Improvement of the Interfacial Fatigue Strength and Milling Behavior of Diamond Coated Tools via Appropriate Annealing

Abstract

:1. Introduction

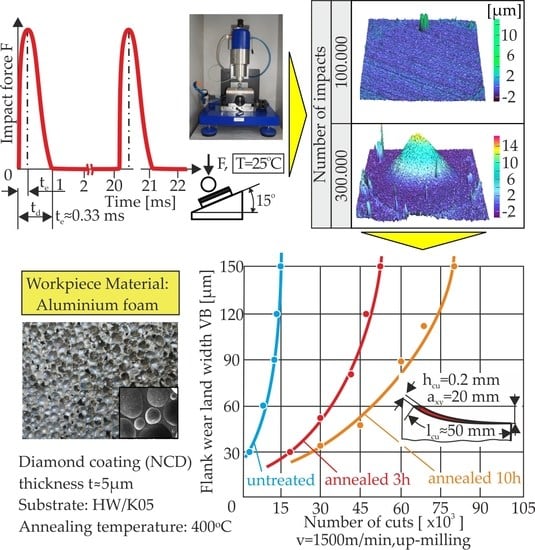

2. Experimental and Computational Details

3. Results and Discussion

3.1. Mechanical Properties of Cemented Carbide Substrates before and after Annealing

3.2. Residual Stresses in NCD Coatings before and after Their Annealings

3.3. Evaluation of the Interfacial Fatigue Strength of Diamond Coated Tools before and after Their Annealings

3.4. Explanation of the Attained Impact Test Results

3.5. Wear Behavior of the Untreated and Annealed Diamond Coated Tools in Milling

3.6. Review of the Obtained Results

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Haubner, R.; Kalss, W. Diamond deposition on hardmetal substrates—Comparison of substrate pre-treatments and industrial applications. Int. J. Refract. Met. Hard Mater. 2010, 28, 475–483. [Google Scholar] [CrossRef]

- Ng, E.-G.; Szablewski, D.; Dumitrescu, M.; Elbestawi, M.A.; Sokolowski, J.H. High speed face milling of an aluminium silicon alloy casting. CIRP Ann. 2004, 53, 69–72. [Google Scholar] [CrossRef]

- Uhlmann, E.; Reimers, W.; Byrne, F.; Klaus, M. Analysis of tool wear and residual stress of CVD diamond coated cemented carbide tools in the machining of aluminum silicon alloys. J. Prod. Eng. 2010, 4, 203–209. [Google Scholar] [CrossRef]

- Polini, R. Chemically vapour deposited diamond coatings on cemented tungsten carbides: Substrate pretreatments, adhesion and cutting performance. Thin Solid Films 2016, 515, 4–13. [Google Scholar] [CrossRef] [Green Version]

- Skordaris, G.; Bouzakis, K.-D.; Kotsanis, T.; Boumpakis, A.; Stergioudi, F.; Christofilos, D.; Lemmer, O.; Kölker, W.; Woda, M. Effect of the crystallinity of diamond coatings on cemented carbide inserts on their cutting performance in milling. CIRP Ann. 2019, 68, 65–68. [Google Scholar] [CrossRef]

- Bouzakis, E.; Bouzakis, K.-D.; Skordaris, G.; Charalampous, P.; Kombogiannis, S.; Lemmer, O. Fatigue strength of diamond coating-substrate interface assessed by inclined impact tests at ambient and elevated temperatures. Diam. Relat. Mater. 2014, 50, 77–85. [Google Scholar] [CrossRef]

- Skordaris, G.; Bouzakis, K.-D.; Charalampous, P.; Kotsanis, T.; Bouzakis, E.; Lemmer, O. Effect of structure and residual stresses of diamond coated cemented carbide tools on the film adhesion and developed wear mechanisms in milling. CIRP Ann. 2016, 65, 101–104. [Google Scholar] [CrossRef]

- Bouzakis, K.-D.; Skordaris, G.; Bouzakis, E.; Charalampous, P.; Kotsanis, T.; Tasoulas, D.; Kombogiannis, S.; Lemmer, O. Effect of the interface fatigue strength of NCD coated hardmetal inserts on their cutting performance in milling. Diam. Relat. Mater. 2015, 59, 80–89. [Google Scholar] [CrossRef]

- Polini, R.; Kumashiro, S.; Jackson, M.J.; Amar, M.; Ahmed, W.; Sein, H. A study of diamond synthesis by hot filament chemical vapor deposition on Nc coatings. J. Mater. Eng. Perform. 2005, 15, 218–222. [Google Scholar] [CrossRef]

- Polini, R.; Barletta, M.; Cristofanilli, G. Wear resistance of nano- and micro-crystalline diamond coatings onto WC–Co with Cr/CrN interlayers. Thin Solid Films 2010, 519, 1629–1635. [Google Scholar] [CrossRef]

- Silva, S.; Mammana, V.P.; Salvadori, M.C.; Monteiro, O.R.; Brown, L.G. WC-Co cutting tool inserts with diamond coatings. Diam. Relat. Mater. 1999, 8, 1913–1918. [Google Scholar] [CrossRef]

- Slack, G.A.; Bartram, S.F. Thermal expansion of some diamondlike crystals. J. Appl. Phys. 1975, 46, 89–98. [Google Scholar]

- Woehrl, N.; Hirte, T.; Posth, O.; Buck, V. Investigation of the coefficient of thermal expansion in nanocrystalline diamond films. Diam. Relat. Mater. 2009, 18, 224–228. [Google Scholar] [CrossRef]

- Lee, D.G.; Fitz-Gerald, J.M.; Singh, R.K. Novel method for adherent diamond coatings on cemented carbide substrates. Surf. Coat. Technol. 1998, 100–101, 187–191. [Google Scholar] [CrossRef]

- Staia, M.H.; D’Alessandria, M.; Quinto, D.T.; Roudet, F.; Marsal Astort, M. High-temperature tribological characterization of commercial TiAlN coatings. J. Phys. Condens. Matter 2006, 18, 1727–1736. [Google Scholar] [CrossRef] [PubMed]

- Ferrari, A.C.; Robertson, J. Origin of the 1150-cm−1 Raman mode in nanocrystalline diamond. Phys. Rev. B 2001, 63, 121405. [Google Scholar] [CrossRef]

- Bouzakis, K.-D.; Michailidis, N.; Hadjiyiannis, S.; Skordaris, G.; Erkens, G. The effect of specimen roughness and indenter tip geometry on the determination accuracy of thin hard coatings stress-strain laws by nanoindentation. Mater. Charact. 2002, 49, 149–156. [Google Scholar] [CrossRef]

- Bouzakis, K.-D.; Skordaris, G.; Bouzakis, E.; Makrimallakis, S.; Kombogiannis, S.; Lemmer, O. Fatigue strength of diamond coatings’ interface assessed by inclined impact test. Surf. Coat. Technol. 2013, 237, 135–141. [Google Scholar] [CrossRef]

- Impact-BZ Ltd. Available online: www.impact-bz.com (accessed on 21 August 2020).

- Teppernegg, T.; Klünsner, T.; Kremsner, C.; Tritremmel, C.; Czettl, C.; Puchegger, S.; Marsoner, S.; Pippan, R.; Ebner, R. High temperature mechanical properties of WC–Co hard metals. Int. J. Refract. Met. Hard Mater. 2016, 56, 139–144. [Google Scholar] [CrossRef]

- Skordaris, G. Fatigue strength of diamond coating-substrate interface quantified by a dynamic simulation of the inclined impact test. J. Mater. Eng. Perform. 2014, 23, 3497–3504. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Skordaris, G.; Kotsanis, T.; Boumpakis, A.; Stergioudi, F. Improvement of the Interfacial Fatigue Strength and Milling Behavior of Diamond Coated Tools via Appropriate Annealing. Coatings 2020, 10, 821. https://doi.org/10.3390/coatings10090821

Skordaris G, Kotsanis T, Boumpakis A, Stergioudi F. Improvement of the Interfacial Fatigue Strength and Milling Behavior of Diamond Coated Tools via Appropriate Annealing. Coatings. 2020; 10(9):821. https://doi.org/10.3390/coatings10090821

Chicago/Turabian StyleSkordaris, Georgios, Tilemachos Kotsanis, Apostolos Boumpakis, and Fani Stergioudi. 2020. "Improvement of the Interfacial Fatigue Strength and Milling Behavior of Diamond Coated Tools via Appropriate Annealing" Coatings 10, no. 9: 821. https://doi.org/10.3390/coatings10090821