Field Emission from Self-Catalyzed GaAs Nanowires

Abstract

:1. Introduction

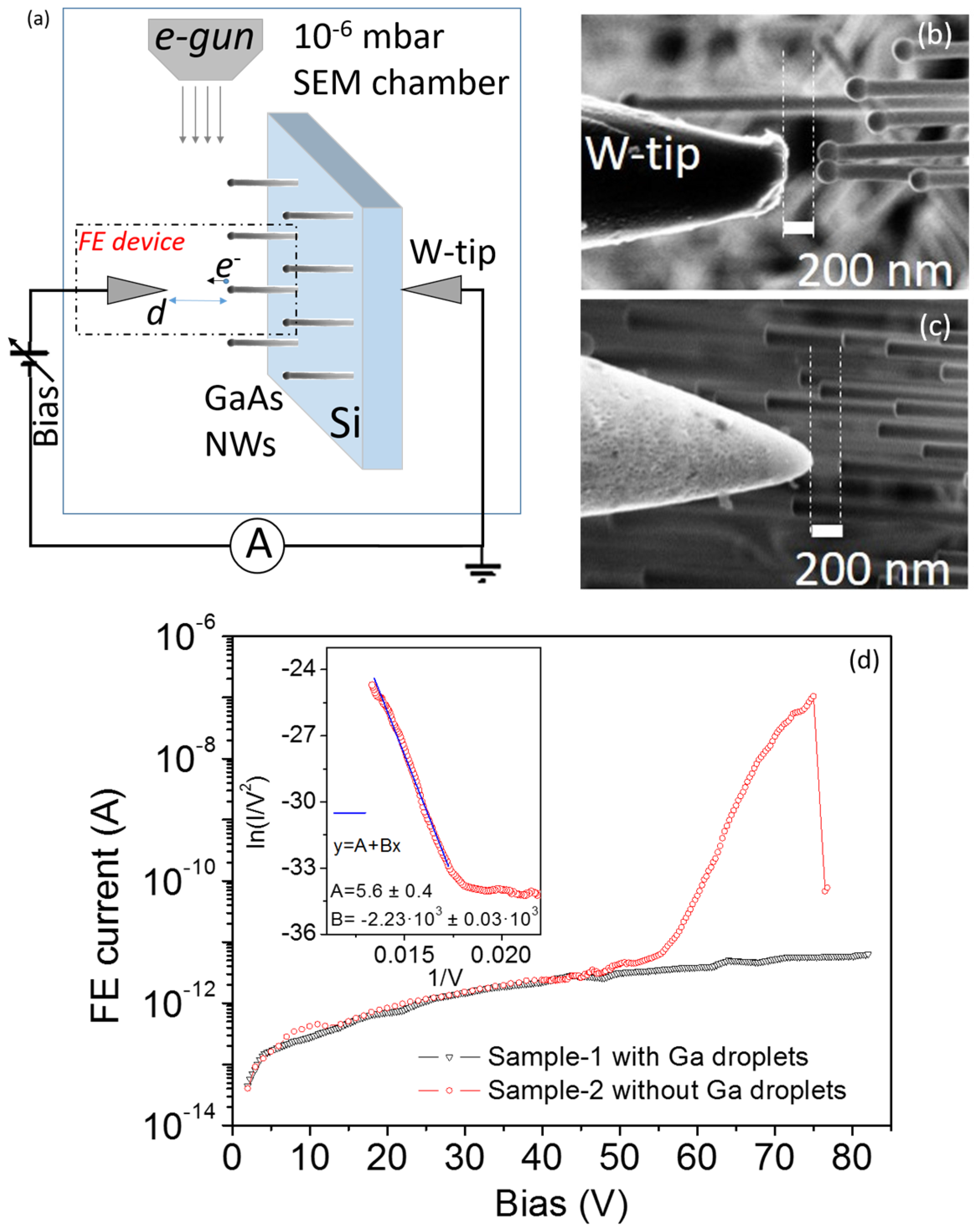

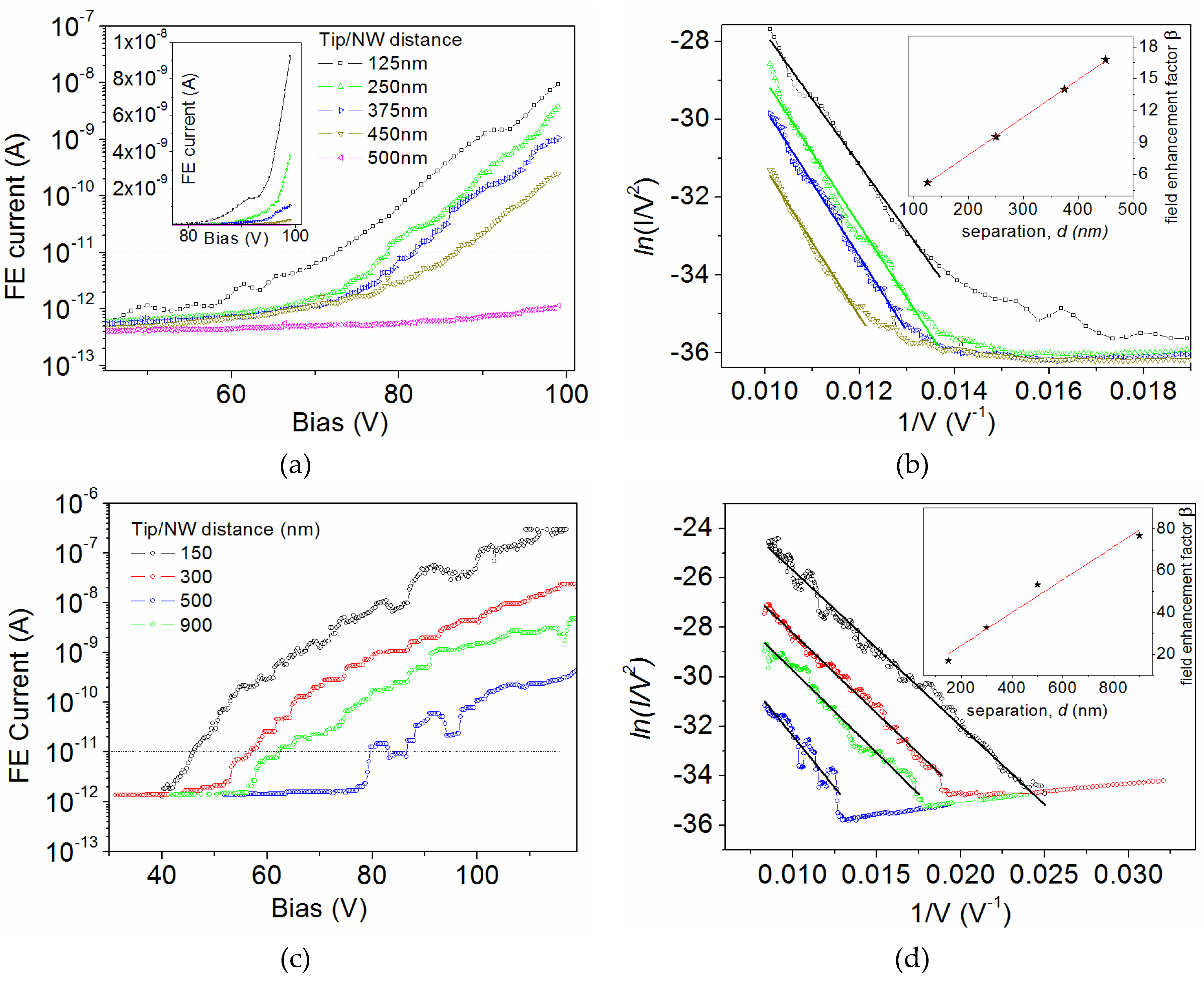

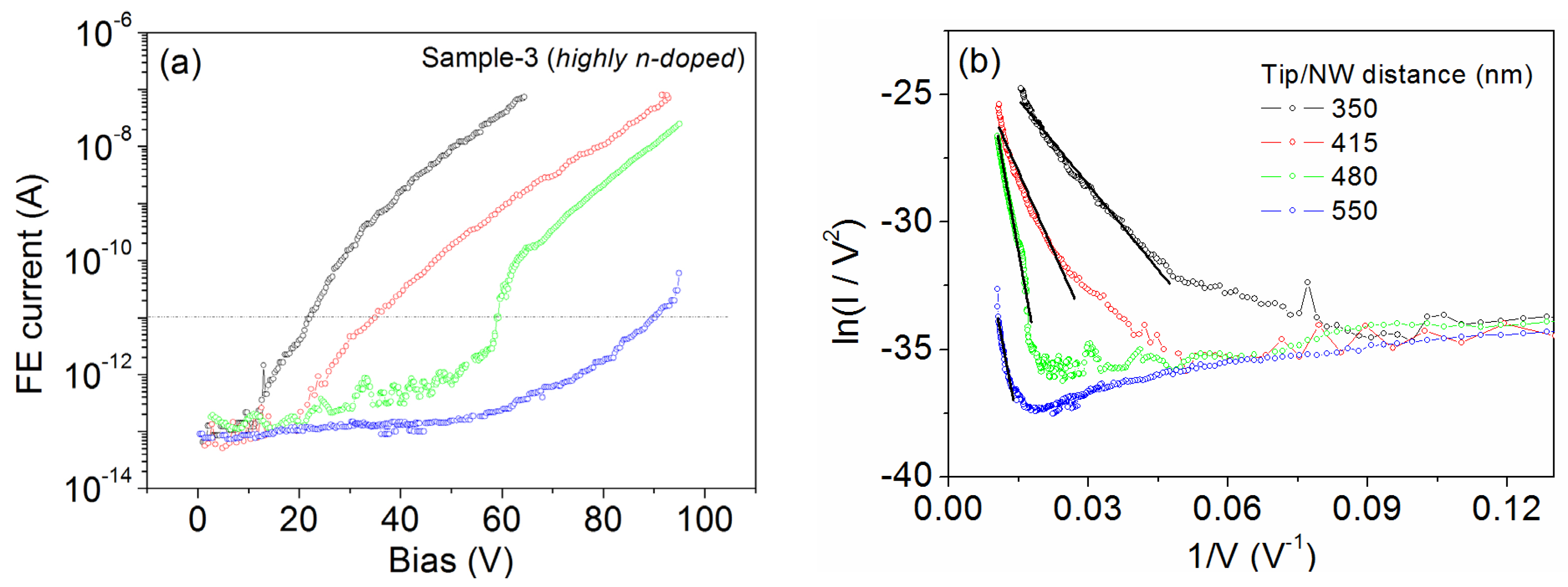

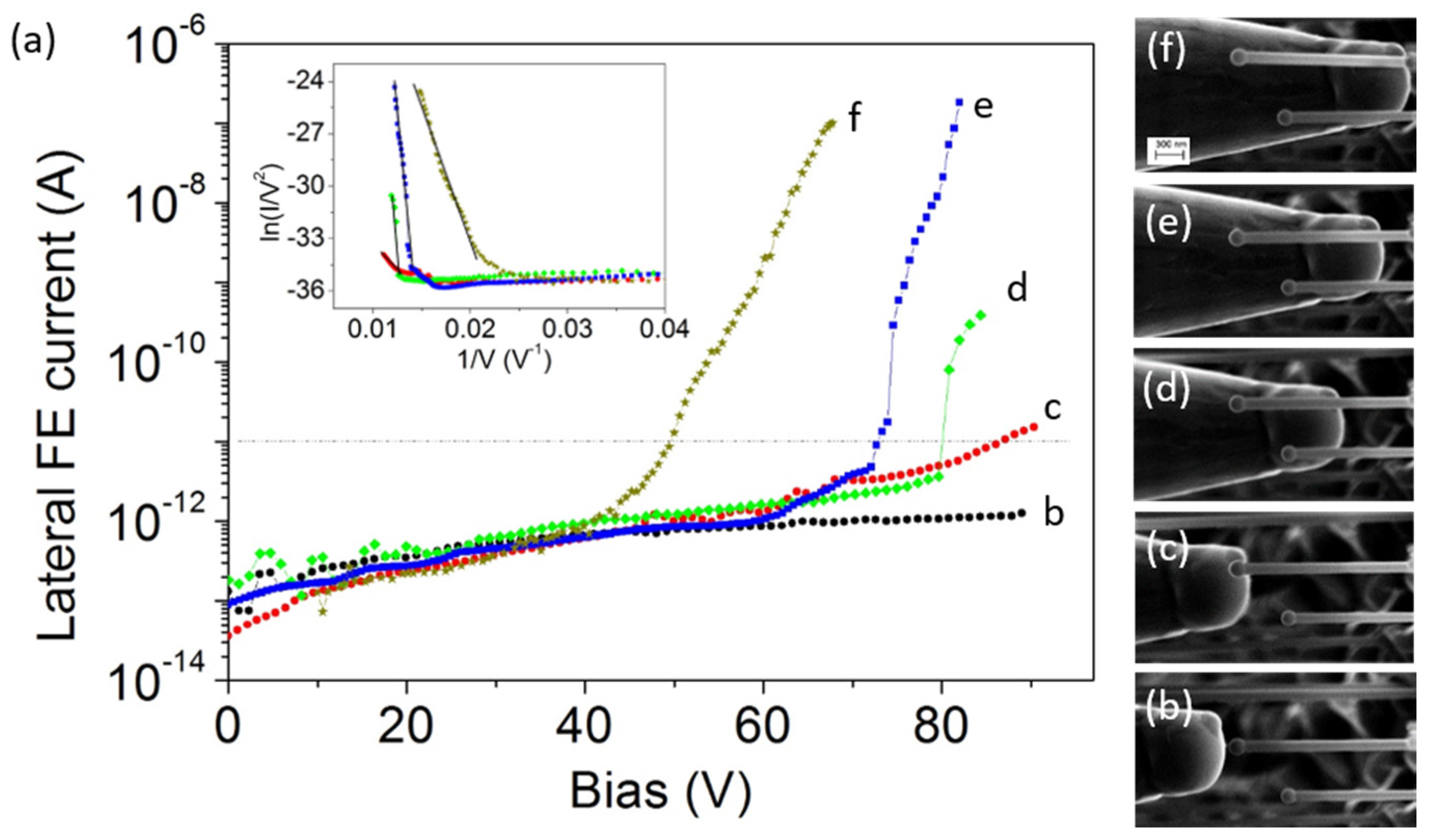

2. Materials and Methods

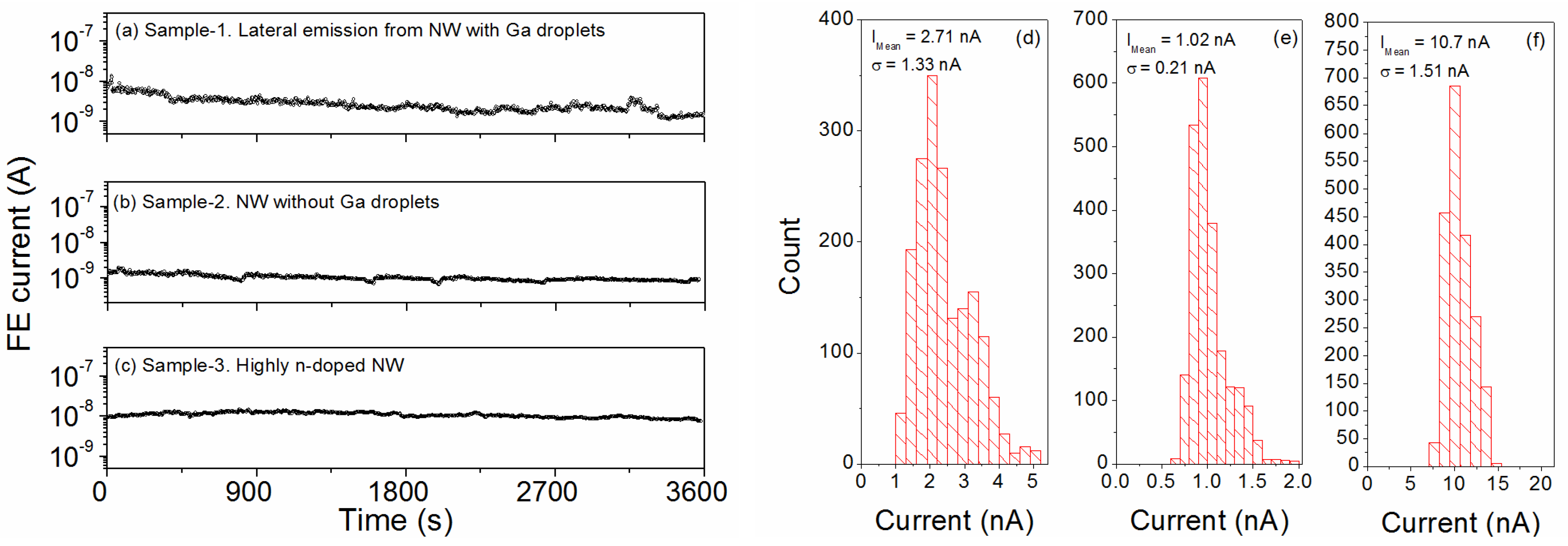

3. Results and Discussion

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Wang, Q.H.; Yan, M.; Chang, R.P.H. Flat panel display prototype using gated carbon nanotube field emitters. Appl. Phys. Lett. 2001, 78, 1294–1296. [Google Scholar] [CrossRef]

- De Heer, W.A.; Ch telain, A.; Ugarte, D. A Carbon Nanotube Field-Emission Electron Source. Science 1995, 270, 1179–1180. [Google Scholar] [CrossRef]

- De Jonge, N.; Allioux, M.; Oostveen, J.T.; Teo, K.B.K.; Milne, W.I. Optical Performance of Carbon-Nanotube Electron Sources. Phys. Rev. Lett. 2005, 94. [Google Scholar] [CrossRef] [PubMed]

- Saito, Y.; Hata, K.; Takakura, A.; Yotani, J.; Uemura, S. Field emission of carbon nanotubes and its application as electron sources of ultra-high luminance light-source devices. Phys. B Condens. Matter 2002, 323, 30–37. [Google Scholar] [CrossRef]

- Field Emission in Microwave Field. In Field Emission in Vacuum Microelectronics; Brodie, I.; Schwoebel, P. (Eds.) Springer US: Boston, MA, USA, 2005; pp. 57–69. ISBN 978-0-306-47450-7. [Google Scholar]

- Lin, P.-H.; Sie, C.-L.; Chen, C.-A.; Chang, H.-C.; Shih, Y.-T.; Chang, H.-Y.; Su, W.-J.; Lee, K.-Y. Field Emission Characteristics of the Structure of Vertically Aligned Carbon Nanotube Bundles. Nanoscale Res. Lett. 2015, 10. [Google Scholar] [CrossRef] [PubMed]

- Di Bartolomeo, A.; Scarfato, A.; Giubileo, F.; Bobba, F.; Biasiucci, M.; Cucolo, A.M.; Santucci, S.; Passacantando, M. A local field emission study of partially aligned carbon-nanotubes by atomic force microscope probe. Carbon 2007, 45, 2957–2971. [Google Scholar] [CrossRef]

- Giubileo, F.; Bartolomeo, A.D.; Scarfato, A.; Iemmo, L.; Bobba, F.; Passacantando, M.; Santucci, S.; Cucolo, A.M. Local probing of the field emission stability of vertically aligned multi-walled carbon nanotubes. Carbon 2009, 47, 1074–1080. [Google Scholar] [CrossRef]

- Wang, M.S.; Peng, L.M.; Wang, J.Y.; Chen, Q. Electron field emission characteristics and field evaporation of a single carbon nanotube. J. Phys. Chem. B 2005, 109, 110–113. [Google Scholar] [CrossRef] [PubMed]

- Passacantando, M.; Bussolotti, F.; Santucci, S.; Di Bartolomeo, A.; Giubileo, F.; Iemmo, L.; Cucolo, A.M. Field emission from a selected multiwall carbon nanotube. Nanotechnology 2008, 19, 395701. [Google Scholar] [CrossRef] [PubMed]

- Di, Y.; Xiao, M.; Zhang, X.; Wang, Q.; Li, C.; Lei, W.; Cui, Y. Large and stable emission current from synthesized carbon nanotube/fiber network. J. Appl. Phys. 2014, 115, 064305. [Google Scholar] [CrossRef]

- Giubileo, F.; Di Bartolomeo, A.; Sarno, M.; Altavilla, C.; Santandrea, S.; Ciambelli, P.; Cucolo, A.M. Field emission properties of as-grown multiwalled carbon nanotube films. Carbon 2012, 50, 163–169. [Google Scholar] [CrossRef]

- Giubileo, F.; Iemmo, L.; Luongo, G.; Martucciello, N.; Raimondo, M.; Guadagno, L.; Passacantando, M.; Lafdi, K.; Di Bartolomeo, A. Transport and field emission properties of buckypapers obtained from aligned carbon nanotubes. J. Mater. Sci. 2017, 52, 6459–6468. [Google Scholar] [CrossRef]

- Kumar, S.; Duesberg, G.S.; Pratap, R.; Raghavan, S. Graphene field emission devices. Appl. Phys. Lett. 2014, 105, 103107. [Google Scholar] [CrossRef]

- Santandrea, S.; Giubileo, F.; Grossi, V.; Santucci, S.; Passacantando, M.; Schroeder, T.; Lupina, G.; Di Bartolomeo, A. Field emission from single and few-layer graphene flakes. Appl. Phys. Lett. 2011, 98, 163109. [Google Scholar] [CrossRef]

- Di Bartolomeo, A.; Giubileo, F.; Iemmo, L.; Romeo, F.; Russo, S.; Unal, S.; Passacantando, M.; Grossi, V.; Cucolo, A.M. Leakage and field emission in side-gate graphene field effect transistors. Appl. Phys. Lett. 2016, 109, 023510. [Google Scholar] [CrossRef]

- Ye, D.; Moussa, S.; Ferguson, J.D.; Baski, A.A.; El-Shall, M.S. Highly Efficient Electron Field Emission from Graphene Oxide Sheets Supported by Nickel Nanotip Arrays. Nano Lett. 2012, 12, 1265–1268. [Google Scholar] [CrossRef] [PubMed]

- Joyce, H.J.; Gao, Q.; Tan, H.H.; Jagadish, C.; Kim, Y.; Zou, J.; Smith, L.M.; Jackson, H.E.; Yarrison-Rice, J.M.; Parkinson, P.; et al. III–V semiconductor nanowires for optoelectronic device applications. Prog. Quantum Electron. 2011, 35, 23–75. [Google Scholar] [CrossRef]

- Li, Y.; Qian, F.; Xiang, J.; Lieber, C.M. Nanowire electronic and optoelectronic devices. Mater. Today 2006, 9, 18–27. [Google Scholar] [CrossRef]

- Krogstrup, P.; Jørgensen, H.I.; Heiss, M.; Demichel, O.; Holm, J.V.; Aagesen, M.; Nygard, J.; i Morral, A.F. Single-nanowire solar cells beyond the Shockley-Queisser limit. Nat. Photonics 2013, 7, 306–310. [Google Scholar] [CrossRef]

- Tian, B.; Kempa, T.J.; Lieber, C.M. Single nanowire photovoltaics. Chem. Soc. Rev. 2009, 38, 16–24. [Google Scholar] [CrossRef] [PubMed]

- Mittal, G.; Lahiri, I. Recent progress in nanostructured next-generation field emission devices. J. Phys. D Appl. Phys. 2014, 47, 323001. [Google Scholar] [CrossRef]

- Choi, Y.; Michan, M.; Johnson, J.L.; Naieni, A.K.; Ural, A.; Nojeh, A. Field-emission properties of individual GaN nanowires grown by chemical vapor deposition. J. Appl. Phys. 2012, 111, 044308. [Google Scholar] [CrossRef]

- Li, E.; Wu, B.; Lv, S.; Cui, Z.; Ma, D.; Shi, W. Field emission properties of Ge-doped GaN nanowires. J. Alloy. Compd. 2016, 681, 324–329. [Google Scholar] [CrossRef]

- Lee, C.J.; Lee, T.J.; Lyu, S.C.; Zhang, Y.; Ruh, H.; Lee, H.J. Field emission from well-aligned zinc oxide nanowires grown at low temperature. Appl. Phys. Lett. 2002, 81, 3648–3650. [Google Scholar] [CrossRef]

- Ulisse, G.; Ciceroni, C.; Carlo, A.D.; Brunetti, F.; Jelenc, J.; Varlec, A.; Remskar, M. Field emission from tungsten oxide nanowires W5O14 film. In Proceedings of the 2015 IEEE 15th International Conference on Nanotechnology (IEEE-NANO), Rome, Italy, 27–30 July 2015; pp. 1190–1193. [Google Scholar]

- Wang, B.; Zheng, Z.; Wu, H.; Zhu, L. Field emission properties and growth mechanism of In2O3 nanostructures. Nanoscale Res. Lett. 2014, 9, 111. [Google Scholar] [CrossRef] [PubMed]

- Di Bartolomeo, A.; Passacantando, M.; Niu, G.; Schlykow, V.; Lupina, G.; Giubileo, F.; Schroeder, T. Observation of field emission from GeSn nanoparticles epitaxially grown on silicon nanopillar arrays. Nanotechnology 2016, 27, 485707. [Google Scholar] [CrossRef] [PubMed]

- Colombo, C.; Spirkoska, D.; Frimmer, M.; Abstreiter, G.; i Morral, A.F. Ga-assisted catalyst-free growth mechanism of GaAs nanowires by molecular beam epitaxy. Phys. Rev. B 2008, 77. [Google Scholar] [CrossRef]

- Jabeen, F.; Grillo, V.; Rubini, S.; Martelli, F. Self-catalyzed growth of GaAs nanowires on cleaved Si by molecular beam epitaxy. Nanotechnology 2008, 19, 275711. [Google Scholar] [CrossRef] [PubMed]

- Bullis, W.M. Properties of gold in silicon. Solid-State Electron. 1966, 9, 143–168. [Google Scholar] [CrossRef]

- Tondare, V.N.; Naddaf, M.; Bhise, A.B.; Bhoraskar, S.V.; Joag, D.S.; Mandale, A.B.; Sainkar, S.R. Stability of field emission current from porous n-GaAs (110). Appl. Phys. Lett. 2002, 80, 1085–1087. [Google Scholar] [CrossRef]

- Asoh, H.; Kotaka, S.; Ono, S. High-aspect-ratio GaAs pores and pillars with triangular cross section. Electrochem. Commun. 2011, 13, 458–461. [Google Scholar] [CrossRef]

- Ono, S.; Kotaka, S.; Asoh, H. Fabrication and structure modulation of high-aspect-ratio porous GaAs through anisotropic chemical etching, anodic etching, and anodic oxidation. Electrochim. Acta 2013, 110, 393–401. [Google Scholar] [CrossRef]

- Asoh, H.; Kotaka, S.; Ono, S. High-aspect-ratio vertically aligned GaAs nanowires fabricated by anodic etching. Mater. Res. Express 2014, 1, 045002. [Google Scholar] [CrossRef]

- Zhi, C.Y.; Bai, X.D.; Wang, E.G. Synthesis and field-electron-emission behavior of aligned GaAs nanowires. Appl. Phys. Lett. 2005, 86, 213108. [Google Scholar] [CrossRef]

- Sanguinetti, S.; Koguchi, N. Droplet epitaxy of nanostructures. In Molecular Beam Epitaxy; Mohamed Henini, Ed.; Elsevier: Asterdam, Netherlands, 2013; pp. 95–111. ISBN 978-0-12-387839-7. [Google Scholar]

- Hakkarainen, T.V.; Schramm, A.; Mäkelä, J.; Laukkanen, P.; Guina, M. Lithography-free oxide patterns as templates for self-catalyzed growth of highly uniform GaAs nanowires on Si (111). Nanotechnology 2015, 26, 275301. [Google Scholar] [CrossRef] [PubMed]

- Smith, R.C.; Cox, D.C.; Silva, S.R.P. Electron field emission from a single carbon nanotube: Effects of anode location. Appl. Phys. Lett. 2005, 87, 103112. [Google Scholar] [CrossRef] [Green Version]

- Fowler, R.H.; Nordheim, L. Electron Emission in Intense Electric Fields. Proc. R. Soc. A Math. Phys. Eng. Sci. 1928, 119, 173–181. [Google Scholar] [CrossRef]

- Bocharov, G.; Eletskii, A. Theory of Carbon Nanotube (CNT)-Based Electron Field Emitters. Nanomaterials 2013, 3, 393–442. [Google Scholar] [CrossRef] [PubMed]

- Inoue, N.; Higashino, T.; Tanahashi, K.; Kawamura, Y. Work function of GaAs (001) surface obtained by the electron counting model. J. Cryst. Growth 2001, 227–228, 123–126. [Google Scholar] [CrossRef]

- Cheng, T.-C.; Chen, P.-Y.; Wu, S.-Y. Paradox of low field enhancement factor for field emission nanodiodes in relation to quantum screening effects. Nanoscale Res. Lett. 2012, 7, 125. [Google Scholar] [CrossRef] [PubMed]

- Edgcombe, C.J.; Valdrè, U. Experimental and computational study of field emission characteristics from amorphous carbon single nanotips grown by carbon contamination. I. Experiments and computation. Philos. Mag. B 2002, 82, 987–1007. [Google Scholar] [CrossRef]

- Edgcombe, C.J.; Valdre, U. Microscopy and computational modelling to elucidate the enhancement factor for field electron emitters. J. Microsc. 2001, 203, 188–194. [Google Scholar] [CrossRef]

- Bonard, J.-M.; Dean, K.A.; Coll, B.F.; Klinke, C. Field Emission of Individual Carbon Nanotubes in the Scanning Electron Microscope. Phys. Rev. Lett. 2002, 89. [Google Scholar] [CrossRef] [PubMed]

- Jo, S.H.; Tu, Y.; Huang, Z.P.; Carnahan, D.L.; Wang, D.Z.; Ren, Z.F. Effect of length and spacing of vertically aligned carbon nanotubes on field emission properties. Appl. Phys. Lett. 2003, 82, 3520–3522. [Google Scholar] [CrossRef]

- Bonard, J.-M.; Weiss, N.; Kind, H.; Stöckli, T.; Forró, L.; Kern, K.; Châtelain, A. Tuning the Field Emission Properties of Patterned Carbon Nanotube Films. Adv. Mater. 2001, 13, 184–188. [Google Scholar] [CrossRef]

- Salehzadeh, O.; Chen, M.X.; Kavanagh, K.L.; Watkins, S.P. Rectifying characteristics of Te-doped GaAs nanowires. Appl. Phys. Lett. 2011, 99, 182102. [Google Scholar] [CrossRef]

- Charlier, J.-C.; Terrones, M.; Baxendale, M.; Meunier, V.; Zacharia, T.; Rupesinghe, N.L.; Hsu, W.K.; Grobert, N.; Terrones, H.; Amaratunga, G.A.J. Enhanced Electron Field Emission in B-doped Carbon Nanotubes. Nano Lett. 2002, 2, 1191–1195. [Google Scholar] [CrossRef]

- Sharma, R.B.; Late, D.J.; Joag, D.S.; Govindaraj, A.; Rao, C.N.R. Field emission properties of boron and nitrogen doped carbon nanotubes. Chem. Phys. Lett. 2006, 428, 102–108. [Google Scholar] [CrossRef]

- Ghosh, P.; Tanemura, M.; Soga, T.; Zamri, M.; Jimbo, T. Field emission property of N-doped aligned carbon nanotubes grown by pyrolysis of monoethanolamine. Solid State Commun. 2008, 147, 15–19. [Google Scholar] [CrossRef]

- Liu, G.; Li, F.; Wang, D.-W.; Tang, D.-M.; Liu, C.; Ma, X.; Lu, G.Q.; Cheng, H.-M. Electron field emission of a nitrogen-doped TiO2 nanotube array. Nanotechnology 2008, 19, 025606. [Google Scholar] [CrossRef] [PubMed]

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Giubileo, F.; Di Bartolomeo, A.; Iemmo, L.; Luongo, G.; Passacantando, M.; Koivusalo, E.; Hakkarainen, T.V.; Guina, M. Field Emission from Self-Catalyzed GaAs Nanowires. Nanomaterials 2017, 7, 275. https://doi.org/10.3390/nano7090275

Giubileo F, Di Bartolomeo A, Iemmo L, Luongo G, Passacantando M, Koivusalo E, Hakkarainen TV, Guina M. Field Emission from Self-Catalyzed GaAs Nanowires. Nanomaterials. 2017; 7(9):275. https://doi.org/10.3390/nano7090275

Chicago/Turabian StyleGiubileo, Filippo, Antonio Di Bartolomeo, Laura Iemmo, Giuseppe Luongo, Maurizio Passacantando, Eero Koivusalo, Teemu V. Hakkarainen, and Mircea Guina. 2017. "Field Emission from Self-Catalyzed GaAs Nanowires" Nanomaterials 7, no. 9: 275. https://doi.org/10.3390/nano7090275

APA StyleGiubileo, F., Di Bartolomeo, A., Iemmo, L., Luongo, G., Passacantando, M., Koivusalo, E., Hakkarainen, T. V., & Guina, M. (2017). Field Emission from Self-Catalyzed GaAs Nanowires. Nanomaterials, 7(9), 275. https://doi.org/10.3390/nano7090275