |

| 4 | E-ammonia | 352 | 252 | 152 | 52 | |

| 5 | E-methanol | 584 | 484 | 384 | 284 | |

| 6 | HVO | 776 | 676 | 576 | 476 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tu, H.; Liu, Z.; Zhang, Y. Study on Cost-Effective Performance of Alternative Fuels and Energy Efficiency Measures for Shipping Decarbonization. J. Mar. Sci. Eng. 2024, 12, 743. https://doi.org/10.3390/jmse12050743

Tu H, Liu Z, Zhang Y. Study on Cost-Effective Performance of Alternative Fuels and Energy Efficiency Measures for Shipping Decarbonization. Journal of Marine Science and Engineering. 2024; 12(5):743. https://doi.org/10.3390/jmse12050743

Chicago/Turabian StyleTu, Huan, Zheyu Liu, and Yufeng Zhang. 2024. "Study on Cost-Effective Performance of Alternative Fuels and Energy Efficiency Measures for Shipping Decarbonization" Journal of Marine Science and Engineering 12, no. 5: 743. https://doi.org/10.3390/jmse12050743

APA StyleTu, H., Liu, Z., & Zhang, Y. (2024). Study on Cost-Effective Performance of Alternative Fuels and Energy Efficiency Measures for Shipping Decarbonization. Journal of Marine Science and Engineering, 12(5), 743. https://doi.org/10.3390/jmse12050743