Structural and Electrical Properties of Annealed Ge2Sb2Te5 Films Grown on Flexible Polyimide

Abstract

:1. Introduction

2. Materials and Methods

2.1. Samples Growth

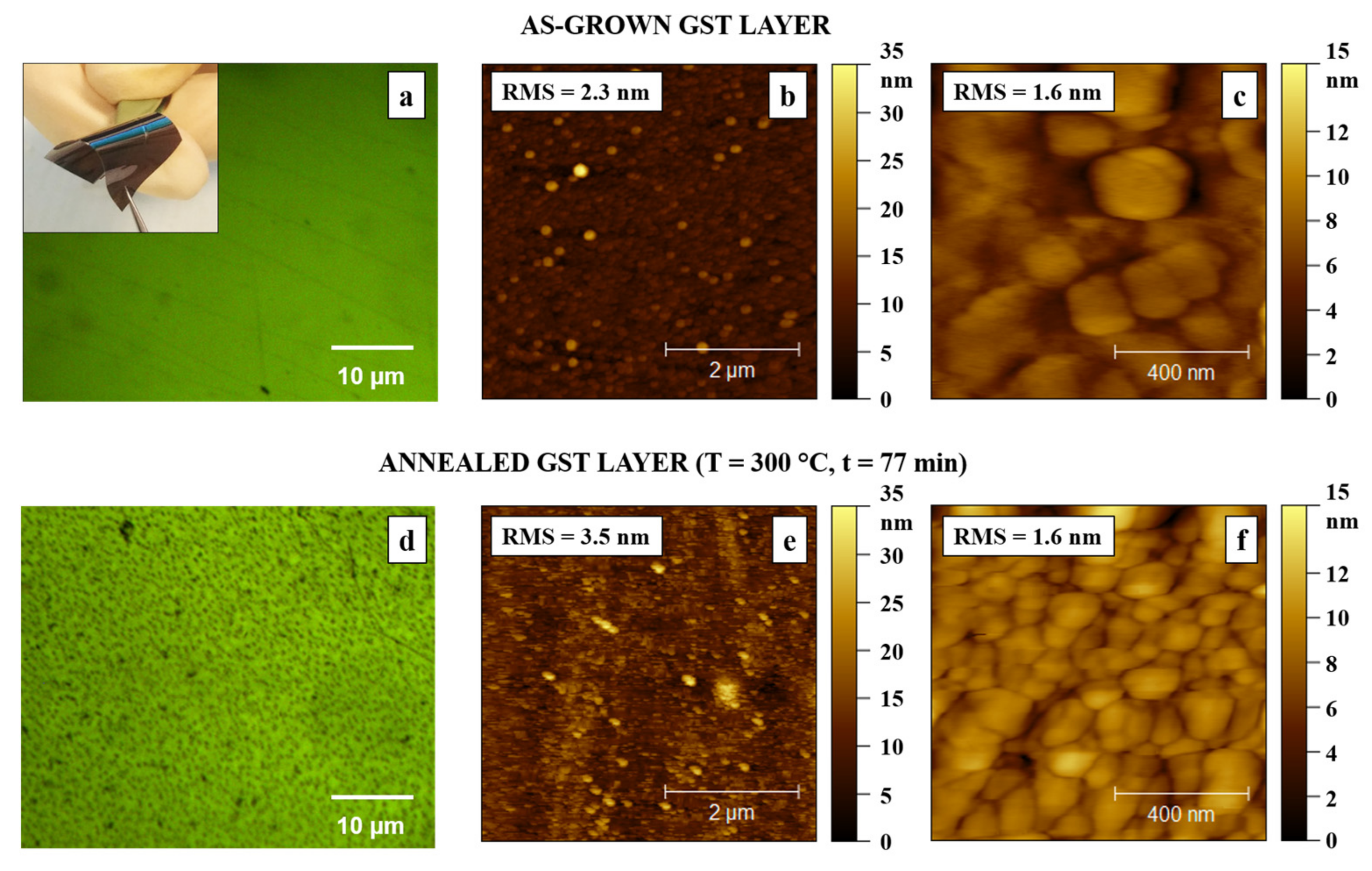

2.2. Morphology Investigation

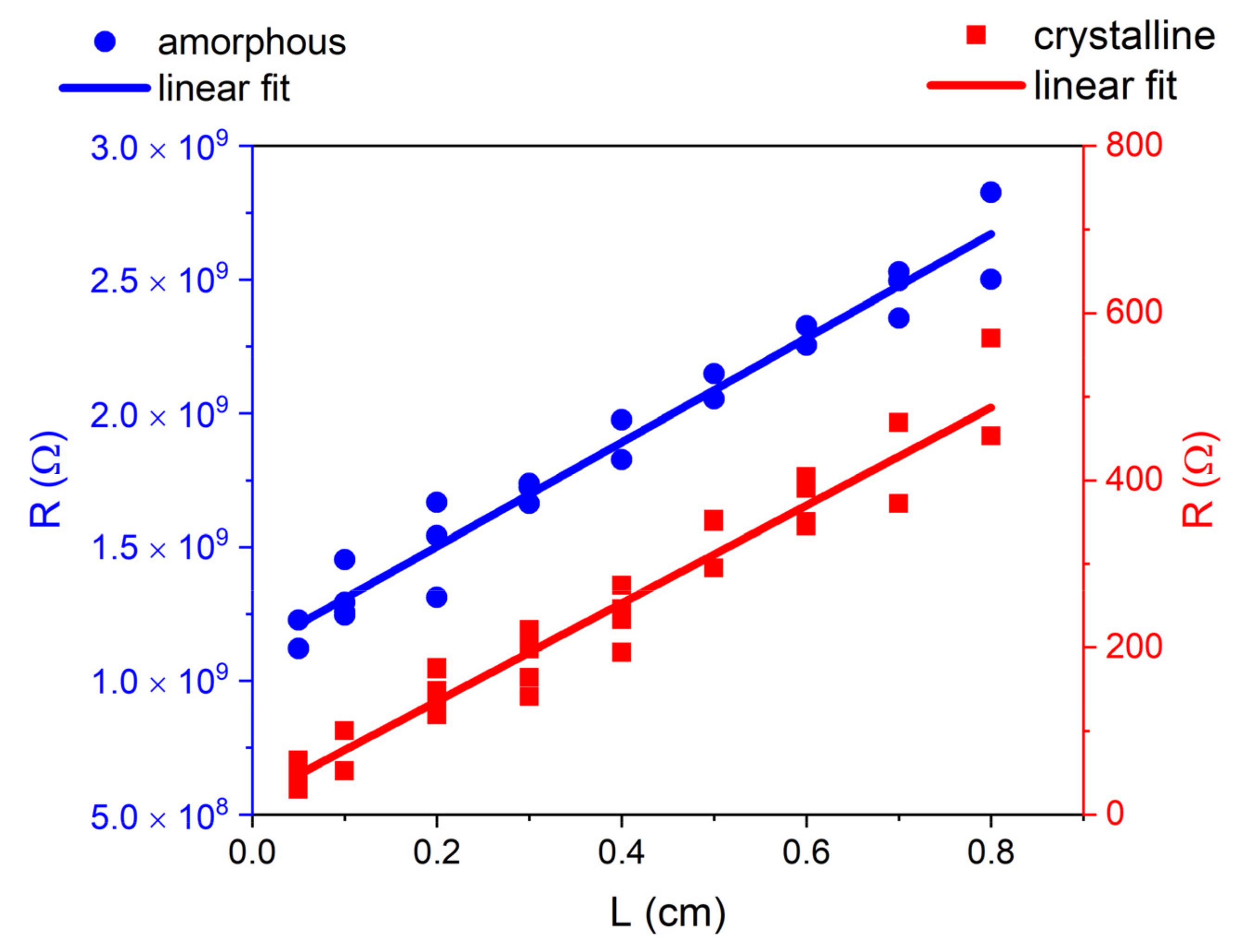

2.3. X-ray Fluorescence (XRF)

2.4. X-ray Diffraction (XRD)

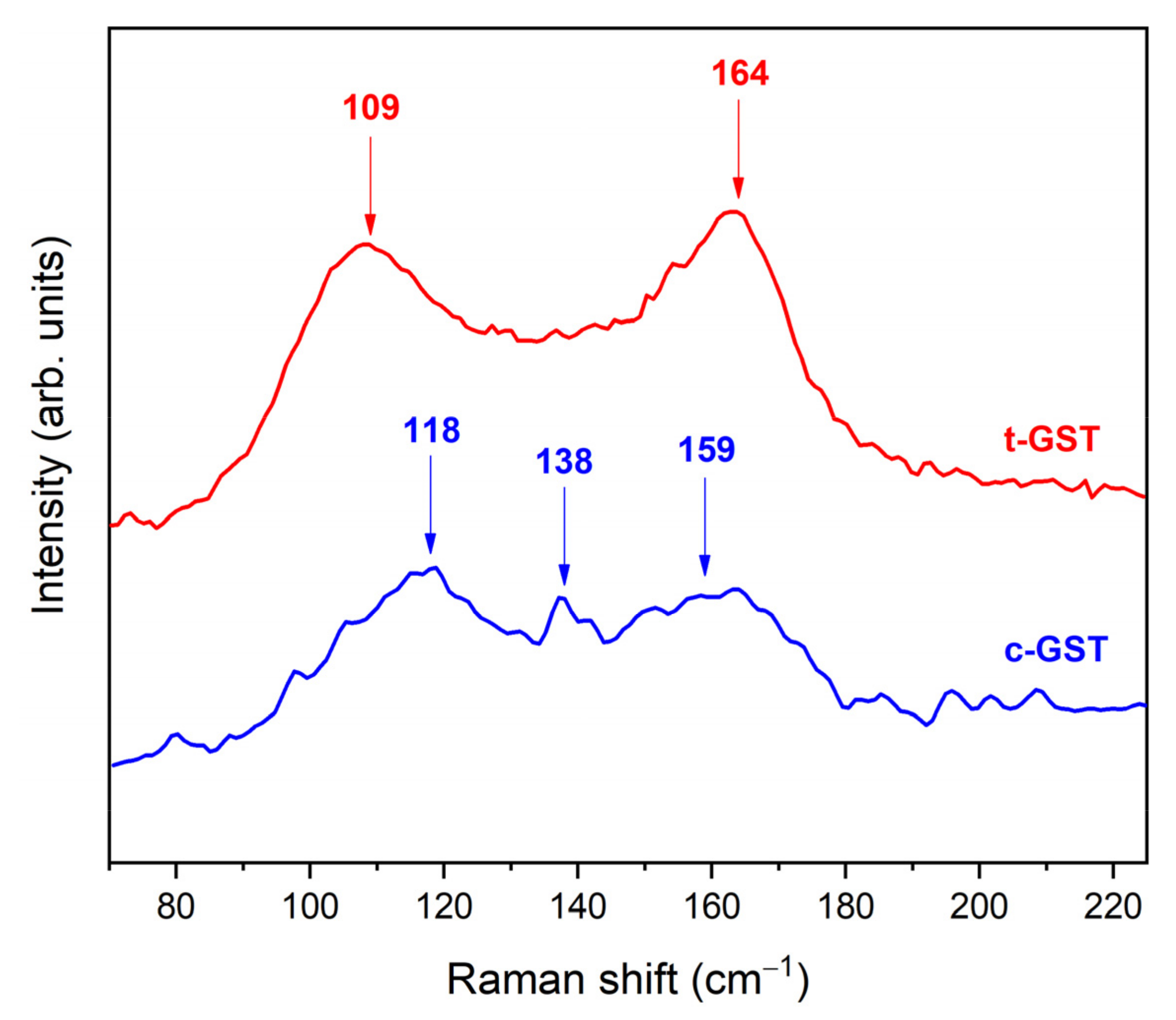

2.5. Raman

2.6. Electrical Measurements

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Marković, D.; Mizrahi, A.; Querlioz, D.; Grollier, J. Physics for Neuromorphic Computing. Nat. Rev. Phys. 2020, 2, 499–510. [Google Scholar] [CrossRef]

- Chua, L. Memristor-The Missing Circuit Element. IEEE Trans. Circuit Theory 1971, 18, 507–519. [Google Scholar] [CrossRef]

- Ambrogio, S.; Balatti, S.; Nardi, F.; Facchinetti, S.; Ielmini, D. Spike-Timing Dependent Plasticity in a Transistor-Selected Resistive Switching Memory. Nanotechnology 2013, 24, 384012. [Google Scholar] [CrossRef] [PubMed]

- Jo, S.H.; Chang, T.; Ebong, I.; Bhadviya, B.B.; Mazumder, P.; Lu, W. Nanoscale Memristor Device as Synapse in Neuromorphic Systems. Nano. Lett. 2010, 10, 1297–1301. [Google Scholar] [CrossRef] [PubMed]

- Chanthbouala, A.; Garcia, V.; Cherifi, R.O.; Bouzehouane, K.; Fusil, S.; Moya, X.; Xavier, S.; Yamada, H.; Deranlot, C.; Mathur, N.D.; et al. A Ferroelectric Memristor. Nature Mater. 2012, 11, 860–864. [Google Scholar] [CrossRef]

- Ambrogio, S.; Ciocchini, N.; Laudato, M.; Milo, V.; Pirovano, A.; Fantini, P.; Ielmini, D. Unsupervised Learning by Spike Timing Dependent Plasticity in Phase Change Memory (PCM) Synapses. Front. Neurosci. 2016, 10, 56. [Google Scholar] [CrossRef] [Green Version]

- Kuzum, D.; Yu, S.; Wong, H.-S.P. Synaptic Electronics: Materials, Devices and Applications. Nanotechnology 2013, 24, 382001. [Google Scholar] [CrossRef]

- Intel® OptaneTM Memory H10 with Solid State Storage. Available online: https://www.intel.com/content/www/us/en/products/details/memory-storage/optane-memory/optane-memory-h10-solid-state-storage.html (accessed on 16 March 2022).

- Wuttig, M.; Yamada, N. Phase-Change Materials for Rewriteable Data Storage. Nature Mater. 2007, 6, 824–832. [Google Scholar] [CrossRef]

- Ji, Y.; Zeigler, D.F.; Lee, D.S.; Choi, H.; Jen, A.K.-Y.; Ko, H.C.; Kim, T.-W. Flexible and Twistable Non-Volatile Memory Cell Array with All-Organic One Diode–One Resistor Architecture. Nat. Commun. 2013, 4, 2707. [Google Scholar] [CrossRef] [Green Version]

- Salvatore, G.A.; Sülzle, J.; Dalla Valle, F.; Cantarella, G.; Robotti, F.; Jokic, P.; Knobelspies, S.; Daus, A.; Büthe, L.; Petti, L.; et al. Biodegradable and Highly Deformable Temperature Sensors for the Internet of Things. Adv. Funct. Mater. 2017, 27, 1702390. [Google Scholar] [CrossRef]

- Online Materials Information Resource—MatWeb. Available online: https://www.matweb.com/ (accessed on 1 April 2022).

- Flexible Printed Circuit Board, Introduction and Importance. Available online: https://www.rs-online.com/designspark/flexible-printed-circuit-board-introduction-and-importance (accessed on 1 April 2022).

- Ni, H.; Liu, J.; Wang, Z.; Yang, S. A Review on Colorless and Optically Transparent Polyimide Films: Chemistry, Process and Engineering Applications. J. Ind. Eng. Chem. 2015, 28, 16–27. [Google Scholar] [CrossRef]

- Herth, E.; Guerchouche, K.; Rousseau, L.; Calvet, L.E.; Loyez, C. A Biocompatible and Flexible Polyimide for Wireless Sensors. Microsyst. Technol. 2017, 23, 5921–5929. [Google Scholar] [CrossRef]

- Díaz Fattorini, A.; Chèze, C.; López García, I.; Petrucci, C.; Bertelli, M.; Righi Riva, F.; Prili, S.; Privitera, S.M.S.; Buscema, M.; Sciuto, A.; et al. Growth, Electronic and Electrical Characterization of Ge-Rich Ge–Sb–Te Alloy. Nanomaterials 2022, 12, 1340. [Google Scholar] [CrossRef] [PubMed]

- Chèze, C.; Righi Riva, F.; Di Bella, G.; Placidi, E.; Prili, S.; Bertelli, M.; Diaz Fattorini, A.; Longo, M.; Calarco, R.; Bernasconi, M.; et al. Interface Formation during the Growth of Phase Change Material Heterostructures Based on Ge-Rich Ge-Sb-Te Alloys. Nanomaterials 2022, 12, 1007. [Google Scholar] [CrossRef] [PubMed]

- Kumar, A.; Cecchini, R.; Wiemer, C.; Mussi, V.; De Simone, S.; Calarco, R.; Scuderi, M.; Nicotra, G.; Longo, M. MOCVD Growth of GeTe/Sb2Te3 Core–Shell Nanowires. Coatings 2021, 11, 718. [Google Scholar] [CrossRef]

- Li, M.; Xie, M.; Ji, H.; Zhou, J.; Jiang, K.; Shang, L.; Li, Y.; Hu, Z.; Chu, J. PLD-Derived Ge2Sb2Te5 Phase-Change Films with Extreme Bending Stability for Flexible Device Applications. Appl. Phys. Lett. 2020, 116, 162102. [Google Scholar] [CrossRef]

- Zhai, F.; Liu, S.; Wang, D.; Liu, N.; Ren, Y.; Hao, Y.; Yang, K. Laser-Induced Phase Transition Processes of Amorphous Ge2Sb2Te5 Films. Optik 2019, 185, 126–131. [Google Scholar] [CrossRef]

- Mun, B.H.; You, B.K.; Yang, S.R.; Yoo, H.G.; Kim, J.M.; Park, W.I.; Yin, Y.; Byun, M.; Jung, Y.S.; Lee, K.J. Flexible One Diode-One Phase Change Memory Array Enabled by Block Copolymer Self-Assembly. ACS Nano. 2015, 9, 4120–4128. [Google Scholar] [CrossRef]

- Daus, A.; Han, S.; Knobelspies, S.; Cantarella, G.; Tröster, G. Ge2Sb2Te5 P-Type Thin-Film Transistors on Flexible Plastic Foil. Materials 2018, 11, 1672. [Google Scholar] [CrossRef] [Green Version]

- Schlich, F.F.; Wyss, A.; Galinski, H.; Spolenak, R. Cohesive and Adhesive Properties of Ultrathin Amorphous and Crystalline Ge2Sb2Te5 Films on Polyimide Substrates. Acta Mater. 2017, 126, 264–271. [Google Scholar] [CrossRef]

- Lu, H.; Thelander, E.; Gerlach, J.W.; Hirsch, D.; Decker, U.; Rauschenbach, B. Ge2Sb2Te5 Phase-Change Films on Polyimide Substrates by Pulsed Laser Deposition. Appl. Phys. Lett. 2012, 101, 031905. [Google Scholar] [CrossRef]

- Pitchappa, P.; Kumar, A.; Prakash, S.; Jani, H.; Medwal, R.; Mishra, M.; Rawat, R.S.; Venkatesan, T.; Wang, N.; Singh, R. Volatile Ultrafast Switching at Multilevel Nonvolatile States of Phase Change Material for Active Flexible Terahertz Metadevices. Adv. Funct. Mater. 2021, 31, 2100200. [Google Scholar] [CrossRef]

- Khan, A.I.; Daus, A.; Islam, R.; Neilson, K.M.; Lee, H.R.; Wong, H.-S.P.; Pop, E. Ultralow–Switching Current Density Multilevel Phase-Change Memory on a Flexible Substrate. Science 2021, 373, 1243–1247. [Google Scholar] [CrossRef] [PubMed]

- DigiZeitschriften: Seitenansicht. Available online: http://www.digizeitschriften.de/dms/img/?PID=GDZPPN002505045 (accessed on 4 April 2022).

- Yamada, N.; Matsunaga, T. Structure of Laser-Crystallized Ge2Sb2+xTe5 Sputtered Thin Films for Use in Optical Memory. J. Appl. Phys. 2000, 88, 7020–7028. [Google Scholar] [CrossRef]

- Momma, K.; Izumi, F. VESTA: A Three-Dimensional Visualization System for Electronic and Structural Analysis. J. Appl. Crystallogr. 2008, 41, 653–658. [Google Scholar] [CrossRef]

- Kozyukhin, S.A.; Nikolaev, I.I.; Lazarenko, P.I.; Valkovskiy, G.A.; Konovalov, O.; Kolobov, A.V.; Grigoryeva, N.A. Direct Observation of Amorphous to Crystalline Phase Transitions in Ge–Sb–Te Thin Films by Grazing Incidence X-Ray Diffraction Method. J. Mater. Sci. Mater. Electron. 2020, 31, 10196–10206. [Google Scholar] [CrossRef]

- Materials Project. Available online: https://materialsproject.org/ (accessed on 30 March 2022).

- Liu, J.; Ni, H.; Wang, Z.; Yang, S.; Zhou, W. Colorless and Transparent High—Temperature-Resistant Polymer Optical Films—Current Status and Potential Applications in Optoelectronic Fabrications. In Optoelectronics—Materials and Devices; Pyshkin, S.L., Ballato, J., Eds.; InTech: London, UK, 2015; ISBN 978-953-51-2174-9. [Google Scholar]

- Nemec, P.; Nazabal, V.; Moréac, A.; Gutwirth, J.; Beneš, L.; Frumar, M. Amorphous and Crystallized Ge-Sb-Te Thin Films Deposited by Pulsed Laser: Local Structure Using Raman Scattering Spectroscopy. Mater. Chem. Phys. 2012, 136, 935–941. [Google Scholar] [CrossRef]

- Bragaglia, V.; Holldack, K.; Boschker, J.E.; Arciprete, F.; Zallo, E.; Flissikowski, T.; Calarco, R. Far-Infrared and Raman Spectroscopy Investigation of Phonon Modes in Amorphous and Crystalline Epitaxial GeTe-Sb2Te3 Alloys. Sci. Rep. 2016, 6, 28560. [Google Scholar] [CrossRef] [Green Version]

- Cecchi, S.; Dragoni, D.; Kriegner, D.; Tisbi, E.; Zallo, E.; Arciprete, F.; Holý, V.; Bernasconi, M.; Calarco, R. Interplay between Structural and Thermoelectric Properties in Epitaxial Sb2+xTe3 Alloys. Adv. Funct. Mater. 2019, 29, 1805184. [Google Scholar] [CrossRef]

- Kapton® HN General-Purpose Polyimide Film. Available online: https://www.dupont.com/products/kapton-hn.html (accessed on 30 March 2022).

- Zallo, E.; Wang, R.; Bragaglia, V.; Calarco, R. Laser Induced Structural Transformation in Chalcogenide Based Superlattices. Appl. Phys. Lett. 2016, 108, 221904. [Google Scholar] [CrossRef] [Green Version]

- Kato, T.; Tanaka, K. Electronic Properties of Amorphous and Crystalline Ge2Sb2Te5 Films. Jpn. J. Appl. Phys. 2005, 44, 7340–7344. [Google Scholar] [CrossRef]

- Lazarenko, P.I.; Sherchenkov, A.A.; Kozyukhin, S.A.; Babich, A.V.; Timoshenkov, S.P.; Gromov, D.G.; Shuliatyev, A.S.; Redichev, E.N. Electrical Properties of the Ge2Sb2Te5 Thin Films for Phase Change Memory Application. AIP Conf. Proc. 2016, 1727, 020013. [Google Scholar] [CrossRef] [Green Version]

- Yakubov, A.; Sherchenkov, A.; Lazarenko, P.; Babich, A.; Terekhov, D.; Dedkova, A. Contact resistance measurements for the Ge2Sb2Te5 thin films. Chalcogenide Lett. 2020, 17, 1–8. [Google Scholar]

- Raoux, S.; Rettner, C.T.; Jordan-Sweet, J.L.; Kellock, A.J.; Topuria, T.; Rice, P.M.; Miller, D.C. Direct Observation of Amorphous to Crystalline Phase Transitions in Nanoparticle Arrays of Phase Change Materials. J. Appl. Phys. 2007, 102, 094305. [Google Scholar] [CrossRef]

- Guo, P.; Sarangan, A.; Agha, I. A Review of Germanium-Antimony-Telluride Phase Change Materials for Non-Volatile Memories and Optical Modulators. Appl. Sci. 2019, 9, 530. [Google Scholar] [CrossRef] [Green Version]

- Bragaglia, V.; Arciprete, F.; Zhang, W.; Mio, A.M.; Zallo, E.; Perumal, K.; Giussani, A.; Cecchi, S.; Boschker, J.E.; Riechert, H.; et al. Metal—Insulator Transition Driven by Vacancy Ordering in GeSbTe Phase Change Materials. Sci. Rep. 2016, 6, 23843. [Google Scholar] [CrossRef]

- Wong, H.-S.P.; Raoux, S.; Kim, S.; Liang, J.; Reifenberg, J.P.; Rajendran, B.; Asheghi, M.; Goodson, K.E. Phase Change Memory. Proc. IEEE 2010, 98, 2201–2227. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bertelli, M.; Díaz Fattorini, A.; De Simone, S.; Calvi, S.; Plebani, R.; Mussi, V.; Arciprete, F.; Calarco, R.; Longo, M. Structural and Electrical Properties of Annealed Ge2Sb2Te5 Films Grown on Flexible Polyimide. Nanomaterials 2022, 12, 2001. https://doi.org/10.3390/nano12122001

Bertelli M, Díaz Fattorini A, De Simone S, Calvi S, Plebani R, Mussi V, Arciprete F, Calarco R, Longo M. Structural and Electrical Properties of Annealed Ge2Sb2Te5 Films Grown on Flexible Polyimide. Nanomaterials. 2022; 12(12):2001. https://doi.org/10.3390/nano12122001

Chicago/Turabian StyleBertelli, Marco, Adriano Díaz Fattorini, Sara De Simone, Sabrina Calvi, Riccardo Plebani, Valentina Mussi, Fabrizio Arciprete, Raffaella Calarco, and Massimo Longo. 2022. "Structural and Electrical Properties of Annealed Ge2Sb2Te5 Films Grown on Flexible Polyimide" Nanomaterials 12, no. 12: 2001. https://doi.org/10.3390/nano12122001