Abrasive Wear Resistance and Tribological Characteristics of Pulsed Hard Anodized Layers on Aluminum Alloy 1011 in Tribocontact with Steel and Ceramics in Various Lubricants

Abstract

:1. Introduction

2. Materials and Methods

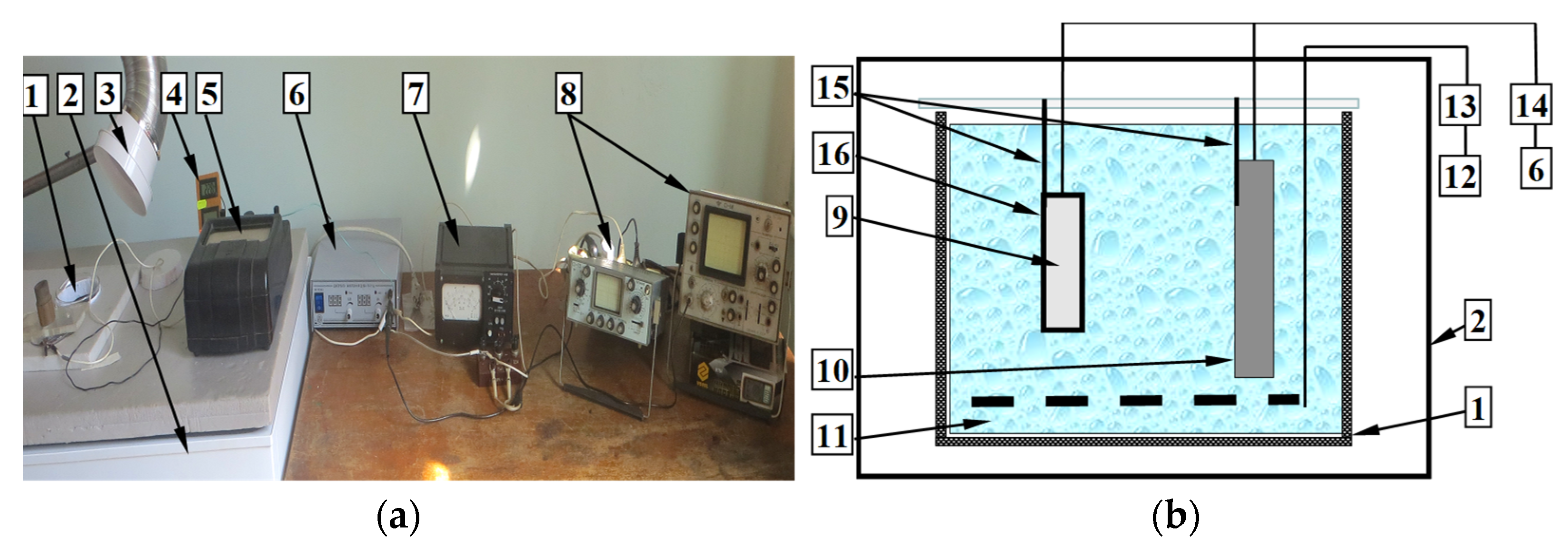

2.1. Technological Features of Pulsed Hard Anodizing of 1011 Aluminum Alloy

2.2. Test Method for Determination of Abrasive Wear Resistance of Hard Anodized Layers

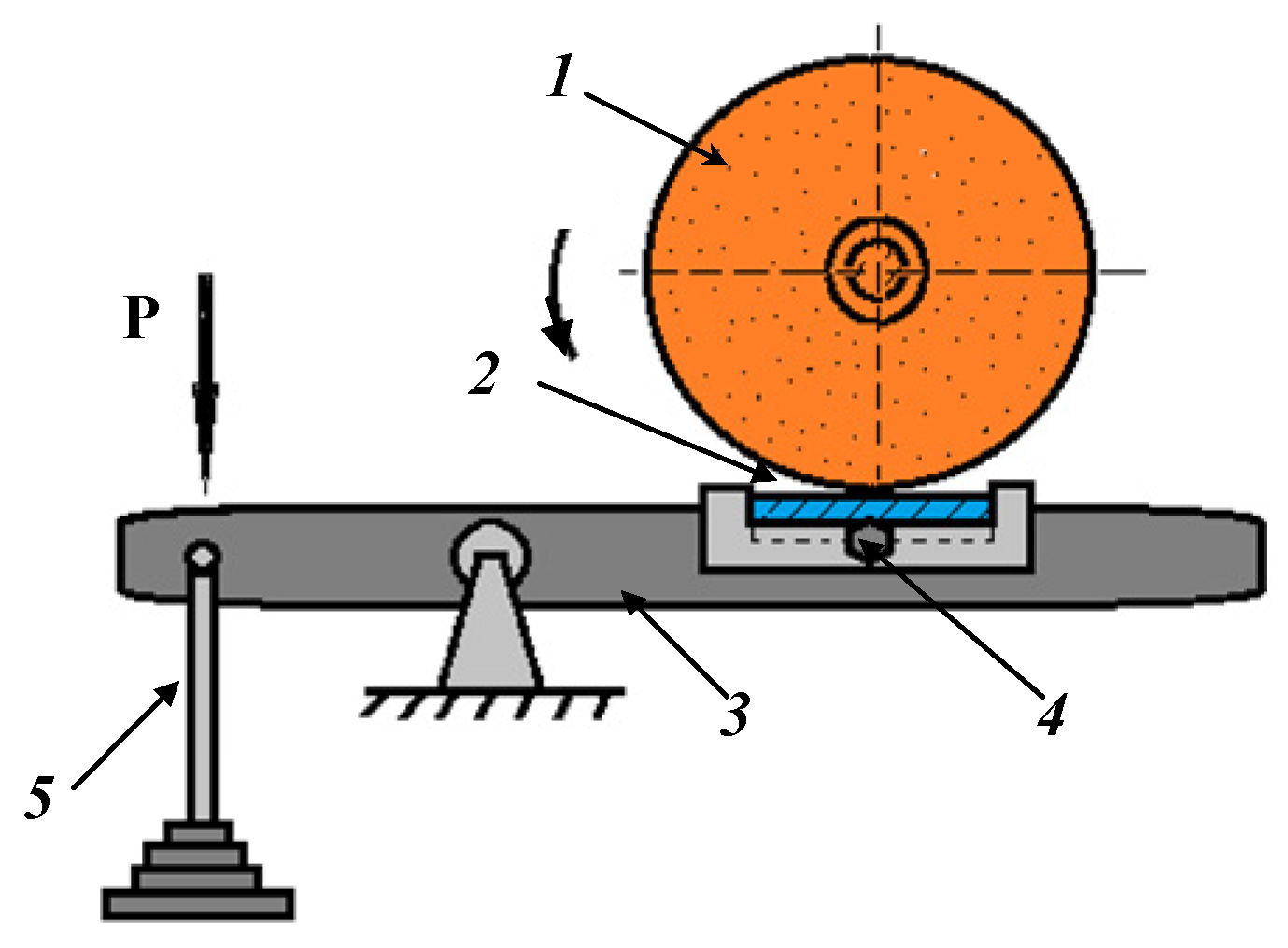

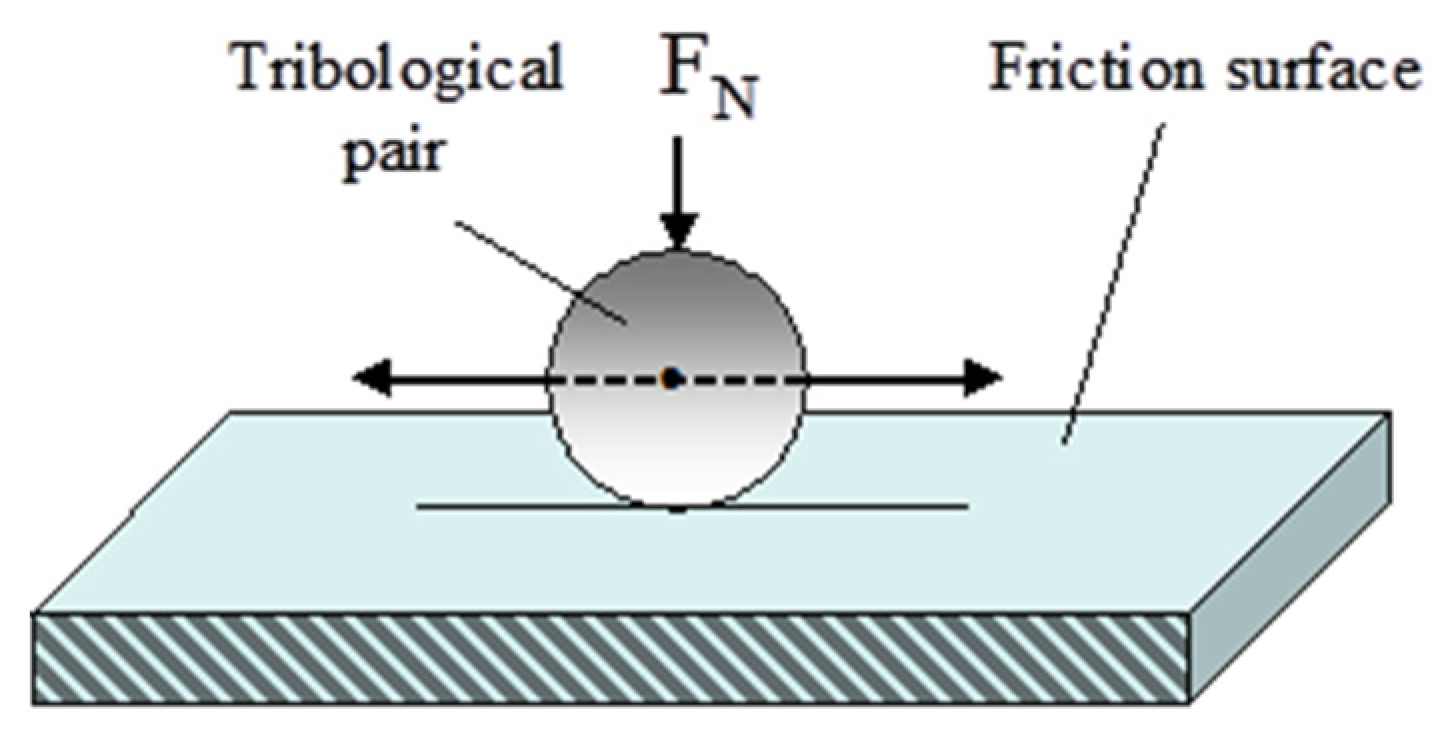

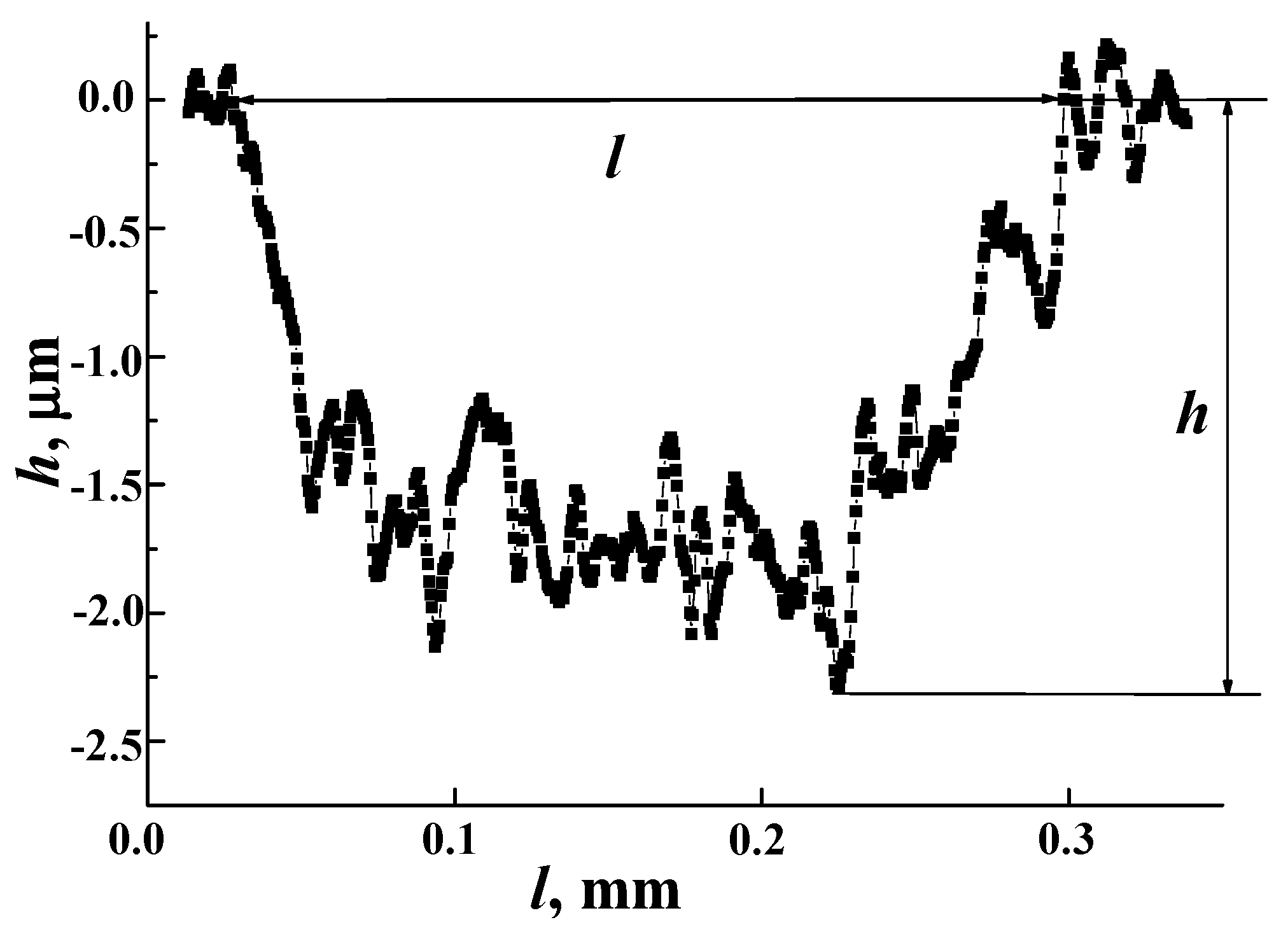

2.3. Test Method for Determining the Wear of Pulsed Hard Anodized Layers under Sliding Conditions

2.4. Other Test Methods Used for Investigations of Pulsed Hard Anodized Layers

3. Results

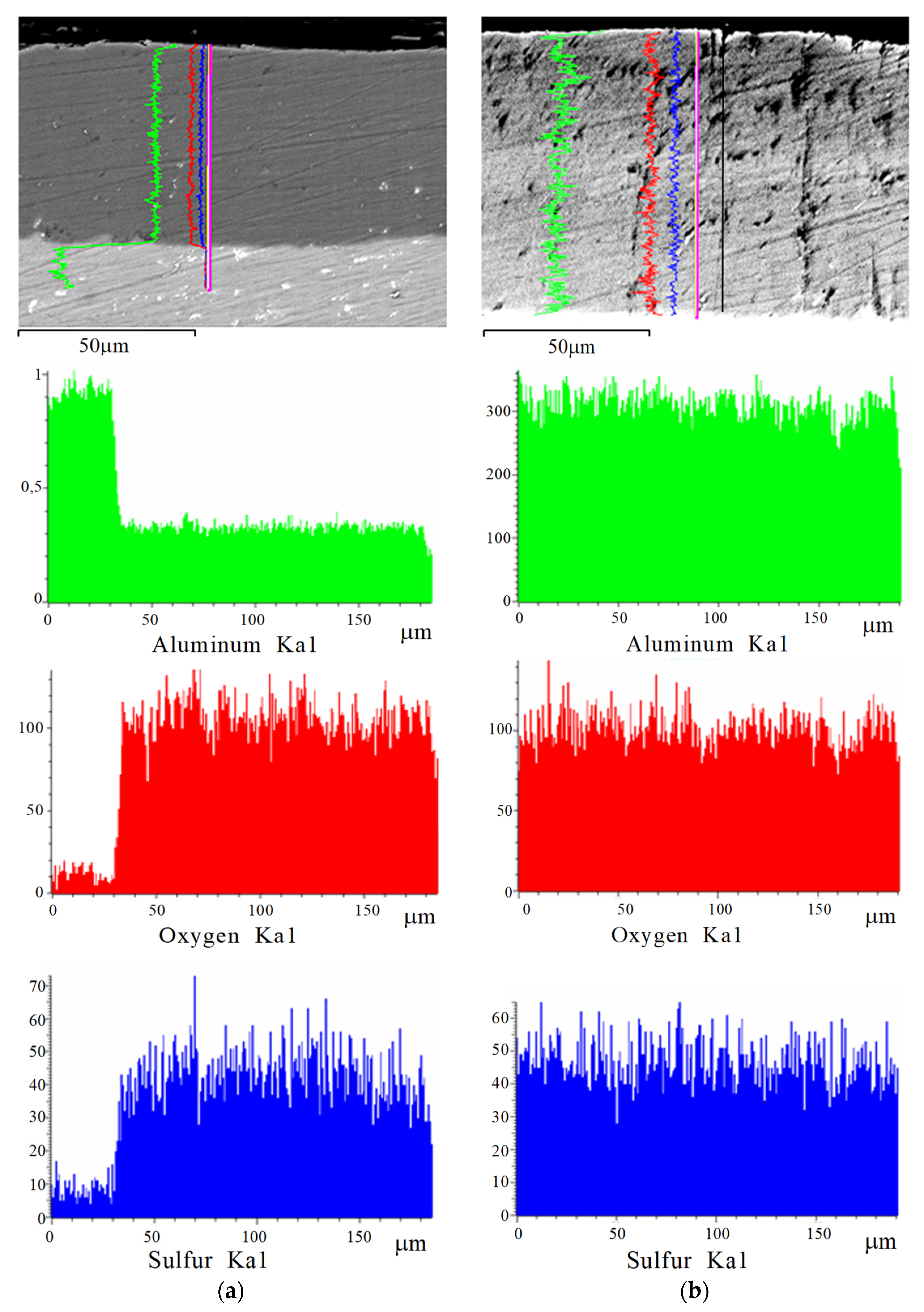

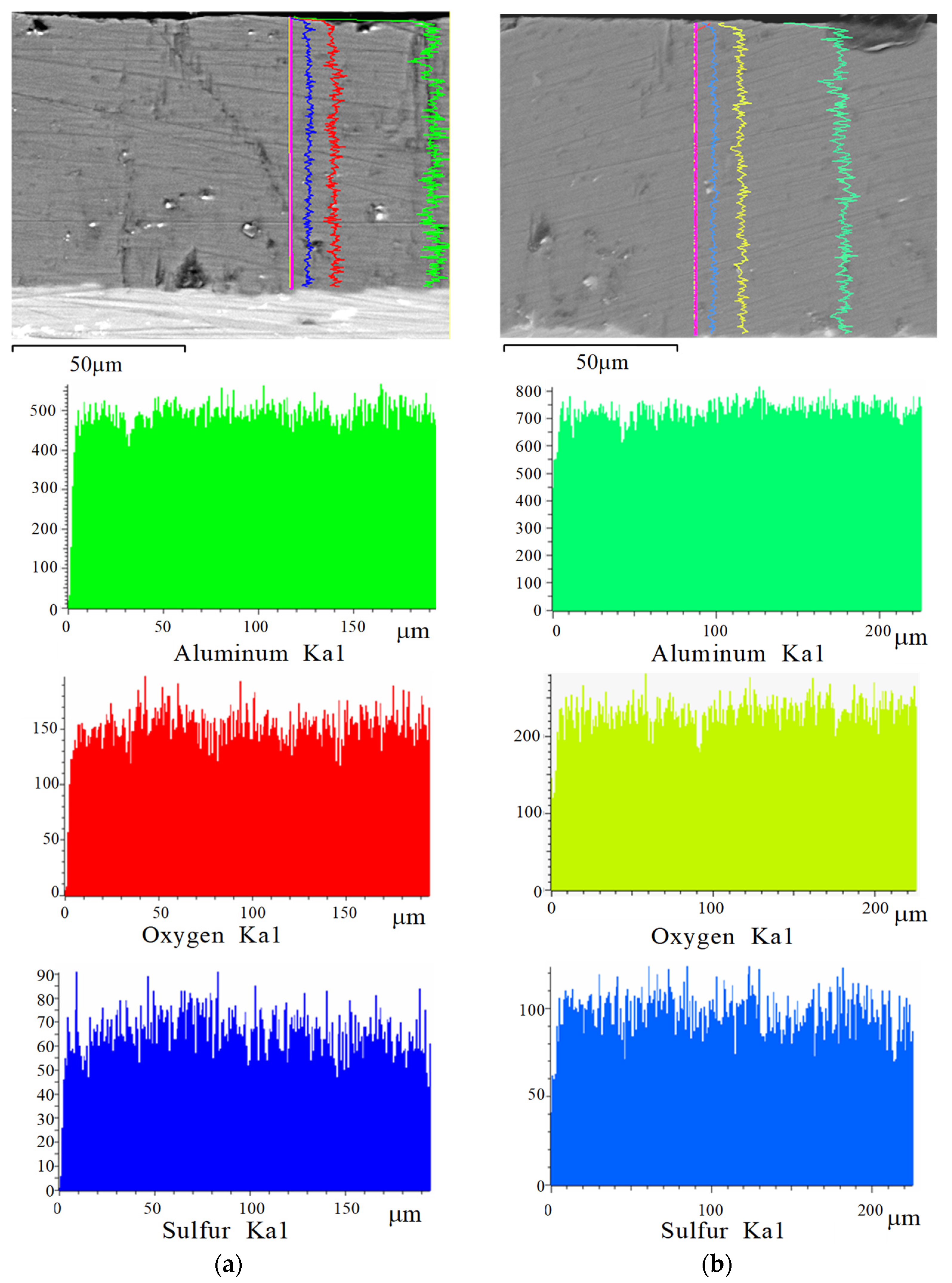

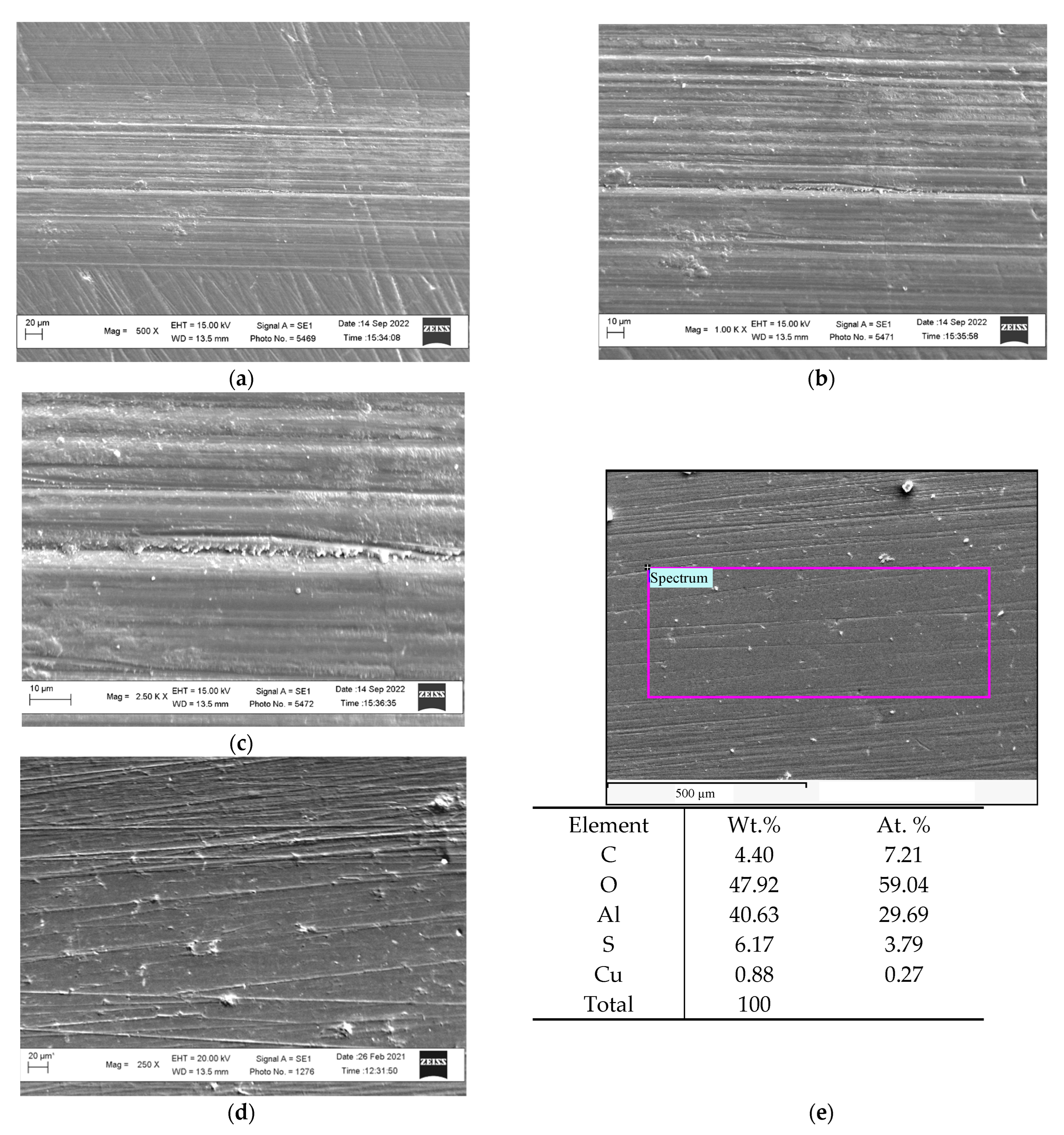

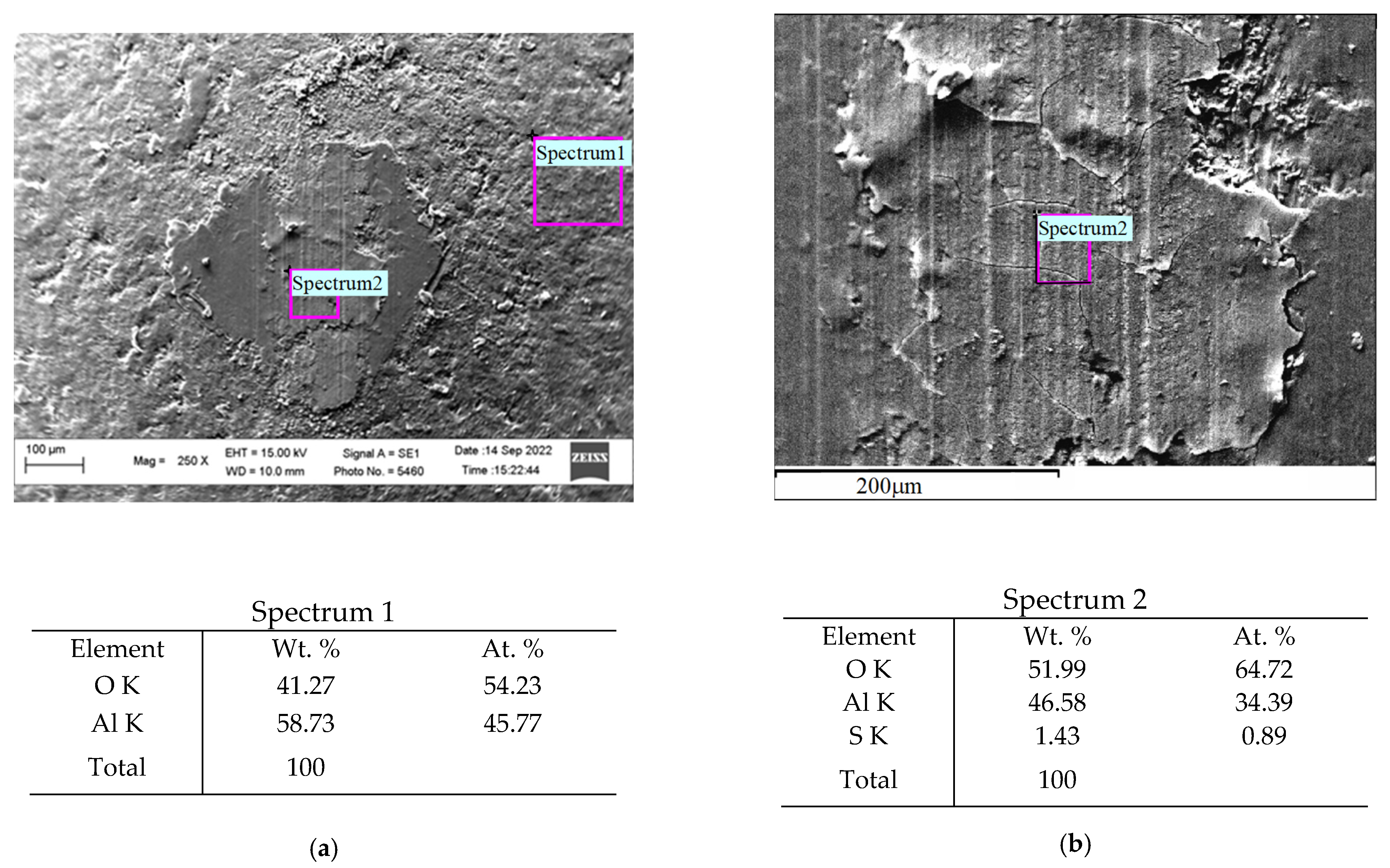

3.1. X-ray Microspectral Analysis of Hard Anodized Layers Synthesized at Direct or Pulsed Current Modes

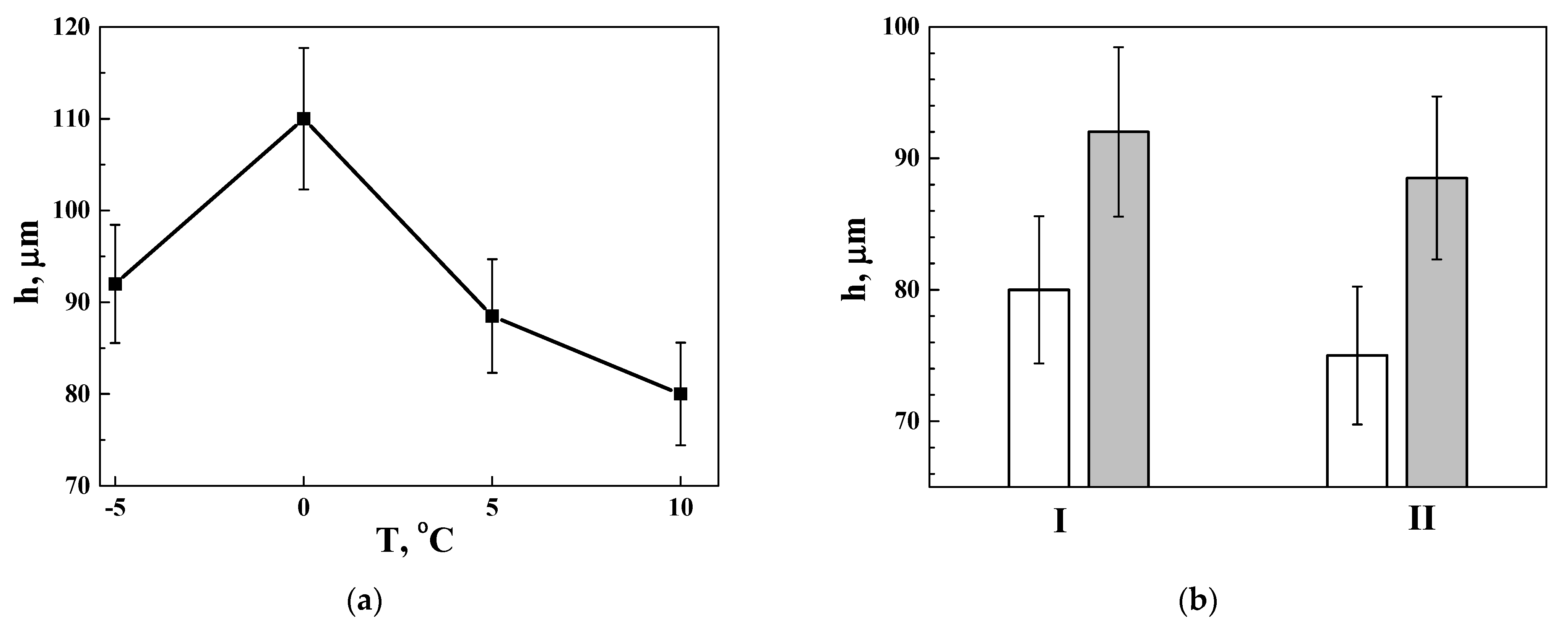

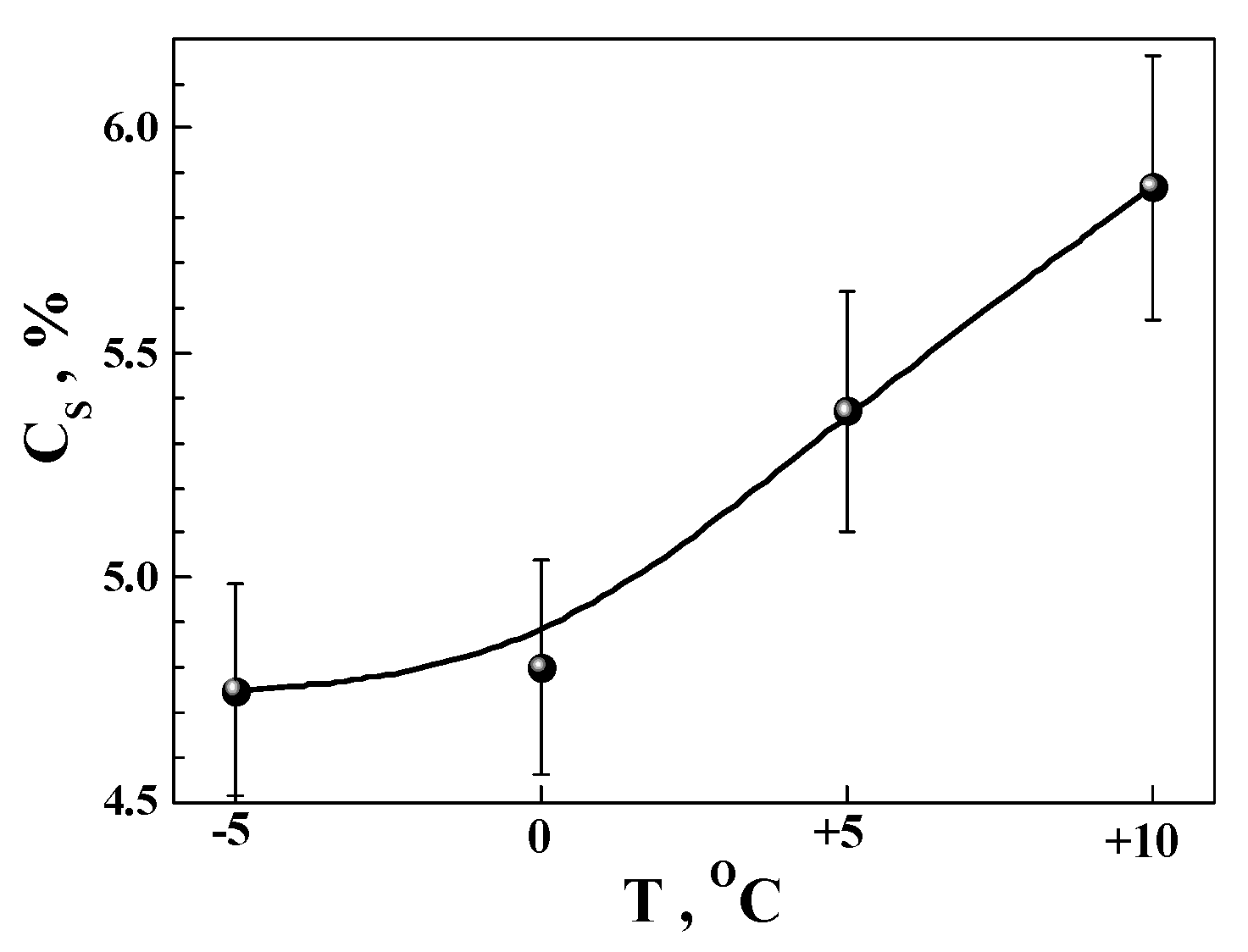

3.2. Effect of Electrolyte Temperature during Pulsed Hard Anodizing on Thickness of Synthesized Layers

3.3. X-ray Phase Analysis of Pulsed Anodized Layers on 1011 Aluminum Alloy

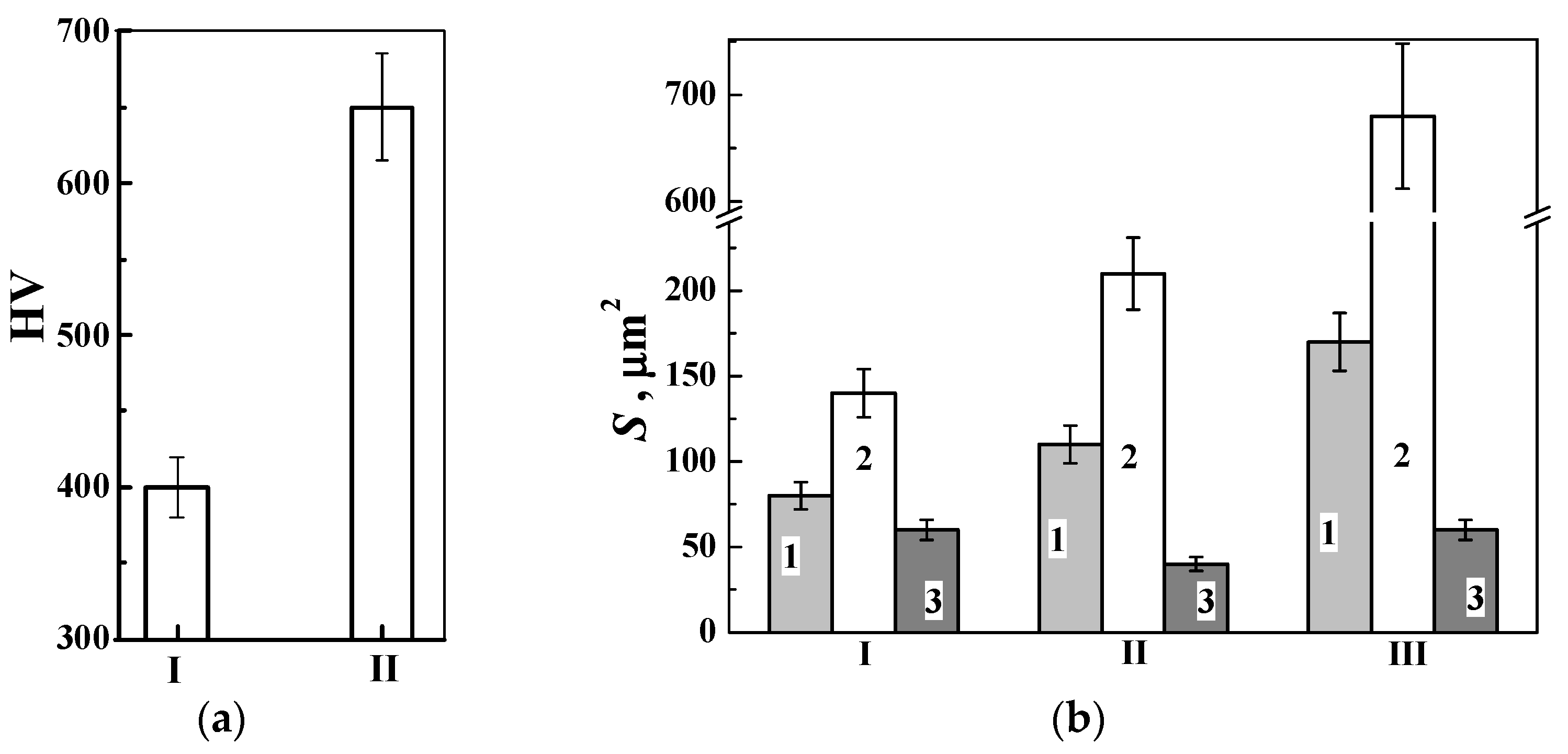

3.4. Hardness and Abrasive Wear Resistance of PHAL Synthesized on Aluminum Alloy 1011

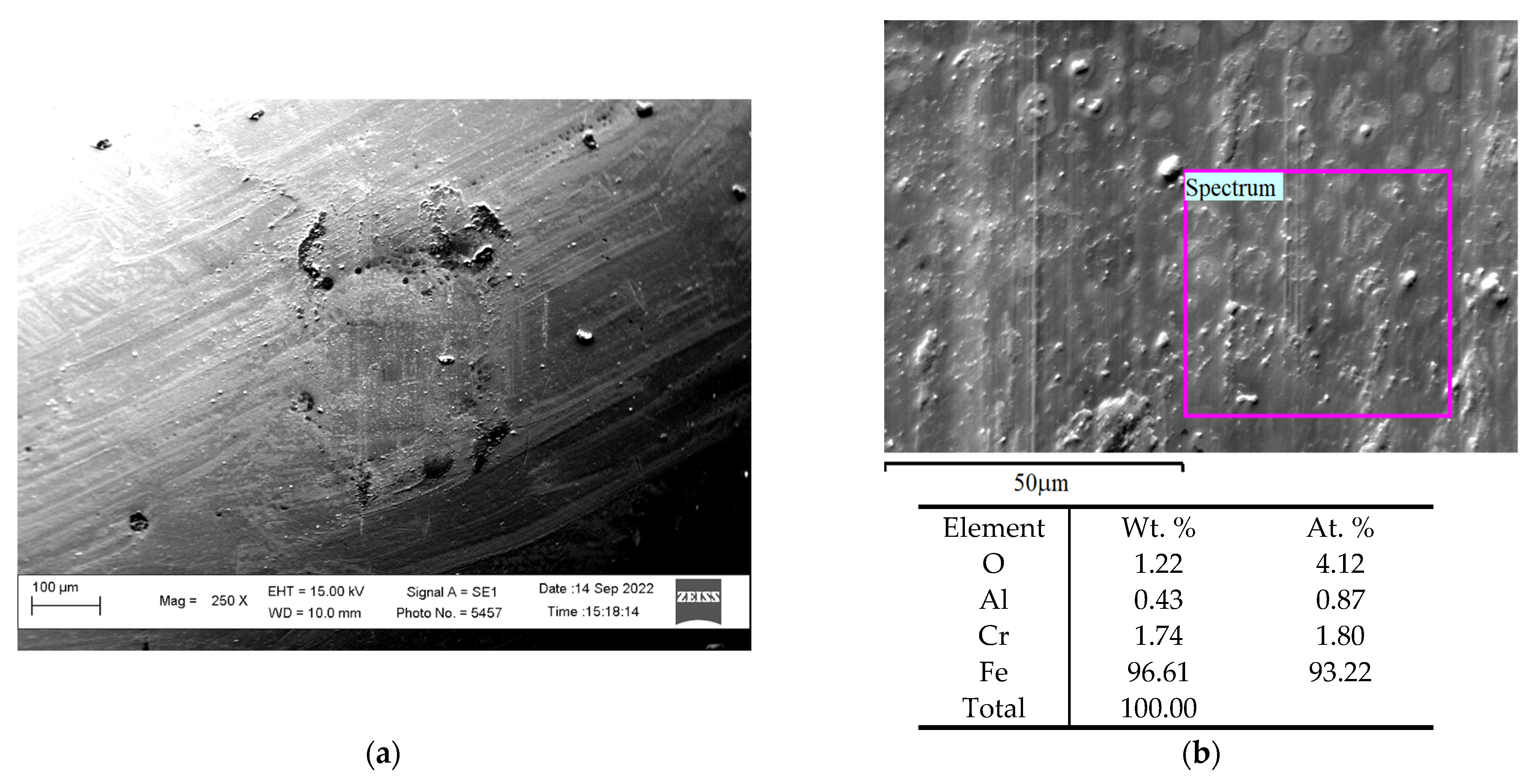

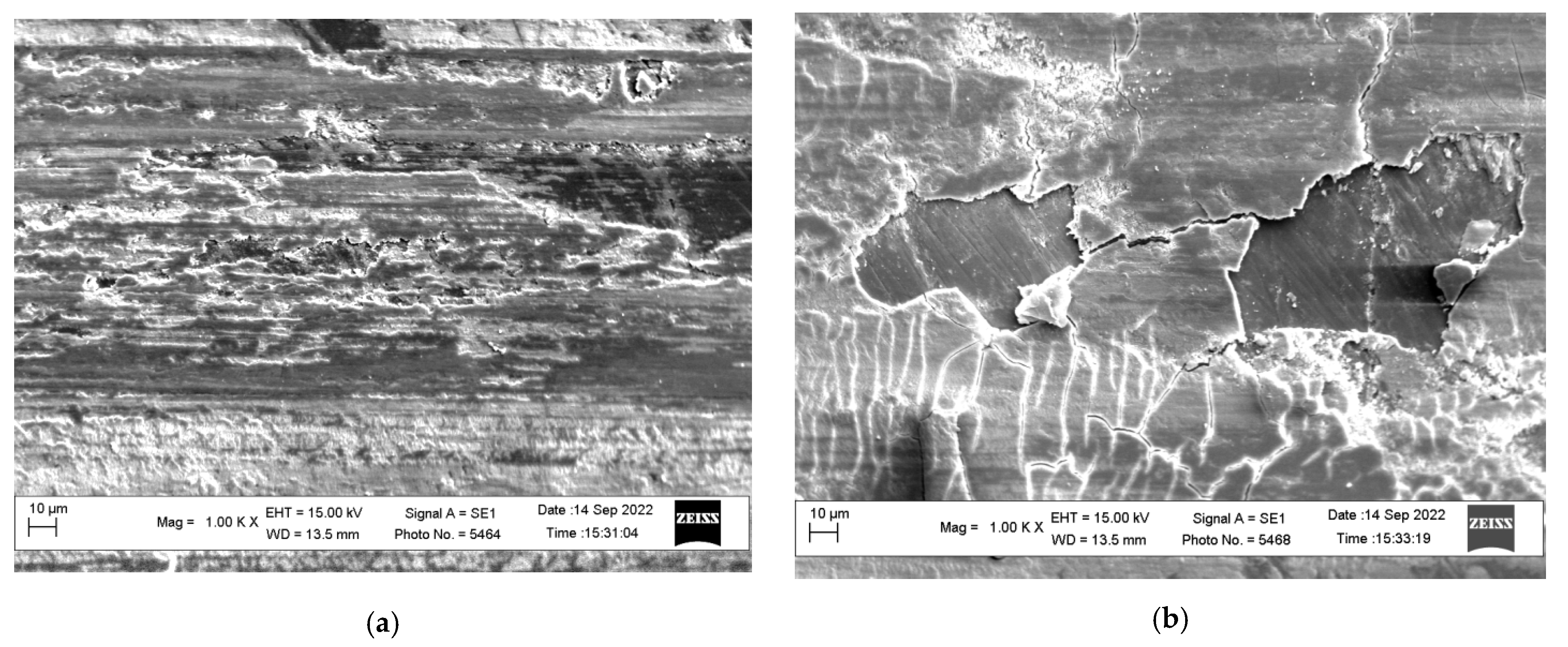

3.5. Tribological Properties of Pulsed Hard Anodized Layers on 1011 Aluminum Alloy Surface

4. Discussion

4.1. Tribological Properties of HA and PHA Layers Synthesized on the Surface of 1011 Aluminum Alloy in Comparison with the Properties of High-Strength 1050 Aluminum Alloy

4.2. Friction Coefficient in Contact Zone of PHAL with Steel and Ceramic Balls under Different Lubrication Conditions

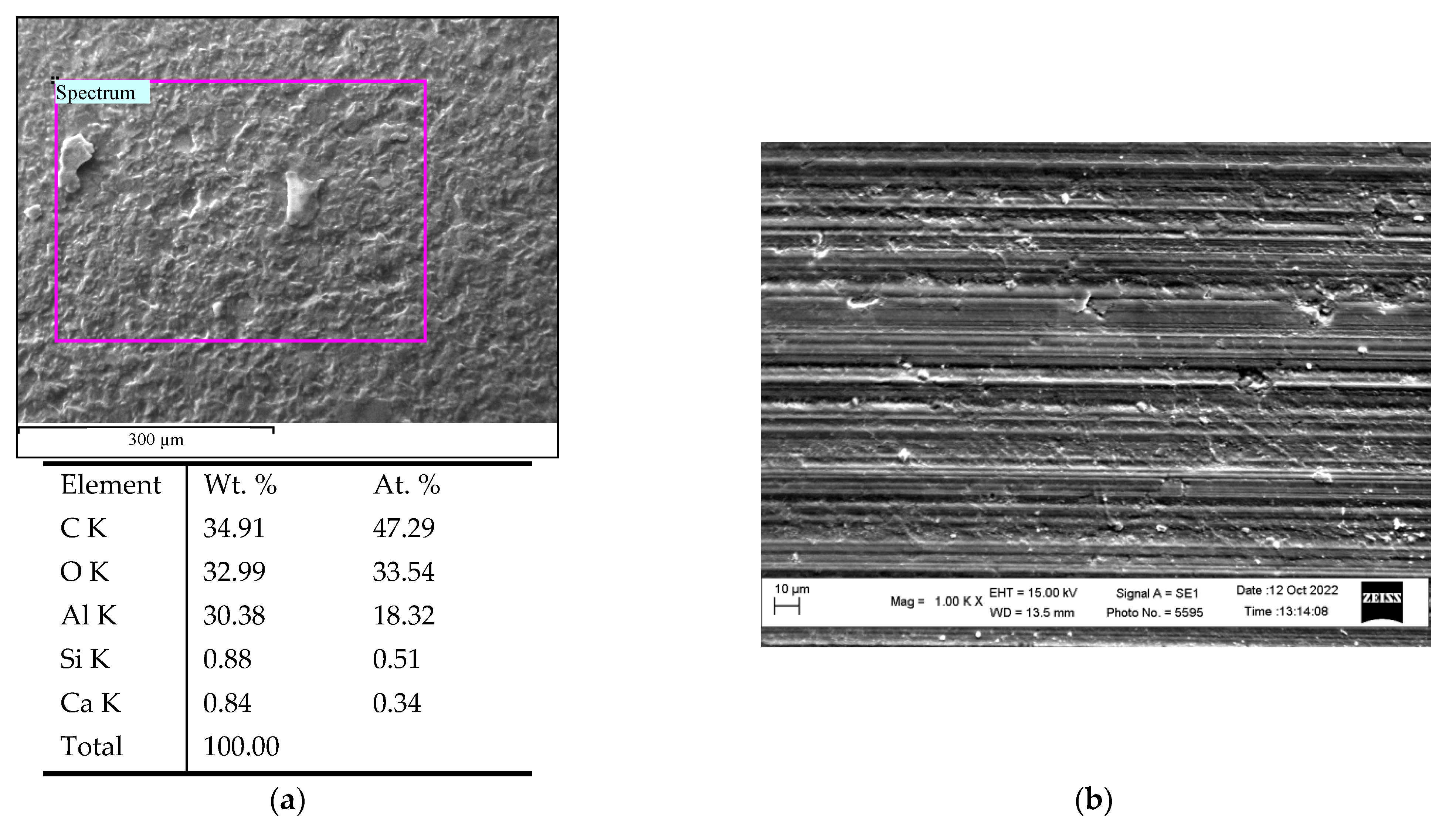

4.3. Peculiarities of the Wear Mechanism during Tribocontact of Pulsed Anodized Layer with Steel and Ceramic Balls

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Peltier, F.; Thierry, D. Review of Cr-free coatings for the corrosion protection of aluminum aerospace alloys. Coatings 2022, 12, 518. [Google Scholar] [CrossRef]

- Rodriguez, L.; Vieu, A.; Balsarin, M.; Combes, P.; Alexis, J.; Esvan, J.; Lesko, S.; Denape, J.; Paris, J.-Y.; Delbé, K. Physico-chemical characterisation and tribological behaviour of micro-arc oxidation coating on aluminium alloy—Comparison with hard anodised oxidation. Wear 2023, 516–517, 204591. [Google Scholar] [CrossRef]

- Fang, L.; Huang, J.; Liu, Y.; Zhang, B.; Li, H. Cored-wire arc spray fabrication of novel aluminium-copper coatings for anti-corrosion/fouling hybrid performances. Surf. Coat. Technol. 2019, 357, 794–801. [Google Scholar] [CrossRef]

- Hutsaylyuk, V.; Student, M.; Zadorozhna, K.; Student, O.; Veselivska, H.; Gvosdetskii, V.; Maruschak, P.; Pokhmurska, H. Improvement of wear resistance of aluminum alloy by HVOF method. J. Mater. Res. Technol. 2020, 9, 16367. [Google Scholar] [CrossRef]

- Student, M.; Hvozdetskyi, V.; Stupnytskyi, T.; Student, O.; Maruschak, P.; Prentkovskis, O.; Skačkauskas, P. Mechanical properties of arc coatings sprayed with cored wires with different charge compositions. Coatings 2022, 12, 925. [Google Scholar] [CrossRef]

- Peng, Z.; Xu, H.; Liu, S.; Qi, Y.; Liang, J. Wear and corrosion resistance of plasma electrolytic oxidation coatings on 6061 Al alloy in electrolytes with aluminate and phosphate. Materials 2021, 14, 4037. [Google Scholar] [CrossRef]

- Huang, X.; Famiyeh, L. Plasma electrolytic oxidation coatings on aluminum alloys: Microstructures, properties, and applications. Mod. Concept Mater. Sci. 2019, 2, 000526. [Google Scholar] [CrossRef]

- Liu, W.; Pu, Y.; Liao, H.; Lin, Y.; He, W. Corrosion and wear behavior of PEO coatings on D16T aluminum alloy with different concentrations of graphene. Coatings 2020, 10, 249. [Google Scholar] [CrossRef]

- Student, M.; Pohrelyuk, I.; Padgurskas, J.; Posuvailo, V.; Hvozdets’kyi, V.; Zadorozhna, K.; Chumalo, H.; Veselivska, H.; Kovalchuk, I.; Kychma, A. Influence of plasma electrolytic oxidation of cast Al-Si alloys on their phase composition and abrasive wear resistance. Coatings 2023, 13, 637. [Google Scholar] [CrossRef]

- Sieber, M.; Simchen, F.; Morgenstern, R.; Scharf, I.; Lampke, T. Plasma electrolytic oxidation of high-strength aluminium alloys—Substrate effect on wear and corrosion performance. Metals 2018, 8, 356. [Google Scholar] [CrossRef]

- Scampone, G.; Timelli, G. Anodizing Al–Si foundry alloys: A critical review. Adv. Eng. Mater. 2022, 24, 2101480. [Google Scholar] [CrossRef]

- Ali, I.; Quazi, M.M.; Zalnezhad, E.; Sarhan, A.A.D.; Sukiman, N.L.; Ishak, M. Hard anodizing of aerospace AA7075-T6 aluminum alloy for improving surface properties. Trans. Indian Inst. Metals 2019, 72, 2773–2781. [Google Scholar] [CrossRef]

- Kwolek, P.; Krupa, K.; Obłój, A.; Kocurek, P.; Wierzbińska, M.; Sieniawski, J. Tribological properties of the oxide coatings produced onto 6061-T6 aluminum alloy in the hard anodizing process. J. Mater. Eng. Perform. 2018, 27, 3268–3275. [Google Scholar] [CrossRef]

- Bazaluk, O.; Dubei, O.; Ropyak, L.; Shovkoplias, M.; Pryhorovska, T.; Lozynskyi, V. Strategy of compatible use of jet and plunger pump with chrome parts in oil well. Energies 2022, 15, 83. [Google Scholar] [CrossRef]

- Dubei, O.Y.; Tutko, T.F.; Ropyak, L.Y.; Shovkoplias, M.V. Development of Analytical Model of Threaded Connection of Tubular Parts of Chrome-Plated Metal Structures. Metallofiz. Noveishie Tekhnol. 2022, 44, 251–272. [Google Scholar] [CrossRef]

- Simchen, F.; Sieber, M.; Kopp, A.; Lampke, T. Introduction to Plasma Electrolytic Oxidation—An Overview of the Process and Applications. Coatings 2020, 10, 628. [Google Scholar] [CrossRef]

- Sikdar, S.; Menezes, P.V.; Maccione, R.; Jacob, T.; Menezes, P.L. Plasma Electrolytic Oxidation (PEO) Process—Processing, Properties, and Applications. Nanomaterials 2021, 11, 1375. [Google Scholar] [CrossRef]

- Ropyak, L.Y.; Velychkovych, A.S.; Vytvytskyi, V.S.; Shovkoplias, M.V. Analytical study of “crosshead–slide rail” wear effect on pump rod stress state. J. Phys. Conf. Ser. 2021, 1741, 012039. [Google Scholar] [CrossRef]

- Wu, Z.; Xia, Y.; Li, G.; Xu, F. Structure and mechanical properties of ceramic coatings fabricated by plasma electrolytic oxidation on aluminized steel. Appl. Surf. Sci. 2007, 253, 8398–8403. [Google Scholar] [CrossRef]

- Wielage, B.; Meyer, D.; Pokhmurska, H.; Alisch, G.; Grund, T. Plasma electrolytic oxidation of arc sprayed aluminium coatings [Plasmaelektrolytische Oxidation Thermisch Gespritzter Aluminiumschichten]. Mater. Werkst. 2008, 39, 920–923. [Google Scholar] [CrossRef]

- Ropyak, L.; Shihab, T.; Velychkovych, A.; Dubei, O.; Tutko, T.; Bilinskyi, V. Design of a two-layer Al–Al2O3 coating with an oxide layer formed by the plasma electrolytic oxidation of Al for the corrosion and wear protections of steel. Prog. Phys. Met. 2023, 24, 319–365. [Google Scholar] [CrossRef]

- Durdu, S.; Aktuğ, S.L.; Korkmaz, K. Characterization and mechanical properties of the duplex coatings produced on steel by electro-spark deposition and micro-arc oxidation. Surf. Coat. Technol. 2013, 236, 303–308. [Google Scholar] [CrossRef]

- Yang, Z.; Guo, X.; Lu, S.; Zhang, Y.; Hu, H.; Lu, K.; Zhang, J. Investigation of Stray Radiation Suppression in Infrared Imaging System Using a Novel Broadband and High-Absorption Ceramic Coating. Appl. Sci. 2021, 11, 4952. [Google Scholar] [CrossRef]

- Bembenek, M.; Makoviichuk, M.; Shatskyi, I.; Ropyak, L.; Pritula, I.; Gryn, L.; Belyakovskyi, V. Optical and Mechanical Properties of Layered Infrared Interference Filters. Sensors 2022, 22, 8105. [Google Scholar] [CrossRef]

- Hutsaylyuk, V.; Student, M.; Posuvailo, V.; Student, O.; Sirak, Y.; Hvozdets’kyi, V.; Maruschak, P.; Veselivska, H. The properties of oxide-ceramic layers with Cu and Ni inclusions synthesizing by PEO method on top of the gas-spraying coatings on aluminium alloys. Vacuum 2020, 179, 109514. [Google Scholar] [CrossRef]

- Moshrefifar, M.; Ebrahimifar, H.; Hakimizad, A. Systematic investigation of silicon content effects on the PEO coatings’ properties on Al–Si binary alloys in silicate-based and tungstate-containing electrolytes. Coatings 2022, 12, 1438. [Google Scholar] [CrossRef]

- Student, M.M.; Dovhunyk, V.M.; Posuvailo, V.M.; Koval’chuk, I.V.; Hvozdets’kyi, V.M. Friction behavior of iron-carbon alloys in couples with plasma-electrolytic oxide-ceramic layers synthesized on D16T alloy. Mater. Sci. 2017, 53, 359–367. [Google Scholar] [CrossRef]

- Lu, X.; Mohedano, M.; Blawert, C.; Matykina, E.; Arrabal, R.; Kainer, K.U.; Zheludkevich, M.L. Plasma electrolytic oxidation coatings with particle additions—A review. Surf. Coat. Technol. 2016, 307, 1165–1182. [Google Scholar] [CrossRef]

- Ovundur, M.; Muhaffel, F.; Cimenoglu, H. Characterization and tribological properties of hard anodized and micro arc oxidized 5754 quality aluminum alloy. Tribol. Ind. 2015, 37, 55–59. [Google Scholar]

- Mohitfar, H.; Mahdavi, S.; Etminanfar, M.; Khalil-Allafi, J. Characteristics and tribological behavior of the hard anodized 6061-T6 Al alloy. J. Alloys Comp. 2020, 842, 155988. [Google Scholar] [CrossRef]

- Nastruzzi, A.; Cicerchia, F.; Fortini, A.; Nastruzzi, C. Gold hard anodized (GHA) materials with antimicrobial surface properties: Mechanical, tribological, and microbiological characterization. Emergent Mater. 2021, 4, 249–263. [Google Scholar] [CrossRef]

- Musza, A.; Windisch, M.; Török, M.; Molnár, T.; Kovács, S.; Sátán-Papp, S.; Szegedi, K.; Ugi, D.; Chinh, N.Q.; Vida, Á. Tribological examination of anodized Al-356 for automotive use. Coatings 2023, 13, 1642. [Google Scholar] [CrossRef]

- Student, M.M.; Pohrelyuk, I.M. Modification of the surfaces of aluminum and titanium alloys aimed at the improvement of their wear resistance and tribological characteristics. Mater. Sci. 2021, 57, 377–386. [Google Scholar] [CrossRef]

- Student, M.M.; Pohrelyuk, I.M.; Hvozdetskyi, V.M.; Veselivska, H.H.; Zadorozhna, K.R.; Mardarevych, R.S.; Dzioba, Y.V. Influence of the composition of electrolyte for hard anodizing of aluminum on the characteristics of oxide layer. Mater. Sci. 2021, 57, 240–247. [Google Scholar] [CrossRef]

- Remešová, M.; Tkachenko, S.; Kvarda, D.; Ročňáková, I.; Gollas, B.; Menelaou, M.; Čelko, L.; Kaiser, J. Effects of anodizing conditions and the addition of Al2O3/PTFE particles on the microstructure and the mechanical properties of porous anodic coatings on the AA1050 aluminium alloy. Appl. Surface Sci. 2020, 513, 145780. [Google Scholar] [CrossRef]

- Martínez-Viademonte, M.P.; Abrahami, S.T.; Hack, T.; Burchardt, M.; Terryn, H. A review on anodizing of aerospace aluminum alloys for corrosion protection. Coatings 2020, 10, 1106. [Google Scholar] [CrossRef]

- Student, M.M.; Pohrelyuk, I.M.; Chumalo, H.V.; Hvozdetskyi, V.M. Improvement of the functional characteristics of coatings obtained by the method of hard anodizing of aluminum alloys. Mater. Sci. 2021, 56, 820–829. [Google Scholar] [CrossRef]

- Juhl, A.D. Why it makes sense to upgrade to pulse anodizing: Mock finishing shop scenarios show how switching from conventional anodizing processes to newer methods can boost productivity while maximizing ROI. Met. Finish. 2009, 107, 24–27. [Google Scholar] [CrossRef]

- Raj, V.M.; Rajaram, P.; Balasubramanian, G.; Vincent, S.; Kanagaraj, D. Pulse anodizing—An overview. Int. J. Surf. Eng. Coat. 2003, 81, 114–121. [Google Scholar] [CrossRef]

- Kwolek, P.; Drapała, D.; Krupa, K.; Obłój, A.; Tokarski, T.; Sieniawski, J. Mechanical properties of a pulsed anodised 5005 aluminium alloy. Surf. Coat. Technol. 2020, 383, 125–233. [Google Scholar] [CrossRef]

- Mohammadi, I.; Afshar, A. Modification of nanostructured anodized aluminum coatings by pulse current mode. Surf. Coat. Technol. 2015, 278, 48–55. [Google Scholar] [CrossRef]

- Tomilo, V.A.; Sokolov, Y.V.; Parshuto, A.A. High-voltage electrochemical oxidation of an aluminum alloy with preliminary electrolytic-plasma surface treatment. News Nat. Acad. Sci. Belarus. Ser. Phys. Techn. Sci. 2013, 2, 25–28. (In Russian) [Google Scholar]

- Bozza, A.; Giovanardi, R.; Manfredini, T.; Mattioli, P. Pulsed current effect on hard anodizing process of 7075-T6 aluminium alloy. Surf. Coat. Technol. 2015, 270, 139–144. [Google Scholar] [CrossRef]

- Bensalah, W.; Elleuch, K.; Feki, M.; Wery, M.; Ayedi, H.F. Optimization of anodic layer properties on aluminium in mixed oxalic/sulphuric acid bath using statistical experimental methods. Surf. Coat. Technol. 2007, 201, 7855–7864. [Google Scholar] [CrossRef]

- Shih, H.H.; Tzou, S.L. Study of anodic oxidation of aluminum in mixed acid using a pulsed current. Surf. Coat. Technol. 2000, 124, 278–285. [Google Scholar] [CrossRef]

- Rajendra, A.; Parmar, B.J.; Sharma, A.K.; Bhojraj, H.; Nayak, M.M.; Rajanna, K. Hard anodisation of aluminium and its application to sensorics. Surf. Eng. 2005, 21, 193–197. [Google Scholar] [CrossRef]

- Aperador, W.; Delgado, A.; Bautista, J. Improved corrosion protection properties in anodic films type porous on 2024 T3 aluminium alloys obtained by pulse reverse plating. Int. J. Electrochem. Sci. 2013, 8, 9607–9617. [Google Scholar] [CrossRef]

- Qian, J.-G.; Wang, C.; Li, D.; Guo, B.-L.; Song, G.-L. Formation mechanism of pulse current anodized film on AZ91D Mg alloy. Trans. Nonferrous Met. Soc. China 2008, 18, 19–23. [Google Scholar] [CrossRef]

- Gudla, V.C.; Jensen, F.; Bordo, K.; Simar, A.; Ambat, R. Effect of high frequencypulsing on the interfacial structure of anodized Aluminium—TiO2. J. Electrochem. Soc. 2015, 162, C303–C310. [Google Scholar] [CrossRef]

- Gudla, V.C.; Bordo, K.; Engberg, S.; Rechendorff, K.; Ambat, R. High frequency pulse anodising of magnetron sputtered Al-Zr and Al-Ti coatings. Mater. Des. 2016, 95, 340–347. [Google Scholar] [CrossRef]

- Gudla, V.C.; Bordo, K.; Jensen, F.; Canulescu, S.; Yuksel, S.; Simar, A.; Ambat, R. High frequency anodising of aluminium—TiO2 surface composites: Anodising behaviour and optical appearance. Surf. Coat. Technol. 2015, 277, 67–73. [Google Scholar] [CrossRef]

- Fratila-Apachitei, L.; Duszczyk, J.; Katgerman, L. AlSi(Cu) anodic oxide layers formed in H2SO4 at low temperature using different current waveforms. Surf. Coat. Technol. 2003, 165, 232–240. [Google Scholar] [CrossRef]

- Bononi, M.; Giovanardi, R.; Bozza, A.; Mattioli, P. Pulsed current effect on hard anodizing process of 2024-T3 aluminium alloy. Surf. Coat. Technol. 2016, 289, 110–117. [Google Scholar] [CrossRef]

- Lee, W.; Schwirn, K.; Steinhart, M.; Pippel, E.; Scholz, R.; Gösele, U. Structural engineering of nanoporous anodic aluminium oxide by pulse anodization of aluminium. Nat. Nanotechnol. 2008, 3, 234–239. [Google Scholar] [CrossRef] [PubMed]

- Saenz de Miera, M.; Curioni, M.; Skeldon, P.; Thompson, G.E. The behaviour of second phase particles during anodizing of aluminium alloys. Corros. Sci. 2010, 52, 2489–2497. [Google Scholar] [CrossRef]

- Saenz de Miera, M.; Curioni, M.; Skeldon, P.; Thompson, G.E. Preferential anodic oxidation of second-phase constituents during anodising of AA2024-T3 and AA7075-T6 alloys. Surf. Interface Anal. 2010, 42, 241–246. [Google Scholar] [CrossRef]

- Raffin, F.; Echouard, J.; Volovitch, P. Influence of the anodizing time on the microstructure and immersion stability of tartaric-sulfuric acid anodized aluminum alloys. Metals 2023, 13, 993. [Google Scholar] [CrossRef]

- Safyari, M.; Mori, G.; Ucsnik, S.; Moshtaghi, M. Mechanisms of hydrogen absorption, trapping and release during galvanostatic anodization of high-strength aluminum alloys. J. Mater. Res. Technol. 2023, 22, 80–88. [Google Scholar] [CrossRef]

- Student, M.; Pohrelyuk, I.; Padgurskas, J.; Hvozdets’kyi, V.; Zadorozna, K.; Chumalo, H.; Student, O.; Kovalchuk, I. The effect of heat treatment on the structural-phase state and abrasive wear resistance of a hard-anodized layer on aluminum alloy 1011. Coatings 2023, 13, 391. [Google Scholar] [CrossRef]

- Ghassemi, M.H.; Abouei, V.; Moshtaghi, M.; Noghani, M.T. The effect of removing worn particles by ultrasonic cleaning on the wear characterization of LM13 alloy. Surf. Eng. Appl. Electrochem. 2015, 51, 382–388. [Google Scholar] [CrossRef]

- Korzekwa, J.; Fal, M.; Gandek-Moszchak, A. DOE application for anslysis of tribological properties of the Al2O3/IF-WS2 surface layers. Open Eng. 2020, 11, 171–181. [Google Scholar] [CrossRef]

- Chen, L.; Liu, Z.; Wang, B.; Song, Q.; Wan, Y.; Chen, L. Surface characterization and tribological performance of anodizing micro-textured aluminum-silicon alloys. Materials 2019, 12, 1862. [Google Scholar] [CrossRef] [PubMed]

- Dervishi, E.; McBride, M.; Edwards, R.; Gutierrez, M.; Li, N.; Buntyn, R.; Hooks, D.E. Mechanical and tribological properties of anodic Al coatings as a function of anodizing conditions. Surf. Coat. Technol. 2022, 444, 128652. [Google Scholar] [CrossRef]

- Christoph, G.G.; Corbató, C.E.; Hofmann, D.A.; Tettenhorst, R.T. The Crystal Structure of Boehmite. Clays Clay Min. 1979, 27, 81–86. [Google Scholar] [CrossRef]

- Saalfeld, H.; Wedde, M. Refinement of the crystal structure of gibbsite, Al(OH)3. Z. Krist. 1974, 139, 129–135. [Google Scholar] [CrossRef]

- Siddiqui, T.U. Experimental investigation on tribological behavior of hard anodized aluminum Tauseef. J. Emerg. Technol. Innov. Res. 2018, 5, 1565–1571. [Google Scholar]

- Soffritti, C.; Fortini, A.; Nastruzzi, A.; Sola, R.; Merlin, M.; Garagnani, G.L. Dry sliding behavior of an aluminum alloy after innovative hard anodizing treatment. Materials 2021, 14, 3281. [Google Scholar] [CrossRef]

- Santecchia, E.; Cabibbo, M.; Magid, A.; Hamouda, S.; Musharavati, F.; Popelka, A.; Spigarelli, S. Dry sliding tribological properties of a hard anodized AA6082 aluminum alloy. Metals 2020, 10, 207. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Student, M.; Pohrelyuk, I.; Padgurskas, J.; Rukuiža, R.; Hvozdets’kyi, V.; Zadorozhna, K.; Veselivska, H.; Student, O.; Tkachuk, O. Abrasive Wear Resistance and Tribological Characteristics of Pulsed Hard Anodized Layers on Aluminum Alloy 1011 in Tribocontact with Steel and Ceramics in Various Lubricants. Coatings 2023, 13, 1883. https://doi.org/10.3390/coatings13111883

Student M, Pohrelyuk I, Padgurskas J, Rukuiža R, Hvozdets’kyi V, Zadorozhna K, Veselivska H, Student O, Tkachuk O. Abrasive Wear Resistance and Tribological Characteristics of Pulsed Hard Anodized Layers on Aluminum Alloy 1011 in Tribocontact with Steel and Ceramics in Various Lubricants. Coatings. 2023; 13(11):1883. https://doi.org/10.3390/coatings13111883

Chicago/Turabian StyleStudent, Mykhailo, Iryna Pohrelyuk, Juozas Padgurskas, Raimundas Rukuiža, Volodymyr Hvozdets’kyi, Khrystyna Zadorozhna, Halyna Veselivska, Oleksandra Student, and Oleh Tkachuk. 2023. "Abrasive Wear Resistance and Tribological Characteristics of Pulsed Hard Anodized Layers on Aluminum Alloy 1011 in Tribocontact with Steel and Ceramics in Various Lubricants" Coatings 13, no. 11: 1883. https://doi.org/10.3390/coatings13111883

APA StyleStudent, M., Pohrelyuk, I., Padgurskas, J., Rukuiža, R., Hvozdets’kyi, V., Zadorozhna, K., Veselivska, H., Student, O., & Tkachuk, O. (2023). Abrasive Wear Resistance and Tribological Characteristics of Pulsed Hard Anodized Layers on Aluminum Alloy 1011 in Tribocontact with Steel and Ceramics in Various Lubricants. Coatings, 13(11), 1883. https://doi.org/10.3390/coatings13111883