The Effect of CO2 Laser Engraving on the Surface Structure and Properties of Spruce Wood

Abstract

1. Introduction

- −

- Determining the total irradiation dose under variable parameters of s CO2 laser (laser power and density) and this dose’s impact on the wood mass loss;

- −

- The influence of the treatment method on the morphology of the wood surface quantified through roughness parameters;

- −

- Changes in FTIR spectra and discolouration corresponding to various engraving parameters;

- −

- Determining the functional dependence of the colour coordinates on the total irradiation dose.

2. Materials and Methods

2.1. Experimental Materials and Irradiation Conditions

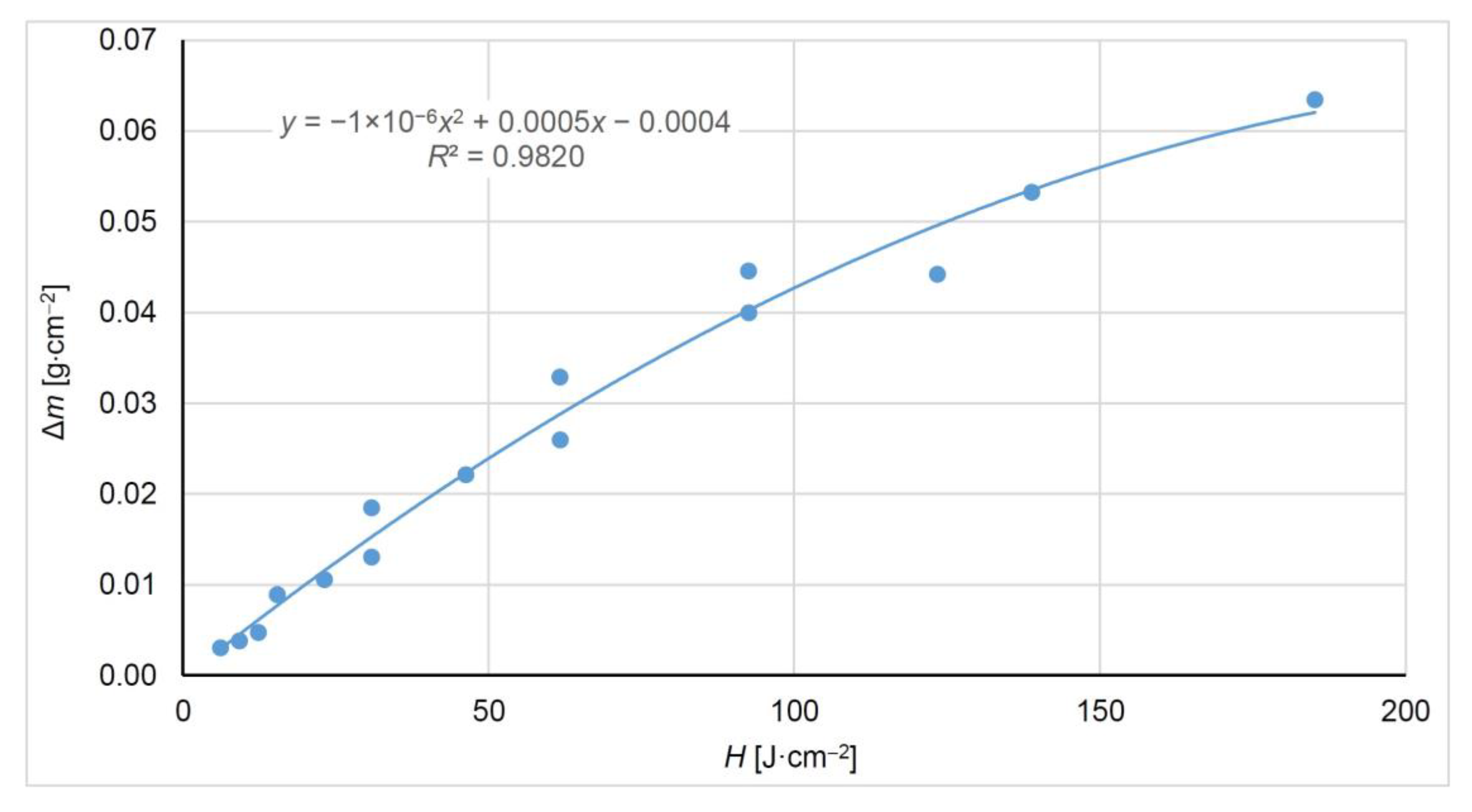

2.2. Evaluation of Weight Loss of Wood Mass

2.3. Evaluation of Wood Surface Morphology

2.4. Evaluation of Colour

2.5. Detecting Chemical Changes after Engraving

3. Results and Discussion

3.1. Total Irradiation Dose and Wood Mass Losses Corresponding to Different Irradiation Parameters

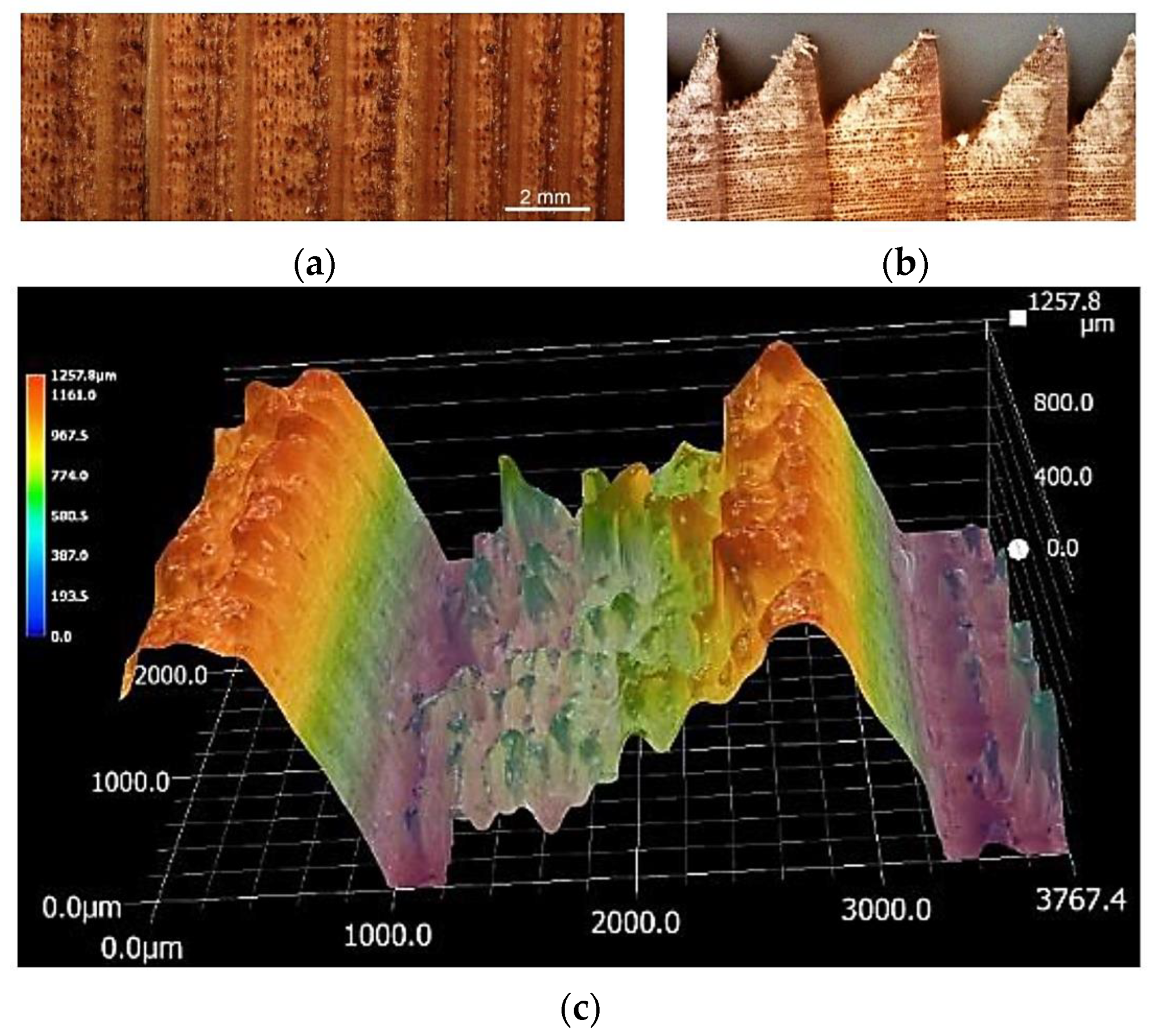

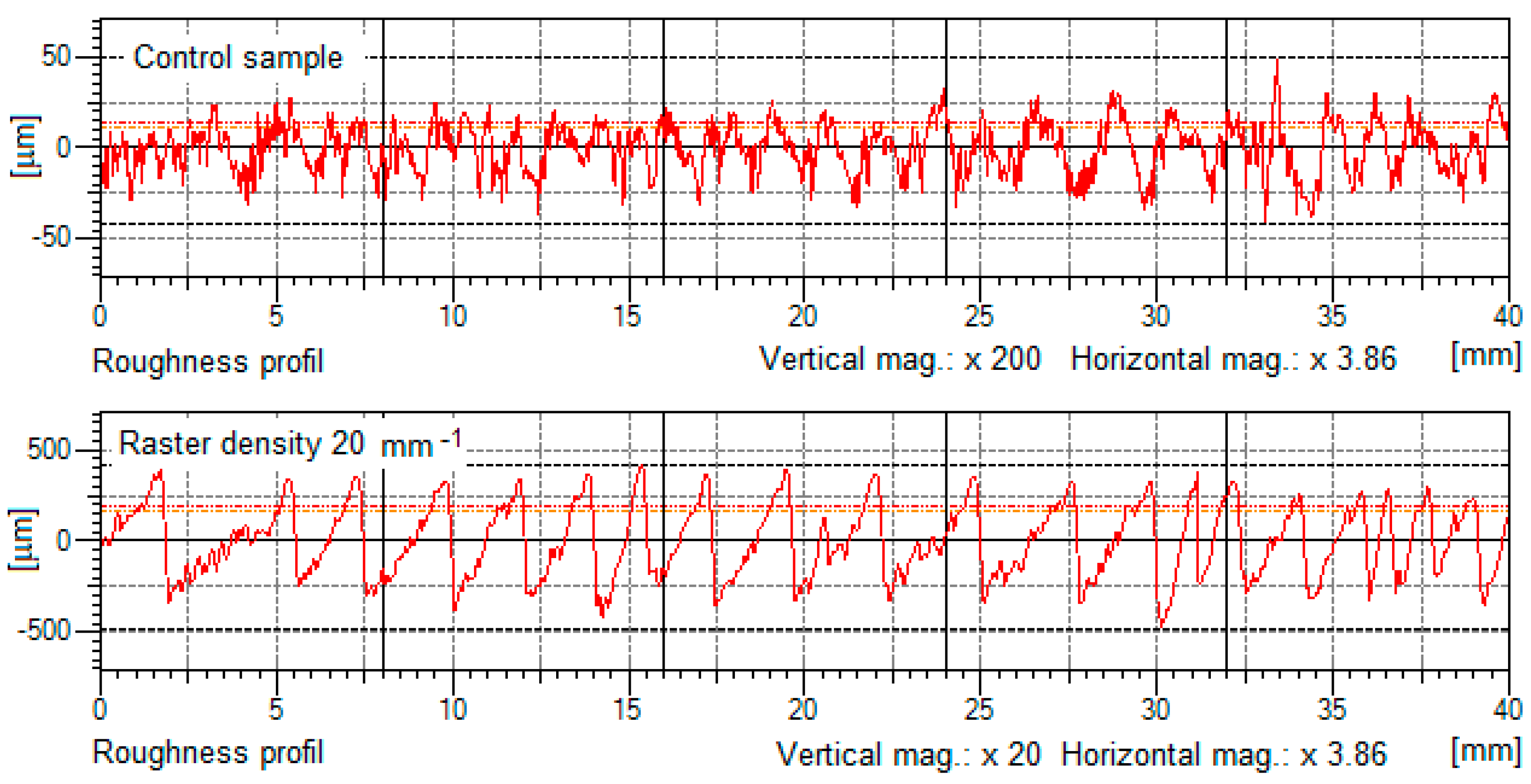

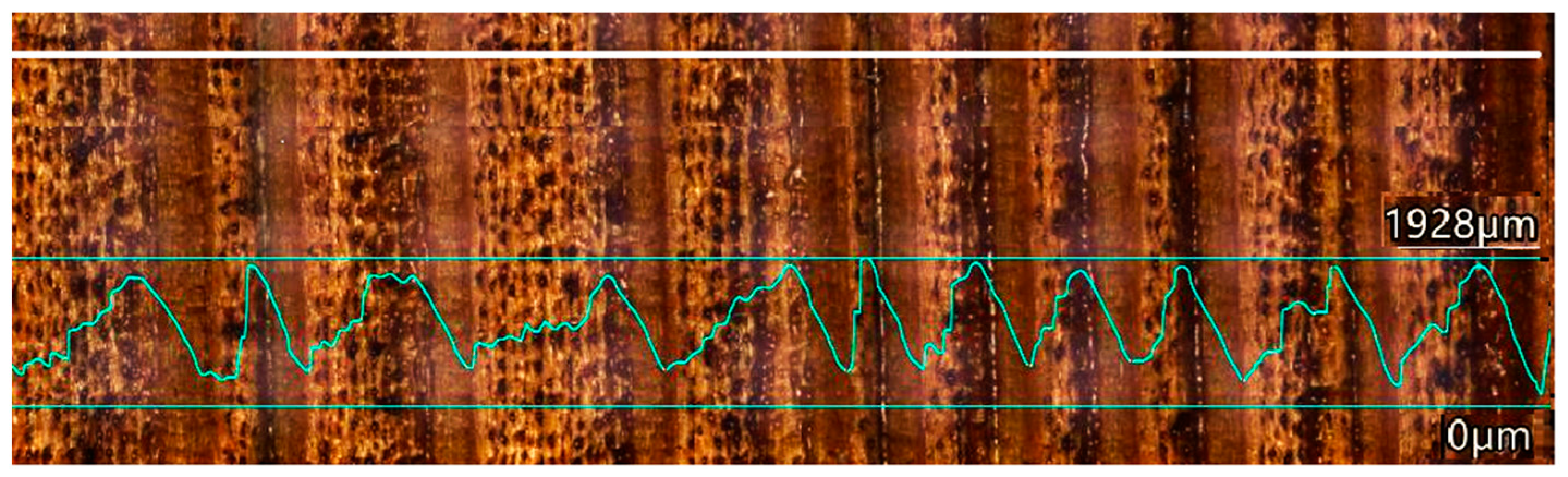

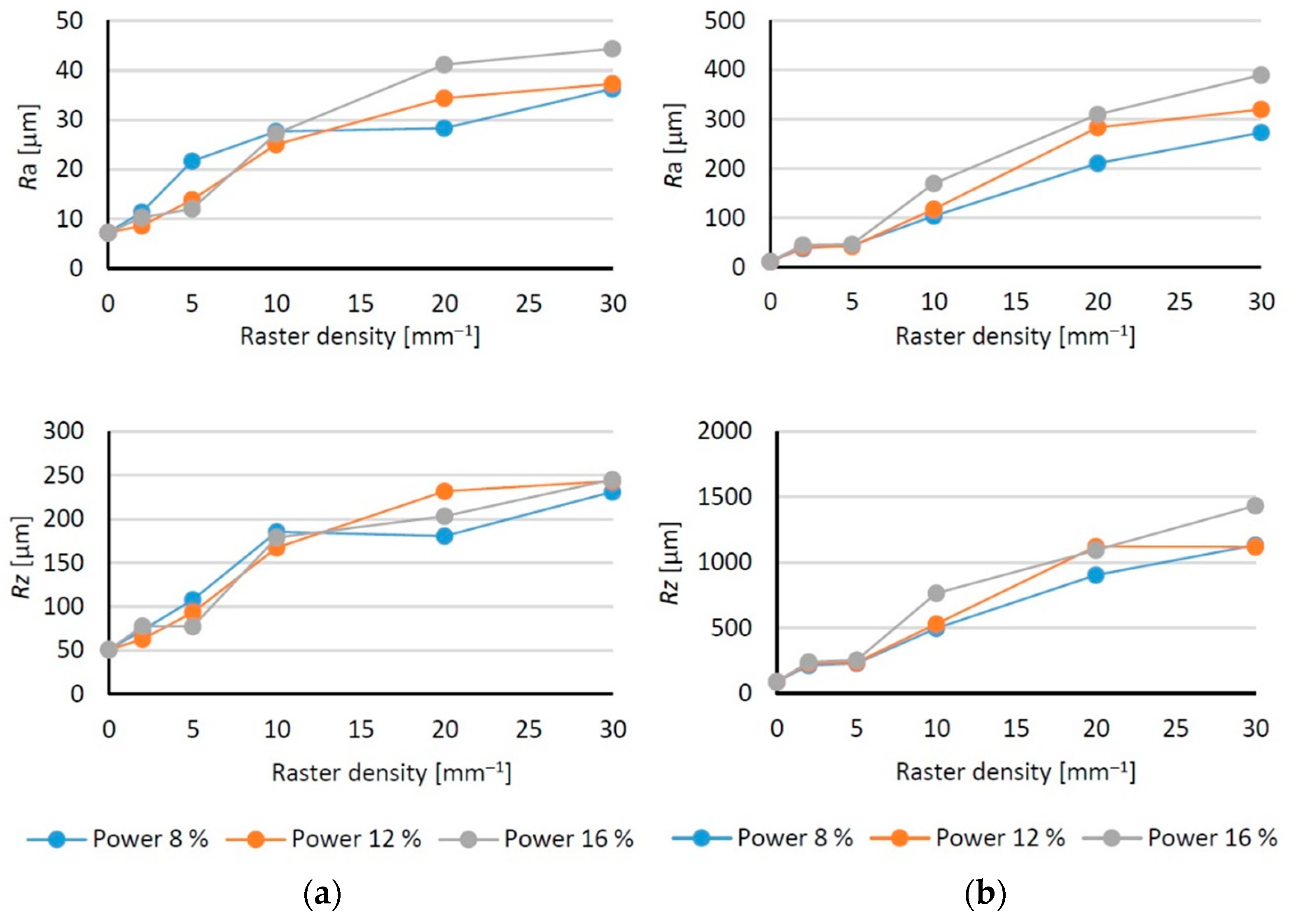

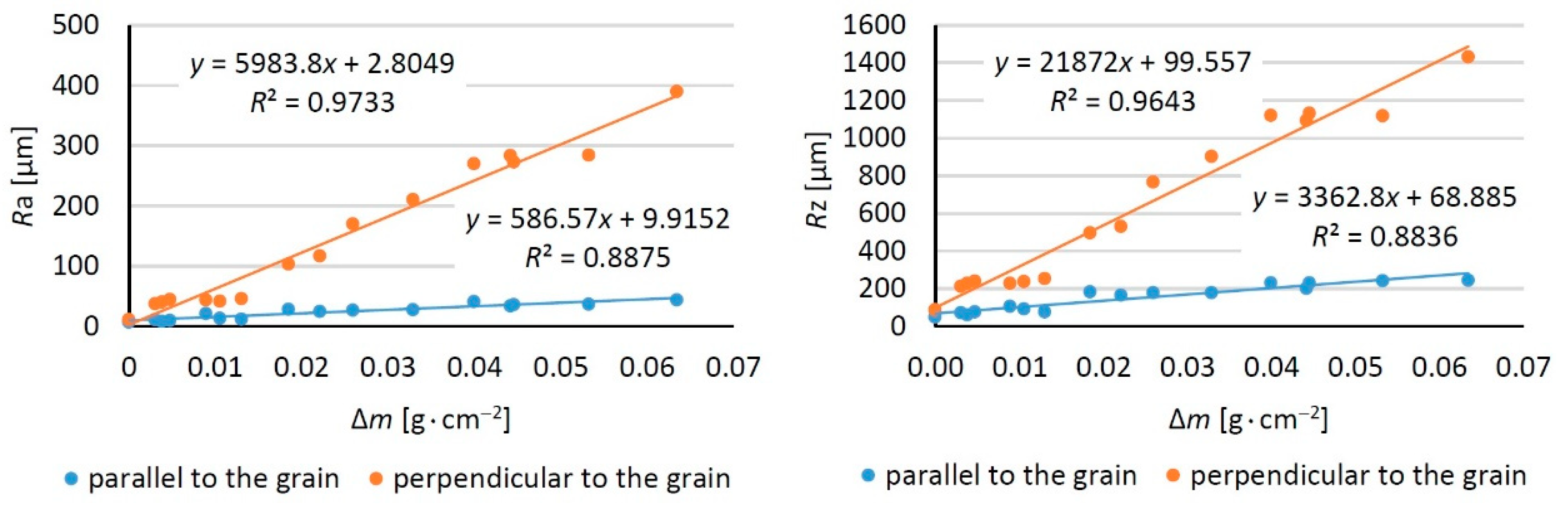

3.2. Roughness of Wood Surfaces Engraved with a CO2 Laser

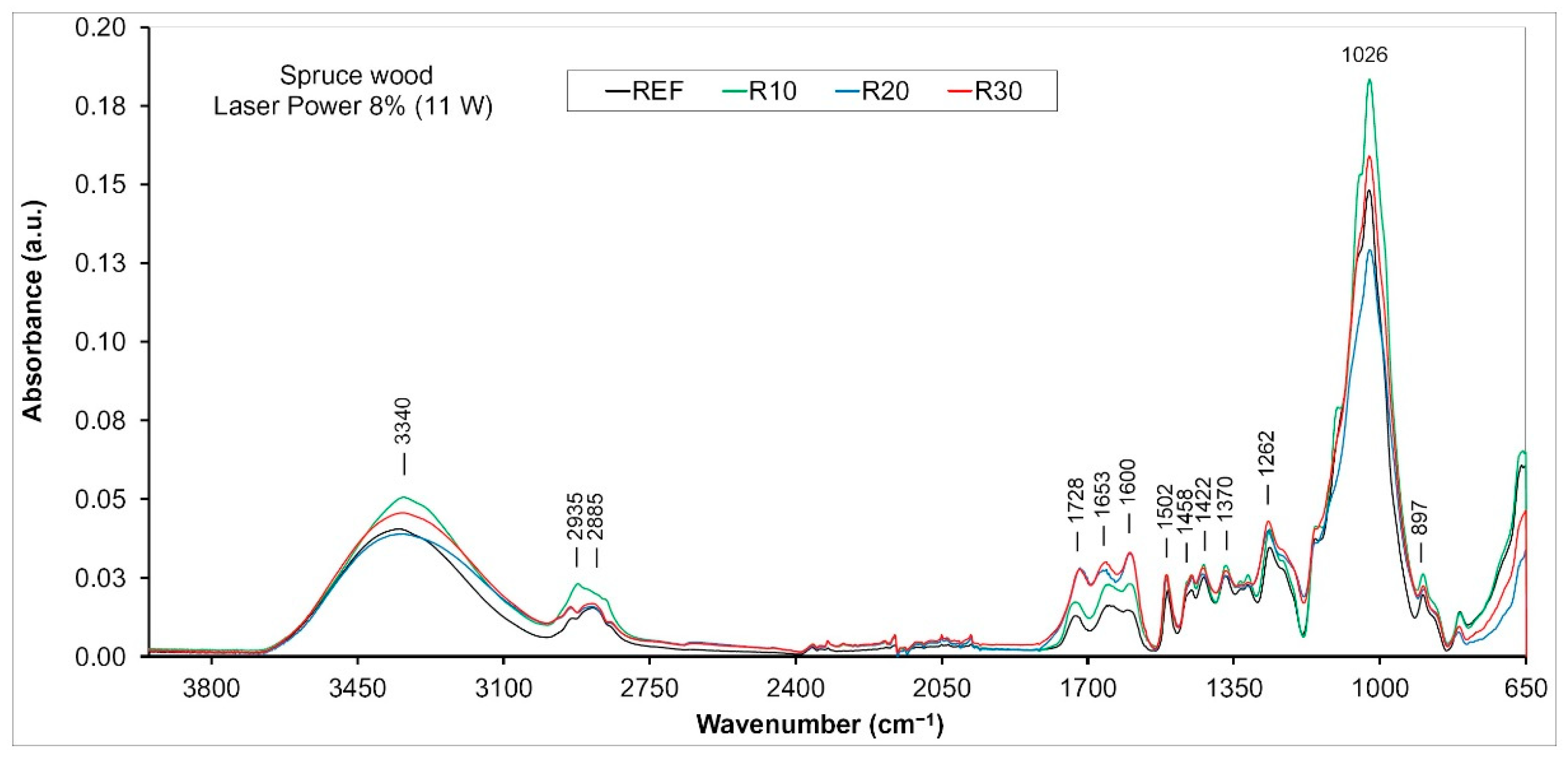

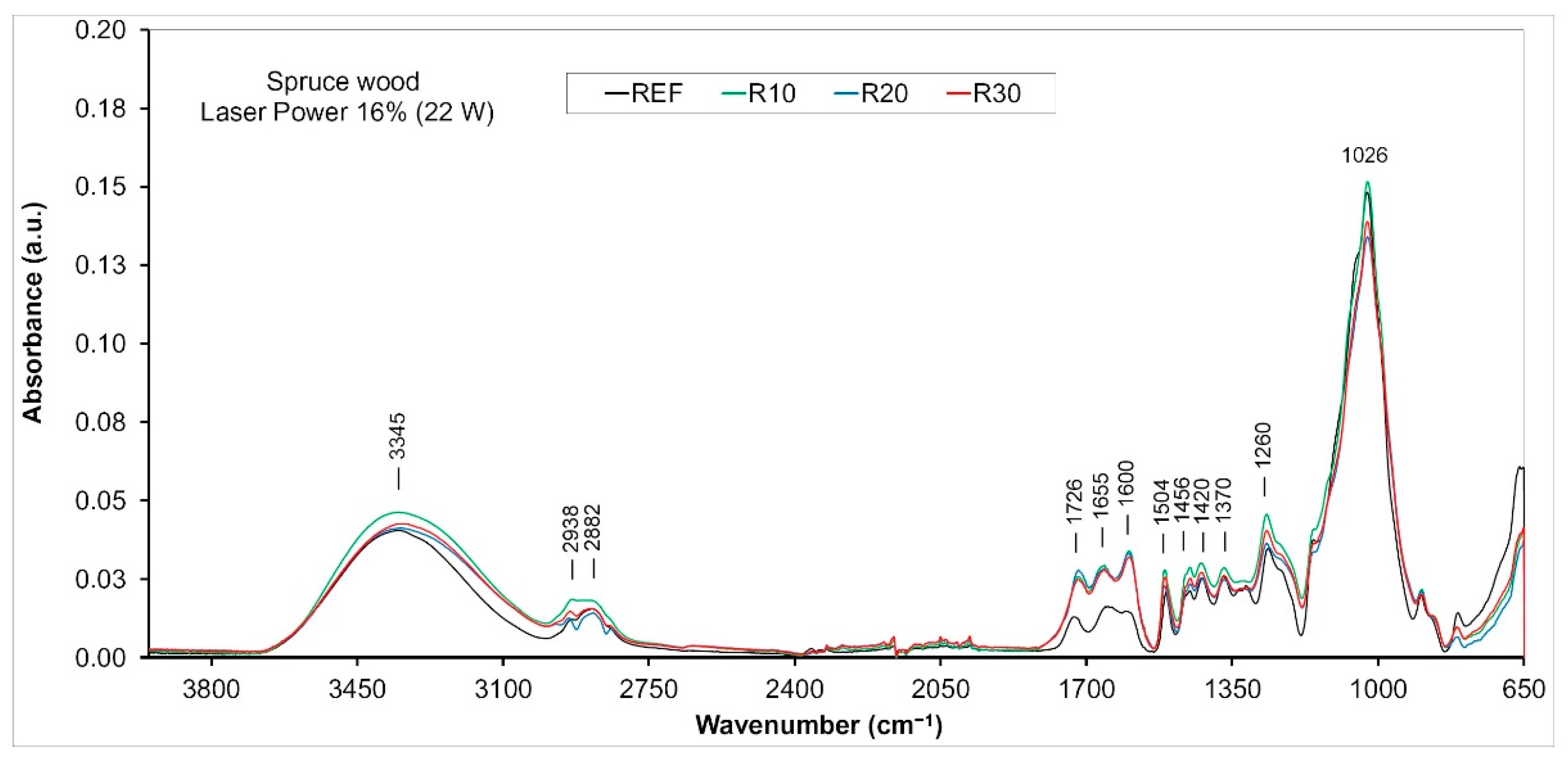

3.3. Changes in the FTIR Spectra

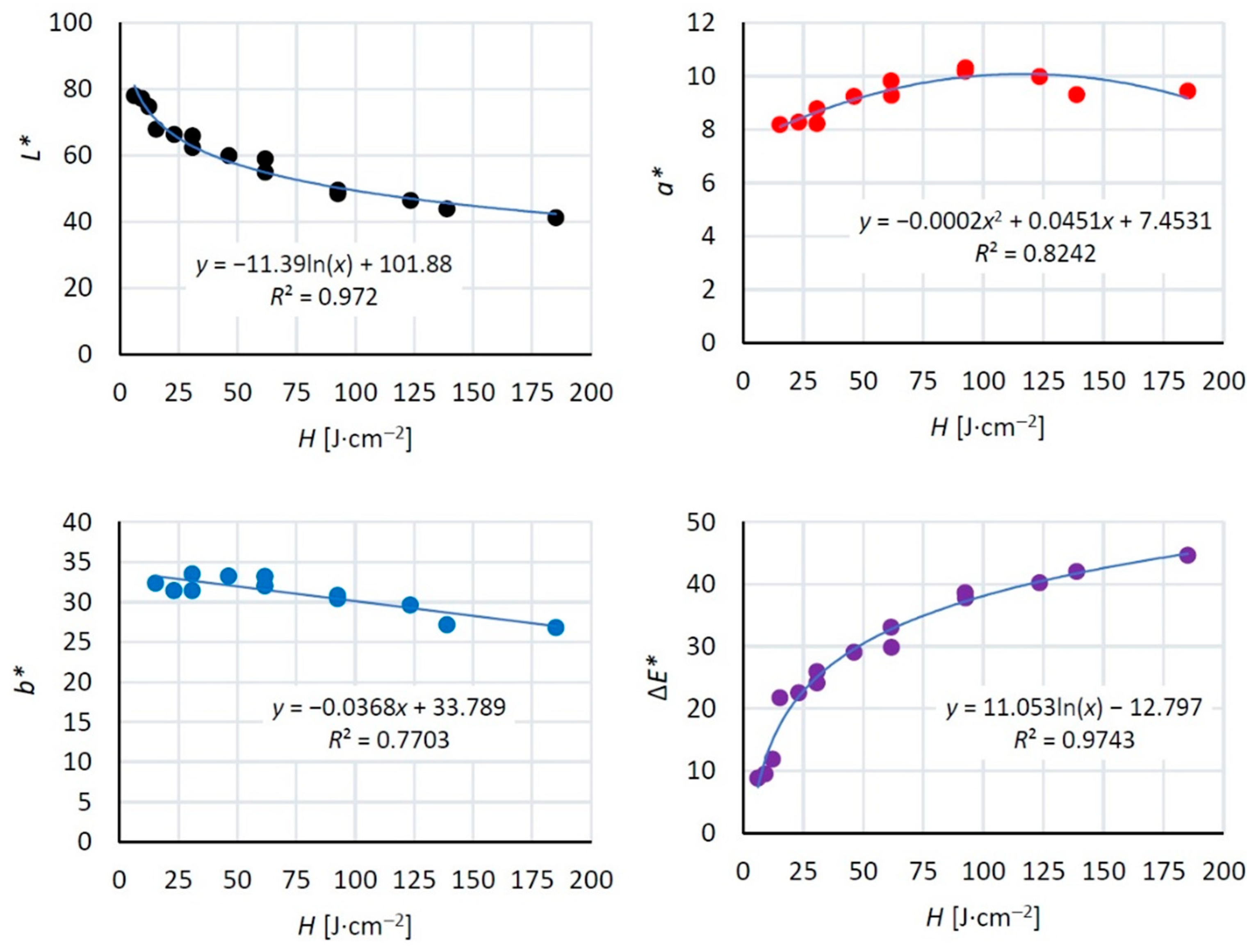

3.4. Spruce Wood Surface Discolouration Related to Engraving

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wust, H.; Haller, P.; Wiedemann, G. Experimental Study of the Effect of a Laser Beam on the Morphology of Wood Surfaces. In Proceedings of the Second European Conference on Wood Modification, Göttingen, Germany, 6–7 October 2005. [Google Scholar]

- Haller, P.; Beyer, E.; Wiedemann, G.; Panzner, M.; Wust, H. Experimental Study of the Effect of a Laser Beam on the Morphology of Wood Surfaces. In Proceedings of the First International Conference of the European Society for Wood Mechanics, Lausanne, Switzerland, 19–21 April 2001; p. 459. [Google Scholar]

- Dolan, J.A. Characterization of Laser Modified Surfaces for Wood Adhesion. Master’s Thesis, The Faculty of Virginia Polytechnic Institute, Blacksburg, VA, USA, 2014; 100p. [Google Scholar]

- Kubovský, I.; Kačík, F. Colour and Chemical Changes of the Lime Wood Surface Due to CO2 Laser Thermal Modification. Appl. Surf. Sci. 2014, 321, 261–267. [Google Scholar] [CrossRef]

- Li, R.; He, C.; Wang, X. Effects of Processing Parameters on Mass Loss and Coating Properties of Poplar Plywood During CO2 Laser Modification. Eur. J. Wood Wood Prod. 2022, 4, 899–906. [Google Scholar] [CrossRef]

- Li, R.; He, C.; Xu, W.; Wang, X.A. Prediction of Surface Roughness of CO2 Laser Modified PoplarWood Via Response Surface Methodology. Maderas. Ciencia y Tecnología 2022, 24, 1–12. [Google Scholar] [CrossRef]

- Kúdela, J.; Kubovský, I.; Andrejko, M. Surface Properties of Beech Wood after CO2 Laser Engraving. Coatings 2020, 10, 77. [Google Scholar] [CrossRef]

- Kúdela, J.; Kubovský, I.; Andrejko, M. Influence of irradiation parameters on structure and properties of oak wood surface engraved with a CO2 laser. Materials 2022, 15, 8384. [Google Scholar] [CrossRef]

- Liu, H.; Hu, Q.; Guo, H.; Wu, R.; Zhang, C. Glaze layer induced by femtosecond laser. Surf. Interfaces 2023, 37, 102716. [Google Scholar] [CrossRef]

- Kim, Y.W.; Song, S.H. Efficient Laser Image Engraving by Work Area Sectioning and Multi-laser Head Cooperation: A Conceptual Study. Int. J. Precis. Eng. Manuf. 2023, 24, 1813–1820. [Google Scholar] [CrossRef]

- Guo, Q.; Wu, Z.; Zhang, C.; Yang, C.; Ma, Y.; Xu, F.; Cao, Z. Study on a New Clean Machining Method Instead of Sanding Technology for Wood. Alex. Eng. J. 2021, 60, 2369–2380. [Google Scholar] [CrossRef]

- Gurău, L.; Petru, A.; Varodi, A.; Timar, M.C. The Influence of CO2 Laser Beam Power Output and Scanning Speed on Surface Roughness and Colour Changes of Beech (Fagus sylvatica). BioResources 2017, 12, 7395–7412. [Google Scholar] [CrossRef]

- Gurău, L.; Coşereanu, C.; Paiu, I. Comparative Surface Quality of Larch (Larix decidua Mill.) Fretwork Patterns Cut through by CNC Routing and by Laser. Appl. Sci. 2021, 11, 6875. [Google Scholar] [CrossRef]

- Gurău, L.; Petru, A. The Influence of CO2 Laser Beam Power Output and Scanning Speed on Surface Quality of Norway Maple (Acer platanoides). BioResources 2018, 13, 8168–8183. [Google Scholar] [CrossRef]

- Gurău, L.; Coșereanu, C.; Timar, M.C.; Lungu, A.; Condoroţeanu, C.D. Comparative Surface Quality of Maple (Acer pseudoplatanus) Cut through by CNC Routing and by CO2 Laser at Different Angles as Related to the Wood Grain. Coatings 2022, 12, 1982. [Google Scholar] [CrossRef]

- Kamperidou, V. Chemical and Structural Characterization of Poplar and Black Pine Wood Exposed to Short Thermal Modification. Drv. Ind. 2021, 72, 155–167. [Google Scholar] [CrossRef]

- Kačík, F.; Kubovský, I. Chemical Changes of Beech Wood Due to CO2 Laser Irradiation. J. Photochem. Photobiol. A 2011, 222, 105–110. [Google Scholar] [CrossRef]

- Petutschnigg, A.; Stöckler, M.; Steinwendner, F.; Schnepps, J.; Gütler, H.; Blinzer, J.; Holzer, H.; Schnabel, T. Laser Treatment of Wood Surfaces for Ski Cores: An Experimental Parameter Study. Adv. Mater. Sci. Eng. 2013, 2013, 123085. [Google Scholar] [CrossRef]

- Li, R.; Xu, W.; Wang, X.; Wang, C. Modeling and Predicting of the Color Changes of Wood Surface During CO2 Laser Modification. J. Clean. Prod. 2018, 183, 818–823. [Google Scholar] [CrossRef]

- Gochev, Z.; Vitchev, P. Colour modifications in plywood by different modes of CO2 laser engraving. Acta Fac. Xylologiae Zvolen 2022, 64, 77–86. [Google Scholar] [CrossRef]

- Chernykh, M.; Zykova, M.; Stollmann, V.; Gilfanov, M. Influence effect of wood laser engraving mode on aesthetic perception of images. Acta Fac. Xylologiae Zvolen 2022, 64, 87–96. [Google Scholar] [CrossRef]

- Li, R.; He, C.; Chen, Y.; Wang, X. Effects of Laser Parameters on the Width of Color Change Area of Poplar Wood Surface During a Single Irradiation. Eur. J. Wood Wood Prod. 2021, 79, 1109–1116. [Google Scholar] [CrossRef]

- Panzner, M.; Wiedemann, G.; Henneberg, K.; Fischer, R.; Wittke, T.; Dietsch, R. Experimental Investigation of the Laser Ablation Process on Wood Surfaces. Appl. Surf. Sci. 1998, 127–129, 787–792. [Google Scholar] [CrossRef]

- Lin, C.J.; Wang, Y.C.; Lin, L.D.; Chiou, C.R.; Wang, Y.N.; Tsai, M.J. Effects of Feed Speed Ratio and Laser Power on Engraved Depth and Color Difference of Moso Bamboo Lamina. J. Mater. Process. Technol. 2008, 198, 419–425. [Google Scholar] [CrossRef]

- Nath, S.; Waugh, D.G.; Ormondroyd, G.A.; Spear, M.J.; Pitman, A.J.; Sahoo, S.; Mason, P. CO2 Laser Interactions with Wood Tissues During Single Pulse Laser-incision. Opt. Laser Technol. 2020, 126, 106069. [Google Scholar] [CrossRef]

- Li, R.; He, C.; Wang, X. Evaluation and Modeling of Processability of Laser Removal Technique for Bamboo Outer Layer. JOM 2021, 73, 2423–2430. [Google Scholar] [CrossRef]

- Arai, I.; Kawasumi, H. Thermal analysis of laser machining in wood III. J. Jpn. Wood Res. Soc. Mokuzai Gakkaishi 1980, 26, 773–782. [Google Scholar]

- Barcikowski, S.; Koch, G.; Odermatt, J. Characterisation and modification of the heat affected zone during laser material processing of wood and wood composites. Holz Roh Werkst. 2006, 64, 94–103. [Google Scholar] [CrossRef]

- Kučerová, V.; Lagaňa, R.; Hýrošová, T. Changes in chemical and optical properties of silver fir (Abies alba L.) wood due to thermal treatment. J. Wood Sci. 2019, 65, 21–31. [Google Scholar] [CrossRef]

- Yang, C.; Jiang, T.; Yu, Y.; Bai, Y.; Song, M.; Miao, Q.; Ma, Y.; Liu, J. Water-jet Assisted Nanosecond Laser Microcutting of Northeast China Ash Wood. Experimental Study. BioResources 2019, 14, 128–138. [Google Scholar] [CrossRef]

- Jurek, M.; Wagnerová, R. Laser Beam Calibration for Wood Surface Colour Treatment. Eur. J. Wood Wood Prod. 2021, 79, 1097–1107. [Google Scholar] [CrossRef]

- Reinprecht, L.; Vidholdová, Z. The Impact of a CO2 Laser on the Adhesion and Mold Resistance of a Synthetic Polymer Layer on a Wood Surface. Forests 2021, 12, 242. [Google Scholar] [CrossRef]

- Lungu, A.; Timar, M.C.; Beldean, E.C.; Georgescu, S.V.; Co¸sereanu, C. Adding Value to Maple (Acer pseudoplatanus) Wood Furniture Surfaces by Different Methods of Transposing Motifs from Textile Heritage. Coatings 2022, 12, 1393. [Google Scholar] [CrossRef]

- Kúdela, J.; Andrejko, M.; Mišíková, O. Wood Surface Morphology Alteration Induced by Engraving with CO2 Laser Under Different Raster Density Values. Acta Fac. Xylologiae Zvolen 2021, 63, 35–47. [Google Scholar] [CrossRef]

- Moliński, W.; Roszyk, E.; Jabloński, A.; Puszyński, J.; Cegiela, J. Mechanical parameters of thermally modified ash wood determined by compression in radial direction. Maderas. Cienc. Tecnol. 2016, 18, 577–586. [Google Scholar] [CrossRef][Green Version]

- Kubovský, I.; Kačíková, D.; Kačík, F. Structural Changes of Oak Wood Main Components Caused by Thermal Modification. Polymers 2020, 12, 485. [Google Scholar] [CrossRef] [PubMed]

- Nada, A.M.A.; Youssef, M.A.; Sha_ei, K.A.; Aalah, A.M. Infrared spectroscopy of some treated lignins. Polym. Degrad. Stabil. 1998, 62, 157–163. [Google Scholar] [CrossRef]

- Nguila Inari, G.; Pétrissans, M.; Gerardin, P. Chemical reactivity of heat-treated wood. Wood Sci. Technol. 2006, 41, 157. [Google Scholar] [CrossRef]

- Esteves, B.; Marques, A.V.; Domingos, I.; Pereira, H. Chemical changes of heat treated pine and eucalypt wood monitored by FTIR. Maderas. Ciencia y Tecnología 2013, 15, 245–258. [Google Scholar] [CrossRef]

- Colom, X.; Carrillo, F.; Nogués, F.; Garriga, P. Structural analysis of photodegraded wood by means of FTIR spectroscopy. Polym. Degrad. Stabil. 2003, 80, 543–549. [Google Scholar] [CrossRef]

- Lagaňa, R.; Csiha, C.; Horváth, N.; Tolvaj, L.; Andor, T.; Kúdela, J.; Németh, R.; Kačík, F.; Ďurkovič, J. Surface properties of thermally treated European beech wood studied by PeakForce Tapping atomic force microscopy and Fourier-transform infrared spectroscopy. Holzforschung 2021, 75, 56–64. [Google Scholar] [CrossRef]

- Chen, Y.; Gao, J.; Fan, Y.; Tshabalala, M.A.; Stark, N.M. Heat-induced chemical and color changes of extractive-free black locust (Robinia pseudoacacia) wood. BioResources 2012, 7, 2236–2248. [Google Scholar] [CrossRef]

- González-Peña, M.M.; Curling, S.F.; Hale, M.D. On the e_ect of heat on the chemical composition and dimensions of thermally-modified wood. Polym. Degrad. Stabil. 2009, 94, 2184–2193. [Google Scholar] [CrossRef]

- Bhagia, S.; Ďurkovič, J.; Lagaňa, R.; Kardošová, M.; Kačík, F.; Cernescu, A.; Schäfer, P.; Yoo, C.G.; Ragauskas, A.J. Nanoscale FTIR and Mechanical Mapping of Plant Cell Walls for Understanding Biomass Deconstruction. ACS Sustain. Chem. Eng. 2022, 10, 3016–3026. [Google Scholar] [CrossRef]

- Popescu, M.C.; Froidevaux, J.; Navi, P.; Popescu, C.M. Structural modifications of Tilia cordata wood during heat treatment investigated by FT-IR and 2D IR correlation spectroscopy. J. Mol. Struct. 2013, 1033, 176–186. [Google Scholar] [CrossRef]

- Kačík, F.; Luptáková, J.; Šmíra, P.; Nasswettrová, A.; Kačíková, D.; Vacek, V. Chemical alterations of pine wood lignin during heat sterilization. BioResources 2016, 11, 3442–3452. [Google Scholar] [CrossRef][Green Version]

- Zhang, P.; Wie, Y.; Liu, Y.; Gao, J.; Chen, Y.; Fan, Y. Heat-Induced Discoloration of Chromophore Structures 402 in Eucalyptus Lignin. Materials 2018, 11, 1686. [Google Scholar] [CrossRef] [PubMed]

- Boukir, A.; Fellak, S.; Doumenq, P. Structural characterization of Argania spinosa Moroccan wooden artifacts during natural degradation progress using infrared spectroscopy (ATR-FTIR) and X-Ray diffraction (XRD). Heliyon 2019, 5, E02477. [Google Scholar] [CrossRef] [PubMed]

- Weiland, J.J.; Guyonnet, R. Study of chemical modifications and fungi degradation of thermally modified wood using DRIFT spectroscopy. Holz Roh Werkst. 2003, 61, 216–220. [Google Scholar] [CrossRef]

- Popescu, M.C.; Gazacu, G.; Singurel, G.; Vasile, C. Study of the process of the water desorption from lignins. Rom. J. Phys. 2006, 51, 277–283. Available online: https://www.academia.edu/4749147/Study_of_the_process_of_the_water_desorption_from_lignins (accessed on 24 July 2022).

- Bourgois, J.; Bartholin, M.C.; Guyonnet, R. Thermal treatment of wood: Analysis of the obtained product. Wood Sci. Technol. 1989, 23, 303–310. [Google Scholar] [CrossRef]

- Faix, O. Fourier transform infrared spectroscopy. In Methods in Lignin Chemistry; Lin, S.Y., Dence, C.W., Eds.; Springer: Berlin, Germany, 1992; pp. 83–109. [Google Scholar]

- Ciolacu, D.; Ciolacu, F.; Popa, V.I. Amorphous cellulose-structure and characterization. Cell. Chem. Technol. 2011, 45, 13–21. Available online: https://www.researchgate.net/publication/279897864_Amorphous_cellulose_-_Structure_and_characterization (accessed on 16 March 2020).

- Allegretti, O.; Travan, L.; Cividini, R. Drying Techniques to Obtain White Beech. In Proceedings of the Wood EDG Conference, Bled, Slovenia, 23 April 2009; Available online: http://timberdry.net/downloads/EDG-SeminarBled/Presentation/EDG (accessed on 25 May 2022).

| Power [%] | 8 | 12 | 16 |

| Power [W] | 11 | 16.5 | 22 |

| Raster density [mm−1] | Irradiation dose H [J∙cm−2] | ||

| 2 | 6.17 | 9.26 | 12.34 |

| 5 | 15.42 | 23.14 | 30.86 |

| 10 | 30.84 | 46.28 | 61.71 |

| 20 | 61.68 | 92.57 | 123.43 |

| 30 | 92.52 | 138.85 | 185.15 |

| Raster Density [mm−1] | Basic Statistical Character. | Laser Power 8% | Laser Power 12% | Laser Power 16% | |||

|---|---|---|---|---|---|---|---|

| Roughness Parameters | |||||||

| Ra | Rz | Ra | Rz | Ra | Rz | ||

| [µm] | |||||||

| Parallel to the Grain | |||||||

| Reference | 7.25 | 50.73 | 7.25 | 50.73 | 7.25 | 50.73 | |

| s | 2.86 | 21.13 | 2.86 | 21.13 | 2.86 | 21.13 | |

| 2 | 11.41 | 73.26 | 8.58 | 62.99 | 10.28 | 77.60 | |

| s | 3.27 | 21.34 | 3.86 | 30.40 | 3.58 | 32.59 | |

| 5 | 21.66 | 107.83 | 13.90 | 93.52 | 12.03 | 77.35 | |

| s | 8.80 | 38.50 | 5.60 | 40.38 | 4.10 | 20.12 | |

| 10 | 27.67 | 180.31 | 25.02 | 167.35 | 27.23 | 179.07 | |

| s | 8.13 | 44.99 | 8.55 | 55.40 | 10.34 | 58.68 | |

| 20 | 28.34 | 185.38 | 34.36 | 231.88 | 41.18 | 203.08 | |

| s | 9.74 | 63.07 | 11.70 | 62.20 | 1.89 | 23.51 | |

| 30 | 36.27 | 231.14 | 37.26 | 243.36 | 44.34 | 245.16 | |

| s | 9.69 | 60.18 | 2.54 | 24.67 | 5.19 | 32.18 | |

| Perpendicular to the grain | |||||||

| Reference | 11.64 | 89.32 | 11.64 | 89.32 | 11.64 | 89.32 | |

| s | 1.58 | 19.20 | 1.58 | 19.20 | 1.58 | 19.20 | |

| 2 | 37.85 | 214.36 | 40.84 | 230.39 | 45.15 | 241.00 | |

| s | 1.34 | 16.32 | 2.27 | 17.22 | 2.01 | 15.14 | |

| 5 | 44.34 | 229.59 | 42.29 | 239.17 | 46.52 | 254.77 | |

| s | 2.17 | 22.33 | 2.23 | 23.31 | 2.68 | 27.13 | |

| 10 | 103.72 | 497.03 | 117.57 | 532.06 | 170.12 | 766.84 | |

| s | 18.18 | 76.13 | 20.86 | 56.64 | 18.24 | 46.68 | |

| 20 | 210.73 | 903.06 | 283.62 | 1074.25 | 310.24 | 1122.00 | |

| s | 34.97 | 103.13 | 9.91 | 31.93 | 5.80 | 18.73 | |

| 30 | 273.03 | 1132.5 | 320.25 | 1245.48 | 389.88 | 1433.28 | |

| s | 17.56 | 70.12 | 8.27 | 37.69 | 7.26 | 46.22 | |

| Colour Coordinate | Basic Statistical Character | Power 8% | |||||

|---|---|---|---|---|---|---|---|

| Raster Density [mm−1] | |||||||

| Reference | 2 | 5 | 10 | 20 | 30 | ||

| L* | 84.93 | 78.14 | 68.03 | 65.93 | 54.99 | 48.48 | |

| s | 0.98 | 0.96 | 1.04 | 1.82 | 2.43 | 1.48 | |

| a* | 3.23 | 4.79 | 8.19 | 8.23 | 9.84 | 10.19 | |

| s | 0.39 | 0.34 | 0.31 | 0.61 | 0.51 | 0.45 | |

| b* | 19.53 | 25.02 | 32.37 | 33.54 | 32.00 | 30.45 | |

| s | 0.99 | 0.61 | 0.83 | 0.91 | 1.64 | 0.63 | |

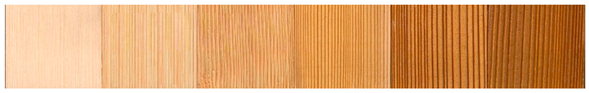

| Visualisation of discolouration of specimens |  | ||||||

| Power 12% | |||||||

| Raster density [mm−1] | |||||||

| Reference | 2 | 5 | 10 | 20 | 30 | ||

| L* | 84.93 | 77.22 | 66.40 | 59.99 | 49.57 | 44.00 | |

| s | 0.98 | 1.45 | 1.17 | 3.72 | 2.55 | 2.06 | |

| a* | 3.23 | 4.86 | 8.29 | 9.25 | 10.33 | 9.31 | |

| s | 0.39 | 0.31 | 0.22 | 0.76 | 0.45 | 0.52 | |

| b* | 19.53 | 24.84 | 31.43 | 33.24 | 30.83 | 27.18 | |

| s | 0.99 | 0.37 | 0.41 | 0.98 | 1.43 | 1.60 | |

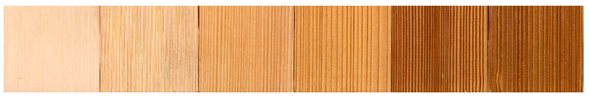

| Visualisation of discolouration of specimens |  | ||||||

| Power 16% | |||||||

| Raster density [mm−1] | |||||||

| Reference | 2 | 5 | 10 | 20 | 30 | ||

| L* | 84.93 | 74.84 | 62.52 | 59.09 | 46.54 | 41.27 | |

| s | 0.98 | 0.66 | 3.79 | 3.38 | 2.32 | 2.15 | |

| a* | 3.23 | 5.33 | 8.78 | 9.29 | 9.98 | 9.45 | |

| s | 0.39 | 0.37 | 0.45 | 0.35 | 0.56 | 0.29 | |

| b* | 19.53 | 25.53 | 31.46 | 33.22 | 29.66 | 26.84 | |

| s | 0.99 | 0.61 | 1.05 | 0.98 | 1.52 | 0.97 | |

| Visualisation of discolouration of specimens |  | ||||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kúdela, J.; Andrejko, M.; Kubovský, I. The Effect of CO2 Laser Engraving on the Surface Structure and Properties of Spruce Wood. Coatings 2023, 13, 2006. https://doi.org/10.3390/coatings13122006

Kúdela J, Andrejko M, Kubovský I. The Effect of CO2 Laser Engraving on the Surface Structure and Properties of Spruce Wood. Coatings. 2023; 13(12):2006. https://doi.org/10.3390/coatings13122006

Chicago/Turabian StyleKúdela, Jozef, Michal Andrejko, and Ivan Kubovský. 2023. "The Effect of CO2 Laser Engraving on the Surface Structure and Properties of Spruce Wood" Coatings 13, no. 12: 2006. https://doi.org/10.3390/coatings13122006

APA StyleKúdela, J., Andrejko, M., & Kubovský, I. (2023). The Effect of CO2 Laser Engraving on the Surface Structure and Properties of Spruce Wood. Coatings, 13(12), 2006. https://doi.org/10.3390/coatings13122006