Nanotransition Materials (NTMs): Photocatalysis, Validated High Effective Sorbent Models Study for Organic Dye Degradation and Precise Mathematical Data’s at Standardized Level

Abstract

:1. Introduction

2. Materials and Methods

2.1. Formation of Copper Oxide Nanoparticles (CuONPs)

2.2. Characterization of the Prepared CuONPs

2.3. Photocatalytic Activity of Synthesized CuONPs

2.4. Adsorption Procedure

2.4.1. Effect of pH on MB Dye Adsorption

2.4.2. Effect of MB Dye Concentration on Adsorption

2.4.3. Effect of Adsorbent Dose

2.4.4. Effect of Temperature on Adsorption

2.5. Error Analysis

2.6. Equilibrium Isotherm Experiment

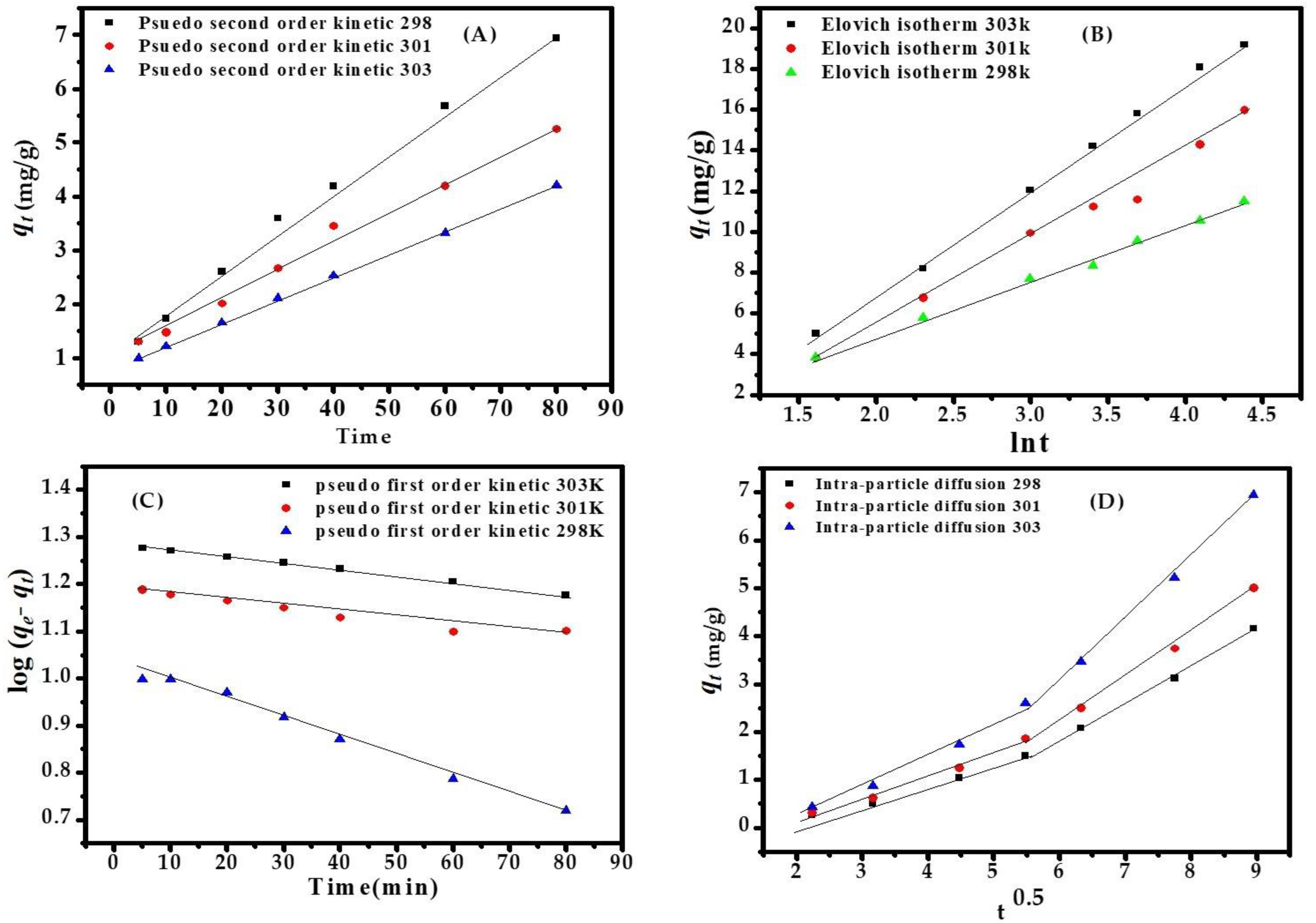

2.6.1. Kinetic Model

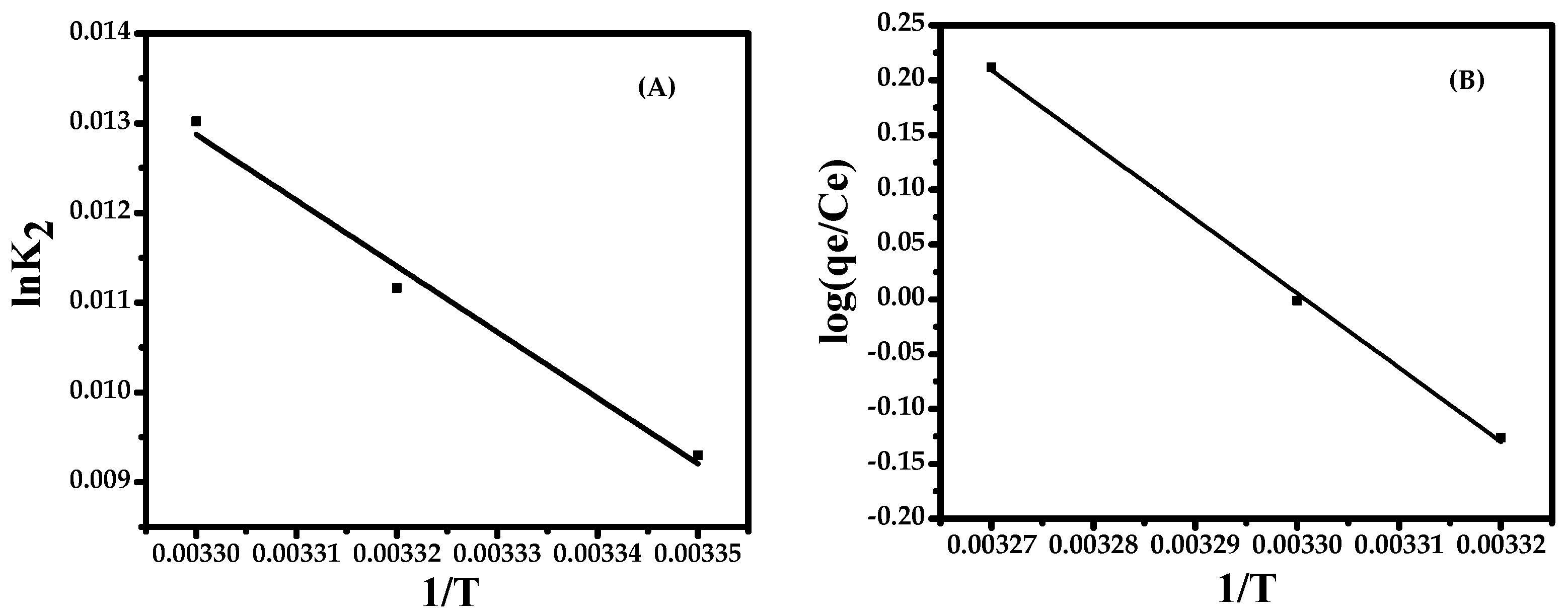

2.6.2. Thermodynamic Study

2.6.3. Lagergren’s Pseudo-First-Order Kinetics

2.6.4. Ho and McKay Pseudo-Second-Order Kinetic Model

2.6.5. The Elovich Equation

2.6.6. Intraparticle Diffusion Equation (IDE)

2.7. Equilibrium Isotherm Models

2.7.1. The Langmuir Adsorption Isotherm

2.7.2. Freundlich Adsorption Isotherm

2.7.3. Dubinin–Radushkevich Adsorption Isotherm

2.7.4. Temkin Isotherm

2.7.5. Harkins–Jura Isotherm

2.7.6. Hasley Isotherm Model

2.8. Thermodynamic Study

3. Results and Discussion

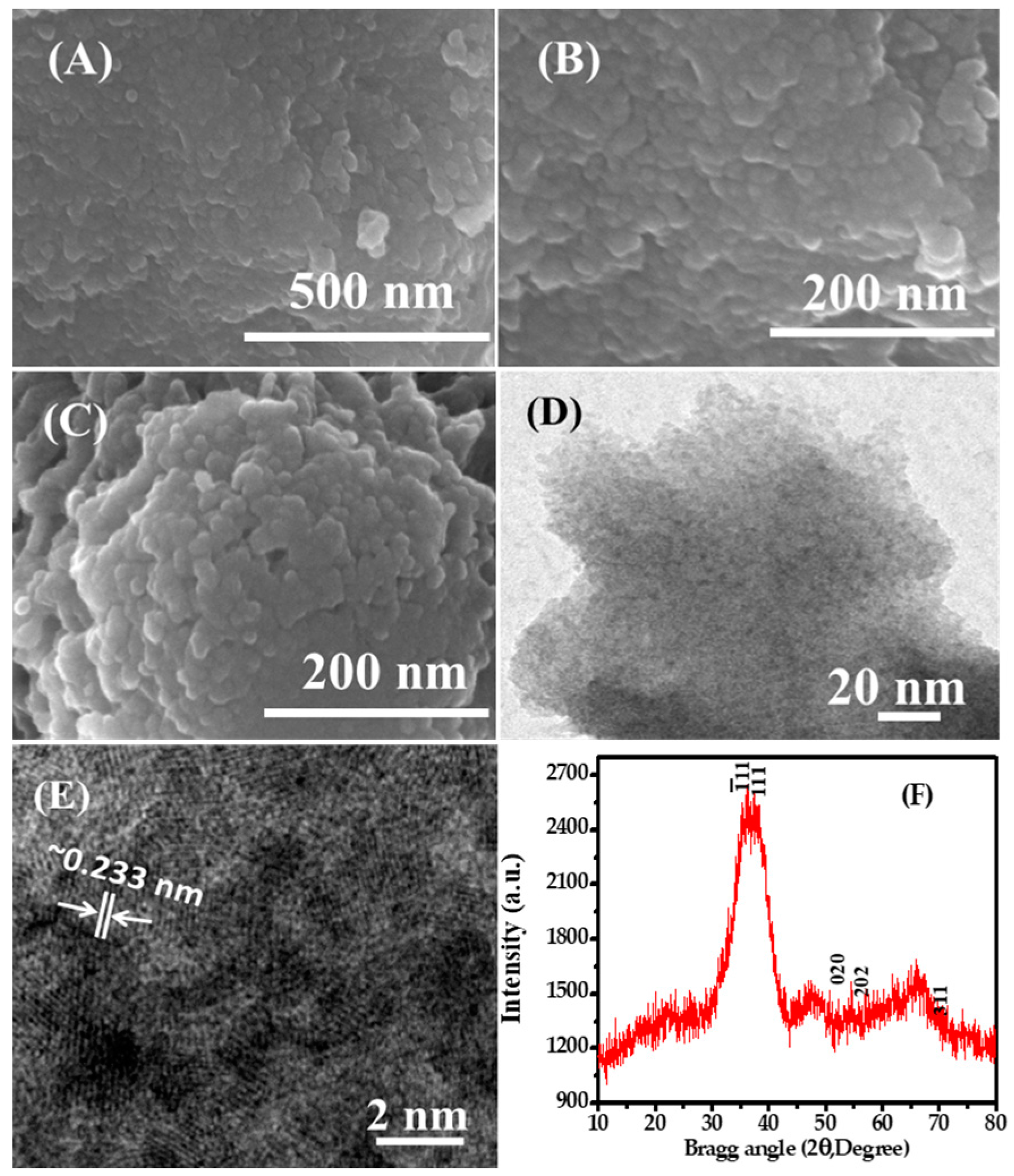

3.1. Structural Morphological Description of Prepared CuONPs (FE-SEM and TEM Results)

3.2. X-ray Diffraction Spectroscopy (XRD)

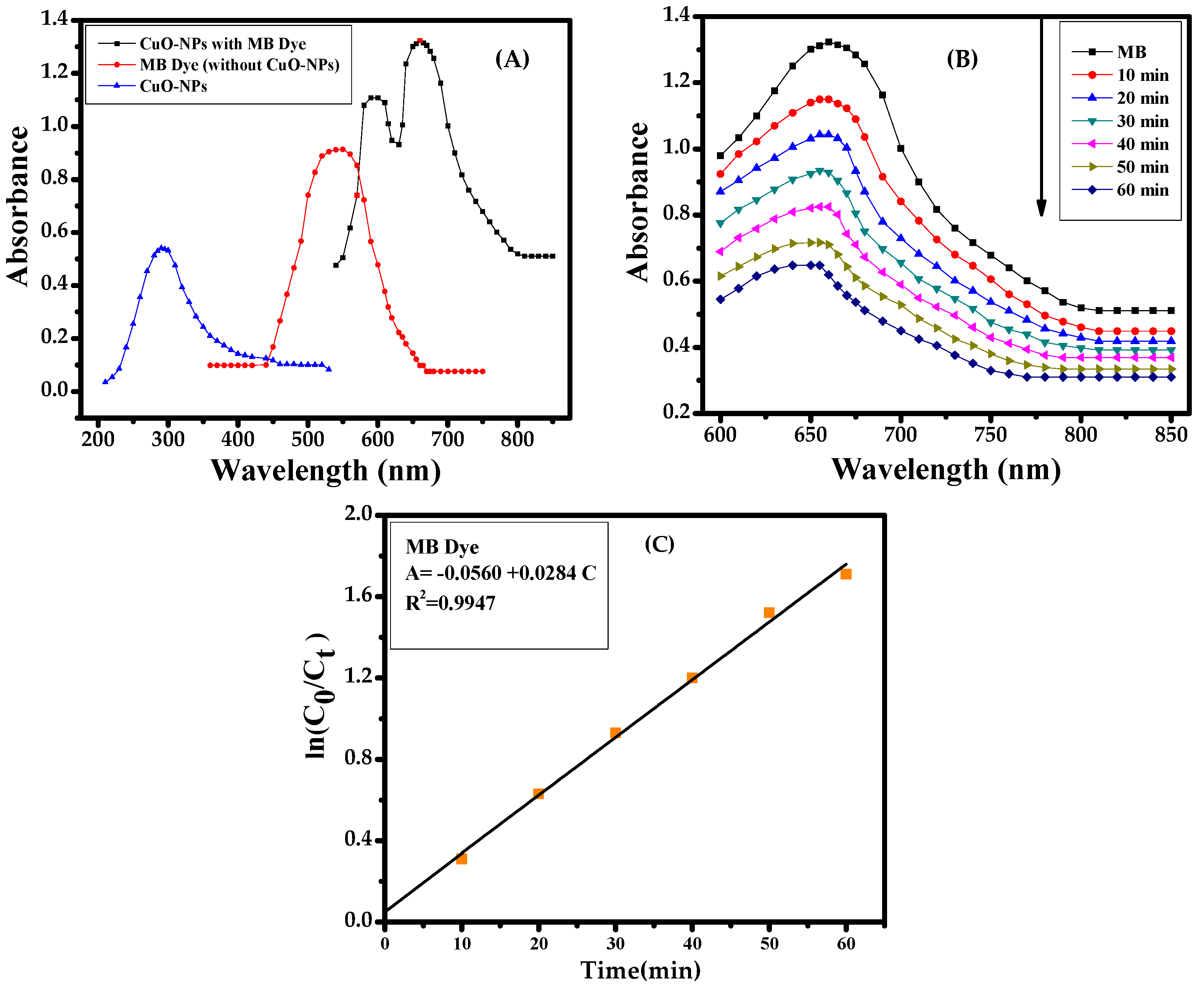

3.3. Catalytic Assessment of CuONPs in the Presence of UV Light

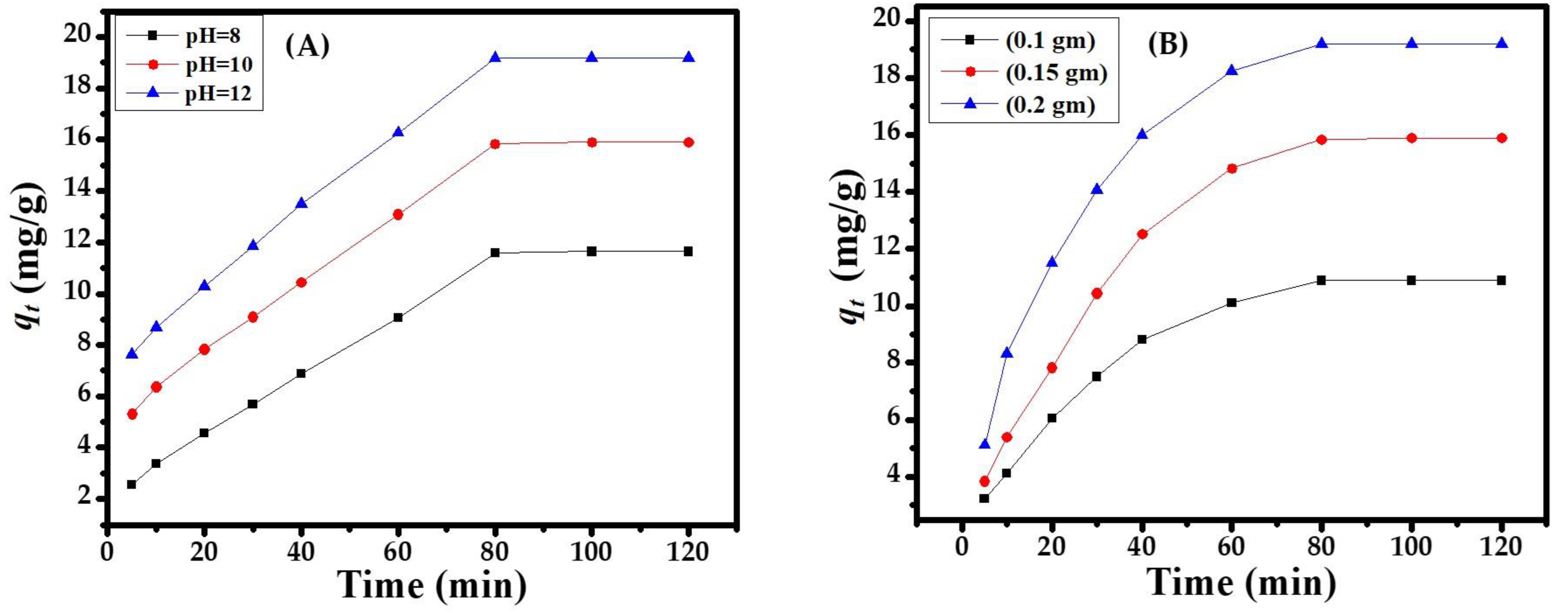

3.3.1. Effect of pH

3.3.2. Effect of Adsorbent Dose

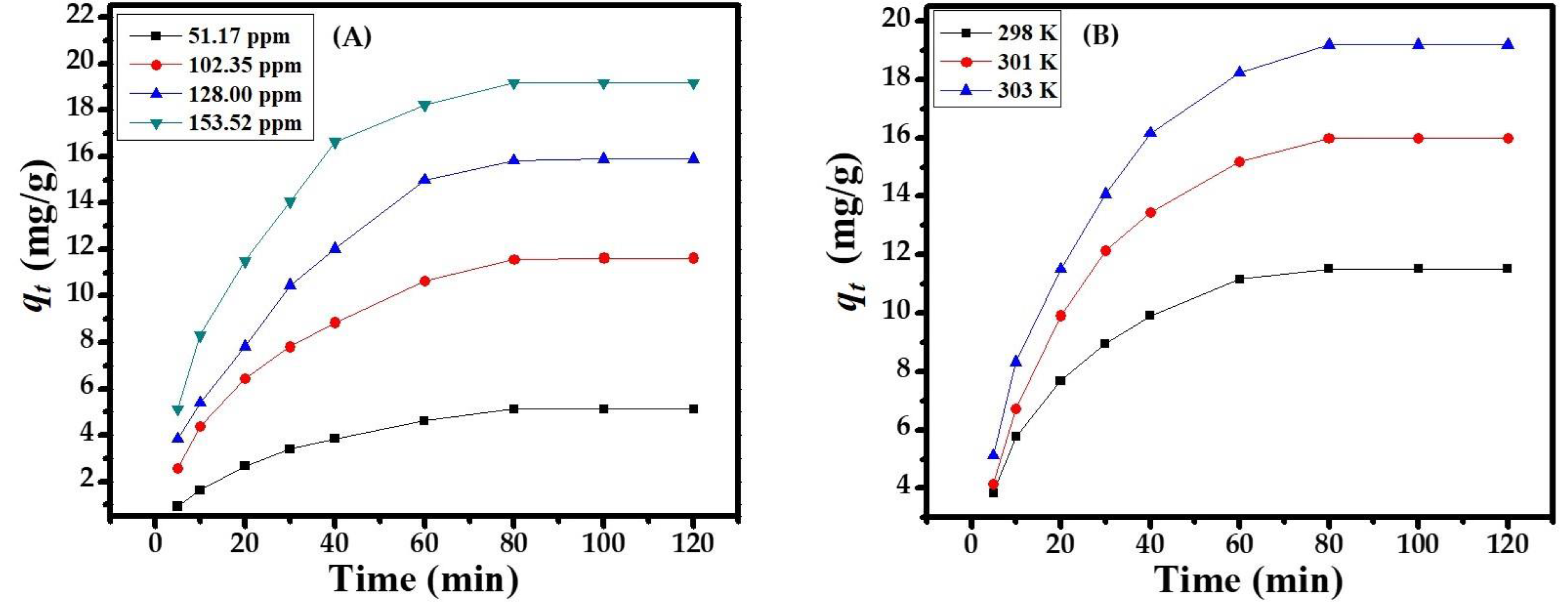

3.3.3. Effect of Concentration

3.3.4. Effect of Temperature

3.4. Adsorption Kinetics

3.5. Adsorption Isotherm

3.6. Activation Energy

3.7. Thermodynamic Assessment

3.8. ErrorAnalysis

4. Conclusions

Supplementary Materials

Author Contributions

Conflicts of Interest

References

- Wahab, R.; Hwang, I.H.; Kim, Y.S.; Musarrat, J.; Siddiqui, M.A.; Seo, H.K.; Tripathy, S.K. Non-hydrolytic synthesis and photo-catalytic studies of ZnO nanoparticles. Chem. Eng. J. 2011, 175, 450–457. [Google Scholar] [CrossRef]

- Farghali, A.A.; Bahgat, M.; Enaiet Allah, A.; Khedr, M.H. Adsorption of Pb(II) ions from aqueous solutions using copper oxide nanostructures. Beni-Suef Univ. J. Basic Appl. Sci. 2013, 2, 61–71. [Google Scholar] [CrossRef]

- El-Shobaky, G.A.; Hassan, H.M.A.; Abdel Halim, K.S.; El-Korashy, S.A.; Mohamed, S.K. Adsorption and photocatalytic degradation of methylene blue dye over Pd-CeO/TiO and CuO-CeO/TiO Catalysts. World J. Chem. 2012, 7, 11–16. [Google Scholar]

- Chatterjee, S.; Tyagiand, A.K.; Ayyub, P. Efficient photocatalytic degradation of Rhodamine B dye by aligned arrays of self-assembled a hydrogen titanate nanotubes. J. Nanomater. 2014, 2014, 36. [Google Scholar] [CrossRef]

- Wahab, R.; Hwang, I.H.; Kim, Y.S.; Shin, H.S. Photocatalytic activity of zinc oxide micro-flowers synthesized via solution method. Chem. Eng. J. 2011, 168, 359–366. [Google Scholar] [CrossRef]

- Wahab, R.; Khan, F.; Ahmad, N.; Shin, H.S.; Musarrat, J.; Al-Khedhairy, A.A. Hydrogen adsorption properties of nano-and microstructures of ZnO. J. Nanomater. 2013, 2013, 101. [Google Scholar] [CrossRef]

- Mishra, Y.K.; Adelung, R. ZnO tetrapod materials for functional applications. Mater. Today 2017. [Google Scholar] [CrossRef]

- Mekatel, E.H.; Amokrane, S.; Aid, A.; Nibou, D.; Trari, M. Adsorption of methyl orange on nanoparticles of a synthetic zeolite NaA/CuO. C. R. Chim. 2015, 18, 336–344. [Google Scholar] [CrossRef]

- Shaheed, M.A.; Hussein, F.H. Adsorption of reactive black 5 on synthesized titanium dioxide nanoparticles: Equilibrium isotherm and kinetic studies. J. Nanomater. 2014, 2014, 3. [Google Scholar] [CrossRef]

- Li, C.; Dong, Y.; Yang, J.; Li, Y.; Huang, C. Modified nano-graphite/Fe3O4 composite as efficient adsorbent for the removal of methyl violet from aqueous solution. J. Mol. Liq. 2014, 196, 348–356. [Google Scholar] [CrossRef]

- Pung, S.Y.; Lee, W.P.; Aziz, A. Kinetic study of organic dye degradation using ZnO particles with different morphologies as a photocatalyst. Int. J. Inorg. Chem. 2012, 2012, 608183. [Google Scholar] [CrossRef]

- Gupta, V.K.; Jain, R.; Mittal, A.; Saleh, T.A.; Nayak, A.; Agarwal, S.; Sikarwar, S. Photo-catalytic degradation of toxic dye amaranth on TiO2/UV in aqueous suspensions. Mater. Sci. Eng. C 2012, 32, 12–17. [Google Scholar] [CrossRef] [PubMed]

- Shu, J.; Song, C.; Xia, H.; Zhang, L.; Peng, J.; Li, C.; Zhang, S. Copper loaded on activated carbon as an efficient adsorbent for removal of methylene blue. RSC Adv. 2017, 7, 14395–14405. [Google Scholar] [CrossRef]

- Liang, Z.; Zhao, Z.; Sun, T.; Shi, W.; Cui, F. Enhanced adsorption of the cationic dyes in the spherical CuO/meso-silica nano composite and impact of solution chemistry. J. Colloid Interface Sci. 2017, 485, 192–200. [Google Scholar] [CrossRef] [PubMed]

- Simeonidis, K.; Mourdikoudis, S.; Kaprara, E.; Mitrakas, M.; Polavarapu, L. Inorganic engineered nanoparticles in drinking water treatment: A critical review. Environ. Sci. Water Res. Technol. 2016, 2, 43–70. [Google Scholar] [CrossRef]

- Wahab, R.; Khan, S.T.; Dwivedi, S.; Ahamed, M.; Musarrat, J.; Al-Khedhairy, A.A. Effective inhibition of bacterial respiration and growth by CuO microspheres composed of thin nano sheets. Colloids Surf. B Biointerfaces 2013, 111, 211–217. [Google Scholar] [CrossRef] [PubMed]

- Sathyamoorthy, R.; Mageshwari, K. Synthesis of hierarchical CuO microspheres: Photocatalytic and antibacterial activities. Phys. E Low-Dimens. Syst. Nanostruct. 2013, 47, 157–161. [Google Scholar] [CrossRef]

- Luo, L.B.; Wang, X.H.; Xie, C.; Li, Z.J.; Lu, R.; Yang, X.B.; Lu, J. One-dimensional CuO nanowire: Synthesis, electrical, and optoelectronic devices application. Nanoscale Res. Lett. 2014, 9, 637. [Google Scholar] [CrossRef] [PubMed]

- Barreca, D.; Comini, E.; Gasparotto, A.; Maccato, C.; Sada, C.; Sberveglieri, G.; Tondello, E. Chemical vapor deposition of copper oxide films and entangled quasi 1D nano architectures as innovative gas sensors. Sens. Actuators B 2009, 141, 270–275. [Google Scholar] [CrossRef]

- Ma, Y.; Jang, H.; Kim, S.J.; Pang, C.; Chae, H. Copper-Assisted direct growth of vertical graphene nanosheets on glass substrates by low-temperature plasma-enhanced chemical vapour deposition process. Nanoscale Res. Lett. 2015, 10, 308. [Google Scholar] [CrossRef] [PubMed]

- Ying, Z.; Lam, F.L.Y.; Xijun, H.; Zifeng, Y. Fabrication of copper nanorods by low-temperature metal organic chemical vapor deposition. Chin. Sci. Bull. 2006, 51, 2662–2668. [Google Scholar]

- Outokesh, M.; Hosseinpour, M.; Ahmadi, S.J.; Mousavand, T.; Sadjadi, S.; Soltanian, W. Hydro thermal Synthesis of CuO Nanoparticles: Study on effects of operational conditions on yield, purity, and size of the nanoparticles. Ind. Eng. Chem. Res. 2011, 50, 3540–3554. [Google Scholar] [CrossRef]

- Kayani, Z.N.; Umer, M.; Riaz, S.; Naseem, S. Characterization of Copper oxide nanoparticles fabricated by the Sol–Gel Method. J. Electron. Mater. 2015, 44, 3704–3709. [Google Scholar] [CrossRef]

- Saravanan, V.; Shankar, P.; Mani, G.K.; Rayappan, J.B.B. Growth and Characterization of spray pyrolysis deposited copper oxide thin films: Influence of substrate and annealing temp eratures. J. Anal. Appl. Pyrolysis 2015, 111, 272–277. [Google Scholar] [CrossRef]

- Ashok, A.; Kumar, A.; Bhosale, R.R.; Saleh, M.A.H.; van den Broeke, L.J.P. Cellulose assisted combustion synthesis of porous Cu–Ni nanopowders. RSC Adv. 2015, 5, 28703–28712. [Google Scholar] [CrossRef]

- Ramyadevi, J.; Jeyasubramanian, K.; Marikani, A.; Rajakumar, G.; Rahuman, A.A. Synthesis and antimicrobial activity of copper nanoparticles. Mater. Lett. 2012, 71, 114–116. [Google Scholar] [CrossRef]

- Misra, S.K.; Dybowska, A.; Berhanu, D.; Luoma, S.N.; Jones, E.V. The complexity of nanoparticle dissolution and its importance in nanotoxicological studies. Sci. Total Environ. 2012, 438, 225–232. [Google Scholar] [CrossRef] [PubMed]

- Nowacka, M.; Sikorska, A.M.; Chrzanowski, Ł.; Ambrożewicz, D.; Rozmanowski, T.; Myszka, K.; Czaczyk, K.; Bula, K.; Jesionowski, T. Electrokinetic and bioactive properties of CuO∙SiO2 oxide composites. Bioelectrochemistry 2012, 87, 50–57. [Google Scholar] [CrossRef] [PubMed]

- World Health Organization (WHO). Environmental Health Criteria; No. 200, Lead.-CH-1211; WHO: Geneva, Switzerland, 1998. [Google Scholar]

- Bladin, P.F. Azo dyes and the blood-brain barrier: Robert Aird’s novel concept in chronic neurological disease (1903–2000). J. Clin. Neurosci. 2014, 21, 33–39. [Google Scholar] [CrossRef] [PubMed]

- Mpousisa, S.; Thysiadisa, S.; Avramidis, N.; Katsamakas, S.; Efthimiopoulos, S.; Sarlia, V. Synthesis and evaluation of gallocyanine dyes as potential agents for the treatment of Alzheimer’s disease and related neurodegenerative tauopathies. Eur. J. Med. Chem. 2016, 108, 28–38. [Google Scholar] [CrossRef] [PubMed]

- Wahab, R.; Khan, F.; Aldahmash, B.A.; Al-Khedhairy, A.A. Statistical Analytical determination of Miniature Zinc Oxide Nanoclusters for Photodegradation of Methylene Red Dye. Nanosci. Nanotechnol. Lett. 2017, 9, 1–7. [Google Scholar] [CrossRef]

- Wahab, R.; Khan, F.; Lutfullah; Al-Khedhairy, A.A. Photocatalytic activity and statistical determination of ball-shaped zinc oxide NPs with methylene blue dye. Inorg. Nano-Met. Chem. 2017, 47, 536–542. [Google Scholar] [CrossRef]

- Wahab, R.; Khan, F.; Mishra, Y.K.; Musarrat, J.; Al-Khedhairy, A.A. Antibacterial studies and statistical design set dataof quasi zinc oxide nanostructures. RSC Adv. 2016, 6, 32328–32339. [Google Scholar] [CrossRef]

- Wahab, R.; Khan, F. Role of Nanostructures for Anti-proliferation of Bacteria and their Quantitative Study Validated by Statistical Analysis. J. Pharm. Innov. 2014, 9, 282–290. [Google Scholar] [CrossRef]

- Wahab, R.; Khan, F. Wet chemically synthesized catalytic nanorods for the deactivation of thymol blue and their statistical analytical applications. Ceram. Int. 2015, 41, 3722–3730. [Google Scholar] [CrossRef]

- Sanjini, N.S.; Winston, B.; Velmathi, S. Effect of Precursors on the Synthesis of CuO Nanoparticles Under Microwave for Photocatalytic Activity Towards Methylene Blue and Rhodamine B Dyes. J. Nanosci. Nanotechnol. 2017, 17, 495–501. [Google Scholar] [CrossRef]

- Xu, J.; Yuvaraja, G.; Zhang, W. Application of chitosan/poly(vinyl alcohol)/CuO (CS/PVA/CuO) beads as an adsorbent material for the removal of Pb(II) from aqueous environment. Colloids Surf. B Biointerfaces 2017, 149, 184–195. [Google Scholar]

- Raizada, A.; Ganguly, D.; Mankad, M.M.; Krishna, R.H.; Nagabhushana, B.M. A Highly Efficient Copper Oxide Nanopowder for Adsorption of Methylene Blue Dye from Aqueous Medium. J. Chem. Eng. Res. 2014, 2, 249–258. [Google Scholar]

- Shaibu, S.E.; Adekola, F.A.; Adegoke, H.I.; Ayanda, O.S. A Comparative Study of the Adsorption of Methylene Blue onto Synthesized Nanoscale Zero-Valent Iron-Bamboo and Manganese-Bamboo Composites. Materials 2014, 7, 4493–4507. [Google Scholar] [CrossRef] [PubMed]

- Gunasekar, V.; Ponnusami, V. Kinetics, Equilibrium, and Thermodynamic Studies on Adsorption of Methylene Blue by Carbonized Plant Leaf Powder. J. Chem. 2013, 2013, 415280. [Google Scholar] [CrossRef]

- Pandian, P.; Arivoli, S.; Marimuthu, V.; Regis, A.P.P. Kinetic, Thermodynamic and Isotherm Studies on the Removal of Methylene Blue Dye using Acid Activated Ipomoea carnea. Int.J. Revolut. Sci. Humanit. 2013, 2, 19–29. [Google Scholar]

- Hadia, M.; Samarghandia, M.R.; McKay, G. Equilibrium two-parameter isotherms of acid dyes sorption by activated carbons: Study of residual errors. Chem. Eng. J. 2010, 160, 408–416. [Google Scholar] [CrossRef]

- Hanna, O.T.; Sandall, O.C. Computational Methods in Chemical Engineering; Prentice-Hall International: Upper Saddle River, NJ, USA, 1995. [Google Scholar]

- Tsai, S.C.; Juang, K.W. Comparison of linear and non-linear forms of isotherm models for strontium sorption on a sodium bentonite. J. Radioanal. Nucl. Chem. 2000, 3, 741–746. [Google Scholar] [CrossRef]

- Kapoor, A.; Yang, R.T. Correlation of equilibrium adsorption data of condensable vapours on porous adsorbents. Gas Sep. Purif. 1989, 3, 187–192. [Google Scholar] [CrossRef]

- Ng, J.C.Y.; Cheung, W.H.; McKay, G. Equilibrium studies of the sorption of Cu(II) ions onto chitosan. J. Colloid Interface Sci. 2002, 255, 64–74. [Google Scholar] [CrossRef] [PubMed]

- Marquardt, D.W. Analgorithm for least-squares estimation of nonlinear parameters. J. Soc. Ind. Appl. Math. 1963, 11, 431–441. [Google Scholar] [CrossRef]

- Langmuir, I. The adsorption of gases on plane surfaces of glass, mica, and platinum. J. Am. Chem. Soc. 1918, 40, 1361–1403. [Google Scholar] [CrossRef]

- Freundlich, H.Z. Over the adsorption in solution. J. Phys. Chem. 1906, 57A, 385–397. [Google Scholar]

- Temkin, M.J.; Pyzhev, V. Kinetics of ammonia synthesis on promoted iron catalysts. Acta Physiochim. URSS 1940, 12, 217–222. [Google Scholar]

- Dubinin, M.M.; Radushkevich, L.V. The equation of the characteristic curve of activated charcoal. Doklady Akademii Nauk SSSR 1947, 55, 327–329. [Google Scholar]

- Harkins, W.D.; Jura, E.J. The decrease of free surface energy as a basis for the development of equations for adsorption isotherms; and the existence of two condensed phases in films on solids. J. Chem. Phys. 1944, 12, 112–113. [Google Scholar] [CrossRef]

- Halsey, G. Physical adsorption on nonuniformsurfaces. J. Chem. Phys. 1948, 16, 931–937. [Google Scholar] [CrossRef]

- Lagergren, S. About the theory of so-called adsorption of soluble substances. Handlingar 1898, 24, 1–39. [Google Scholar]

- Ho, Y.S.; Mckay, G. The kinetics of sorption of basic dyes from aqueous solution by sphagnum moss peat. Can. J. Chem. Eng. 1998, 76, 822–827. [Google Scholar] [CrossRef]

- Yakout, S.M.; Elsherif, E. Batch kinetics, isotherm and thermodynamic studies of adsorption of strontium from aqueous solutions onto low cost rice-straw based carbon. Carbon Sci. Techol. 2010, 1, 144–153. [Google Scholar]

- Weber, J.W.J.; Morris, J.C. Kinetics of Adsorption of Carbon from Solution. J. Sanit. Eng. Div. Am. Soc. Civ. Eng. 1963, 89, 31–60. [Google Scholar]

- Zhang, X.; Sun, S.; Lv, J.; Tang, L.; Kong, C.; Song, X.; Yang, Z. Nanoparticle-aggregated CuO nano ellipsoids for high-performance non-enzymatic glucose detection. J. Mater. Chem. A 2014, 2, 10073–10080. [Google Scholar] [CrossRef]

- Li, X.; Li, C.; Akihiro, Y.; Hao, X.; Zuo, Z.; Wang, Z.; Abudula, A.; Guan, G. Facile fabrication of CuO microcube@Fe–Co3O4nanosheet array as a high-performance electrocatalyst for the oxygen evolution reaction. J. Mater. Chem. A 2017, 5, 21740–21749. [Google Scholar] [CrossRef]

- Zaman, S.; Zainelabdin, A.; Amin, G.; Nour, O.; Willander, M. Efficient catalytic effect of CuO nano structures on the degradation of organic dyes. J. Phys. Chem. Solids 2012, 73, 1320–1325. [Google Scholar] [CrossRef]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Khan, F.; Wahab, R.; Hagar, M.; Alnoman, R.; Lutfullah; Rashid, M. Nanotransition Materials (NTMs): Photocatalysis, Validated High Effective Sorbent Models Study for Organic Dye Degradation and Precise Mathematical Data’s at Standardized Level. Nanomaterials 2018, 8, 134. https://doi.org/10.3390/nano8030134

Khan F, Wahab R, Hagar M, Alnoman R, Lutfullah, Rashid M. Nanotransition Materials (NTMs): Photocatalysis, Validated High Effective Sorbent Models Study for Organic Dye Degradation and Precise Mathematical Data’s at Standardized Level. Nanomaterials. 2018; 8(3):134. https://doi.org/10.3390/nano8030134

Chicago/Turabian StyleKhan, Farheen, Rizwan Wahab, Mohamed Hagar, Rua Alnoman, Lutfullah, and Mohd Rashid. 2018. "Nanotransition Materials (NTMs): Photocatalysis, Validated High Effective Sorbent Models Study for Organic Dye Degradation and Precise Mathematical Data’s at Standardized Level" Nanomaterials 8, no. 3: 134. https://doi.org/10.3390/nano8030134