The Surface Morphology of a Ti–6Al–4V Fiber-Lasered Nitride Layer

Abstract

:1. Introduction

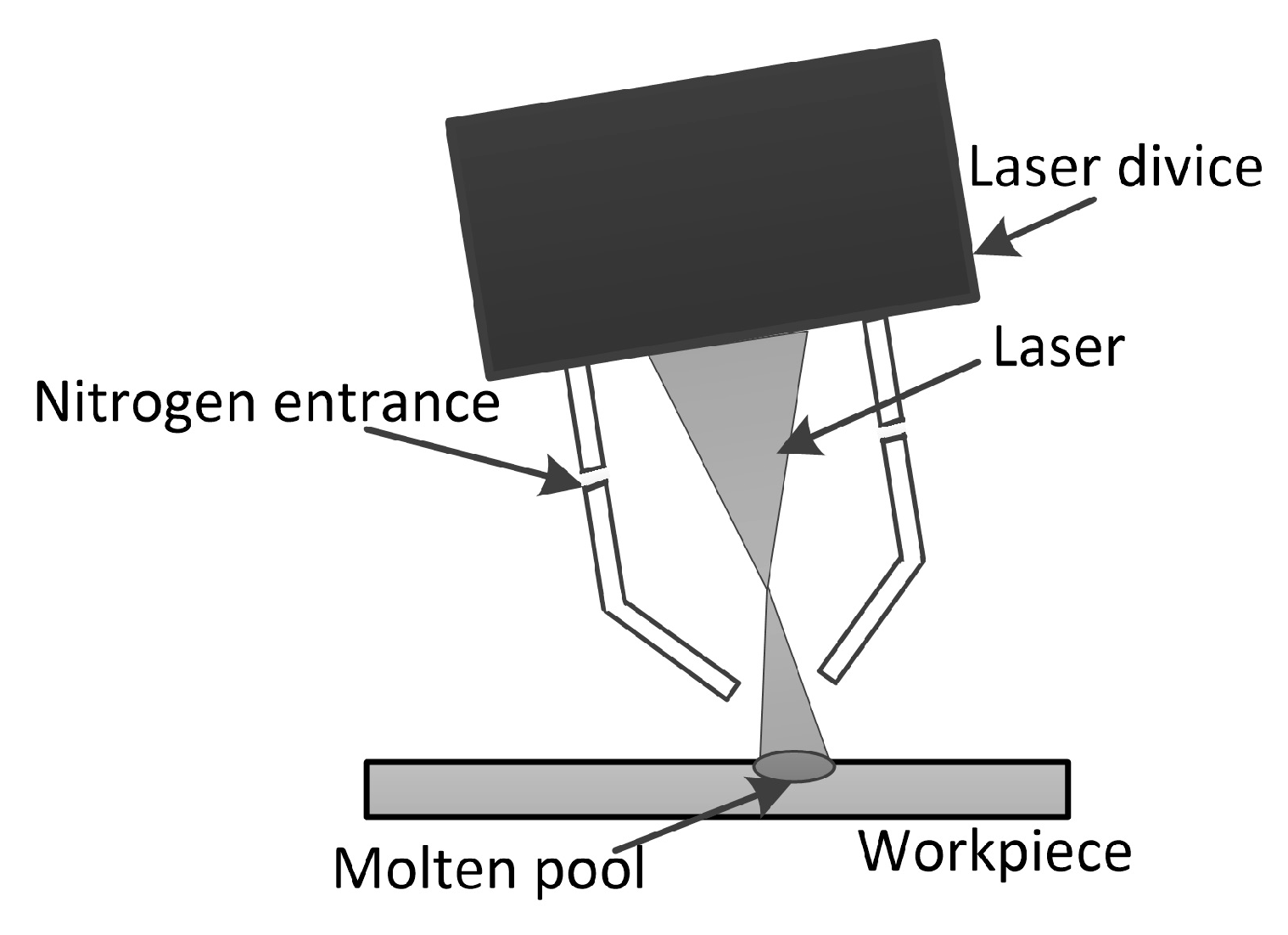

2. Materials and Methods

3. Results and Discussion

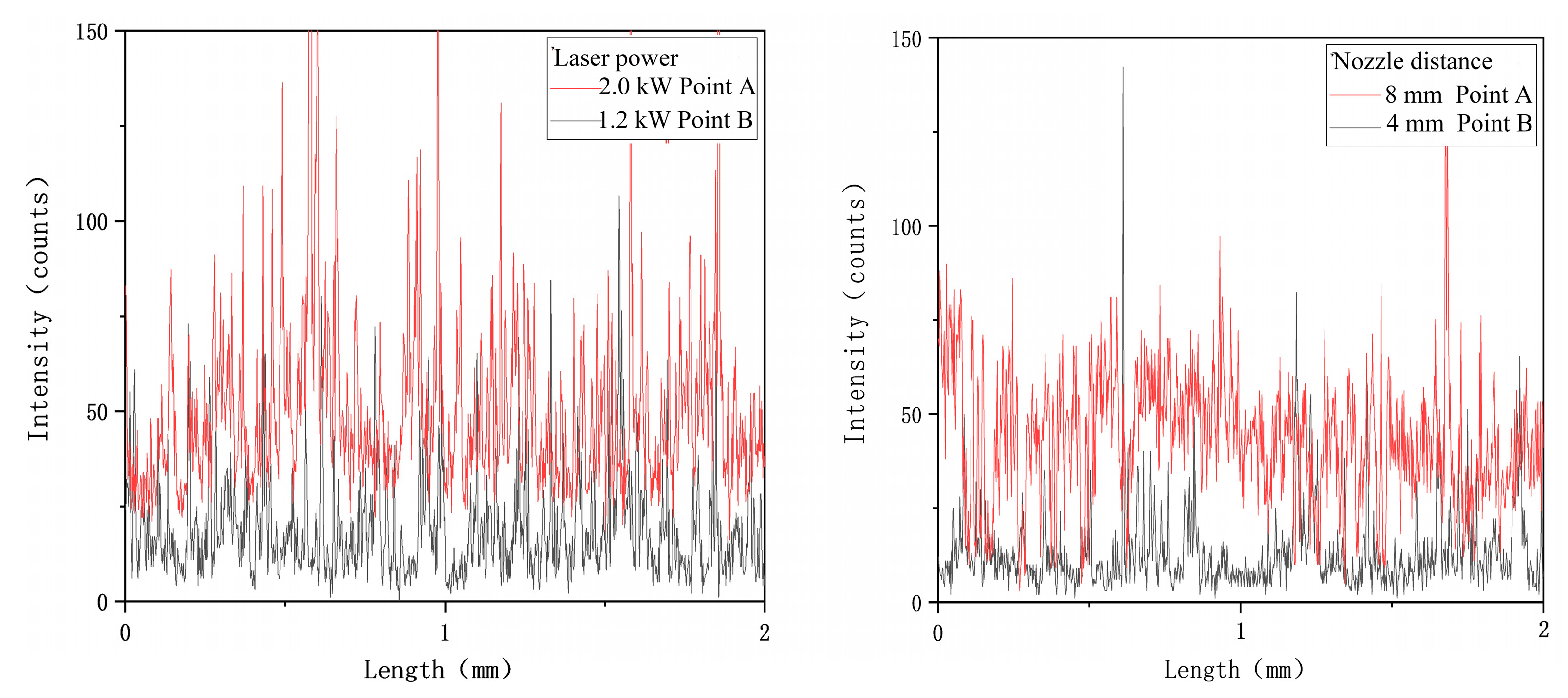

3.1. Effect of Laser Power on Surface Morphology

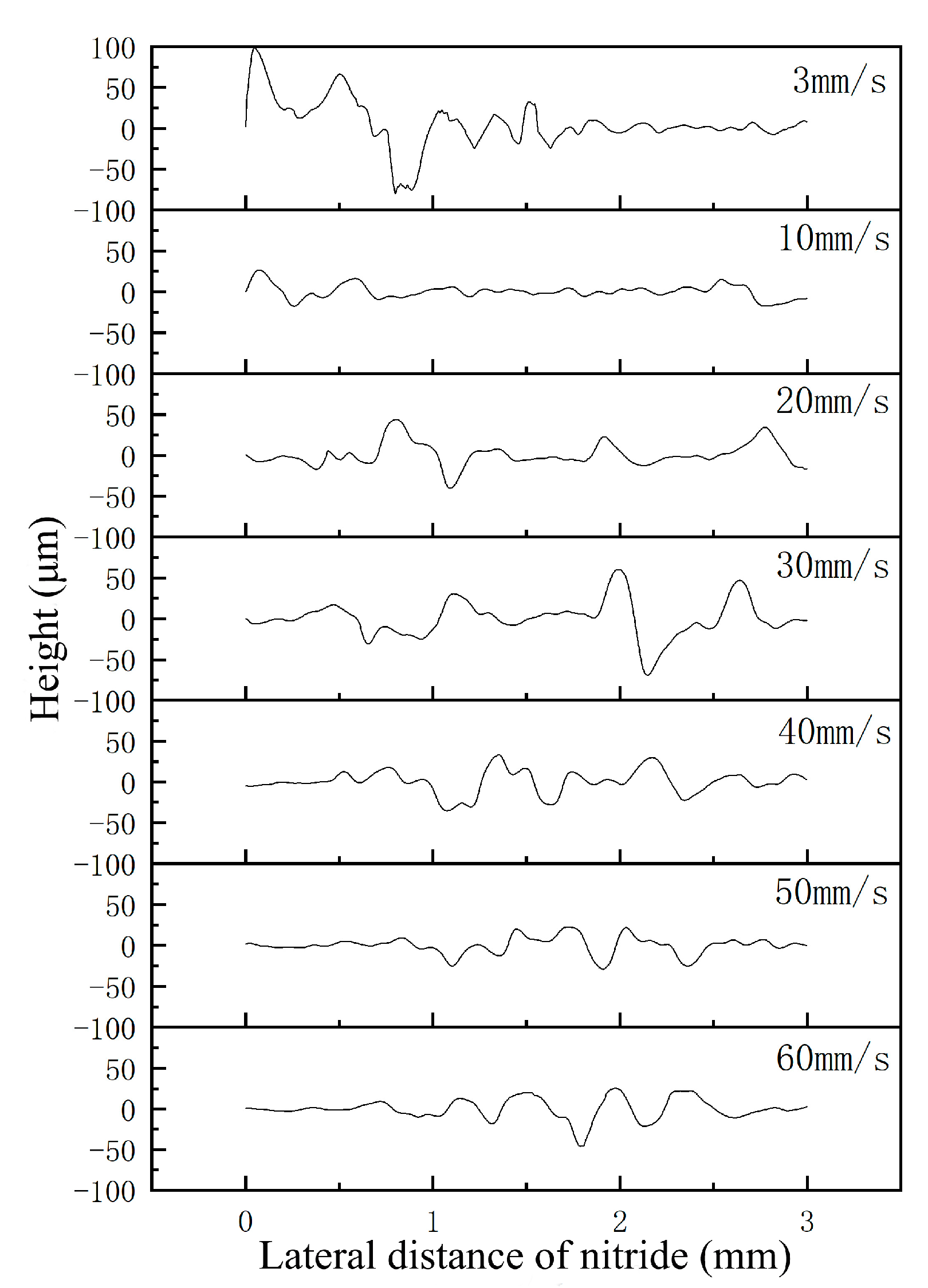

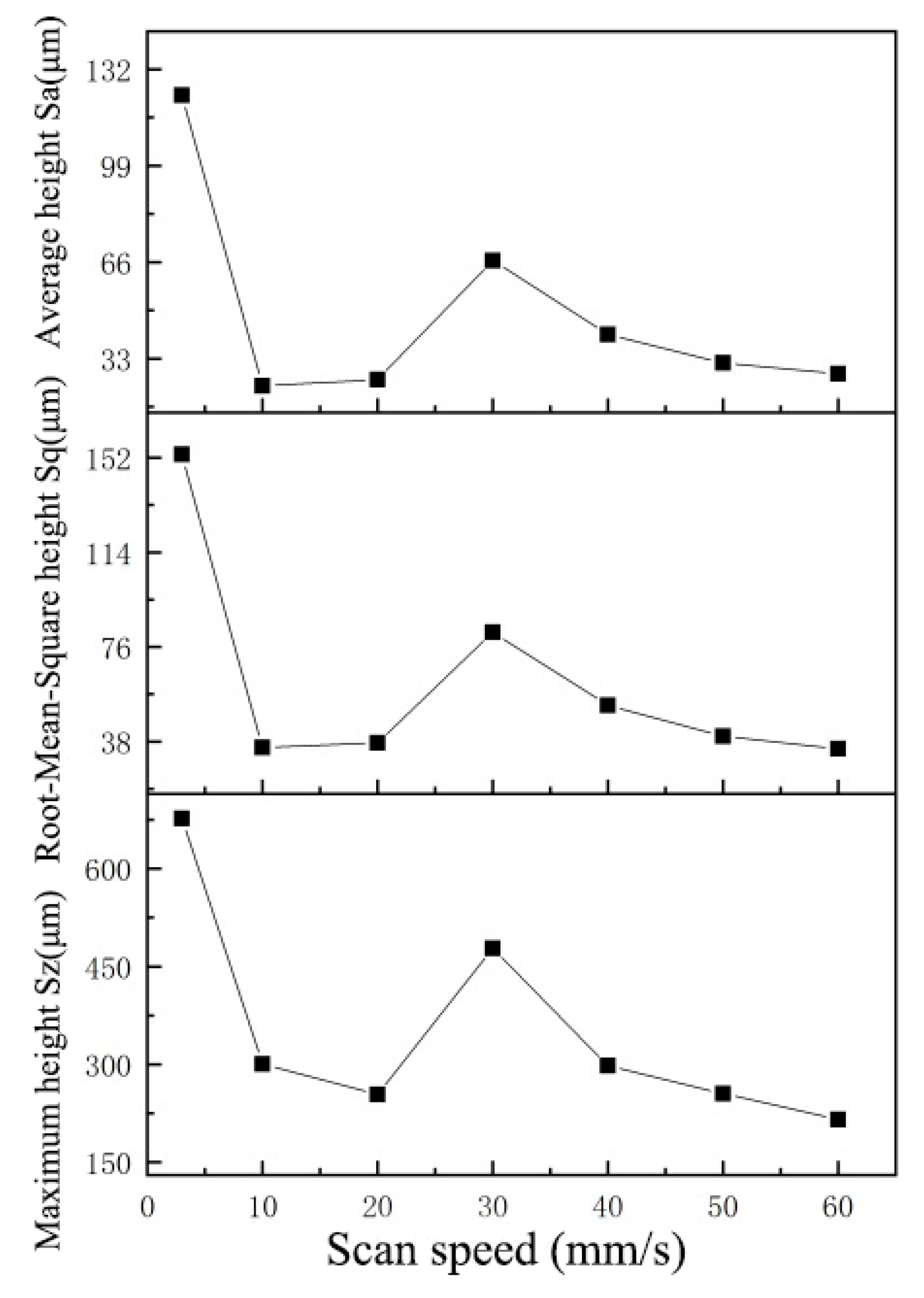

3.2. Effect of Laser Scanning Speed on Surface Morphology

3.3. Effect of Nozzle Distance on Surface Morphology

3.4. Effect of Nitrogen Flow Rate on Surface Morphology

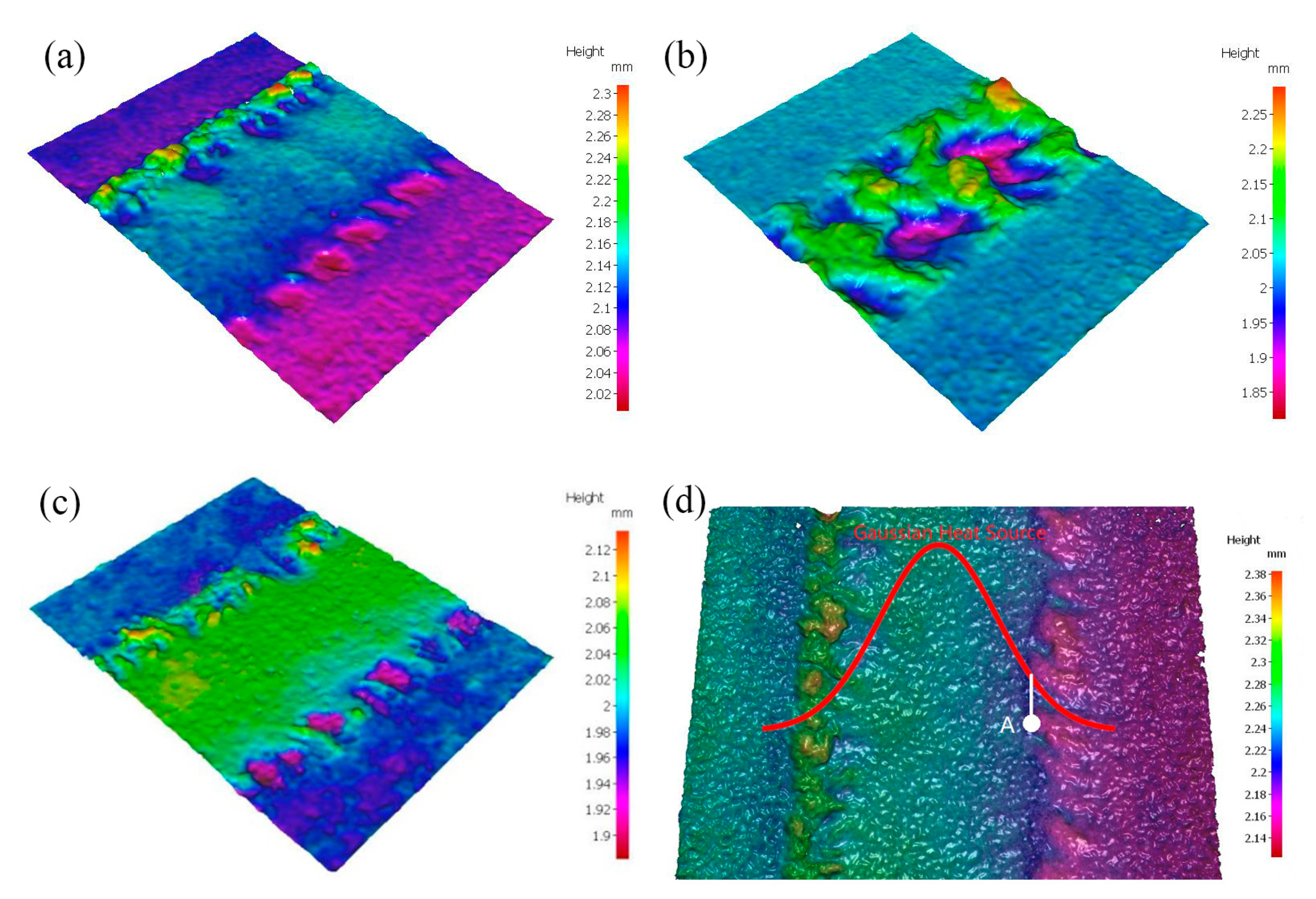

3.5. Mechanism Analysis

4. Conclusions

- (1)

- The laser power mainly affects the surface oxidation of the nitride layer. High laser power causes severe surface oxidation. The laser scanning speed mainly affects the surface roughness, which will increase when the scanning speed is too high or low. The nozzle distance has a great influence on the surface morphology, so the nozzle distance must be strictly controlled at 3~5 mm for an ideal surface morphology. The nitrogen flow rate has little influence on the surface morphology, so we recommend that a low nitrogen flow rate be used. A nitride layer with an optimal surface morphology can be obtained using the process parameters of group 5 in Table 2.

- (2)

- A large heat input and a high nitrogen flow rate cause an increase in the amount of TiN and TiO2 black powders on the surface of the nitride layer.

- (3)

- Surface oxidation does not affect the formation of a continuous TiN layer and surface roughness. The critical energy density leading to an increase in roughness is less than 3.1 × 104 W/cm2.

Author Contributions

Funding

Conflicts of Interest

References

- Da Silva Briguente, N.; Aparecida, L.; Oñoro, J.; Perpétuo Briguente, F.; Assis Resende, F.; Lidovino dos Reis, J.; Pereira Reis, D.A.; de Oliveira, A.C. The influence of laser nitriding on creep behavior of Ti-4Al-4V alloy with widmanstätten microstructure. Metals 2019, 9, 236. [Google Scholar] [CrossRef] [Green Version]

- Ohtsu, N.; Yamane, M.; Kodama, K.; Wagatsuma, K. Surface hardening of titanium by pulsed Nd: YAG laser irradiation at 1064-and 532-nm wavelengths in nitrogen atmosphere. Appl. Surf. Sci. 2010, 257, 691–695. [Google Scholar] [CrossRef]

- Kamat, A.M.; Copley, S.M.; Segall, A.E.; Todd, J.A. Laser-sustained plasma (LSP) nitriding of titanium: A review. Coatings 2019, 9, 283. [Google Scholar] [CrossRef] [Green Version]

- Hu, C.; Xin, H.; Watson, L.M.; Baker, T.N. Analysis of the phases developed by laser nitriding Ti6Al4V alloys. Acta Mater. 1997, 45, 4311–4322. [Google Scholar] [CrossRef]

- Singh, R.; Kurella, A.; Dahotre, N.B. Laser surface modification of Ti–6Al–4V: Wear and corrosion characterization in simulated biofluid. J. Biomater. Appl. 2006, 21, 49–73. [Google Scholar] [CrossRef] [PubMed]

- Singh, R.; Martin, M.; Dahotre, N.B. Influence of laser surface modification on corrosion behavior of stainless steel 316L and Ti–6Al–4V in simulated biofluid. Surf. Eng. 2005, 21, 297–306. [Google Scholar] [CrossRef]

- Kamat, A.M.; Copley, S.M.; Todd, J.A. Effect of processing parameters on microstructure during laser-sustained plasma (LSP) nitriding of commercially-pure titanium. Acta Mater. 2016, 107, 72–82. [Google Scholar] [CrossRef]

- Yilbas, B.S.; Karatas, C.; Keles, O.; Usta, I.Y.; Ahsan, M. CO2 laser gas assisted nitriding of Ti–6Al–4V alloy. Appl. Surf. Sci. 2006, 252, 8557–8564. [Google Scholar] [CrossRef]

- Sathish, S.; Geetha, M.; Pandey, N.D.; Richard, C.; Asokamani, R. Studies on the corrosion and wear behavior of the laser nitrided biomedical titanium and its alloys. Mater. Sci. Eng. C 2010, 30, 376–382. [Google Scholar] [CrossRef]

- Singh, S.; Tiwari, S.K.; Singh, R. Influence of laser scanning speed on nitrided Ti6Al4V surface. Surf. Eng. 2017, 9, 1–9. [Google Scholar] [CrossRef]

- Chen, X.; Wu, G.; Wang, R.; Guo, W.; Yang, J.; Cao, S.; Wang, Y.; Han, W. Laser nitriding of titanium alloy in the atmosphere environment. Surf. Coat. Technol. 2007, 201, 4843–4846. [Google Scholar] [CrossRef]

- Abboud, J.H.; Fidel, A.F.; Benyounis, K.Y. Surface nitriding of Ti–6Al–4V alloy with a high power CO2 laser. Opt. Laser Technol. 2008, 40, 405–414. [Google Scholar] [CrossRef]

- Chan, C.-W.; Lee, S.; Smith, G.C.; Donaghy, C. Fibre laser nitriding of titanium and its alloy in open atmosphere for orthopaedic implant applications: Investigations on surface quality, microstructure and tribological properties. Surf. Coat. Technol. 2017, 309, 628–640. [Google Scholar] [CrossRef] [Green Version]

- Katahira, K.; Tanida, Y.; Takesue, S.; Komotori, J. Rapid surface nitriding of titanium alloy by a nanosecond fiber laser under atmospheric conditions. Cirp Ann. 2018, 67, 563–566. [Google Scholar] [CrossRef]

- Ng, C.-H.; Chan, C.-W.; Man, H.-C.; Waugh, D.; Lawrence, J. Modifications of surface properties of beta Ti by laser gas diffusion nitriding. J. Laser Appl. 2016, 28, 022505. [Google Scholar] [CrossRef]

- Meng, W.; Xu, Z.; Ma, Q.; Yin, X.; Fang, J. Pulse fiber laser welding of AISI 321-AISI 405 stainless steel thick plates butt joints. J. Mater. Process. Technol. 2019, 271, 214–225. [Google Scholar] [CrossRef]

- Nassar, A.R.; Akarapu, R.; Copley, S.M.; Todd, J.A. Investigations of laser-sustained plasma and its role in laser nitriding of titanium. J. Phys. D Appl. Phys. 2012, 45, 185401. [Google Scholar] [CrossRef]

- Thomann, A.L.; Boulmer-Leborgne, C.; Andreazza-Vignolle, C.; Andreazza, P.; Hermann, J.; Blondiaux, G. Metal surface nitriding by laser induced plasma. J. Appl. Phys. 2012, 80, 4673–4684. [Google Scholar] [CrossRef]

- Kloosterman, A.B.; Hosson, J.T.M.D. Microstructural characterization of laser nitrided titanium. Scr. Metall. Et Mater. 1995, 33, 567–573. [Google Scholar] [CrossRef] [Green Version]

- Kaspar, J.; Bretschneider, J.; Jacob, S.; Bonß, S.; Winderlich, B.; Brenner, B. Microstructure, hardness and cavitation erosion behaviour of Ti–6Al–4V laser nitrided under different gas atmospheres. Surf. Eng. 2007, 23, 99–106. [Google Scholar] [CrossRef]

| Element | Al | V | Fe | C | N | H | Ti |

|---|---|---|---|---|---|---|---|

| Concentration (wt.%) | 5.7 | 3.9 | 0.3 | 0.1 | 0.05 | 0.015 | Others |

| Group | Power (kW) | Scanning Speed (mm/s) | Nozzle Distance (mm) | Nitrogen Flow Rate (L/min) |

|---|---|---|---|---|

| 1 | 1.0/1.2/1.4/1.6/1.8/2.0 | 10 | 3 | 10 |

| 2 | 1.4 | 3/10/20/30/40/50/60 | 3 | 10 |

| 3 | 1.4 | 10 | 3/4/5/6/7/8 | 10 |

| 4 | 1.4 | 10 | 3 | 2/5/10/15/20/23 |

| 5 | 1.4 | 10 | 3 | 10 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guo, J.; Shi, Y.; Geng, P.; Zhang, G.; Zhu, M. The Surface Morphology of a Ti–6Al–4V Fiber-Lasered Nitride Layer. Coatings 2020, 10, 451. https://doi.org/10.3390/coatings10050451

Guo J, Shi Y, Geng P, Zhang G, Zhu M. The Surface Morphology of a Ti–6Al–4V Fiber-Lasered Nitride Layer. Coatings. 2020; 10(5):451. https://doi.org/10.3390/coatings10050451

Chicago/Turabian StyleGuo, Jinchang, Yu Shi, Peibiao Geng, Gang Zhang, and Ming Zhu. 2020. "The Surface Morphology of a Ti–6Al–4V Fiber-Lasered Nitride Layer" Coatings 10, no. 5: 451. https://doi.org/10.3390/coatings10050451