Design and Characterization of a Sharp GaAs/Zn(Mn)Se Heterovalent Interface: A Sub-Nanometer Scale View

Abstract

:1. Introduction

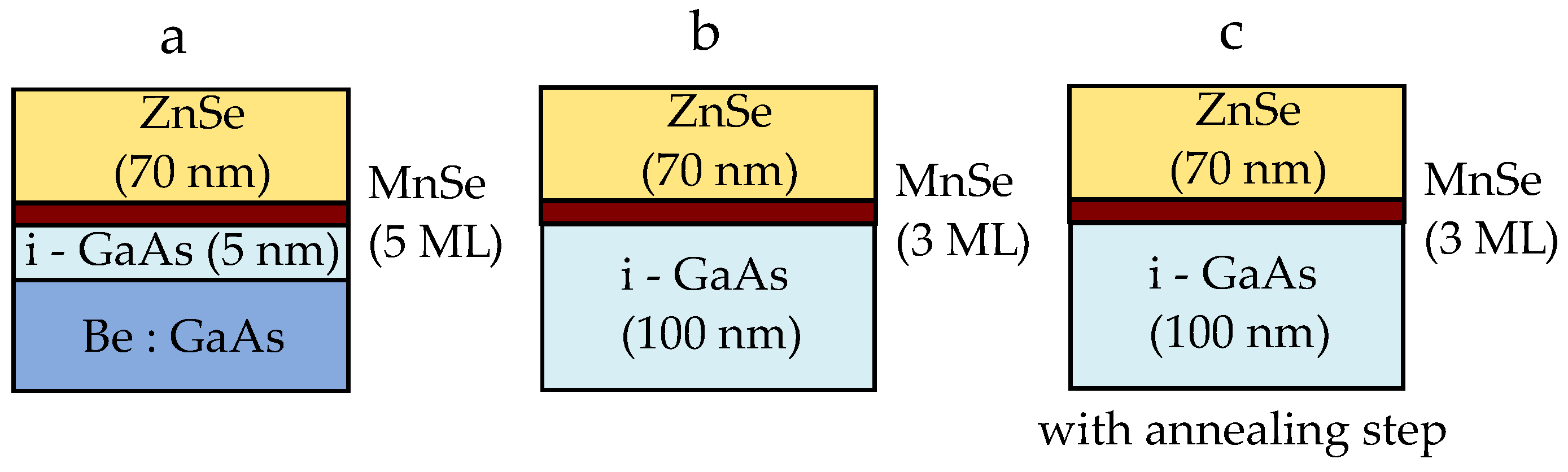

2. Materials and Methods

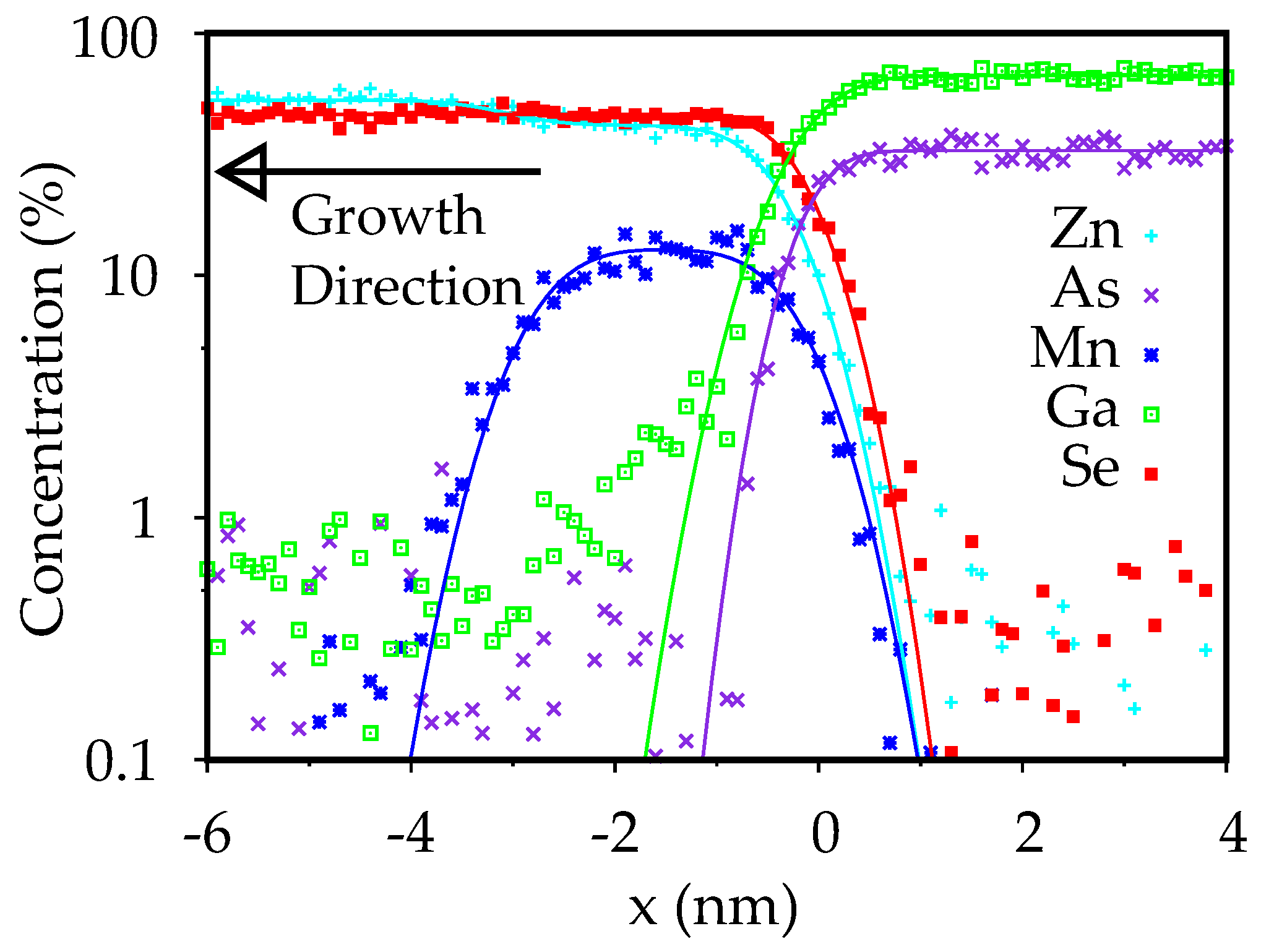

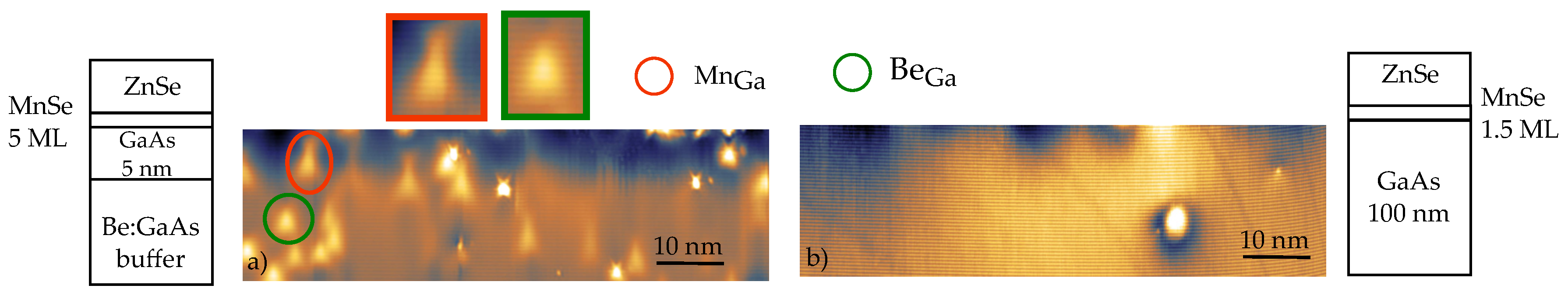

3. Results

- The different bond strengths of Zn and Mn with Se and the interdiffusion taking place during growth and annealing.

- The Zn–Se bond is stronger than the MnSe bond; therefore, when the Se concentration at the growth surface is sufficiently high, there is no competition between Zn and Mn to form a bond with Se, and the segregation of Mn is suppressed [21].

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

Appendix A

References

- Cibert, J.; Scalbert, D. Diluted Magnetic Semiconductors: Basic Physics and Optical Properties; Springer: Berlin, Germany, 2008; Volume 157. [Google Scholar]

- Awschalom, D.D.; Flatté, M.E. Challenges for semiconductor spintronics. Nat. Phys. 2007, 3, 153. [Google Scholar] [CrossRef]

- Fiederling, R.; Keim, M.; Reuscher, G.; Ossau, W.; Schmidt, G.; Waag, A.; Molenkamp, L.W. Injection and detection of a spin-polarized current in a light-emitting diode. Nature 1999, 402, 787–790. [Google Scholar] [CrossRef]

- Oestreich, M.; Hübner, J.; Hägele, D.; Klar, P.J.; Heimbrodt, W.; Rühle, W.W.; Ashenford, D.E.; Lunn, B. Spin injection into semiconductors. Appl. Phys. Lett. 1999, 74, 1251–1253. [Google Scholar] [CrossRef]

- Chuang, P.; Ho, S.; Smith, L.W.; Sfigakis, F.; Pepper, M.; Chen, C.; Fan, J.; Griffiths, J.P.; Farrer, I.; Beere, H.E.; et al. All-electric all-semiconductor spin field-effect transistors. Nat. Nanotechnol. 2015, 10, 35–39. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Dietl, T.; Ohno, H. Dilute ferromagnetic semiconductors: Physics and spintronic structures. Rev. Mod. Phys. 2014, 86, 187–251. [Google Scholar] [CrossRef] [Green Version]

- Chen, C.; Hsu, Y.; Lin, Y.; Lu, S. AlGaN/GaN HEMTs on Silicon with Hybrid Schottky-Ohmic Drain for Improved DC Characteristics. J. Phys. Chem. C 2008, 112, 17964–17968. [Google Scholar] [CrossRef]

- Jungwirth, T.; Wang, K.Y.; Mašek, J.; Edmonds, K.W.; König, J.; Sinova, J.; Polini, M.; Goncharuk, N.A.; MacDonald, A.H.; Sawicki, M.; et al. Prospects for high temperature ferromagnetism in (Ga,Mn)As semiconductors. Phys. Rev. B 2005, 72, 165204. [Google Scholar] [CrossRef] [Green Version]

- Nazmul, A.M.; Amemiya, T.; Shuto, Y.; Sugahara, S.; Tanaka, M. High Temperature Ferromagnetism in GaAs-Based Heterostructures with Mn δ-Doping. Phys. Rev. Lett. 2005, 95, 017201. [Google Scholar] [CrossRef] [Green Version]

- Dorokhin, M.V.; Danilov, Y.A.; Demina, P.B.; Kulakovskii, V.D.; Vikhrova, O.V.; Zaitsev, S.V.; Zvonkov, B.N. Emission properties of InGaAs/GaAs heterostructures with δ Mn-doped barrier. J. Phys. D Appl. Phys. 2008, 41, 245110. [Google Scholar] [CrossRef]

- Buyanova, I.A.; Rudko, G.Y.; Chen, W.M.; Toropov, A.A.; Sorokin, S.V.; Ivanov, S.V.; Kop’ev, P.S. Control of spin functionality in ZnMnSe-based structures: Spin switching versus spin alignment. Appl. Phys. Lett. 2003, 82, 1700–1702. [Google Scholar] [CrossRef]

- Jonker, B.T.; Hanbicki, A.T.; Park, Y.D.; Itskos, G.; Furis, M.; Kioseoglou, G.; Petrou, A.; Wei, X. Quantifying electrical spin injection: Component-resolved electroluminescence from spin-polarized light-emitting diodes. Appl. Phys. Lett. 2001, 79, 3098–3100. [Google Scholar] [CrossRef]

- Toropov, A.; Sedova, I.; Sorokin, S.; Terent’ev, Y.; Ivchenko, E.; Ivanov, S. Resonant spin-dependent electron coupling in a III-V/II-VI heterovalent double quantum well. Phys. Rev. B 2005, 71, 195312. [Google Scholar] [CrossRef] [Green Version]

- Liu, X.; Prasad, A.; Nishio, J.; Weber, E.R.; Liliental-Weber, Z.; Walukiewicz, W. Native point defects in low-temperature-grown GaAs. Appl. Phys. Lett. 1995, 67, 279–281. [Google Scholar] [CrossRef]

- Pereira, L.M.C.; Wahl, U.; Decoster, S.; Correia, J.G.; Amorim, L.M.; Da Silva, M.R.; Araújo, J.P.; Vantomme, A. Stability and diffusion of interstitial and substitutional Mn in GaAs of different doping types. Phys. Rev. B 2012, 86, 125206. [Google Scholar] [CrossRef] [Green Version]

- Sorokin, S.; Shubina, T.; Toropov, A.; Sedova, I.; Sitnikova, A.; Zolotareva, R.; Ivanov, S.; Kop’ev, P. Peculiarities of migration-enhanced-epitaxy (MEE) versus molecular beam epitaxy (MBE) growth kinetics of CdSe fractional monolayers in ZnSe. J. Cryst. Growth 1999, 201–202, 461–464. [Google Scholar] [CrossRef]

- Cadel, E.; Vurpillot, F.; Lardé, R.; Duguay, S.; Deconihout, B. Depth resolution function of the laser assisted tomographic atom probe in the investigation of semiconductors. J. Appl. Phys. 2009, 106, 044908. [Google Scholar] [CrossRef]

- Gault, B.; Moody, M.P.; de Geuser, F.; Haley, D.; Stephenson, L.T.; Ringer, S.P. Origin of the spatial resolution in atom probe microscopy. Appl. Phys. Lett. 2009, 95, 034103. [Google Scholar] [CrossRef]

- Vurpillot, F.; Da Costa, G.; Menand, A.; Blavette, D. Structural analyses in three-dimensional atom probe: A Fourier transform approach. J. Microsc. 2001, 203, 295–302. [Google Scholar] [CrossRef] [Green Version]

- Koelling, S.; Gilbert, M.; Goossens, J.; Hikavyy, A.; Richard, O.; Vandervorst, W. High depth resolution analysis of Si/SiGe multilayers with the atom probe. Appl. Phys. Lett. 2009, 95, 144106. [Google Scholar] [CrossRef]

- Nakayama, T.; Kangawa, Y.; Shiraishi, K. Atomic Structures and Electronic Properties of Semiconductor Interfaces; Elsevier: Amsterdam, The Netherlands, 2011; Volume 1.04, pp. 113–174. [Google Scholar]

- Komissarova, T.A.; Lebedev, M.V.; Sorokin, S.V.; Klimko, G.V.; Sedova, I.V.; Gronin, S.V.; Komissarov, K.A.; Calvet, W.; Drozdov, M.N.; Ivanov, S.V. Electronic, structural and chemical properties of GaAs/ZnSe heterovalent interfaces as dependent on MBE growth conditions andex situannealing. Semicond. Sci. Technol. 2017, 32, 045012. [Google Scholar] [CrossRef]

- Mahieu, G.; Grandidier, B.; Deresmes, D.; Nys, J.; Stiévenard, D.; Ebert, P. Direct Evidence for Shallow Acceptor States with Nonspherical Symmetry in GaAs. Phys. Rev. Lett. 2005, 94, 1–4. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yakunin, A.; Silov, A.; Koenraad, P.; Wolter, J.; Van Roy, W.; De Boeck, J.; Tang, J.M.; Flatté, M. Spatial Structure of an Individual Mn Acceptor in GaAs. Phys. Rev. Lett. 2004, 92, 1–4. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ebert, P. Atomic structure of point defects in compound semiconductor surfaces. Surf. Sci. Rep. 2001, 5, 121–303. [Google Scholar] [CrossRef]

- Ivanov, S.; Sorokin, S.; Sedova, I. Molecular Beam Epitaxy of Wide Gap II-VI Laser Heterostructures. In Molecular Beam Epitaxy; Henini, M., Ed.; Elsevier: Oxford, UK, 2018; pp. 571–595. [Google Scholar]

- Ivanov, S.; Sorokin, S.; Kop’ev, P.; Kim, J.; Jung, H.; Park, H. Composition, stoichiometry and growth rate control in molecular beam epitaxy of ZnSe based ternary and quaternary alloys. J. Cryst. Growth 1996, 159, 16–20. [Google Scholar] [CrossRef]

- Wierts, A.; Ulloa, J.M.; Celebi, C.; Koenraad, P.M.; Boukari, H.; Maingault, L.; André, R.; Mariette, H. Cross-sectional scanning tunneling microscopy study on II–VI multilayer structures. Appl. Phys. Lett. 2007, 91, 161907. [Google Scholar] [CrossRef] [Green Version]

- Gao, Y. A new secondary ion mass spectrometry technique for III-V semiconductor compounds using the molecular ions CsM+. J. Appl. Phys. 1988, 67, 3760. [Google Scholar] [CrossRef]

- Wittmaack, K. Mechanism of MCs+ formation in Cs based secondary ion mass spectrometry. Surf. Sci. 2012, 606, L18–L21. [Google Scholar] [CrossRef]

- Kaufmann, K.; Wahl, S.; Meyer, S.; Hagendorf, C. Quantitative elemental analysis of photovoltaic Cu(In,Ga)Se2thin films using MCs+ clusters. Surf. Interface Anal. 2012, 45, 434–436. [Google Scholar] [CrossRef]

- Gavelle, M.; Scheid, E.; Cristiano, F.; Armand, C.; Hartmann, J.M.; Campidelli, Y.; Halimaoui, A.; Fazzini, P.F.; Marcelot, O. Detection of Cs2Ge+ clusters for the quantification of germanium atoms by secondary ion mass spectrometry: Application to the characterization of Si1−xGex layers (0 ≤ x ≤ 1) and germanium diffusion in silicon. J. Appl. Phys. 2007, 102, 074904. [Google Scholar] [CrossRef]

- Van Vaeck, L.; Adriaens, A.; Gijbels, R. Static secondary ion mass spectrometry (S-SIMS) Part 1: Methodology and structural interpretation. Mass Spectrom. Rev. 1999, 18, 1–47. [Google Scholar] [CrossRef]

- Wilson, R.G. SIMS quantification in Si, GaAs, and diamond—An update. Int. J. Mass Spectrom. Ion Process. 1995, 143, 43–49. [Google Scholar] [CrossRef]

- Thompson, K.; Lawrence, D.; Larson, D.; Olson, J.; Kelly, T.; Gorman, B. In situ site-specific specimen preparation for atom probe tomography. Ultramicroscopy 2007, 107, 131–139. [Google Scholar] [CrossRef] [PubMed]

- Miller, M.K.; Russell, K.F.; Thompson, K.; Alvis, R.; Larson, D.J. Review of Atom Probe FIB-Based Specimen Preparation Methods. Microsc. Microanal. 2007, 13, 428–436. [Google Scholar] [CrossRef] [PubMed]

- Prosa, T.; Lawrence, D.; Olson, D.; Larson, D.; Marquis, E. Backside Lift-Out Specimen Preparation: Reversing the Analysis Direction in Atom Probe Tomography. Microsc. Microanal. 2009, 15, 298–299. [Google Scholar] [CrossRef] [Green Version]

- Du, S.; Burgess, T.; Gault, B.; Gao, Q.; Bao, P.; Li, L.; Cui, X.; Kong Yeoh, W.; Liu, H.; Yao, L.; et al. Quantitative dopant distributions in GaAs nanowires using atom probe tomography. Ultramicroscopy 2013, 132, 186–192. [Google Scholar] [CrossRef] [PubMed]

| Element | (nm) | (nm) | (nm) | |

|---|---|---|---|---|

| Mn | ||||

| Ga | ||||

| As | ||||

| Zn | ||||

| Se |

| a | 0.07 | ||||

| b | 0.007 | ||||

| c | 0.15 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Grossi, D.F.; Koelling, S.; Yunin, P.A.; Koenraad, P.M.; Klimko, G.V.; Sorokin, S.V.; Drozdov, M.N.; Ivanov, S.V.; Toropov, A.A.; Silov, A.Y. Design and Characterization of a Sharp GaAs/Zn(Mn)Se Heterovalent Interface: A Sub-Nanometer Scale View. Nanomaterials 2020, 10, 1315. https://doi.org/10.3390/nano10071315

Grossi DF, Koelling S, Yunin PA, Koenraad PM, Klimko GV, Sorokin SV, Drozdov MN, Ivanov SV, Toropov AA, Silov AY. Design and Characterization of a Sharp GaAs/Zn(Mn)Se Heterovalent Interface: A Sub-Nanometer Scale View. Nanomaterials. 2020; 10(7):1315. https://doi.org/10.3390/nano10071315

Chicago/Turabian StyleGrossi, Davide F., Sebastian Koelling, Pavel A. Yunin, Paul M. Koenraad, Grigory V. Klimko, Sergey V. Sorokin, Mikhail N. Drozdov, Sergey V. Ivanov, Alexey A. Toropov, and Andrei Y. Silov. 2020. "Design and Characterization of a Sharp GaAs/Zn(Mn)Se Heterovalent Interface: A Sub-Nanometer Scale View" Nanomaterials 10, no. 7: 1315. https://doi.org/10.3390/nano10071315