The Study on Feasibility and Welding Characteristics of GMAW Surfacing Remanufacturing of H13 Steel Cutter Ring of TBM Hob

Abstract

:1. Introduction

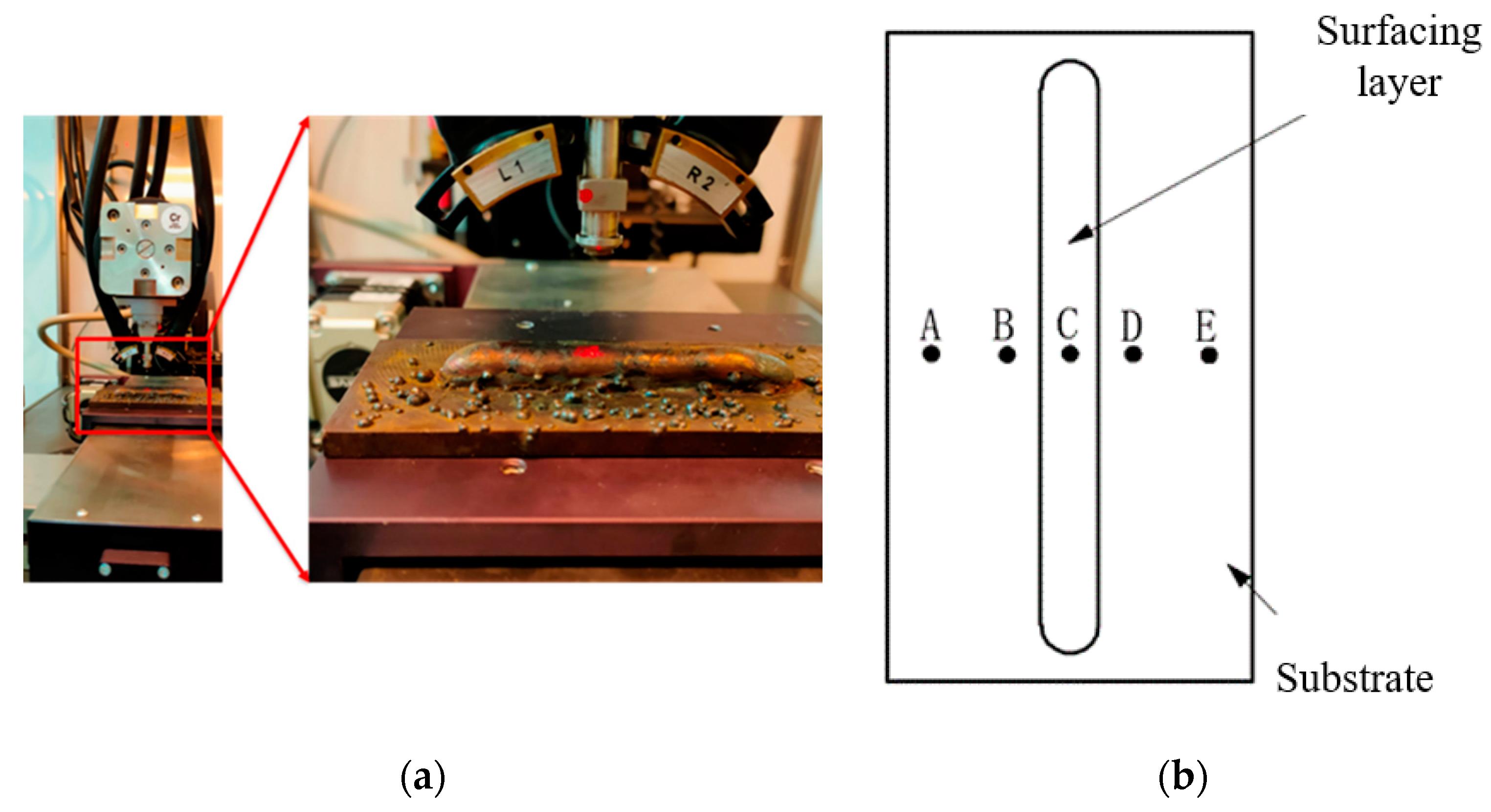

2. Methods and Procedures of Experiment

3. Analysis of Experiment Results

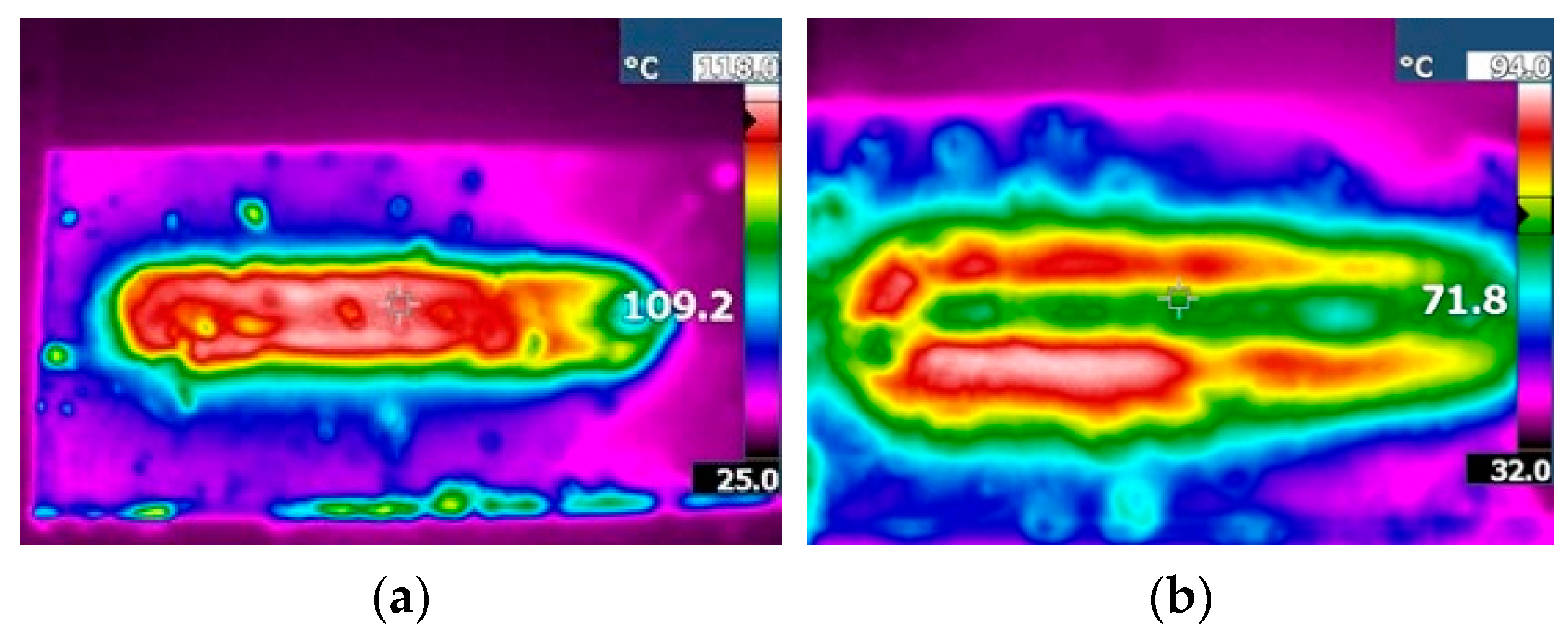

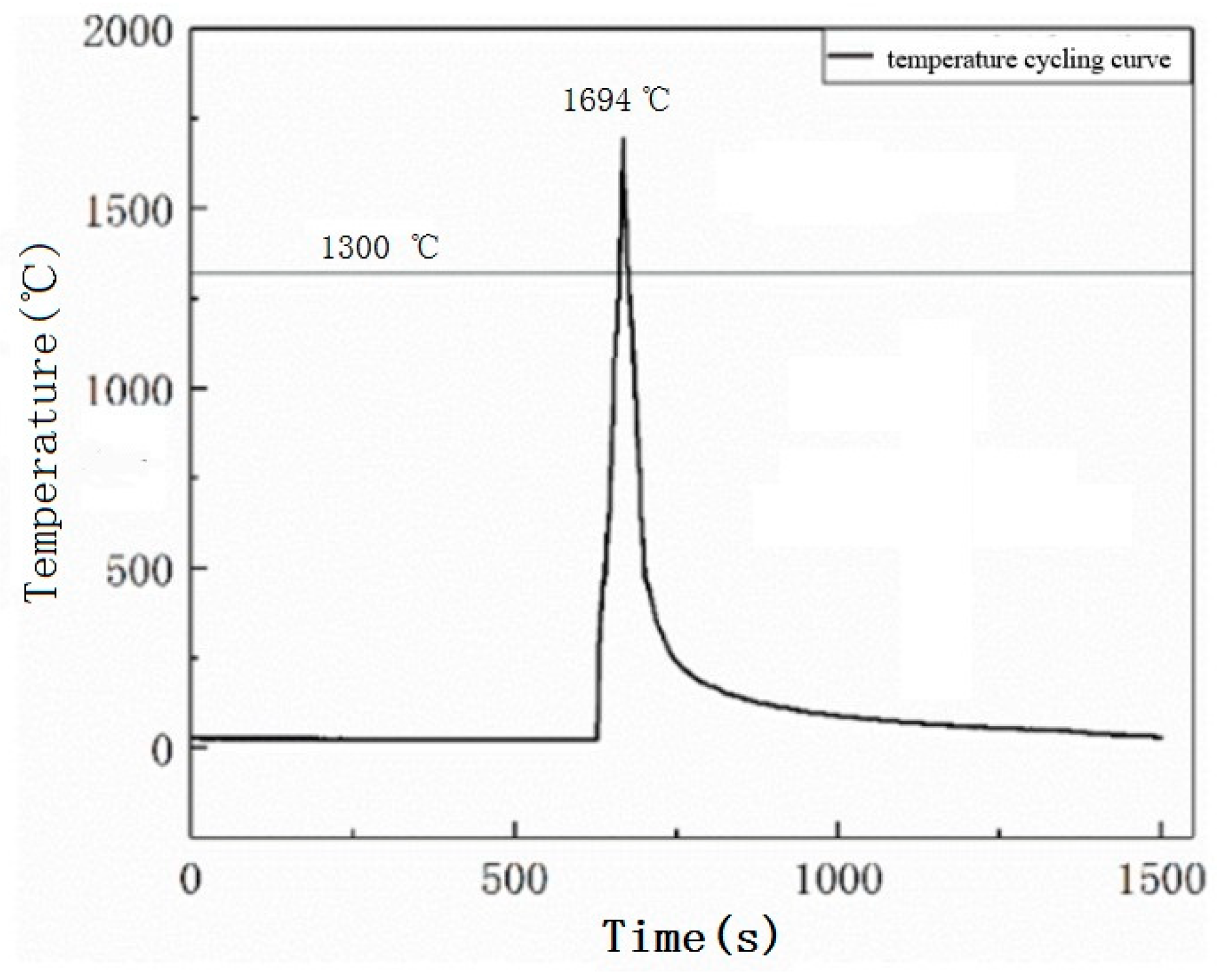

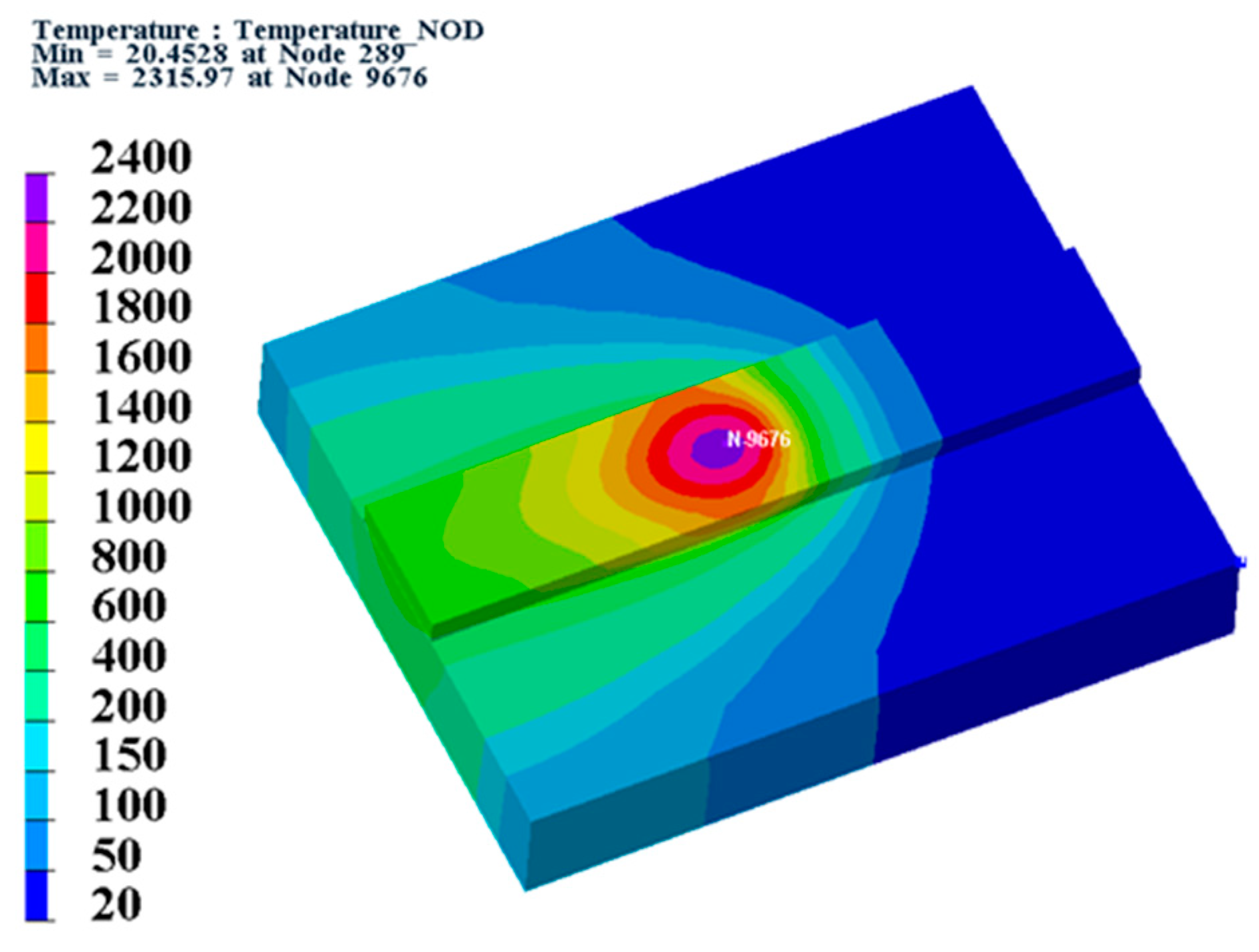

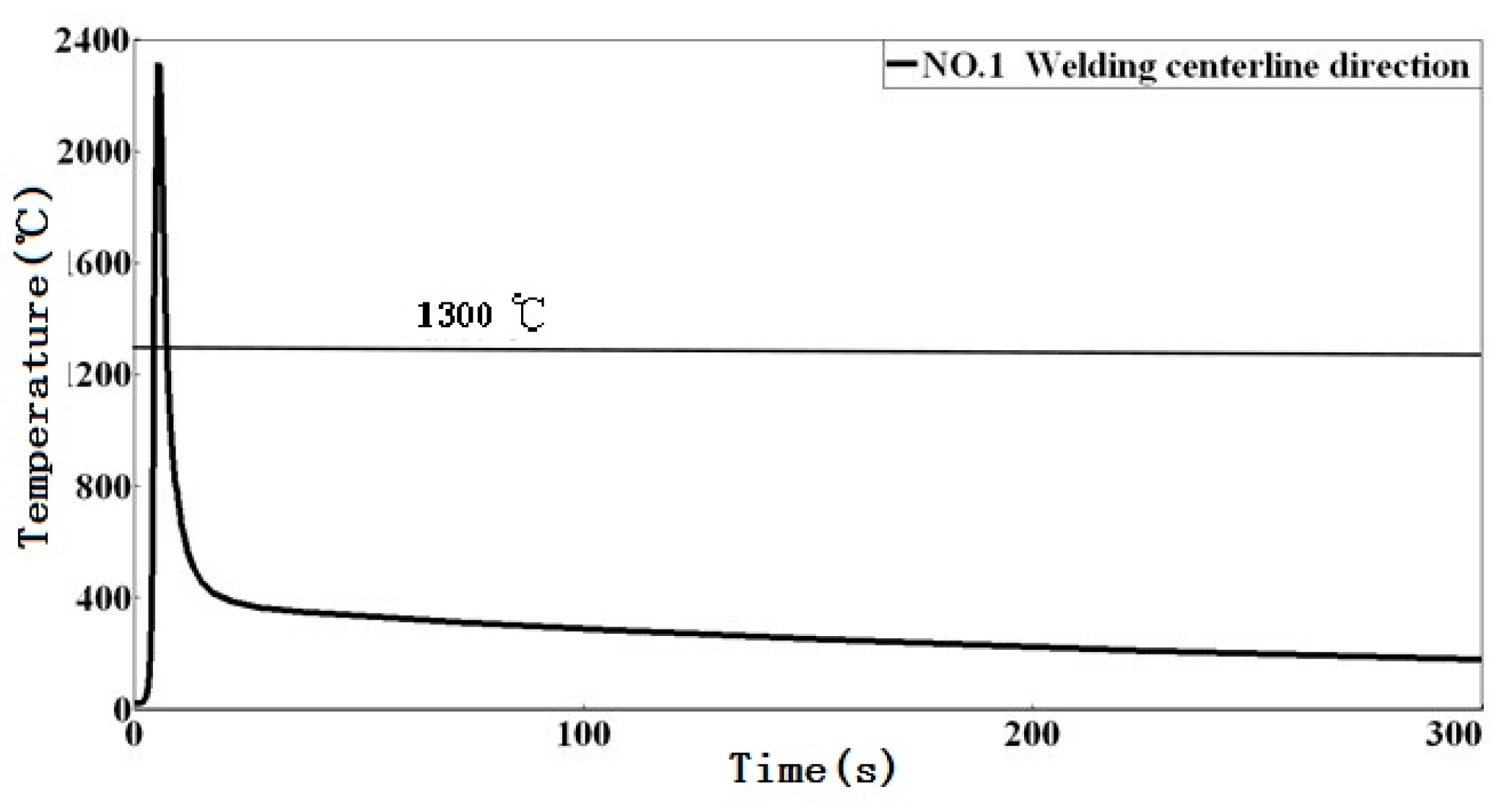

3.1. Analysis of Temperature Field

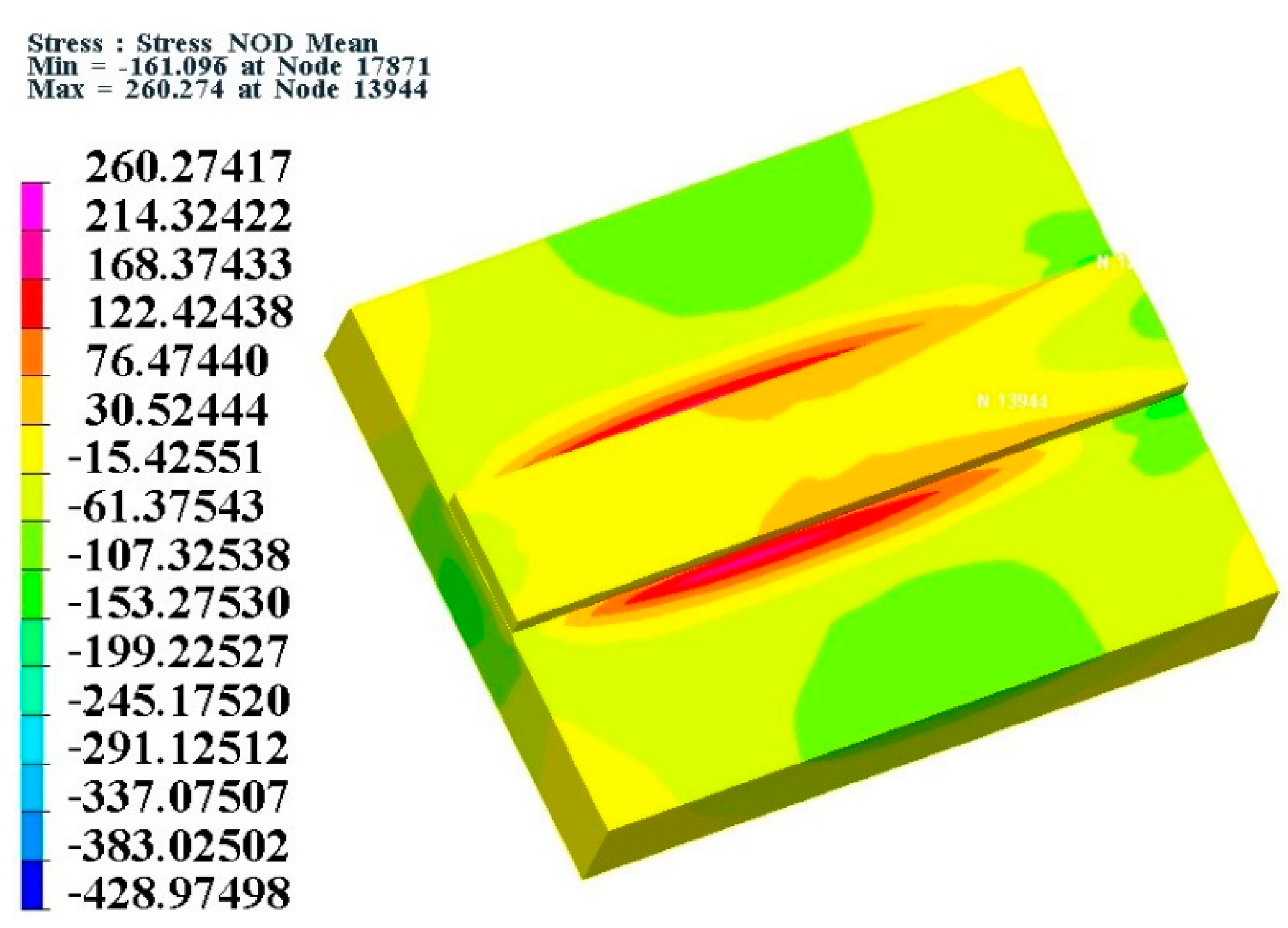

3.2. Analysis of Stress Field

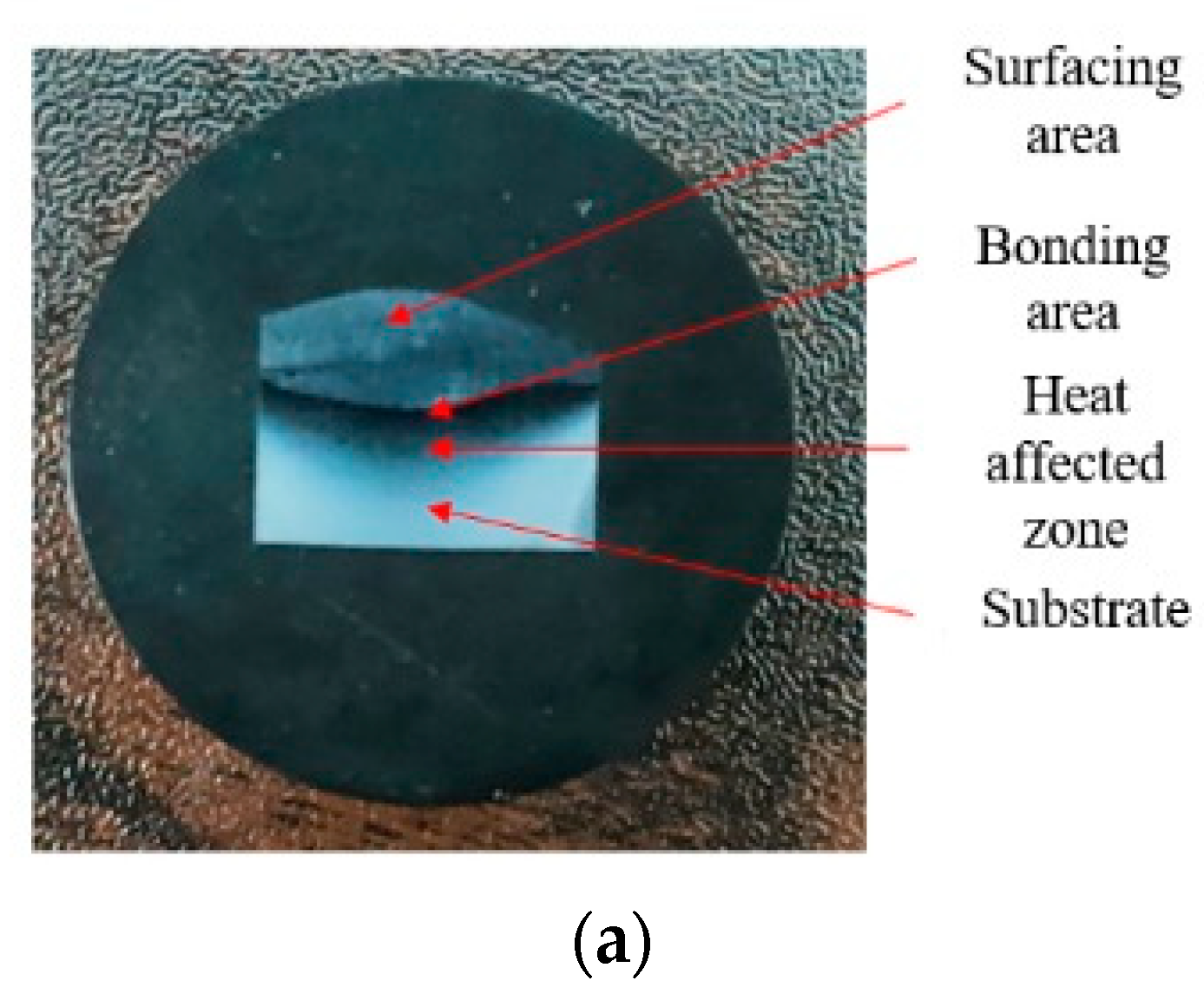

3.3. Analysis of Structure

- On the base metal shown in Figure 5b, because the base metal is less affected by heat, the structure produced is mainly tempered martensite and a small amount of sorbite.

- In the heat affected zone shown in Figure 5c, due to the high surfacing speed and cooling speed produced by metal active gas (MAG)welding, it is conducive to the transformation of austenite into martensite. Therefore, the structure in the heat affected zone is mainly martensite, and there are some retained austenite, a small amount of ferrite and pearlite (the main structure of H13 steel in annealed state), etc. According to the top-down direction in Figure 5a, the heat affected zone is divided into overheating zone, normalizing zone and a small amount of microstructure transformation zone. Affected by the thermal cycle in the surfacing process, the temperature of heat affected zone increases gradually. When the austenite transformation temperature is reached, some grains will grow up and some structures will transform into austenite, from the end of surfacing to the beginning of cooling, due to the local heat dissipation of base material, the temperature of heat affected zone decreases and the microstructure changes again. This process is repeated during surfacing, resulting in this area being equivalent to multiple heat treatments of different degrees, so the structure will have obvious changes.

- In the bonding zone shown in Figure 5d, the formed structure is mainly martensite, and there are also some carbides at the edges of the white ferrite grains; the bonding zone is located between the surfacing layer and the base metal, which is the transition zone, where the quality of the structure is generally poor. This is because the temperature of the bonding zone during the surfacing process is higher than the solidus line but lower than the liquidus line. The metal is in a molten state at this time. The uneven distribution of chemical composition in base metal and welding wire leads to the uneven distribution of microstructure, which makes the microstructure and properties of bonding area much worse than other areas; the existence of the bonding zone further indicates that there is atomic diffusion and migration between the surfacing layer and the base metal, and the liquid metal of the surfacing layer interacts with the solid base metal, resulting in metallurgical bonding. The main chemical elements C, Cr, Mo and V of H13 steel plate and H13 steel flux cored wire are the same, so the fusion among them is better. The bonding zone is mainly formed by the infiltration of carbon and alloy elements, and the diffusion speed is determined by the element concentration gradient, temperature, time and atomic mobility. Because the cooling rate of MAG surfacing process is very fast, the contact time between liquid phase and base metal solid phase is very short, which finally leads to the short diffusion time of elements and the narrow bonding zone.

- In the surfacing area shown in Figure 5e, f, the main structures formed are petal-like dendrites, off-white equiaxed martensite, and white eutectic alloy carbides between dendrites, etc. Among them, the main forms of alloy carbides are M3C and M7C3 types; the alloy carbides containing Cr will increase the hardness of the surfacing layer after being dispersed and precipitated, and will also improve the hardenability of the material and promote the formation of martensite. The carbide formed by Mn element can maintain the plasticity and toughness of the material while increasing the strength of the material. Higher W content can significantly improve the red hardness and thermal strength of H13 steel.

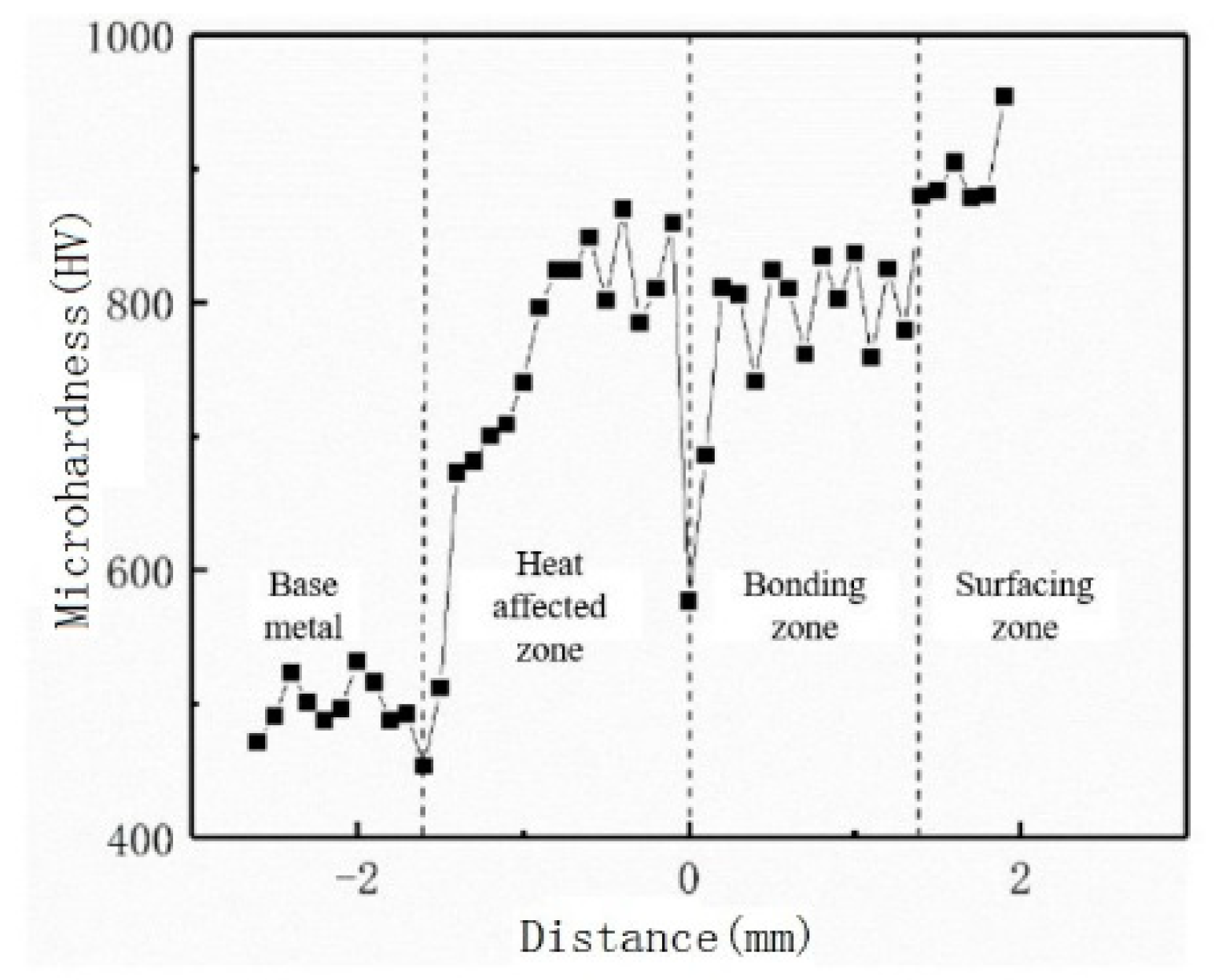

3.4. Analysis of Hardness

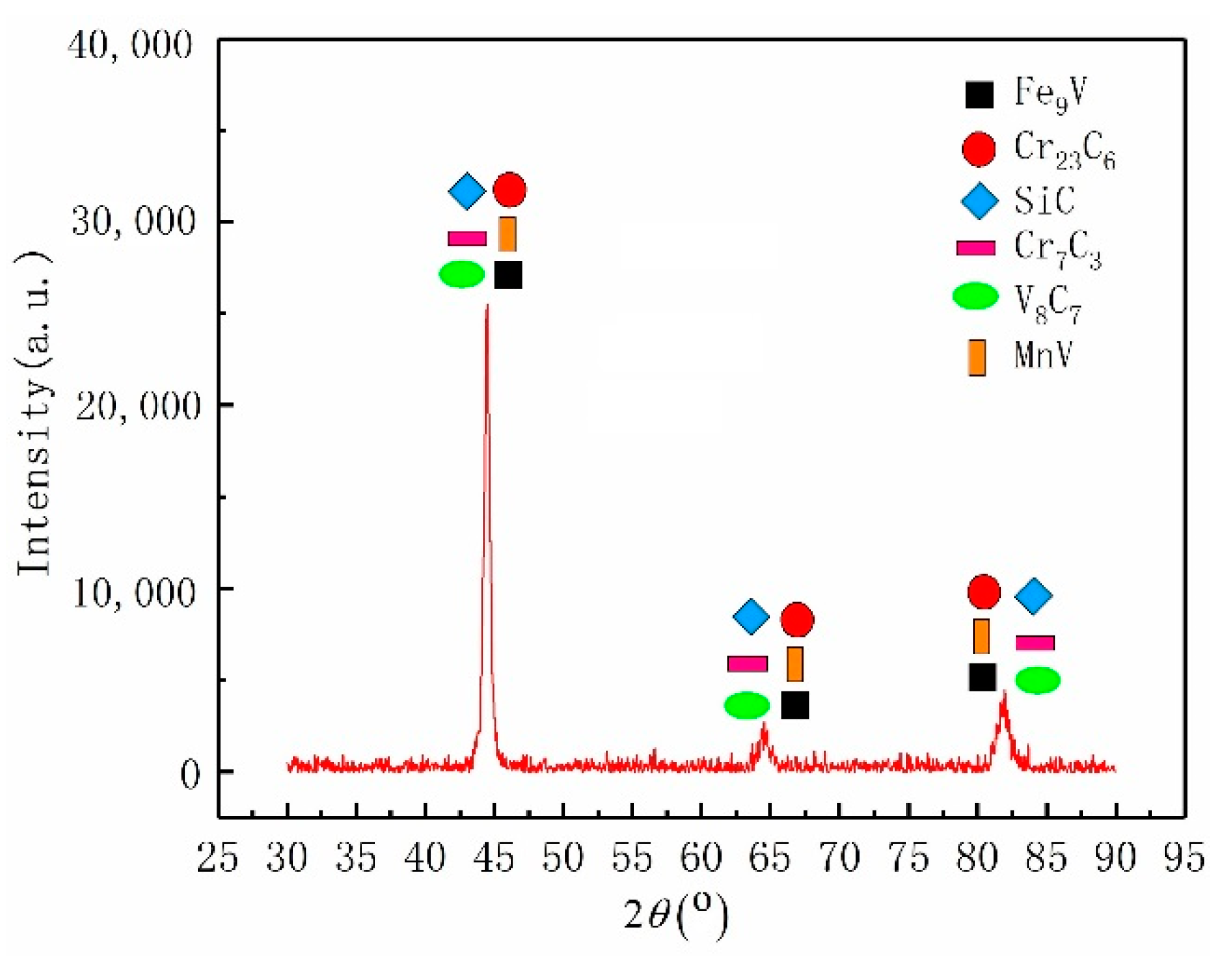

3.5. Analysis of Phase

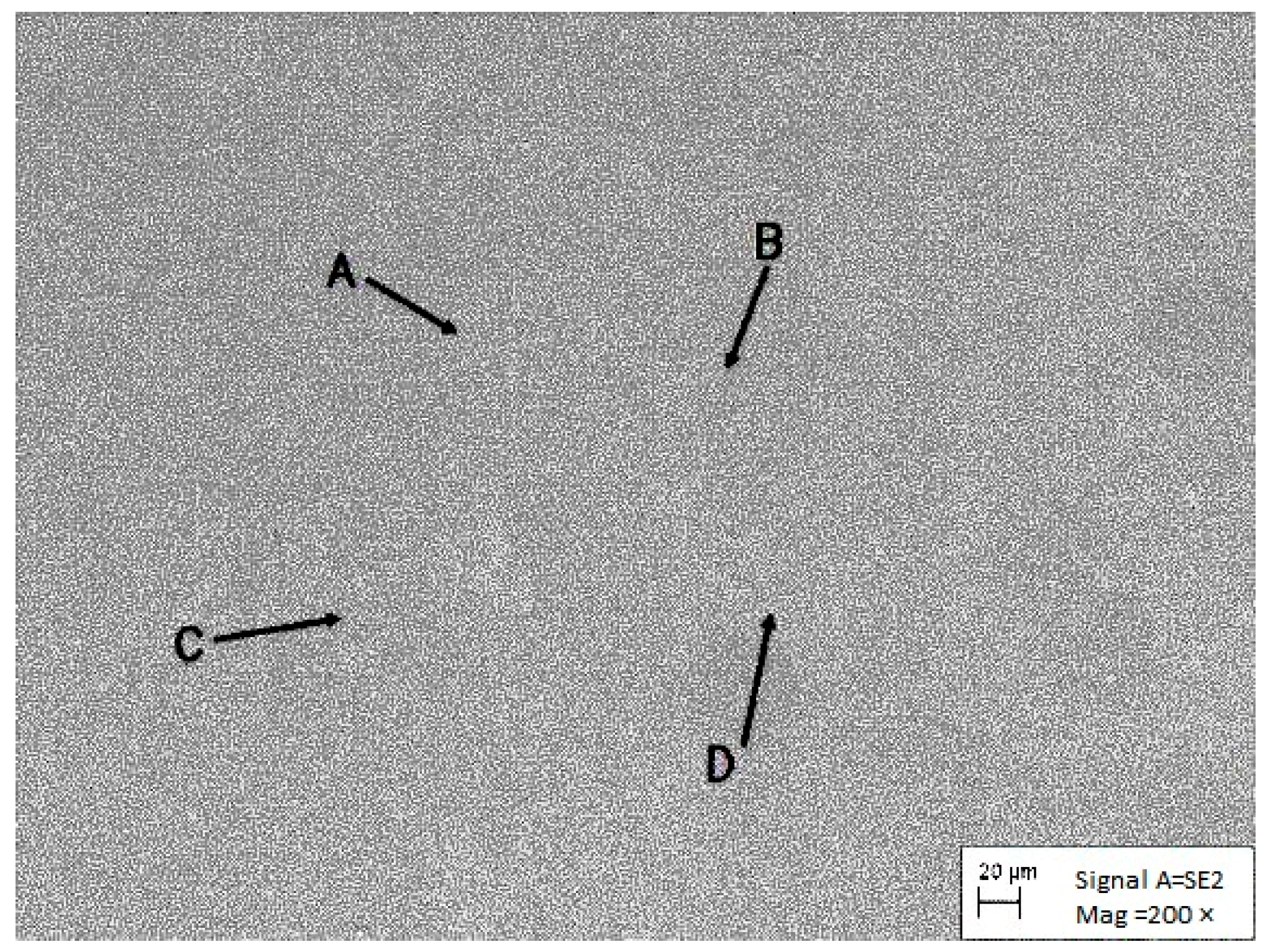

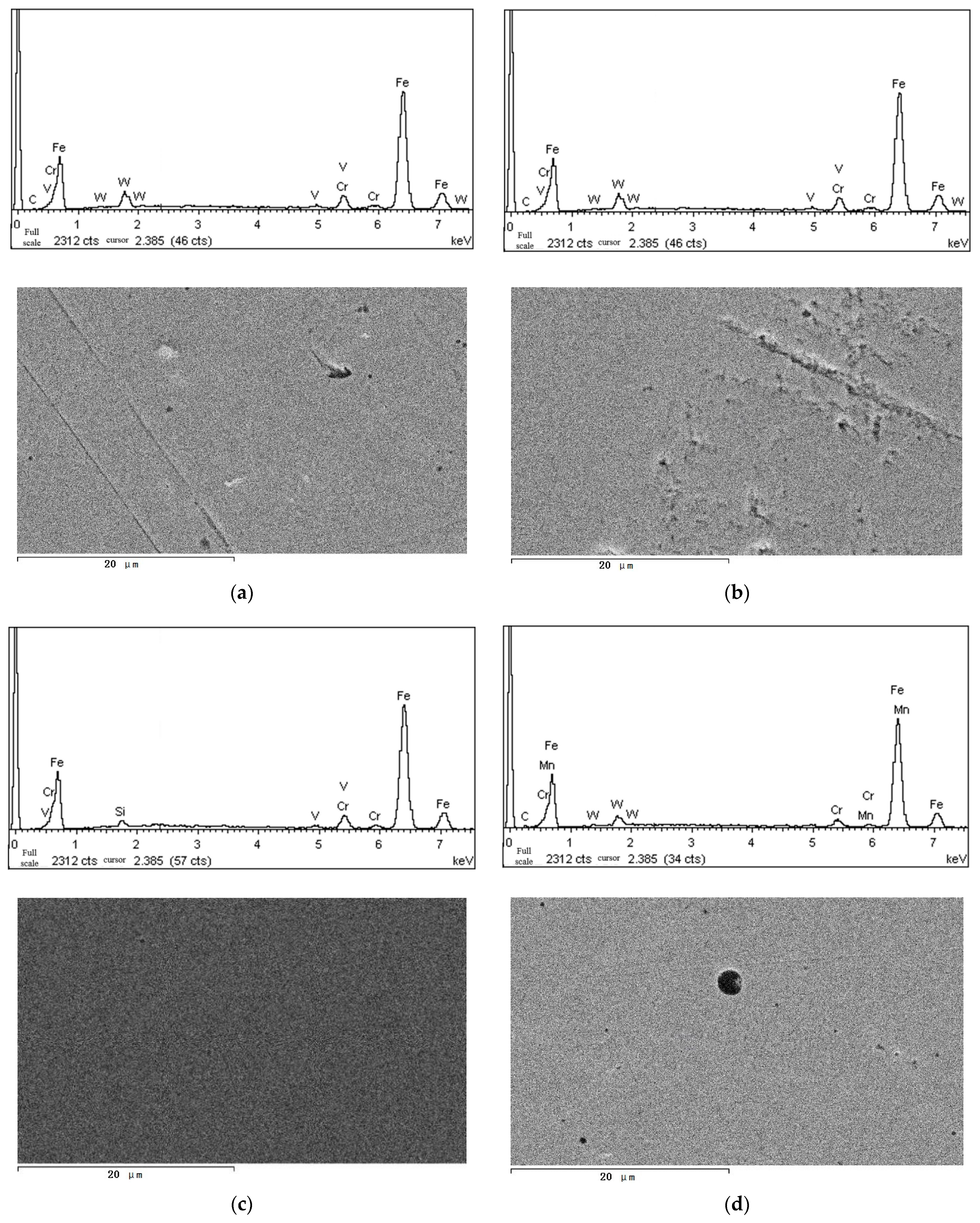

3.6. Analysis of Morphology

4. Simulation Modeling Analysis of H13 Steel Surfacing Remanufacturing

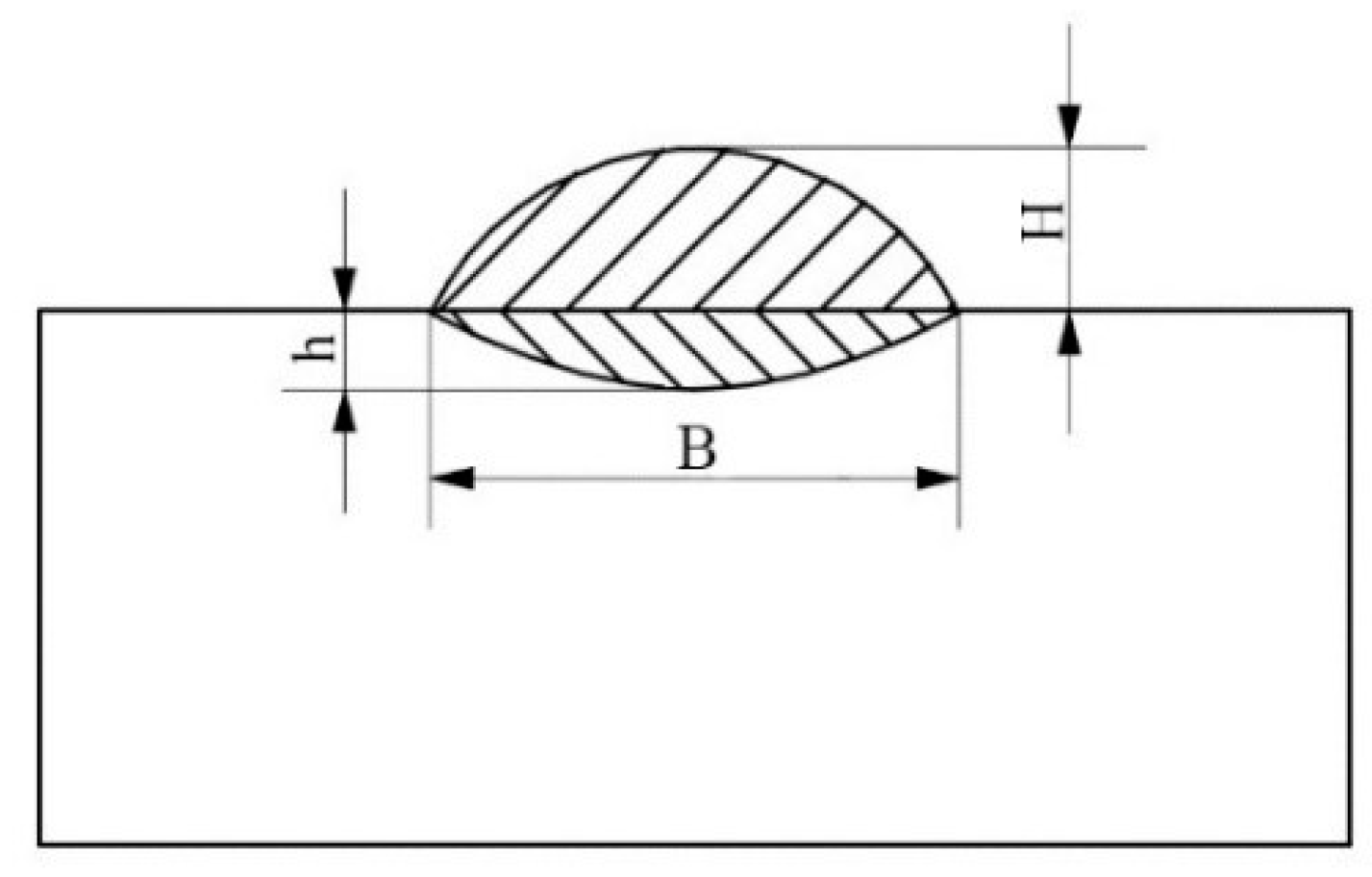

4.1. Establishment of Finite Element Model

4.2. Analysis of Simulation Temperature Field

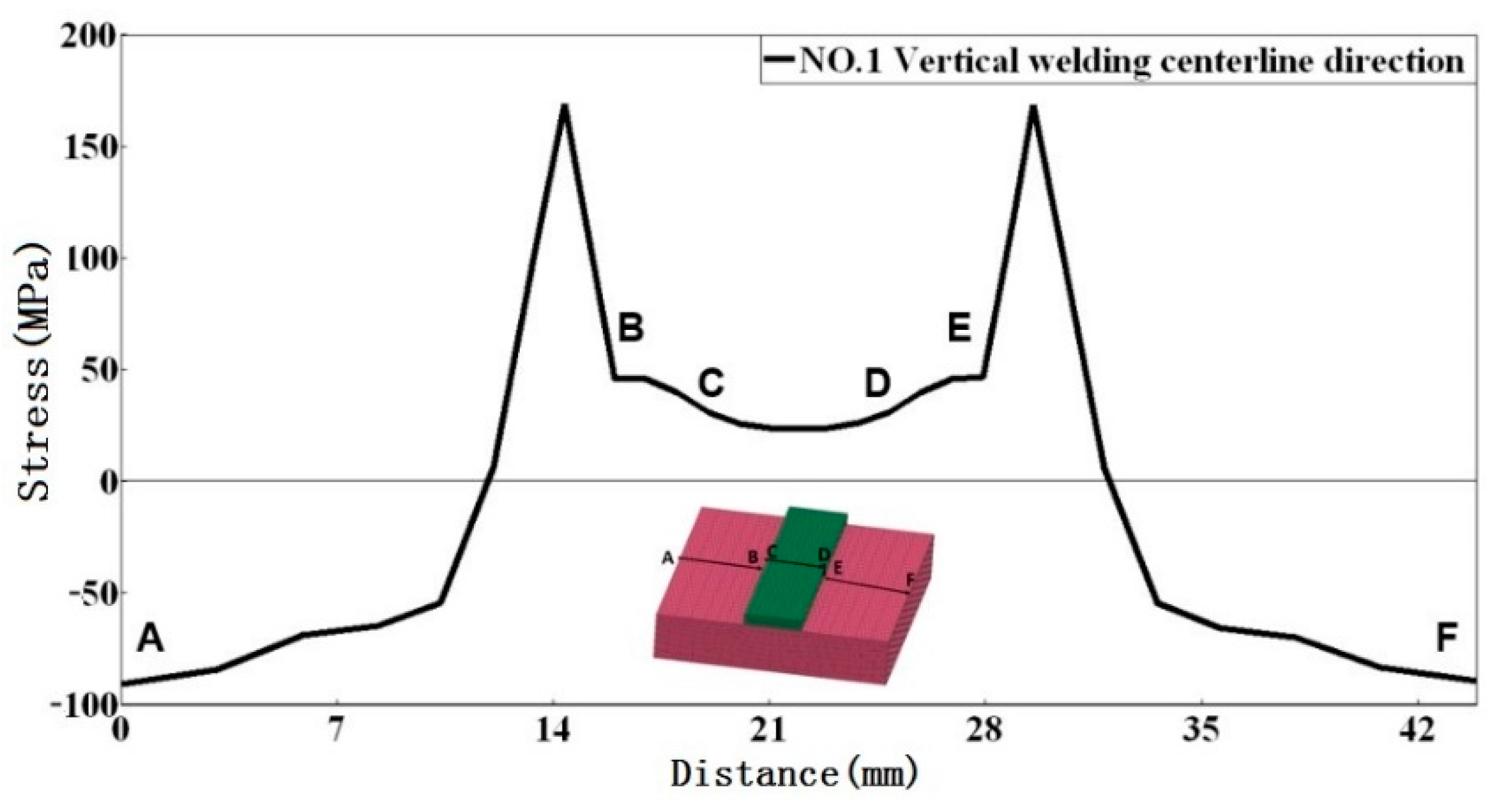

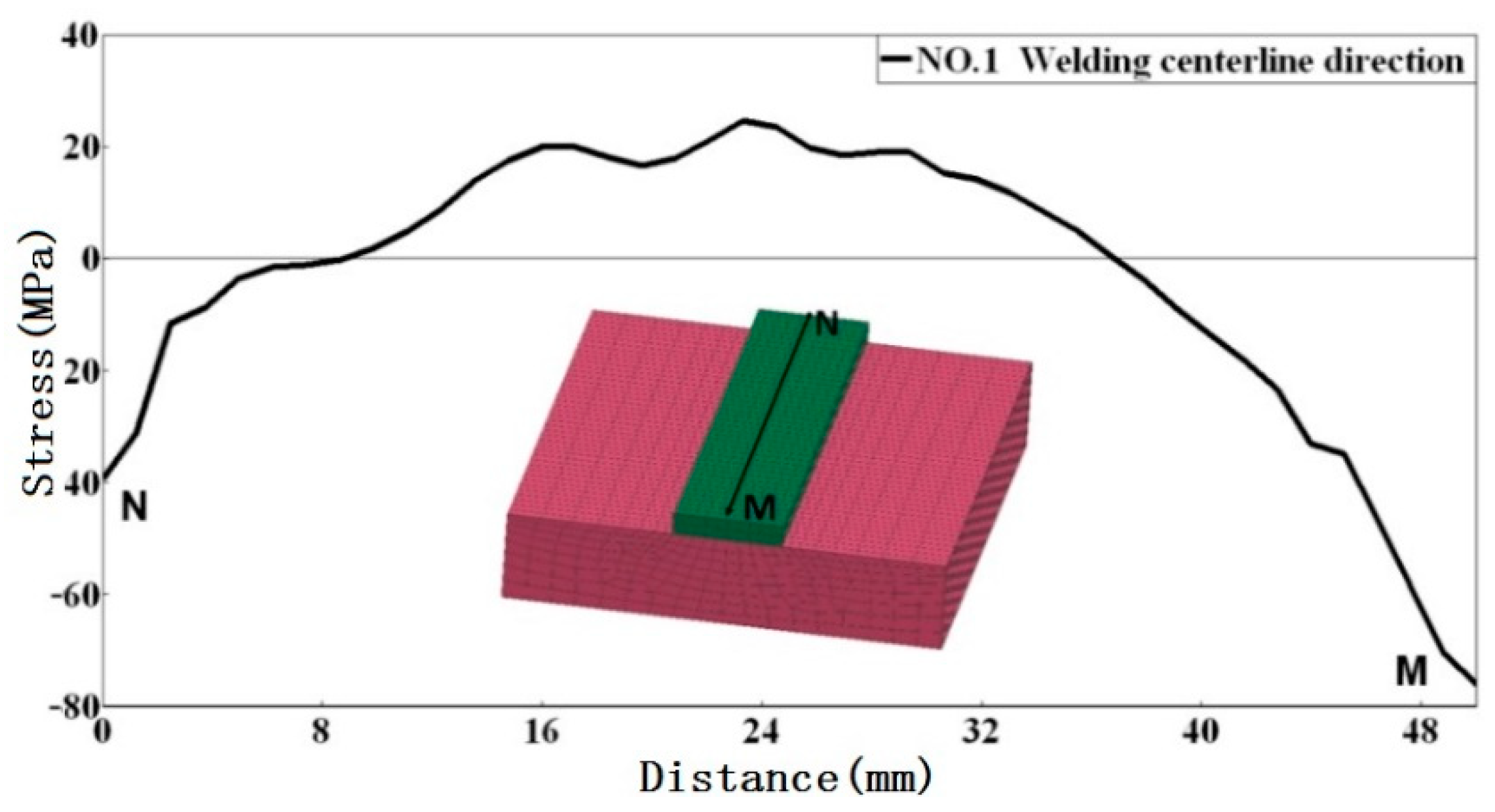

4.3. Analysis of Simulation Stress Field

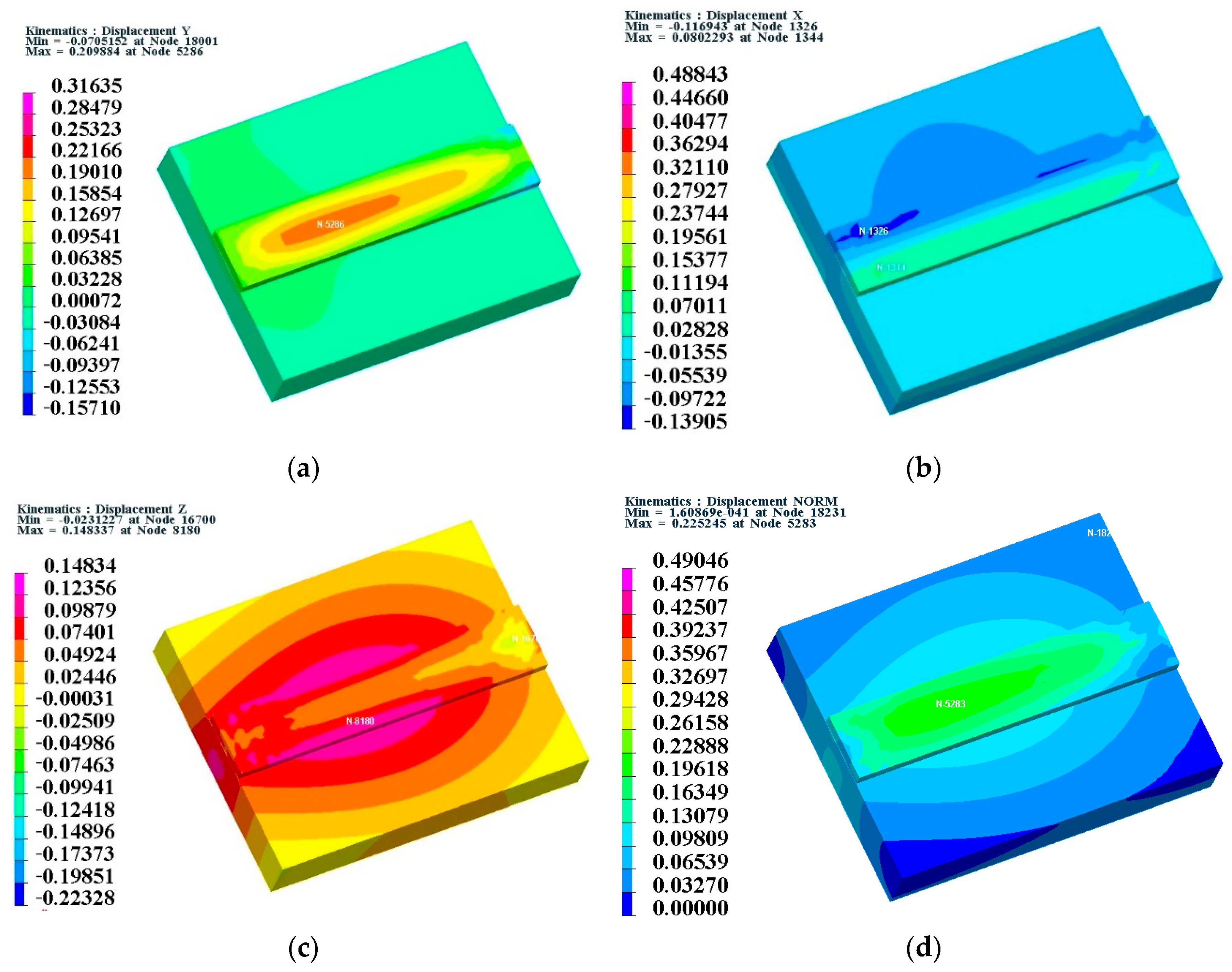

4.4. Simulation Deformation Field

5. Conclusions and Discussions

- The simulation analysis shows that during the stress distribution of the H13 steel surfacing process, the surfacing layer has to undergo stress formation and release; the residual deformation of the surfacing welding is mainly in the surfacing layer, and the direction of large deformation occurs in the thickness direction of the surfacing layer. This phenomenon is basically the same as the test result carried out by Nie et al. [20], that is, the maximum residual stress is located in the junction between the deposit and substrate when the deposit is finished.

- The deformation of the surfacing layer is small, which basically does not affect the forming quality of the base metal, while the deformation of the base metal is relatively large, which may affect the quality of the surfacing welding. In the follow-up surfacing repair, it is necessary to formulate corresponding processes to reduce the deformation of the base metal.

- The surfacing layer and the base metal are physically and metallurgically combined, and the surfacing layer has no obvious defects such as pores, inclusions and cracks; the hardness of the surfacing layer is about 1.5 times the hardness of the parent material; the eutectic carbides in the surfacing layer of H13 steel are mainly V8C7 and SiC, the secondary carbides are Cr23C6 and Cr7C3.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhang, Z.H. Discussion on curve length wear coefficient of inner cutter on full face rock tunnel boring machine. J. Constr. Mach. 2008, 39, 20–22. [Google Scholar]

- Yan, Y.; Feng, S.L.; Liu, B.S.; Yue, C.C.; Liu, X.; Cai, Q. Study on mechanical properties of 6Cr5Mo2V steel for cutter ring of new type shield machine. J. Mold Manuf. 2019, 19, 86–89. [Google Scholar]

- Deng, M.J.; Tan, Z.S. Existing problems and construction technology development direction of super long tunnel cluster TBM trial driving stage. J. Mod. Tunn. Technol. 2019, 56, 1–12. [Google Scholar]

- Liu, Y.J. Discussion on common remanufacturing repair technology. J. Shanxi Coking Coal Technol. 2015, 39, 51–53. [Google Scholar]

- Luo, S.Y.; Ma, Z.H.; Wang, J.B.; Huang, W.R. Research on key problems of reusing old shield machine. J. Civ. Eng. Archit. 2020, 27, 101–105. [Google Scholar]

- Pawlowski, L. Thick laser coatings: A review. J. Therm. Spray Technol. 1999, 8, 279–295. [Google Scholar] [CrossRef]

- Zhang, T.S.; Dai, D.Q.; Xing, P.L. Manufacture and repair of forging dies by surfacing welding. J. Weld. 1957, 5, 10–16. [Google Scholar]

- Wang, X.Z.; Zhu, M.; Shi, Y.; Fan, D. Simulation and analysis of droplet transfer behavior in double wire bypass coupled arc GMAW. J. Mech. Eng. 2016, 52, 54–58. [Google Scholar] [CrossRef]

- Ai, M.P.; Lai, K.X. 5CrNiMo Study on surfacing repair process of hot forging die. J. Forg. Technol. 2009, 34, 114–116. [Google Scholar]

- Liu, Z.; Gao, A.Y.; Zhao, S.G.; Pan, A.S.; Jiang, J.; Xing, X.Q. 42CrMo Evolution of microstructure and properties of surfacing layer for continuous casting roll. J. Anhui Univ. Technol. 2020, 37, 223–228. [Google Scholar]

- Pi, Y.P.; Xiong, J.; Zhao, H.H.; Chen, H. GTAW Tracking algorithm of solid liquid boundary point at the end of molten pool in wire filling additive manufacturing. J. Weld. 2019, 40, 104–109. [Google Scholar]

- Tang, Q.; Chen, P.; Chen, J.Q.; Liang, Y. Numerical simulation of laser hybrid welding deformation based on SYSWELD. J. Weld. 2019, 40, 32–36. [Google Scholar]

- Zhang, L.; Guo, Z.; Zhou, W.; Bi, G.J.; Han, B. Influence of welding speed and welding current on hump weld of vertical high speed GMAW. J. Weld. 2020, 41, 56–61. [Google Scholar]

- Lv, X.Q.; Wang, X.; Xu, L.Y.; Jing, H.Y.; Han, Y.D. Multi objective optimization of MAG welding process parameters based on combination model. J. Weld. 2020, 41, 6–11. [Google Scholar]

- Yang, D.Q.; Wang, X.W.; Huang, Y.; Li, X.P.; Wang, K.H. Microstructure and properties of 18Ni martensitic steel produced by GMA. J. Weld. 2020, 41, 6–9. [Google Scholar]

- Pan, J.J.; He, X.X.; Zhao, P.C.; Hu, Y.T.; Liang, Y. Numerical analysis of molten pool fluctuation during droplet transfer in pulsed twin wire GMAW. J. Weld. 2020, 41, 90–96. [Google Scholar]

- Liu, L.J.; Liu, D.Y.; Wang, X.L.; Li, J.Q.; Cui, Y.B.; Jia, Z.X. Parameter optimization of laser cladding ceramic repair layer on H13 steel. J. Weld. 2020, 41, 65–70. [Google Scholar]

- Prado, T.; Pereira, A.; Fenollera, M.; Mathia, T.G. Simple discriminatory methodology for wear analysis of cutting tools: Impact on work piece surface morphology in case of differently milled kinetics steel H13. Materials 2020, 13, 215. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wang, X.; Wang, J.; Gao, Z.; Hu, W. Fabrication of graded surfacing layer for the repair of failed H13 mandrel using submerged arc welding technology. J. Mater. Process. Technol. 2018, 262, 182–188. [Google Scholar] [CrossRef]

- Nie, Z.; Wang, G.; James, D.; Narayanan, B.; Zhang, S.; Schwam, D.; Kottman, M.; Rong, Y.K. Experimental study and modeling of H13 steel deposition using laser hot-wire additive manufacturing. J. Mater. Process. Technol. 2016, 235, 171–186. [Google Scholar] [CrossRef]

| Surfacing Current | Surfacing Voltage | Wire Feeding Speed | Surfacing Speed | Wire Feeding Angle |

|---|---|---|---|---|

| 23.5 A | 190 V | 10 mm/s | 5 mm/s | 90° |

| Chemical Composition | C | Mn | Cr | Mo | Si | V | P | S | Fe |

|---|---|---|---|---|---|---|---|---|---|

| wt.% | 0.4 | 0.3 | 5.1 | 1.6 | 0.9 | 1.1 | 0.03 | 0.02 | Bal. |

| Chemical Composition | C | Cr | Mn | W | V | Fe |

|---|---|---|---|---|---|---|

| wt.% | 0.50 | 5.50 | 1.50 | 2.00 | 1.00 | Bal. |

| Position | Fe | Cr | V | W | Si | C | Mn |

|---|---|---|---|---|---|---|---|

| Point A | 90.75 | 5.35 | 0.9 | 9.26 | – | – | – |

| Point B | 92.65 | 4.61 | 0.76 | 1.98 | – | – | – |

| Point C | 90.70 | 5.67 | 0.94 | – | 2.69 | – | – |

| Point D | 77.58 | 2.82 | – | 1.68 | – | 3.96 | 1.26 |

| Parameters | Values | Parameters | Values |

|---|---|---|---|

| Surfacing current | 23.5 A | Surfacing current | 190 V |

| Surfacing speed | 5 mm/s | Substrate temperature | 20 °C |

| Surfacing distance | 50 mm | Molten pool width | 10 mm |

| Molten pool depth | 3 mm | Ambient temperature | 20 °C |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, M.; He, S.; Jiang, B.; Yao, X.; Zhang, K. The Study on Feasibility and Welding Characteristics of GMAW Surfacing Remanufacturing of H13 Steel Cutter Ring of TBM Hob. Coatings 2021, 11, 1559. https://doi.org/10.3390/coatings11121559

Zhang M, He S, Jiang B, Yao X, Zhang K. The Study on Feasibility and Welding Characteristics of GMAW Surfacing Remanufacturing of H13 Steel Cutter Ring of TBM Hob. Coatings. 2021; 11(12):1559. https://doi.org/10.3390/coatings11121559

Chicago/Turabian StyleZhang, Moyun, Shihai He, Boyan Jiang, Xuming Yao, and Kui Zhang. 2021. "The Study on Feasibility and Welding Characteristics of GMAW Surfacing Remanufacturing of H13 Steel Cutter Ring of TBM Hob" Coatings 11, no. 12: 1559. https://doi.org/10.3390/coatings11121559

APA StyleZhang, M., He, S., Jiang, B., Yao, X., & Zhang, K. (2021). The Study on Feasibility and Welding Characteristics of GMAW Surfacing Remanufacturing of H13 Steel Cutter Ring of TBM Hob. Coatings, 11(12), 1559. https://doi.org/10.3390/coatings11121559