Influence of Hybrid Surface Modification on Biocompatibility and Physicochemical Properties of Ti-6Al-4V ELI Titanium

Abstract

:1. Introduction

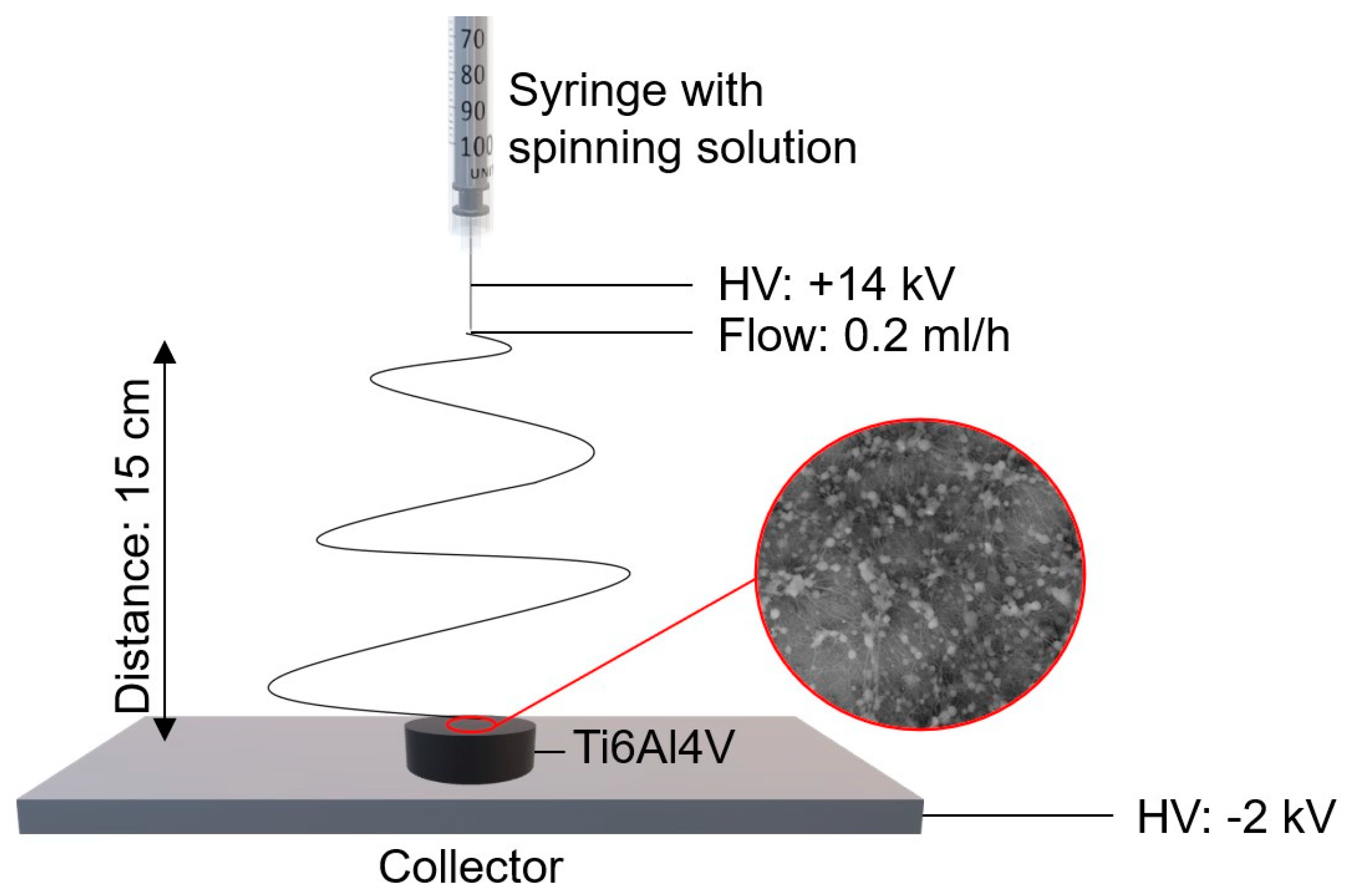

2. Materials and Methods

3. Results

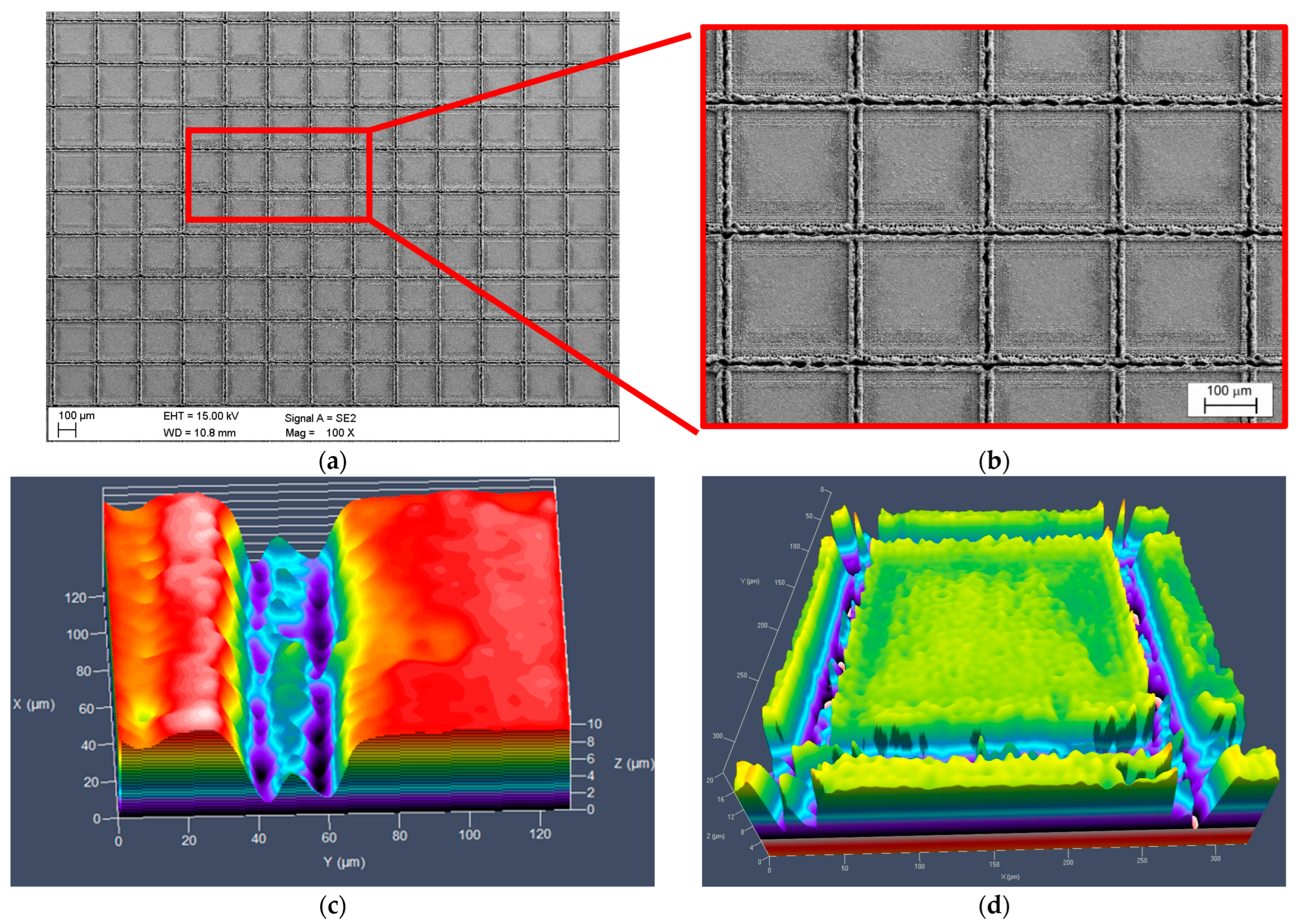

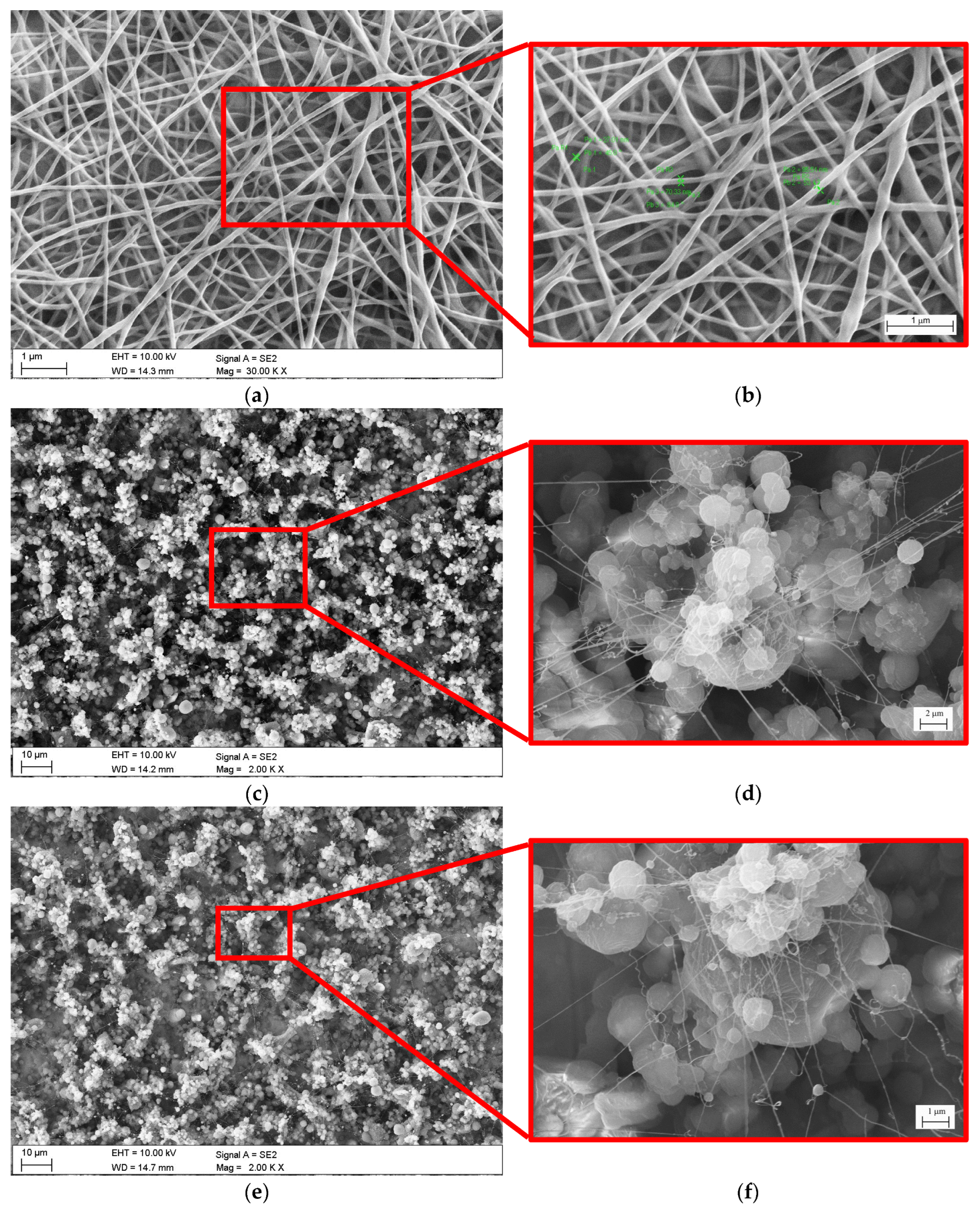

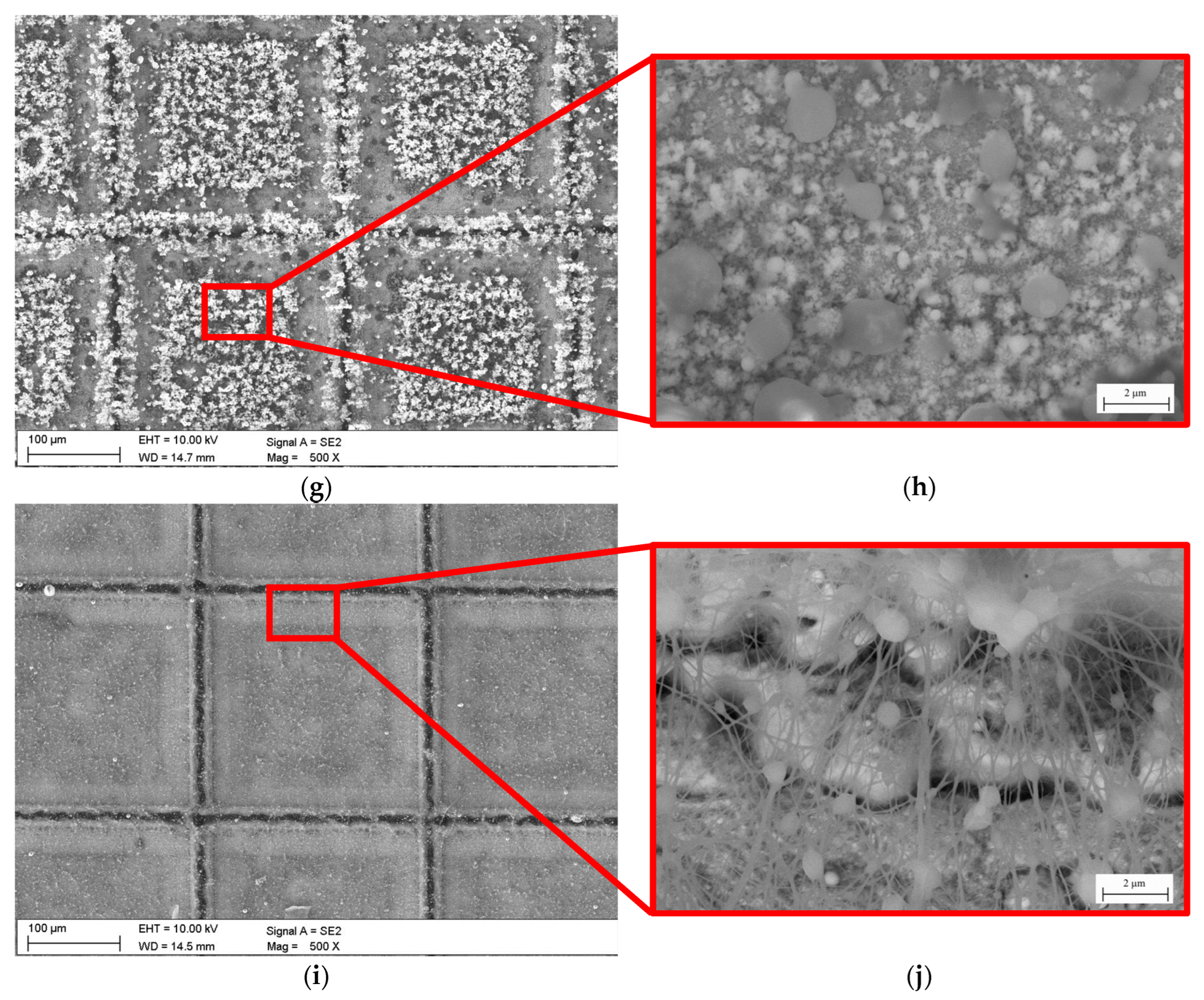

3.1. Surface Morphology Analysis

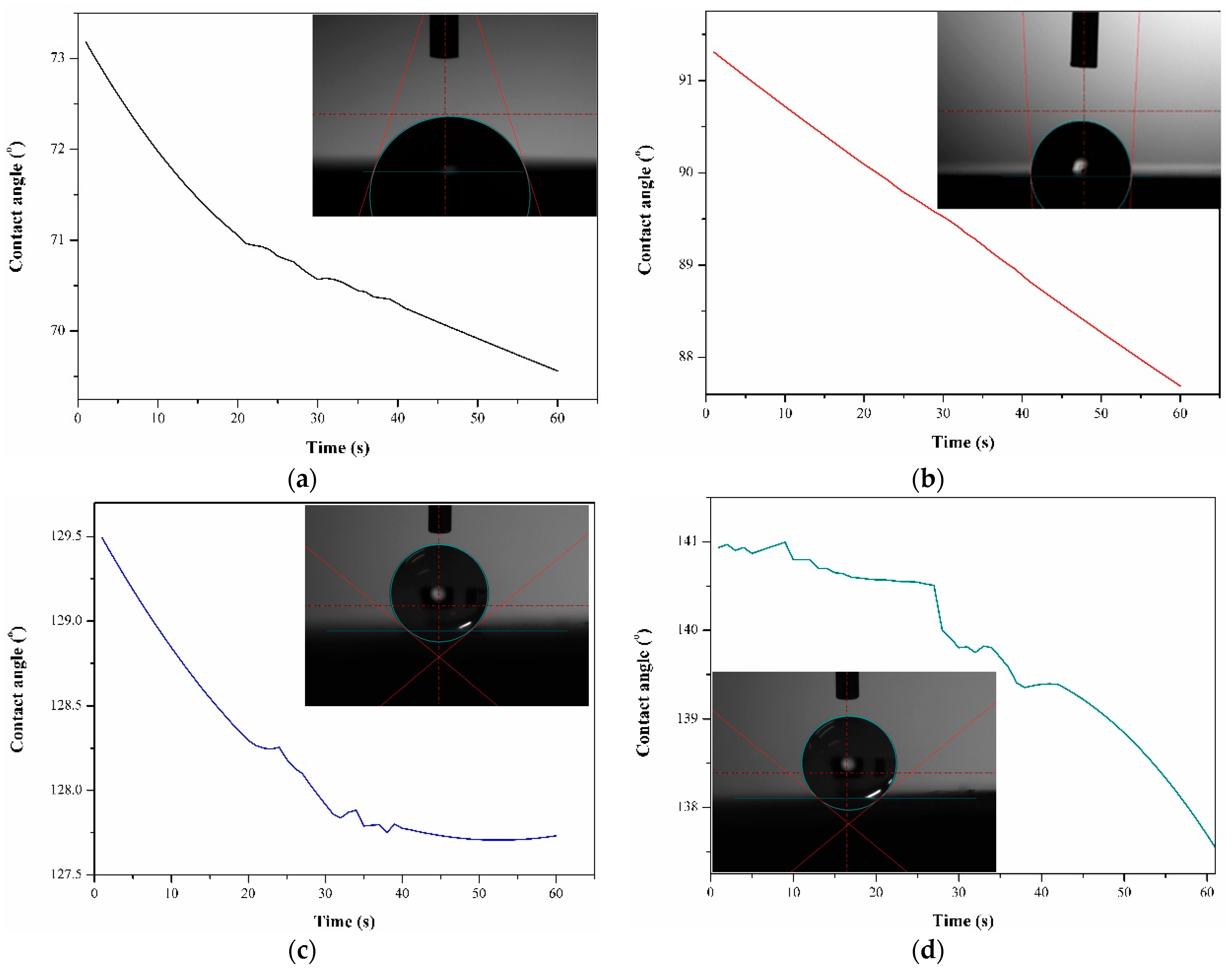

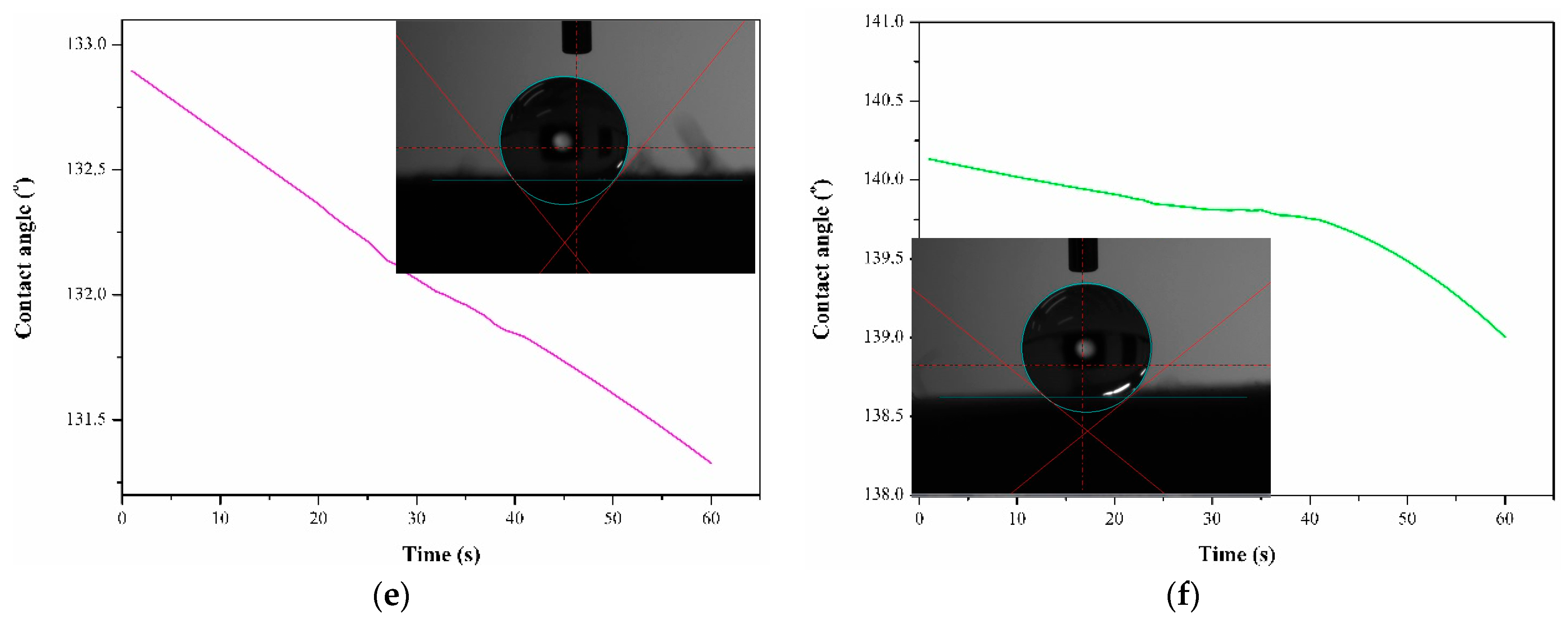

3.2. Wettability Test

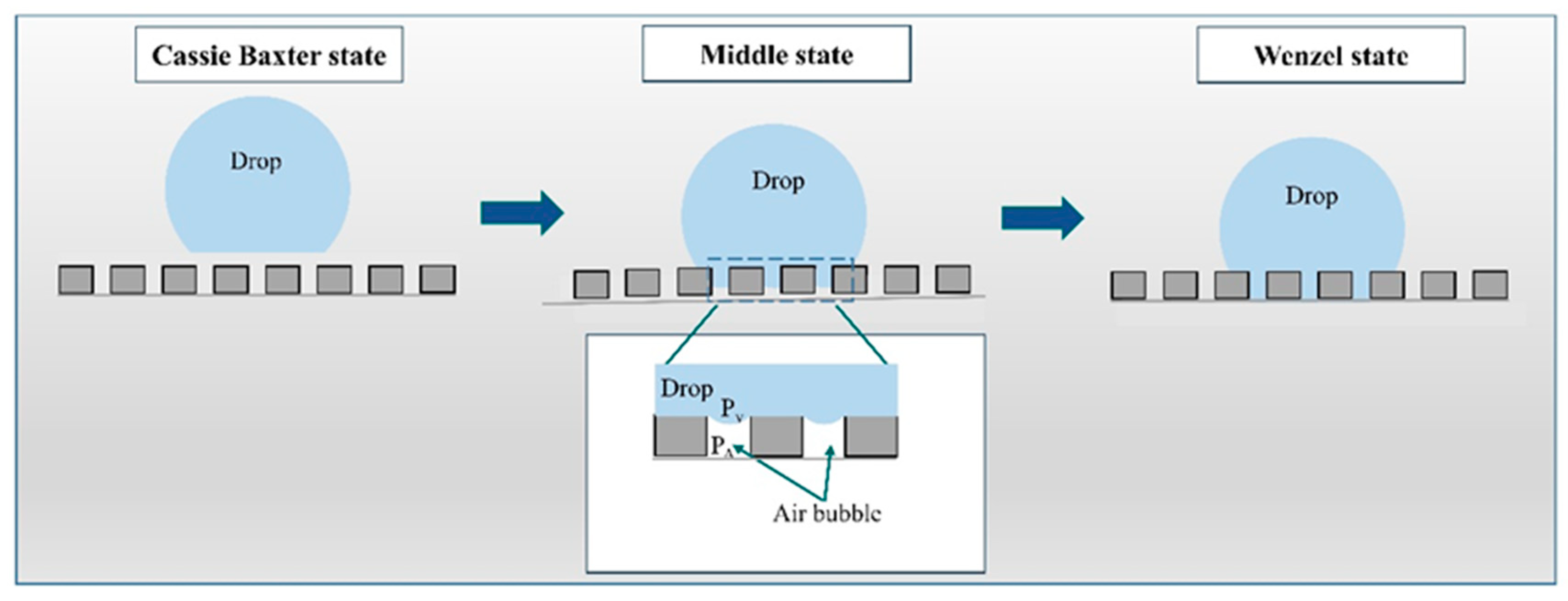

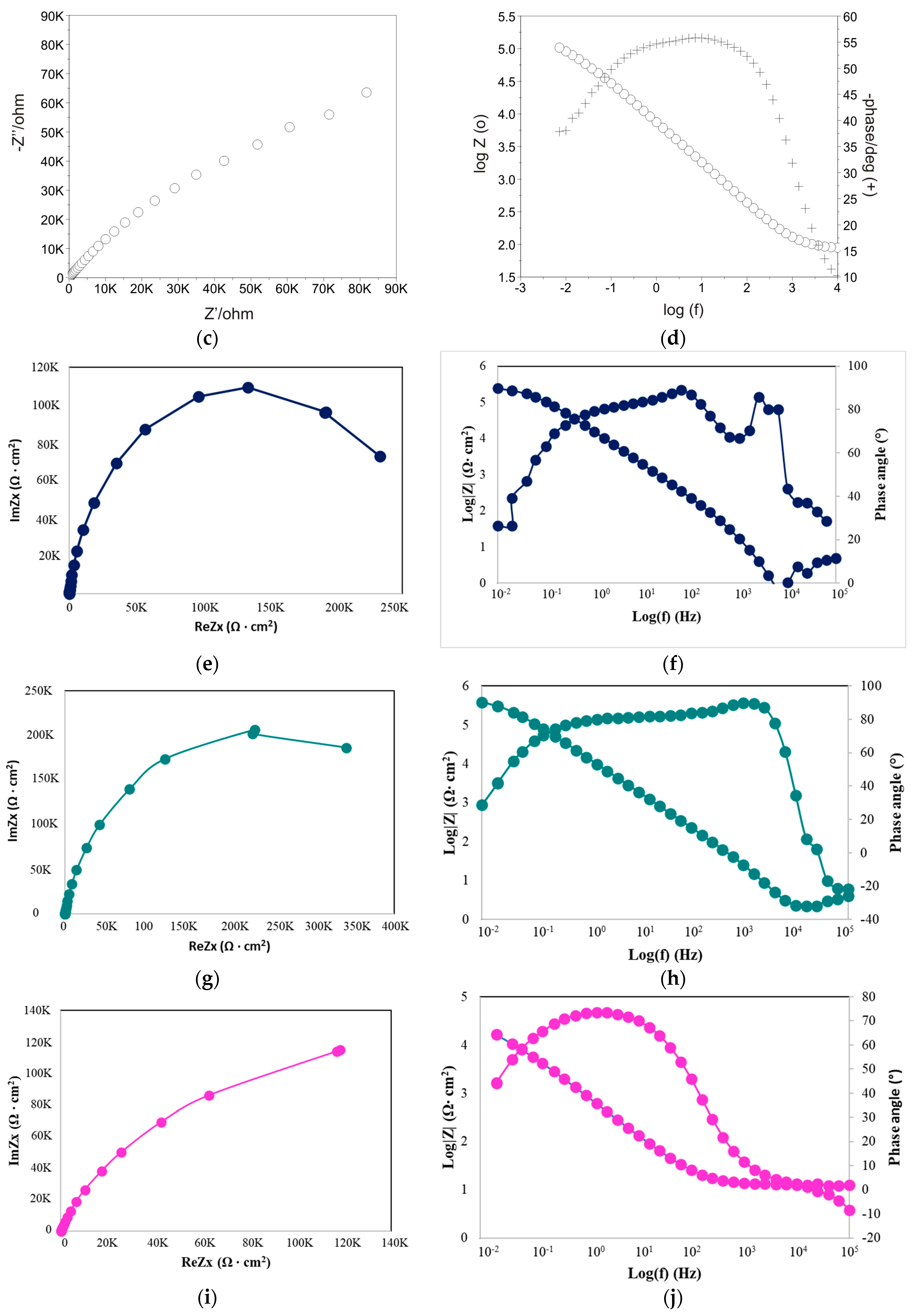

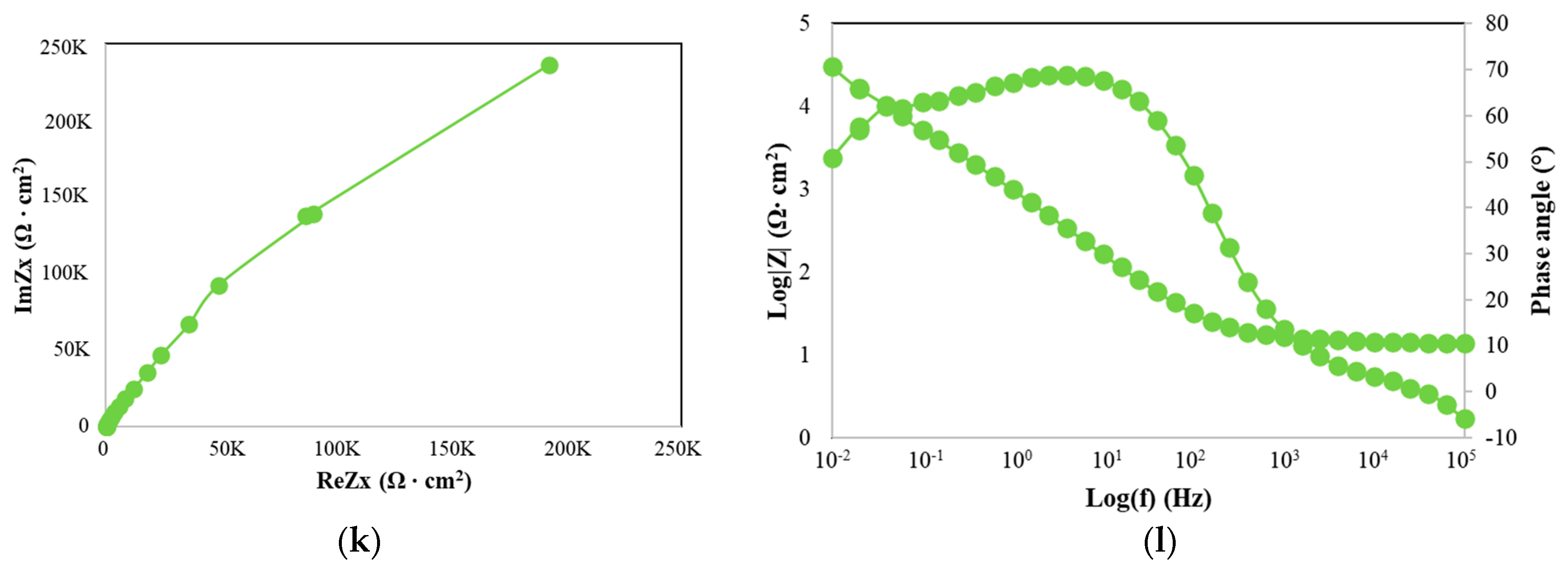

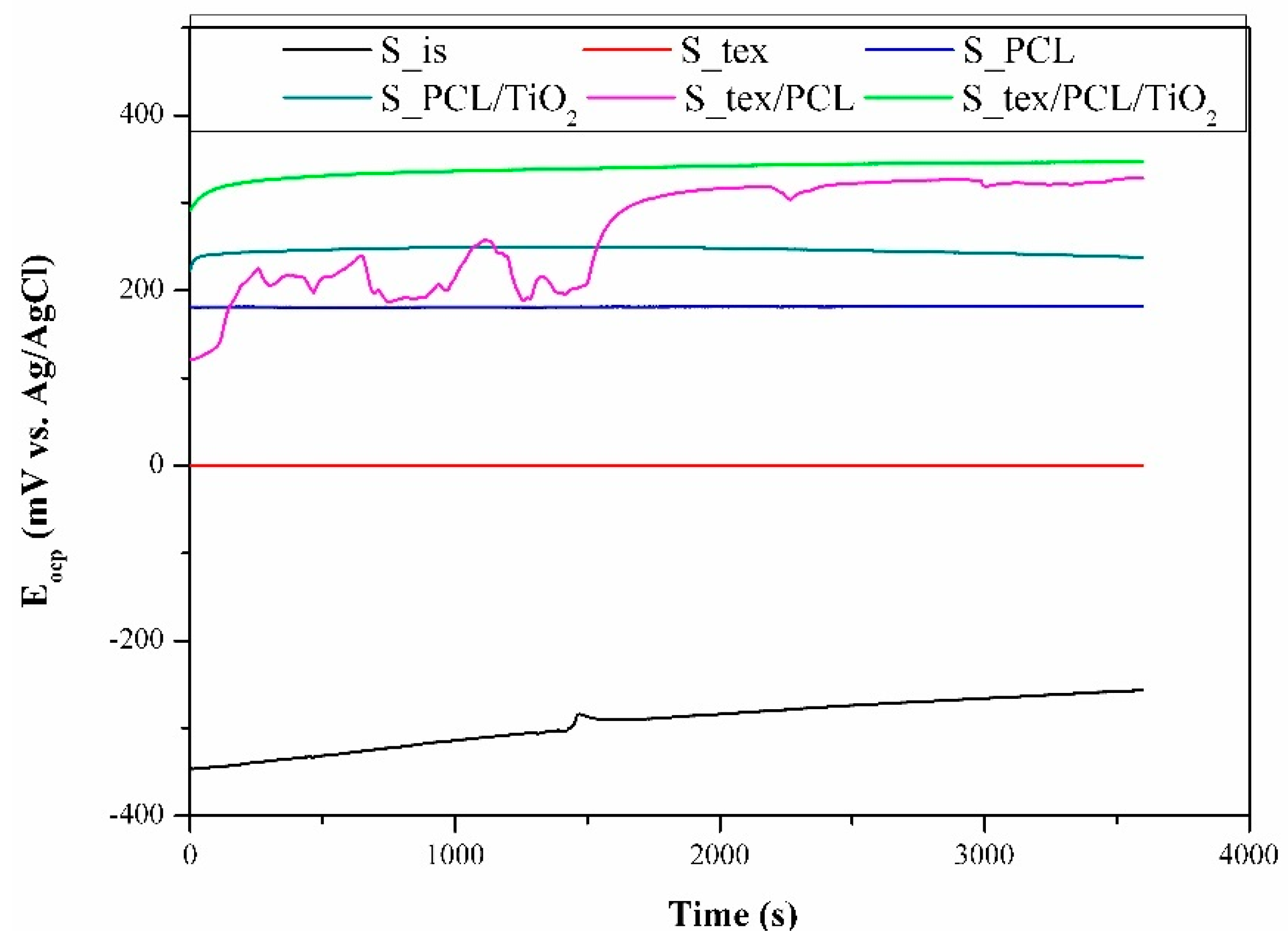

3.3. EIS Test

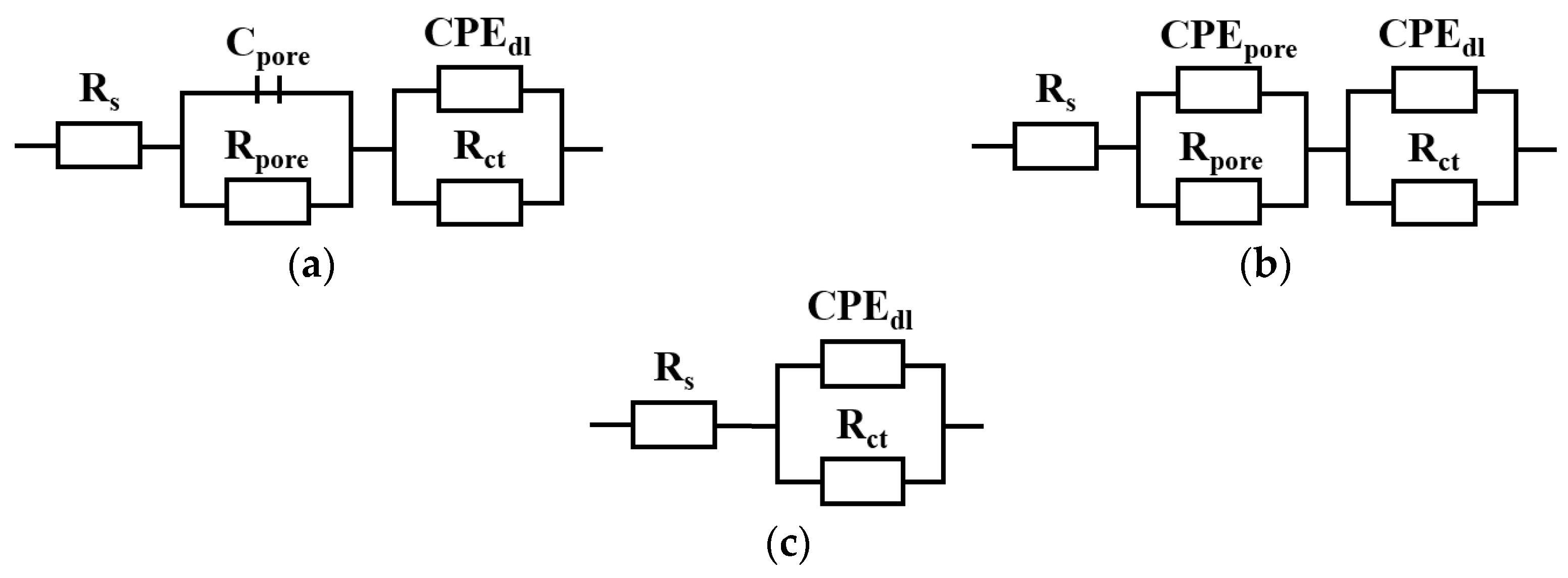

3.4. Potentiodynamic Test

3.5. Inductively Coupled Plasma Atomic Emission Spectroscopy

3.6. Cytotoxicity Tests

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Hamidi, M.F.F.A.; Harun, W.S.W.; Samykano, M.; Ghani, S.A.C.; Ghazalli, Z.; Ahmad, F.; Sulong, A.B. A review of biocompatible metal injection moulding process parameters for biomedical applications. Mater. Sci. Eng. C 2017, 78, 1263–1276. [Google Scholar] [CrossRef]

- Li, K.; Yao, W.; Xie, Y.; Zhang, J.; Li, B.; Wan, Z.; Zhang, Z.; Lu, L.; Tang, Y. A strongly hydrophobic and serum-repelling surface composed of CrN films deposited on laser-patterned microstructures that was optimized with an orthogonal experiment. Surf. Coat. Technol. 2020, 391, 125708. [Google Scholar] [CrossRef]

- Hedberg, Y.S. Role of proteins in the degradation of relatively inert alloys in the human body. npj Mater. Degrad. 2018, 2, 26. [Google Scholar] [CrossRef]

- Ionescu, F.; Reclaru, L.; Ardelean, L.C.; Blatter, A. Comparative analysis of the corrosion resistance of titanium alloys intended to come into direct or prolonged contact with live tissues. Materials 2019, 12, 2841. [Google Scholar] [CrossRef] [PubMed]

- Yu, F.; Addison, O.; Davenport, A.J. A synergistic effect of albumin and H2O2 accelerates corrosion of Ti6Al4V. Acta Biomater. 2015, 26, 355–365. [Google Scholar] [CrossRef] [PubMed]

- Woźniak, A.; Walke, W.; Jakóbik-Kolon, A.; Ziębowicz, B.; Brytan, Z.; Adamiak, M. The Influence of ZnO Oxide Layer on the Physicochemical Behavior of Ti6Al4V Titanium Alloy. Materials 2021, 14, 230. [Google Scholar] [CrossRef] [PubMed]

- Wang, C.; Tian, P.; Cao, H.; Sun, B.; Yan, J.; Xue, Y.; Lin, H.; Ren, T.; Han, S.; Zhao, X. Enhanced Biotribological and Anticorrosion Properties and Bioactivity of Ti6Al4V Alloys with Laser Texturing. ACS Omega 2022, 7, 31081–31097. [Google Scholar] [CrossRef] [PubMed]

- Iwabuchi, A.; Lee, J.W.; Uchidate, M. Synergistic effect of fretting wear and sliding wear of Co-alloy and Ti-alloy in Hanks’ solution. Wear 2007, 263, 492–500. [Google Scholar] [CrossRef]

- Beake, B.D.; Liskiewicz, T.W. Comparison of nano-frètting and nano-scratch tests on biomedical materials. Tribol. Int. 2013, 63, 123–131. [Google Scholar] [CrossRef]

- Babis, G.C.; Stavropoulos, N.A.; Sasalos, G.; Ochsenkuehn-Petropoulou, M.; Megas, P. Metallosis and elevated serum levels of tantalum following failed revision hip arthroplasty—A case report. Acta Orthop. 2014, 85, 677–680. [Google Scholar] [CrossRef]

- Kao, W.H.; Su, Y.L.; Horng, J.H.; Chang, C.Y. Tribological, electrochemical and biocompatibility properties of Ti6Al4V alloy produced by selective laser melting method and then processed using gas nitriding, CN or Ti-C:H coating treatments. Surf. Coat. Technol. 2018, 350, 172–187. [Google Scholar] [CrossRef]

- Conradi, M.; Kocijan, A.; Klobčar, D.; Podgornik, B. Tribological response of laser-textured Ti6Al4V alloy under dry conditions and lubricated with Hank’s solution. Tribol. Int. 2021, 160, 107049. [Google Scholar] [CrossRef]

- Ye, Y.; Wang, C.; Chen, H.; Wang, Y.; Zhao, W.; Mu, Y. Micro/Nanotexture Design for Improving Tribological Properties of Cr/GLC Films in Seawater. Tribol. Trans. 2017, 60, 95–105. [Google Scholar] [CrossRef]

- Tewelde, F.B.; Zhou, T.; Zhou, J.; Guo, W.; Zhao, B.; Ge, X.; Wang, W.; Wang, X.; Wang, X. Asymmetric surface texturing for directional friction control under dry sliding condition. Tribol. Int. 2023, 181, 108321. [Google Scholar] [CrossRef]

- Song, S.; Xiao, G.; Liu, Y.; Zhou, K.; Liu, S.; Huang, J. Tribological response of groove-textured surface with compressive stress on Ti6Al4V processed by laser and abrasive belt. Tribol. Int. 2023, 180, 108265. [Google Scholar] [CrossRef]

- Wang, C.; Hong, J.; Cui, M.; Huang, H.; Zhang, L.; Yan, J. The effects of simultaneous laser nitriding and texturing on surface hardness and tribological properties of Ti6Al4V. Surf. Coat. Technol. 2022, 437, 128358. [Google Scholar] [CrossRef]

- Huang, J.; Guan, Y.; Ramakrishna, S. Tribological behavior of femtosecond laser-textured leaded brass. Tribol. Int. 2021, 162, 107115. [Google Scholar] [CrossRef]

- Dinesh Babu, P.; Vignesh, S.; Vignesh, M.; Balamurugan, C. Enhancement of wear resistance of Ti—6Al—4V alloy by picosecond laser surface micro texturing process. J. Cent. South Univ. 2018, 25, 1836–1848. [Google Scholar] [CrossRef]

- Conradi, M.; Kocijan, A.; Klobčar, D.; Godec, M. Influence of Laser Texturing on Microstructure, Surface and Corrosion Properties of Ti-6Al-4V. Metals 2020, 10, 1504. [Google Scholar] [CrossRef]

- Sadeghi, M.; Kharaziha, M.; Salimijazi, H.R.; Tabesh, E. Role of micro-dimple array geometry on the biological and tribological performance of Ti6Al4V for biomedical applications. Surf. Coat. Technol. 2019, 362, 282–292. [Google Scholar] [CrossRef]

- Erdemir, A. Review of engineered tribological interfaces for improved boundary lubrication. Tribol. Int. 2005, 38, 249–256. [Google Scholar] [CrossRef]

- Chebolu, A.; Laha, B.; Ghosh, M.; Nagahanumaiah. Investigation on bacterial adhesion and colonisation resistance over laser-machined micro patterned surfaces. Micro Nano Lett. 2013, 8, 280–283. [Google Scholar] [CrossRef]

- Veiko, V.; Karlagina, Y.; Zernitckaia, E.; Egorova, E.; Radaev, M.; Yaremenko, A.; Chernenko, G.; Romanov, V.; Shchedrina, N.; Ivanova, E.; et al. Laser-Induced µ-Rooms for Osteocytes on Implant Surface: An In Vivo Study. Nanomaterials 2022, 12, 4229. [Google Scholar] [CrossRef] [PubMed]

- Nathanael, A.J.; Oh, T.H. Biopolymer Coatings for Biomedical Applications. Polymers 2020, 12, 3061. [Google Scholar] [CrossRef] [PubMed]

- Pallickal Babu, S.; Sam, S.; Joseph, B.; Kalarikkal, N.; Radhakrishnan, E.K.; Nair, R.; Thomas, S. Nanoscale polymer coatings for biomedical implants. In Polymer-Based Nanoscale Materials for Surface Coatings; Elsevier: Amsterdam, The Netherlands, 2023; pp. 435–457. [Google Scholar] [CrossRef]

- Wang, T.; Xu, Y.; Liu, Z.; Li, G.; Guo, Y.; Lian, J.; Zhang, Z.; Ren, L. A chitosan/polylactic acid composite coating enhancing the corrosion resistance of the bio-degradable magnesium alloy. Prog. Org. Coat. 2023, 178, 107469. [Google Scholar] [CrossRef]

- Ghanbari, A.; Bordbar-Khiabani, A.; Warchomicka, F.; Sommitsch, C.; Yarmand, B.; Zamanian, A. PEO/Polymer hybrid coatings on magnesium alloy to improve biodegradation and biocompatibility properties. Surf. Interfaces 2023, 36, 102495. [Google Scholar] [CrossRef]

- Alabbasi, A.; Liyanaarachchi, S.; Kannan, M.B. Polylactic acid coating on a biodegradable magnesium alloy: An in vitro degradation study by electrochemical impedance spectroscopy. Thin Solid Film. 2012, 520, 6841–6844. [Google Scholar] [CrossRef]

- Liu, S.; Chen, C.; Chen, L.; Zhu, H.; Zhang, C.; Wang, Y. Pseudopeptide polymer coating for improving biocompatibility and corrosion resistance of 316L stainless steel. RSC Adv. 2015, 5, 98456–98466. [Google Scholar] [CrossRef]

- Zhu, Y.; Liu, W.; Ngai, T. Polymer coatings on magnesium-based implants for orthopedic applications. J. Polym. Sci. 2022, 60, 32–51. [Google Scholar] [CrossRef]

- Huang, Z.M.; Zhang, Y.Z.; Kotaki, M.; Ramakrishna, S. A review on polymer nanofibers by electrospinning and their applications in nanocomposites. Compos. Sci. Technol. 2003, 63, 2223–2253. [Google Scholar] [CrossRef]

- Matysiak, W.; Tanski, T.; Smok, W. Electrospinning as a Versatile Method of Composite Thin Films Fabrication for Selected Applications. Solid State Phenom. 2019, 293, 35–49. [Google Scholar] [CrossRef]

- Chen, Z.; Zhang, Z.; Ouyang, Y.; Chen, Y.; Yin, X.; Liu, Y.; Ying, H.; Yang, W. Electrospinning polycaprolactone/collagen fiber coatings for enhancing the corrosion resistance and biocompatibility of AZ31 Mg alloys. Colloids Surf. A Physicochem. Eng. Asp. 2023, 662, 131041. [Google Scholar] [CrossRef]

- Abdal-hay, A.; Barakat, N.A.M.; Lim, J.K. Influence of electrospinning and dip-coating techniques on the degradation and cytocompatibility of Mg-based alloy. Colloids Surf. A Physicochem. Eng. Asp. 2013, 420, 37–45. [Google Scholar] [CrossRef]

- Vurat, M.T.; Elçin, A.E.; Elçin, Y.M. Osteogenic composite nanocoating based on nanohydroxyapatite, strontium ranelate and polycaprolactone for titanium implants. Trans. Nonferrous Met. Soc. China 2018, 28, 1763–1773. [Google Scholar] [CrossRef]

- Karthega, M.; Pranesh, M.; Poongothai, C.; Srinivasan, N. Poly caprolactone/titanium dioxide nanofiber coating on AM50 alloy for biomedical application. J. Magnes. Alloys 2021, 9, 532–547. [Google Scholar] [CrossRef]

- Kim, J.; Mousa, H.M.; Park, C.H.; Kim, C.S. Enhanced corrosion resistance and biocompatibility of AZ31 Mg alloy using PCL/ZnO NPs via electrospinning. Appl. Surf. Sci. 2017, 396, 249–258. [Google Scholar] [CrossRef]

- Rajabi, T.; Naffakh-Moosavy, H.; Bagheri, F.; Sadrnezhaad, S.K.; Pour, H.M. Tailoring metallurgical and biological characteristics of Ti–6Al–4V alloy by synergetic application of Nd:YAG laser and drug-loaded electrospun PVA. J. Mater. Res. Technol. 2023, 24, 3759–3771. [Google Scholar] [CrossRef]

- Camargo, E.R.; Serafim, B.M.; da Cruz, A.F.; Soares, P.; de Oliveira, C.C.; Saul, C.K.; Marino, C.E.B. Bioactive response of PMMA coating obtained by electrospinning on ISO5832-9 and Ti6Al4V biomaterials. Surf. Coat. Technol. 2021, 412, 127033. [Google Scholar] [CrossRef]

- Huerta-Murillo, D.; García-Girón, A.; Romano, J.M.; Cardoso, J.T.; Cordovilla, F.; Walker, M.; Dimov, S.S.; Ocaña, J.L. Wettability modification of laser-fabricated hierarchical surface structures in Ti-6Al-4V titanium alloy. Appl. Surf. Sci. 2019, 463, 838–846. [Google Scholar] [CrossRef]

- Santhosh, S.; Balasivanandha Prabu, S. Nano hydroxyapatite-polysulfone coating on Ti-6Al-4V substrate by electrospinning. Int. J. Mater. Res. 2013, 104, 1254–1262. [Google Scholar] [CrossRef]

- Cho, S.J.; Kim, B.; An, T.; Lim, G. Replicable multilayered nanofibrous patterns on a flexible film. Langmuir 2010, 26, 14395–14399. [Google Scholar] [CrossRef] [PubMed]

- Martinez-Prieto, N.; Ehmann, K.; Cao, J. Near-field electrospinning on nonconductive substrates using AC fields. Procedia CIRP 2020, 93, 120–124. [Google Scholar] [CrossRef]

- Choi, W.S.; Kim, G.H.; Shin, J.H.; Lim, G.; An, T. Electrospinning onto Insulating Substrates by Controlling Surface Wettability and Humidity. Nanoscale Res. Lett. 2017, 12, 610. [Google Scholar] [CrossRef]

- Gittens, R.A.; Scheideler, L.; Rupp, F.; Hyzy, S.L.; Geis-Gerstorfer, J.; Schwartz, Z.; Boyan, B.D. A review on the wettability of dental implant surfaces II: Biological and clinical aspects. Acta Biomater. 2014, 10, 2907–2918. [Google Scholar] [CrossRef] [PubMed]

- Melo-Fonseca, F.; Guimarães, B.; Gasik, M.; Silva, F.S.; Miranda, G. Experimental analysis and predictive modelling of Ti6Al4V laser surface texturing for biomedical applications. Surf. Interfaces 2022, 35, 102466. [Google Scholar] [CrossRef]

- Reggio, C.; Barberi, J.; Ferraris, S.; Spriano, S. Functionalization of Ti6Al4V Alloy with Polyphenols: The Role of the Titanium Surface Features and the Addition of Calcium Ions on the Adsorption Mechanism. Metals 2023, 13, 1347. [Google Scholar] [CrossRef]

- Sheela, S.; AlGhalban, F.M.; Khalil, K.A.; Laoui, T.; Gopinath, V.K. Synthesis and Biocompatibility Evaluation of PCL Electrospun Membranes Coated with MTA/HA for Potential Application in Dental Pulp Capping. Polymers 2022, 14, 4862. [Google Scholar] [CrossRef]

- Sahoo, B.N.; Kandasubramanian, B.; Thomas, A. Effect of TiO2 Powder on the Surface Morphology of Micro/Nanoporous Structured Hydrophobic Fluoropolymer Based Composite Material. J. Polym. 2013, 2013, 615045. [Google Scholar] [CrossRef]

- Ogihara, H.; Xie, J.; Saji, T. Factors determining wettability of superhydrophobic paper prepared by spraying nanoparticle suspensions. Colloids Surf. A Physicochem. Eng. Asp. 2013, 434, 35–41. [Google Scholar] [CrossRef]

- Yamauchi, R.; Itabashi, T.; Wada, K.; Tanaka, T.; Kumagai, G.; Ishibashi, Y. Photofunctionalised Ti6Al4V implants enhance early phase osseointegration. Bone Jt. Res. 2017, 6, 331–336. [Google Scholar] [CrossRef]

- Khan, S.; Azimi, G.; Yildiz, B.; Varanasi, K.K. Role of surface oxygen-to-metal ratio on the wettability of rare-earth oxides. Appl. Phys. Lett. 2015, 106, 061601. [Google Scholar] [CrossRef]

- Oliveira, V.M.C.A.; Aguiar, C.; Vazquez, A.M.; Robin, A.; Barboza, M.J.R. Improving corrosion resistance of Ti–6Al–4V alloy through plasma-assisted PVD deposited nitride coatings. Corros. Sci. 2014, 88, 317–327. [Google Scholar] [CrossRef]

- Dai, N.; Zhang, L.C.; Zhang, J.; Zhang, X.; Ni, Q.; Chen, Y.; Wu, M.; Yang, C. Distinction in corrosion resistance of selective laser melted Ti-6Al-4V alloy on different planes. Corros. Sci. 2016, 111, 703–710. [Google Scholar] [CrossRef]

- Woźniak, A.; Adamiak, M.; Ziębowicz, B. The Surface Morphology and Electrochemical Properties of Pure Titanium Obtained by Selective Laser Melting Method. Solid State Phenom. 2020, 308, 21–32. [Google Scholar] [CrossRef]

- Woźniak, A.; Staszuk, M.; Reimann, Ł.; Bialas, O.; Brytan, Z.; Voinarovych, S.; Kyslytsia, O.; Kaliuzhnyi, S.; Basiaga, M.; Admiak, M. The influence of plasma-sprayed coatings on surface properties and corrosion resistance of 316L stainless steel for possible implant application. Arch. Civ. Mech. Eng. 2021, 21, 148. [Google Scholar] [CrossRef]

- Woźniak, A.; Adamiak, M.; Chladek, G.; Bonek, M.; Walke, W.; Bialas, O. The Influence of Hybrid Surface Modification on the Selected Properties of CP Titanium Grade II Manufactured by Selective Laser Melting. Materials 2020, 13, 2829. [Google Scholar] [CrossRef] [PubMed]

- Kadowaki, N.T.; Martinez, G.A.S.; Robin, A. Electrochemical behavior of three CP titanium dental implants in artificial saliva. Mater. Res. 2009, 12, 363–366. [Google Scholar] [CrossRef]

- Annamalai, M.; Gopinadhan, K.; Han, S.A.; Saha, S.; Park, H.J.; Cho, E.B.; Kumar, B.; Patra, A.; Kim, S.W.; Venkatesan, T. Surface energy and wettability of van der Waals structures. Nanoscale 2016, 8, 5764–5770. [Google Scholar] [CrossRef]

- Yue, L.; Wang, Z.; Li, L. Material morphological characteristics in laser ablation of alpha case from titanium alloy. Appl. Surf. Sci. 2012, 258, 8065–8071. [Google Scholar] [CrossRef]

- Bussoli, M.; Desai, T.; Batani, D.; Gakovic, B.; Trtica, M. Nd:YAG laser interaction with titanium implant surfaces for medical applications. Radiat. Eff. Defects Solids 2008, 163, 349–356. [Google Scholar] [CrossRef]

- Kosec, T.; Legat, A.; Kovač, J.; Klobčar, D. Influence of Laser Colour Marking on the Corrosion Properties of Low Alloyed Ti. Coatings 2019, 9, 375. [Google Scholar] [CrossRef]

- Xu, Y.; Li, Z.; Zhang, G.; Wang, G.; Zeng, Z.; Wang, C.; Wang, C.; Zhao, S.; Zhang, Y.; Ren, T. Electrochemical corrosion and anisotropic tribological properties of bioinspired hierarchical morphologies on Ti-6Al-4V fabricated by laser texturing. Tribol. Int. 2019, 134, 352–364. [Google Scholar] [CrossRef]

- Pfleging, W.; Kumari, R.; Besser, H.; Scharnweber, T.; Majumdar, J.D. Laser surface textured titanium alloy (Ti–6Al–4V): Part 1—Surface characterization. Appl. Surf. Sci. 2015, 355, 104–111. [Google Scholar] [CrossRef]

- Grabowski, A.; Sozańska, M.; Adamiak, M.; Kępińska, M.; Florian, T. Laser surface texturing of Ti6Al4V alloy, stainless steel and aluminium silicon alloy. Appl. Surf. Sci. 2018, 461, 117–123. [Google Scholar] [CrossRef]

- Wang, C.; Li, Z.; Zhao, H.; Zhang, G.; Ren, T.; Zhang, Y. Enhanced anticorrosion and antiwear properties of Ti–6Al–4V alloys with laser texture and graphene oxide coatings. Tribol. Int. 2020, 152, 106475. [Google Scholar] [CrossRef]

- Brittain, H.G.; Barbera, G.; DeVincentis, J.; Newman, A.W. Titanium Dioxide. Anal. Profiles Drug Subst. Excip. 1992, 21, 659–691. [Google Scholar] [CrossRef]

- Ziębowicz, A.; Woźniak, A.; Ziębowicz, B.; Kosiel, K.; Chladek, G. The Effect of Atomic Layer Deposition of ZrO2 on the Physicochemical Properties of Cobalt based Alloys Intended for Prosthetic Dentistry. Arch. Metall. Mater. 2018, 63, 1077–1082. [Google Scholar] [CrossRef] [PubMed]

- Woźniak, A.; Bialas, O.; Adamiak, M. Improvement of the properties of Ti6Al7Nb titanium alloy in terms of the type of surface modification. Arch. Metall. Mater. 2020, 65, 735–741. [Google Scholar] [CrossRef]

- Palanisamy, M.S.; Kulandaivelu, R.; Nellaiappan, S.N.T.S. Improving the corrosion resistance and bioactivity of magnesium by a carbonate conversion-polycaprolactone duplex coating approach. New J. Chem. 2020, 44, 4772–4785. [Google Scholar] [CrossRef]

- Mojarad Shafiee, B.; Torkaman, R.; Mahmoudi, M.; Emadi, R.; Karamian, E. An improvement in corrosion resistance of 316L AISI coated using PCL-gelatin composite by dip-coating method. Prog. Org. Coat. 2019, 130, 200–205. [Google Scholar] [CrossRef]

- Singh, N.; Batra, U.; Kumar, K.; Mahapatro, A. Investigating TiO2–HA–PCL hybrid coating as an efficient corrosion resistant barrier of ZM21 Mg alloy. J. Magnes. Alloys 2021, 9, 627–646. [Google Scholar] [CrossRef]

- DǍnǍilǍ, E.; Benea, L. The effect of surface roughness on corrosion behavior of Ti-6Al-4V alloy in saliva solution. In Proceedings of the 2015 E-Health and Bioengineering Conference (EHB), Iasi, Romania, 19–21 November 2015. [Google Scholar] [CrossRef]

- Jeong, C.; Choi, C.-H.; Sheppard, K. Nano-Engineering of Superhydrophobic Aluminum Surfaces for Anti-Corrosion. Ph.D. Thesis, Stevens Institute of Technology, Hoboken, NJ, USA, 2013. Volume 115. [Google Scholar]

- Zhang, F.; Zhao, L.; Chen, H.; Xu, S.; Evans, D.G.; Duan, X.; Zhang, F.; Zhao, L.L.; Chen, H.Y.; Xu, S.L.; et al. Corrosion Resistance of Superhydrophobic Layered Double Hydroxide Films on Aluminum. Angew. Chem. 2008, 120, 2500–2503. [Google Scholar] [CrossRef]

- Acatay, K.; Simsek, E.; Ow-Yang, C.; Menceloglu, Y.Z.; Acatay, K.; Simsek, E.; Ow-Yang, C.; Menceloglu, Y.Z. Tunable, Superhydrophobically Stable Polymeric Surfaces by Electrospinning. Angew. Chem. 2004, 116, 5322–5325. [Google Scholar] [CrossRef]

- Ning, T.; Xu, W.; Lu, S. Fabrication of superhydrophobic surfaces on zinc substrates and their application as effective corrosion barriers. Appl. Surf. Sci. 2011, 258, 1359–1365. [Google Scholar] [CrossRef]

- Zhang, F.; Chen, S.; Dong, L.; Lei, Y.; Liu, T.; Yin, Y. Preparation of superhydrophobic films on titanium as effective corrosion barriers. Appl. Surf. Sci. 2011, 257, 2587–2591. [Google Scholar] [CrossRef]

- Khoshnood, N.; Frampton, J.P.; Alavi Zaree, S.R.; Jahanpanah, M.; Heydari, P.; Zamanian, A. The corrosion and biological behavior of 3D-printed polycaprolactone/chitosan scaffolds as protective coating for Mg alloy implants. Surf. Coat. Technol. 2024, 477, 130368. [Google Scholar] [CrossRef]

- Catauro, M.; Bollino, F.; Giovanardi, R.; Veronesi, P. Modification of Ti6Al4V implant surfaces by biocompatible TiO2/PCL hybrid layers prepared via sol-gel dip coating: Structural characterization, mechanical and corrosion behavior. Mater. Sci. Eng. C 2017, 74, 501–507. [Google Scholar] [CrossRef] [PubMed]

- Asri, R.I.M.; Harun, W.S.W.; Samykano, M.; Lah, N.A.C.; Ghani, S.A.C.; Tarlochan, F.; Raza, M.R. Corrosion and surface modification on biocompatible metals: A review. Mater. Sci. Eng. C 2017, 77, 1261–1274. [Google Scholar] [CrossRef] [PubMed]

- Chen, Q.; Thouas, G.A. Metallic implant biomaterials. Mater. Sci. Eng. R Rep. 2015, 87, 1–57. [Google Scholar] [CrossRef]

- Rautray, T.R.; Narayanan, R.; Kim, K.H. Ion implantation of titanium based biomaterials. Prog. Mater. Sci. 2011, 56, 1137–1177. [Google Scholar] [CrossRef]

- Tsai, W.T.; Lin, C.L.; Pan, S.J. Susceptibility of Ti-6Al-4V alloy to stress corrosion cracking in a Lewis-neutral aluminium chloride-1-ethyl-3-methylimidazolium chloride ionic liquid. Corros. Sci. 2013, 76, 494–497. [Google Scholar] [CrossRef]

| Parameter | Value (u) | |

|---|---|---|

| RF power | 1.0 kW | |

| Plasma flow | 15 (L/min) | |

| Auxiliary flow | 1.5 (L/min) | |

| Nebulizer pressure | 210 (kPa) | |

| Pump rate | 15 (rpm) | |

| Emission lines | Ti | λ = 334.188; 334.941 and 336.122 (nm) |

| Al | λ = 237.312 and 396.152 (nm) | |

| V | λ = 268.796; 292.401; 309.310 and 311.837 (nm) | |

| Name | Surface Condition |

|---|---|

| S_is | Samples in the initial state—after mechanical grinding and polishing |

| S_tex | Samples after laser-texturing process |

| S_PCL | Samples with PCL nanofiber layer de-posted by electrospinning method |

| S_PCL/TiO2 | Samples with PCL/TiO2 nanofiber layer de-posted by electrospinning method |

| S_tex/PCL | Samples after laser-texturing process and with PCL nanofiber layer de-posted by electrospinning method |

| S_tex/PCL/TiO2 | Samples after laser-texturing process and with PCL/TiO2 nanofiber layer de-posted by electrospinning method |

| Name | Contact Angle (°) | Surface Free Energy (mJ/m2) | |||

|---|---|---|---|---|---|

| Distilled Water | Diiodomethane | ||||

| S_is | 68.7 ± 2.9 | 47.0 ± 3.1 | 36.6 | 22.7 | 18.9 |

| S_tex | 95.4 ± 3.9 | 42.0 ± 2.8 | 39.4 | 38.1 | 1.7 |

| S_ PCL | 128.2 ± 1.4 | 17.2 ± 1.1 | 106.6 | 85.7 | 20.9 |

| S_PCL/TiO2 | 137.8 ± 1.2 | 10.4 ± 0.7 | 116.4 | 91.1 | 25.3 |

| S_tek/PCL | 133.3 ± 2.1 | 13.5 ± 3.4 | 111.0 | 88.3 | 22.6 |

| S_tex/PCL/TiO2 | 137.9 ± 1.5 | - | - | - | - |

| No | Name | Rpore (Ω·cm2) | Rct (kΩ·cm2) |

|---|---|---|---|

| 1 | S_is | 30 | 432 |

| 2 | S_tex | 48 | 393 |

| 3 | S_PCL | 10 | 885 |

| 4 | S_PCL/TiO2 | 650 | 244 |

| 5 | S_tex/PCL | 650 | 890 |

| 6 | S_tex/PCL/TiO2 | - | 890 |

| No | Name | Ecorr (mV vs. Ag/AgCl) | Etr (mV vs. Ag/AgCl) | Eb (mV vs. Ag/AgCl) | icorr (µA/cm2) |

|---|---|---|---|---|---|

| 1 | S_is | −301 ± 27 | 1952 ± 35 | - | 0.033 |

| 2 | S_tex | +110 ± 35 | 1794 ± 41 | - | 0.052 |

| 3 | S_PCL | +172 ± 12 | - | 2290 ± 39 | 0.019 |

| 4 | S_PCL/TiO2 | +220 ± 26 | 2392 ± 32 | - | 0.012 |

| 5 | S_tex/PCL | +275 ± 52 | 2446 ± 57 | - | 0.015 |

| 6 | S_tex/PCL/TiO2 | +296 ± 44 | 2652 ± 61 | - | 0.011 |

| No | Name | Release Ions (mg/L) | ||

|---|---|---|---|---|

| Ti | V | Al | ||

| 1 | S_is | 1.03 | 0.06 | 0.07 |

| 2 | S_tex | 1.63 | 0.06 | 0.09 |

| 3 | S_PCL | 0.91 | 0.04 | 0.05 |

| 4 | S_PCL/TiO2 | 0.67 | 0.03 | 0.05 |

| 5 | S_tex/PCL | 0.80 | 0.04 | 0.05 |

| 6 | S_tex/PCL/TiO2 | 0.82 | 0.05 | 0.05 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Woźniak, A.; Smok, W.; Szewczenko, J.; Staszuk, M.; Chladek, G. Influence of Hybrid Surface Modification on Biocompatibility and Physicochemical Properties of Ti-6Al-4V ELI Titanium. J. Funct. Biomater. 2024, 15, 52. https://doi.org/10.3390/jfb15030052

Woźniak A, Smok W, Szewczenko J, Staszuk M, Chladek G. Influence of Hybrid Surface Modification on Biocompatibility and Physicochemical Properties of Ti-6Al-4V ELI Titanium. Journal of Functional Biomaterials. 2024; 15(3):52. https://doi.org/10.3390/jfb15030052

Chicago/Turabian StyleWoźniak, Anna, Weronika Smok, Janusz Szewczenko, Marcin Staszuk, and Grzegorz Chladek. 2024. "Influence of Hybrid Surface Modification on Biocompatibility and Physicochemical Properties of Ti-6Al-4V ELI Titanium" Journal of Functional Biomaterials 15, no. 3: 52. https://doi.org/10.3390/jfb15030052