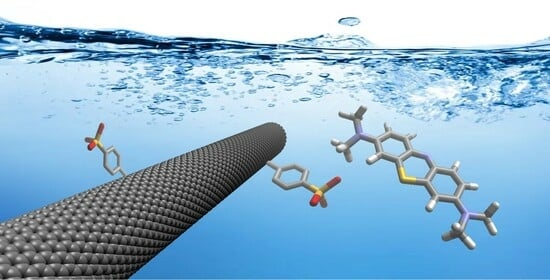

Enhanced Adsorption of Methylene Blue Dye on Functionalized Multi-Walled Carbon Nanotubes

Abstract

:1. Introduction

2. Materials and Methods

2.1. Sample Treatments

2.1.1. Bath Sonication

2.1.2. Tip Sonication

2.1.3. Preparation of Solutions for the Adsorption Experiments

2.1.4. Shaking during Adsorption

2.1.5. Centrifugation

2.2. Synthesis of MWCNT-PhSO3− (MWCNT-S)

2.3. Characterization of MWCNT-S

2.3.1. Thermogravimetric Analysis (TGA)

2.3.2. Dynamic Light Scattering (DLS)

2.3.3. UV–Vis Measurements

2.3.4. X-ray Photoelectron Spectroscopy

2.3.5. Transmission Electron Microscopy (TEM)

2.4. Preparation of the MB Solutions

2.5. Batch Kinetic Experiments

2.6. Batch Equilibrium Experiments

2.7. Effect of the Adsorbent Dosage

2.8. Effect of Temperature

2.9. Effect of pH

2.10. Effect of Ionic Strength

2.11. Regeneration Tests

3. Results and Discussion

3.1. MWCNT-S Synthesis and Characterization

3.2. Kinetic Studies

3.3. Adsorption Isotherms

3.4. Effect of the Adsorbent Dose

3.5. Effect of Temperature

3.6. Possibility of MWCNT-S Regeneration

3.6.1. Effect of pH

3.6.2. Effect of Ionic Strength

3.6.3. Regeneration Tests

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Garg, V.K.; Amita, M.; Kumar, R.; Gupta, R. Basic dye (methylene blue) removal from simulated wastewater by adsorption using Indian Rosewood sawdust: A timber industry waste. Dye. Pigment. 2004, 63, 243–250. [Google Scholar] [CrossRef]

- Parakala, S.; Moulik, S.; Sridhar, S. Effective separation of methylene blue dye from aqueous solutions by integration of micellar enhanced ultrafiltration with vacuum membrane distillation. Chem. Eng. J. 2019, 375, 122015. [Google Scholar] [CrossRef]

- Hou, C.; Hu, B.; Zhu, J. Photocatalytic Degradation of Methylene Blue over TiO2 Pretreated with Varying Concentrations of NaOH. Catalysts 2018, 8, 575. [Google Scholar] [CrossRef]

- Koyuncu, H.; Kul, A.R. Removal of methylene blue dye from aqueous solution by nonliving lichen (Pseudevernia furfuracea (L.) Zopf.), as a novel biosorbent. Appl. Water Sci. 2020, 10, 72. [Google Scholar] [CrossRef]

- Li, Y.; Du, Q.; Liu, T.; Peng, X.; Wang, J.; Sun, J.; Wang, Y.; Wu, S.; Wang, Z.; Xia, Y.; et al. Comparative study of methylene blue dye adsorption onto activated carbon, graphene oxide, and carbon nanotubes. Chem. Eng. Res. Des. 2013, 91, 361–368. [Google Scholar] [CrossRef]

- Khan, I.; Saeed, K.; Zekker, I.; Zhang, B.; Hendi, A.H.; Ahmad, A.; Ahmad, S.; Zada, N.; Ahmad, H.; Shah, L.A.; et al. Review on Methylene Blue: Its Properties, Uses, Toxicity and Photodegradation. Water 2022, 14, 242. [Google Scholar] [CrossRef]

- Katheresan, V.; Kansedo, J.; Lau, S.Y. Efficiency of various recent wastewater dye removal methods: A review. J. Environ. Chem. Eng. 2018, 6, 4676–4697. [Google Scholar] [CrossRef]

- Solayman, H.M.; Hossen, M.A.; Abd Aziz, A.; Yahya, N.Y.; Leong, K.H.; Sim, L.C.; Monir, M.U.; Zoh, K.-D. Performance evaluation of dye wastewater treatment technologies: A review. J. Environ. Chem. Eng. 2023, 11, 109610. [Google Scholar] [CrossRef]

- Donkadokula, N.Y.; Kola, A.K.; Naz, I.; Saroj, D. A review on advanced physico-chemical and biological textile dye wastewater treatment techniques. Rev. Environ. Sci. Bio/Technol. 2020, 19, 543–560. [Google Scholar] [CrossRef]

- Kallawar, G.A.; Bhanvase, B.A. A review on existing and emerging approaches for textile wastewater treatments: Challenges and future perspectives. Environ. Sci. Pollut. Res. 2024, 31, 1748–1789. [Google Scholar] [CrossRef]

- Abid, M.F.; Zablouk, M.A.; Abid-Alameer, A.M. Experimental study of dye removal from industrial wastewater by membrane technologies of reverse osmosis and nanofiltration. Iran. J. Environ. Health Sci. Eng. 2012, 9, 17. [Google Scholar] [CrossRef] [PubMed]

- Hassani, A.H.; Mirzayee, R.; Nasseri, S.; Borghei, M.; Gholami, M.; Torabifar, B. Nanofiltration process on dye removal from simulated textile wastewater. Int. J. Environ. Sci. Technol. 2008, 5, 401–408. [Google Scholar] [CrossRef]

- Liang, C.-Z.; Sun, S.-P.; Li, F.-Y.; Ong, Y.-K.; Chung, T.-S. Treatment of highly concentrated wastewater containing multiple synthetic dyes by a combined process of coagulation/flocculation and nanofiltration. J. Membr. Sci. 2014, 469, 306–315. [Google Scholar] [CrossRef]

- Wang, H.; Yang, J.; Zhang, H.; Zhao, J.; Liu, H.; Wang, J.; Li, G.; Liang, H. Membrane-based technology in water and resources recovery from the perspective of water social circulation: A review. Sci. Total Environ. 2024, 908, 168277. [Google Scholar] [CrossRef] [PubMed]

- Asif, M.B.; Kim, S.; Nguyen, T.S.; Mahmood, J.; Yavuz, C.T. Covalent Organic Framework Membranes and Water Treatment. J. Am. Chem. Soc. 2024, 146, 3567–3584. [Google Scholar] [CrossRef]

- dos Santos, A.B.; Cervantes, F.J.; van Lier, J.B. Review paper on current technologies for decolourisation of textile wastewaters: Perspectives for anaerobic biotechnology. Bioresour. Technol. 2007, 98, 2369–2385. [Google Scholar] [CrossRef]

- Shama, S.; Iffat, N. Role of the Biofilms in Wastewater Treatment. In Microbial Biofilms; Dharumadurai, D., Nooruddin, T., Eds.; IntechOpen: Rijeka, Croatia, 2016; Chapter 7. [Google Scholar]

- Kumar, M.S.; Sonawane, S.H.; Bhanvase, B.A.; Bethi, B. Treatment of ternary dye wastewater by hydrodynamic cavitation combined with other advanced oxidation processes (AOP’s). J. Water Process Eng. 2018, 23, 250–256. [Google Scholar] [CrossRef]

- Vinayagam, V.; Palani, K.N.; Ganesh, S.; Rajesh, S.; Akula, V.V.; Avoodaiappan, R.; Kushwaha, O.S.; Pugazhendhi, A. Recent developments on advanced oxidation processes for degradation of pollutants from wastewater with focus on antibiotics and organic dyes. Environ. Res. 2024, 240, 117500. [Google Scholar] [CrossRef]

- Samarasinghe, L.V.; Muthukumaran, S.; Baskaran, K. Recent advances in visible light-activated photocatalysts for degradation of dyes: A comprehensive review. Chemosphere 2024, 349, 140818. [Google Scholar] [CrossRef]

- Gul, A.; Ma’amor, A.; Khaligh, N.G.; Muhd Julkapli, N. Recent advancements in the applications of activated carbon for the heavy metals and dyes removal. Chem. Eng. Res. Des. 2022, 186, 276–299. [Google Scholar] [CrossRef]

- Hung, Y.-T.; Lo, H.H.; Wang, L.K.; Taricska, J.R.; Li, K.H. Granular Activated Carbon Adsorption. In Physicochemical Treatment Processes; Wang, L.K., Hung, Y.-T., Shammas, N.K., Eds.; Humana Press: Totowa, NJ, USA, 2005; pp. 573–633. [Google Scholar]

- Sahoo, T.R.; Prelot, B. Adsorption processes for the removal of contaminants from wastewater: The perspective role of nanomaterials and nanotechnology. In Nanomaterials for the Detection and Removal of Wastewater Pollutants; Elsevier: Amsterdam, The Netherlands, 2020; pp. 161–222. [Google Scholar]

- Zare, K.; Gupta, V.K.; Moradi, O.; Makhlouf, A.S.H.; Sillanpää, M.; Nadagouda, M.N.; Sadegh, H.; Shahryari-ghoshekandi, R.; Pal, A.; Wang, Z.-j.; et al. A comparative study on the basis of adsorption capacity between CNTs and activated carbon as adsorbents for removal of noxious synthetic dyes: A review. J. Nanostruct. Chem. 2015, 5, 227–236. [Google Scholar] [CrossRef]

- Iijima, S. Helical microtubules of graphitic carbon. Nature 1991, 354, 56–58. [Google Scholar] [CrossRef]

- Upadhyayula, V.K.K.; Deng, S.; Mitchell, M.C.; Smith, G.B. Application of carbon nanotube technology for removal of contaminants in drinking water: A review. Sci. Total Environ. 2009, 408, 1–13. [Google Scholar] [CrossRef]

- Homaeigohar, S. The Nanosized Dye Adsorbents for Water Treatment. Nanomaterials 2020, 10, 295. [Google Scholar] [CrossRef]

- Rostami, M.S.; Khodaei, M.M.; Rostami, S. Polymer-based nanocomposites reinforced with functionalized-MWCNT and their utilizing as sorbent for removal of MB and Cd2+ ion from water media: A review. J. Organomet. Chem. 2022, 957, 122170. [Google Scholar] [CrossRef]

- Osorio-Aguilar, D.-M.; Saldarriaga-Noreña, H.-A.; Murillo-Tovar, M.-A.; Vergara-Sánchez, J.; Ramírez-Aparicio, J.; Magallón-Cacho, L.; García-Betancourt, M.-L. Adsorption and Photocatalytic Degradation of Methylene Blue in Carbon Nanotubes: A Review with Bibliometric Analysis. Catalysts 2023, 13, 1480. [Google Scholar] [CrossRef]

- Isaeva, V.I.; Vedenyapina, M.D.; Kurmysheva, A.Y.; Weichgrebe, D.; Nair, R.R.; Nguyen, N.P.; Kustov, L.M. Modern Carbon–Based Materials for Adsorptive Removal of Organic and Inorganic Pollutants from Water and Wastewater. Molecules 2021, 26, 6628. [Google Scholar] [CrossRef]

- Sarkar, B.; Mandal, S.; Tsang, Y.F.; Kumar, P.; Kim, K.-H.; Ok, Y.S. Designer carbon nanotubes for contaminant removal in water and wastewater: A critical review. Sci. Total Environ. 2018, 612, 561–581. [Google Scholar] [CrossRef] [PubMed]

- Jun, L.Y.; Mubarak, N.M.; Yee, M.J.; Yon, L.S.; Bing, C.H.; Khalid, M.; Abdullah, E.C. An overview of functionalised carbon nanomaterial for organic pollutant removal. J. Ind. Eng. Chem. 2018, 67, 175–186. [Google Scholar] [CrossRef]

- Yao, Y.; Xu, F.; Chen, M.; Xu, Z.; Zhu, Z. Adsorption behavior of methylene blue on carbon nanotubes. Bioresour. Technol. 2010, 101, 3040–3046. [Google Scholar] [CrossRef] [PubMed]

- Yao, Y.; Xu, F.; Chen, M.; Xu, Z.; Zhu, Z. Adsorption of cationic methyl violet and methylene blue dyes onto carbon nanotubes. In Proceedings of the 2010 IEEE 5th International Conference on Nano/Micro Engineered and Molecular Systems, Xiamen, China, 20–23 January 2010; pp. 1083–1087. [Google Scholar]

- Rodríguez, A.; Ovejero, G.; Sotelo, J.L.; Mestanza, M.; García, J. Adsorption of dyes on carbon nanomaterials from aqueous solutions. J. Environ. Sci. Health Part A 2010, 45, 1642–1653. [Google Scholar] [CrossRef]

- Ghaffar, A.; Younis, M.N. Interaction and thermodynamics of methylene blue adsorption on oxidized multi-walled carbon nanotubes. Green Process. Synth. 2015, 4, 209–217. [Google Scholar] [CrossRef]

- Ortega, P.F.R.; Trigueiro, J.P.C.; Santos, M.R.; Denadai, Â.M.L.; Oliveira, L.C.A.; Teixeira, A.P.C.; Silva, G.G.; Lavall, R.L. Thermodynamic Study of Methylene Blue Adsorption on Carbon Nanotubes Using Isothermal Titration Calorimetry: A Simple and Rigorous Approach. J. Chem. Eng. Data 2017, 62, 729–737. [Google Scholar] [CrossRef]

- Bahr, J.L.; Yang, J.; Kosynkin, D.V.; Bronikowski, M.J.; Smalley, R.E.; Tour, J.M. Functionalization of Carbon Nanotubes by Electrochemical Reduction of Aryl Diazonium Salts: A Bucky Paper Electrode. J. Am. Chem. Soc. 2001, 123, 6536–6542. [Google Scholar] [CrossRef] [PubMed]

- Shuit, S.H.; Ng, E.P.; Tan, S.H. A facile and acid-free approach towards the preparation of sulphonated multi-walled carbon nanotubes as a strong protonic acid catalyst for biodiesel production. J. Taiwan Inst. Chem. Eng. 2015, 52, 100–108. [Google Scholar] [CrossRef]

- Wei, Y.; Ling, X.; Zou, L.; Lai, D.; Lu, H.; Xu, Y. A facile approach toward preparation of sulfonated multi-walled carbon nanotubes and their dispersibility in various solvents. Colloids Surf. A Physicochem. Eng. Asp. 2015, 482, 507–513. [Google Scholar] [CrossRef]

- Hameed, B.H.; Din, A.T.M.; Ahmad, A.L. Adsorption of methylene blue onto bamboo-based activated carbon: Kinetics and equilibrium studies. J. Hazard. Mater. 2007, 141, 819–825. [Google Scholar] [CrossRef] [PubMed]

- Aslam, M.M.-A.; Kuo, H.-W.; Den, W.; Usman, M.; Sultan, M.; Ashraf, H.J.S. Functionalized carbon nanotubes (CNTs) for water and wastewater treatment: Preparation to application. Sustainability 2021, 13, 5717. [Google Scholar] [CrossRef]

- Salice, P.; Fabris, E.; Sartorio, C.; Fenaroli, D.; Figa, V.; Casaletto, M.P.; Cataldo, S.; Pignataro, B.; Menna, E.J.C. An insight into the functionalisation of carbon nanotubes by diazonium chemistry: Towards a controlled decoration. Carbon 2014, 74, 73–82. [Google Scholar] [CrossRef]

- Vicentini, N.; Gatti, T.; Salice, P.; Scapin, G.; Marega, C.; Filippini, F.; Menna, E.J.C. Covalent functionalization enables good dispersion and anisotropic orientation of multi-walled carbon nanotubes in a poly (l-lactic acid) electrospun nanofibrous matrix boosting neuronal differentiation. Carbon 2015, 95, 725–730. [Google Scholar] [CrossRef]

- Suarato, G.; Pressi, S.; Menna, E.; Ruben, M.; Petrini, E.M.; Barberis, A.; Miele, D.; Sandri, G.; Salerno, M.; Schirato, A.; et al. Modified Carbon Nanotubes Favor Fibroblast Growth by Tuning the Cell Membrane Potential. ACS Appl. Mater. Interfaces 2024, 16, 3093–3105. [Google Scholar] [CrossRef] [PubMed]

- Osswald, S.; Havel, M.; Gogotsi, Y. Monitoring oxidation of multiwalled carbon nanotubes by Raman spectroscopy. J. Raman Spectrosc. 2007, 38, 728–736. [Google Scholar] [CrossRef]

- Abuilaiwi, F.A.; Laoui, T.; Al-Harthi, M.; Atieh, M.A. Engineering. Modification and functionalization of multiwalled carbon nanotube (MWCNT) via fischer esterification. Arab. J. Sci. Eng. 2010, 35, 37–48. [Google Scholar]

- Kouklin, N.; Tzolov, M.; Straus, D.; Yin, A.; Xu, J.M. Infrared absorption properties of carbon nanotubes synthesized by chemical vapor deposition. Appl. Phys. Lett. 2004, 85, 4463–4465. [Google Scholar] [CrossRef]

- Biesinger, M.C. Accessing the robustness of adventitious carbon for charge referencing (correction) purposes in XPS analysis: Insights from a multi-user facility data review. Appl. Surf. Sci. 2022, 597, 153681. [Google Scholar] [CrossRef]

- Okpalugo, T.I.T.; Papakonstantinou, P.; Murphy, H.; McLaughlin, J.; Brown, N.M.D. High resolution XPS characterization of chemical functionalised MWCNTs and SWCNTs. Carbon 2005, 43, 153–161. [Google Scholar] [CrossRef]

- Sun, J.; Hwang, J.Y.; Jankowski, P.; Xiao, L.; Sanchez, J.S.; Xia, Z.; Lee, S.; Talyzin, A.V.; Matic, A.; Palermo, V.J.S. Critical role of functional groups containing N, S, and O on graphene surface for stable and fast charging Li-S batteries. Small 2021, 17, 2007242. [Google Scholar] [CrossRef]

- Vicentini, N.; Gatti, T.; Salerno, M.; Gomez, Y.S.H.; Bellon, M.; Gallio, S.; Marega, C.; Filippini, F.; Menna, E. Effect of different functionalized carbon nanostructures as fillers on the physical properties of biocompatible poly (l-lactic acid) composites. Mater. Chem. Phys. 2018, 214, 265–276. [Google Scholar] [CrossRef]

- Bhattacharjee, S. DLS and zeta potential–what they are and what they are not? J. Control. Release 2016, 235, 337–351. [Google Scholar] [CrossRef]

- Kolesnikova, A.; Eremin, Y.S.; Grekhov, A.M. Time-stability dispersion of carbon nanotubes in chloroform. Phys. Procedia 2015, 72, 51–55. [Google Scholar] [CrossRef]

- Liu, H.; Wang, J.; Wang, J.; Cui, S. Sulfonitric treatment of multiwalled carbon nanotubes and their dispersibility in water. Mater. Chem. Phys. 2018, 11, 2442. [Google Scholar] [CrossRef] [PubMed]

- Wu, F.-C.; Tseng, R.-L.; Huang, S.-C.; Juang, R.-S. Characteristics of pseudo-second-order kinetic model for liquid-phase adsorption: A mini-review. Chem. Eng. J. 2009, 151, 1–9. [Google Scholar] [CrossRef]

- Lazaridis, N.; Asouhidou, D.D. Kinetics of sorptive removal of chromium (VI) from aqueous solutions by calcined Mg–Al–CO3 hydrotalcite. Water Res. 2003, 37, 2875–2882. [Google Scholar] [CrossRef] [PubMed]

- Qu, Y.; Zhang, C.; Li, F.; Bo, X.; Liu, G.; Zhou, Q. Equilibrium and kinetics study on the adsorption of perfluorooctanoic acid from aqueous solution onto powdered activated carbon. J. Hazard. Mater. 2009, 169, 146–152. [Google Scholar] [CrossRef]

- Jeirani, Z.; Niu, C.H.; Soltan, J. Adsorption of emerging pollutants on activated carbon. Rev. Chem. Eng. 2017, 33, 491–522. [Google Scholar] [CrossRef]

- Lagergren, S. About the theory of so-called adsorption of soluble substances. J. Water Resour. Prot. 1898, 24, 1–39. [Google Scholar]

- Ho, Y.-S.; McKay, G. Pseudo-second order model for sorption processes. Process Biochem. 1999, 34, 451–465. [Google Scholar] [CrossRef]

- Al-Ghouti, M.A.; Da’ana, D.A. Guidelines for the use and interpretation of adsorption isotherm models: A review. J. Hazard. Mater. 2020, 393, 122383. [Google Scholar] [CrossRef]

- Foo, K.Y.; Hameed, B.H. Insights into the modeling of adsorption isotherm systems. Chem. Eng. J. 2010, 156, 2–10. [Google Scholar] [CrossRef]

- Arias Arias, F.; Guevara, M.; Tene, T.; Angamarca, P.; Molina, R.; Valarezo, A.; Salguero, O.; Vacacela Gomez, C.; Arias, M.; Caputi, L.S. The adsorption of methylene blue on eco-friendly reduced graphene oxide. Nanomaterials 2020, 10, 681. [Google Scholar] [CrossRef] [PubMed]

- Chen, L.; Yang, J.; Zeng, X.; Zhang, L.; Yuan, W. Adsorption of methylene blue in water by reduced graphene oxide: Effect of functional groups. Mater. Express 2013, 3, 281–290. [Google Scholar] [CrossRef]

- Mahiuddin, M.; Ochiai, B.J.T. Lemon juice assisted green synthesis of reduced graphene oxide and its application for adsorption of methylene blue. Technologies 2021, 9, 96. [Google Scholar] [CrossRef]

- El Qada, E.N.; Allen, S.J.; Walker, G.M. Adsorption of methylene blue onto activated carbon produced from steam activated bituminous coal: A study of equilibrium adsorption isotherm. Chem. Eng. J. 2006, 124, 103–110. [Google Scholar] [CrossRef]

- Shahryari, Z.; Goharrizi, A.S.; Azadi, M. Experimental study of methylene blue adsorption from aqueous solutions onto carbon nano tubes. Int. J. Water Resour. Environ. Eng. 2010, 2, 016–028. [Google Scholar] [CrossRef]

- Selen, V.; Güler, Ö.; Özer, D.; Evin, E. Synthesized multi-walled carbon nanotubes as a potential adsorbent for the removal of methylene blue dye: Kinetics, isotherms, and thermodynamics. Desalination Water Treat. 2016, 57, 8826–8838. [Google Scholar] [CrossRef]

- Crumrine, D.S.; Shankweiler, J.M.; Hoffman, R.V. The use of sulfur-33 chemical shifts to determine pKa’s of arenesulfonic acids. J. Org. Chem. 1986, 51, 5013–5015. [Google Scholar] [CrossRef]

| N° | Assignment | Wavenumber | |

|---|---|---|---|

| MWCNT | MWCNT-S | ||

| 1 | OH stretching | 3442 | 3442 |

| 2 | CHx groups stretching | 2853; 2922 | 2853; 2922 |

| 3 | C=C stretching of CNTs backbone | 1633 | 1633 |

| 4 | COO− stretching | 1563 | 1563 |

| 5 | SO3− group stretching | - | 1086; 1186 |

| Sample | C sp2 | C sp3/C-S | C-OH | Carbonyl Groups | Carboxylic Groups | Atomic C/O/S Ratio |

|---|---|---|---|---|---|---|

| MWCNT | 284.1 eV 84.2% | 285.1 eV 3.7% | 286.2 eV 6.6% | 287.6 eV 3.5% | 288.6 eV 2.0% | 95.6:4.4:0 |

| MWCNT-S | 284.1 eV 86.8% | 285.1 eV 4.0% | 286.2 eV 5.7% | 287.6 eV 2.6% | 288.6 eV 0.9% | 81.8:15.6:2.6 |

| Kinetic Parameters | Values | |

|---|---|---|

| MWCNT | MWCNT-S | |

| Pseudo-first-order kinetic model | ||

| R2 | 0.4034 | 0.7936 |

| k1 (L/min) | - | - |

| Pseudo-second-order kinetic model | ||

| R2 | 0.9953 | 0.9999 |

| k2 (g/min·mg) | 9.11 × 10−3 | 2.18 × 10−2 |

| qe (mg/g) | 67.3 | 150.8 |

| Adsorption Isotherm Parameters | Values | |

|---|---|---|

| MWCNT | MWCNT-S | |

| Langmuir Isotherm | ||

| R2 | 0.99649 | 0.99516 |

| KL (L/min) | 2.28 | 8.08 × 10−1 |

| qm | 55.18 | 150.15 |

| Freundlich Isotherm | ||

| R2 | 0.60046 | 0.71371 |

| KF (g/min·mg) | - | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ceroni, L.; Benazzato, S.; Pressi, S.; Calvillo, L.; Marotta, E.; Menna, E. Enhanced Adsorption of Methylene Blue Dye on Functionalized Multi-Walled Carbon Nanotubes. Nanomaterials 2024, 14, 522. https://doi.org/10.3390/nano14060522

Ceroni L, Benazzato S, Pressi S, Calvillo L, Marotta E, Menna E. Enhanced Adsorption of Methylene Blue Dye on Functionalized Multi-Walled Carbon Nanotubes. Nanomaterials. 2024; 14(6):522. https://doi.org/10.3390/nano14060522

Chicago/Turabian StyleCeroni, Ludovica, Stefania Benazzato, Samuel Pressi, Laura Calvillo, Ester Marotta, and Enzo Menna. 2024. "Enhanced Adsorption of Methylene Blue Dye on Functionalized Multi-Walled Carbon Nanotubes" Nanomaterials 14, no. 6: 522. https://doi.org/10.3390/nano14060522