1. Introduction

With the development of urbanization, the disposal of waste has become a major issue of worldwide concern. Despite significant progress in reducing waste volume by reuse and recycling, especially since promotion of waste strategies, the bulk of municipal waste is still disposed of in landfill sites, representing about 48% of the municipal waste in the UK [

1]. The disposal of waste in landfill sites requires careful design; otherwise it might cause, or contribute to, an environmental health risk.

The environmental risk resulting from the landfill disposal of waste materials mainly arises through the production of leachate and landfill gas. Leachate can be described as the liquid draining from a landfill site in the form of suspended materials, dissolved components of waste materials, byproducts from degradation

etc., through percolation within the site [

2,

3]. Because leachate contains harmful and complex compounds,

i.e. organic matter leading to high Chemical Oxygen Demand (COD) and Biological Oxygen Demand (BOD), and heavy metals, e.g., iron, copper

etc [

3], leachate can adversely affect plant growth, contaminate the drinking water and impair the ecosystem as it penetrates the soils or groundwater.Moreover, leachate treatment is one of the most difficult problems to handle, as it could be released from the start of landfill operations until potentially many decades after closure [

4]. Thus, it should be treated until they meet environmental criteria.

With natural resources being exploited at an increasing rate, as well as the threat of climate change, the concept of Sustainable Development has been given more and more attention. Sustainable Development may be broadly defined as “

the principles of the current process of economic and technological development to ensure that the use of environmental resources to satisfy present demands is managed in a way that they are not left so damaged or impoverished they cannot be used by future generations” [

5]. In this context, landfill gas (LFG), if uncontrolled, is considered as one of the main sources of greenhouse gas emissions, especially in producing large amounts of methane, which is about 21 times more potent than CO

2 [

6]. Thus, not only reducing waste, but also reusing, recycling and recovering value from the waste materials, should be the significant indicators to achieve the goal of sustainable development. In particular, landfill should be the last resort and then only to receive certain specific types and amounts of waste materials [

6]. However, as long as landfill still remains a disposal option, leachate and gas will be generated and thus remain a potential environmental risk to the public.

Thus, in considering how to minimize the potential environmental risk posed by the disposal of waste in landfill, effort should be directed at leachate treatment and landfill gas recovery. A conceptually alternative treatment system is presented below to control leachate and landfill gas, ultimately to reduce the environmental risk and carbon footprint, as well as to save energy and the cost of disposal.

2. Approach for Landfill Leachate Treatment

Conventional treatments of landfill leachate mainly comprise the transfer method, and biological, chemical and physical approaches [

7,

8]. Leachate transfer is an indirect treating approach, in which a piping system is built into the landfill site, to transfer leachate to a local sewage plant for treatment together with municipal sewage. This approach has been implemented for many years, and is especially common in some Asian countries such as South Korea, China

etc. [

9,

10]. Although it is comparatively easy to maintain and operate with lower economic cost, this option still has many uncertainties on its treating performance which inhibit further application. For example, the heavy metals and non-biodegradable organics contained in the leachate may cause negative influences and difficulties for municipal wastewater purification [

9,

10,

11].

The biological, chemical and physical approaches are derived from the conventional waste water treatment technology [

12]. The prime principle of the biological treatment is using microorganisms or bacteria to degrade organic compounds to carbon dioxide under aerobic conditions and to biogas under anaerobic conditions. Hence, the biological approach can be mainly divided into aerobic and anaerobic treatment [

13]. Biological treatment is beneficial for leachate with high organic content, especially reflected in COD, BOD and TSS (Total Suspended Solids) removal [

14]. With the development of various kinds of biological treatment process, such as Sequencing Batch Reactor (SBR), Upflow Anaerobic Sludge Blanket Reactor (UASBR), Simultaneous Aerobic and Anaerobic (SAA) bioreactor system, combined anaerobic digester and activated sludge system

etc., current studies have demonstrated that the main organic pollutants such as COD, BOD, NH4+-N

etc. can be reduced to varying extents. In particular, it is noteworthy that the best removal efficiency of the above mentioned organic constituents can be up to 90% [

15,

16,

17,

18]. However, if the leachate contains toxic substances, such as organochlorines

etc., the effect of biological processes is restricted, as pollutants are emitted into the air, water and the sewage sludge [

7]. In addition, older leachate with biorefractory contaminants and high content of ammonia is not amenable to conventional biological processes due to inhibition of the microorganisms in activated sludge [

19,

20].

In contrast to the biological treatment methods, physical and chemical treatment processes cannot be deemed as “real” methods, but can be applied as effective pre-treatments, or for final purification of wastewater through specific contaminant treatment such as ammonia removal, as well as in combination with other treatment process, e.g., biological treatment [

4,

8]. Specifically, the physical and chemical process mainly consists of flotation, coagulation-flocculation, adsorption, stripping, and chemical oxidation

etc. to reduce the non-biodegradable organic matters (high ammonia contents, colloidal particles), heavy metals, toxic compounds, and color [

19,

20,

21,

22,

23,

24]. However, due to the process of leachate stabilization through aging of the landfill site, combined with varying emission standards set within different countries, the physical-chemical or biological treatments alone cannot always be relied upon to minimize the environmental impact.

In addition to conventional treatment, thermal treatments of leachate such as evaporation, chemical stripping, distillation, incineration, wet air oxidation, vitrification

etc. have been developed to separate the solutions and suspensions of inorganic and organic leachate components in terms of their different thermal behaviors [

7]. However, thermal treatments have been rarely reported in the current studies, apart from those specific to evaporation [

25]. Controlled evaporation is best achieved using heat to convert the liquid leachate,

i.e. concentrating the solution into a small volume at or close to crystallization point, to reduce its contained toxicity and non-biodegradability. Although there are also some disadvantages of thermal treatment for landfill leachate, particularly the need for careful air pollution control due to the volatile components emitted in the exhaust gas, and high inorganic salt concretion on the furnace wall resulting in reduced heat transfer, it is still considered to be suitable for treating all types of leachate, especially with toxic components [

7,

11,

26]. For instance, fewer separate processing steps are used to handle leachate compared to the conventional treatments in which more sequential units are involved. Moreover, conventional leachate treatments (physical, chemical and biological treatment) are often implemented off site, which require strict conditions such as for biodegradation activity, long term residence time

etc., and may result in environmental risk during transportation as well as incurring a transportation cost [

26,

27]. In essence, the thermal treatment of leachate, has been mainly developed in the form of evaporation, using landfill gas as the energy source [

25,

28,

29]. Thus, the operations cost can be reduced. In a typical case, Power Strategies L.L.C has designed a leachate treatment system called “Vaporator”, not only employing landfill gas for evaporation, but also using the resulting vapor to produce electricity by means of a Reciprocating Internal Combustion (RIC) engine [

30].

3. An Alternative System for Landfill Gas and Leachate Control

As indicated by the above review, conventional treatment through combined biological and physico-chemical processes has been considered to be the most appropriate technology for landfill leachate treatment and control for many years. However, the disadvantages should also be mentioned, e.g., secondary environmental pollution to the air due to physical and chemical reactions during the treating process, high cost of the corresponding chemical additives, process operation and maintenance, low energy recovery

etc. [

31].

Therefore, a novel term “treat waste by using waste” is proposed to aid the conceptual design for landfill leachate control, considering one kind of waste material which can be recycled or reused as the “feedstock”, deemed as the direct or indirect source to treat other kinds of waste. Here, the authors suggest that certain by-products from landfill disposal can be used in this way, in this instance using landfill gas to treat leachate, noting the successful experience of leachate evaporation directly fuelled by landfill gas. However, this proposed alternative treatment system chooses incineration instead of evaporation technology, and mainly focuses on examining a possible relationship between the existing landfill site and an incinerator located nearby, and comparing this with a conventional leachate evaporation system located in the landfill site. In particular, landfill gas is considered as indirect utilization through producing methane to improve incinerator combustion in comparison with direct utilization for evaporation. Although using landfill gas for leachate thermal treatment is claimed to reduce fuel and operational costs, the detailed economic feasibility has not been stated in current literature. This study will provide insight to compare the potential economic benefit derived from the proposed alternative treatment system.

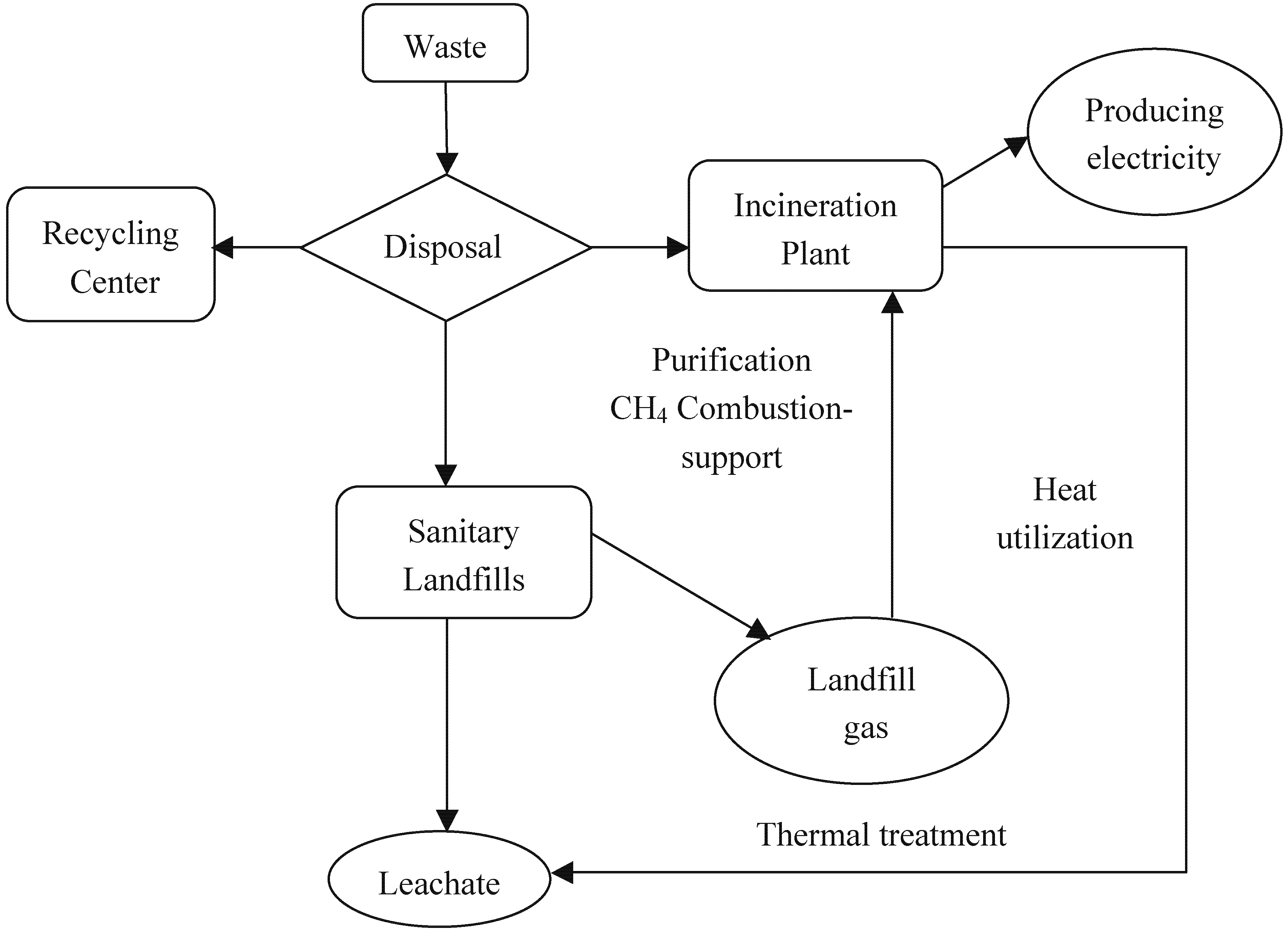

In

Figure 1, three typical waste disposal approaches are invoked: recycling or reusing, incineration and sanitary landfill. Whilst, in order to relieve the pressure on sanitary landfill, recycling or reuse are the preferred options in terms of the “hierarchy of waste management”, those components of the waste with significant calorific value, together with hazardous waste, can be sent directly to the incineration plant for thermal treatment. Through the energy recovery system, landfill gas can be purified as methane and collected as the combustion support for the incinerators, and helping to reduce the requirement for combustion improvers like diesel, gasoline

etc. [

32]. In the manner of an “energy from waste” scheme, the incineration plant can be used not only to generate electricity, but also to thermally treat the leachate from the landfill site.

Figure 1.

Conceptual alternative treatment system for landfill gas and leachate treatment.

Figure 1.

Conceptual alternative treatment system for landfill gas and leachate treatment.

3.1. Analysis of Technical Possibility

From the above conceptual model (See

Figure 1), the key to technical possibility is to determine whether landfill gas could be effectively recovered and utilized as the combustion improver for the incinerator, the heat provided by the incinerator being used thermally to treat the leachate. Current research demonstrates that energy recovery from landfill gas reduces environmental impact, especially greenhouse gas emission, particularly compared with uncontrolled flare combustion directly in air [

33,

34]. There are several options to recover and reutilize landfill gas, including direct heating applications, electricity generation, feedstock for chemical manufacturing processes, purification to pipeline quality gas, soil remediation, heat recovery from landfill flares

etc. [

33,

35,

36]. It is clear that landfill gas can be purified by industrial processing. Accordingly, methane can be separated from landfill gas through certain technological processes, for example using physical, chemical or biological washing procedures to extract it [

7], followed by transport by pipelines to the designated industrial plant.

Leachate incineration, compared to evaporation, can be deemed as complete oxidation, which is more efficient for treating leachate with high concentration of organic components, or toxic and non-biodegradable substances [

7]. Leachate can be injected directly into the incineration flare, without a separate and previous evaporation, which is easy and simple to handle and the total volume can be reduced to less than 5% of original volume [

29]. Atabarut and Ekinci [

26] have investigated two different incineration systems for leachate treatment in Turkey, viz. ‘double-phase liquid waste incineration system’ and ‘new pilot-scale incineration system’. The former system can only partially deal with organics and may result in an agglomeration problem. In the case of the latter, leachate treatment has been demonstrated by experiment, without giving rise to any malodorous problem and significant corrosion.

However, such factors related to heat loss as temperature, residence time and injection rate should be emphasized during the process of leachate incineration. Generally speaking, residence time between 0.25 and 1.0 second, as well as temperature above the auto-ignition temperature (>870 Celsius) of Volatile Organic Compunds (VOC) can guarantee complete incineration. Furthermore, the leachate injection rate should not be so high as to result in lower furnace temperature, and thus to increase exhaust gas volume and exit velocity [

27,

29].

Based on the above discussion, it is considered that the main technical specifications for the conceptual prototype of alternative treatment system can be embodied by existing technology, through which landfill gas will be recovered as the combustion improver for incineration, combined with thermal treatment of the leachate.

3.2. Preliminary Economic Comparison

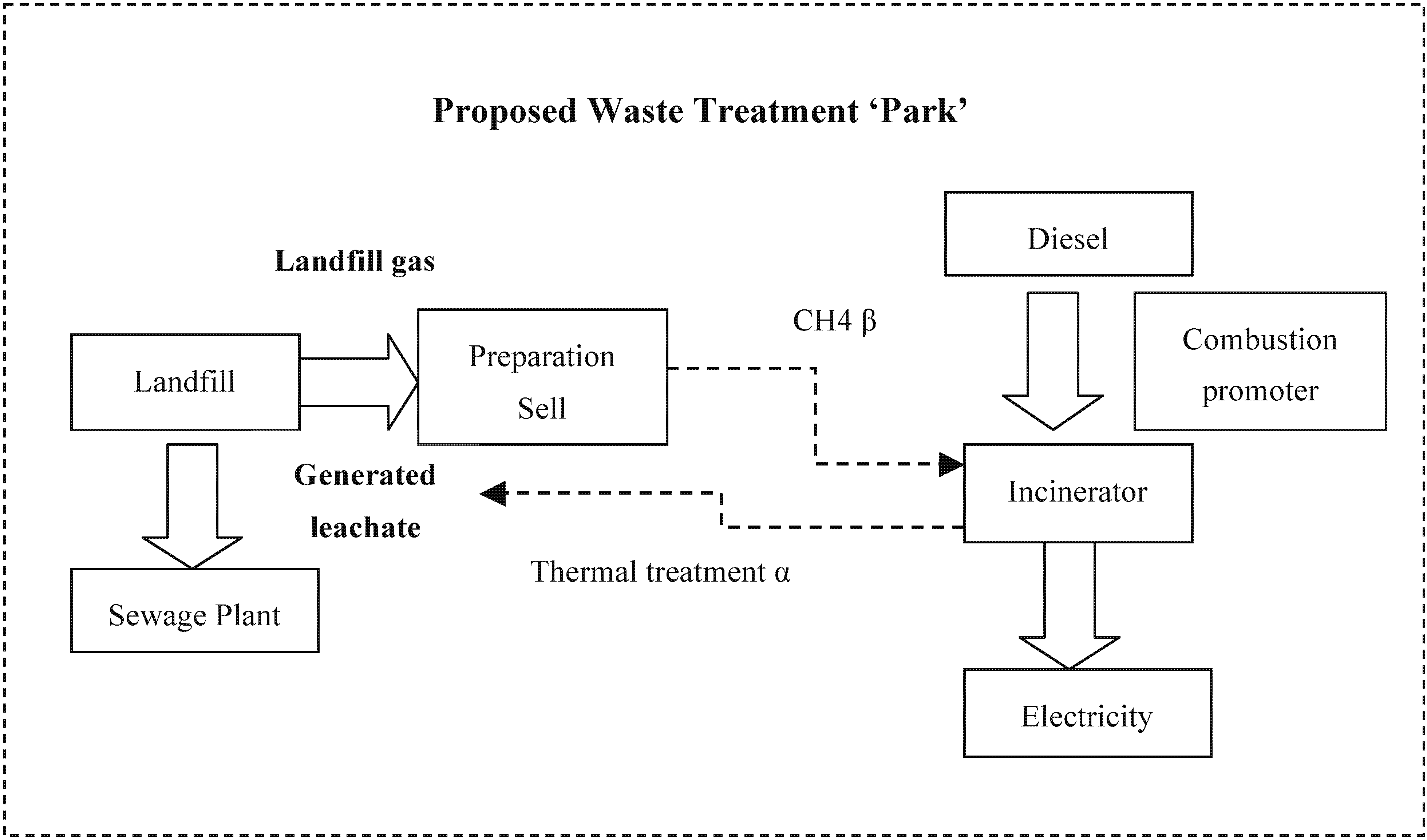

Suppose municipal wastes are treated in a unified planning area, in which landfill and incinerator are located as a waste treatment ‘park’. Thus, the total economic benefit is the sum of the contributions from landfill and incineration.

Figure 2 illustrates a possible relationship between a landfill site and associated incinerator. Assume that landfill and incinerator operate without any connection (separate operation) in the initial stage. Subsequently, an energy recovery system has been built to collect and purify the landfill gas with a view to selling the product. The leachate is initially pre-treated, then transferred to the municipal sewage plant for further treatment. In addition, diesel has been used as the combustion promoter to incinerate waste and the energy used to generate electricity.

In this study, total economic benefit analysis will be carried out by the comparing the original benefit assuming separate operation, and the expected benefit derived from our conceptual alternative treatment system. Let denote the original total economic benefit of the proposed waste treatment park with no connection between landfill and incinerator, which can be expressed as follows.

where:

GL = annual waste gate fee for landfill

GI = annual waste gate fee for incineration

Pele = annual profit for electricity generation from incinerator

Plg = annual profit from selling prepared landfill gas

CLm = annual maintenance cost for landfill

CIm = annual maintenance cost for incinerator

Cleachate = annual cost paid to sewage plant for leachate treatment

Cfuel = annual cost for diesel purchasing

Figure 2.

Possible connection between landfill and incinerator in a proposed waste treatment ‘park’.

Figure 2.

Possible connection between landfill and incinerator in a proposed waste treatment ‘park’.

In Equation (1), suppose that the parameters like

GL,

GI,

Pele,

CLm,

CIm will not change upon the implementation of the conceptual design. However,

Plg,

Cleachate and

Cfuel will be changed accordingly, and can be obtained as follows.

where:

Mlg = annual output of purified landfill gas (CH4) through energy recovery system

q = selling price of purified landfill gas (CH4), per tonne

Mleachate = annual output of landfill leachate

Ct·l = sewage treatment cost for leachate, per tonne

Idiesel = annual diesel consumption for incineration

Pindustrial = industrial price of diesel, per tonne

Substituting Equations (2), (3) and (4), Equation (1) becomes:

With the proposed alternative treatment system being implemented in the future, there is a possible connection between landfill and incinerator as reflected by dashed-line arrows (See

Figure 2). A percentage β of purified landfill gas will be sent to the incinerator as the combustion promoter, as well as a percentage α of leachate consumed by thermal treatment. Let

E denote the total expected cost benefit of the conceptual model, which can be derived as follows.

Comparison between the original and expected benefit can be obtained by the subtraction of Equations (6) and (5), which is expressed below.

As the complete combustion value of CH

4 (55.5 MJ/kg) is above diesel (44.8 MJ/kg)

J1 >

J2,

![Challenges 03 00278 i008]()

since at least

Pindustrial ≥

q. Thus,

E −

O > 0 which means the expected economic benefit is above original one. Essentially, this preliminary analysis indicates that the alternative treatment system for waste disposal may provide a greater economic benefit.

4. Discussion

The alternative treatment system assumes that landfill disposal and incineration occur at the same site, which is highly influenced by both quality and quantity of landfill gas and leachate. This study mainly focuses on the situation of old saturated landfills that have been completed by an incineration facility in order to enlarge its lifetime, with the hypothesis that LFG is a stable source of the combustion substitute for leachate incineration. But there are uncertainties in evaluating the technical possibility of the alternative system, as the production of landfill gas is a complex process, depending upon many factors, such as characteristics of wastes (e.g., biodegradable and organic, moisture content), the presence of micro-organisms, suitable aerobic and anaerobic conditions, the degree of initial compaction

etc. [

3,

37]. LFG generation rate also changes over time, may be influenced by the type of landfill (e.g., aerobic, semi-aerobic, anaerobic, or bioreactor landfill), waste density

etc. [

14,

37].

The developed countries are expected to reduce landfill disposal, thus decreasing the landfill gas emissions, by improving waste recycling, amd employing reusing technologies [

38]. However, when a landfill site enters the closure phase of its life, while generation of LFG may decrease, it may still continue for decades after the closure [

39]. This argument proves that landfill gas still could be a stable source for energy utilization, except for the phase of intensive gas production, which may not affect the operation of the proposed alternative system. For example, empirical studies have found the energy values from the extracted waste of post-closure landfill can still reach the level required for incineration [

39,

40].

As stated previously, leachate is a hazardous liquid waste with a content of non-biodegradable organic matter, ammonia-nitrogen, heavy metals, chlorinated organic compounds and inorganic salts [

41]. Thus, the long-term behaviours of leachate should be taken into account with landfill operation, in order for appropriate treatment until its quality meets environmental criteria. It is not recommended in the proposed treatment system to incinerate wastes with high chloride concentration, in order to avoid generation of dioxins. However, huge advances in new technologies for landfill leachate treatment have been reported in recent years. In the last two decades, landfill sites in developed countries have been equipped with highly efficient on-site landfill treatment systems, for instance, the treatments based on membrane (MBR) and advanced oxidation technologies [

8]. These technologies have been shown to be a potential alternative for conventional and combined landfill leachate treatments, based on their high removal efficiency (for both BOD and COD), flexibility (both old and young landfill sites), low level of residues

etc. [

8,

41,

42,

43], and which could be considered as the auxiliary approach for our proposed system.

With regard to the economic analysis, the proposed alternative treatment system is based on the assumption that the energy recovery system required to purify and collect LFG has already been constructed at the landfill site. This requires the installation of landfill gas collection pipes from the early stages of landfill construction, and the building of a methane gas refinery. Thus, the initial investment and further maintenance cost should be taken into account to validate the economic analysis. This highlights the need to consider this proposal in the context of an integrated ‘waste treatment park’, rather than as a subsequent development in conjunction with an existing landfill site.

5. Conclusions

This study provides an alternative treatment system that combines the technology of landfill with incineration for waste disposal, through which the recycled landfill gas is transferred to an incinerator as the combustion promoter and heat is used to thermally treat the leachate, in order to reduce the energy consumption and disposal cost. According to the technical possibility analysis, the proposed conceptual model can be designed based on existing technology. Greater benefits could be generated, deriving from the preliminary economic comparison. With the development of technology for landfill gas reutilization and leachate incineration, this conceptual prototype can be realized in the near future, as well as providing a template for leachate and landfill gas control.

However, the authors recognize that there are still some limitations involved in this conceptual design. The economic analysis presented in this study is limited in scope owing to the assumptions made concerning the claimed economic benefits of combining existing technologies, and through the creation of an integrated waste treatment park, designed both to eliminate the difficulties associated with the transport of landfill gas and to reduce the costs of leachate treatment. Furthermore, the not inconsiderable capital costs associated with treatment of gaseous emissions, and the operational costs of ash disposal, have not been considered in this analysis. Thus, further work will center on improvements to the conceptual alternative treatment system, on developing the economic feasibility by using cost-benefit analyses, and on a more detailed consideration of both technical and economic feasibility of combining a landfill site with an incineration plant.

since at least Pindustrial ≥ q. Thus, E − O > 0 which means the expected economic benefit is above original one. Essentially, this preliminary analysis indicates that the alternative treatment system for waste disposal may provide a greater economic benefit.

since at least Pindustrial ≥ q. Thus, E − O > 0 which means the expected economic benefit is above original one. Essentially, this preliminary analysis indicates that the alternative treatment system for waste disposal may provide a greater economic benefit.