Microstructure and Tribological Performance of HVAF-Sprayed Ti-6Al-4V Coatings

Abstract

:1. Introduction

- Ductility and workability;

- Fracture toughness;

- Heat and creep resistance;

- Weldability, thermal processability, and strength [2].

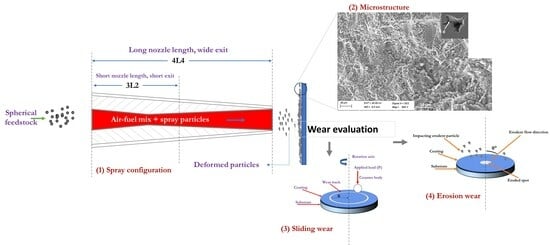

2. Experimental

2.1. Materials

2.2. Alloy Coating Deposition

2.3. Characterization and Performance Tests

2.3.1. Sample Preparation and Microstructure Analysis

2.3.2. Microhardness

2.3.3. Wear Performance Tests

3. Results and Discussion

3.1. Microstructure: Materials and as-Sprayed Coatings

3.2. Microhardness and Wear Performance

3.2.1. Microhardness

3.2.2. Sliding Wear

3.2.3. Erosion Wear

4. Conclusions

- The HVAF technique is capable of depositing Ti-6Al-4V coatings with very high density using an appropriate nozzle configuration;

- The microhardness of the coatings is similar, which correlates with their sliding wear performance;

- The densest of the coatings (<0.5%) compared well with the bulk Ti-6Al-4V material under both sliding and erosive wear conditions and showed improved erosive performance over the bulk Ti-6Al-4V sample;

- The measured properties and the wear performance of the tested coatings are suggestive of the promise of HVAF deposition of Ti-6Al-4V coatings for component repair.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Liu, S.; Shin, Y.C. Additive Manufacturing of Ti6Al4V Alloy: A Review, in Materials and Design; Elsevier: Amsterdam, The Netherlands, 2019. [Google Scholar]

- Browning, J.A. Hypervelocity impact fusion—A technical note. J. Therm. Spray Technol. 1992, 1, 289–292. [Google Scholar] [CrossRef]

- Hussain, T. Cold Spraying of Titanium: A Review of Bonding Mechanisms, Microstructure and Properties. In Key Engineering Materials; Trans Tech Publications, Ltd.: Stafa-Zurich, Switzerland, 2012; pp. 53–90. [Google Scholar]

- Inagaki, I.; Takechi, T.; Ariyasu, Y.S.N. Application and Features of Titanium for the Aerospace Industry. Nippon. Steel Sumitomo Met. Tech. Rep. 2014, 106, 22–27. [Google Scholar]

- Tao, W.; Huapeng, D.; Jie, T.; Hao, W. Recent Repair Technology for Aero-Engine Blades. Recent Pat. Eng. 2015, 9, 132–141. [Google Scholar] [CrossRef]

- Wu, Z.; David, S.A.; Leonard, D.N.; Feng, Z.; Bei, H. Microstructures and mechanical properties of a welded CoCrFeMnNi high-entropy alloy. Sci. Technol. Weld. Join. 2018, 23, 585–595. [Google Scholar] [CrossRef]

- Qin, Y.; Zhang, D.; Jiang, W.; He, X. Microstructure and Mechanical Properties of Welded Joints of Titanium Alloy Ti60 after Laser Welding and Subsequent Heat Treatment. Met. Sci. Heat Treat. 2021, 62, 689–695. [Google Scholar] [CrossRef]

- Davis, J.R. (Ed.) Handbook of Thermal Spray Technology; ASM International: Kinsman Road Materials Park, OH, USA, 2004; p. 332. [Google Scholar]

- Owoseni, T.A.; Bai, M.; Curry, N.; Lester, E.H.; Grant, D.M.; Hussain, T. Residual Stress Measurement of Suspension HVOF-Sprayed Alumina Coating via a Hole-Drilling Method. J. Therm. Spray Technol. 2020, 29, 1339–1350. [Google Scholar] [CrossRef]

- Sadeghimeresht, E.; Hooshyar, H.; Markocsan, N.; Joshi, S.; Nylén, P. Oxidation Behavior of HVAF-Sprayed NiCoCrAlY Coating in H2–H2O Environment. Oxid. Met. 2016, 86, 299–314. [Google Scholar] [CrossRef]

- Björklund, S.; Goel, S.; Joshi, S. Function-dependent coating architectures by hybrid powder-suspension plasma spraying: Injector design, processing, and concept validation. Mater. Des. 2018, 142, 56–65. [Google Scholar] [CrossRef]

- Yasoda, R.D.; Huang, Y.; Kiran, R.; Qi, X. Post-fire Performance of Wire-arc-Sprayed Zn-15Al Coatings. J. Therm. Spray Technol. 2023, 32, 1518–1534. [Google Scholar] [CrossRef]

- Koivuluoto, H. A Review of Thermally Sprayed Polymer Coatings. J. Therm. Spray Technol. 2022, 31, 1750–1764. [Google Scholar] [CrossRef]

- Li, C.J. Thermal Spraying of Light Alloys. In Surface Engineering of Light Alloys; Elsevier: Amsterdam, The Netherlands, 2010; pp. 184–241. [Google Scholar]

- Sundararajan, G.; Prasad, K.U.; Rao, D.S.; Joshi, S.V. A comparative study of tribological behavior of plasma and D-gun sprayed coatings under different wear modes. J. Mater. Eng. Perform. 1998, 7, 343–351. [Google Scholar] [CrossRef]

- Turunen, E.; Varis, T.; Gustafsson, T.E.; Keskinen, J.; Fält, T.; Hannula, S.-P. Parameter optimization of HVOF sprayed nanostructured alumina and alumina–nickel composite coatings. Surf. Coat. Technol. 2006, 200, 4987–4994. [Google Scholar] [CrossRef]

- Eklund, J.; Phother, J.; Sadeghi, E.; Joshi, S.; Liske, J. High-Temperature Corrosion of HVAF-Sprayed Ni-Based Coatings for Boiler Applications. Oxid. Met. 2019, 91, 729–747. [Google Scholar] [CrossRef]

- Lima, R.S.; Marple, B.R. From APS to HVOF spraying of conventional and nanostructured titania feedstock powders: A study on the enhancement of the mechanical properties. Surf. Coat. Technol. 2006, 200, 3428–3437. [Google Scholar] [CrossRef]

- Liu, Y.; Fischer, T.E.; Dent, A. Comparison of HVOF and plasma-sprayed alumina/titania coatings—Microstructure, mechanical properties, and abrasion behavior. Surf. Coat. Technol. 2003, 167, 68–76. [Google Scholar] [CrossRef]

- Xu, Z.; Chen, L.; Shi, X.; Zhang, Q.; Ibrahim, A.M.; Zhai, W.; Yao, J.; Zhu, Q.; Xiao, Y. Formation of Friction Layers in Graphene-Reinforced TiAl Matrix Self-Lubricating Composites. Tribol. Trans. 2015, 58, 668–678. [Google Scholar] [CrossRef]

- Shitole, P.P.; Gawande, S.H.; Desale, G.R.; Nandre, B.D. Effect of Impacting Particle Kinetic Energy on Slurry Erosion Wear. J. Bio- Tribo-Corros. 2015, 1, 29. [Google Scholar] [CrossRef]

- Bolelli, G.; Cannillo, V.; Gadow, R.; Killinger, A.; Lusvarghi, L.; Manfredini, T.; Müller, P. Properties of Al2O3 coatings by High Velocity Suspension Flame Spraying (HVSFS): Effects of injection systems and torch design. Surf. Coat. Technol. 2015, 270, 175–189. [Google Scholar] [CrossRef]

- Gupta, A.; Pattnayak, A.; Abhijith, N.V.; Kumar, D.; Chaudhry, V.; Mohan, S. Development of alumina-based hybrid composite coatings for high temperature erosive and corrosive environments. Ceram. Int. 2023, 49, 862–874. [Google Scholar] [CrossRef]

- Owoseni, T.A.; Romero, A.R.; Pala, Z.; Venturi, F.; Lester, E.H.; Grant, D.M.; Hussain, T. YAG thermal barrier coatings deposited by suspension and solution precursor thermal spray. Ceram. Int. 2021, 47, 23803–23813. [Google Scholar] [CrossRef]

- Ganvir, A.; Curry, N.; Markocsan, N.; Nylén, P.; Toma, F.-L. Comparative study of suspension plasma sprayed, and suspension high velocity oxy-fuel sprayed YSZ thermal barrier coatings. Surf. Coat. Technol. 2015, 268, 70–76. [Google Scholar] [CrossRef]

- Zhang, J.; Alpas, A.T. Transition between mild and severe wear in aluminium alloys. Acta Mater. 1997, 45, 513–528. [Google Scholar] [CrossRef]

- Ma, A.M.; Liu, D.; Zhang, X.; Liu, D.; He, G.; Yin, X. Solid particle erosion behavior and failure mechanism of TiZrN coatings for Ti-6Al-4V alloy. Surf. Coat. Technol. 2021, 426, 127701. [Google Scholar] [CrossRef]

- Shuai, J.T.; Zuo, X.; Wang, Z.; Sun, L.; Chen, R.; Wang, L.; Wang, A.; Ke, P. Erosion behavior and failure mechanism of Ti/TiAlN multilayer coatings eroded by silica sand and glass beads. J. Mater. Sci. Technol. 2021, 80, 179–190. [Google Scholar] [CrossRef]

- Tortuero, S.; Garrido, M.A.; Poza, P.; Rodríguez, J. Evaluating the erosion resistance of Ti6Al4V coatings deposited by cold spray. Wear 2020, 454–455, 203337. [Google Scholar] [CrossRef]

- Alroy, R.J.; Pandey, R.; Kamaraj, M.; Sivakumar, G. Role of process parameters on microstructure, mechanical properties, and erosion performance of HVAF sprayed Cr3C2-NiCr coatings. Surf. Coat. Technol. 2022, 449, 128941. [Google Scholar] [CrossRef]

- Gupta, R.K.; Kumar, V.A.; Mathew, C.; Rao, G.S. Strain hardening of Titanium alloy Ti6Al4V sheets with prior heat treatment and cold working. Mater. Sci. Eng. A 2016, 662, 537–550. [Google Scholar] [CrossRef]

| S/N | Spray Sessions | Configurations | |

|---|---|---|---|

| Nozzle Length | Exit Size | ||

| 1. | Run-1 | Long | Wide |

| 2. | Run-2 | Long | Small |

| 3. | Run-3 | Short | Wide |

| 4. | Run-4 | Short | Small |

| Spray Parameters | Spray Runs | |||

|---|---|---|---|---|

| 1 | 2 | 3 | 4 | |

| Nozzle type | 4L4C | 4L2C | 3L4C | 3L2C |

| Air pressure (MPa) | 0.7 | 0.67 | 0.7 | 0.65 |

| Fuel 1 pressure—propane (MPa) | 0.65 | 0.67 | 0.65 | 0.68 |

| Fuel 2 pressure—propane (MPa) | 0.65 | 0.67 | 0.65 | 0.68 |

| Carrier gas pressure—N2 (l/min) | 40 | 40 | 40 | 40 |

| Feed rate (g/min) | 100 | 100 | 100 | 100 |

| Pass velocity (m/min) | 100 | 100 | 100 | 100 |

| Pass spacing (mm/rev.) | 5 | 5 | 5 | 5 |

| Spray distance (mm) | 200 | 200 | 200 | 200 |

| Number of passes | 10 | 10 | 10 | 10 |

| Coating Features | Spray Runs | |||

|---|---|---|---|---|

| 1 | 2 | 3 | 4 | |

| Porosity (%) | 2–3 | 0.5–1 | 1–2 | <0.5 |

| Thickness (mm) | 0.65 | 0.32 | 0.32 | 0.30 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Owoseni, T.A.; Ciudad de Lara, I.; Mathiyalagan, S.; Björklund, S.; Joshi, S. Microstructure and Tribological Performance of HVAF-Sprayed Ti-6Al-4V Coatings. Coatings 2023, 13, 1952. https://doi.org/10.3390/coatings13111952

Owoseni TA, Ciudad de Lara I, Mathiyalagan S, Björklund S, Joshi S. Microstructure and Tribological Performance of HVAF-Sprayed Ti-6Al-4V Coatings. Coatings. 2023; 13(11):1952. https://doi.org/10.3390/coatings13111952

Chicago/Turabian StyleOwoseni, Tunji A., Irene Ciudad de Lara, Sribalaji Mathiyalagan, Stefan Björklund, and Shrikant Joshi. 2023. "Microstructure and Tribological Performance of HVAF-Sprayed Ti-6Al-4V Coatings" Coatings 13, no. 11: 1952. https://doi.org/10.3390/coatings13111952