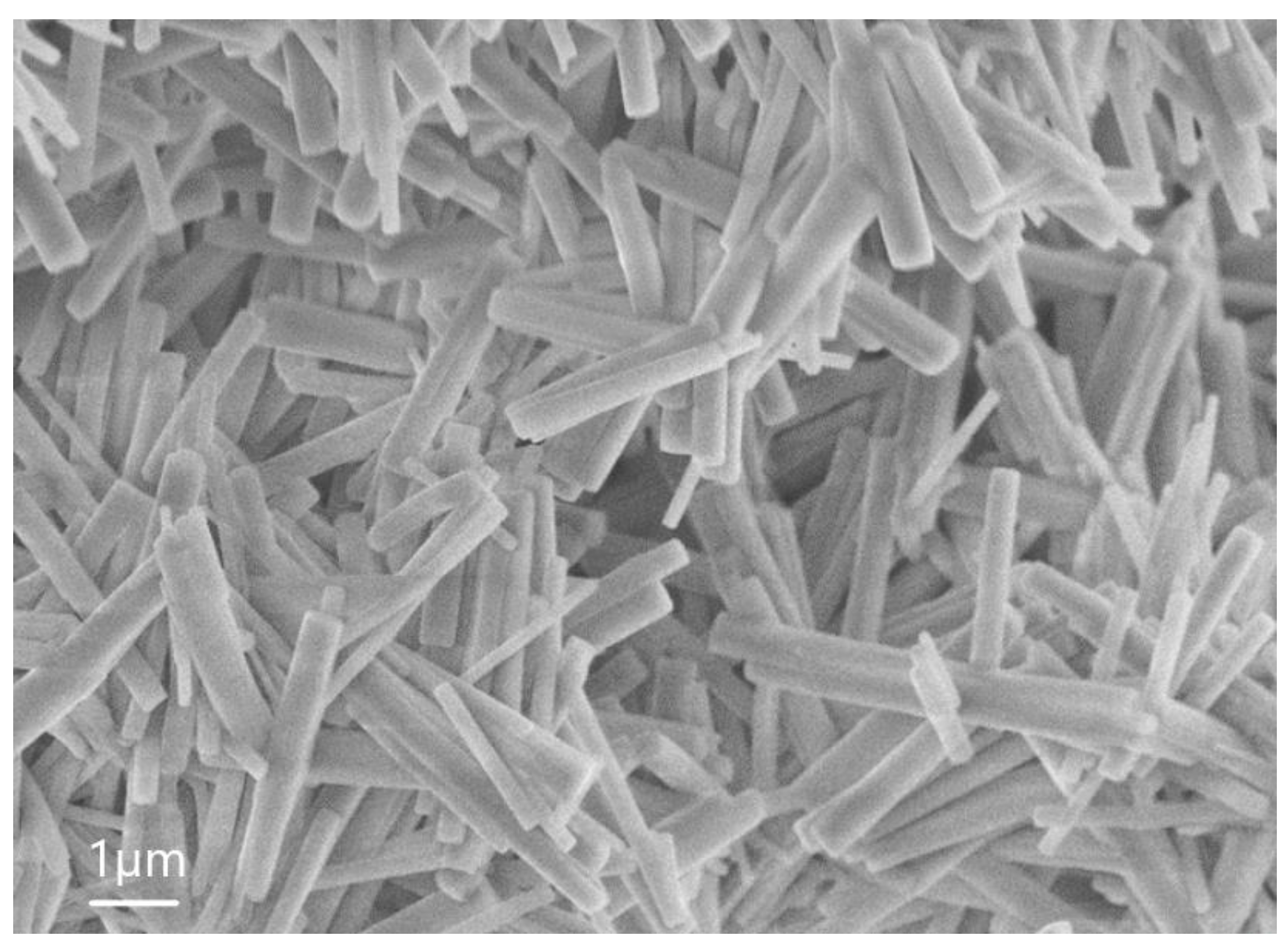

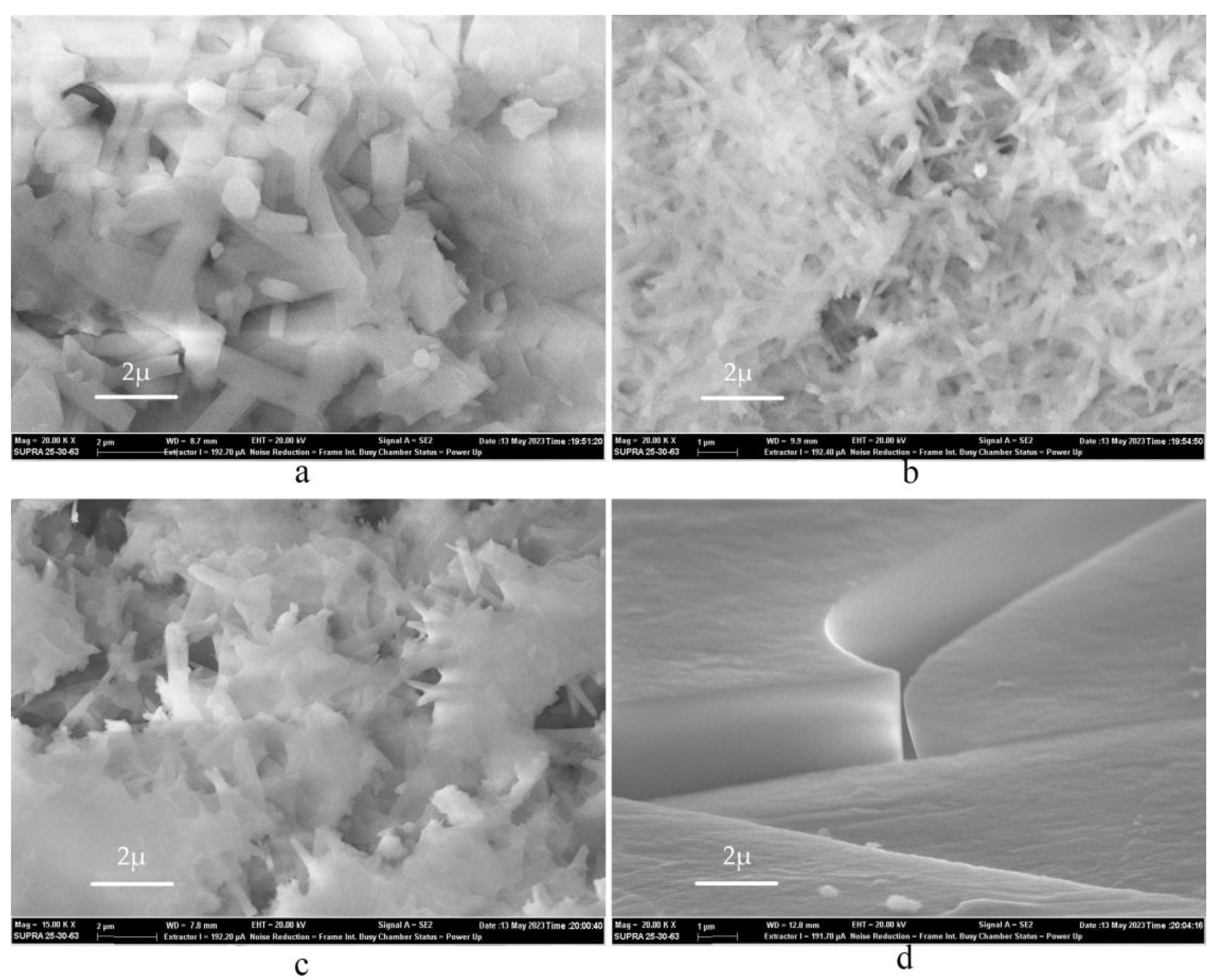

Synthesis under Normal Conditions and Morphology and Composition of AlF3 Nanowires

Abstract

:1. Introduction

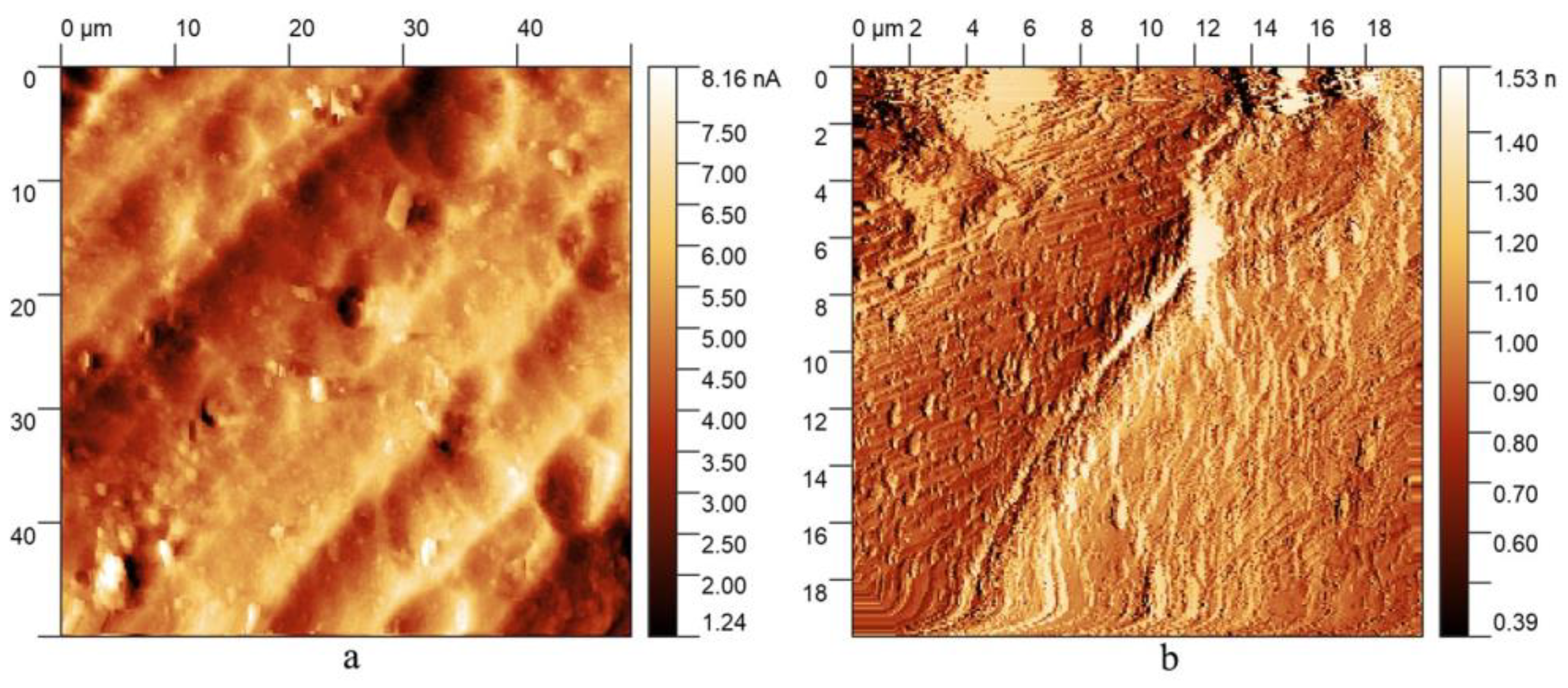

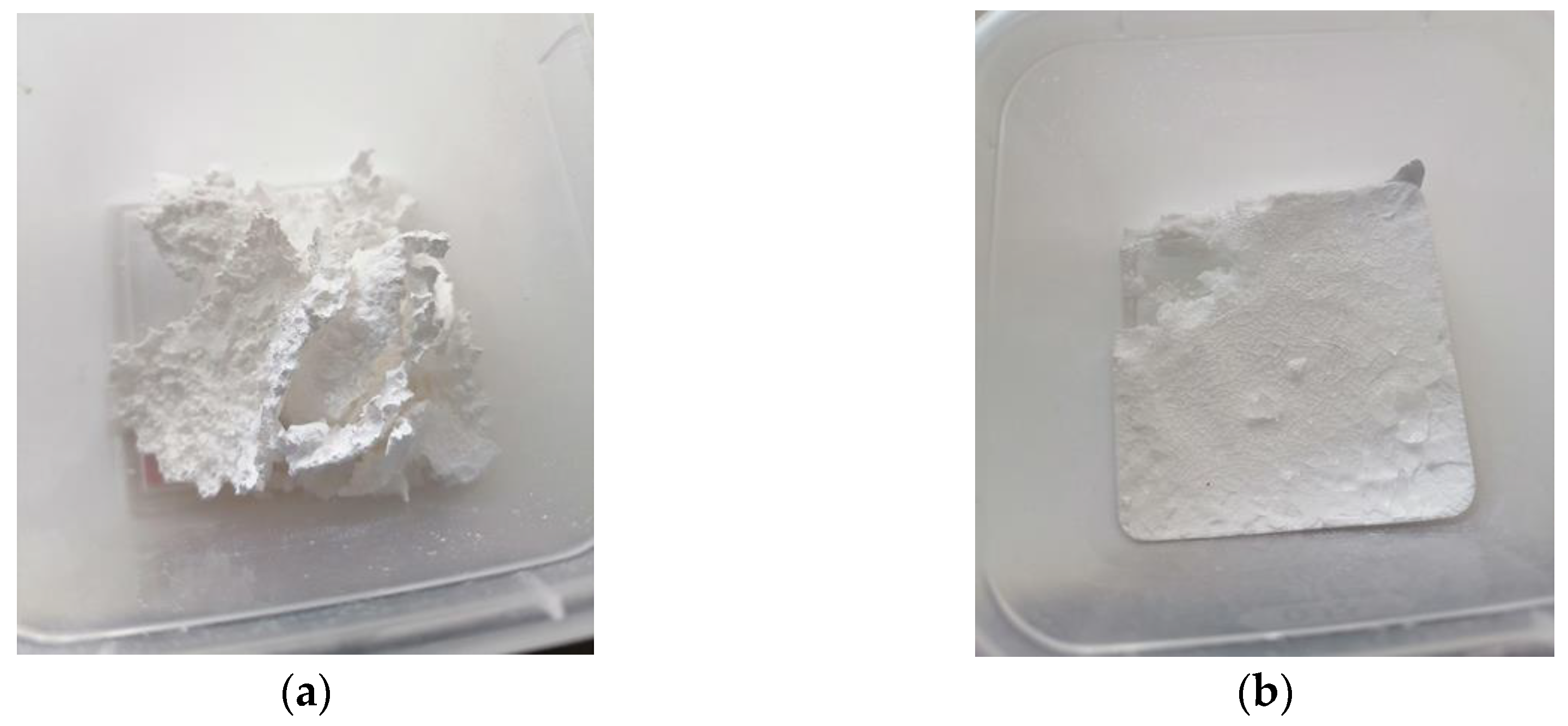

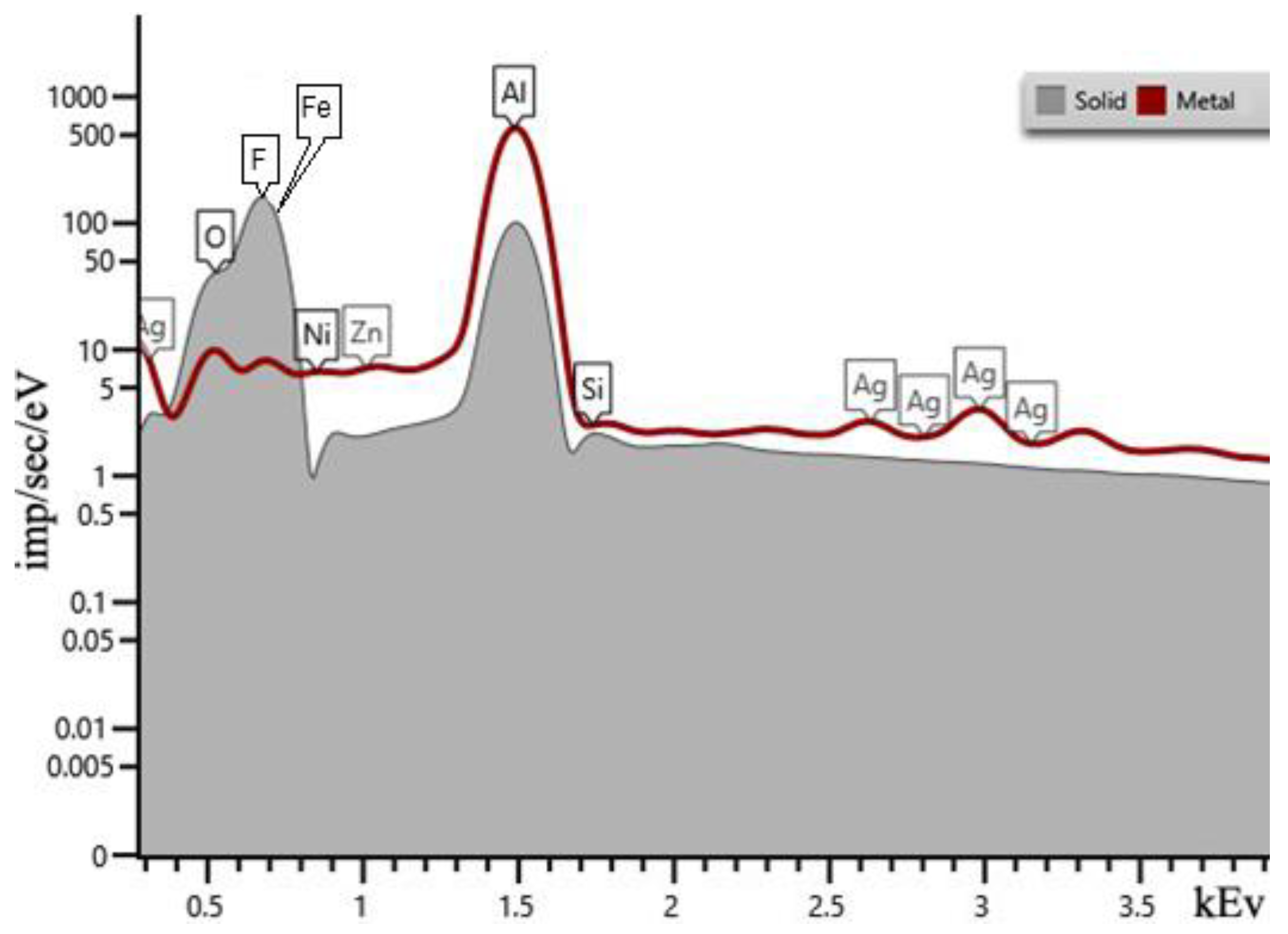

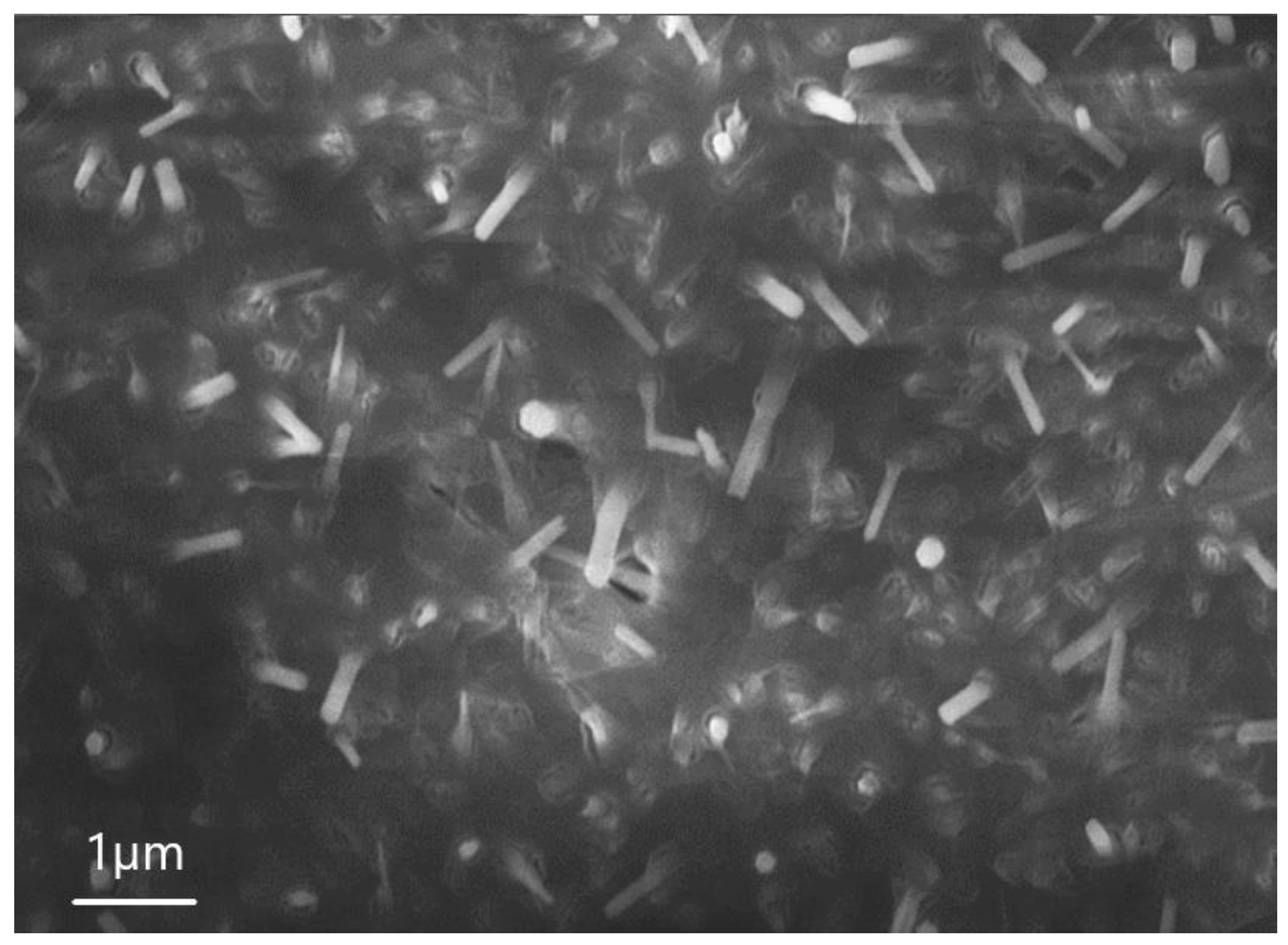

2. Design of Experiments

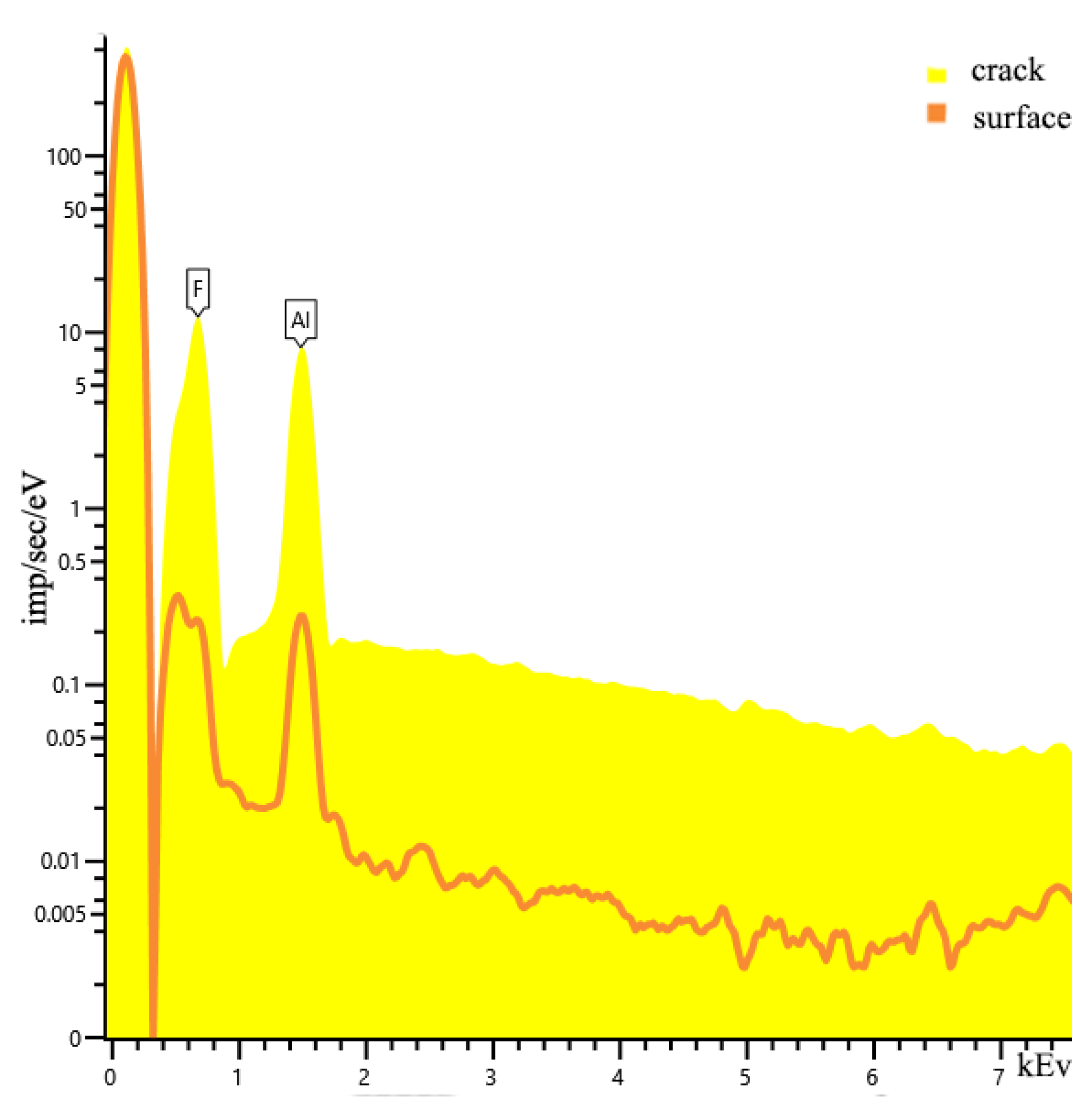

3. Results

4. Discussion and Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Kemnitz, E.; Menz, D.H. Fluorinated metal oxides and metal fluorides as heterogeneous catalysts. Prog. Solid State Chem. 1998, 26, 97–153. [Google Scholar] [CrossRef]

- Murthy, J.K.; Gross, U.; Rudiger, S.; Unveren, E.; Kemnitz, E. Mixed metal fluorides as doped Lewis acidic catalyst systems: A comparative study involving novel high surface area metal fluorides. J. Fluor. Chem. 2004, 125, 937–949. [Google Scholar] [CrossRef]

- Tang, S.; Hu, X.; Yu, J.; Liu, A.; Shi, Z.; Li, Z.; Zhang, Y.; Wang, Z. Dissolution reaction of TiO2 in molten 6.58NaF-AlF3: A Raman spectroscopy and computational simulation study. J. Mol. Liq. 2022, 367, 120431. [Google Scholar] [CrossRef]

- Zhou, H.; Wang, G.; Wang, L.; Zhang, Z.; Hou, H.; Zhong, Q.; Xiao, J. Enhanced effect of AlF3 and its Co-regulatory effect with micron-scaled α-Al2O3 nuclei on alumina crystal growth in high-temperature calcination process. Ceram. Int. 2023, 49, 6563–6572. [Google Scholar] [CrossRef]

- Becker, C.; Braun, T.; Paulus, B. Theoretical Study on the Lewis Acidity of the Pristine AlF3 and Cl-Doped α-AlF3 Surfaces. Catalysts 2021, 11, 565. [Google Scholar] [CrossRef]

- Xie, J.; Sendek, A.D.; Cubuk, E.D.; Zhang, X.; Lu, Z.; Gong, Y.; Wu, T.; Shi, F.; Liu, W.; Reed, E.J.; et al. Atomic Layer Deposition of Stable LiAlF4 Lithium Ion Conductive Interfacial Layer for Stable Cathode Cycling. ACS Nano 2017, 11, 7019–7027. [Google Scholar] [CrossRef]

- Fujihara, S.; Tokumo, K. Chemical processing for inorganic fluoride and oxyfluoride materials having optical functions. J. Fluor. Chem. 2009, 130, 1106–1110. [Google Scholar] [CrossRef]

- Fujihara, S.; Kato, T.; Kimura, T. Sol-gel synthesis and luminescent properties of oxyfluoride LaOF: Eu3+ thin films. J. Mater. Sci. Lett. 2001, 20, 687–689. [Google Scholar] [CrossRef]

- Du, Y.-P.; Zhang, Y.-W.; Yan, Z.-G.; Sun, L.-D.; Yan, C.-H. Highly Luminescent Self-Organized Sub-2-nm EuOF Nanowires. J. Am. Chem. Soc. 2009, 131, 16364–16365. [Google Scholar] [CrossRef]

- Feng, W.; Sun, L.-D.; Zhang, Y.-W.; Yan, C.-H. Synthesis and assembly of rare earth nanostructures directed by the principle of coordination chemistry in solution-based process. Coord. Chem. Rev. 2010, 254, 1038–1053. [Google Scholar] [CrossRef]

- Busse, L.E.; Lu, G.; Tran, D.C.; Sigel, G.H., Jr. A combined DSC/optical microscopy study of crystallization in fluorozirconate glasses upon cooling from the melt. Mater. Sci. Forum. 1985, 5–6, 219–228. [Google Scholar] [CrossRef]

- Shi, Y.; Li, Y.; Zhang, L.; Cai, F.; Cao, X.; Li, X.; Wei, S.; Long, W.; Yu, H.; Sun, B.; et al. Mechanism of oxide film removal by KF-AlF3 and CsF-AlF3 mixed fluxes on Cu and Al base metals and their effect on wettability. J. Adv. Join. Process. 2022, 6, 100128. [Google Scholar] [CrossRef]

- Al-Assadi, Z.I.; Sultan, M.F. Comparative Study for Designing Two Optical Multilayers Stacks ThF4/AlF3 and ThF4/LiF. Al-Mustansiriyah J. Sci. 2022, 33, 98–102. [Google Scholar] [CrossRef]

- Gutiérrez-Luna, N.; Perea-Abarca, B.; Espinosa-Yáñez, L.; Honrado-Benítez, C.; de Lis, T.; Marcos, L.V.R.-D.; Aznárez, J.A.; Larruquert, J.I. Temperature Dependence of AlF3 Protection on Far-UV Al Mirrors. Coatings 2019, 9, 428. [Google Scholar] [CrossRef]

- Zhang, J.; Liu, M.; Yu, J.; Wang, R.; Jia, S.; Liu, Z.; Farrell, G.; Wang, S.; Wang, P. Praseodymium mid-infrared emission in AlF3-based glass sensitized by ytterbium. Opt. Express 2021, 29, 34166–34174. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Vehkamäki, M.; Heikkilä, M.; Mattinen, M.; Putkonen, M.; Leskelä, M.; Ritala, M. Atomic Layer Deposition of Insulating AlF3/Polyimide Nanolaminate Films. Coatings 2021, 11, 355. [Google Scholar] [CrossRef]

- Marciano, M.A.; Camilleri, J.; Lucateli, R.L.; Costa, R.M.; Matsumoto, M.A.; Duarte, M.A.H. Physical, chemical, and biological properties of white MTA with additions of AlF3. Clin. Oral Investig. 2019, 23, 33–41. [Google Scholar] [CrossRef]

- Luo, Z.; Lei, W.; Wang, X.; Pan, J.; Pan, Y.; Xia, S. AlF3 coating as sulfur immobilizers in cathode material for high performance lithium-sulfur batteries. J. Alloy Compd. 2020, 812, 152132. [Google Scholar] [CrossRef]

- Lei, C.; Markoulidis, F.; Ashitaka, Z.; Lekakou, C. Reduction of porous carbon/Al contact resistance for an electric double-layer capacitor (EDLC). Electrochim. Acta 2013, 92, 183–187. [Google Scholar] [CrossRef]

- Zhang, J.; Zhang, D.; Wang, Z.; Zheng, F.; Zhong, R.; Hong, R. AlF3 coating improves cycle and voltage decay of Li-rich manganese oxides. J. Mater. Sci. 2023, 58, 4525–4540. [Google Scholar] [CrossRef]

- Rodríguez, S.J.; Candia, A.E.; Passeggi, M.C.G.; Albanesi, E.A.; Ruano, G.D. A theoretical study on the intercalation and diffusion of AlF3 in graphite: Its application in rechargeable batteries. Phys. Chem. Chem. Phys. 2021, 23, 19579–19589. [Google Scholar] [CrossRef] [PubMed]

- Adhitama, E.; van Wickeren, S.; Neuhaus, K.; Frankenstein, L.; Demelash, F.; Javed, A.; Haneke, L.; Nowak, S.; Winter, M.; Gomez-Martin, A.; et al. Revealing the Role, Mechanism, and Impact of AlF3 Coatings on the Interphase of Silicon Thin Film Anodes. Adv. Energy Mater. 2022, 12, 2201859. [Google Scholar] [CrossRef]

- Padamata, S.K.; Yasinskiy, A.; Polyakov, P. Electrode processes in the KF–AlF3–Al2O3 melt. New J. Chem. 2020, 44, 5152–5164. [Google Scholar] [CrossRef]

- Abdullayev, A.; Klimm, D.; Kamutzki, F.; Gurlo, A.; Bekheet, M.F. AlF3-assisted flux growth of mullite whiskers and their application in fabrication of porous mullite-alumina monoliths. Open Ceram. 2021, 7, 100145. [Google Scholar] [CrossRef]

- Estruga, M.; Meng, F.; Li, L.; Chen, L.; Li, X.; Jin, S. Large-scale solution synthesis of α-AlF3·3H2O nanorods under low supersaturation conditions and their conversion to porous β-AlF3 nanorods. J. Mater. Chem. 2012, 22, 20991–20997. [Google Scholar] [CrossRef]

- Han, W.; Wang, H.; Liu, B.; Li, X.; Tang, H.; Li, Y.; Liu, H. PVDF mediated fabrication of freestanding AlF3 sub-microspheres: Facile and controllable synthesis of α, β and θ-AlF3. Mater. Chem. Phys. 2019, 240, 122287. [Google Scholar] [CrossRef]

- Jia, W.-Z.; Lu, J.-Q.; Chen, P.; Wang, Y.-J.; Luo, M.-F. A novel method for the synthesis of well-crystallized β-AlF3 with high surface area derived from γ-Al2O3. J. Mater. Chem. 2011, 21, 8987–8990. [Google Scholar] [CrossRef]

- Liu, W.; Meng, L.; Liu, X.; Gao, L.; Wang, X.; Kang, J.; Ju, J.; Deng, N.; Cheng, B.; Kang, W. 3D spiny AlF3/Mullite heterostructure nanofiber as solid-state polymer electrolyte fillers with enhanced ionic conductivity and improved interfacial compatibility. J. Energy Chem. 2023, 76, 503–515. [Google Scholar] [CrossRef]

- Mao, W.; Bai, Y.; Jia, Z.; Qin, Y.; Wang, B.; Zhang, W.; Lu, J.; Kemnitz, E. The ethylene glycol-mediated sol–gel synthesis of nano AlF3: Structural and acidic properties after different post treatments. Dalton Trans. 2022, 51, 935–945. [Google Scholar] [CrossRef]

- Deng, X.; Ji, P.; Yin, J.; Wang, Y.; Song, C.; Li, S.; Zhang, Y.; Ding, X.; Ran, S.; Zhang, H.; et al. Fabrication and characterization of mullite-whisker-reinforced lightweight porous materials with AlF3·3H2O. Ceram. Int. 2022, 48, 14891–14898. [Google Scholar] [CrossRef]

- Kemnitz, E. Nanoscale metal fluorides: A new class of heterogeneous catalysts. Catal. Sci. Technol. 2015, 5, 786–806. [Google Scholar] [CrossRef]

- Kemnitz, E.; Groß, U.; Rüdiger, S.; Shekar, C.S. Amorphous Metal Fluorides with Extraordinary High Surface Areas. Angew. Chem. Int. Ed. 2003, 42, 4251–4254. [Google Scholar] [CrossRef] [PubMed]

- Krysztafkiewicz, A.; Rager, B.; Maik, M. Silica recovery from waste obtained in hydrofluoric acid and aluminum fluoride production from fluosilicic acid. J. Hazard. Mater. 1996, 48, 31–49. [Google Scholar] [CrossRef]

- Le Bail, A.; Jacoboni, C.; Leblanc, M.; De Pape, R.; Duroy, H.; Fourquet, J. Crystal structure of the metastable form of aluminum trifluoride β-AlF3 and the gallium and indium homologs. J. Solid State Chem. 1988, 77, 96–101. [Google Scholar] [CrossRef]

- Dubrovskii, V.G. Theory of VLS Growth of Compound Semiconductors; Semiconductors and Semimetals, v. 93; Fontcuberta, A., Morral, I., Dayeh, S.A., Jagadish, C., Eds.; Academic Press: Burlington, NJ, USA, 2015; pp. 1–78. [Google Scholar]

| Sample | Percentage of HF Solution Concentration, % | |

|---|---|---|

| 1.1 | 40 | 12.49 |

| 2.1 | 32.6 | 10.67 |

| 3.1 | 29.4 | 9.77 |

| 4.1 | 24.5 | 11.34 |

| 5.1 | 16.3 | 10.12 |

| 6.1 | 8 | 14.32 |

| Sample | Percentage of Solution Concentration, % | |

|---|---|---|

| 1.2 | 40 | 120.65 |

| 2.2 | 32.6 | 93.31 |

| 3.2 | 29.4 | 81.04 |

| 4.2 | 24.5 | 53.81 |

| 5.2 | 16.3 | 115.37 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dautov, A.; Kotlyar, K.; Butusov, D.; Novikov, I.; Khafizova, A.; Karimov, A. Synthesis under Normal Conditions and Morphology and Composition of AlF3 Nanowires. Nanomaterials 2023, 13, 2413. https://doi.org/10.3390/nano13172413

Dautov A, Kotlyar K, Butusov D, Novikov I, Khafizova A, Karimov A. Synthesis under Normal Conditions and Morphology and Composition of AlF3 Nanowires. Nanomaterials. 2023; 13(17):2413. https://doi.org/10.3390/nano13172413

Chicago/Turabian StyleDautov, Albert, Kotstantin Kotlyar, Denis Butusov, Ivan Novikov, Aliya Khafizova, and Artur Karimov. 2023. "Synthesis under Normal Conditions and Morphology and Composition of AlF3 Nanowires" Nanomaterials 13, no. 17: 2413. https://doi.org/10.3390/nano13172413