State of the Art and Perspectives on Surface-Strengthening Process and Associated Mechanisms by Shot Peening

Abstract

:1. Introduction

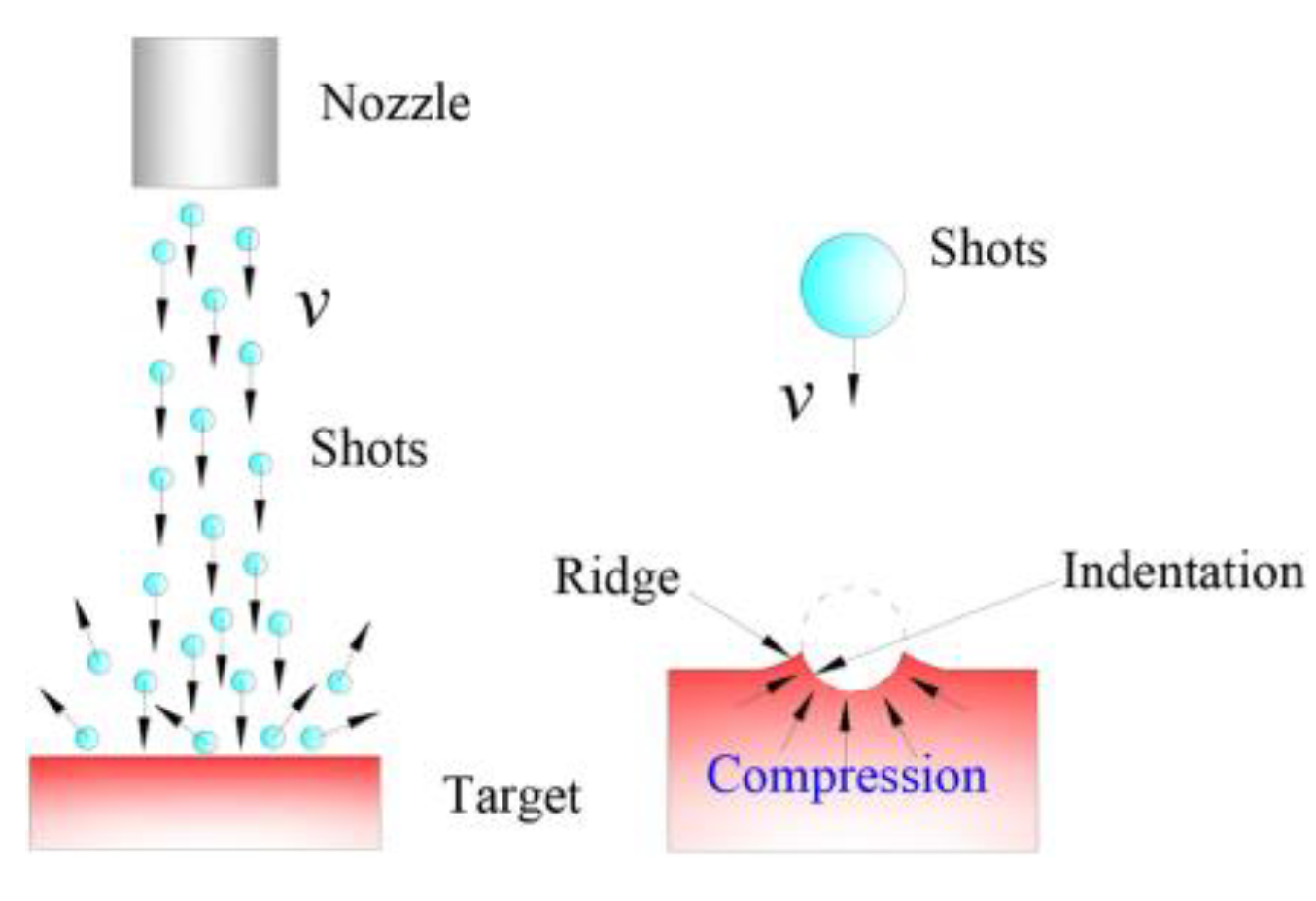

2. Development and Classification of the Shot Peening Technology

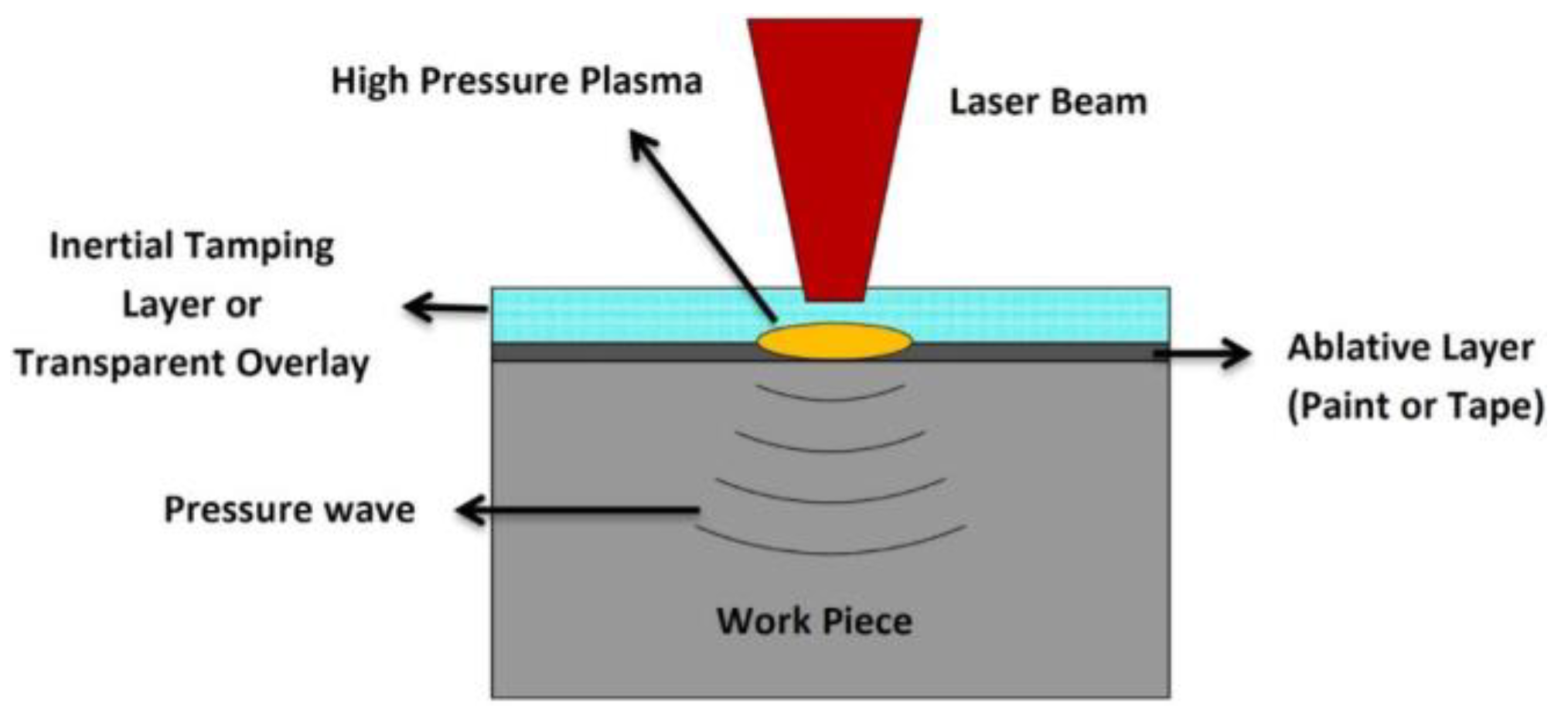

2.1. Laser Shock Peening

2.2. Micro-Particle Shot Peening

2.3. High Pressure Water Jet Shot Peening

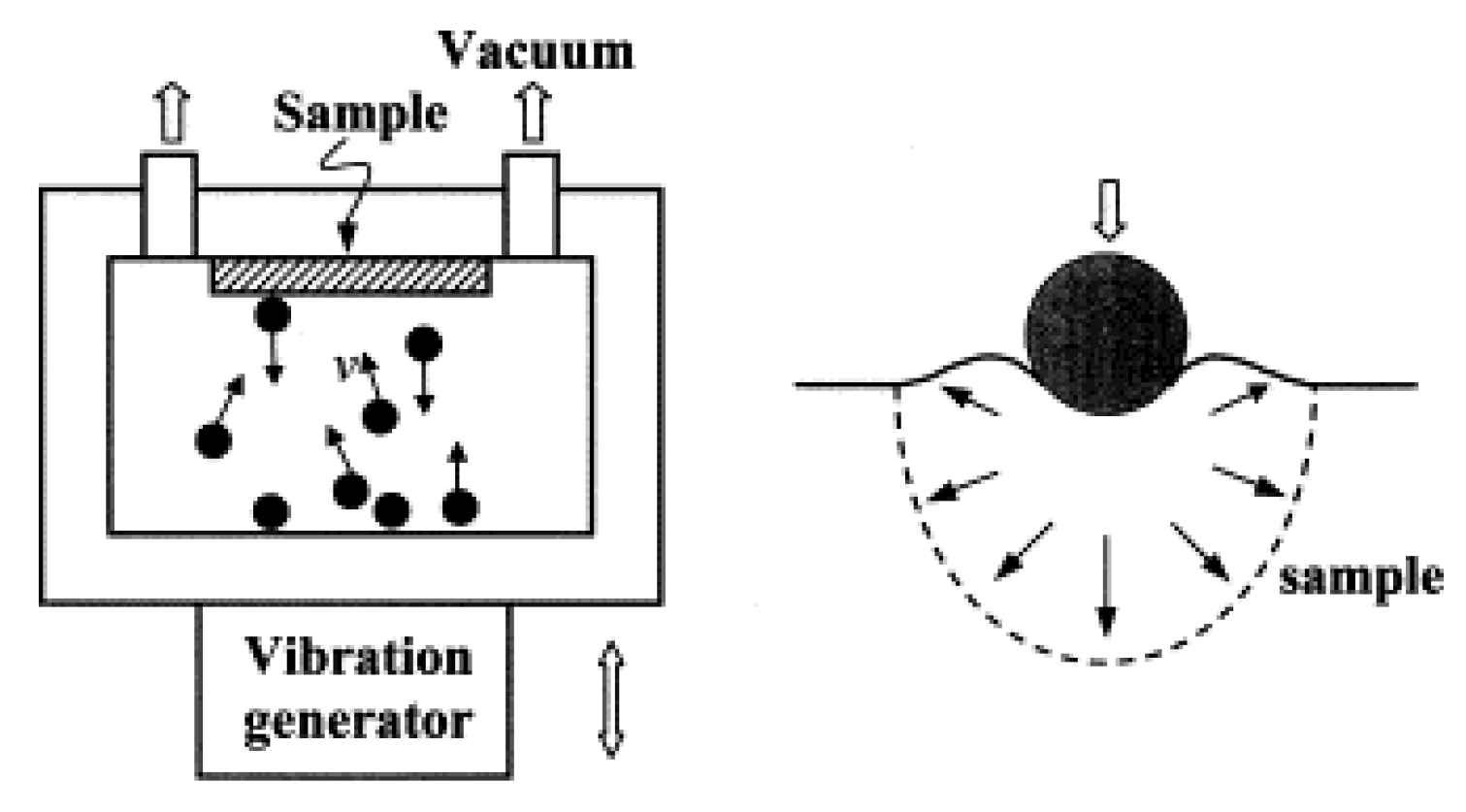

2.4. Ultrasonic Shot Peening

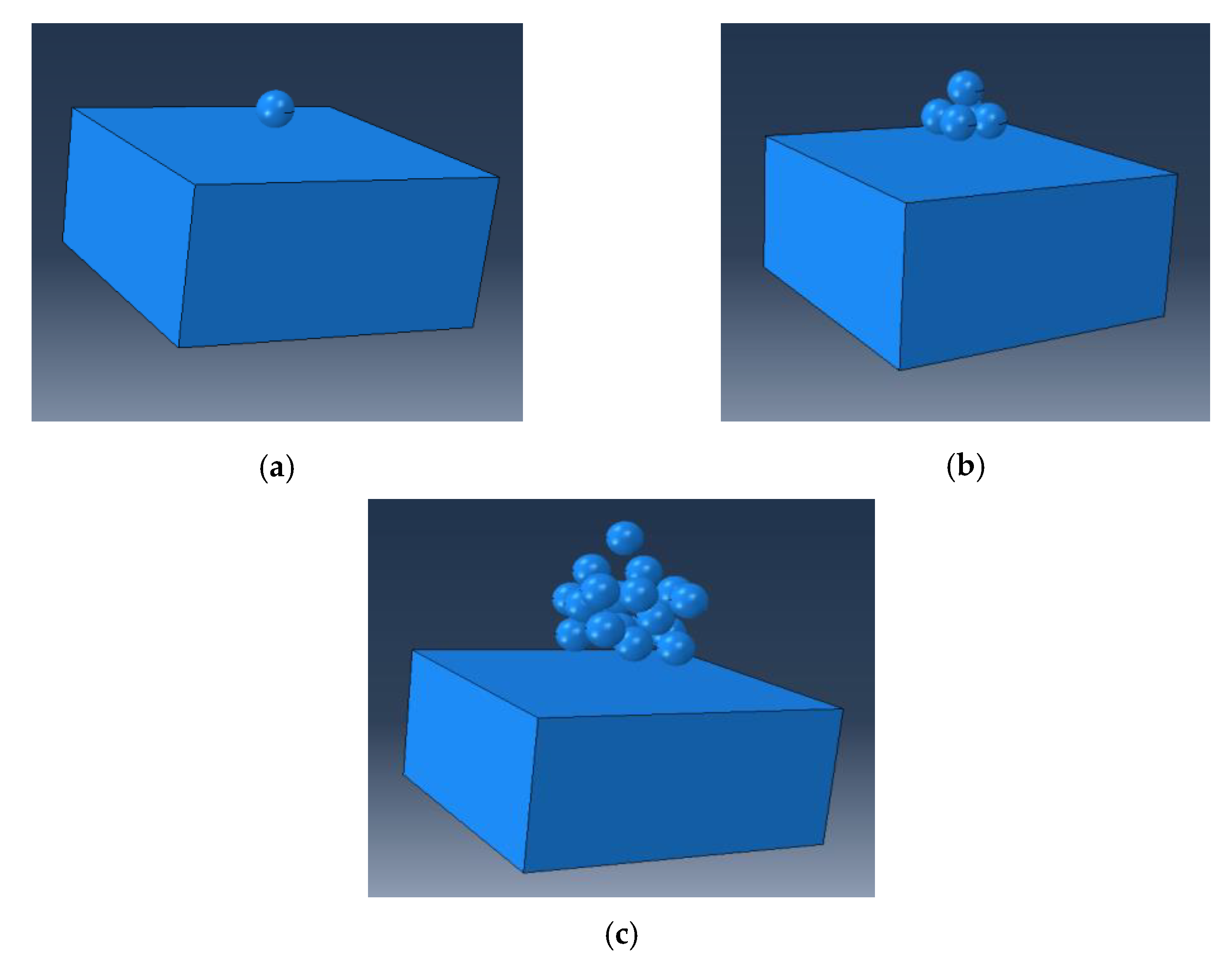

3. Numerical Investigation of the Shot Peening Process

4. Fundamental of the Traditional Shot Peening Technology

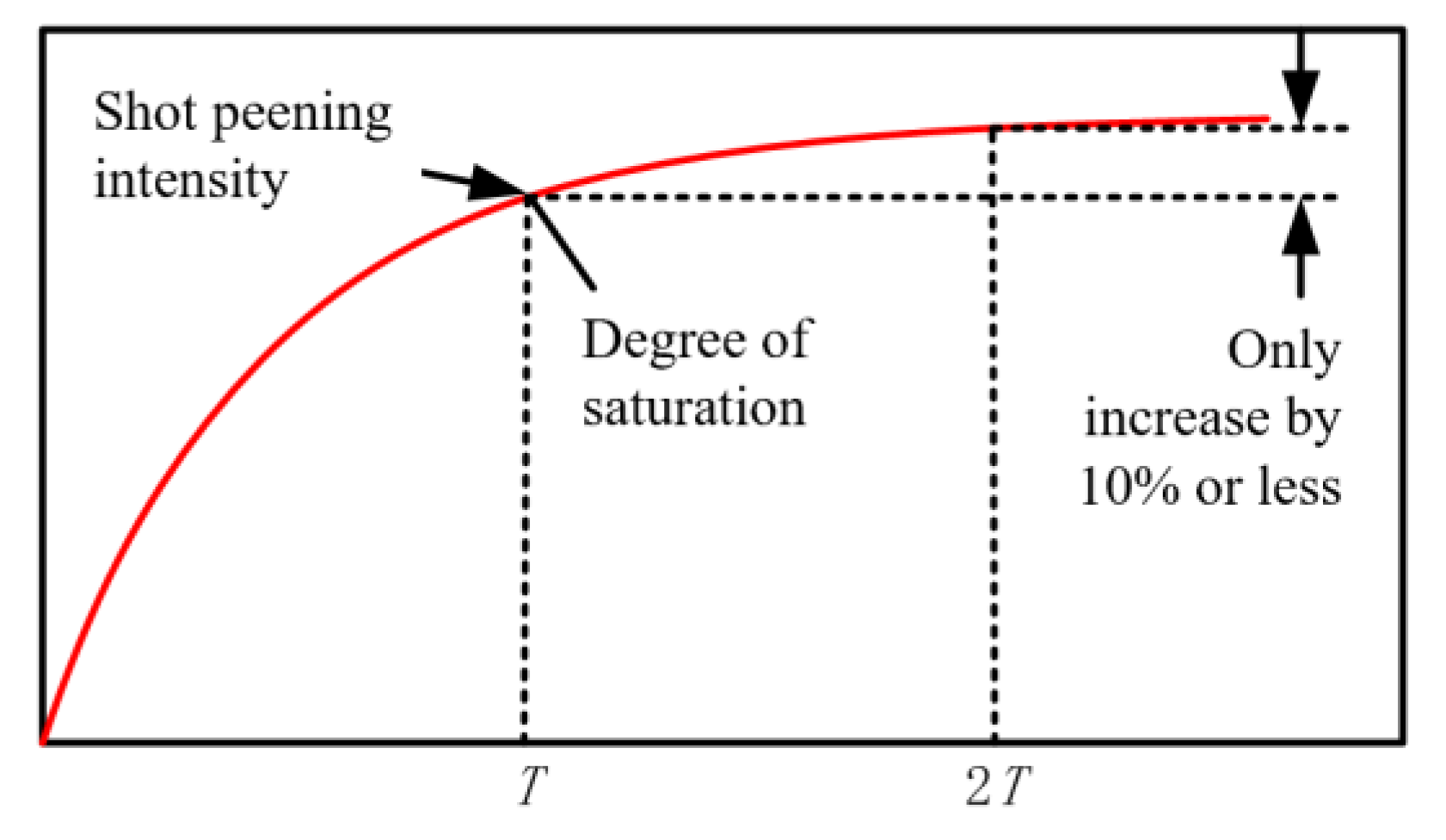

4.1. Shot Peening Process Parameters

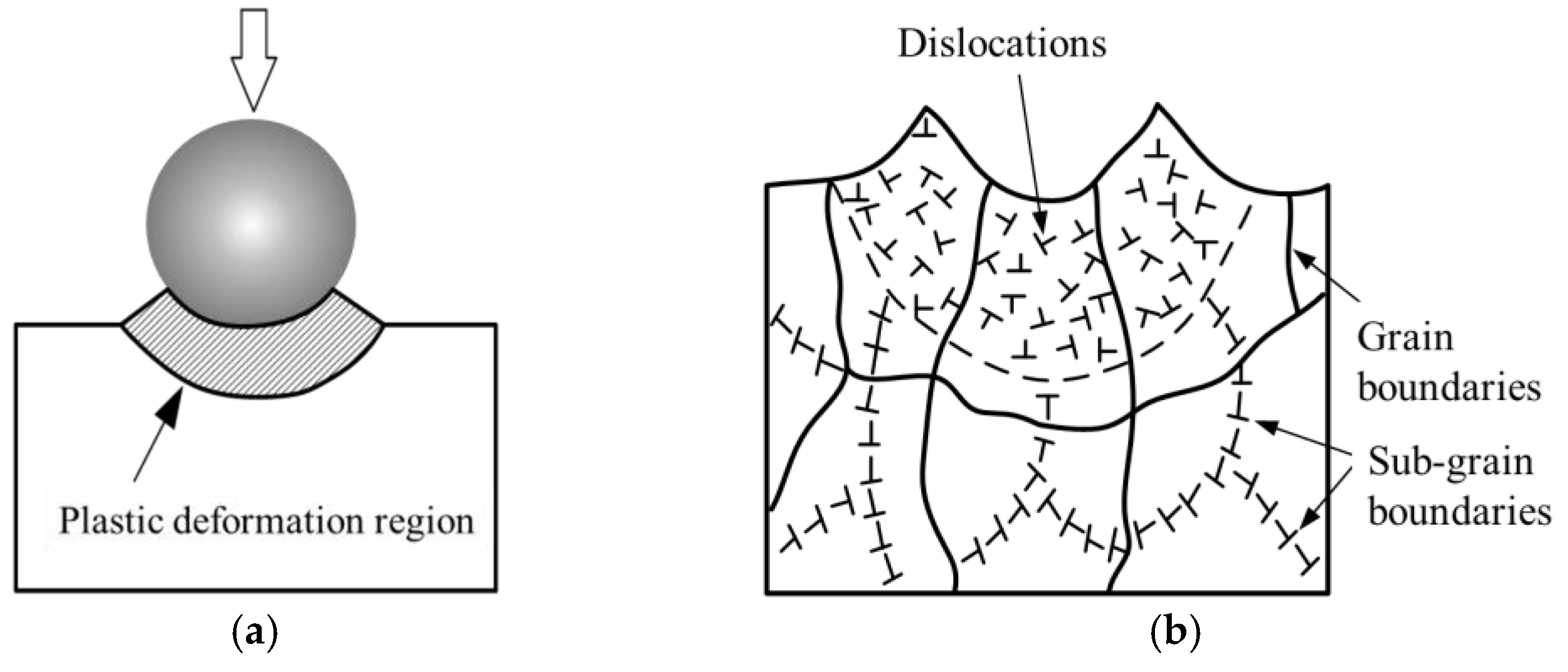

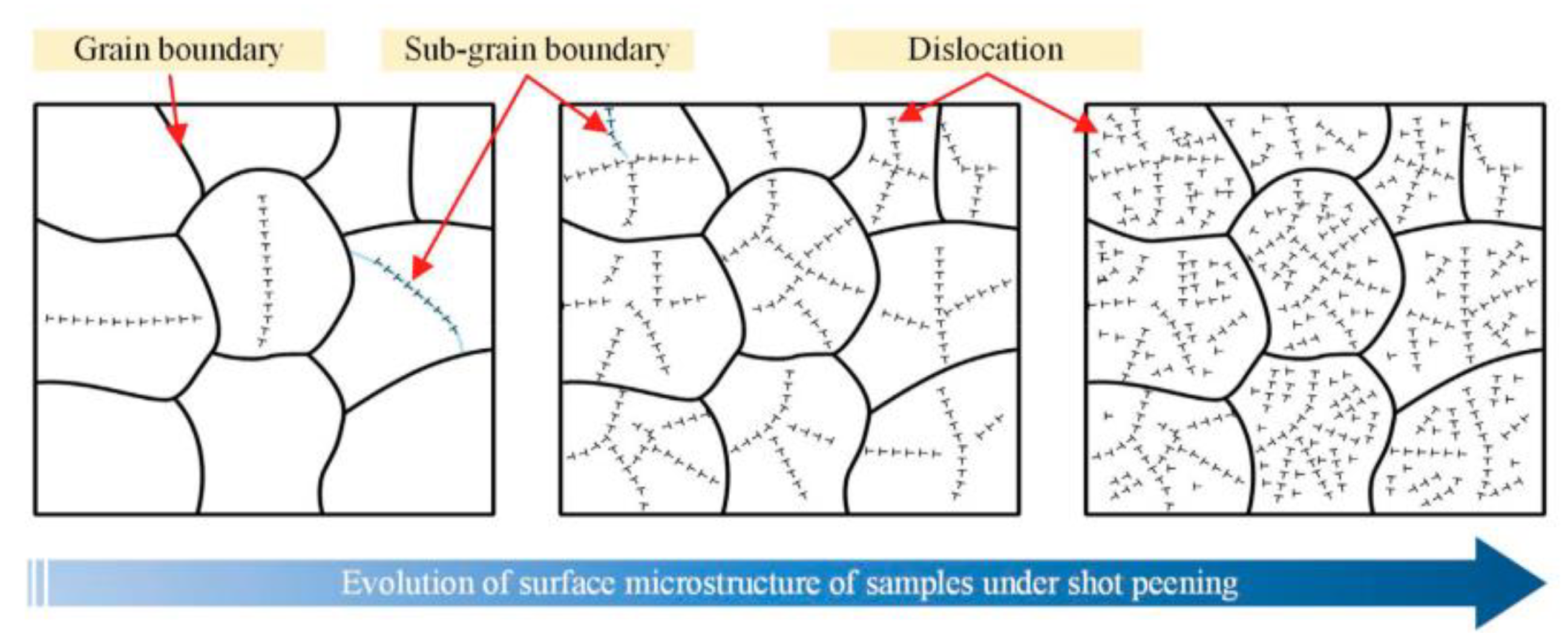

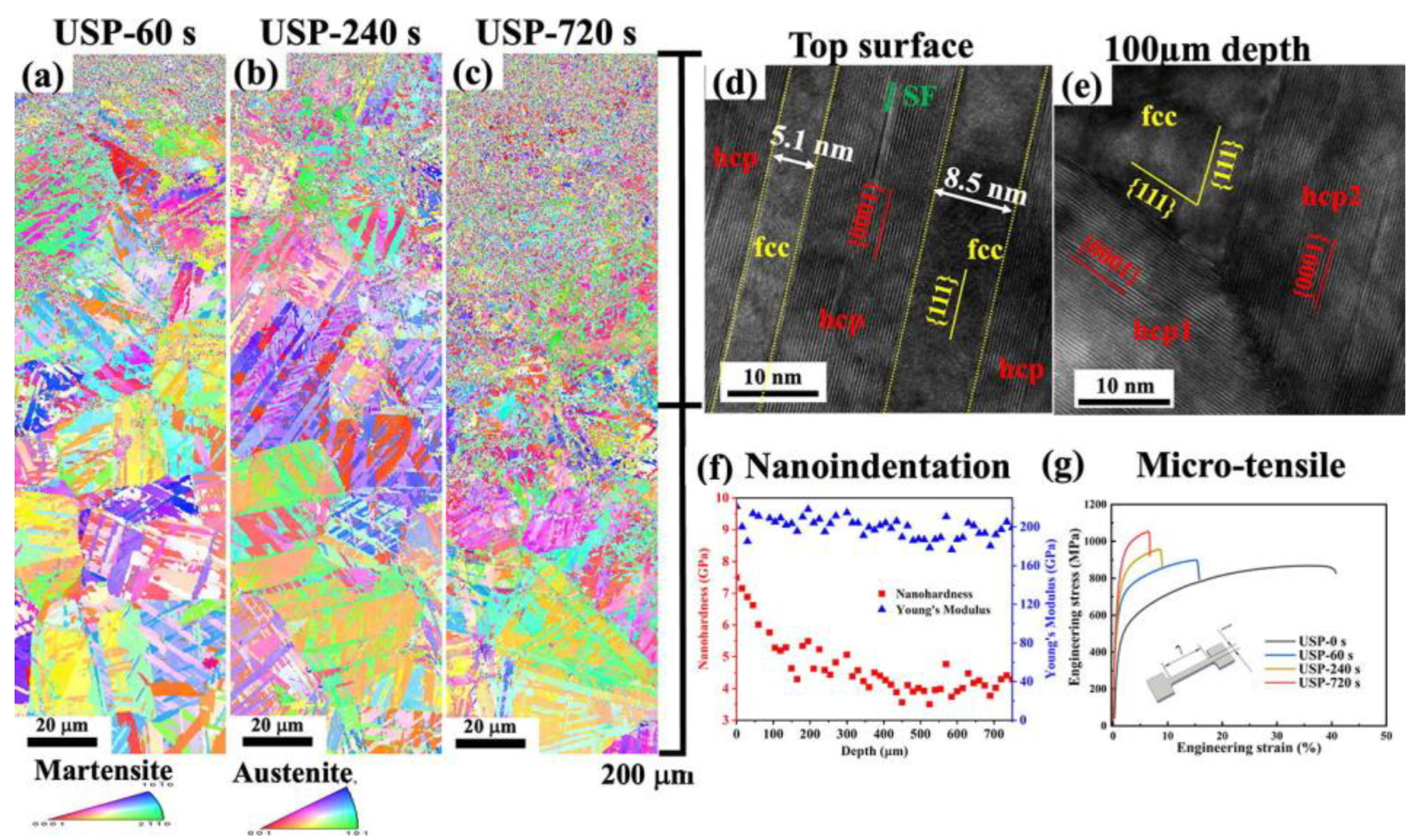

4.2. Shot Peening Strengthening Mechanisms

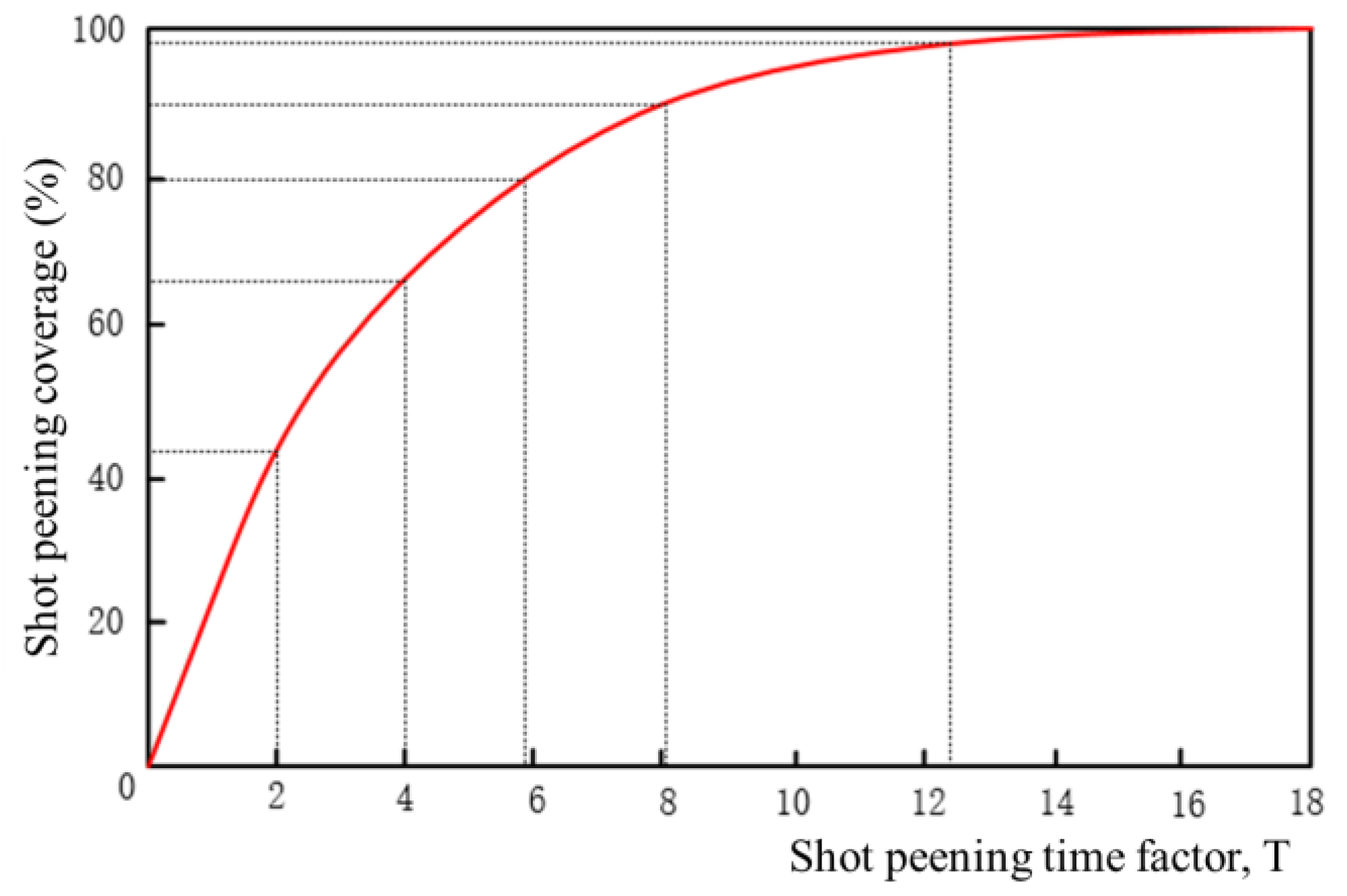

4.3. Shot Peening Coverage

5. Perspectives of the Shot Peening Technology

- (1)

- New Materials: As new materials are developed and introduced into various industries, shot peening technology will need to adapt to meet the challenges of processing these materials. The use of new materials such as composites, ceramics, and metal matrix composites will require new shot peening strategies that can produce the desired surface characteristics and compressive stress profiles.

- (2)

- Advanced Manufacturing Processes: The rise of advanced manufacturing processes such as additive manufacturing, laser cladding, and hybrid manufacturing will require new shot peening techniques to ensure the surface integrity of the manufactured components. Shot peening will need to be integrated into these advanced manufacturing processes to optimize their performance and enhance their properties.

- (3)

- Digitalization: The digitalization of manufacturing processes is an ongoing trend that is likely to continue in the future. Shot peening technology can be integrated with digitalization to create a more efficient and data-driven process. The use of sensors, artificial intelligence, and machine learning algorithms can be employed to optimize shot peening parameters and improve the quality of the finished product.

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ji, R.; Qi, Z.; Chen, J.; Zhang, L.; Lin, K.; Lu, S.; Li, Y. Numerical and Experimental Investigation on the Abrasive Flow Machining of Artificial Knee Joint Surface. Crystals 2023, 13, 430. [Google Scholar] [CrossRef]

- Yuan, H.; Yang, W.; Zhang, L.; Hong, T. Model Development of Stress Intensity Factor on 7057T6 Aluminum Alloy Using Extended Finite Element Method. Coatings 2023, 13, 581. [Google Scholar] [CrossRef]

- Wang, Y.Y.; Wang, Z.; Ni, P.C.; Wang, D.J.; Guo, S.H.; Chen, Z.Z. Experimental and numerical study on regulation of cutting temperature during the circular sawing of 45 steel. Coatings 2023. submitted. [Google Scholar]

- Tangwarodomnukun, V.; Kringram, S.; Zhu, H.; Qi, H.; Rujisamphan, N. Fabrication of superhydrophobic surface on AISI316L stainless steel using a nanosecond pulse laser. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2022, 236, 680–693. [Google Scholar] [CrossRef]

- Saetang, V.; Qi, H.; Smerchit, T.; Rujisamphan, N. Laser scribing of fluorine-doped tin oxide coated on glass substrate in air and water. Opt. Laser Technol. 2022, 153, 108280. [Google Scholar] [CrossRef]

- Qi, H.; Wang, Y.; Qi, Z.; Shi, L.; Fang, Z.; Zhang, L.; Riemer, O.; Karpuschewski, B. A Novel Grain-Based DEM Model for Evaluating Surface Integrity in Scratching of RB-SiC Ceramics. Materials 2022, 15, 8486. [Google Scholar] [CrossRef]

- Charee, W.; Qi, H.; Saetang, V. Underwater laser micromachining of silicon in pressurized environment. Int. J. Adv. Manuf. Technol. 2022, 122, 3161–3169. [Google Scholar] [CrossRef]

- Lei, Y.; Wang, Z.; Qi, H. Strengthening Performance Optimization of Single Ball Impact Treatment by Evaluating Residual Stress. Materials 2022, 15, 3719. [Google Scholar] [CrossRef]

- Qi, H.; Shi, L.; Teng, Q.; Hong, T.; Tangwarodomnukun, V.; Liu, G.; Li, H.N. Subsurface damage evaluation in the single abrasive scratching of BK7 glass by considering coupling effect of strain rate and temperature. Ceram. Int. 2022, 48, 8661–8670. [Google Scholar] [CrossRef]

- Shi, H.; Liu, G.; Yang, G.; Bi, Q.; Zhao, Y.; Wang, B.; Sun, X.; Liu, X.; Qi, H.; Xu, W.; et al. Analytical modelling of edge chipping in scratch of soda-lime glass considering strain-rate hardening effect. Ceram. Int. 2021, 47, 26552–26566. [Google Scholar] [CrossRef]

- Yu, J.; Chen, J.; Ho, H. Effect of laser cladding Ti/B4C/dr40-based composite coatings for the surface strengthening of shaft part. Opt. Laser Technol. 2023, 157, 108721. [Google Scholar] [CrossRef]

- Li, K.; Liu, X.; Liu, Y.; Wu, X.; Zhang, W.; Yang, J.; Li, W.; Zhou, S. Strengthening layer with nano-twins in titanium alloy induced by laser surface re-melting: Mechanism of high strength and ductility. Mater. Charact. 2023, 196, 112632. [Google Scholar] [CrossRef]

- Qian, H.; Chen, M.; Qi, Z.; Teng, Q.; Qi, H.; Zhang, L.; Shan, X. Review on Research and Development of Abrasive Scratching of Hard Brittle Materials and Its Underlying Mechanisms. Crystals 2023, 13, 428. [Google Scholar] [CrossRef]

- Wu, B.; Li, D.R.; Zhou, Y.; Zhu, D.; Zhao, Y.P.; Qiao, Z.K.; Chen, B.; Wang, X.L.; Lin, Q. Construction of a calibration field of absolute gravity in a cave using the Cold Atom Gravimeter. Sensors 2023. submitted. [Google Scholar]

- Qi, H.; Xing, W.; Tan, W.; Lin, H.; Guo, H.J.; Chen, M.Z.; Tang, H.P. Effect of the sintering process on mechanical behaviors of Zirconia ceramics by NanoParticle Jetting. Ceram. Int. 2023. submitted. [Google Scholar]

- Xu, Q.; Zhou, J.; Jiang, D.; Yang, X.; Qiu, Z. Improved low-temperature mechanical properties of FH36 marine steel after ultrasonic surface rolling process. J. Alloys Compd. 2023, 937, 168401. [Google Scholar] [CrossRef]

- Yuan, H.; You, Z.; Zhuo, Y.; Ye, X.; Zhu, L.; Yang, W. Numerical and Experimental Study on Reasonable Coverage of Shot Peening on ZGMn13 High Manganese Steel. Front. Mater. 2022, 9. [Google Scholar] [CrossRef]

- Hua, J.; Liu, J.; Liu, P.; Zhao, X.; Chen, C.; Ren, R. Investigation on WEA fatigue spalling of U71MnG rail material subject to laser quenching surface treatment. Wear 2023, 512, 204560. [Google Scholar] [CrossRef]

- Goulmy, J.P.; Boyer, V.; Retraint, D.; Kanoute, P.; Toualbi, L.; Rouhaud, E. Modeling of the shot peening of a nickel alloy with the consideration of both residual stresses and work hardening. Int. J. Solids Struct. 2023, 264, 112120. [Google Scholar] [CrossRef]

- Wang, C.; Lai, Y.; Wang, L.; Wang, C. Dislocation-based study on the influences of shot peening on fatigue resistance. Surf. Coat. Technol. 2020, 383, 125247. [Google Scholar] [CrossRef]

- Wang, Y.; Huang, A.; Wu, M.; Gu, H. Corrosion of alumina-magnesia castable by high manganese steel with respect to steel cleanness. Ceram. Int. 2019, 45, 9884–9890. [Google Scholar] [CrossRef]

- Chen, H.; Wang, S.; Lu, S.; Qiao, Y.; Wang, X.; Fan, N.; Guo, P.; Niu, J. Simulation and experimental validation of residual stress and surface roughness of high manganese steel after shot peening. Procedia CIRP 2018, 71, 227–231. [Google Scholar] [CrossRef]

- Bagheri, S.; Guagliano, M. Review of shot peening processes to obtain nanocrystalline surfaces in metal alloys. Surf. Eng. 2009, 25, 3–14. [Google Scholar] [CrossRef]

- Bagherifard, S. Enhancing the Structural Performance of Lightweight Metals by Shot Peening. Adv. Eng. Mater. 2019, 21, 1801140. [Google Scholar] [CrossRef]

- Świetlicki, A.; Szala, M.; Walczak, M. Effects of Shot Peening and Cavitation Peening on Properties of Surface Layer of Metallic Materials—A Short Review. Materials 2022, 15, 2476. [Google Scholar] [CrossRef]

- Soyama, H.; Korsunsky, A.M. A critical comparative review of cavitation peening and other surface peening methods. J. Mater. Process. Technol. 2022, 305, 117586. [Google Scholar] [CrossRef]

- Menezes, M.R.; Godoy, C.; Buono, V.T.L.; Schvartzman, M.M.M.; Avelar-Batista Wilson, J.C. Effect of shot peening and treatment temperature on wear and corrosion resistance of sequentially plasma treated AISI 316L steel. Surf. Coat. Technol. 2017, 309, 651–662. [Google Scholar] [CrossRef]

- González, J.; Bagherifard, S.; Guagliano, M.; Fernández Pariente, I. Influence of different shot peening treatments on surface state and fatigue behaviour of Al 6063 alloy. Eng. Fract. Mech. 2017, 185, 72–81. [Google Scholar] [CrossRef]

- Gerin, B.; Pessard, E.; Morel, F.; Verdu, C. Influence of surface integrity on the fatigue behaviour of a hot-forged and shot-peened C70 steel component. Mater. Sci. Eng. A 2017, 686, 121–133. [Google Scholar] [CrossRef]

- Gujba, A.K.; Medraj, M. Laser Peening Process and Its Impact on Materials Properties in Comparison with Shot Peening and Ultrasonic Impact Peening. Materials 2014, 7, 7925–7974. [Google Scholar] [CrossRef]

- Rubio-González, C.; Ocaña, J.L.; Gomez-Rosas, G.; Molpeceres, C.; Paredes, M.; Banderas, A.; Porro, J.; Morales, M. Effect of laser shock processing on fatigue crack growth and fracture toughness of 6061-T6 aluminum alloy. Mater. Sci. Eng. A 2004, 386, 291–295. [Google Scholar] [CrossRef]

- Zhang, H.; Cai, Z.; Chi, J.; Sun, R.; Che, Z.; Zhang, H.; Guo, W. Fatigue crack growth in residual stress fields of laser shock peened Ti6Al4V titanium alloy. J. Alloys Compd. 2021, 887, 161427. [Google Scholar] [CrossRef]

- Chung, Y.-H.; Chen, T.-C.; Lee, H.-B.; Tsay, L.-W. Effect of Micro-Shot Peening on the Fatigue Performance of AISI 304 Stainless Steel. Metals 2021, 11, 1408. [Google Scholar] [CrossRef]

- Kikuchi, S.; Nakamura, Y.; Nambu, K.; Ando, M. Effect of shot peening using ultra-fine particles on fatigue properties of 5056 aluminum alloy under rotating bending. Mater. Sci. Eng. A 2016, 652, 279–286. [Google Scholar] [CrossRef]

- Morita, T.; Noda, S.; Kagaya, C. Influences of Fine-Particle Bombarding and Conventional Shot Peening on Surface Properties of Steel. Mater. Trans. 2014, 55, 646–652. [Google Scholar] [CrossRef]

- Chakkravarthy, V.; Oliveira, J.P.; Mahomed, A.; Yu, N.; Manojkumar, P.; Lakshmanan, M.; Zhang, L.; Raja, V.; Jerome, S.; Prabhu, T.R.; et al. Effect of abrasive water jet peening on NaCl-induced hot corrosion behavior of Ti–6Al–4V. Vacuum 2023, 210, 111872. [Google Scholar] [CrossRef]

- Soyama, H. Comparison between the improvements made to the fatigue strength of stainless steel by cavitation peening, water jet peening, shot peening and laser peening. J. Mater. Process. Technol. 2019, 269, 65–78. [Google Scholar] [CrossRef]

- Kumar, P.; Mahobia, G.S.; Singh, V.; Chattopadhyay, K. Low cycle fatigue behaviour of Ti-13Nb-13Zr alloy in ultrasonic shot peened and stress relieved condition. Int. J. Fatigue 2023, 166, 107289. [Google Scholar] [CrossRef]

- Tao, N.R.; Wang, Z.B.; Tong, W.P.; Sui, M.L.; Lu, J.; Lu, K. An investigation of surface nanocrystallization mechanism in Fe induced by surface mechanical attrition treatment. Acta Mater. 2002, 50, 4603–4616. [Google Scholar] [CrossRef]

- Badreddine, J.; Rouhaud, E.; Micoulaut, M.; Retraint, D.; Remy, S.; François, M.; Viot, P.; Doubre-Baboeuf, G.; Saunier, D.B.L.; Desfontaine, V. Simulation and experimental approach for shot velocity evaluation in ultrasonic shot peening. Mech. Ind. 2011, 12, 223–229. [Google Scholar] [CrossRef]

- Okura, Y.; Sasaki, H.; Soyama, H. Effect of Mechanical Properties on Fatigue Life Enhancement of Additive Manufactured Titanium Alloy Treated by Various Peening Methods. In Proceedings of the Advanced Surface Enhancement, Singapore, 10–13 September 2020; pp. 88–96. [Google Scholar]

- Kokubun, T.; Soyama, H. Evaluation of fatigue crack propagation in surface modification layer of duralumin treated by various peening. Trans. JSME 2017, 83, 1–15. [Google Scholar]

- Bai, F.; Saalbach, K.-A.; Wang, L.; Wang, X.; Twiefel, J. Impact of time on ultrasonic cavitation peening via detection of surface plastic deformation. Ultrasonics 2018, 84, 350–355. [Google Scholar] [CrossRef] [PubMed]

- Gao, Y.; Wu, B.; Liu, Z.; Zhou, Y.; Shen, N.; Ding, H. Ultrasonic Cavitation Peening of Stainless Steel and Nickel Alloy. J. Manuf. Sci. Eng. 2013, 136, 014502. [Google Scholar] [CrossRef]

- Mathias, M.; Göcke, A.; Pohl, M. The residual stress, texture and surface changes in steel induced by cavitation. Wear 1991, 150, 11–20. [Google Scholar] [CrossRef]

- Cheng, Z.; Qin, S.; Fang, Z. Numerical Modeling and Experimental Study on the Material Removal Process Using Ultrasonic Vibration-Assisted Abrasive Water Jet. Front. Mater. 2022, 9, 250. [Google Scholar] [CrossRef]

- Qi, H.; Wen, D.; Lu, C.; Li, G. Numerical and experimental study on ultrasonic vibration-assisted micro-channelling of glasses using an abrasive slurry jet. Int. J. Mech. Sci. 2016, 110, 94–107. [Google Scholar] [CrossRef]

- Qi, H.; Wen, D.; Yuan, Q.; Zhang, L.; Chen, Z. Numerical investigation on particle impact erosion in ultrasonic-assisted abrasive slurry jet micro-machining of glasses. Powder Technol. 2017, 314, 627–634. [Google Scholar] [CrossRef]

- Zhang, L.; Yuan, Z.; Qi, Z.; Cai, D.; Cheng, Z.; Qi, H. CFD-based study of the abrasive flow characteristics within constrained flow passage in polishing of complex titanium alloy surfaces. Powder Technol. 2018, 333, 209–218. [Google Scholar] [CrossRef]

- Zhang, L.; Ji, R.; Fu, Y.; Qi, H.; Kong, F.; Li, H.; Tangwarodomnukun, V. Investigation on particle motions and resultant impact erosion on quartz crystals by the micro-particle laden waterjet and airjet. Powder Technol. 2020, 360, 452–461. [Google Scholar] [CrossRef]

- Qi, H.; Qin, S.; Cheng, Z.; Zou, Y.; Cai, D.; Wen, D. DEM and experimental study on the ultrasonic vibration-assisted abrasive finishing of WC-8Co cemented carbide cutting edge. Powder Technol. 2021, 378, 716–723. [Google Scholar] [CrossRef]

- Hu, W.; Teng, Q.; Hong, T.; Saetang, V.; Qi, H. Stress field modeling of single-abrasive scratching of BK7 glass for surface integrity evaluation. Ceram. Int. 2022, 48, 12819–12828. [Google Scholar] [CrossRef]

- Qi, H.; Qin, S.; Cheng, Z.; Teng, Q.; Hong, T.; Xie, Y. Towards understanding performance enhancing mechanism of micro-holes on K9 glasses using ultrasonic vibration-assisted abrasive slurry jet. J. Manuf. Process. 2021, 64, 585–593. [Google Scholar] [CrossRef]

- Zhou, J.; Sun, Z. Numerical characterization of shot peening induced work hardening gradient and verification based on FEM analysis. Int. J. Solids Struct. 2022, 244, 111586. [Google Scholar] [CrossRef]

- Marini, M.; Piona, F.; Fontanari, V.; Bandini, M.; Benedetti, M. A new challenge in the DEM/FEM simulation of the shot peening process: The residual stress field at a sharp edge. Int. J. Mech. Sci. 2020, 169, 105327. [Google Scholar] [CrossRef]

- Murugaratnam, K.; Utili, S.; Petrinic, N. A combined DEM–FEM numerical method for Shot Peening parameter optimisation. Adv. Eng. Softw. 2015, 79, 13–26. [Google Scholar] [CrossRef]

- Zhao, J.; Tang, J.; Zhou, W.; Jiang, T.; Liu, H.; Xing, B. Numerical modeling and experimental verification of residual stress distribution evolution of 12Cr2Ni4A steel generated by shot peening. Surf. Coat. Technol. 2022, 430, 127993. [Google Scholar] [CrossRef]

- Meguid, S.A.; Shagal, G.; Stranart, J.C.; Daly, J. Three-dimensional dynamic finite element analysis of shot-peening induced residual stresses. Finite Elem. Anal. Des. 1999, 31, 179–191. [Google Scholar] [CrossRef]

- Kim, T.; Lee, H.; Hyun, H.C.; Jung, S. Effects of Rayleigh damping, friction and rate-dependency on 3D residual stress simulation of angled shot peening. Mater. Des. 2013, 46, 26–37. [Google Scholar] [CrossRef]

- Hong, T.; Wang, Z.W.; Yuan, J.L. Numerical simulation of shot peening process using Finite Element and Discrete Element Method. China Mech. Eng. 2008, 19, 0–1316. [Google Scholar]

- Liu, C.C. Finite Element Simulation of Shot Peening and its Experimental Verfication; Northeastern University: Boston, MA, USA, 2014. [Google Scholar]

- Wang, L.P. Numerical Simulation Research for Compressive Residual Stress and Surface Roughness of Shot Peening; Shandong University: Jinan, China, 2015. [Google Scholar]

- Majzoobi, G.H.; Azizi, R.; Alavi Nia, A. A three-dimensional simulation of shot peening process using multiple shot impacts. J. Mater. Process. Technol. 2005, 164, 1226–1234. [Google Scholar] [CrossRef]

- Li, Y.Z.; Wang, F.; Lv, J.; Xu, K.W. Finite Element analysis for shot-peening models of single shot impact and multiple impingment. J. Xi’an Jiaotong Univ. 2007, 41, 5. [Google Scholar]

- Zhang, H.W.; Chen, J.Q.; Zhang, Y.D. Numerical simulation of shot-peening process based on multiple shot model. J. Plast. Eng. 2012, 19, 8. [Google Scholar]

- Miao, H.Y.; Larose, S.; Perron, C.; Levesque, M. On the potential applications of a 3D random finite element model for the simulation of shot peening. Adv. Eng. Softw. 2009, 40, 1023–1038. [Google Scholar] [CrossRef]

- Li, Y.; Lei, L.P.; Zeng, P. Shot stream Finite Element model for shot peening numerical simulation and its experimental study. J. Mech. Eng. 2011, 47, 6. [Google Scholar] [CrossRef]

- Wang, Y.Z.; Li, F.; Chen, Y.Y.; Zhang, Y.P.; Wu, Z.G.; Wang, C. TC4 shot peening simulation and experiment. J. Beijing Univ. Aeronaut. Astronaut. 2019, 9, 1723–1731. [Google Scholar]

- Sheng, X.F.; Li, Z.; Zhao, K.Y.; Cheng, X.Q. Numerical simulation research on strengthening effect of shot peening at identical intensity. Surf. Technol. 2018, 47, 7. [Google Scholar]

- Qin, Z.; Li, B.; Zhang, H.; Youani Andre Wilfried, T.; Gao, T.; Xue, H. Effects of shot peening with different coverage on surface integrity and fatigue crack growth properties of 7B50-T7751 aluminum alloy. Eng. Fail. Anal. 2022, 133, 106010. [Google Scholar] [CrossRef]

- Unal, O.; Varol, R. Almen intensity effect on microstructure and mechanical properties of low carbon steel subjected to severe shot peening. Appl. Surf. Sci. 2014, 290, 40–47. [Google Scholar] [CrossRef]

- Guagliano, M. Relating Almen intensity to residual stresses induced by shot peening: A numerical approach. J. Mater. Process. Technol. 2001, 110, 277–286. [Google Scholar] [CrossRef]

- Xin, Z.L. Shot peening process design intensit. Tool Eng. 2018, 52, 4. [Google Scholar]

- Su, K.; Zhang, J.; Li, H.; Ji, D.; Hu, L. Anti-fatigue strengthening mechanism of conventional shot peening and micro-shot peening on bare and micro-arc oxidation coated 6082-T6 aluminum alloy. Mater. Lett. 2023, 331, 133442. [Google Scholar] [CrossRef]

- Fang, B.W. Controlled Shot Peening and Residual Stress Theory; Shandong Science and Technology Press: Jinan, China, 1991. [Google Scholar]

- Choi, Y. Influence of rake angle on surface integrity and fatigue performance of machined surfaces. Int. J. Fatigue 2017, 94, 81–88. [Google Scholar] [CrossRef]

- Gao, Y.K. Improvement of fatigue property in 7050–T7451 aluminum alloy by laser peening and shot peening. Mater. Sci. Eng. A 2011, 528, 3823–3828. [Google Scholar] [CrossRef]

- Wang, Z.; Xie, L.; Zhang, Q.; Ali, R.A.; Chen, W.; Zhou, L. Surface layer strengthening mechanism of 2060 aluminum–lithium alloy after shot-peening. J. Mater. Res. Technol. 2023, 23, 4615–4633. [Google Scholar] [CrossRef]

- Li, W.; Liu, P.; Zhao, S.; Zhang, K.; Ma, F.; Liu, X.; Chen, X.; He, D. Microstructural evolution, mechanical properties and strengthening mechanism of TiN/Ni nanocomposite film. J. Alloys Compd. 2017, 691, 159–164. [Google Scholar] [CrossRef]

- Yin, F.; Zhang, X.; Chen, F.; Hu, S.; Ming, K.; Zhao, J.; Xie, L.; Liu, Y.; Hua, L.; Wang, J. Understanding the microstructure refinement and mechanical strengthening of dual-phase high entropy alloy during ultrasonic shot peening. Mater. Des. 2023, 227, 111771. [Google Scholar] [CrossRef]

- Gangaraj, S.M.H.; Guagliano, M.; Farrahi, G.H. An approach to relate shot peening finite element simulation to the actual coverage. Surf. Coat. Technol. 2014, 243, 39–45. [Google Scholar] [CrossRef]

- Li, R.; Liu, D.; Wei, Z.; Xuan, L.; Qiao, M.; Xia, M. Influence of shot peening and surface integrity on the fatigue properties of 300M steel. Mech. Sci. Technol. Aerosp. Eng. 2011, 30, 1418–1423. [Google Scholar]

- Wu, J.; Liu, H.; Wei, P.; Zhu, C.; Lin, Q. Effect of shot peening coverage on hardness, residual stress and surface morphology of carburized rollers. Surf. Coat. Technol. 2020, 384, 125273. [Google Scholar] [CrossRef]

- Zhang, L. Analysis and Research of Shot Peening Coverage; Soochow University: Suzhou, China, 2015. [Google Scholar]

| Surface-Strengthening Methods | Characteristics | New Advances |

|---|---|---|

| LSP | Deeper surface-strengthening layer; more stable energy; lower roughness; better thermal stability. However, point-by-point strengthening; expensive equipment; more complex operations. | LSP plus MSP; LSP coupling low temperature; LSP coupling high temperature. |

| MSP | Larger surface-strengthening layer; higher maturity, stronger applicability and most widely application; simpler operation; lower cost and higher efficiency. However, significantly increased roughness. | MSP plus vibration finishing; pre-tensile stress MSP; secondary MSP; in situ warm MSP; wet MSP. |

| WJSP | Better surface roughness; easier processing of narrow and small parts. | Cavitation peening by WJSP. |

| USP | Shallower bombardment indentations; more environmentally friendly; lower cost and higher efficiency. Limited by part shape and sealed chamber. | Ultrasonic hammering method. |

| Materials | Vickers Hardness | Residual Stress, MPa | Reference | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Non-Peened | LSP | MSP | WJSP | USP | Non-Peened | LSP | MSP | WJSP | USP | ||

| Titanium alloy Ti6Al4V | 344 | 338 | 386 | 367 | −220 | −450 | −348 | −648 | [41] | ||

| Aluminum alloy A2017 | 130 | 280 | 180 | 160 | 20 | −211 | −248 | −297 | [42] | ||

| Aluminum alloy A5005 | 55 | 75 | [43] | ||||||||

| Nickel alloy 200 | 116 | 154 | [44] | ||||||||

| Carbon steel AISI1045 | −40 | −200 | [45] | ||||||||

| Shot Types | Scope of Application |

|---|---|

| Steel shot | Low hardness, typically in the range of 40 to 50 HRC, with good ductility of cast steel shots, high recovery rate, and suitable for moderate strength shot peening. |

| Wire-cut shot | High hardness, typically ranging from 55 to 62 HRC, good toughness, prone to breakage, and low recovery rate, suitable for high-intensity shot peening applications. |

| Ceramic shot | High hardness, generally ranging from 57 to 63 HRC, with the outstanding feature of high density and high hardness. Initially used for reinforcement of aircraft components. Due to the high strength of ceramic beads, with long lifespan and low cost, it has now been extended to the surface strengthening of colored metals such as titanium alloys and aluminum alloys. |

| Glass shot | Low hardness, suitable for materials such as titanium, aluminum, magnesium, and others that cannot be contaminated by ferrous materials. It can also be used as a secondary treatment after steel shot peening to eliminate ferrous contamination and reduce the roughness of the components. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xie, X.; Zhang, L.; Zhu, L.; Li, Y.; Hong, T.; Yang, W.; Shan, X. State of the Art and Perspectives on Surface-Strengthening Process and Associated Mechanisms by Shot Peening. Coatings 2023, 13, 859. https://doi.org/10.3390/coatings13050859

Xie X, Zhang L, Zhu L, Li Y, Hong T, Yang W, Shan X. State of the Art and Perspectives on Surface-Strengthening Process and Associated Mechanisms by Shot Peening. Coatings. 2023; 13(5):859. https://doi.org/10.3390/coatings13050859

Chicago/Turabian StyleXie, Xiaodong, Li Zhang, Liangliang Zhu, Yanbiao Li, Tao Hong, Weibo Yang, and Xiaohang Shan. 2023. "State of the Art and Perspectives on Surface-Strengthening Process and Associated Mechanisms by Shot Peening" Coatings 13, no. 5: 859. https://doi.org/10.3390/coatings13050859