Experimental Formation and Mechanism Study for Super-High Dielectric Constant AlOx/TiOy Nanolaminates

Abstract

:1. Introduction

2. Materials and Methods

3. Results

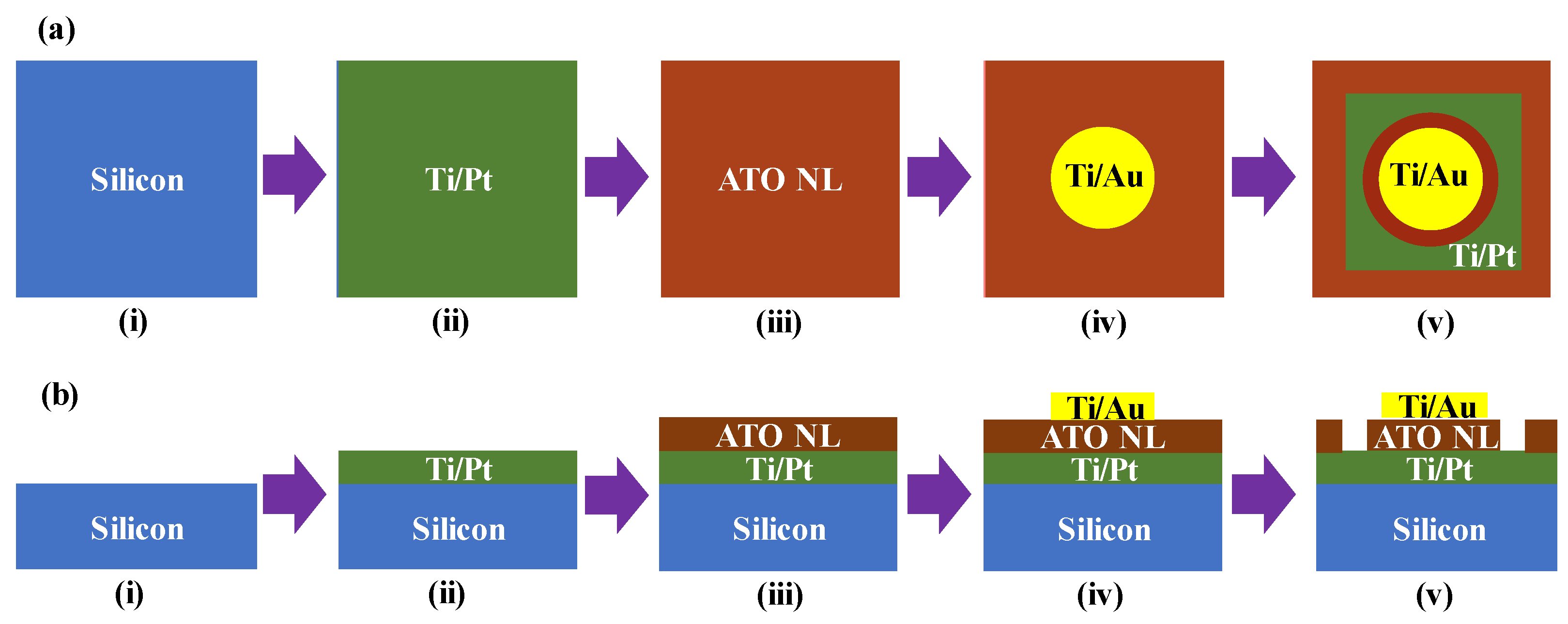

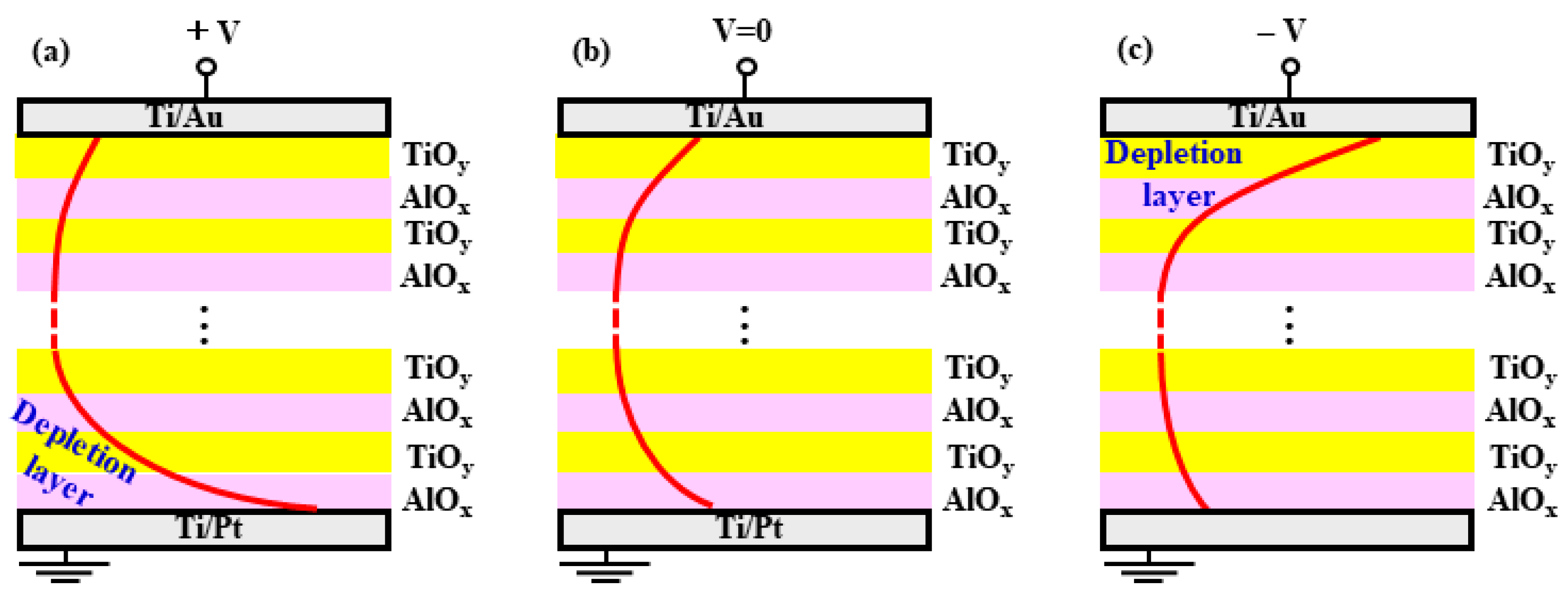

3.1. Schematic Diagram for the Capacitor and EDX Mapping for the ATO NL

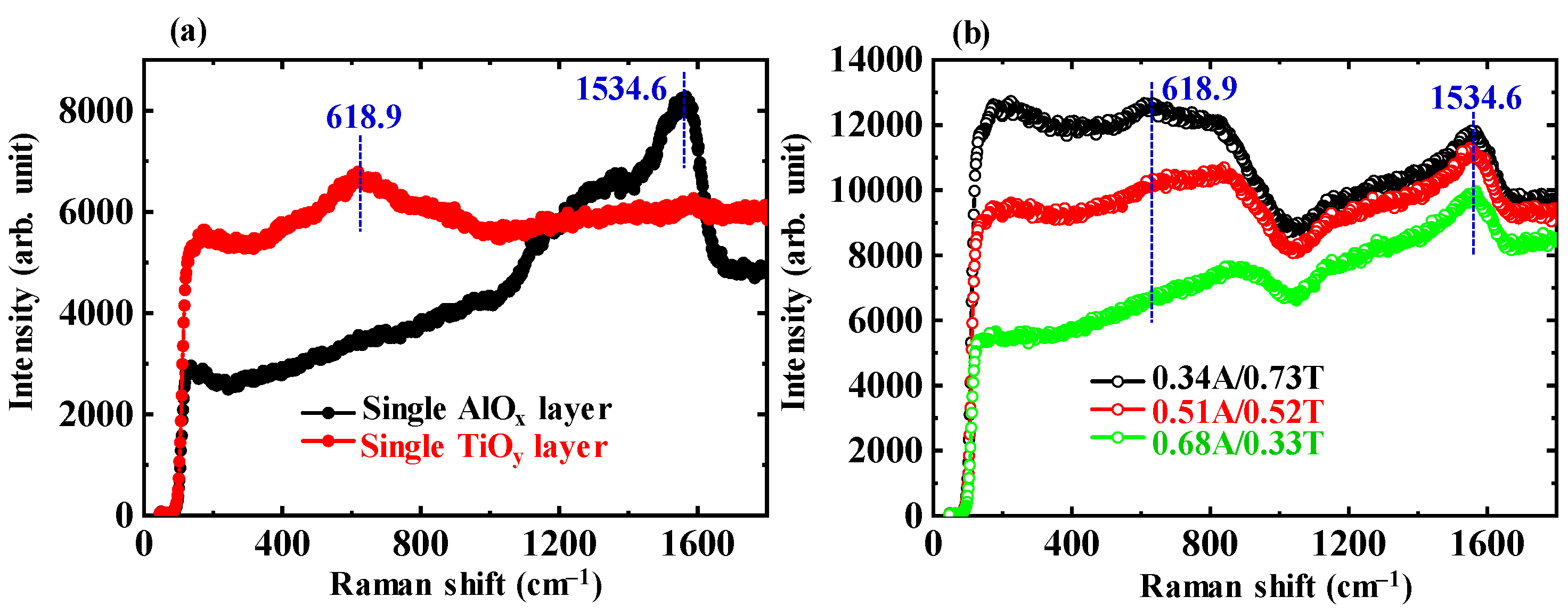

3.2. Raman Spectra for the ATO NLs

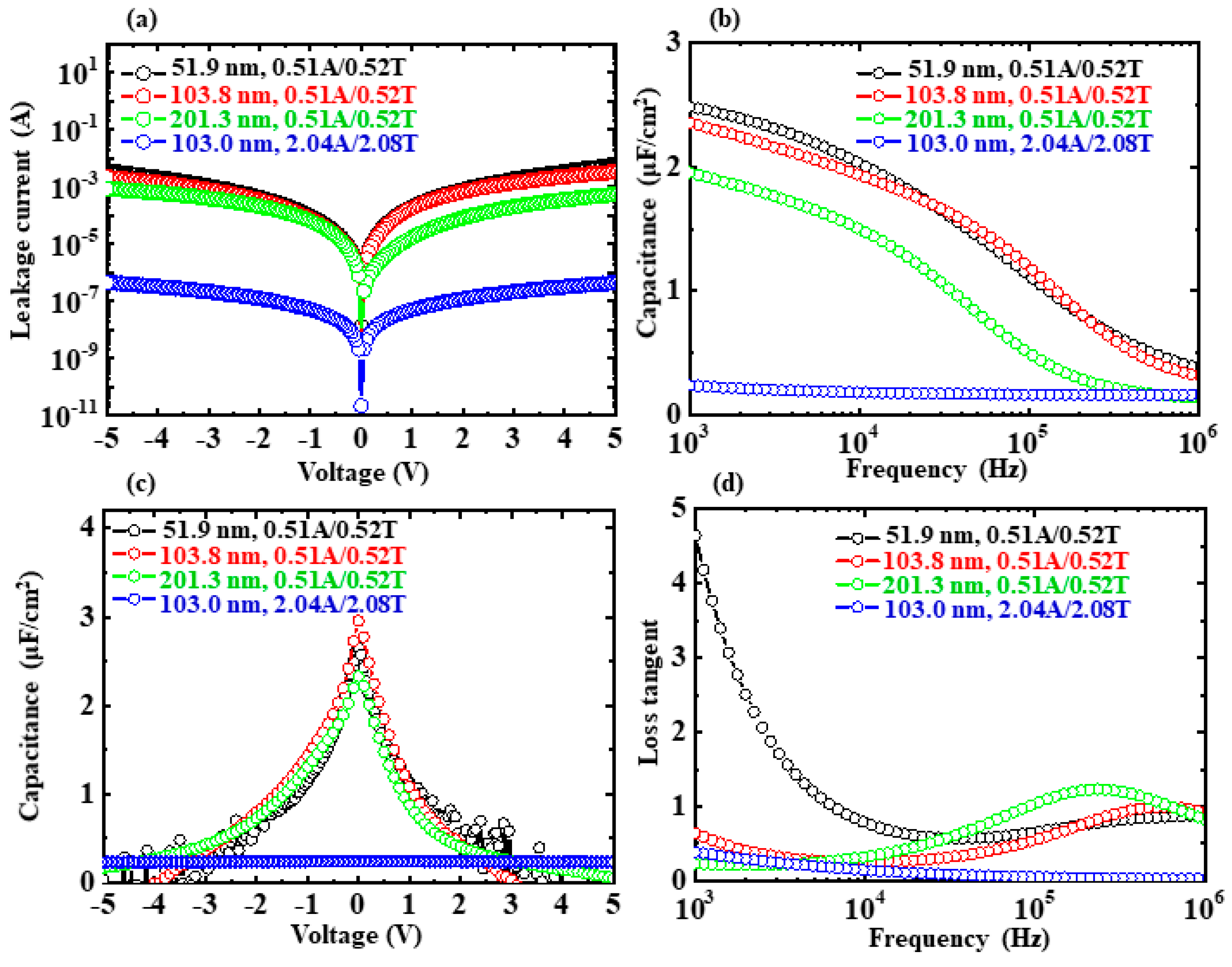

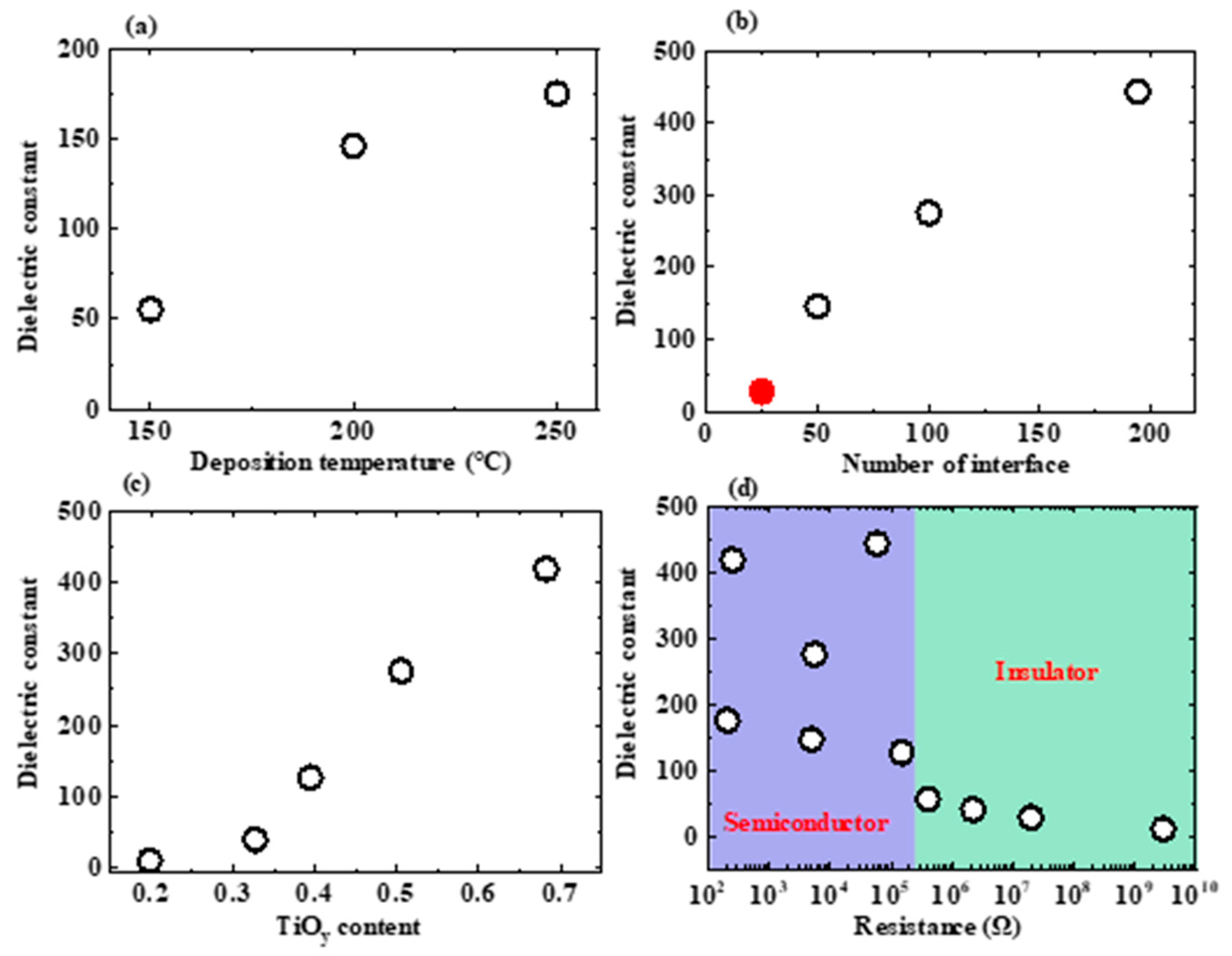

3.3. Effects of Deposition Temperature on Electrical Properties of the Capacitors

3.4. Effects of the Number of ATO Interfaces on Electrical Properties of the Capacitors

3.5. Effects of AlOx and TiOy Contents on Electrical Properties of the Capacitors

3.6. Impedance Properties of the Capacitors

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Raza, W.; Ali, F.; Raza, N.; Luo, Y.; Kim, K.-H.; Yang, J.; Kumar, S.; Mehmood, A.; Kwon, E.E. Recent Advancements in Supercapacitor Technology. Nano Energy 2018, 52, 441–473. [Google Scholar] [CrossRef]

- Okuda, T.; Murotani, T. A Four-Level Storage 4-Gb DRAM. IEEE J. Solid-State Circuits. 1997, 32, 1743–1747. [Google Scholar] [CrossRef]

- Auciello, O.; Fan, W.; Kabius, B.; Saha, S.; Carlisle, J.A.; Chang, R.P.H.; Lopez, C.; Irene, E.A.; Baragiola, R.A. Hybrid Titanium–Aluminum Oxide Layer as Alternative High-K Gate Dielectric for the Next Generation of Complementary Metal–Oxide–Semiconductor Devices. Appl. Phys. Lett. 2005, 86, 042904. [Google Scholar] [CrossRef]

- Cheng, C.C.; Chien, C.H.; Luo, G.L.; Liu, J.-C.; Kei, C.-C.; Liu, D.-R.; Hsiao, C.-N.; Yang, C.-H.; Chang, C.-Y. Characteristics of Atomic-Layer-Deposited Al2O3 High-K Dielectric Films Grown on Ge Substrates. J. Electrochem. Society 2008, 155, G203. [Google Scholar] [CrossRef]

- Jin, P.; He, G.; Xiao, D.; Gao, J.; Liu, M.; Lv, J.; Liu, Y.; Zhang, M.; Wang, P.; Sun, Z. Microstructure, Optical, Electrical Properties, and Leakage Current Transport Mechanism of Sol–Gel-Processed High-K Hfo2 Gate Dielectrics. Ceram. Intern 2016, 42, 6761–6769. [Google Scholar] [CrossRef]

- Liu, J.; Liao, M.; Imura, M.; Tanaka, A.; Iwai, H.; Koide, Y. Low on-resistance diamond field-effect transistor with high-k ZrO2 as dielectric. Sci. Rep. 2014, 4, 6395. [Google Scholar] [CrossRef] [Green Version]

- Frunză, R.C.; Kmet, B.; Jankovec, M.M.; Topič, M.; Malič, B. Ta2O5-based high-k dielectric thin films from solution processed at low temperatures. Mater. Res. Bull. 2014, 50, 323–328. [Google Scholar] [CrossRef]

- Kadoshima, M.; Hiratani, M.; Shimamoto, Y.; Torii, K.; Miki, H.; Kimura, S.; Nabatame, T. Rutile-Type Tio2 Thin Film for High-K Gate Insulator. Thin Solid Films. 2003, 424, 224–228. [Google Scholar] [CrossRef]

- Konofaos, N.; Evangelou, E.K.; Wang, Z.; Kugler, V.; Helmersson, U. Electrical Characterization of SrTiO3/Si Interfaces. J. Non Cryst. Solids 2002, 303, 185–189. [Google Scholar] [CrossRef]

- Craciun, F.; Dimitriu, E.; Vasile, B.S.; Negrila, C.; Trusca, R.; Birjega, R.; Cernea, M. The Enhancement Mechanism of Dielectric Properties of Pb (Zr,Ti)O3 Via (Mg2+, Sb3+) Incorporation for Supercapacitors. Mater. Today Chem. 2020, 18, 100350. [Google Scholar] [CrossRef]

- Liu, J.; Liao, M.; Imura, M.; Oosato, H.; Watanabe, E.; Koide, Y. Electrical Properties of Atomic Layer Deposited Hfo2/Al2O3 Multilayer on Diamond. Diam. Relat. Mater. 2015, 54, 55–58. [Google Scholar] [CrossRef]

- Cho, M.H.; Roh, Y.S.; Whang, C.N.; Jeong, K.; Choi, H.J.; Nam, S.W.; Ko, D.-H.; Lee, J.H.; Lee, N.I.; Fujihara, K. Dielectric Characteristics of Al2O3–Hfo2 Nanolaminates on Si (100). Appl. Phys. Lett. 2002, 81, 1071–1073. [Google Scholar] [CrossRef]

- Martínez-Castelo, J.R.; López, J.; Domínguez, D.; Murillo, E.; Machorro, R.; Borbón-Nuñez, H.A.; Fernandez-Alvarez, I.; Arias, A.; Curiel, M.; Nedev, N.; et al. Structural and Electrical Characterization of Multilayer Al2O3/Zno Nanolaminates Grown by Atomic Layer Deposition. Mater. Sci. Semin. Proc. 2017, 71, 290–295. [Google Scholar] [CrossRef]

- Li, W.; Auciello, O.; Premnath, R.N.; Kabius, B. Giant Dielectric Constant Dominated by Maxwell–Wagner Relaxation in Al2O3/Tio2 Nanolaminates Synthesized by Atomic Layer Deposition. Appl. Phys. Lett. 2010, 96, 162907. [Google Scholar] [CrossRef]

- Li, W.; Chen, Z.; Premnath, R.N.; Kabius, B.; Auciello, O. Controllable Giant Dielectric Constant in Alox/Tioy Nanolaminates. J. Appl. Phys. 2011, 110, 024106. [Google Scholar] [CrossRef]

- Lee, G.; Lai, B.K.; Phatak, C.; Katiyar, R.S.; Auciello, O. Interface-Controlled High Dielectric Constant Al2O3/Tiox Nanolaminates with Low Loss and Low Leakage Current Density for New Generation Nanodevices. J. Appl. Phys. 2013, 114, 027001. [Google Scholar] [CrossRef]

- Liu, J.; Auciello, O.; Obaldia, E. Science and Technology of Integrated Super-High Dielectric Constant Alox/Tioy Nanolaminates/Diamond for MOS Capacitors and Mosfets. Carbon 2021, 172, 112–121. [Google Scholar] [CrossRef]

- Auciello, O.; Lee, G.; Wu, C.; Chen, Y.; Alcantar-Peña, J.J.; Mejia, I.; de Obaldía, E. Super High-Dielectric-Constant Oxide Films for Next-Generation Nanoelectronics and Supercapacitors for Energy Storage. MRS Bull. 2020, 45, 231–238. [Google Scholar] [CrossRef]

- Jones, M.N.; Kwon, Y.W.; Norton, D.P. Dielectric Constant and Current Transport for Hfo2 Thin Films on ITO. Appl. Phys. A 2005, 81, 285–288. [Google Scholar] [CrossRef]

- Birey, H. Thickness Dependence of The Dielectric Constant and Resistance of Al2O3 Films. J. Appl. Phys. 1977, 48, 5209–5212. [Google Scholar] [CrossRef]

- Warlimont, H.; Martienssen, W. Springer Handbook of Materials Data; Springer Nature: Cham, Switzerland, 2018. [Google Scholar]

- Takeuchi, M.; Itoh, T.; Nagasaka, H. Dielectric Properties of Sputtered Tio2 Films. Thin Solid Films 1978, 51, 83–88. [Google Scholar] [CrossRef]

- Ágoston, P.; Albe, K.; Nieminen, R.M. Intrinsic N-Type Behavior in Transparent Conducting Oxides: A Comparative Hybrid-Functional Study of In2O3, Sno2, and Zno. Phys. Rev. Lett. 2009, 103, 245501. [Google Scholar] [CrossRef] [Green Version]

- Anitha, V.C.; Banerjee, A.N.; Joo, S.W. Recent Developments in Tio2 As N-And P-Type Transparent Semiconductors: Synthesis, Modification, Properties, and Energy-Related Applications. J. Mater. Sci. 2015, 50, 7495–7536. [Google Scholar] [CrossRef]

- Ortega, N.; Kumar, A.; Katiyar, R.S.; Scott, J.F. Maxwell-Wagner Space Charge Effects on the Pb (Zr,Ti)O3–Cofe2o4 Multilayers. Appl. Phys. Lett. 2007, 91, 102902. [Google Scholar] [CrossRef]

- Iatusunskyi, I.; Coy, E.; Viter, R.; Nowaczyk, G.; Jancelewicz, M.; Baleviciute, I.; Załęski, K.; Jurga, S. Study on Structural, Mechanical, and Optical Properties of Al2O3− Tio2 Nanolaminates Prepared by Atomic Layer Deposition. J. Phys. Chem. C. 2015, 119, 20591–20599. [Google Scholar] [CrossRef]

- Coy, E.; Yate, L.; Kabacinska, Z.; Jancelewicz, M.; Jurga, S.; Iatsunskyi, I. Topographic Reconstruction and Mechanical Analysis of Atomic Layer Deposited Al2O3/Tio2 Nanolaminates by Nanoindentation. Mater. Design. 2016, 111, 584–591. [Google Scholar] [CrossRef]

- Iniewski, K.; Balasiński, A.; Majkusiak, B.; Beck, R.; Jakubowski, A. Series Resistance in a MOS Capacitor with a Thin Gate Oxide. Solid State Electron. 1989, 32, 137–140. [Google Scholar] [CrossRef]

- Liao, M.; Liu, J.; Sang, L.; Coathup, D.; Li, J.; Imura, M.; Koide, Y.; Ye, H. Impedance Analysis of Al2O3/H-Terminated Diamond Metal-Oxide-Semiconductor Structures. Appl. Phys. Lett. 2015, 106, 083506. [Google Scholar] [CrossRef] [Green Version]

- Misra, V.; Öztürk, M.C. Field effect transistors. In The Electrical Engineering Handbook; Elsevier Academic Press: Cambridge, MA, USA, 2005; pp. 109–126. [Google Scholar]

| ATO NL Deposition Temperature (°C) | ATO Sublayer Thickness (nm) | ATO NL Thickness (nm) | Number of ATO Interfaces | Leakage Current (A)@1 V | Resistance (Ω) | Cmax (μF/cm2) | k | EOT (nm) | tanδ @1 kHz |

|---|---|---|---|---|---|---|---|---|---|

| 150 | 0.51/0.50 | 51.1 | 50 | 2.48 × 10−6 | 4.02 × 105 | 0.96 | 55.4 | 3.6 | 0.29 |

| 200 | 0.51/0.52 | 51.9 | 50 | 2.02 × 10−4 | 4.96 × 103 | 2.49 | 146.0 | 1.4 | 4.64 |

| 250 | 0.47/0.46 | 46.9 | 50 | 4.92 × 10−3 | 2.03 × 102 | 3.30 | 174.9 | 1.0 | 871 |

| 200 | 0.51/0.52 | 103.8 | 100 | 1.80 × 10−4 | 5.54 × 103 | 2.35 | 275.6 | 1.5 | 0.65 |

| 200 | 0.51/0.52 | 201.3 | 194 | 1.70 × 10−5 | 5.88 × 104 | 1.95 | 443.5 | 1.8 | 0.23 |

| 200 | 2.04/2.04 | 103.0 | 25 | 5.06 × 10−8 | 1.98 × 107 | 0.24 | 27.9 | 14.4 | 0.38 |

| 200 | 0.34/0.73 | 101.8 | 100 | 3.98 × 10−3 | 2.51 × 102 | 3.64 | 418.7 | 0.9 | 81.0 |

| 200 | 0.60/0.39 | 99.8 | 100 | 6.72 × 10−6 | 1.49 × 105 | 1.12 | 126.3 | 3.1 | 0.36 |

| 200 | 0.68/0.33 | 101.0 | 100 | 4.52 × 10−7 | 2.21 × 106 | 0.35 | 39.9 | 9.9 | 1.08 |

| 200 | 0.77/0.19 | 100.1 | 100 | 3.42 × 10−10 | 2.93 × 109 | 0.09 | 10.2 | 38.3 | 0.05 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, J.; Okamura, M.; Mashiko, H.; Imura, M.; Liao, M.; Kikuchi, R.; Suzuka, M.; Koide, Y. Experimental Formation and Mechanism Study for Super-High Dielectric Constant AlOx/TiOy Nanolaminates. Nanomaterials 2023, 13, 1256. https://doi.org/10.3390/nano13071256

Liu J, Okamura M, Mashiko H, Imura M, Liao M, Kikuchi R, Suzuka M, Koide Y. Experimental Formation and Mechanism Study for Super-High Dielectric Constant AlOx/TiOy Nanolaminates. Nanomaterials. 2023; 13(7):1256. https://doi.org/10.3390/nano13071256

Chicago/Turabian StyleLiu, Jiangwei, Masayuki Okamura, Hisanori Mashiko, Masataka Imura, Meiyong Liao, Ryosuke Kikuchi, Michio Suzuka, and Yasuo Koide. 2023. "Experimental Formation and Mechanism Study for Super-High Dielectric Constant AlOx/TiOy Nanolaminates" Nanomaterials 13, no. 7: 1256. https://doi.org/10.3390/nano13071256