Nanoemulsified D-Limonene Reduces the Heat Resistance of Salmonella Senftenberg over 50 Times

Abstract

:1. Introduction

2. Results

3. Discussion

4. Materials and Methods

4.1. Bacterial Strain

4.2. Preparation of Nanoemulsions

4.3. Heat Treatments

4.4. Mathematical Modelling and Data Analysis

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Majowicz, S.E.; Musto, J.; Scallan, E.; Angulo, F.J.; Kirk, M.; O’Brien, S.; Jones, T.F.; Fazil, A.; Hoekstra, R.M. The global burden of nontyphoidal Salmonella gastroenteritis. Clin. Infect. Dis. 2010, 50, 882–889. [Google Scholar] [CrossRef] [PubMed]

- L’Ecuyer, P.B.; Diego, J.; Murphy, D.; Trovillion, E.; Jones, M.; Sahm, D.F.; Fraser, V.J. Nosocomial outbreak of gastroenteritis due to Salmonella. Clin. Infect. Dis. 1996, 23, 734–742. [Google Scholar] [CrossRef] [PubMed]

- Kumar, A.; Kumar, S. Survival kinetics of Salmonella enterica serotype senftenberg (S. senftenberg) after heat and acid stress. World J. Microbiol. Biotechnol. 2003, 19, 985–987. [Google Scholar] [CrossRef]

- Martínez-Urtaza, J.; Peiteado, J.; Lozano-León, A.; García-Martín, O. Detection of Salmonella Senftenberg associated with high saline environments in mussel processing facilities. J. Food Prot. 2004, 67, 256–263. [Google Scholar] [CrossRef] [PubMed]

- Mañas, P.; Pagán, R.; Álvarez, I.; Condón, S. Survival of Salmonella Senftenberg 775 W to current whole egg pasteurization treatments. Food Microbiol. 2003, 20, 593–600. [Google Scholar] [CrossRef]

- Muñoz-Cuevas, M.; Metris, A.; Baranyi, J. Predictive modelling of Salmonella: From cell-cycle measurements to e-models. Food Res. Int. 2012, 45, 852–862. [Google Scholar] [CrossRef]

- Davidson, C.M.; Boothroyd, M.; Georgala, D.L. Thermal resistance of Salmonella senftenberg. Nature 1966, 212, 1060–1061. [Google Scholar] [CrossRef] [PubMed]

- Beuchat, L.R. Thermal inactivation of yeasts in fruit juices supplemented with food preservatives and sucrose. J. Food Sci. 1982, 47, 1679–1682. [Google Scholar] [CrossRef]

- Vermeulen, A.; Dang, T.D.T.; Geeraerd, A.H.; Bernaerts, K.; Debevere, J.; Van Impe, J.; Devlieghere, F. Modelling the unexpected effect of acetic and lactic acid in combination with pH and aw on the growth/no growth interface of Zygosaccharomyces bailii. Int. J. Food Microbiol. 2008, 124, 79–90. [Google Scholar] [CrossRef] [PubMed]

- Burt, S. Essential oils: Their antibacterial properties and potential applications in foods-a review. Int. J. Food Microbiol. 2004, 94, 223–253. [Google Scholar] [CrossRef] [PubMed]

- Ait-Ouazzou, A.; Loran, S.; Bakkali, M.; Laglaoui, A.; Rota, C.; Herrera, A.; Pagán, R.; Conchello, P. Chemical composition and antimicrobial activity of essential oils of Thymus algeriensis, Eucalyptus globulus and Rosmarinus officinalis from Morocco. J. Sci. Food Agric. 2011, 91, 2643–2651. [Google Scholar] [CrossRef] [PubMed]

- Cosentino, S.; Tuberoso, C.I.G.; Pisano, B.; Satta, M.; Mascia, V.; Arzedi, E.; Palmas, F. In Vitro In Vitro antimicrobial activity and chemical composition of Sardinian thymus essential oils. Lett. Appl. Microbiol. 1999, 29, 130–135. [Google Scholar] [CrossRef] [PubMed]

- Oussalah, M.; Cailllet, S.; Lacroix, M. Mechanism of action of Spanish oregano, Chinese cinnamon, and savory essential oils against cell membranes and walls of Escherichia coli O157:H7 and Listeria monocytogenes. J. Food Prot. 2006, 69, 1046–1055. [Google Scholar] [CrossRef] [PubMed]

- Severino, R.; Vu, K.D.; Donsì, F.; Salmieri, S.; Ferrari, G.; Lacroix, M. Antimicrobial effects of different combined non-thermal treatments against Listeria monocytogenes in broccoli florets. J. Food Eng. 2014, 124, 1–10. [Google Scholar] [CrossRef]

- Weiss, J.; Gaysinsky, S.; Davidson, M.; McClements, J. Nanostructured encapsulation systems: Food antimicrobials. In Global Issues in Food Science and Technology; Barbosa-Cánovas, G., Mortimer, A., Lineback, D., Spiess, W., Buckle, K., Colonna, P., Eds.; Academic Press: New York, NY, USA, 2009; pp. 425–479. [Google Scholar]

- Sikkema, J.; Debont, J.A.M.; Poolman, B. Interactions of cyclic hydrocarbons with biological membranes. J. Biol. Chem. 1994, 269, 8022–8028. [Google Scholar] [PubMed]

- Sun, J. D-Limonene: Safety and clinical applications. Altern. Med. Rev. 2007, 12, 259–264. [Google Scholar] [PubMed]

- Cava-Roda, R.M.; Taboada, A.; Palop, A.; López-Gómez, A.; Marín-Iniesta, F. Heat resistance of Listeria monocytogenes in semi-skim milk supplemented with vanillin. Int. J. Food Microbiol. 2012, 157, 314–318. [Google Scholar] [CrossRef] [PubMed]

- Juneja, V.K.; Altuntas, E.G.; Ayhan, K.; Hwang, C.; Sheen, S.; Friedman, M. Predictive model for the reduction of heat resistance of Listeria monocytogenes in ground beef by the combined effect of sodium chloride and apple polyphenols. Int. J. Food Microbiol. 2013, 164, 54–59. [Google Scholar] [CrossRef] [PubMed]

- Cherrat, L.; Espina, L.; Bakkali, M.; García-Gonzalo, D.; Pagán, R.; Laglaoui, A. Chemical composition and antioxidant properties of Lauris nobilis L. and Myrtus communis L. essential oils from Morocco and evaluation of their antimicrobial activity acting alone or in combined processes for food preservation. J. Sci. Food Agric. 2014, 94, 1197–1204. [Google Scholar] [CrossRef] [PubMed]

- Espina, L.; Condón, S.; Pagán, R.; García-Gonzalo, D. Synergistic effect of orange essential oil or (+)-limonene with heat treatments to inactivate Escherichia coli O157:H7 in orange juice at lower intensities while maintaining hedonic acceptability. Food Bioprocess Technol. 2014, 7, 471–481. [Google Scholar] [CrossRef]

- Donsì, F.; Annunziata, M.; Sessa, M.; Ferrari, G. Nanoencapsulation of essential oils to enhance their antimicrobial activity in foods. LWT Food Sci. Technol. 2011, 44, 1908–1914. [Google Scholar] [CrossRef]

- Li, P.H.; Chiang, B.H. Process optimization and stability of D-limonene-in-water nanoemulsions prepared by ultrasonic emulsification using response surface methodology. Ultrason. Sonochem. 2012, 19, 192–197. [Google Scholar] [CrossRef] [PubMed]

- Landry, K.; Chang, Y.; McClements, D.; McLandsborough, L. Effectiveness of a novel spontaneous carvacrol nanoemulsion against Salmonella enterica Enteritidis and Escherichia coli O157:H7 on contaminated mung bean and alfalfa seeds. Int. J. Food Microbiol. 2014, 187, 15–21. [Google Scholar] [CrossRef] [PubMed]

- Donsì, F.; Cuomo, A.; Marchese, E.; Ferrari, G. Infusion of essential oils for food stabilization: Unraveling the role of nanoemulsion-based delivery systems on mass transfer and antimicrobial activity. Innov. Food Sci. Emerg. Technol. 2014, 22, 212–220. [Google Scholar] [CrossRef]

- Sundrarajan, M.; Rukmani, A. Durable antibacterial finishing on cotton by impregnation of limonene microcapsules. Adv. Chem. Lett. 2013, 1, 40–43. [Google Scholar] [CrossRef]

- Ghosh, V.; Mukherjee, A.; Chandrasekaran, N. Eugenol-loaded antimicrobial nanoemulsion preserves fruit juices against microbial spoilage. Colloid Surf. B 2014, 114, 392–397. [Google Scholar] [CrossRef] [PubMed]

- Moghimi, R.; Aliahmadi, A.; McClements, D.J.; Rafati, H. Investigation of the effectiveness of nanoemulsion from sage oil as antibacterial agents on some food borne pathogens. LWT Food Sci. Technol. 2016, 71, 69–76. [Google Scholar] [CrossRef]

- Salvia-Trujillo, L.; Rojas-Grau, M.A.; Soliva-Fortuny, R.; Martín-Belloso, O. Impact of microfluidization or ultrasound processing on the antimicrobial activity against Escherichia coli of lemongrass oil-loaded nanoemulsions. Food Control 2014, 37, 292–297. [Google Scholar] [CrossRef]

- Maté, J.; Periago, P.M.; Palop, A. Combined effect of a nanoemulsion of D-limonene and nisin on Listeria monocytogenes growth and viability in culture media and foods. Food Sci. Tehcnol. Int. 2016, 22, 146–152. [Google Scholar] [CrossRef] [PubMed]

- Lu, W.C.; Huang, D.W.; Wang, C.C.R.; Yeh, C.H.; Tsai, J.C.; Huang, Y.T.; Li, P.H. Preparation, characterization, and antimicrobial activity of nanoemulsions incorporating citral essential oil. J. Food Drug Anal 2017. [Google Scholar] [CrossRef]

- Maté, J.; Periago, P.M.; Palop, A. When nanoemulsified, D-limonene reduces Listeria monocytogenes heat resistance about one hundred times. Food Control 2016, 59, 824–828. [Google Scholar] [CrossRef]

- Maté, J.; Periago, P.M.; Ros-Chumillas, M.; Grullón, C.; Huertas, J.P.; Palop, A. Fat and fibre interfere with the dramatic effect that nanoemulsified D-limonene has on the heat resistance of Listeria monocytogenes. Food Microbiol. 2017, 62, 270–274. [Google Scholar] [CrossRef] [PubMed]

- Luis-Villarroya, A.; Espina, L.; García-Gonzalo, D.; Bayarri, S.; Pérez, C.; Pagán, R. Bioactive properties of a propolis-based dietary supplement and its use in combination with mild heat for apple juice preservation. Int. J. Food Microbiol. 2015, 205, 90–97. [Google Scholar] [CrossRef] [PubMed]

- Pan, K.; Chen, H.; Davidson, P.M.; Zhong, Q. Thymol nanoencapsulated by sodium caseinate: Physical and anti-listerial properties. J. Agric. Food Chem. 2014, 62, 1649–1657. [Google Scholar] [CrossRef] [PubMed]

- Weiss, J.; McClements, D.J.; Davidson, P.M. Nanoscalar dispersion of antimicrobials: Effect on food safety. World Food Sci. 2014, 16, 8–19. [Google Scholar]

- Zhang, Z.; Vriesekoop, F.; Yuan, Q.; Liand, H. Effects of nisin on the antimicrobial activity of D-limonene and its nanoemulsion. Food Chem. 2014, 150, 307–312. [Google Scholar] [CrossRef] [PubMed]

- Conesa, R.; Andreu, S.; Fernández, P.S.; Esnoz, A.; Palop, A. Nonisothermal heat resistance determinations with the thermoresistometer Mastia. J. Appl. Microbiol. 2009, 107, 506–513. [Google Scholar] [CrossRef] [PubMed]

- Mafart, P.; Couvert, O.; Gaillard, S.; Leguerinel, I. On calculating sterility in thermal preservation methods: Applications of the Weibull frequency distribution model. Int. J. Food Microbiol. 2002, 72, 107–113. [Google Scholar] [CrossRef]

- Garre, A.; Fernández, P.S.; Lindqvist, R.; Egea, J.A. Bioinactivation: Software for modelling dynamic microbial inactivation. Food Res. Int. 2017, 93, 66–74. [Google Scholar] [CrossRef]

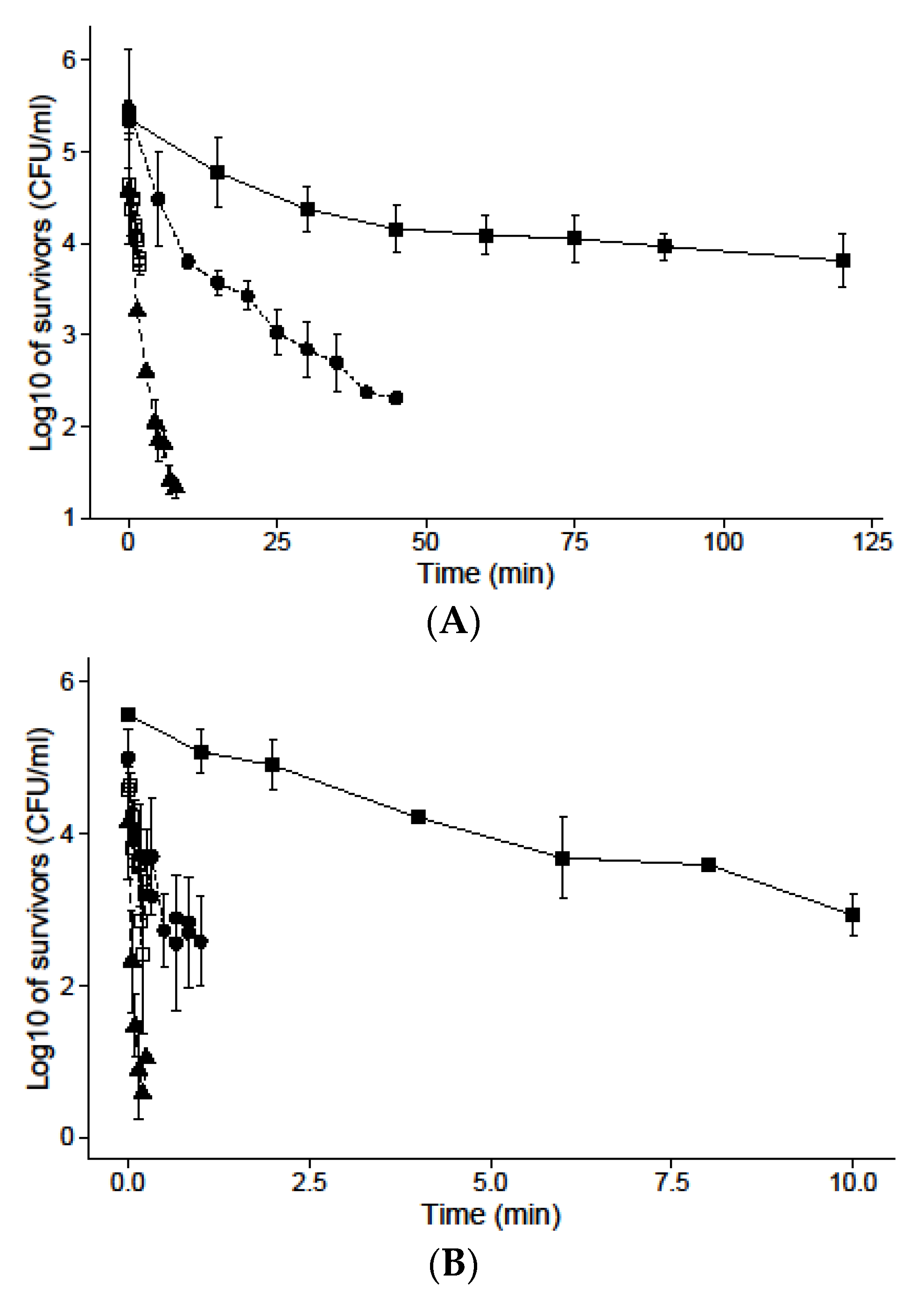

| D-Limonene (mM) | (min) | z (°C) | p | RMSE |

|---|---|---|---|---|

| Control (0) | 32.13 ± 3.12 | 3.83 ± 0.18 | 0.52 | 0.41 |

| 0.1 | 4.71 ± 0.30 | 3.33 ± 0.10 | 0.38 | |

| 0.5 | 1.38 ± 0.09 | 3.65 ± 0.12 | 0.40 | |

| 1 | 0.65 ± 0.03 | 3.14 ± 0.06 | 0.40 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ros-Chumillas, M.; Garre, A.; Maté, J.; Palop, A.; Periago, P.M. Nanoemulsified D-Limonene Reduces the Heat Resistance of Salmonella Senftenberg over 50 Times. Nanomaterials 2017, 7, 65. https://doi.org/10.3390/nano7030065

Ros-Chumillas M, Garre A, Maté J, Palop A, Periago PM. Nanoemulsified D-Limonene Reduces the Heat Resistance of Salmonella Senftenberg over 50 Times. Nanomaterials. 2017; 7(3):65. https://doi.org/10.3390/nano7030065

Chicago/Turabian StyleRos-Chumillas, María, Alberto Garre, Javier Maté, Alfredo Palop, and Paula M. Periago. 2017. "Nanoemulsified D-Limonene Reduces the Heat Resistance of Salmonella Senftenberg over 50 Times" Nanomaterials 7, no. 3: 65. https://doi.org/10.3390/nano7030065