High-Performance Biomemristor Embedded with Graphene Quantum Dots

Abstract

:1. Introduction

2. Materials and Methods

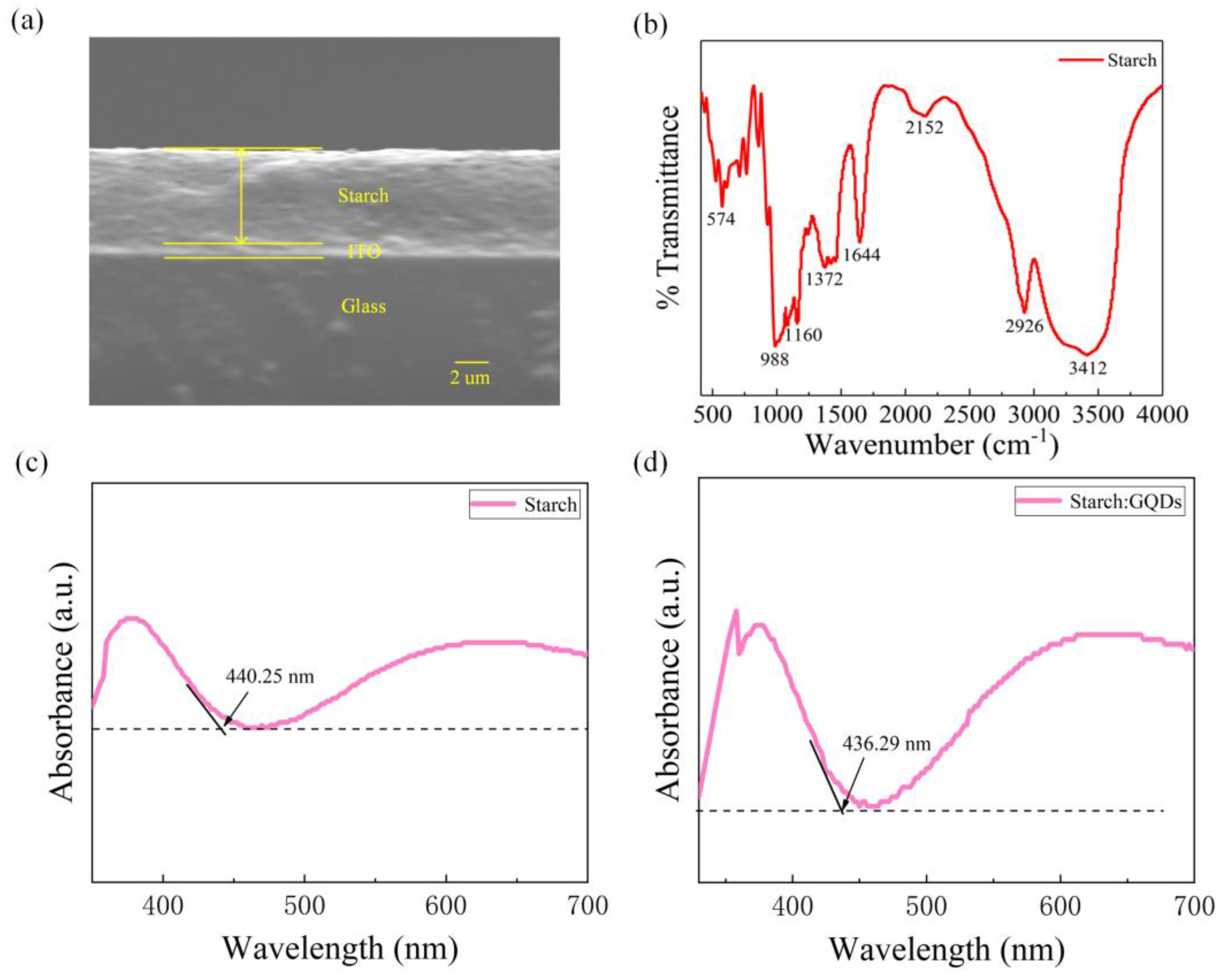

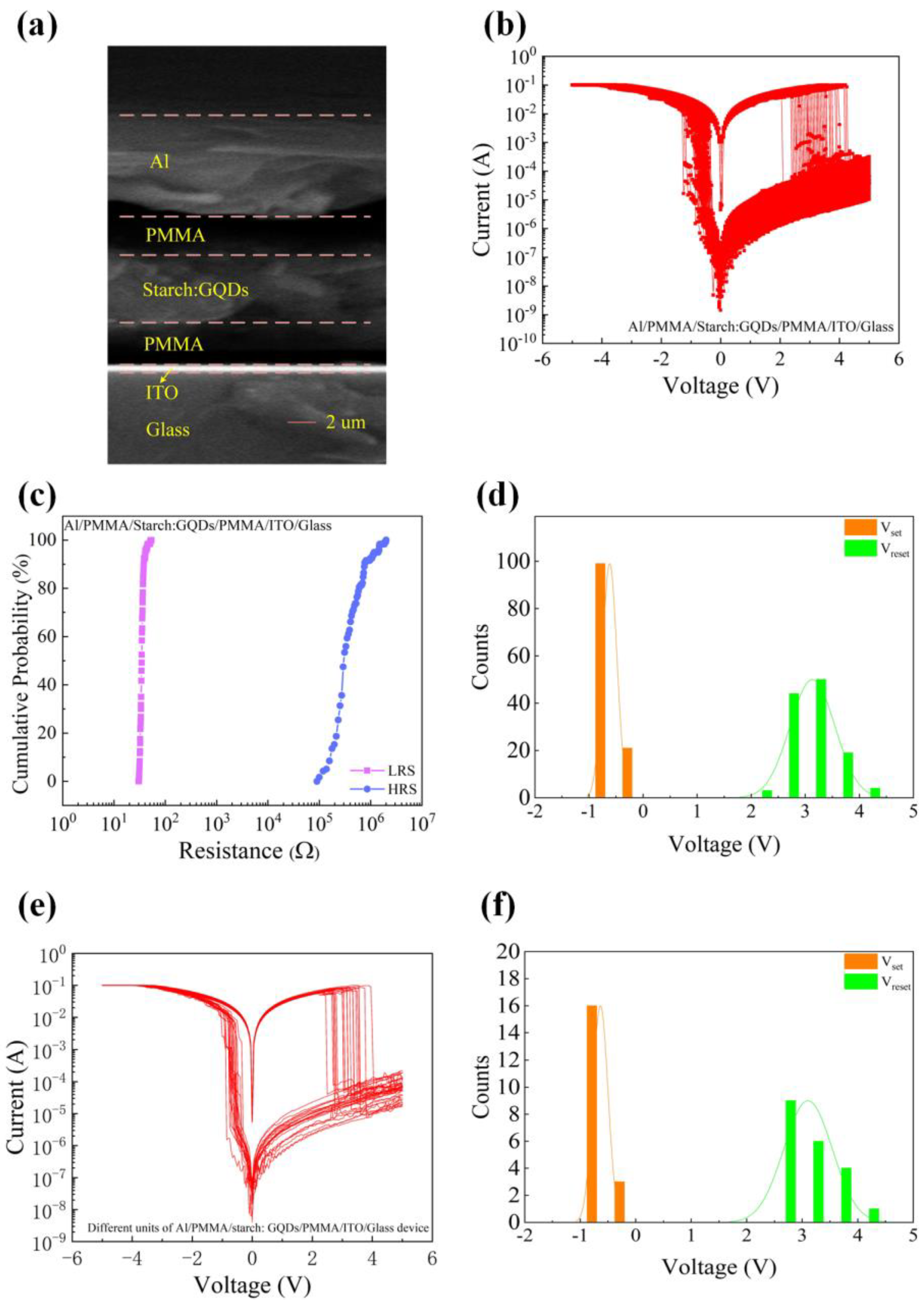

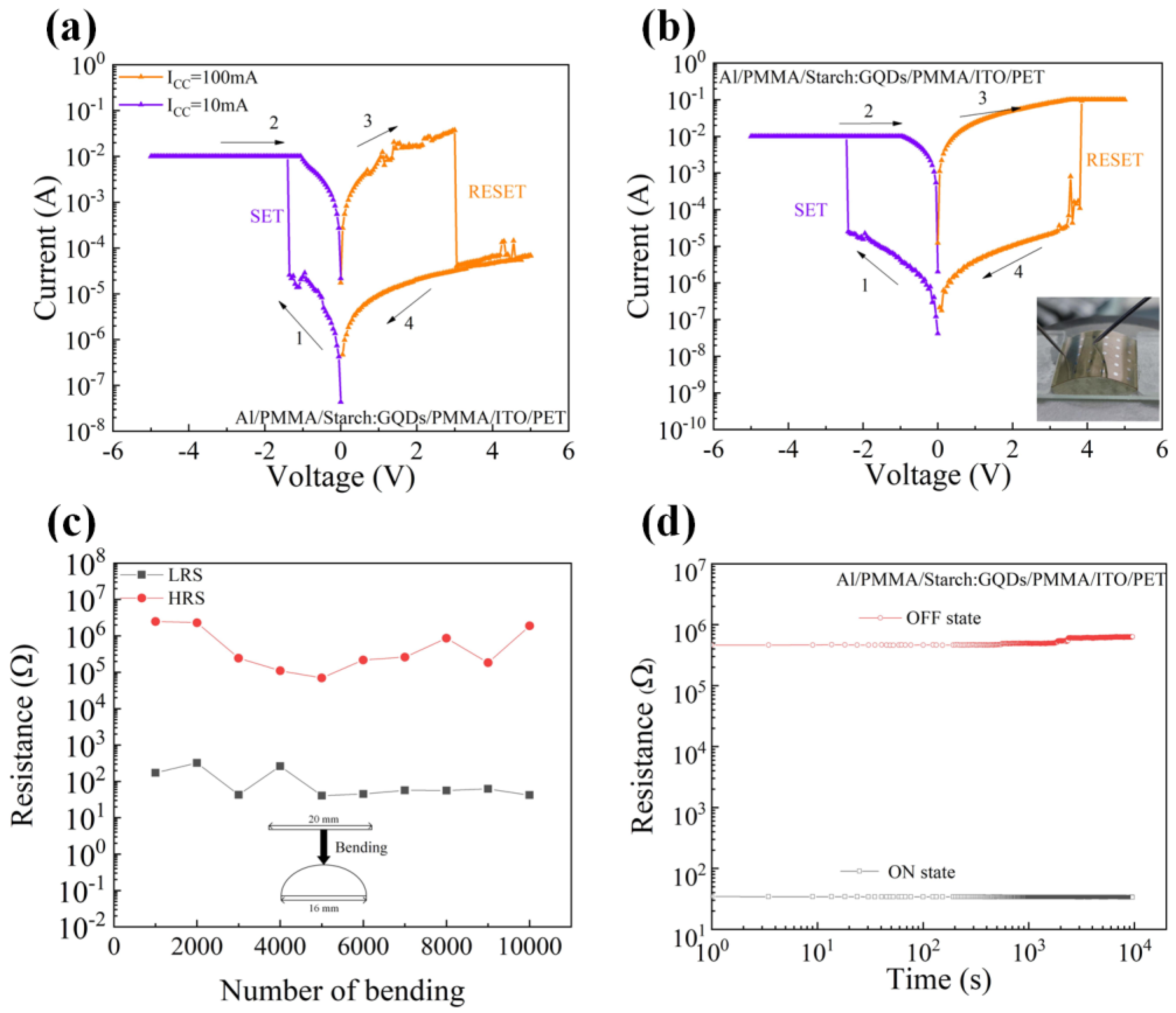

3. Results

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wang, L.; Xie, J.C.; Wen, D.Z. Forming-free plant resistive random access memory based on the Coulomb blockade effect produced by gold nanoparticles. Chem. Phys. 2023, 25, 18132–18138. [Google Scholar] [CrossRef]

- Tao, D.W.; Chen, J.B.; Jiang, Z.J.; Qi, B.J.; Zhang, K.; Wang, C.W. Making reversible transformation from electronic to ionic resistive switching possible by applied electric field in an asymmetrical Al/TiO2/FTO nanostructure. Appl. Surf. Sci. 2020, 502, 144124. [Google Scholar] [CrossRef]

- Ai, R.B.; Zu, N.N.; Li, R.; Qi, B.J. From gradual change to abrupt change in Ni-Al layered double hydroxide memristor by adsorbed small molecule oxadiazole. Sens. Actuator A Phys. 2021, 323, 112671. [Google Scholar] [CrossRef]

- Gul, F.; Efeoglu, H. ZnO and ZnO1−x based thin film memristors: The effects of oxygen deficiency and thickness in resistive switching behavior. Ceram. Int. 2017, 43, 10770–10775. [Google Scholar] [CrossRef]

- Aziz, T.N.T.A.; Rosli, A.B.; Yusoff, M.M.; Herman, S.H.; Zulkifli, Z. Transparent hybrid ZnO-graphene film for high stability switching behavior of memristor device. Mater. Sci. Semicond. Process. 2019, 89, 68–76. [Google Scholar] [CrossRef]

- Wang, L.; Zhu, H.Y.; Wen, D.Z. Tunable multistate data storage device based on silkworm hemolymph and graphene oxide. Ceram. Int. 2021, 47, 33865–33874. [Google Scholar] [CrossRef]

- Kang, M.; Baeg, K.J.; Khim, D.; Noh, Y.Y.; Kim, D.Y. Printed, Flexible, Organic Nano-Floating-Gate Memory: Effects of Metal Nanoparticles and Blocking Dielectrics on Memory Characteristics. Adv. Funct. Mater. 2013, 23, 3503–3512. [Google Scholar] [CrossRef]

- Wu, E.; Ando, T.; Kim, Y.; Muralidhar, R.; Cartier, E.; Jamison, P.; Wang, M.M.; Narayanan, V. A maximum extreme-value distribution model for switching conductance of oxide-RRAM in memory applications. Appl. Phys. Lett. 2020, 116, 082901. [Google Scholar] [CrossRef]

- Raeis-Hosseini, N.; Rho, J. Solution-Processed Flexible Biomemristor Based on Gold-Decorated Chitosan. ACS Appl. Mater. Interfaces 2021, 13, 5445–5450. [Google Scholar] [CrossRef]

- Gogurla, N.; Mondal, S.P.; Sinha, A.K.; Katiyar, A.K.; Banerjee, W.; Kundu, S.C.; Ray, S.K. Transparent and flexible resistive switching memory devices with a very high ON/OFF ratio using gold nanoparticles embedded in a silk protein matrix. Nanotechnology 2013, 24, 345202. [Google Scholar] [CrossRef]

- Abbas, Y.; Dugasani, S.R.; Raza, M.T.; Jeon, Y.R.; Park, S.H.; Choi, C. The observation of resistive switching characteristics using transparent and biocompatible Cu2+-doped salmon DNA composite thin film. Nanotechnology 2019, 30, 335203. [Google Scholar] [CrossRef] [PubMed]

- Che, Y.; Zhang, Y.T.; Cao, X.L.; Song, X.X.; Cao, M.X.; Dai, H.T.; Yang, J.B.; Zhang, G.Z.; Yao, J.Q. Low operating voltage ambipolar graphene oxide-floating-gate memory devices based on quantum dots. J. Mater. Chem. C 2016, 4, 1420–1424. [Google Scholar] [CrossRef]

- Hafsi, B.; Boubaker, A.; Guerin, D.; Lenfant, S.; Kalboussi, A.; Lmimouni, K. N-type polymeric organic flash memory device: Effect of reduced graphene oxide floating gate. Org. Electron. 2017, 45, 81–88. [Google Scholar] [CrossRef]

- Lin, Y.; Wang, Z.Q.; Zhang, X.; Zeng, T.; Bai, L.; Kang, Z.H.; Wang, C.H.; Zhao, X.N.; Xu, H.Y.; Liu, Y.C. Photoreduced nanocomposites of graphene oxide/N-doped carbon dots toward all-carbon memristive synapses. NPG Asia Mater. 2020, 12, 64. [Google Scholar] [CrossRef]

- Sun, Y.M.; Lu, J.G.; Ai, C.P.; Wen, D.Z. Nonvolatile memory devices based on poly(vinyl alcohol) plus graphene oxide hybrid composites. Chem. Phys. 2016, 18, 11341–11347. [Google Scholar]

- Xin, Y.; Zhao, X.F.; Zhang, H.Y.; Wang, S.H.; Bai, L.; Kang, Z.H.; Wang, C.H.; Wang, C.; Ma, D.G.; Yan, P.F. Bistable electrical switching and nonvolatile memory effect in poly (9,9-dioctylfluorene-2,7-diyl) and multiple-walled carbon nanotubes. Org. Electron. 2019, 74, 110–117. [Google Scholar] [CrossRef]

- Murgunde, B.K.; Rabinal, M.K. Solution processed bilayer junction of silk fibroin and semiconductor quantum dots as multilevel memristor devices. Org. Electron. 2017, 48, 276–284. [Google Scholar] [CrossRef]

- Sokolov, A.S.; Ali, M.; Riaz, R.; Abbas, Y.; Ko, M.J.; Choi, C. Silver-Adapted Diffusive Memristor Based on Organic Nitrogen-Doped Graphene Oxide Quantum Dots (N-GOQDs) for Artificial Biosynapse Applications. Adv. Funct. Mater. 2019, 29, 1807504. [Google Scholar] [CrossRef]

- Rehman, M.M.; Siddiqui, G.U.; Kim, S.; Choi, K.H. Resistive switching effect in the planar structure of all-printed, flexible and rewritable memory device based on advanced 2D nanocomposite of graphene quantum dots and white graphene flakes. J. Phys. D Appl. Phys. 2017, 50, 335104. [Google Scholar] [CrossRef]

- Murgunde, B.K.; Rabinal, M.K.; Kalasad, M.N.; Choi, K.H. Biologically active nanocomposite of DNA-PbS nanoparticles: A new material for nonvolatile memory devices. Appl. Surf. Sci. 2018, 427, 344–353. [Google Scholar] [CrossRef]

- Yan, X.B.; Zhang, L.; Yang, Y.Q.; Zhou, Z.Y.; Zhao, J.H.; Zhang, Y.Y.; Liu, Q.; Chen, J.S. Highly improved performance in Zr0.5Hf0.5O2 films inserted with graphene oxide quantum dots layer for resistive switching nonvolatile memory. Adv. Funct. Mater. 2017, 5, 11046–11052. [Google Scholar]

- Zhang, P.; Xu, B.H.; Gao, C.X.; Chen, G.L.; Gao, M.Z. Facile Synthesis of Co9Se8 Quantum Dots as Charge Traps for Flexible Organic Resistive Switching Memory Device. ACS Appl. Mater. Interfaces 2016, 8, 30336–30343. [Google Scholar] [CrossRef] [PubMed]

- Valov, I. Interfacial interactions and their impact on redox-based resistive switching memories (ReRAMs). Semicond. Sci. Technol. 2017, 32, 093006. [Google Scholar] [CrossRef]

- Hong, S.K.; Kim, J.E.; Kim, S.O.; Cho, B.J. Analysis on switching mechanism of graphene oxide resistive memory device. J. Appl. Phys. 2011, 11, 044506. [Google Scholar] [CrossRef]

- Ke, J.J.; Namura, K.; Retamal, J.R.D.; Ho, C.H.; Minamitake, H.; Wei, T.C.; Tsai, D.S.; Lin, C.H.; Suzuki, M.; He, J.H. Surface-Controlled Metal Oxide Resistive Memory. IEEE Electron. Device Lett. 2015, 36, 1307–1309. [Google Scholar] [CrossRef]

- Sarkar, K.J.; Sarkar, K.; Pal, B. Graphene quantum dots as charge trap elements for nonvolatile flash memory. J. Phys. Chem. Solids 2018, 122, 137–142. [Google Scholar] [CrossRef]

- Wang, L.; Wang, Y.T.; Wen, D.Z. Tunable biological nonvolatile multilevel data storage devices. Chem. Phys. 2021, 23, 24834–24841. [Google Scholar] [CrossRef]

- He, X.L.; Zhang, J.; Wang, W.B.; Xuan, W.P.; Wang, X.Z.; Zhang, Q.L.; Smith, C.G.; Luo, J.K. Transient Resistive Switching Devices Made from Egg Albumen Dielectrics and Dissolvable Electrodes. ACS Appl. Mater. Interfaces 2016, 8, 10954–10960. [Google Scholar] [CrossRef]

- Mukherjee, C.; Hota, M.K.; Naskar, D.; Kundu, S.C.; Maiti, C.K. Resistive switching in natural silkfibroin protein-based biomemristors. Phys. Status Solidi A 2013, 210, 1797–1805. [Google Scholar] [CrossRef]

- Li, T.; Xu, Y.; Lei, M.; Zhao, Y.; Sun, B.; Elshekh, H.; Zheng, L.; Zhang, X.; Hou, W.; Zhao, Y. The pH-controlled memristive effect in a sustainable bioelectronic device prepared using lotus root. Mater. Today Sustain. 2020, 7–8, 100029. [Google Scholar] [CrossRef]

- Fang, S.L.; Liu, W.H.; Li, X.; Wang, X.L.; Geng, L.; Wu, M.S.; Huang, X.D.; Han, C.Y. Biodegradable transient resistive random-access memory based on MoO3/MgO/MoO3 stack. Mater. Today Sustain. 2019, 115, 244102. [Google Scholar] [CrossRef]

- Wang, L.; Wen, D.Z. Nonvolatile Bio-Memristor Based on Silkworm Hemolymph Proteins. Sci. Rep. 2017, 7, 17418. [Google Scholar] [CrossRef]

- Shi, C.Y.; Lan, J.L.; Wang, J.J.; Zhang, S.; Lin, Y.H.; Zhu, S.H.; Stegmann, A.E.; Yu, R.; Yan, X.B.; Liu, X.Y. Flexible and Insoluble Artificial Synapses Based on Chemical Cross-Linked Wool Keratin. Adv. Funct. Mater. 2020, 30, 2002882. [Google Scholar] [CrossRef]

- Park, Y.; Lee, J.S. Artificial Synapses with Short- and Long-Term Memory for Spiking Neural Networks Based on Renewable Materials. ACS Nano 2017, 11, 8962–8969. [Google Scholar] [CrossRef] [PubMed]

- Shi, C.Y.; Lan, J.L.; Wang, J.J.; Sushko, M.R.A.; Qiu, W.; Yan, X.B.; Liu, X.Y. Silk Flexible Electronics: From Bombyx mori Silk Ag Nanoclusters Hybrid Materials to Mesoscopic Memristors and Synaptic Emulators. Adv. Funct. Mater. 2019, 29, 1904777. [Google Scholar] [CrossRef]

- Raeis-Hosseini, N.; Lee, J.S. Controlling the Resistive Switching Behavior in Starch-Based Flexible Biomemristors. ACS Appl. Mater. Interfaces 2016, 8, 7326–7332. [Google Scholar] [CrossRef] [PubMed]

- Chang, Y.C.; Jian, J.C.; Chuang, M.Y.; Hsu, Y.L.; Huang, W.Y.; Young, S.J. Metal and carbon filaments in biomemory devices through controlling the Al/apple pectin interface. ACS Appl. Electron. Mater. 2020, 9, 2798–2805. [Google Scholar] [CrossRef]

- Ghosh, T.; Kandpal, S.; Pathak, D.K.; Tanwar, M.; Rani, C.; Chaudhary, A.; Kumar, R. Aloe vera flower extract as a botanical resistive memory element: A natural memristor! ACS Appl. Electron. Mater. 2021, 3, 1556–1559. [Google Scholar] [CrossRef]

- Qi, Y.M.; Sun, B.; Fu, G.Q.; Li, T.T.; Zhu, S.H.; Zheng, L.; Mao, S.S.; Kan, X.; Lei, M.; Chen, Y.Z. A nonvolatile organic resistive switching memory based on lotus leaves. Chem. Phys. 2019, 516, 168–174. [Google Scholar] [CrossRef]

- Ren, J.; Liu, G.; Qu, Q.; Zhao, S.Q.; Xu, J.; Ma, D.X. Starch discrimination with Fourier transform infrared spectroscopy (FTIR) and two-dimensional correlation infrared spectroscopy (2D-IR). Chin. Agric. Sci. Bull. 2015, 31, 58–64. [Google Scholar]

- Chen, L.; Huang, Y.R.; Li, X.X.; Li, L. Infrared spectroscopy study on the crystal structure of modified starch. Sci. Agric. Sin. 2007, 40, 2821–2826. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, L.; Yang, J.; Zhang, X.; Wen, D. High-Performance Biomemristor Embedded with Graphene Quantum Dots. Nanomaterials 2023, 13, 3021. https://doi.org/10.3390/nano13233021

Wang L, Yang J, Zhang X, Wen D. High-Performance Biomemristor Embedded with Graphene Quantum Dots. Nanomaterials. 2023; 13(23):3021. https://doi.org/10.3390/nano13233021

Chicago/Turabian StyleWang, Lu, Jing Yang, Xiafan Zhang, and Dianzhong Wen. 2023. "High-Performance Biomemristor Embedded with Graphene Quantum Dots" Nanomaterials 13, no. 23: 3021. https://doi.org/10.3390/nano13233021