Photo-Induced Doping in a Graphene Field-Effect Transistor with Inkjet-Printed Organic Semiconducting Molecules

Abstract

:1. Introduction

2. Materials and Methods

2.1. Graphene Growth and GFET Fabrication

2.2. Organic Semiconductors Ink Preparation

2.3. Ink-Jet Printing

2.4. Graphene FET Characterization

2.5. Photoresponse Measurements

3. Results and Discussion

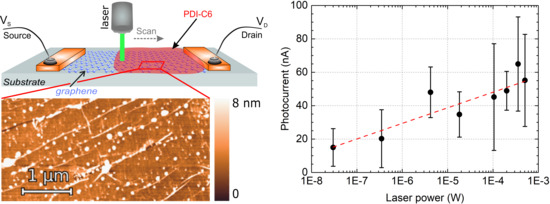

3.1. Inkjet Printing of Organic Molecules

3.1.1. Non-Covalent Functionalization of Graphene by an Array of Organic Molecules

3.1.2. Formation of a Heterojunction in GFET via Local Organic Molecular Printing

3.2. Photoresponse in Doped Graphene/Organic Nanostructures

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Gobbi, M.; Orgiu, E.; Samorì, P. When 2D materials meet molecules: Opportunities and challenges of hybrid organic/inorganic van der Waals heterostructures. Adv. Mater. 2018, 30, 1706103. [Google Scholar] [CrossRef] [Green Version]

- Xu, X.; Wang, C.; Liu, Y.; Wang, X.; Gong, N.; Zhu, Z.; Shi, B.; Ren, M.; Cai, W.; Rupp, R.A.; et al. A graphene P–N junction induced by single-gate control of dielectric structures. J. Mater. Chem. C 2019, 7, 8796–8802. [Google Scholar] [CrossRef]

- Tarasov, A.; Zhang, S.; Tsai, M.-Y.; Campbell, P.M.; Graham, S.; Barlow, S.; Marder, S.R.; Vogel, E.M. Controlled doping of large-area trilayer MoS2 with molecular reductants and oxidants. Adv. Mater. 2015, 27, 1175–1181. [Google Scholar] [CrossRef]

- Wei, P.; Liu, N.; Lee, H.R.; Adijanto, E.; Ci, L.; Naab, B.D.; Zhong, J.Q.; Park, J.; Chen, W.; Cui, Y.; et al. Tuning the Dirac point in CVD-grown graphene through solution processed n-type doping with 2-(2-methoxyphenyl)-1,3-dimethyl-2,3-dihydro-1H-benzoimidazole. Nano Lett. 2013, 13, 1890–1897. [Google Scholar] [CrossRef]

- Kim, S.; Zhao, P.; Aikawa, S.; Einarsson, E.; Chiashi, S.; Maruyama, S. Highly stable and tunable n-type graphene field-effect transistors with poly(vinyl alcohol) films. ACS Appl. Mater. Inter. 2015, 7, 9702–9708. [Google Scholar] [CrossRef]

- Yun, J.M.; Park, S.; Hwang, Y.H.; Lee, E.S.; Maiti, U.; Moon, H.; Kim, B.H.; Bae, B.S.; Kim, Y.H.; Kim, S.O. Complementary p-and n-Type polymer doping for ambient stable graphene inverter. ACS Nano 2013, 8, 650–656. [Google Scholar] [CrossRef]

- Huo, N.; Konstantatos, G. Recent progress and future prospects of 2D-based photodetectors. Adv. Mater. 2018, 30, 1801164. [Google Scholar] [CrossRef]

- Kim, J.B.; Li, J.; Choi, Y.; Whang, D.; Hwang, E.; Cho, J.H. Photosensitive graphene P–N junction transistors and ternary inverters. ACS Appl. Mater. Inter. 2018, 10, 12897–12903. [Google Scholar] [CrossRef]

- Würthner, F.; Saha-Möller, C.R.; Fimmel, B.; Ogi, S.; Leowanawat, P.; Schmidt, D. Perylene bisimide dye assemblies as archetype functional supramolecular materials. Chem. Rev. 2016, 116, 962–1052. [Google Scholar] [CrossRef]

- Marcia, M.; Hirsch, A.; Hauke, F. Perylene-based non-covalent functionalization of 2D materials. FlatChem 2017, 1, 89–103. [Google Scholar] [CrossRef] [Green Version]

- Ehli, C.; Oelsner, C.; Guldi, D.M.; Mateo-Alonso, A.; Prato, M.; Schmidt, C.; Backes, C.; Hauke, F.; Hirsch, A. Manipulating single-wall carbon nanotubes by chemical doping and charge transfer with perylene dyes. Nat. Chem. 2009, 1, 243. [Google Scholar] [CrossRef]

- Stergiou, A.; Tagmatarchis, N. Fluorene–perylene diimide arrays onto graphene sheets for photocatalysis. ACS Appl. Mater. Inter. 2016, 8, 21576–21584. [Google Scholar] [CrossRef]

- Yu, H.; Joo, P.; Lee, D.; Kim, B.S.; Oh, J.H. Photoinduced charge-carrier dynamics of phototransistors based on perylene diimide/reduced graphene oxide core/shell p–n junction nanowires. Adv. Opt. Mater. 2015, 3, 241–247. [Google Scholar] [CrossRef]

- Shin, D.H.; Choi, S.-H. Graphene-based semiconductor heterostructures for photodetectors. Micromachines 2018, 9, 350. [Google Scholar] [CrossRef] [Green Version]

- Sowade, E.; Ramon, E.; Mitra, K.Y.; Martínez-Domingo, C.; Pedró, M.; Pallarès, J.; Loffredo, F.; Viollani, F.; Gomes, H.L.; Teres, L.; et al. All-inkjet-printed thin-film transistors: Manufacturing process reliability by root cause analysis. Sci. Rep. 2016, 6, 33490. [Google Scholar] [CrossRef]

- Kwon, J.; Takeda, Y.; Fukuda, K.; Cho, K.; Tokito, S.; Jung, S. Three-dimensional, inkjet-printed organic transistors and integrated circuits with 100% yield, high uniformity, and long-term stability. ACS Nano 2016, 10, 10324–10330. [Google Scholar] [CrossRef]

- Kwon, Y.-J.; Park, Y.D.; Lee, W.H. Inkjet-printed organic transistors based on organic semiconductor/insulating polymer blends. Materials 2016, 9, 650. [Google Scholar] [CrossRef] [Green Version]

- Mitra, K.Y.; Alalawe, A.; Voigt, S.; Boeffel, C.; Baumann, R.R. Manufacturing of all inkjet-printed organic photovoltaic cell arrays and evaluating their suitability for flexible electronics. Micromachines 2018, 9, 642. [Google Scholar] [CrossRef] [Green Version]

- Grimaldi, I.A.; Barra, M.; Del Mauro, A.D.G.; Loffredo, F.; Cassinese, A.; Villani, F.; Minarini, C. Inkjet printed perylene diimide based OTFTs: Effect of the solvent mixture and the printing parameters on film morphology. Synth. Met. 2012, 161, 2618–2622. [Google Scholar] [CrossRef]

- Wang, J.; Dong, T.; Zhong, Z.; Zheng, H.; Xu, W.; Ying, L.; Wang, J.; Peng, J.; Cao, Y. Uniform inkjet-printed films with single solvent. Thin Solid Film. 2018, 667, 21–27. [Google Scholar] [CrossRef]

- Kireev, D.; Sarik, D.; Wu, T.; Xie, X.; Wolfrum, B.; Offenhausser, A. High throughput transfer technique: Save your graphene. Carbon 2016, 107, 319–324. [Google Scholar] [CrossRef]

- Liang, X.; Sperling, B.A.; Calizo, I.; Cheng, G.; Hacker, C.A.; Zhang, Q.; Obeng, Y.; Yan, K.; Peng, H.; Li, Q.; et al. Toward clean and crackless transfer of graphene. ACS Nano 2011, 5, 9144–9153. [Google Scholar] [CrossRef]

- Kireev, D.; Brambach, M.; Seyock, S.; Maybeck, V.; Fu, W.Y.; Wolfrum, B.; Offenhausser, A. Graphene transistors for interfacing with cells: Towards a deeper understanding of liquid gating and sensitivity. Sci. Rep. 2017, 7, 6658. [Google Scholar] [CrossRef]

- Kozhemyakina, N.V.; Englert, J.M.; Yang, G.; Spiecker, E.; Schmidt, C.D.; Hauke, F.; Hirsch, A. Non-covalent chemistry of graphene: Electronic communication with dendronized perylene bisimides. Adv. Mater. 2010, 22, 5483–5487. [Google Scholar] [CrossRef]

- Angelella, M.; Wang, C.; Tauber, M.J. Resonance Raman spectra of a perylene bis(dicarboximide) chromophore in ground and lowest triplet states. J. Phys. Chem. A 2013, 117, 9196–9204. [Google Scholar] [CrossRef]

- Liu, B.; Yang, C.-M.; Liu, Z.; Lai, C.-S. N-doped graphene with low intrinsic defect densities via a solid source doping technique. Nanomaterials 2017, 7, 302. [Google Scholar] [CrossRef] [Green Version]

- Kim, I.; Haverinen, H.M.; Li, J.; Jabbour, G.E. Enhancement of device performance of organic solar cells by an interfacial perylene derivative layer. ACS Appl. Mater. Inter. 2010, 2, 1390–1394. [Google Scholar] [CrossRef]

- Zhang, Z.; Huang, H.; Yang, X.; Zang, L. Tailoring electronic properties of graphene by π–π stacking with aromatic molecules. J. Phys. Chem. Lett. 2011, 2, 2897–2905. [Google Scholar] [CrossRef]

- Yang, H.; Hernandez, Y.; Schlierf, A.; Felten, A.; Eckmann, A.; Johal, S.; Louette, P.; Pireaux, J.-J.; Feng, X.; Mullen, K.; et al. A simple method for graphene production based on exfoliation of graphite in water using 1-pyrenesulfonic acid sodium salt. Carbon 2013, 53, 357–365. [Google Scholar] [CrossRef]

- Farmer, D.B.; Golizadeh-Mojarad, R.; Perebeinos, V.; Lin, Y.-M.; Tulevski, G.S.; Tsang, J.C.; Avouris, P. Chemical doping and electron-hole conduction asymmetry in graphene devices. Nano Lett. 2009, 9, 388–392. [Google Scholar] [CrossRef] [Green Version]

- Giubileo, F.; Di Bartolomeo, A. The role of contact resistance in graphene field-effect devices. Prog. Surf. Sci. 2017, 92, 143–175. [Google Scholar] [CrossRef] [Green Version]

- Xia, F.; Mueller, T.; Golizadeh-Mojarad, R.; Freitag, M.; Lin, Y.M.; Tsang, J.; Perebeinos, V.; Avouris, P. Photocurrent imaging and efficient photon detection in a graphene transistor. Nano Lett. 2009, 9, 1039–1044. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Luongo, G.; Grillo, A.; Giubileo, F.; Iemmo, L.; Lukosius, M.; Alvarado Chavarin, C.; Wenger, C.; Di Bartolomeo, A. Graphene Schottky Junction on Pillar Patterned Silicon Substrate. Nanomaterials 2019, 9, 659. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wang, S.; Sekine, Y.; Suzuki, S.; Maeda, F.; Hibino, H. Photocurrent generation of a single-gate graphene p–n junction fabricated by interfacial modification. Nanotechnology 2015, 26, 385203. [Google Scholar] [CrossRef]

- Gabor, N.M.; Song, J.C.; Ma, Q.; Nair, N.L.; Taychatanapat, T.; Watanabe, K.; Taniguchi, T.; Levitov, L.S.; Jarillo-Herrero, P. Hot carrier–assisted intrinsic photoresponse in graphene. Science 2011, 334, 648–652. [Google Scholar] [CrossRef] [Green Version]

- Fang, H.; Hu, W. Photogating in low dimensional photodetectors. Adv. Sci. 2017, 4, 1700323. [Google Scholar] [CrossRef]

- Jones, G.F.; Pinto, R.M.; De Sanctis, A.; Nagareddy, V.K.; Wright, C.D.; Alves, H.; Craciun, M.F.; Russo, S. Highly efficient rubrene–graphene charge-transfer interfaces as phototransistors in the visible regime. Adv. Mater. 2017, 29, 1702993. [Google Scholar] [CrossRef]

- De Sanctis, A.; Jones, G.F.; Wehenkel, D.J.; Bezares, F.; Koppens, F.H.; Craciun, M.F.; Russo, S. Extraordinary linear dynamic range in laser-defined functionalized graphene photodetectors. Sci. Adv. 2017, 3, e1602617. [Google Scholar] [CrossRef] [Green Version]

- Emelianov, A.V.; Kireev, D.; Offenhäusser, A.; Otero, N.; Romero, P.M.; Bobrinetskiy, I.I. Thermoelectrically driven photocurrent generation in femtosecond laser patterned graphene junctions. ACS Photonics 2018, 5, 3107–3115. [Google Scholar] [CrossRef]

- Lee, Y.; Yu, S.H.; Jeon, J.; Kim, H.; Lee, J.Y.; Kim, H.; Ahn, J.-H.; Hwang, E.; Cho, J.H. Hybrid structures of organic dye and graphene for ultrahigh gain photodetectors. Carbon 2015, 88, 165–172. [Google Scholar] [CrossRef]

- Kim, C.O.; Hwang, S.W.; Kim, S.; Shin, D.H.; Kang, S.S.; Kim, J.M.; Jang, C.W.; Kim, J.H.; Lee, K.W.; Choi, S.H.; et al. High-performance graphene-quantum-dot photodetectors. Sci. Rep. 2014, 4, 5603. [Google Scholar] [CrossRef] [Green Version]

- Tan, W.C.; Shih, W.H.; Chen, Y.F. A highly sensitive graphene-organic hybrid photodetector with a piezoelectric substrate. Adv. Funct. Mater. 2014, 24, 6818–6825. [Google Scholar] [CrossRef]

- Kim, J.M.; Kim, S.; Choi, S.H. High-performance nip-type perovskite photodetectors employing graphene-transparent conductive electrodes n-type doped with amine group molecules. ACS Sustain. Chem. Eng. 2018, 7, 734–739. [Google Scholar] [CrossRef]

- Freitag, M.; Low, T.; Xia, F.; Avouris, P. Photoconductivity of biased graphene. Nat. Photonics 2013, 7, 53. [Google Scholar] [CrossRef] [Green Version]

- Emelianov, A.V.; Kireev, D.; Levin, D.D.; Bobrinetskiy, I.I. The effect of ultraviolet light on structural properties of exfoliated and CVD graphene. Appl. Phys. Lett. 2016, 109, 173101. [Google Scholar] [CrossRef]

| Junction’s Material | Method | Min. Resolution, µm | Max. R (A·W−1) | Rev |

|---|---|---|---|---|

| FeCl3 | cw laser | 5 | 0.1·10−3 | [38] |

| Oxygen groups | fs laser | 1 | 0.1 | [39] |

| Organic dye (rhodamine 6G) | drop cast | - | 460 | [40] |

| Graphene quantum dots | drop cast | - | 1 | [41] |

| Lithium enriched SU-8 | Photolithography | 2 | 0.025 | [2] |

| Silane SAMs | e-beam lithography | 10 | 0.03 | [34] |

| P3HT:PCBM | Spin coating | - | ~0.05 | [42] |

| Perovskite | Spin coating | - | 0.343 | [43] |

| Rhodamine 6G | Photolithography | ~1 | - | [8] |

| PDI-C6 | Inkjet printing | 50 | 0.5 | This work |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nekrasov, N.; Kireev, D.; Omerović, N.; Emelianov, A.; Bobrinetskiy, I. Photo-Induced Doping in a Graphene Field-Effect Transistor with Inkjet-Printed Organic Semiconducting Molecules. Nanomaterials 2019, 9, 1753. https://doi.org/10.3390/nano9121753

Nekrasov N, Kireev D, Omerović N, Emelianov A, Bobrinetskiy I. Photo-Induced Doping in a Graphene Field-Effect Transistor with Inkjet-Printed Organic Semiconducting Molecules. Nanomaterials. 2019; 9(12):1753. https://doi.org/10.3390/nano9121753

Chicago/Turabian StyleNekrasov, Nikita, Dmitry Kireev, Nejra Omerović, Aleksei Emelianov, and Ivan Bobrinetskiy. 2019. "Photo-Induced Doping in a Graphene Field-Effect Transistor with Inkjet-Printed Organic Semiconducting Molecules" Nanomaterials 9, no. 12: 1753. https://doi.org/10.3390/nano9121753