Recovery of Rare Earth Elements by Carbon-Based Nanomaterials—A Review

Abstract

:1. Introduction

2. Waste of Electrical and Electronic Equipment

3. Technology-Critical Elements

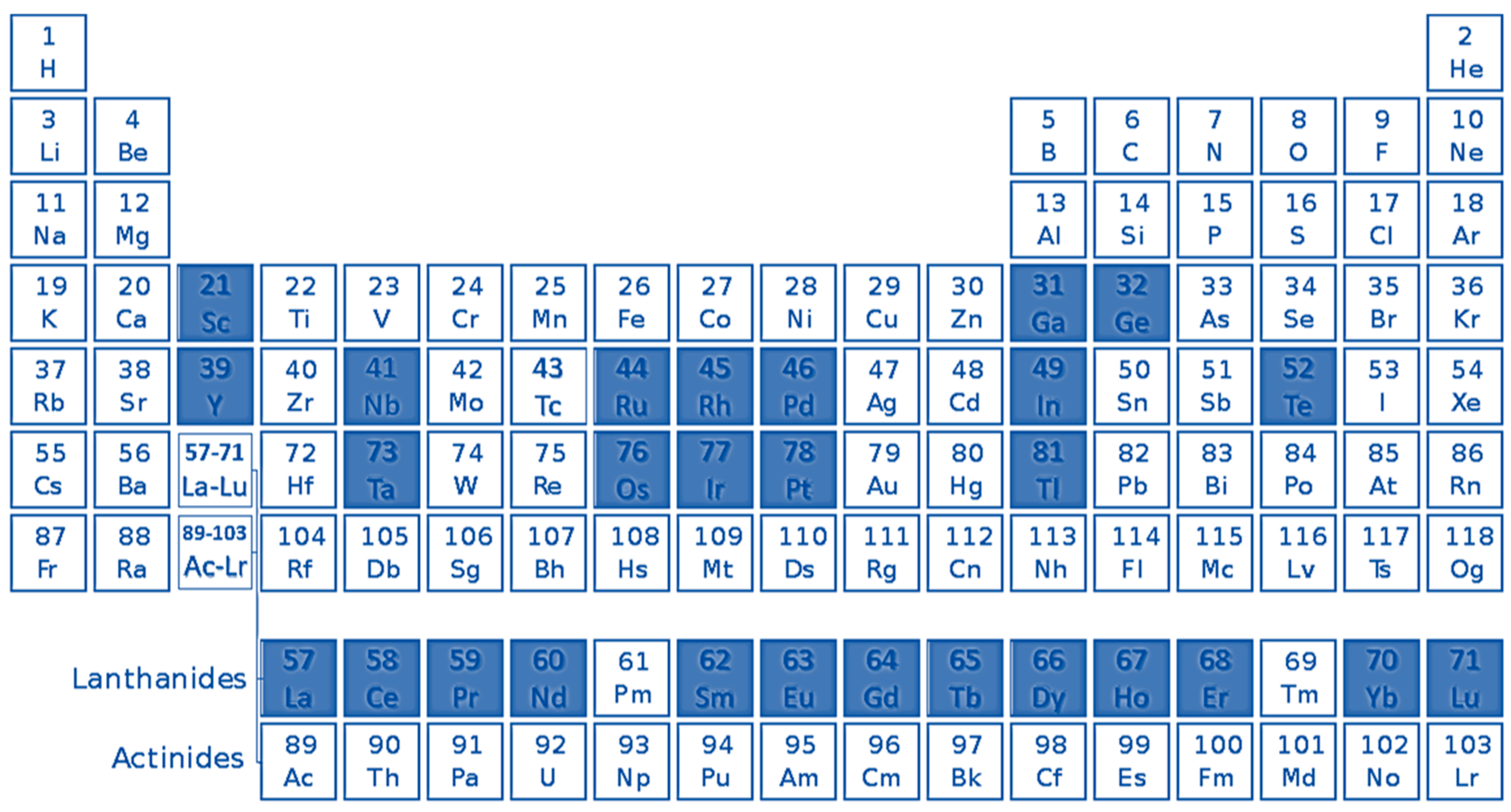

3.1. Rare-Earth Elements: Properties and Applications

3.2. Industrial Applications of Rare Earth Elements

- Magnets: Many REEs have important magnetic applications, such is the case of Neodymium-Iron-Boron magnets, which also contain Pr, Dy, and Sm ions. The main applications for permanent magnets are industrial motors, hard-disc drives, hybrid and electric vehicles, and wind turbines.

- Batteries: Nickel metal hydride batteries (NiMH) are excellent for portable electronics, containing mainly La and Ce ions. NiMH batteries have also been extensively used in hybrid and electric vehicles; however, its dependence is decreasing with the growing and development of more efficient Li-ion batteries.

- Metallurgy: Light rare earth are used to improve the mechanical characteristics of alloyed steel, for desulfurization, to bind trace elements in stainless steel and in magnesium and aluminum alloys.

- Catalysts: REEs have an important role in catalysis, for example, La used in fluid catalytic cracking (FCC) in oil refineries—which increases oil refinery yields by up to 7%—, and Ce in catalytic converters for cars.

- Polishing powder and glass additives: Cerium oxide is widely used as a polishing agent and as an additive in the production of glass, in the discoloration and removal of impurities.

- Phosphors: End-of-life fluorescent lamps are a rich source of heavy rare earth elements (HREEs), such as Eu, Tb and Y. HREEs are important constituents of tri-phase phosphor lighting used for linear fluorescent lamp tubes and compact fluorescent lamps, as well as LCD backlights for flat panel displays.

3.3. Evidence of Anthropogenic Rare Earth in Aquatic Systems

4. Recovery of Rare Earth from E-Waste

4.1. Recycling and Barriers to End-of-Life Recycling

4.2. Steps of e-Waste Treatment

4.3. Overview of Recovery Methodologies to Aqueous Systems

4.3.1. Preconcentration Methods—Solid-Phase Extraction

4.3.2. Sorption a Promising Process to Recover Rare Earth Elements

- pH of the batch, because it will affect the metal ions and the sorbent; the surface charge of the sorbents depends on the acidity of the surrounding electrolyte; since the sorption of REEs occur mainly by electrostatic forces, the surface charge of the sorbents needs to be negative;

- Temperature, because inadequate temperatures can decrease the efficiency of the sorption process;

- Dose of sorbent, since theoretically recovery rate increases with the dose;

- REE initial concentration because, for the same dose of sorbent, higher values of concentration, lead to lower sorption rates;

- Stirring speed, which controls the dispersion of particles and the mass transfer rate.

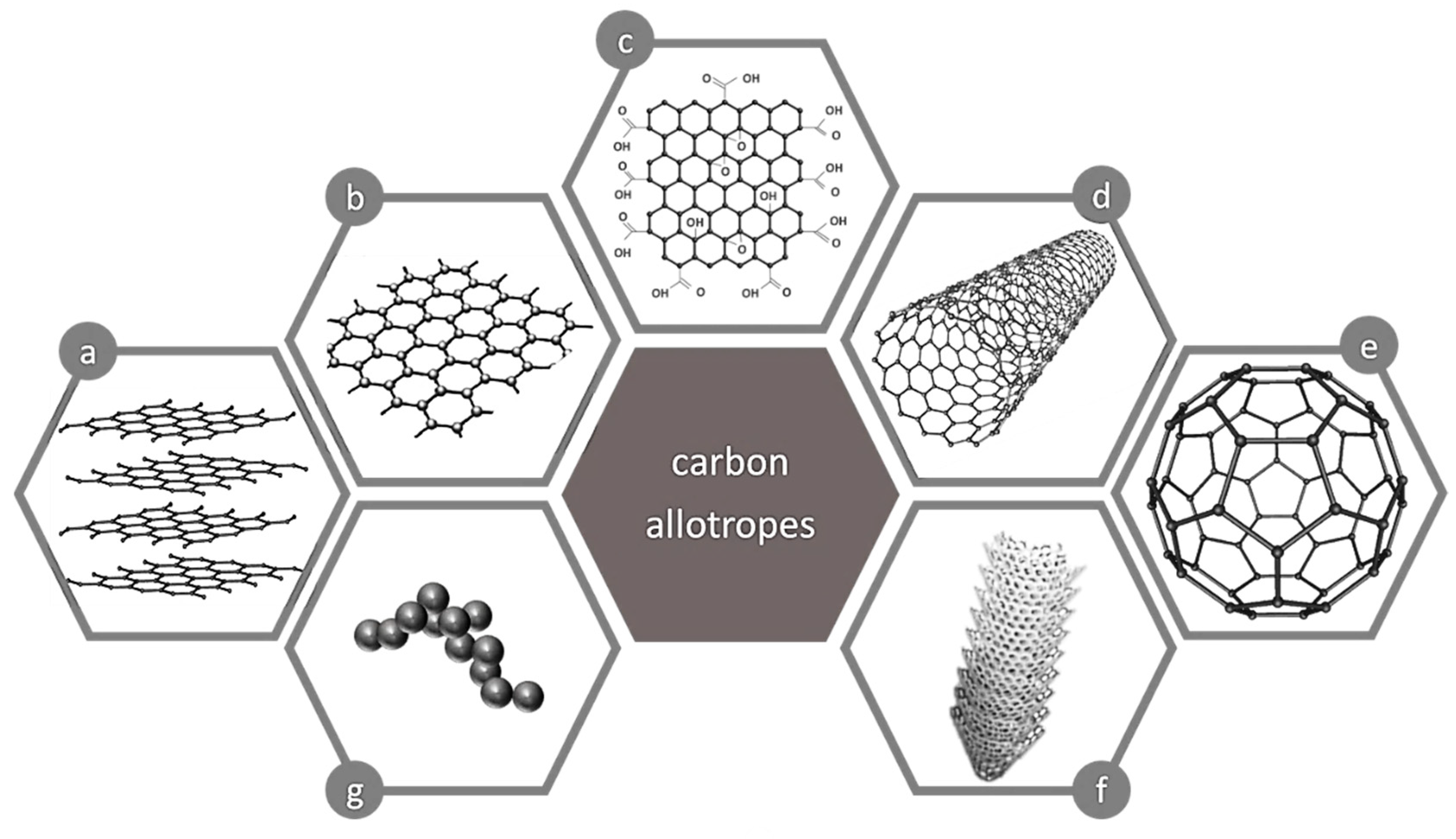

4.3.3. Carbon-Based Nanomaterials Applied in Solid Phase Extraction

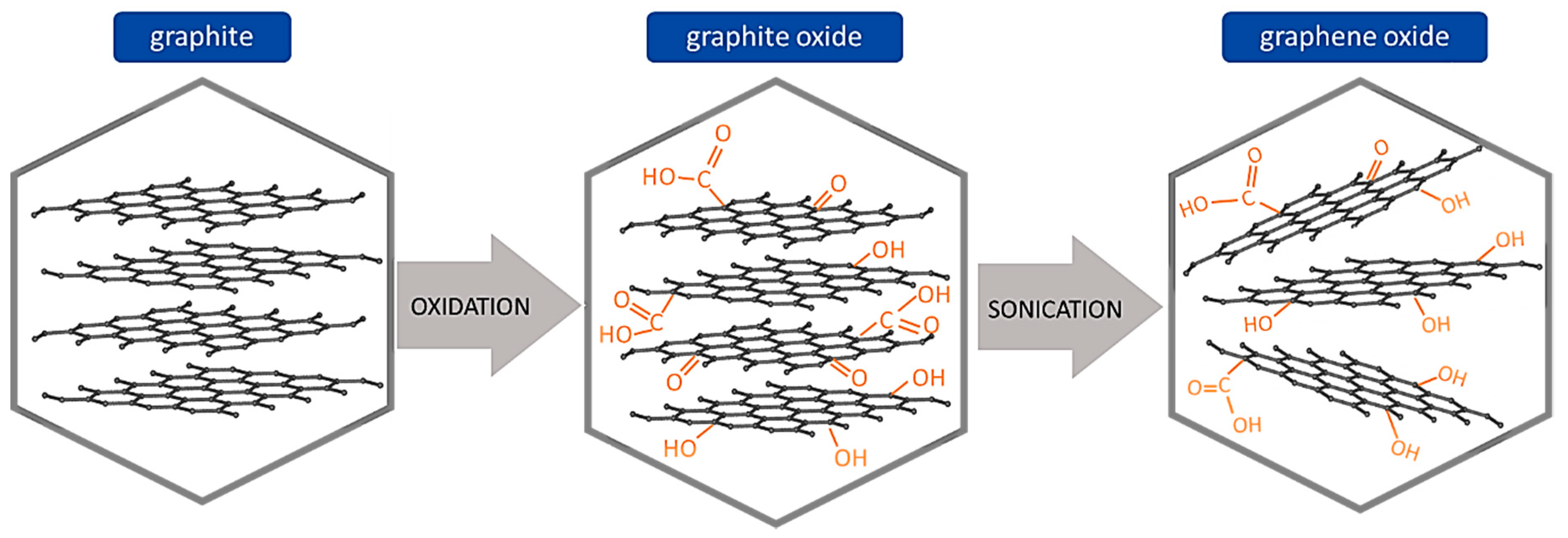

A. Graphene and Graphene Oxide

| Ref., Year | Sorbent | Type of Water | Type of System | REEs (III) | [REEs]0 (µg/L) | pH | T (°C) | Time of Contact (h) | m(Sorbent)/ V(Solution) (mg/L) | qm (mg/g) or REEs Adsorption (%) |

|---|---|---|---|---|---|---|---|---|---|---|

| [94], 2017 | GO colloid | Ultrapure | Multi elements | La, Nd, Gd, Y | 5 × 103 | 6 | r.t. | 0.5 | 10 × 102 | La = 85.7 mg/g Nd = 189 mg/g Gd = 226 mg/g Y = 136 mg/g |

| [95], 2017 | GO colloid | Ultrapure | Multi elements | La, Nd, Gd, Y | (5–50) 103 | 3-8 | 5–45 | 0.02–2 | 10 × 102 | |

| [91], 2015 | GO | Ultrapure | Mono element | Eu | 10 × 103 NaClO4 = 0.01 mol/L | 4.5, 7 | 20 | 0–24 | 10 × 102 | 90%, 89.7 mg/g |

| [92], 2015 | MGO | Ultrapure | Mono element | Eu | 10 × 103 NaClO4 = 0.01 mol/L | 4.5, 7 | 20 | 0–24 | 10 × 102 | 80%, 70.2 mg/g |

| [92], 2015 | GO e MGO | Ultrapure | Mono element | Eu | (1–50) ×103 | 2–11 | 20, 40, 60 | 0–24 | 10 × 102 | |

| [101], 2012 | GONS | Ultrapure | Mono element | Eu (1) | 51 × 103 NaClO4 = 0.01 mol/L | 2 4.5 6 7 | 25 | 48 | 2 × 102 | 65%, 167.16 mg/g 161.29 mg/g 175.44 mg/g 100% |

| [101], 2012 | GONS | Ultrapure | Mono element | Eu | 51 × 103 NaClO4 = 0.01 mol/L | 2–11 | 25, 45, 65 | 48 | 2 × 102 | |

| [100], 2016 | GO | Ultrapure | Mono element | Eu | 10 × 103 NaCl = 0.1, 0.01, 0.001 mol/L | 5.5 | 20 | 0–24 | 5 × 102 | 100%, 143 mg/g |

| [100], 2016 | GO-OSO3H | Ultrapure | Mono element | Eu | 10 × 103 NaCl = 0.1, 0.01, 0.001 mol/L | 5.5 | 20 | 0–24 | 5 × 102 | 90%, 125 mg/g |

| [100], 2016 | GO e GO-OSO3H | Ultrapure | Mono element | Eu | 10 × 103 NaCl = 0.1, 0.01, 0.001 mol/L | 1–11 | 20 | 0–24 | 5 × 102 | |

| [92], 2014 | GO colloid | Ultrapure | Mono element | Gd | 12 × 103 | 5.9 (2–11) | 30 | 0.5 | 0.4 × 102 | 287 mg/g |

| [93], 2014 | GO colloid | Ultrapure | Mono element | Y | 12 × 103 | 5.9 | 30, 40 | 0.42 | 0.4 × 102 | 190 mg/g |

| [99], 2016 | GO | Ultrapure | Mono element | Eu | 0.01 × 103 NaCl = 0.01M | 5.0, 2.7–7.3 | r.t. | 48 | 1 × 102 | 78.0 mg/g, 97% |

| [99], 2016 | GO | Ultrapure | Mono element | Eu | (0.01–100) × 103 | 1–8 2,4,6 | r.t. | 48 | 1 × 102 | |

| [98], 2017 | GO | Ultrapure | Mono element | Sc | 300 × 103 | 2 4 | r.t. | 4 | 50 × 102 | ~ 95%, 36.5 mg/g 39.7 mg/g |

| [98], 2017 | GO | Ultrapure | Mono element | Sc | (1–300) × 103 | 1–5.5 | r.t. | 0.02–0.5 | 50 × 102 | |

| [96], 2017 | 30%Mo4W8@EDMG, 30%Mo2W10@EDMG | Ultrapure | Mono element | Ce | 10 × 103 | 6 (2–6) | 20 | 0.08–3 | 17 × 102 | 90.9 mg/g, 96.2 mg/g |

| [95], 2014 | MPANI-GO | Ultrapure | Multi elements | Y, La, Ce, Pr, Nd, Sm, Eu, Gd, Tb, Dy, Ho, Er, Tm, Yb, Lu | 0.01 × 103 | 4 | r.t. | 0.33 | 4 × 102 | Y = 8.10, La = 15.5, Ce = 8.60, Pr = 11.1, Nd = 8.50, Sm = 7.70, Eu = 11.0, Gd = 16.3, Tb = 11.8, Dy = 16.0, Ho = 8.10, Er = 15.2, Tm = 10.4, Yb = 10.3, Lu = 14.9 mg/g |

| [96], 2014 | MPANI-GO | Ultrapure | Multi elements | Y, La, Ce, Pr, Nd, Sm, Eu, Gd, Tb, Dy, Ho, Er, Tm, Yb, Lu | (0.00025, 0.0005, 0.001, 0.002, 0.01) × 103 | 2–9 | r.t. | 0.02–0.25, 0.33 | (0.25–20) × 102 | |

| [90], 2013 | PANI@GO | HClO4 (aq) 0.01 mol/L | Mono element | Eu | 15 × 103 | 3 | 25 | 48 | 2.5 × 102 | 251 mg/g |

| [97], 2017 | TGA/CdTeQDs/Fe3O4/rGONS | Distilled | Mono element | Ce | 0.05 × 103 (1–100) × 103 | 5.0 | 35 | 0.17 | 7 × 102 | 95% 56.8 mg/g |

| [102], 2017 | TGA/CdTeQDs/Fe3O4/rGONS | Distilled | Mono element | Ce | (1–100) × 103 | 2-8 | 35 | 0.02–0.25 | (2–9) × 102 | |

| [102], 2014 | GTiP-1 | Ultrapure | Mono element | Eu | 100 × 103 | 1 3.7 5.5 7.3 | 25 | 2 | 10 × 102 | ~ 3.0% ~ 32% 35% ~ 72% |

| [103], 2014 | GTiP-2 | Ultrapure | Mono element | Eu | 100 × 103 | 1 3.7 5.5 7.3 | 25 | 2 | 10 × 102 | ~ 10% ~ 45% 50% ~ 80% |

| [103], 2014 | GO | Ultrapure | Mono element | Eu | 100 × 103 | 1 3.7 5.5 7.3 | 25 | 2 | 10 × 102 | ~ 7.0% ~ 20% 20% ~ 28% |

| [103], 2014 | GO, GTiP-1, GTiP-2 | Ultrapure | Mono element | Eu | (5–200) × 103 Na+ = 1, 10, 100, 1000 mM | 1.7, 3.7, 5.5, 7.3 | 25 | 2, 4 | 10,000 × 102 |

B. Carbon Nanotubes

| Ref., Year | Sorbent | Type of Water | Type of System | REEs (III) | [REEs]0 (µg/L) | pH | T (°C) | Time of Contact (h) | m (sorbent)/ V(solution) (mg/L) | qm (mg/g) or REEs Adsorption (%) |

|---|---|---|---|---|---|---|---|---|---|---|

| [98], 2017 | CNTs-COOH | Ultrapure | Mono element | Sc | 300 × 103 | 2 4 | r.t. | 4 | 50 × 102 | 37.9 mg/g 42.5 mg/g |

| [98], 2017 | CNTs-COOH | Ultrapure | Mono element | Sc | (1–300) × 103 | 1–5.5 | r.t. | 0.02–0.5 | 50 × 102 | - |

| [106], 2013 | MWCNTs-oxidized | Distilled | Multi elements | Ce | 20 × 103 20 × 103 10 × 103 | 5 | 30 | 2 | 12 × 102 10 × 102 10 × 102 | ~ 87% ~ 82% ~ 97% |

| [107], 2013 | MWCNTs-oxidized | Distilled | Multi elements | Sm | 20 × 103 20 × 103 10 × 103 | 5 | 30 | 2 | 12 × 102 10 × 102 10 × 102 | ~ 98% ~ 95% ~ 100% |

| [107], 2013 | MWCNTs-oxidized | Distilled | Multi elements | Ce, Sm | (10, 20, 50, 75, 100, 150, 200) × 103 | 2–8 | 30, 40, 50, 60 | 0.08, 0.17, 0.25, 0.33, 0.5, 0.67, 0.83, 1, 1.25, 1.5, 2 | (2, 4, 6, 8, 10, 12) × 102 | - |

| [107], 2014 | MWCNTs-oxidized | Distilled | Multi elements | La | 20 × 103 20 × 103 10 × 103 | 5 | 30 | 2 | 12 × 102 10 × 102 10 × 102 | 80% 80% 93% |

| [108], 2014 | MWCNTs-oxidized | Distilled | Multi elements | Dy | 20 × 103 20 × 103 10 × 103 | 5 | 30 | 2 | 12 × 102 10 × 102 10 × 102 | 98% 97% 98% |

| [108], 2014 | MWCNTs-oxidized | Distilled | Multi elements | La, Dy | (10–200) × 103 | 2–6 | 30, 40, 50, 60 | 0.08, 0.17, 0.25, 0.33, 0.5, 0.67, 0.83, 1, 1.25, 1.5, 2 | (2–12) ×102 | |

| [112], 2011 | TA-MWCNTs | Distilled | Multi elements | La Tb Lu | 40 × 103 | 5 | 20 | 1 | 50 × 102 | 5.35 mg/g, 8.55 mg/g, 3.97 mg/g |

| [113], 2011 | TA-MWCNTs | Distilled | Mono element | La | 40 × 103 | 5 | 20 | 1 | 50 × 102 (with 0.12 × 102 being TA) | 75% |

| [113], 2011 | TA-MWCNTs | Distilled | Multi elements | (La, Tb, Lu) | 40 × 103 | 1.5–4 | 20 | 1 | 50 × 102 | 0.4–6.0 mg/g |

| [113], 2011 | TA-MWCNTs | Distilled | Multi elements | (La, Tb, Lu) | (5–50) × 103 | 1.5–7 | 20 | 0.08–2 | (20–200) × 102 | - |

| [110], 2009 | MWCNTs-oxidized | Milli-Q | Mono element | Eu | 0.99 × 103 | 5 (2–8) | 25 | 96 | 6 × 102 | 90.0% |

| [109], 2009 | MWCNTs/Fe3O4 composite | Milli-Q | Mono element | Eu a | 0.061 × 103 NaClO4 = 0.1 mol/L | 5.5 | 25 | 48 | 6 × 102 | ~ 100% |

| [110], 2009 | MWCNTs/Fe3O4 composite | Milli-Q | Mono element | Eu a | 0.61 × 103, 6.1 × 103 | 2.5–7 | 25 | 48 | 6 × 102 | - |

| [105], 2015 | PES/PVA/MWCNT/ D2EHPA beads | HCl (aq, 0.5 mol/L) | Mono element | Y | 1000 × 103 | – | 30 | 8 | 1000 × 102 | 95% |

| [106], 2015 | Y | (80–3300) × 103 | – | 30–65 | 0–8 | 1000 × 102 | 44.1 mg/g | |||

| [106], 2015 | Multi elements | Y Sm La | 100 × 103 | – | 30 | 4 | 1000 × 102 | 94% 82% 30% | ||

| [106], 2015 | PES/PVA/MWCNT/ D2EHPA beads | HCl (aq, 0.5 mol/L) | Multi elements | Y, Sm, La | (150–1000) × 103 | – | 30 | 0–8 | 1000 × 102 | - |

| [111], 2008 | MWCNTs-oxidized | Distilled | Mono element | Eu | 0.03 × 103 NaClO4 = 0.001, 0.01, 0.1 mol/L | 6 (2–7) | 25 | 48 | 6 × 102 | 98% for all the ionic strengths |

| [108], 2015 | mIIP-CS/CNT composite | Distilled | Multi elements | Gd b | 10 × 103 | 7 | 20 33 43 | 4 | 20 × 102 c | 79.5 mg/g 109 mg/g 122 mg/g |

| [109], 2015 | mNIP-CS/CNT composite | Distilled | Multi elements | Gd b | 10 × 103 | 7 | 33 | 4 | 20 × 102 c | 96.2 mg/g |

| [109], 2015 | mIIP-CS/CNT and mNIP-CS/CNT composites | Distilled | Multi elements | Gd b | (2, 10, 50, 100, 200) × 103 | 2–7 | 20, 33, 43 | 0.05–8 | 20 × 102 c | - |

C. Other Carbon Materials

5. Conclusions Remarks and Perspectives

Funding

Conflicts of Interest

References

- Cobelo-García, A.; Filella, M.; Croot, P.; Frazzoli, C.; Du Laing, G.; Ospina-Alvarez, N.; Rauch, S.; Salaun, P.; Schäfer, J.; Zimmermann, S. COST action TD1407: Network on technology-critical elements (NOTICE)—from environmental processes to human health threats. Environ. Sci. Pollut. Res. 2015, 22, 15188–15194. [Google Scholar] [CrossRef] [PubMed]

- Environmental Law Alliance Worldwide Overview of Mining and its Impacts. In Guidebook for Evaluating Mining Project EIAs; Environmental Law Alliance Worldwide: Eugene, OR, USA, 2014; pp. 3–18.

- Rim, K.T.; Koo, K.H.; Park, J.S. Toxicological Evaluations of Rare Earths and Their Health Impacts to Workers: A Literature Review. Saf. Health Work 2013, 4, 12–26. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Rim, K.-T. Effects of rare earth elements on the environment and human health: A literature review. Toxicol. Environ. Health Sci. 2016, 8, 189–200. [Google Scholar] [CrossRef]

- Yang, L.; Wang, X.; Nie, H.; Shao, L.; Wang, G.; Liu, Y. Residual levels of rare earth elements in freshwater and marine fish and their health risk assessment from Shandong, China. Mar. Pollut. Bull. 2016, 107, 393–397. [Google Scholar] [CrossRef] [PubMed]

- Pagano, G.; Aliberti, F.; Guida, M.; Oral, R.; Siciliano, A.; Trifuoggi, M.; Tommasi, F. Rare earth elements in human and animal health: State of art and research priorities. Environ. Res. 2015, 142, 215–220. [Google Scholar] [CrossRef]

- Gonzalez, V.; Vignati, D.A.L.; Leyval, C.; Giamberini, L. Environmental fate and ecotoxicity of lanthanides: Are they a uniform group beyond chemistry? Environ. Int. 2014, 71, 148–157. [Google Scholar] [CrossRef]

- Meryem, B.; Ji, H.; Gao, Y.; Ding, H.; Li, C. Distribution of rare earth elements in agricultural soil and human body (scalp hair and urine) near smelting and mining areas of Hezhang, China. J. Rare Earths 2016, 34, 1156–1167. [Google Scholar] [CrossRef]

- Hao, Z.; Li, Y.; Li, H.; Wei, B.; Liao, X.; Liang, T.; Yu, J. Levels of rare earth elements, heavy metals and uranium in a population living in Baiyun Obo, Inner Mongolia, China: A pilot study. Chemosphere 2015, 128, 161–170. [Google Scholar] [CrossRef]

- Wei, B.; Li, Y.; Li, H.; Yu, J.; Ye, B.; Liang, T. Rare earth elements in human hair from a mining area of China. Ecotoxicol. Environ. Saf. 2013, 96, 118–123. [Google Scholar] [CrossRef]

- Atibu, E.K.; Devarajan, N.; Laffite, A.; Giuliani, G.; Salumu, J.A.; Muteb, R.C.; Mulaji, C.K.; Otamonga, J.P.; Elongo, V.; Mpiana, P.T.; et al. Assessment of trace metal and rare earth elements contamination in rivers around abandoned and active mine areas. The case of Lubumbashi River and Tshamilemba Canal, Katanga, Democratic Republic of the Congo. Chem. Geochem. 2016, 76, 353–362. [Google Scholar] [CrossRef]

- Zhuang, M.; Zhao, J.; Li, S.; Liu, D.; Wang, K.; Xiao, P.; Yu, L.; Jiang, Y.; Song, J.; Zhou, J.; et al. Concentrations and health risk assessment of rare earth elements in vegetables from mining area in Shandong, China. Chemosphere 2016, 168, 578–582. [Google Scholar] [CrossRef]

- Kulaksiz, S.; Bau, M. Anthropogenic dissolved and colloid/nanoparticle-bound samarium, lanthanum and gadolinium in the Rhine River and the impending destruction of the natural rare earth element distribution in rivers. Earth Planet. Sci. Lett. 2013, 362, 43–50. [Google Scholar] [CrossRef]

- Hatje, V.; Bruland, K.W.; Flegal, A.R. Determination of rare earth elements after pre-concentration using NOBIAS-chelate PA-1® resin: Method development and application in the San Francisco Bay plume. Mar. Chem. 2014, 160, 34–41. [Google Scholar] [CrossRef]

- Zaimes, G.G.; Hubler, B.J.; Wang, S.; Khanna, V. Environmental Life Cycle Perspective on Rare Earth Oxide Production. ACS Sustain. Chem. Eng. 2015, 3, 237–244. [Google Scholar] [CrossRef]

- Tansel, B. From electronic consumer products to e-wastes: Global outlook, waste quantities, recycling challenges. Environ. Int. 2017, 98, 35–45. [Google Scholar] [CrossRef]

- Hobohm, J.; Kuchta, K. Innovative Recovery Strategies of Rare Earth and Other Critical Metals from Electric and Electronic Waste; Sociedad Española de Mineralogía: Huelva, Spain, 2015. [Google Scholar]

- Baldé, C.P.; Forti, V.; Gray, V.; Kuehr, R.; Stegmann, P. The Global E-Waste Monitor 2017; United Nations University (UNU): Bonn, Germany; International Telecommunication Union (ITU): Geneva, Switzerland; International Solid Waste Association (ISWA): Vienna, Austria, 2017. [Google Scholar]

- Tsamis, A.; Coyne, M. Recovery of Rare Earths from Electronic Wastes: An Opportunity for High-Tech SMEs; Centre for Strategy and Evaluation Services LLP: Brussels, Belgium, 2015. [Google Scholar]

- Directorate General Enterprise and Industry EU Critical Raw Materials Profiles; European Commission: Brussels, Belgium, 2014; pp. 77–85.

- Zepf, V. Rare Earth Elements; Springer Science & Business Media: Berlin, Germany, 2013; ISBN 978-3-642-35457-1. [Google Scholar]

- European Rare Earths Competency Network (ERECON). Strengthening the European Rare Earths Supply-Chain Challenges and Policy Options; European Comission: Brussels, Belgium, 2014. [Google Scholar]

- Royen, H.; Fortkamp, U. Rare Earth Elements—Purification, Separation and Recycling; Environmental Research Institute: Stockholm, Sweden, 2016. [Google Scholar]

- Dutta, T.; Kim, K.H.; Uchimiya, M.; Kwon, E.E.; Jeon, B.H.; Deep, A.; Yun, S.T. Global demand for rare earth resources and strategies for green mining. Environ. Res. 2016, 150, 182–190. [Google Scholar] [CrossRef]

- Shriver, D.; Weller, M.; Overton, T.; Rourke, J.; Armstrong, F. Inorganic Chemistry; W. H. Freeman and Company: New York, NY, USA, 2014; ISBN 978-1-4292-9906-0. [Google Scholar]

- Huang, C. Rare Earth Coordination Chemistry: Fundamentals and Applications; John Wiley & Sons: Hoboken, NJ, USA, 2010; ISBN 978-0-470-82485-6. [Google Scholar]

- Series, S. Spectroscopic Properties of Rare Earths in Optical Materials; Liu, G., Jacquier, B., Eds.; Springer Science & Business Media: Berlin, Germany, 2005. [Google Scholar]

- Binnemans, K.; Jones, P.T.; Blanpain, B.; Van Gerven, T.; Yang, Y.; Walton, A.; Burchert, M. Recycling of Rare Earth: A Critical Review. J. Clean. Prod. 2013, 51, 1–22. [Google Scholar] [CrossRef]

- Ruiz-Mercado, G.J.; Gonzalez, M.A.; Smith, R.L.; Meyer, D.E. A conceptual chemical process for the recycling of Ce, Eu, and Y from LED flat panel displays. Resour. Conserv. Recycl. 2017, 126, 42–49. [Google Scholar] [CrossRef]

- Yang, Y.; Walton, A.; Sheridan, R.; Güth, K.; Gauß, R.; Gutfleisch, O.; Buchert, M.; Steenari, B.-M.; Van Gerven, T.; Jones, P.T.; et al. REE Recovery from End-of-Life NdFeB Permanent Magnet Scrap: A Critical Review. J. Sustain. Metall. 2017, 3, 122–149. [Google Scholar] [CrossRef]

- Abrahami, S.T.; Xiao, Y.; Yang, Y. Rare-earth elements recovery from post-consumer hard-disc drives. Miner. Process. Extr. Metall. 2015, 124, 106–115. [Google Scholar] [CrossRef]

- München, D.D.; Veit, H.M. Neodymium as the main feature of permanent magnets from hard disk drives (HDDs). Waste Manag. 2017, 61, 372–376. [Google Scholar] [CrossRef]

- Firdaus, M.; Rhamdhani, M.A.; Durandet, Y.; Rankin, W.J.; McGregor, K. Review of High-Temperature Recovery of Rare Earth (Nd/Dy) from Magnet Waste. J. Sustain. Metall. 2016, 2, 276–295. [Google Scholar] [CrossRef] [Green Version]

- Yoon, H.-S.S.; Kim, C.-J.J.; Chung, K.-W.W.; Kim, S.-D.D.; Lee, J.-Y.Y.; Kumar, J.R. Solvent extraction, separation and recovery of dysprosium (Dy) and neodymium (Nd) from aqueous solutions: Waste recycling strategies for permanent magnet processing. Hydrometallurgy 2016, 165, 27–43. [Google Scholar] [CrossRef]

- Binnemans, K.; Jones, P.T. Perspectives for the recovery of rare earths from end-of-life fluorescent lamps. J. Rare Earths 2014, 32, 195–200. [Google Scholar] [CrossRef] [Green Version]

- Tan, Q.; Li, J.; Zeng, X. Rare Earth Elements Recovery from Waste Fluorescent Lamps: A Review. Crit. Rev. Environ. Sci. Technol. 2015, 45, 749–776. [Google Scholar] [CrossRef]

- Wu, Y.; Yin, X.; Zhang, Q.; Wang, W.; Mu, X. The recycling of rare earths from waste tricolor phosphors in fluorescent lamps: A review of processes and technologies. Resour. Conserv. Recycl. 2014, 88, 21–31. [Google Scholar] [CrossRef]

- Pyrzynska, K.; Kubiak, A.; Wysocka, I. Application of solid phase extraction procedures for rare earth elements determination in environmental samples. Talanta 2016, 154, 15–22. [Google Scholar] [CrossRef] [PubMed]

- Liang, T.; Li, K.; Wang, L. State of rare earth elements in different environmental components in mining areas of China. Environ. Monit. Assess. 2014, 186, 1499–1513. [Google Scholar] [CrossRef]

- Innocenzi, V.; Ippolito, N.M.; De Michelis, I.; Prisciandaro, M.; Medici, F.; Vegliò, F. A review of the processes and lab-scale techniques for the treatment of spent rechargeable NiMH batteries. J. Power Sources 2017, 362, 202–218. [Google Scholar] [CrossRef]

- Lister, T.E.; Wang, P.; Anderko, A. Recovery of critical and value metals from mobile electronics enabled by electrochemical processing. Hydrometallurgy 2014, 149, 228–237. [Google Scholar] [CrossRef] [Green Version]

- Kim, D.; Powell, L.E.; Delmau, L.H.; Peterson, E.S.; Herchenroeder, J.; Bhave, R.R. Selective Extraction of Rare Earth Elements from Permanent Magnet Scraps with Membrane Solvent Extraction. Environ. Sci. Technol. 2015, 49, 9452–9459. [Google Scholar] [CrossRef] [PubMed]

- Sun, Z.; Xiao, Y.; Agterhuis, H.; Sietsma, J.; Yang, Y. Recycling of metals from urban mines—A strategic evaluation. J. Clean. Prod. 2016, 112, 2977–2987. [Google Scholar] [CrossRef]

- Itoh, H. The recent trend of e-waste recycling and rare metal recovery in Japan. Wit Trans. Ecol. Environ. 2014, 180, 3–14. [Google Scholar]

- Kaya, M. Recovery of metals and nonmetals from electronic waste by physical and chemical recycling processes. Waste Manag. 2016, 57, 64–90. [Google Scholar] [CrossRef]

- Haque, N.; Hughes, A.; Lim, S.; Vernon, C. Rare Earth Elements: Overview of Mining, Mineralogy, Uses, Sustainability and Environmental Impact. Resources 2014, 3, 614–635. [Google Scholar] [CrossRef] [Green Version]

- Hidayah, N.N.; Abidin, S.Z. The evolution of mineral processing in extraction of rare earth elements using solid-liquid extraction over liquid-liquid extraction: A review. Miner. Eng. 2017, 112, 103–113. [Google Scholar] [CrossRef] [Green Version]

- Zhu, L.L.; Guo, L.; Zhang, Z.J.; Chen, J.; Zhang, S.M. The Preparation of Supported Ionic Liquids (SILs) and Their Application in Rare Metals Separation. Sci. China Chem. 2012, 55, 1479–1487. [Google Scholar] [CrossRef]

- Xiao, S.; Yang, J.; Ji, C.; Jiu, M. Solvent impregnated resin prepared using task-specific ionic liquids for rare earth separation. J. Rare Earths 2009, 27, 932–936. [Google Scholar]

- Ferella, F.; Innocenzi, V.; Maggiore, F. Oil refining spent catalysts: A review of possible recycling technologies. Resour. Conserv. Recycl. 2016, 108, 10–20. [Google Scholar] [CrossRef]

- Abhilash, S.S.; Meshram, P.; Pandey, B.D. Metallurgical processes for the recovery and recycling of lanthanum from various resources—A review. Hydrometallurgy 2016, 160, 47–59. [Google Scholar]

- Meshram, P.; Pandey, B.D.; Mankhand, T.R. Process optimization and kinetics for leaching of rare earth metals from the spent Ni-metal hydride batteries. Waste Manag. 2016, 51, 196–203. [Google Scholar] [CrossRef]

- Duclos, L.; Svecova, L.; Laforest, V.; Mandil, G.; Thivel, P.X. Process development and optimization for platinum recovery from PEM fuel cell catalyst. Hydrometallurgy 2016, 160, 79–89. [Google Scholar] [CrossRef]

- Bian, Y.; Guo, S.; Jiang, L.; Liu, J.; Tang, K.; Ding, W. Recovery of Rare Earth Elements from NdFeB Magnet by VIM-HMS Method. ACS Sustain. Chem. Eng. 2016, 4, 810–818. [Google Scholar] [CrossRef]

- Bandara, H.M.D.; Field, K.D.; Emmert, M.H. Rare earth recovery from end-of-life motors employing green chemistry design principles. Green Chem. 2016, 18, 753–759. [Google Scholar] [CrossRef]

- Dupont, D.; Binnemans, K. Rare-earth recycling using a functionalized ionic liquid for the selective dissolution and revalorization of Y2O3:Eu3+ from lamp phosphor waste. Green Chem. 2015, 17, 856–868. [Google Scholar] [CrossRef]

- Tunsu, C.; Petranikova, M.; Gergorić, M.; Ekberg, C.; Retegan, T. Reclaiming rare earth elements from end-of-life products: A review of the perspectives for urban mining using hydrometallurgical unit operations. Hydrometallurgy 2015, 156, 239–258. [Google Scholar] [CrossRef]

- Tan, Q.; Deng, C.; Li, J. Innovative Application of Mechanical Activation for Rare Earth Elements Recovering: Process Optimization and Mechanism Exploration. Sci. Rep. 2016, 6, 19961–19970. [Google Scholar] [CrossRef]

- Fisher, A.; Kara, D. Determination of rare earth elements in natural water samples—A review of sample separation, preconcentration and direct methodologies. Anal. Chim. Acta 2016, 935, 1–29. [Google Scholar] [CrossRef]

- Cao, W.; Hu, S.-S.; Ye, L.-H.; Cao, J.; Xu, J.-J.; Pang, X.-Q. Trace-chitosan-wrapped multi-walled carbon nanotubes as a new sorbent in dispersive micro solid-phase extraction to determine phenolic compounds. J. Chromatogr. A 2015, 1390, 13–21. [Google Scholar] [CrossRef]

- Giakisikli, G.; Anthemidis, A.N. Magnetic materials as sorbents for metal/metalloid preconcentration and/or separation. A review. Anal. Chim. Acta 2013, 789, 1–16. [Google Scholar] [CrossRef] [PubMed]

- Ghazaghi, M.; Mousavi, H.Z.; Rashidi, A.M.; Shirkhanloo, H.; Rahighi, R. Graphene-silica hybrid in efficient preconcentration of heavy metal ions via novel single-step method of moderate centrifugation-assisted dispersive micro solid phase extraction. Talanta 2016, 150, 476–484. [Google Scholar] [CrossRef]

- Hu, Y.; Pan, J.; Zhang, K.; Lian, H.; Li, G. Novel applications of molecularly-imprinted polymers in sample preparation. Trends Anal. Chem. 2013, 43, 37–52. [Google Scholar] [CrossRef]

- Branger, C.; Meouche, W.; Margaillan, A. Recent advances on ion-imprinted polymers. React. Funct. Polym. 2013, 73, 859–875. [Google Scholar] [CrossRef]

- Dhand, V.; Rhee, K.Y.; Ju Kim, H.; Ho Jung, D.; Dhand, V.; Rhee, K.Y.; Ju Kim, H.; Ho Jung, D. A Comprehensive Review of Graphene Nanocomposites: Research Status and Trends. J. Nanomater. 2013, 2013, 763953–763966. [Google Scholar] [CrossRef]

- Pastrana-Martínez, L.M.; Morales-Torres, S.; Gomes, H.T.; Silva, A.M.T. Nanotubos e grafeno: Os primos mais jovens na família do carbono! Química 2013, 128, 21–27. [Google Scholar]

- Yu, S.; Wang, X.X.; Tan, X.; Wang, X.X. Sorption of radionuclides from aqueous systems onto graphene oxide-based materials: A review. Inorg. Chem. Front. 2015, 2, 593–612. [Google Scholar] [CrossRef]

- Guerrero-Contreras, J.; Caballero-Briones, F. Graphene oxide powders with different oxidation degree, prepared by synthesis variations of the Hummers method. Mater. Chem. Phys. J. 2015, 153, 209–220. [Google Scholar] [CrossRef]

- Katsnelson, M.I. Graphene: Carbon in two dimensions. Mater. Today 2007, 10, 20–27. [Google Scholar] [CrossRef]

- Valles, C.; Drummond, C.; Saadaoui, H.; Furtado, C.A.; He, M.; Roubeau, O.; Ortolani, L.; Monthioux, M.; Pe, A. Solutions of Negatively Charged Graphene Sheets and Ribbons Solutions of Negatively Charged Graphene Sheets and Ribbons. J. Am. Chem. Soc. 2008, 130, 15802–15804. [Google Scholar] [CrossRef]

- Lavin-Lopez, M.D.P.; Romero, A.; Garrido, J.; Sanchez-Silva, L.; Valverde, J.L. Influence of different improved hummers method modifications on the characteristics of graphite oxide in order to make a more easily scalable method. Ind. Eng. Chem. Res. 2016, 55, 12836–12847. [Google Scholar] [CrossRef]

- Paredes, J.I.; Villar-Rodil, S.; Martínez-Alonso, A.; Tascón, J.M.D. Graphene Oxide Dispersions in Organic Solvents. Langmuir 2008, 24, 10560–10564. [Google Scholar] [CrossRef]

- Kovtyukhova, N.I. Layer-by-layer assembly of ultrathin composite films from micron-sized graphite oxide sheets and polycations. Chem. Mater. 1999, 11, 771–778. [Google Scholar] [CrossRef]

- Yu, Y.-Y.; Kang, B.H.; Lee, Y.D.; Lee, S.B.; Ju, B.-K. Effect of fluorine plasma treatment with chemically reduced grapheneoxide thin films as hole transport layer in organic solar cells. Appl. Surf. Sci. 2013, 287, 91–96. [Google Scholar] [CrossRef]

- Nikolakopoulou, A.; Tasis, D.; Sygellou, L.; Dracopoulos, V.; Galiotis, C.; Lianos, P. Study of the thermal reduction of graphene oxide and of its application as electrocatalyst in quasi-solid state dye-sensitized solarcells in combination with PEDOT. Electrochim. Acta 2013, 111, 698–706. [Google Scholar] [CrossRef]

- Ma, C.; Liu, W.; Shi, M.; Lang, X.; Chu, Y.; Chen, Z.; Zhao, D.; Lin, W.; Hardacre, C. Low loading platinum nanoparticles on reduced graphene oxide-supported tungsten carbide crystallites as a highly active electrocatalyst for methanol oxidation. Electrochim. Acta 2013, 114, 133–141. [Google Scholar] [CrossRef]

- Marcano, D.C.; Kosynkin, D.V.; Berlin, J.M.; Sinitskii, A.; Sun, Z.; Slesarev, A.; Alemany, L.B.; Lu, W.; Tour, J.M. Improved Synthesis of Graphene Oxide. ACS Nano 2010, 4, 4806–4814. [Google Scholar] [CrossRef]

- Li, J.; Zeng, X.; Ren, T.; van der Heide, E. The Preparation of Graphene Oxide and Its Derivatives and Their Application in Bio-Tribological Systems. Lubricants 2014, 2, 137–161. [Google Scholar] [CrossRef] [Green Version]

- Dreyer, D.R.; Park, S.; Bielawski, C.W.; Ruoff, R.S. The chemistry of graphene oxide. Chem. Soc. Rev. 2010, 39, 228–240. [Google Scholar] [CrossRef]

- Chung, D.D.L. A review of exfoliated graphite. J. Mater. Sci. 2016, 51, 554–568. [Google Scholar] [CrossRef]

- Acik, M.; Chabal, Y.J. A Review on Thermal Exfoliation of Graphene Oxide. J. Mater. Sci. Res. 2012, 2, 101–112. [Google Scholar]

- Zhao, F.; Repo, E.; Meng, Y.; Wang, X.; Yin, D.; Sillanpää, M. An EDTA-b-cyclodextrin material for the adsorption of rare earth elements and its application in preconcentration of rare earth elements in seawater. J. Colloid Interface Sci. 2016, 465, 215–224. [Google Scholar] [CrossRef]

- Dupont, D.; Brullot, W.; Bloemen, M.; Verbiest, T.; Binnemans, K. Selective Uptake of Rare Earths from Aqueous Solutions by EDTA- Functionalized Magnetic and Nonmagnetic Nanoparticles. ACS Appl. Mater. Interfaces 2014, 6, 4980–4988. [Google Scholar] [CrossRef]

- Noack, C.W.; Perkins, K.M.; Callura, J.C.; Washburn, N.R.; Dzombak, D.A.; Karamalidis, A.K. Effects of ligand chemistry and geometry on rare earth element partitioning from saline solutions to functionalized adsorbents. ACS Sustain. Chem. Eng. 2016, 4, 6115–6124. [Google Scholar] [CrossRef]

- Ogata, T.; Narita, H.; Tanaka, M. Adsorption mechanism of rare earth elements by adsorbents with diglycolarnic acid ligands. Hydrometallurgy 2016, 163, 156–160. [Google Scholar] [CrossRef]

- Juère, E.; Florek, J.; Larivière, D.; Kim, K.; Kleitz, F. Support effects in rare earth element separation using diglycolamide-functionalized mesoporous silica. New J. Chem. 2016, 40, 4325–4334. [Google Scholar] [CrossRef]

- Sengupta, A.; Deb, A.K.S.; Dasgupta, K.; Adyaa, V.C.; Ali, S.M. Diglycolamic acid-functionalized multiwalled carbon nanotubes as a highly efficient sorbent for f-block elements: Experimental and theoretical investigations. New J. Chem. 2017, 41, 4531–4545. [Google Scholar] [CrossRef]

- Yang, S.; Zong, P.; Ren, X.; Wang, Q.; Wang, X. Rapid and Highly E ffi cient Preconcentration of Eu(III) by Core—Shell Structured Fe3O4@Humic Acid Magnetic Nanoparticles. ACS Appl. Mater. Interfaces 2012, 4, 6891–6900. [Google Scholar] [CrossRef]

- Huang, C.; Hu, B. Silica-coated magnetic nanoparticles modified with γ-mercaptopropyltrimethoxysilane for fast and selective solid phase extraction of trace amounts of Cd, Cu, Hg, and Pb in environmental and biological samples prior to their determination by inductively co. Spectrochim. Acta Part B Spectrosc. 2008, 63, 437–444. [Google Scholar] [CrossRef]

- Sun, Y.; Shao, D.; Chen, C.; Yang, S.; Wang, X. Highly efficient enrichment of radionuclides on graphene oxide-supported polyaniline. Environ. Sci. Technol. 2013, 47, 9904–9910. [Google Scholar] [CrossRef]

- Li, D.; Zhang, B.; Xuan, F. The sorption of Eu(III) from aqueous solutions by magnetic graphene oxides: A combined experimental and modeling studies. J. Mol. Liq. 2015, 211, 203–209. [Google Scholar] [CrossRef]

- Chen, W.; Wang, L.; Zhuo, M.; Liu, Y.; Wang, Y.; Li, Y. Facile and highly efficient removal of trace Gd(III) by adsorption of colloidal graphene oxide suspensions sealed in dialysis bag. J. Hazard. Mater. 2014, 279, 546–553. [Google Scholar] [CrossRef]

- Chen, W.; Wang, L.; Zhuo, M.; Wang, Y.; Fu, S.; Li, Y.; Wu, S. Reusable colloidal graphene oxide suspensions combined with dialysis bags for recovery of trace Y(III) from aqueous solutions. RSC Adv. 2014, 4, 58778–58787. [Google Scholar] [CrossRef]

- Ashour, R.M.; Abdelhamid, H.N.; Abdel-Magied, A.F.; Abdel-Khalek, A.A.; Ali, M.M.; Uheida, A.; Muhammed, M.; Zou, X.; Dutta, J. Rare Earth Ions Adsorption onto Graphene Oxide Nanosheets. Solvent Extr. Ion Exch. 2017, 35, 91–103. [Google Scholar] [CrossRef]

- Su, S.; Chen, B.; He, M.; Hun, B.; Xiao, Z.; Hu, B.; Xiao, Z. Determination of trace/ultratrace rare earth elements in environmental samples by ICP-MS after magnetic solid phase extraction with Fe3O4@SiO2@polyaniline-graphene oxide composite. Talanta 2014, 119, 458–466. [Google Scholar] [CrossRef]

- Fakhri, H.; Mahjoub, A.R.; Aghayan, H. Effective removal of methylene blue and cerium by a novel pair set of heteropoly acids based functionalized graphene oxide: Adsorption and photocatalytic study. Chem. Eng. Res. Des. 2017, 120, 303–315. [Google Scholar] [CrossRef]

- Farzin, L.; Shamsipur, M.; Shanehsaz, M.; Sheibani, S. A new approach to extraction and preconcentration of Ce(III) from aqueous solutions using magnetic reduced graphene oxide decorated with thioglycolic-acid-capped CdTe QDs. Int. J. Environ. Anal. Chem. 2017, 97, 854–867. [Google Scholar] [CrossRef]

- Kilian, K.; Pyrzyńska, K.; Pęgier, M. Comparative Study of Sc(III) Sorption onto Carbon-based Materials. Solvent Extr. Ion Exch. 2017, 35, 450–459. [Google Scholar] [CrossRef]

- Xie, Y.; Helvenston, E.M.; Shuller-Nickles, L.C.; Powell, B.A. Surface Complexation Modeling of Eu(III) and U(VI) Interactions with Graphene Oxide. Environ. Sci. Technol. 2016, 50, 1821–1827. [Google Scholar] [CrossRef]

- Yao, T.; Xiao, Y.; Wu, X.; Guo, C.; Zhao, Y.; Chen, X. Adsorption of Eu(III) on sulfonated graphene oxide: Combined macroscopic and modeling techniques. J. Mol. Liq. 2016, 215, 443–448. [Google Scholar] [CrossRef]

- Sun, Y.; Wang, Q.; Chen, C.; Tan, X.; Wang, X. Interaction between Eu(III) and Graphene Oxide Nanosheets Investigated by Batch and Extended X-ray Absorption Fine Structure Spectroscopy and by Modeling Techniques. Environ. Sci. Technol. 2012, 46, 6020–6027. [Google Scholar] [CrossRef]

- Li, C.; Huang, Y.; Lin, Z. Fabrication of titanium phosphate@graphene oxide nanocomposite and its super performance on Eu3+ recycling. J. Mater. Chem. A 2014, 2, 14979–14985. [Google Scholar] [CrossRef]

- Lasorsa, C.; Perez, M.; Lerner, B.; Toper, I.; Versaci, R.; Lamagna, A.; Boselli, A. Optimization of a Carbon Nanotubes Manufacturing Process by the Technique of PECVD. Procedia Mater. Sci. 2012, 1, 558–563. [Google Scholar] [CrossRef] [Green Version]

- Bierdel, M.; Buchholz, S.; Michele, V.; Mleczko, L.; Rudolf, R.; Voetz, M.; Wolf, A. Industrial production of multiwalled carbon nanotubes. Phys. Status Solidi 2007, 244, 3939–3943. [Google Scholar] [CrossRef]

- Yadav, K.K.; Dasgupta, K.; Singh, D.K.; Anitha, M.; Varshney, L.; Singh, H. Solvent impregnated carbon nanotube embedded polymeric composite beads: An environment benign approach for the separation of rare earths. Sep. Purif. Technol. 2015, 143, 115–124. [Google Scholar] [CrossRef]

- Behdani, F.N.; Rafsanjani, A.T.; Torab-Mostaedi, M.; Mohammadpour, S.M.A.K. Adsorption ability of oxidized multiwalled carbon nanotubes towards aqueous Ce(III) and Sm(III). Korean J. Chem. Eng. 2013, 30, 448–455. [Google Scholar] [CrossRef]

- Koochaki-Mohammadpour, S.M.A.; Torab-Mostaedi, M.; Talebizadeh-Rafsanjani, A.; Naderi-Behdani, F. Adsorption Isotherm, Kinetic, Thermodynamic, and Desorption Studies of Lanthanum and Dysprosium on Oxidized Multiwalled Carbon Nanotubes. J. Dispers. Sci. Technol. 2014, 35, 244–254. [Google Scholar] [CrossRef]

- Li, K.; Gao, Q.; Yadavalli, G.; Shen, X.; Lei, H.; Han, B.; Xia, K.; Zhou, C. Selective Adsorption of Gd3+ on a Magnetically Retrievable Imprinted Chitosan/Carbon Nanotube Composite with High Capacity. ACS Appl. Mater. Interfaces 2015, 7, 21047–21055. [Google Scholar] [CrossRef]

- Chen, C.L.; Wang, X.K.; Nagatsu, M. Europium Adsorption on Multiwall Carbon Nanotube/Iron Oxide Magnetic Composite in the Presence of Polyacrylic Acid. Environ. Sci. Technol. 2009, 43, 2362–2367. [Google Scholar] [CrossRef]

- Fan, Q.H.; Shao, D.D.; Hu, J.; Chen, C.L.; Wu, W.S.; Wang, X.K. Adsorption of humic acid and Eu(III) to multi-walled carbon nanotubes: Effect of pH, ionic strength and counterion effect. Radiochim. Acta 2009, 97, 141–148. [Google Scholar] [CrossRef]

- Chen, C.; Hu, J.; Xu, D.; Tan, X.; Meng, Y.; Wang, X. Surface complexation modeling of Sr(II) and Eu(III) adsorption onto oxidized multiwall carbon nanotubes. J. Colloid Interface Sci. 2008, 323, 33–41. [Google Scholar] [CrossRef]

- Tong, S.; Zhao, S.; Zhou, W.; Li, R.; Jia, Q. Modification of multi-walled carbon nanotubes with tannic acid for the adsorption of La, Tb and Lu ions. Microchim. Acta 2011, 174, 257–264. [Google Scholar] [CrossRef]

- Kammerer, D.R.; Kammerer, J.; Carle, R. Resin Adsorption and Ion Exchange to Recover and Fractionate Polyphenols. In Polyphenols in Plants; Elsevier: Amsterdam, The Netherlands, 2014; pp. 219–230. ISBN 9780123979346. [Google Scholar]

- Gupta, V.K. Suhas Application of low-cost adsorbents for dye removal—A review. J. Environ. Manag. 2009, 90, 2313–2342. [Google Scholar] [CrossRef]

- Smith, Y.R.; Bhattacharyya, D.; Willhard, T.; Misra, M. Adsorption of aqueous rare earth elements using carbon black derived from recycled tires. Chem. Eng. J. 2016, 296, 102–111. [Google Scholar] [CrossRef] [Green Version]

- Chen, S.; Xiao, M.; Lu, D.; Zhan, X. Carbon nanofibers as solid-phase extraction adsorbent for the preconcentration of trace rare earth elements and their determination by inductively coupled plasma mass spectrometry. Anal. Lett. 2007, 40, 2105–2115. [Google Scholar] [CrossRef]

- Agrawal, Y.K. Poly(β-Styryl)-(1,2-Methanofullerene-C60)-61-Formo Hydroxamic Acid for the Solid Phase Extraction, Separation and Preconcentration of Rare Earth Elements. Fuller. Nanotub. Carbon Nanostruct. 2007, 15, 353–365. [Google Scholar] [CrossRef]

- Chen, S.; Xiao, M.; Lu, D.; Zhan, X. Use of a microcolumn packed with modified carbon nanofibers coupled with inductively coupled plasma mass spectrometry for simultaneous on-line preconcentration and determination of trace rare earth elements in biological samples. Rapid Commun. Mass Spectrom. 2007, 21, 2524–2528. [Google Scholar] [CrossRef]

- Gad, H.M.H.; Awwad, N.S. Factors affecting on the sorption/desorption of Eu (III) using activated carbon. Sep. Sci. Technol. 2007, 42, 3657–3680. [Google Scholar] [CrossRef]

- Marwani, H.M.; Albishri, H.M.; Jalal, T.A.; Soliman, E.M. Study of isotherm and kinetic models of lanthanum adsorption on activated carbon loaded with recently synthesized Schiff’s base. Arab. J. Chem. 2017, 10, 1032–1040. [Google Scholar] [CrossRef]

- Saha, D.; Akkoyunlu, S.D.; Thorpe, R.; Hensley, D.K.; Chen, J. Adsorptive recovery of neodymium and dysprosium in phosphorous functionalized nanoporous carbon. J. Environ. Chem. Eng. 2017, 5, 4684–4692. [Google Scholar] [CrossRef]

- Perreault, L.L.; Giret, S.; Gagnon, M.; Florek, J.; Larivière, D.; Kleitz, F. Functionalization of Mesoporous Carbon Materials for Selective Separation of Lanthanides under Acidic Conditions. ACS Appl. Mater. Interfaces 2017, 9, 12003–12012. [Google Scholar] [CrossRef]

| Element (Symbol) * | Application and End Use | Ref. |

|---|---|---|

| Sc | aerospace framework/components, high-intensity street lamps/additive in metal-halide lamps and mercury vapor lamps, radioactive tracing agent in oil refineries. | [15,19,22,27,28] |

| Y | TV sets, cancer treatment drugs, enhances strength of alloys, lasers, high temperature superconductors, microwave filters, energy-efficient light bulbs, spark plugs, gas mantles | [15,19,22,27,29] |

| La | camera lenses, battery-electrodes, hydrogen storage, fluid catalysts for oil refineries | [15,20,22,27,28] |

| Ce | catalytic converters, colored glass, steel production, chemical oxidizing agent | [15,19,22,27,28] |

| Pr | magnets, welding goggles, lasers | [15,22,27,30,31,32] |

| Nd | permanent magnets, microphones, electric motors of hybrid automobiles, lasers | [15,19,22,27,30,31,32,33,34] |

| Pm | nuclear batteries | [15,22] |

| Sm | cancer treatment, nuclear reactor control rods, X-ray lasers, masers, magnets | [15,19,22,27] |

| Eu | color TV screens, fluorescent glass, genetic screening tests | [15,19,22,27,29,35,36,37] |

| Gd | shielding in nuclear reactors, nuclear marine propulsion, increases durability of alloys | [15,19,22,27,28] |

| Tb | TV sets, fuel cells, sonar systems, florescence lamps, lasers | [15,16,19,22,27,36] |

| Dy | commercial lighting, hard disk devices, transducers, magnets | [15,19,22,27,30,31,32,33,34] |

| Ho | lasers, glass coloring, high-strength magnets | [15,16,19,22] |

| Er | glass colorant, signal amplification for fiber optic cables, metallurgical uses | [15,16,19,22] |

| Tm | high efficiency lasers, portable X-ray machines, high temperature superconductor | [15,16,19,22] |

| Yb | improves stainless steel, lasers, ground monitoring devices | [15,16,19,22] |

| Lu | refining petroleum, LED light bulbs, integrated circuit manufacturing | [15,16,19,22] |

| REEs | Magnets | Batteries | Metallurgy | Catalysts | Polishing | Glass | Phosphors | Ceramics | Others | Total |

|---|---|---|---|---|---|---|---|---|---|---|

| La | 0 | 26 | 10 | 45 | 1 | 5 | 1 | 1 | 9 | 100 |

| Ce | 0 | 3 | 19 | 18 | 36 | 12 | 4 | 1 | 8 | 100 |

| Pr | 73 | 0 | 4 | 0 | 2 | 0 | 12 | 7 | 2 | 100 |

| Nd | 89 | 0 | 2 | 2 | 0 | 1 | 1 | 4 | 0 | 100 |

| Sm | 97 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 3 | 100 |

| Eu | 0 | 0 | 0 | 0 | 0 | 0 | 96 | 0 | 4 | 100 |

| Gd | 35 | 0 | 28 | 0 | 0 | 0 | 23 | 0 | 14 | 100 |

| Tb | 24 | 0 | 0 | 0 | 0 | 0 | 71 | 0 | 5 | 100 |

| Dy | 98 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 2 | 100 |

| Er | 0 | 0 | 0 | 0 | 0 | 72 | 25 | 0 | 3 | 100 |

| Y | 0 | 0 | 0 | 0 | 0 | 0 | 79 | 21 | 0 | 100 |

| Ho, Tm, Yb, Lu | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 100 | 100 |

| All REEs | 20 | 8 | 11 | 20 | 15 | 7 | 9 | 3 | 6 | 100 |

| REE | Recycle | Method used | % Recovery | Reference |

|---|---|---|---|---|

| REE | Permanent Magnet (Review) | Hydro and Pyrometallurgy | NA | [43] |

| La, Ce | Oil refining Catalyst (Review) | Hydrometallurgy | NA | [48] |

| La, Nd | NiMH magnets (Review) | Hydrometallurgy | NA | [49] |

| Ce, Pr, Nd, Sm | NiMH magnets | Hydrometallurgy | 98.1 (Nd), 95.5 (Sm), 95.5 (Pr), 89.4 (Ce) | [50] |

| Pr | Fuel cell catalyst | Hydrometallurgy | 76 | [51] |

| Pr, Nd | Permanent Magnet | Vacuum Induction melting, hydrolysis and magnetic separation | 93 (99.7% purity) | [52] |

| Pr, Nd, Dy | Motors | Hydrometallurgy | 82 (99% purity) | [53] |

| Eu, Y | Phosphor (lamps) | Hydrometallurgy | 100 (99.9% purity) | [54] |

| Eu, Y | Fluorescent lamp | Hydrometallurgy | 99.9 | [55] |

| Eu, Tb, Y | Phosphor (lamps) | Mechanical Activation and leaching | 89.4 (Tb), 93.1 (Eu), 94.6 (Eu) | [56] |

| Method | Oxidants | Toxicity | Advantages | Disadvantages |

|---|---|---|---|---|

| Brodie Method | KClO3, HNO3 | Yes | - |

|

| Staudenmaier Method | KClO3 (NaClO3), HNO3, H2SO4 | Yes | - |

|

| Hummers Method | KMnO4, H2SO4, NaNO3 | No (NOx is released) |

|

|

| Modified Hummers Method | KMnO4, H2SO4, NaNO3, KMnO4, H2SO4 | No (NOx is released) |

|

|

| Improved Hummers Method | KMnO4, H2SO4, H3PO4 | No |

|

|

| Ref., Year | Sorbent | Type of Water | Type of System | REEs (III) | [REEs]0 (µg/L) | pH | T (°C) | Time of Contact (h) | m(sorbent)/ V(solution) (mg/L) | qm (mg/g) or REEs Adsorption (%) |

|---|---|---|---|---|---|---|---|---|---|---|

| [101], 2012 | AC (Activated Carbon) | Ultrapure | Mono elemental | Eu | 10 × 103 NaClO4 = 0.01 mol/L | 4.5 | 25 | 48 | 2 × 102 | 20.0 mg/g |

| [98], 2017 | AC-COOH | Ultrapure | Mono elemental | Sc | 300 × 103 | 2 | r.t. | 4 | 50 × 102 | 2.10 mg/g |

| AC-COOH | Ultrapure | Mono elemental | Sc | 300 × 103 | 4 | r.t. | 4 | 50 × 102 | 2.20 mg/g | |

| AC-COOH | Ultrapure | Mono elemental | Sc | (1–300) × 103 | 1–5.5 | r.t. | 0.02–4 | 50 × 102 | ||

| [115], 2016 | F-CCB (Functionalized commercial carbon black) | Ultrapure | Multi elemental | La, Ce, Nd, Sm, Y | 100 × 103 | neutral pH | 25 | 24 | 0.25 × 102 | La = 15%, Ce = 41%, Nd = 23%, Sm = 14%, Y = 17% |

| F-CCB (Functionalized commercial carbon black) | Ultrapure | Multi elemental | (0.03, 0.05, 0.15) × 102 | La = 12%, 13%, 14% Ce = 36%, 36%, 35% Nd = 10%, 12%, 16% Sm = 10%, 10%, 13% Y = 12%, 13%, 13% | ||||||

| RTCB (Recycled tire carbon black) | Ultrapure | Multi elemental | 0.25 × 102 | La = 28%, Ce = 68%, Nd = 34%, Sm = 41%, Y = 28% | ||||||

| RTCB (Recycled tire carbon black) | Ultrapure | Multi elemental | La, Ce Nd, Sm, Y | 100 × 103 | neutral pH | 25 | 24 | (0.03, 0.05, 0.15) × 102 | La = 3.5%, 6.0%, 18% Ce = 11%, 15%, 42% Nd = 5.0%, 7.5%, 22% Sm = 5.5%, 9.0%, 26% Y = 3.5%, 6.0%, 18% | |

| F-AC (Functionalized activated carbon) | Ultrapure | Multi elemental | La, Ce Nd, Sm Y | 100 × 103 | neutral pH | 25 | 24 | 0.25 × 102 (0.03, 0.05, 0.15) × 102 | La = 7.5%, Ce = 12%, Nd = 31%, Sm = 7.5%, Y = 12.5% La = 1.5%, 2.5%, 6.5% Ce = 2.5%, 8.0%, 11% Nd = 9.0%, 17%, 24% Sm = 0%, 7.5%, 5% Y = 6.0%, 9.0%, 11% | |

| CCB (commercial carbon black) | Ultrapure | Multi elemental | La, Ce Nd, Sm Y | 100 × 103 | neutral pH | 25 | 24 | (0.15, 0.25) × 102 | La = 2.5%, 2.5% Ce = 1.0%, 1.0% Nd = 5.0%, 8.0% Sm = 1.0%, 2.5% Y = 2.5%, 3.0% | |

| CCB (commercial carbon black) | (0.03, 0.05) × 102 | La= 2.5%, Ce = 1.0%, Nd = 5.0%, Sm = 1.0%, Y = 2.5% | ||||||||

| AC | (0.15, 0.25) × 102 | La =1.0%, Ce =1.0%, Nd = 12.5%, Sm = 0%, Y = 0% | ||||||||

| [116], 2016 | AC | Milli-Q | Multi elemental | La Ce Nd Sm Y | 100 × 103 | neutral pH | 25 | 24 | (0.03, 0.05) × 102 | La = 1.0%, 1.5% Ce = 1.0%, 1.0% Nd = 7.5%, 8.0% Sm = 0%, 1.0% Y = 1.5%, 1.0% |

| RTCB (Recycled tire carbon black) | Ultrapure | Multi elemental | La Ce Nd Sm Y | 20 × 103 | neutral pH | 80 | 1 | 0.5 × 102 | La = 40%, Ce = 95%, Nd = 75%, Sm = 80%, Y = 63% | |

| 2 | 0.5 × 102 | La = 45%, Ce = 95%, Nd = 80%, Sm = 82%, Y = 72% | ||||||||

| 12 | 0.5 × 102 | La = 75%, Ce = 95%, Nd = 91%, Sm = 95%, Y = 90% | ||||||||

| 25 | 1 | 0.5 × 102 | La = 25%, Ce = 85%, Nd = 68%, Sm = 60%, Y = 48% | |||||||

| 2 | 0.5 × 102 | La = 45%, Ce = 90%, Nd = 70%, Sm = 73%, Y = 60% | ||||||||

| [116], 2016 | RTCB (Recycled tire carbon black) | Ultrapure | Multi elemental | La, Ce Nd, Sm Y | 20 × 103 | neutral pH | 25 | 12 | 0.5 × 102 | La = 60%, Ce = 95% Nd = 83%, Sm = 88%, Y = 77% |

| 100 × 103 | 40 | 24 | 0.05 × 102 | La = 5.5%, Ce = 23%, Nd = 9.0%, Sm = 9.0%, Y = 9.0% | ||||||

| 100 × 103 | 60 | 24 | 0.05 × 102 | La = 7.5%, Ce = 25% Nd = 16%, Sm = 16%, Y = 16% | ||||||

| 100 × 103 | 80 | 24 | 0.05 × 102 | La = 13%, Ce = 30% Nd = 20%, Sm = 20%, Y = 21% | ||||||

| 100 × 103 | 40 | 24 | 0.25 × 102 | La = 29%, Ce = 75% Nd = 40%, Sm = 40%, Y = 40% | ||||||

| 100 × 103 | 60 | 24 | 0.25 × 102 | La = 323%, Ce = 81%, Nd = 50%, Sm = 55%, Y = 50%, | ||||||

| 100 × 103 | 80 | 24 | 0.25 × 102 | La= 48%, Ce = 84% Nd = 58%, Sm = 60%, Y = 60% | ||||||

| 100 × 103 | 40 | 24 | 0.5 × 102 | La= 45%, Ce = 85% Nd = 65%, Sm = 68%, Y = 60% | ||||||

| 100 × 103 | 40 | 24 | 0.5 × 102 | La= 45%, Ce = 85% Nd = 65%, Sm = 68%, Y = 60% | ||||||

| 100 × 103 | 40 | 24 | 0.5 × 102 | La = 45%, Ce = 85% Nd = 65%, Sm = 68%, Y = 60% | ||||||

| [116] 2016 | RTCB (Recycled tire carbon black) | Ultrapure | Multi elemental | La, Ce, Nd, Sm, Y | 100 × 103 | neutral pH | 60 | 24 | 0.5 × 102 | La = 52%, Ce = 90% Nd = 70%, Sm = 72%, Y = 70% |

| 80 | La = 69%, Ce = 90% Nd = 75%, Sm = 75%, Y = 75% | |||||||||

| F-CCB, RTCB, F-AC, AC | Ultrapure (Shaker: 200 rpm) | Multi elemental | La, Ce, Nd, Sm, Y | (100–200) × 103 | neutral pH | 25, 40, 60, 80 | 1–24 | (0.25–0.5) × 102 | ||

| [119], 2007 | H-APC AC (HPO4-APC activated carbon) | Ultrapure | Mono elemental | Eu | 50 × 103 | 5 | 20 | 2 | 2.5 × 102 5 × 102 7.5 × 102 10 × 102 12.5 × 102 15 × 102 17.5 × 102 | 45% 60% 60% 72% 80% 90% 93% |

| H-APC AC | Ultrapure | Mono elemental | Eu | 50 × 103 | 2 5 6 7 | 20 | 2 | 10 × 102 | 20.0 mg/g 32.0 mg/g 47.0 mg/g 50.0 mg/g | |

| H-APC AC | Ultrapure | Mono elemental | Eu | 50 × 103 | 5 | 20 | 1 2 | 10 × 102 | 29.0 mg/g 29.0 mg/g | |

| H-APC AC | Ultrapure | Mono elemental | Eu | 50 × 103 | 5 | 20 40 60 | 2 | 10 × 102 | 28.9 mg/g 29.0 mg/g 29.9 mg/g | |

| H-APC AC | Laboratory wastewaters | Mono elemental | Eu | - | 5 | 20 | 0.7 | 5 × 102 10 × 102 15 × 102 20 × 102 25 × 102 | 98% 98% 99% 99% 99% | |

| [120], 2017 | AC-DETADHBA | Distilled | Multi elemental | La | 5 × 103 | 6 5 4 | 25 | 1 | 25 mg* | 99. 6%, 145 mg/g 85% 40% |

| AC-DETADHBA | Distilled | Multi elemental | La | 5 × 103 | 6 | 25 | 0.17 0.5 1 | 25 mg* | 121 mg/g 135 mg/g 145 mg/g | |

| AC-COOH | Distilled | Multi elemental | La | 5 × 103 | 6 | 25 | 1 | 25 mg* | 89.5 mg/g | |

| [121], 2017 | AC-DETADHBA | Distilled | Multi elemental | La | (10–400) ×103 | 1–7 | 25 | 0.002,0.0083, 0.33, 0.67, 0.83 | 25 mg* | |

| [121], 2017 | AC-DETADHBA | Tap water | Mono elemental | La | 5 × 103 10 × 103 50 × 103 | 6 | 25 | 1 | 25 mg* | 99% 100% 96% |

| Lake water | 100% 100% 93% | |||||||||

| Seawater | 99% 100% 93% | |||||||||

| [121], 2017 | Phosphorous functionalized nanoporous carbon | Ultrapure | Multi elemental | Nd Dy | 0.5 × 103 | 6.1 6.6 | 25 | 4 | 10 × 102 | Nd = 336 mg/g Dy = 344 mg/g |

| 3 0.033 | Nd = 68,0% Dy = 67.0% | |||||||||

| [122], 2017 | CMK-8 | Milli-Q | Multi elemental | Sm | 0.02 × 103 | 2.6 | r.t. | 0.5 2.5 | 10 × 102 | 1 mg/g 1.5 mg/g |

| CMK-8-O (CMK-8-Oxidezed) | Milli-Q | Multi elemental | Sm | 0.07 × 103 | 2.6 | r.t. | 0.5 1 2.5 | 10 × 102 | 14 mg/g 13.8 mg/g 13 mg/g | |

| CMK-8-DGO (DGO: Diglycolyl-type organic) | Milli-Q | Multi elemental | La | 0.0003 × 103 | 2.6 3.8 5.7 | r.t. | 4 | 10 × 102 | 23 mg/g 27 mg/g 22 mg/g | |

| CMK-8 | Milli-Q | Multi elemental | Sm | (0.0025–0.025) × 103 | 2.6 | r.t. | 4 | 10 × 102 | 8 mg/g | |

| CMK-8-O (CMK-8-Oxidezed) | Milli-Q | Multi elemental | Sm | (0.05–0.2) × 103 | 2.6 | r.t. | 4 | 10 × 102 | 23 mg/g | |

| CMK-8-DGO (DGO: Diglycolyl-type organic) | Milli-Q | Multi elemental | La | (0.01–0.1) × 103 | 2.6 | r.t. | 4 | 10 × 102 | 10 mg/g |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cardoso, C.E.D.; Almeida, J.C.; Lopes, C.B.; Trindade, T.; Vale, C.; Pereira, E. Recovery of Rare Earth Elements by Carbon-Based Nanomaterials—A Review. Nanomaterials 2019, 9, 814. https://doi.org/10.3390/nano9060814

Cardoso CED, Almeida JC, Lopes CB, Trindade T, Vale C, Pereira E. Recovery of Rare Earth Elements by Carbon-Based Nanomaterials—A Review. Nanomaterials. 2019; 9(6):814. https://doi.org/10.3390/nano9060814

Chicago/Turabian StyleCardoso, Celso E. D., Joana C. Almeida, Cláudia B. Lopes, Tito Trindade, Carlos Vale, and Eduarda Pereira. 2019. "Recovery of Rare Earth Elements by Carbon-Based Nanomaterials—A Review" Nanomaterials 9, no. 6: 814. https://doi.org/10.3390/nano9060814