3.1. Characterization of the Catalysts

The EDXRF spectra of (0.2% Pd; 1.1% Au)/SiO

2 and (1.1% Pd; 0.4% Au)/SiO

2 are presented in

Figure 1. The spectra show Au lines (Lα, Lβ, Lγ at 9.71, 11.44 and 13.38 keV, respectively), Pd lines (Lα and Lβ at 2.84 and 2.99 keV, respectively), as well as a Kα Si line at 1.74 keV. The results of the EDXRF and XPS analyses were compared with the actual values of the Au- and Pd-loading in

Table 1.

For lower Au concentrations both EDXRF or XPS provide similar results which are comparable with the designed values of the Au load (

Table 1, entry 1). In turn for the higher Au loads (

Table 1, entries 2–5) XPS always indicated higher Au content than EDXRF. This result can be explained if we realized that X-rays (EDXRF) have a much larger penetration range compared to XPS which focuses only on the surface area. Accordingly, EDXRF relates to the bulk proportion while XPS—to the surface ratio. The surface and bulk metal to SiO

2 ratios can take the same values only for the small amounts of the metal, when the surface portion of SiO

2 enveloped by the metal can be neglected. Otherwise, both ratios will take a different value. The higher the percentage of the metal the higher also is the surface fraction occupied by the metal and the higher the difference between the bulk and the surface concentrations and therefore between the XPS and EDXRF analyses. The comparison of the results for pure Au and its mixtures with Pd (

Table 1, entry 2 vs. entries 4 and 5) indicates that this effect is specific for each metal and/or bimetallic mixture. As the weight percentage corresponds to the bulk ratio, EDXRF correlates much better with the designed metal load. To additionally prove the above-mentioned hypothesis, we performed the Atomic Absorption Spectrometry (ASA) analyses of the 0.1% and 0.7% samples. The obtained results were 0.11 ± 0.0071 wt.% for 0.1% Au/SiO

2 and 0.695 ± 0.0495 wt.% for 0.7% Au/SiO

2, which compares very well with the EDXRF results. Interestingly, the only catalyst for which we obtained the same weight percentage of Au by the XPS and EDXRF analyses is the 0.1% Au/SiO

2 system. It is also this system where Au should remain well distributed, located in the large distances between individual Au clusters. Accordingly, this should also be an optimal catalyst structure.

The XRD results of the nanogold catalysts are presented in

Figure 2, which shows the X-ray diffraction patterns of the 0.7% Au/SiO

2, 0.1% Au/SiO

2, (1.1% Au; 0.4% Pd)/SiO

2, and (0.2% Pd; 1.1% Au)/SiO

2 catalysts in the range of the 2θ angle from 10 to 120 degrees. It clearly shows the diffraction lines that correspond to the pure face-centered cubic (Fm3m) phase of Au NPs (JCPDS 01-089-3697), while the considerably weaker lines of the cubic (Fm3m) phase of Pd NPs also overlaps the Au diffraction peaks. The broad peak at the low angle range is due to the silica. The Scherrer equation was used to calculate the average size of the crystalline particles. Their size was estimated from the highest intensity XRD peak (2θ

111~38.2° for Au and 2θ

111~39.1° for Pd NPs) and values from about 2 nm to about 10 nm were obtained. The lattice parameters (Å) of the investigated nanoparticles (calculated with the “Chekcell v.4” computer program) as well as the average crystallite dimensions (D) that were determined using the XRD method are listed in

Table 2. In particular, we could observe that the 0.1% Au/SiO

2 (

Table 2, entry 1) allows one to fully control the narrow range of Au NPs size at 7 nm. This complies with the previously discussed results of the EDXRF vs. XPS analyses.

The photoelectron spectra were used to derive the atomic and weight concentrations of the main elements and to obtain information about their chemical state, including potential formation about the PdAu alloy. In particular, the concentration of Au nanoparticles on SiO

2 carrier was found to be close to the values that were obtained from EDXRF (see

Table 1) only for the lowest Au content. Taking into account the much lower escape depth of photoelectrons (up to 3–4 nm) than those of fluorescent photons, it concluded that there was a uniform distribution of nanoparticles on the surface of the core particles. The higher the concentrations of Au that was supported on SiO

2 and also on C the higher the difference between the XPS and EDXRF values that were determined was. This might be related to the more complete coating of the silica/carbon carriers, which leads to a reduced XPS signal from the support. The same is true for the PdAu nanoparticles. The total weight concentration was higher when it was derived from the XPS spectra. The relative intensity of the Au and Pd photoemission lines permitted some conclusions to be drawn about the core–shell structure of the mixed nanoparticles. Both samples showed a similar Pd–Au weight ratio of about 1:2 and an atomic concentration close to 1:1. This may be connected to the formation of an ordered PdAu alloy mainly on the surface of the nanoparticles. The formation of such an alloy is well recognized [

16,

17].

A fitting of the Au 4f photoemission lines (

Figure 3) confirmed the formation of the Au chemical state with a relatively low binding energy of about 83.4 eV. A similar energy level was reported for alloyed PdAu nanoparticles [

17]. The analysis of the oxidation state of Pd is difficult because the most pronounced photoemission line—Pd 3d is overlapping with the stronger Au 4d one. Thus, we performed such analysis for the Pd 4p line which is relatively weak and their behavior in various chemical states is almost not present in the literature. However, we were able to fit the spectra and for both sample containing Pd we found at least two chemical states separated by a few eV. The low binding energy doublet can be assigned to PdAu alloy while the higher energy one to oxidized Pd, which is probably PdO but higher oxidation state cannot be excluded. The results of XRD (

Table 2) confirmed that the alloying as the lattice constant that was derived from the Pd diffraction lines was higher than for the pure Pd for both samples, thereby indicating the formation of an alloy.

In the (1.1% Pd; 0.4% Au)/SiO

2, the metallic nanoparticles that were distributed on the surface of SiO

2 particles were arranged individually or as conglomerates (

Figure 4a–c). The Au and Pd have the same structure (space group 227), a similar atomic radius, and their lattice parameters differed only slightly. Therefore, they created particles of solid solutions. The size of the particles had a lognormal distribution with the average particle dimensions of approximately 17 nm (

Figure 4d,e). In the 0.1% Au/SiO

2 catalyst, the gold nanoparticles were not heterogeneously distributed on the surface of the SiO

2 particles. The particles were smaller and their size distribution could also be described using a lognormal distribution with the average particle dimensions of approximately 7 nm (

Figure 4f).

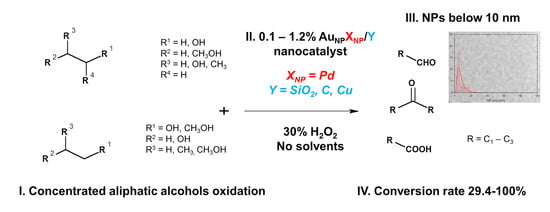

3.2. Design and Structure of the Catalysts

When considering the carrier for nanogold dispersions, SiO

2 and C were selected as the support for the samples of the model catalysts. The catalytic feasibility of SiO

2 or C as a nanogold support have already been investigated in some oxidation reactions [

18,

19]. For example, we can refer to the work of Kapkowski et al. [

18] on the efficiency of Au/SiO

2 catalysts in glycerol oxidation using H

2O

2/H

2O as a “clean” oxidant. Another good example might be the work of Carretin et al. [

19] on the superior catalytic properties of a 1% wt. Au/graphite catalyst in glycerol oxidation under mild reaction conditions (60 °C, 3 h, water as the solvent). Advantageously, the alcohol oxidation in the case of both of the studies that are cited proceeded under environmentally friendly conditions. However, the application of the reported catalytic systems was limited to certain types of alcohols. Here, in contrast to the literature examples, the studies on the catalytic feasibility of the resulting nano-dispersions were extended to a broader range of alcohols.

As to the different levels of Au-loading in the resulting samples, 0.1%, 0.7% and 1.2% wt. were the nominal values. The actual values of Au-loading as measured using EDXRF analysis were consistent with the nominal ones (

Table 1 vs.

Table S1). In an attempt to modify the catalytic properties by the formation of bimetallic active sites, a nano-Pd was selected as the second metal to enrich the active phase of the catalysts. It was assumed that synergistic interactions at the bimetallic active sites Au–Pd might lead to an increase in catalytic activity and stability in alcohol oxidation.

The TEM, SEM, XPS, and XRD analytical techniques were used to characterize the structure, dimensions and texture properties of the synthesized catalysts. The mean particle size of the nanometals in the active phase of the resulting catalysts was estimated by an XRD measurement (

Table 2). The results proved that the mean particle size and distribution of the particle size of the resulting Au nanodispersions varied depending on the level of metal loading (

Table 2, e.g., 0.1% Au/SiO

2 vs. 0.7% Au/SiO

2), the type of material of the support (

Table 2, e.g., 0.1% Au/SiO

2 vs. 0.2% Au/C), and the co-presence of a second metallic active phase (

Table 1, e.g., (1.1% Pd; 0.4% Au)/SiO

2 vs. (0.1% Pd; 1.1% Au)/SiO

2 vs. 0.7% Au/SiO

2). In all of the samples, the mean Au particle size did not exceed the critical value of 10 nm (Entries 1–5 in

Table 2), which is regarded as being crucial in terms of the catalytic activity of Au. According to the literature, supported Au nanoparticles less than 10 nm in size, especially those ca. 5 nm, are typically required for catalysis [

20]. It is worth noting that the resulting samples predominantly exhibited a narrow size distribution with the exception of samples 0.7% Au/SiO

2 and (0.2% Pd; 1.1% Au)/SiO

2 (Entries 2 and 6 in

Table 2). The observed deviation from the narrow size distribution might be ascribed to a partial sintering of the Au nanoparticles for the samples that had a high level of Au-loading on the SiO

2 support.

The model oxidation reactions of alcohols in the presence of the resulting catalysts (

Table 3 and

Table 4) were performed using aqueous hydrogen peroxide as the oxidant under solvent-free and base-free conditions in order to test the catalytic activity in a sustainable and environmentally benign system. When selecting the model alcohols, the criterion that the chemical reactivity of alcohols could be controlled by changing chemical structure was taken into account. Namely, a reactivity of aliphatic alcohols significantly increases in benzylic position [

21]. Therefore, representatives of unactivated alcohols, namely 1-propanol and 1,2-propanediol, were used as the model alcohols in order to examine the catalytic capability for substrates that are more resistant to oxidation. A comparative evaluation of the catalytic performance was carried out taking into account the values of turnover number, turnover frequency, reaction conversion, selectivity, and yield of the main products that were obtained (

Table 3 and

Table 4). These parameters varied depending on the catalyst forms. The results clearly proved that using the catalytic properties of 0.1% Au/SiO

2 to activate the conversion of the alcohols were considerably greater compared to the other catalysts (Entry 1 vs. entries 2–5 in

Table 3 and

Table 4). The catalytic system of 0.1% Au/SiO

2 afforded the highest conversion of ca. 77% and 100% for the oxidation of 1-propanol and 1,2-propanodiol, respectively (Entry 1 in

Table 3 and

Table 4). Compared to the blank sample and the pure unsupported carriers (used as blind samples), the selectivity of the investigated reaction obviously prefers the formation of the products of oxygenation more than a direct carbonyl product, e.g., formic acid or propionic acid in 1-propanol oxidation instead direct propanol (

Table 3 entries 1 vs. 6 and 7). In addition, among the catalysts that were tested, 0.1% Au/SiO

2 had notably higher values of the turnover number (TON) and turnover frequency (TOF) (Entry 1 vs. entries 2–5 in

Table 3 and

Table 4). The large discrepancy in the TON or TOF values between 0.1% Au/SiO

2 and the other catalysts confirmed that 0.1% Au/SiO

2 exhibited the highest catalytic efficiency among the samples that were analyzed. The selectivity of the 0.1% Au/SiO

2 system varied depending on the structure of the substrate. In particular, the catalytic oxidation of 1-proponol over 0.1% Au/SiO

2 into acetic acid afforded a moderate selectivity ca. 57% (Entry 1 in

Table 3), while the oxidation of 1,2-propanodiol in the presence of 0.1% Au/SiO

2 resulted in a high selectivity of acetic acid ca. 95% (Entry 1 in

Table 4).

The analysis of the data from

Table 2,

Table 3 and

Table 4 offered insight on how the structure of the catalysts might affect the catalytic performance. For instance, the results confirmed that the catalytic performance of the Au/SiO

2 system was strongly affected by the level of Au-loading. As was mentioned previously, the 0.1% Au/SiO

2 catalyst had the highest degree of conversions among the catalysts that were used (Entry 1 in

Table 3 and

Table 4). Surprisingly, however, increasing the level of Au loading from 0.1% to 0.7% wt. for the Au/SiO

2 system caused a dramatic decline in the degree of conversions (Entry 2 in

Table 3 and

Table 4). The oxidation over the 0.7% Au/SiO

2 catalyst resulted in poor conversions of ca. 5% and 7% for the reactions with 1-propanol and 1,2-propanodiol, respectively. Furthermore, an analysis of the data from

Table 2,

Table 3 and

Table 4 suggests that the catalytic activity of the Au dispersions may be sensitive to the particle size of the nano-Au as well as their size distribution. In this context, the particle size of nanometals for dispersions such as 0.7% Au/SiO

2 or (0.2% Pd; 1.1% Au)/SiO

2 (Entries 2 and 5 in

Table 2) appeared to be insufficient to facilitate alcohol conversions (Entries 2 and 5 in

Table 3 and

Table 4). A further analysis of the data from

Table 2 suggested that the particle size of the active phase might be affected by changes in the level of Au-loading. In this respect, a higher level of Au-loading could result in the partial sintering of the Au-particles, and subsequently could lead to a wide size distribution of the Au particles as was observed for the 0.7% Au/SiO

2 or (0.2% Pd; 1.1% Au)/SiO

2 (Entries 2 and 5 in

Table 2). This phenomenon might also contribute to the worsening of the catalytic performance of the resulting samples. It is worth mentioning that the 0.1% Au/SiO

2 catalyst appeared optimal, as expected from the EDXRF and XPS analyses. A possible reason for the deactivation of similar systems of AuPd alloys was ascribed by Hutchings et al. for the high Au-to-Pd ratio alloys which are especially sensitive to the high reaction temperature [

22]. The results that were obtained also confirmed that the catalytic performance of the catalysts might be affected by the type of support, i.e., replacing the SiO

2 support with a C support for the catalysts with a 0.2% wt. Au loading afforded higher conversion values and resulted in a moderate improvement of the catalytic efficiency (Entry 2 in

Table 3 and

Table 4 vs. Entry 3 in

Table 3 and

Table 4). In this context, better wettability of polar silica carrier by polar reagents can explain the difference between the SiO

2 vs. C carrier. Moreover, the results presented in

Table 3 and

Table 4 indicate that oxidation depends upon many factors. In particular, paradoxically the highest conversion is observed either for the 0.1% Au/SiO

2 or for the non-catalytic or SiO

2 catalyzed reaction. However, it is only the catalytic 0.1% Au/SiO

2 system where the conversion and selectivity are high enough, e.g., this can reach as much as ca. 95% AA for 1,2-propanediol (

Table 4, entry 1). The individual values for 1-propanol (

Table 3) or 1,2-propanediol (

Table 4) compares as follows: (0.1% Au/SiO

2 ca. 77%:

Table 3, entry 1; 100%:

Table 4, entry 1) vs. (none catalyst ca. 47%:

Table 3, entry 7; 90%:

Table 4, entry 7) vs. (none catalyst ca. 97%:

Table 3, entry 6; 85%:

Table 4, entry 6). To explain this effect, we should understand that the Au NPs catalyze not only the oxidation of alcohol but also the decomposition of H

2O

2. The latter effect is especially visible at higher temperatures. Therefore, an increasing temperature, from one side, enhances the reaction but, from the other side, enhances also the decomposition of the oxidant. In this context our previous experiments showed that 85 °C appeared more or less optimal for the process. In turn, in the non-catalytic or SiO

2 catalyzed systems the decomposition of H

2O

2 is much slower, therefore, the conversion at high temperature can be still high; however, the selectivity of the reaction is much lower and the reaction yields a variety of products. As the importance of the decomposition of H

2O

2 increases with the increase of the metal load, therefore, also the conversions are lower when Au load increases.

The studies also enabled an examination into whether the presence of bimetallic sites in the active phase of (1.1% Pd; 0.4% Au)/SiO

2 and (0.2% Pd; 1.1% Au)/SiO

2 enhanced the catalytic performance. However, the conjugation of Au and Pd appeared to be less important than was expected. Although this did not afford a significant improvement of the alcohol conversions (Entries 4 and 5 in

Table 3 and

Table 4), a synergistic effect could be observed for 1-propanol at (0.2% Pd; 1.1% Au)/SiO

2 where the selectivity of the acetic acid formation amounted to 100% compared to the other catalysts (Entry 4 vs. entries 1–3 and 5 in

Table 3). On the other hand, the selectivity of oxidation of 1-propanol to acetic acid at the (1.1%Pd; 0.4% Au)/SiO

2 catalyst was lower (ca. 20%), when the formation of other byproducts was promoted with the highest selectivity of ca. 79.9% compared to the other catalytic systems (Entry 5 vs. entries 1–4 in

Table 3). Another example of the synergic effect between Au and the Pd alloy is that the selectivity of the formation of acetone (ca. 50%) and 1-hydroxyacetone (ca. 50%) was enhanced while the oxidation of 1,2-propanediol at (1.1% Pd; 0.4% Au)/SiO

2 compared to the other catalytic systems (Entry 4 vs. entries 1–3 and 6 in

Table 4).

From the above comparative analyses, it can be concluded that 0.1% Au/SiO

2 had the most advantageous catalytic performance and appeared to be the most potent catalyst among the resulting samples. Therefore, 0.1% Au/SiO

2 was selected for further studies whose aim was to examine its catalytic utility in the oxidation of a broader spectrum of alcohols. In order to investigate the scope of alcohol oxidation with the 0.1% Au/SiO

2–H

2O

2 system, the studies were extended to various structurally different alcohols. The reactions were carried out under the same experimental conditions as was the case of the previous model reactions. The results of this part of the studies are summarized in

Table 5, which covers the main products of the oxidation of the alcohols. The formation of acetic acid was specifically monitored as this product could have been formed in all of the cases. The highest oxidation yields to acetic acid were observed for the dihydric alcohols, i.e., 1,2-propanediol of ca. 94.8% and 2,3-butanediol, ca. 57.6% (Entries 6 and 8 in

Table 5). For the oxidation of the monoalcohols, the highest acetic acid yields were observed for 1-propanol and 2-propanol at 43.4% and 51.7%, respectively (Entries 2 and 3 in

Table 5). The low nanogold content and good wettability of the carrier by polar reagents enabled the efficient use of hydrogen peroxide, thus promoting the formation of organic acids. It should also be remembered that the values of the conversion, selectivity, and yield of acetic acid and other products that were obtained varied from moderate to high depending on the alcohol substrate (Entries 1–6 in

Table 5). The results confirmed that under mild reaction conditions, the 0.1% Au/SiO

2–H

2O

2 system can effectively facilitate the catalytic oxidation of various nonactivated alcohols, including the most inactive primary aliphatic alcohols.

In

Figure 5 we illustrated the conversion and selectivity of oxidation as a function of the ratio of 1,2-propanediol to H

2O

2 for 0.1% Au/SiO

2. Milder oxidation conditions helped, to a limited extent, to avoid deep oxidative decomposition of the reactants to AA or FA acids. The possible reaction mechanism can involve two complementary routes (

Scheme 1). First one comprises the C–C bond cleavage in 1,2-propanediol yielding formaldehyde and acetaldehyde (ACDE), which are further oxidized to the corresponding acids (AA or FA). In turn, a second route involves (oxy)dehydrogenation to hydroxyacetone (HYNE) and acetone (ACNE). In the last stage of oxidation, the latter two C

3 products are oxidized to acetic acid (AA) and formic acid (FA). For the concentration of propylene glycol to H

2O

2/H

2O of 1:1, 1:3, and 1:5 we observed a high fraction of C

3 products (HYNE and ACNE), respectively. The increasing concentration of oxidant (10, 15, and 20 moles) enhanced the oxidative degradation of this reactants. For the concentration of 1:20 AA was the only product in the reaction mixture, because FA was oxidized to CO

2. Nanogold has been extensively studied as a catalyst for glycerol, propane-1,2-diol, n-alkyl alcohol oxidation in the presence of Brönsted bases or base free conditions using oxygen and peroxides as oxidants [

23,

24,

25]. The Au/SiO

2 system appeared also an efficient catalyst in oxidation of cyclohexene or D-glucose [

26]. Della Pina et al. described oxidation of 1,2-propanediol at 0.5% Au/TiO

2 and 1.0% AuPd/TiO

2 with O

2 to lactate with acetate and formate as byproducts (conversion up to 95%). Also, benzyl alcohol can be oxidized by H

2O

2 in the presence of Au nanoparticles (1 nm) deposited at SBA-15 silica carrier with 96% conversion which yielded benzylic acid as a main product [

23]. Dimitratos et al. obtained benzylic acid at the Au/SBA-15 catalyst suspended in the water/K

2CO

3 system with 96% conversion degree and 87% selectivity. In turn, the Au/C system used in catalytic oxidation of glycerol, propylene or ethylene glycol in water/sodium hydroxide yielded acidic products [

24,

25]. These were also the main products of our reactions (

Table 5). Moreover, the conversion and selectivity to AA could be high (

Figure 5). Although the oxidation of C

3 alcohols to AA may seem unattractive, AA is an important reagent and intermediate and solvent from the industrial point of view.

The search for an efficient, versatile, and green system for the oxidation of alcohols remains a significant challenge [

27]. In view of presented results, the 0.1% Au/SiO

2 catalyst seems to have prospects for wide applications for alcohol oxidation, and notably, SiO

2 appears to be a promising support material for nanogold particles. This is an intriguing finding taking into account the recent trends in the investigation for an optimal material for nano-Au support, which is one use of reducible metal oxides, usually Fe

3O

4, ZnO, CeO

2, and TiO

2 [

28]. In fact, the interactions between the active phase and active support (e.g., Au–TiO

2, Au–Fe

3O

4) via the formation of oxygen vacancies in reducible metal oxides are recognized as being one of the most effective ways to enhance the catalytic properties [

29]. By contrast, SiO

2 is a representative of the non-reducible metal oxides, which are regarded as being relatively inert materials for nano-Au support [

30]. In contrast to Au/TiO

2, which has been discussed in the most detail, Au/SiO

2 has been minimally studied primarily due to the low activity of SiO

2 and the difficulties in preparing catalysts [

30,

31]. The typical deposition method of Au on SiO

2 might pose a problem due to the low point of the zero charge of SiO

2 [

31]; however; we have previously showed the performance of such catalysts [

15]. The utility of SiO

2 as a support for Au can be beneficial from the practical point of view and seems to provide some advantages over the reducible metal oxides. First of all, SiO

2 has a greatly developed specific surface area that has a high porosity, which, in turn, can favor good dispersions of Au nanoparticles [

32]. By contrast, TiO

2 features a low surface area, especially after calcination, and requires further modifications to facilitate Au dispersion [

33]. Most importantly, the results of our study have proven that the deposition of Au on SiO

2 with a level of Au loading as low as 0.1% wt. led to an efficient catalytic system for the oxidation of a broad spectrum of alcohols under mild reaction conditions. To the best of our knowledge, this result is being reported for the first time. Of course, the pioneering studies of Cao’s group [

34] provided proof that 1% wt. Au/TiO

2–H

2O

2 was a highly effective system in Cao et al.’s [

34] procedure; however; this means that the Au loading was ten times higher than the level of Au that was needed in the Au/SiO

2–H

2O

2 system that is reported here. The additional advantage of SiO

2 as the material for Au support is its relatively low price and higher chemical stability [

35] compared to other materials such as TiO

2. As to its catalytic stability, the commercially available Au/TiO

2 tends to deteriorate during storage as it is both light- and moisture-sensitive [

36]. The study of Sárkány on acetylene hydrogenation [

37] demonstrated that the deactivation of Au/TiO

2 proceeded faster than in the case Au/SiO

2. In the studies of Masoud et al. on the selective hydrogenation of butadiene [

38], the Au/SiO

2 catalysts clearly outperformed the Au/TiO

2 catalysts after a certain time-on-stream. In addition, SiO

2 is generally recognized as being safe by the FDA [

39,

40], whereas TiO

2 exhibits some level of toxicity [

41]. This is an important advantage of using Au/SiO

2 as a catalyst, especially in the case alcohol oxidation for pharmaceutical syntheses.

As the fine chemical industry moves toward green and sustainable chemistry, the proposed 0.1% Au/SiO2–H2O2 system could be a prospective approach towards the development of an efficient catalytic nanogold platform for the oxidation of a broad spectrum of alcohols.