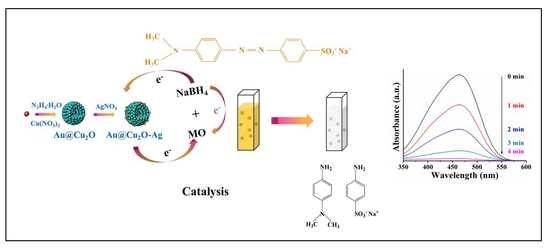

A Novel Au@Cu2O-Ag Ternary Nanocomposite with Highly Efficient Catalytic Performance: Towards Rapid Reduction of Methyl Orange Under Dark Condition

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Synthesis of Au@Cu2O NCs

2.3. Synthesis of Au@Cu2O-Ag NCs

2.4. Catalytic Activity Measurement

2.5. Characterization

3. Results and Discussion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Muthu, K.; Priya, S. Green synthesis, characterization and catalytic activity of silver nanoparticles using Cassia auriculata flower extract separated fraction. Spectrochim. Acta A 2017, 179, 66–72. [Google Scholar] [CrossRef] [PubMed]

- Zhou, X.; Xu, M.; Wang, L.; Liu, X. The Adsorption of Methylene Blue by an Amphiphilic Block Co-Poly (Arylene Ether Nitrile) Microsphere-Based Adsorbent: Kinetic, Isotherm, Thermodynamic and Mechanistic Studies. Nanomaterials 2019, 9, 1356. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lutsyk, P.; Arif, R.; Hruby, J.; Bukivskyi, A.; Vinijchuk, O.; Shandura, M.; Yakubovskyi, V.; Kovtun, Y.; Rance, G.A.; Fay, M.; et al. A sensing mechanism for the detection of carbon nanotubes using selective photoluminescent probes based on ionic complexes with organic dyes. Light Sci. Appl. 2016, 5, e16028. [Google Scholar] [CrossRef] [PubMed]

- Hameed, B.B.; Ismail, Z.Z. Decolorization, biodegradation and detoxification of reactive red azo dye using non-adapted immobilized mixed cells. Biochem. Eng. J. 2018, 137, 71–77. [Google Scholar] [CrossRef]

- Zhao, H.; Zhang, G.; Zhang, Q. MnO2/CeO2 for catalytic ultrasonic degradation of methyl orange. Ultrason. Sonochem. 2014, 21, 991–996. [Google Scholar] [CrossRef] [PubMed]

- Gong, R.; Ye, J.; Dai, W.; Yan, X.; Hu, J.; Hu, X.; Li, S.; Huang, H. Adsorptive Removal of Methyl Orange and Methylene Blue from Aqueous Solution with Finger-Citron-Residue-Based Activated Carbon. Ind. Eng. Chem. Res. 2013, 52, 14297–14303. [Google Scholar] [CrossRef]

- Cai, R.; Zhang, B.; Shi, J.; Li, M.; He, Z. Rapid Photocatalytic Decolorization of Methyl Orange under Visible Light Using VS4/Carbon Powder Nanocomposites. ACS Sustain. Chem. Eng. 2017, 5, 7690–7699. [Google Scholar] [CrossRef]

- Li, J.; Zhao, H.; Ma, C.; Han, Q.; Li, M.; Liu, H. Preparation of Fe3O4@polyoxometalates Nanocomposites and Their Efficient Adsorption of Cationic Dyes from Aqueous Solution. Nanomaterials 2019, 9, 649. [Google Scholar] [CrossRef] [Green Version]

- Raj, S.I.; Jaiswal, A.; Uddin, I. Tunable porous silica nanoparticles as a universal dye adsorbent. RSC Adv. 2019, 9, 11212–11219. [Google Scholar] [CrossRef] [Green Version]

- Li, S.; Zhang, H.; Hu, S.; Liu, J.; Zhu, Q.; Zhang, S. Synthesis of Hierarchical Porous Carbon in Molten Salt and Its Application for Dye Adsorption. Nanomaterials 2019, 9, 1098. [Google Scholar] [CrossRef] [Green Version]

- Zhang, B.; Wang, Z.; Peng, X.; Wang, Z.; Zhou, L.; Yin, Q. A Novel Route to Manufacture 2D Layer MoS2 and g-C3N4 by Atmospheric Plasma with Enhanced Visible-Light-Driven Photocatalysis. Nanomaterials 2019, 9, 1139. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Chen, S.; Huang, Y.; Han, X.; Wu, Z.; Lai, C.; Wang, J.; Deng, Q.; Zeng, Z.; Deng, S. Simultaneous and efficient removal of Cr(VI) and methyl orange on LDHs decorated porous carbons. Chem. Eng. J. 2018, 352, 306–315. [Google Scholar] [CrossRef]

- Pargoletti, E.; Pifferi, V.; Falciola, L.; Facchinetti, G.; Depaolini, A.R.; Davoli, E.; Marelli, M.; Cappelletti, G. A detailed investigation of MnO2 nanorods to be grown onto activated carbon. High efficiency towards aqueous methyl orange adsorption/degradation. Appl. Surf. Sci. 2019, 472, 118–126. [Google Scholar] [CrossRef] [Green Version]

- Ma, X.; Dai, Y.; Yu, L.; Huang, B. Energy transfer in plasmonic photocatalytic composites. Light Sci. Appl. 2016, 5, e16017. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Feng, Q.; Li, S.; Ma, W.; Fan, H.-J.; Wan, X.; Lei, Y.; Chen, Z.; Yang, J.; Qin, B. Synthesis and characterization of Fe3O4/ZnO-GO nanocomposites with improved photocatalytic degradation methyl orange under visible light irradiation. J. Alloys Compd. 2018, 737, 197–206. [Google Scholar] [CrossRef]

- Szeto, W.; Li, J.; Huang, H.; Leung, D.Y.C. VUV/TiO2 photocatalytic oxidation process of methyl orange and simultaneous utilization of the lamp-generated ozone. Chem. Eng. Sci. 2018, 177, 380–390. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, Y.Y.; Kou, Q.; Chen, Y.; Han, D.L.; Wang, D.D.; Lu, Z.Y.; Chen, L.; Yang, J.H.; Xing, S. Eco-friendly seeded Fe3O4-Ag nanocrystals: A new type of highly efficient and low cost catalyst for methylene blue reduction. RSC Adv. 2018, 8, 2209–2218. [Google Scholar] [CrossRef] [Green Version]

- Liu, Y.; Zhang, Y.; Kou, Q.; Chen, Y.; Sun, Y.; Han, D.; Wang, D.; Lu, Z.; Chen, L.; Yang, J.; et al. Highly Efficient, Low-Cost, and Magnetically Recoverable FePt-Ag Nanocatalysts: Towards Green Reduction of Organic Dyes. Nanomaterials 2018, 8, 329. [Google Scholar] [CrossRef] [Green Version]

- Chen, Y.; Zhang, Y.; Kou, Q.; Liu, Y.; Han, D.; Wang, D.; Sun, Y.; Zhang, Y.; Wang, Y.; Lu, Z.; et al. Enhanced Catalytic Reduction of 4-Nitrophenol Driven by Fe3O4-Au Magnetic Nanocomposite Interface Engineering: From Facile Preparation to Recyclable Application. Nanomaterials 2018, 8, 353. [Google Scholar] [CrossRef] [Green Version]

- Leteba, G.M.; Mitchell, D.R.G.; Levecque, P.B.J.; Lang, C.I. Solution-Grown Dendritic Pt-Based Ternary Nanostructures for Enhanced Oxygen Reduction Reaction Functionality. Nanomaterials 2018, 8, 462. [Google Scholar] [CrossRef] [Green Version]

- Xie, P.; Qi, Y.; Wang, R.; Wu, J.; Li, X. Aqueous Gold Nanoparticles Generated by AC and Pulse-Power-Driven Plasma Jet. Nanomaterials 2019, 9, 1488. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Pincella, F.; Isozaki, K.; Miki, K. A visible light-driven plasmonic photocatalyst. Light Sci. Appl. 2014, 3, e133. [Google Scholar] [CrossRef] [Green Version]

- Linnenbank, H.; Grynko, Y.; Fo¨rstner, J.; Linden, S. Second harmonic generation spectroscopy on hybrid plasmonic/dielectric nanoantennas. Light Sci. Appl. 2016, 5, e16013. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Shan, H.; Ying, Y.; Wang, X.; Yang, L.; Zu, S.; Du, B.; Han, T.; Li, B.; Yu, L.; Wu, J.; et al. Direct observation of ultrafast plasmonic hot electron transfer in the strong coupling regime. Light Sci. Appl. 2019, 8, 9. [Google Scholar] [CrossRef] [Green Version]

- Islam, M.T.; Jing, H.; Yang, T.; Zubia, E.; Goos, A.G.; Bernal, R.A.; Botez, C.E.; Narayan, M.; Chan, C.K.; Noveron, J.C. Fullerene stabilized gold nanoparticles supported on titanium dioxide for enhanced photocatalytic degradation of methyl orange and catalytic reduction of 4-nitrophenol. J. Environ. Chem. Eng. 2018, 6, 3827–3836. [Google Scholar] [CrossRef]

- Kuo, M.Y.; Hsiao, C.F.; Chiu, Y.H.; Lai, T.H.; Fang, M.J.; Wu, J.Y.; Chen, J.W.; Wu, C.L.; Wei, K.H.; Lin, H.C.; et al. Au@Cu2O core@shell nanocrystals as dual-functional catalysts for sustainable environmental applications. Appl. Catal. B Environ. 2019, 242, 499–506. [Google Scholar] [CrossRef]

- Sai, C.D.; Ngac, A.B. Effect of core-shell structure on optical properties of Au-Cu2O nanoparticles. Physica. B 2018, 532, 216–220. [Google Scholar] [CrossRef]

- Li, D.; Wang, Z.L.; Wang, Z. Phase Separation Prior to Alloying Observed in Vacuum Heating of Hybrid Au/Cu2O Core-Shell Nanoparticles. J. Phys. Chem. C 2017, 121, 1387–1392. [Google Scholar] [CrossRef]

- Pougin, A.; Dodekatos, G.; Dilla, M.; Tüysüz, H.; Strunk, J. Au@TiO2 Core-Shell Composites for the Photocatalytic Reduction of CO2. Chemistry 2018, 24, 12416–12425. [Google Scholar] [CrossRef]

- Jency, D.A.; Parimaladevi, R.; Umadevi, M. Au-TiO2 Core Shell Motif Scavenger: Facile Synthesis, High SERS Effect, Synergistic Photocatalytic Activity. J. Clust. Sci. 2018, 29, 793–804. [Google Scholar] [CrossRef]

- Hamidi, F.; Aslani, F. TiO2-based Photocatalytic Cementitious Composites: Materials, Properties, Influential Parameters, and Assessment Techniques. Nanomaterials 2019, 9, 1444. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kumar, A.; Kumar, A.; Sharma, G.; Al-Muhtaseb, A.H.; Naushad, M.; Ghfar, A.A.; Stadler, F.J. Quaternary magnetic BiOCl/g-C3N4/Cu2O/Fe3O4 nano-junction for visible light and solar powered degradation of sulfamethoxazole from aqueous environment. Chem. Eng. J. 2018, 334, 462–478. [Google Scholar] [CrossRef]

- Guo, S.; Wang, Y.; Zhang, F.; Gao, R.; Liu, M.; Dong, L.; Liu, Y.; Zhang, Y.; Chen, L. In Situ Synthesis of Ag@Cu2O-rGO Architecture for Strong Light-Matter Interactions. Nanomaterials 2018, 8, 444. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhu, J.; Lu, N.; Chen, W.; Kong, L.; Yang, Y.; Ma, D.; Huang, S. Influence of Au Nanoparticle Shape on Au@Cu2O Heterostructures. J. Nanomater. 2015, 16, 1–9. [Google Scholar] [CrossRef]

- Zhang, L.; Blom, D.A.; Wang, H. Au-Cu2O Core-Shell Nanoparticles: A Hybrid Metal-Semiconductor Heteronanostructure with Geometrically Tunable Optical Properties. Chem. Mater. 2011, 23. [Google Scholar] [CrossRef]

- Sasmal, A.K.; Pal, J.; Sahoo, R.; Kartikeya, P.; Dutta, S.; Pal, T. Superb Dye Adsorption and Dye Sensitized Change of Cu2O-Ag Crystal Faces in the Dark. J. Phys. Chem. C 2016, 120, 21580–21588. [Google Scholar] [CrossRef]

- Chen, R.; Lu, J.; Liu, S.; Zheng, M.; Wang, Z. The preparation of Cu2O@Au yolk/shell structures for efficient photocatalytic activity with a self-generated acid etching method. J. Mater. Sci. 2017, 53, 1781–1790. [Google Scholar] [CrossRef]

- Naz, G.; Shamsuddin, M.; Butt, F.K.; Bajwa, S.Z.; Khan, W.S.; Irfan, M.; Irfan, M. Au/Cu2O core/shell nanostructures with efficient photoresponses. Chin. J. Phys. 2019, 59, 307–316. [Google Scholar] [CrossRef]

- Zhang, X.; Chen, Y.L.; Liu, R.-S.; Tsai, D.P. Plasmonic photocatalysis. Rep. Prog. Phys. 2013, 76, 046401. [Google Scholar] [CrossRef] [Green Version]

- Polte, J.; Ahner, T.T.; Delissen, F.; Sokolov, S.; Emmerling, F.; Thunemann, A.F.; Kraehnert, R. Mechanism of gold nanoparticle formation in the classical citrate synthesis method derived from coupled in situ XANES and SAXS evaluation. J. Am. Chem. Soc. 2010, 132, 1296–1301. [Google Scholar] [CrossRef]

- Lin, Y.K.; Chiang, Y.J.; Hsu, Y.J. Metal-Cu2O core-shell nanocrystals for gas sensing applications: Effect of metal composition. Sens. Actuators B Chem. 2014, 204, 190–196. [Google Scholar] [CrossRef]

- Meir, N.; Plante, I.J.L.; Flomin, K.; Chockler, E.; Moshofsky, B.; Diab, M.; Volokh, M.; Mokari, T. Studying the chemical, optical and catalytic properties of noble metal (Pt, Pd, Ag, Au)-Cu2O core-shell nanostructures grown via a general approach. J. Math. Chem. A 2013, 1, 1763–1769. [Google Scholar] [CrossRef]

- Lee, C.; Shin, K.; Lee, Y.J.; Jung, C.; Lee, H.M. Effects of shell thickness on Ag-Cu2O core-shell nanoparticles with bumpy structures for enhancing photocatalytic activity and stability. Catal. Today 2017, 303, 313. [Google Scholar] [CrossRef]

- Chen, G.; Niu, M.; Cui, L.; Bao, F.; Zhou, L.; Wang, Y. Facile Synthesis and Formation Mechanism of Metal Chalcogenides Hollow Nanoparticles. J. Phys. Chem. C 2009, 113, 7522–7525. [Google Scholar] [CrossRef]

- Celorrio, V.; Montes de Oca, M.G.; Plana, D.; Moliner, R.; Lázaro, M.J.; Fermín, D.J. Effect of Carbon Supports on Electrocatalytic Reactivity of Au-Pd Core-Shell Nanoparticles. J. Phys. Chem. C 2012, 116, 6275–6282. [Google Scholar] [CrossRef]

- Liu, Y.; Kou, Q.; Wang, D.; Chen, L.; Sun, Y.; Lu, Z.; Zhang, Y.; Wang, Y.; Xing, S.G. Rational synthesis and tailored optical and magnetic characteristics of Fe3O4-Au composite nanoparticles. J. Mater. Sci. 2017, 52, 10163–10174. [Google Scholar] [CrossRef]

- Chen, L.; Liu, M.; Zhao, Y.; Kou, Q.; Wang, Y.; Liu, Y.; Zhang, Y.; Yang, J.; Jung, Y.M. Enhanced catalyst activity by decorating of Au on Ag@Cu2O nanoshell. Appl. Surf. Sci. 2018, 435, 72–78. [Google Scholar] [CrossRef]

- Lu, C.; Qi, L.; Yang, J.; Wang, X.; Zhang, D.; Xie, J.; Ma, J. One-Pot Synthesis of Octahedral Cu2O Nanocages via a Catalytic Solution Route. Adv. Mater. 2005, 17, 2562–2567. [Google Scholar] [CrossRef]

- Du, X.; Luo, S.; Du, H. Monodisperse and self-assembled Pt-Cu nanoparticles as an efficient electrocatalyst for the methanol oxidation reaction. J. Mater. Chem. A 2016, 4, 1579–1585. [Google Scholar] [CrossRef]

- Ranjith Kumar, D.; Manoj, D.; Santhanalakshmi, J. Optimization of site specific adsorption of oleylamine capped CuO nanoparticles on MWCNTs for electrochemical determination of guanosine. Sens. Actuators B Chem. 2013, 188, 603–612. [Google Scholar] [CrossRef]

- Chen, L.; Zhang, F.; Deng, X.; Xue, X.; Wang, L.; Sun, Y.; Feng, J.; Zhang, Y.; Wang, Y.; Jung, Y.M. SERS study of surface plasmon resonance induced carrier movement in Au@Cu2O core-shell nanoparticles. Spectrochim. Acta A 2018, 189, 608–612. [Google Scholar] [CrossRef] [PubMed]

- Liao, J.; Feng, Y.; Wu, S.; Ye, H.; Zhang, J.; Zhang, X.; Xie, F.; Li, H. Hexagonal CuCo2O4 Nanoplatelets, a Highly Active Catalyst for the Hydrolysis of Ammonia Borane for Hydrogen Production. Nanomaterials 2019, 9, 360. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lei, M.; Wu, W.; Yang, S.; Zhang, X.; Xing, Z.; Ren, F.; Xiao, X.; Jiang, C. Design of Enhanced Catalysts by Coupling of Noble Metals (Au, Ag) with Semiconductor SnO2 for Catalytic Reduction of 4-Nitrophenol. Part. Part. Syst. Charact. 2016, 33, 212–220. [Google Scholar] [CrossRef]

- Chen, Y.; Wu, T.; Xing, G.; Kou, Y.; Li, B.; Wang, X.; Gao, M.; Chen, L.; Wang, Y.; Yang, J.; et al. Fundamental Formation of Three-Dimensional Fe3O4 Microcrystals and Practical Application in Anchoring Au as Recoverable Catalyst for Effective Reduction of 4-Nitrophenol. Ind. Eng. Chem. Res. 2019, 58, 15151–15161. [Google Scholar] [CrossRef]

- Zhou, Y.; Liu, F. Highly efficient visible light-driven Ag/FeOOH/MMT composite photo-catalyst for degrading phenol. Appl. Phys. A Mater. 2019, 125. [Google Scholar] [CrossRef]

- Huang, Y.; Fang, Y.; Zhang, Z.; Zhu, L.; Sun, M. Nanowire-supported plasmonic waveguide for remote excitation of surface-enhanced Raman scattering. Light Sci. Appl. 2014, 3, e199. [Google Scholar] [CrossRef] [Green Version]

- Siampour, H.; Kumar, S.; Davydov, V.A.; Kulikova, L.F.; Agafonov, V.N.; Bozhevolnyi, S.I. On-chip excitation of single germanium vacancies in nanodiamonds embedded in plasmonic waveguides. Light Sci. Appl. 2018, 7, 61. [Google Scholar] [CrossRef]

- Kumar, M.; Deka, S. Multiply twinned AgNi alloy nanoparticles as highly active catalyst for multiple reduction and degradation reactions. ACS Appl. Mater. Interfaces 2014, 6, 16071–16081. [Google Scholar] [CrossRef]

- Yao, J.; Quan, Y.; Gao, M.; Gao, R.; Chen, L.; Liu, Y.; Lang, J.; Shen, H.; Zhang, Y.; Yang, L.; et al. AgNPs decorated Mg-doped ZnO heterostructure with dramatic SERS activity for trace detection of food contaminants. J. Math. Chem. C 2019, 7, 8199–8208. [Google Scholar] [CrossRef]

- Sun, M.; Zhang, Z.; Wang, P.; Li, Q.; Ma, F.; Xu, H. Remotely excited Raman optical activity using chiral plasmon propagation in Ag nanowires. Light Sci. Appl. 2013, 2, e112. [Google Scholar] [CrossRef]

- Xiong, J.; Li, Z.; Chen, J.; Zhang, S.; Wang, L.Z.; Dou, S.X. Facile synthesis of highly efficient one-dimensional plasmonic photocatalysts through Ag@Cu2O core-shell heteronanowires. ACS Appl. Mater. Interfaces 2014, 6, 15716–15725. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhuo, X.L.; Yip, H.K.; Cui, X.M.; Wang, J.F.; Lin, H.Q. Colour routing with single silver nanorods. Light Sci. Appl. 2019, 8, 39. [Google Scholar] [CrossRef] [Green Version]

- Li, D.; Sun, X.; Jia, Y.; Stockman, M.I.; Paudel, H.P.; Song, H.; Jiang, H.; Li, Z. Direct observation of localized surface plasmon field enhancement by Kelvin probe force microscopy. Light Sci. Appl. 2017, 6, e17038. [Google Scholar] [CrossRef] [PubMed]

- Huang, J.F.; Vongehr, S.; Tang, S.; Lu, H.; Shen, J.; Meng, X. Ag dendrite-based Au/Ag bimetallic nanostructures with strongly enhanced catalytic activity. Langmuir 2009, 25, 11890–11896. [Google Scholar] [CrossRef] [PubMed]

- Das, R.; Sypu, V.S.; Paumo, H.K.; Bhaumik, M.; Maharaj, V.; Maity, A. Silver decorated magnetic nanocomposite (Fe3O4@PPy-MAA/Ag) as highly active catalyst towards reduction of 4-nitrophenol and toxic organic dyes. Appl. Catal. B Environ. 2019, 244, 546–558. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, T.; Kou, Y.; Zheng, H.; Lu, J.; Kadasala, N.R.; Yang, S.; Guo, C.; Liu, Y.; Gao, M. A Novel Au@Cu2O-Ag Ternary Nanocomposite with Highly Efficient Catalytic Performance: Towards Rapid Reduction of Methyl Orange Under Dark Condition. Nanomaterials 2020, 10, 48. https://doi.org/10.3390/nano10010048

Wu T, Kou Y, Zheng H, Lu J, Kadasala NR, Yang S, Guo C, Liu Y, Gao M. A Novel Au@Cu2O-Ag Ternary Nanocomposite with Highly Efficient Catalytic Performance: Towards Rapid Reduction of Methyl Orange Under Dark Condition. Nanomaterials. 2020; 10(1):48. https://doi.org/10.3390/nano10010048

Chicago/Turabian StyleWu, Tong, Yichuan Kou, Hui Zheng, Jianing Lu, Naveen Reedy Kadasala, Shuo Yang, Chenzi Guo, Yang Liu, and Ming Gao. 2020. "A Novel Au@Cu2O-Ag Ternary Nanocomposite with Highly Efficient Catalytic Performance: Towards Rapid Reduction of Methyl Orange Under Dark Condition" Nanomaterials 10, no. 1: 48. https://doi.org/10.3390/nano10010048