Graphene Oxide as a Factor Modifying the Properties of Wood

Abstract

1. Introduction

2. Materials and Methods

2.1. Preparation of Research Material

2.2. Characterization of Quality Parameters

2.2.1. XRD Analysis

2.2.2. TG/DTG Analysis

2.2.3. SEM Analysis

2.2.4. Assessment of Water Absorption

2.3. Characterization of Biological Parameters

2.3.1. Growth of Fungi on Wood

2.3.2. Growth of Fungi on Sabouraud Dextrose Agar Medium

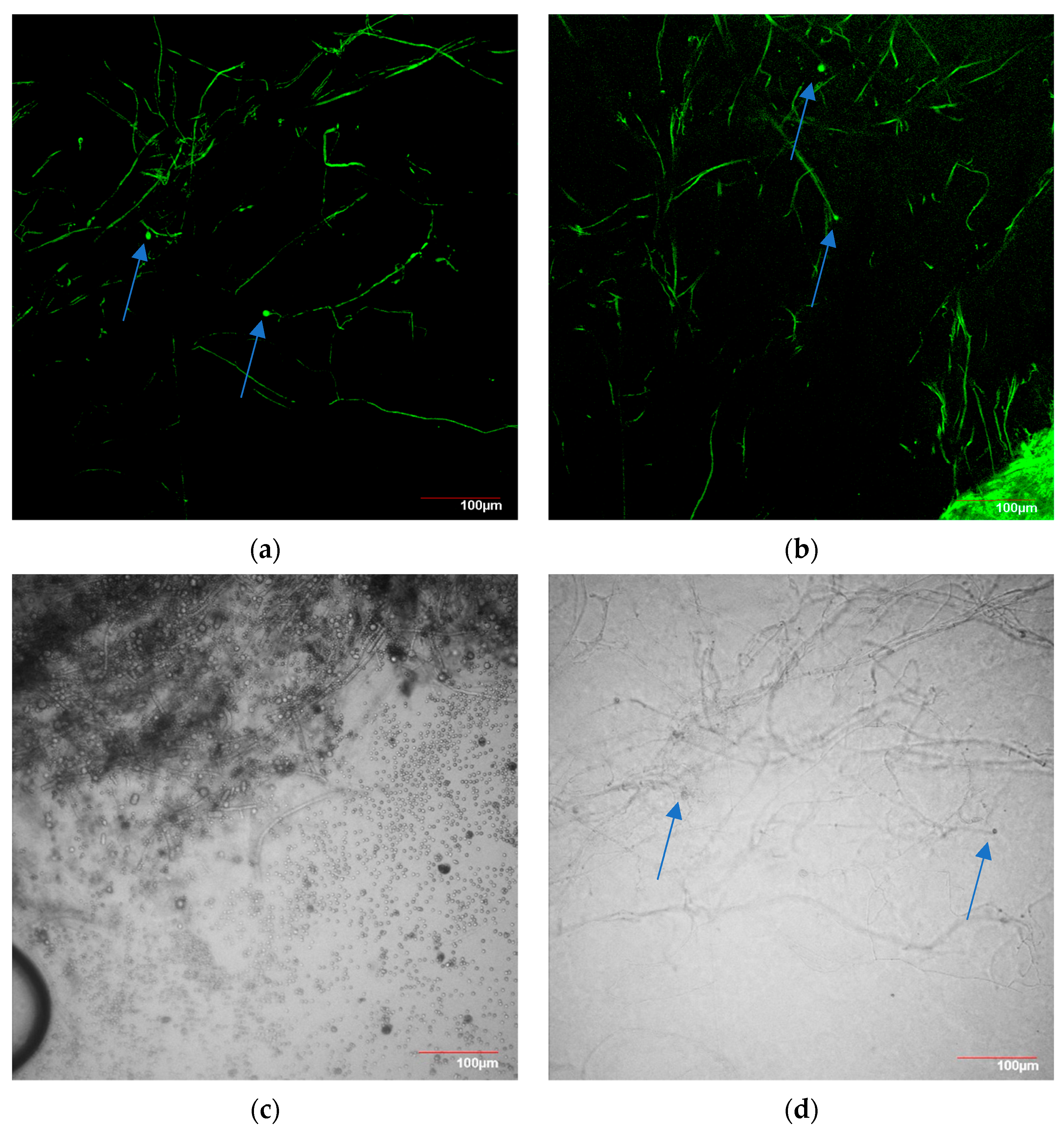

2.3.3. The Effect of Graphene Oxide on Mold Fungus Cells

3. Results

3.1. Characterization of Structural Parameters

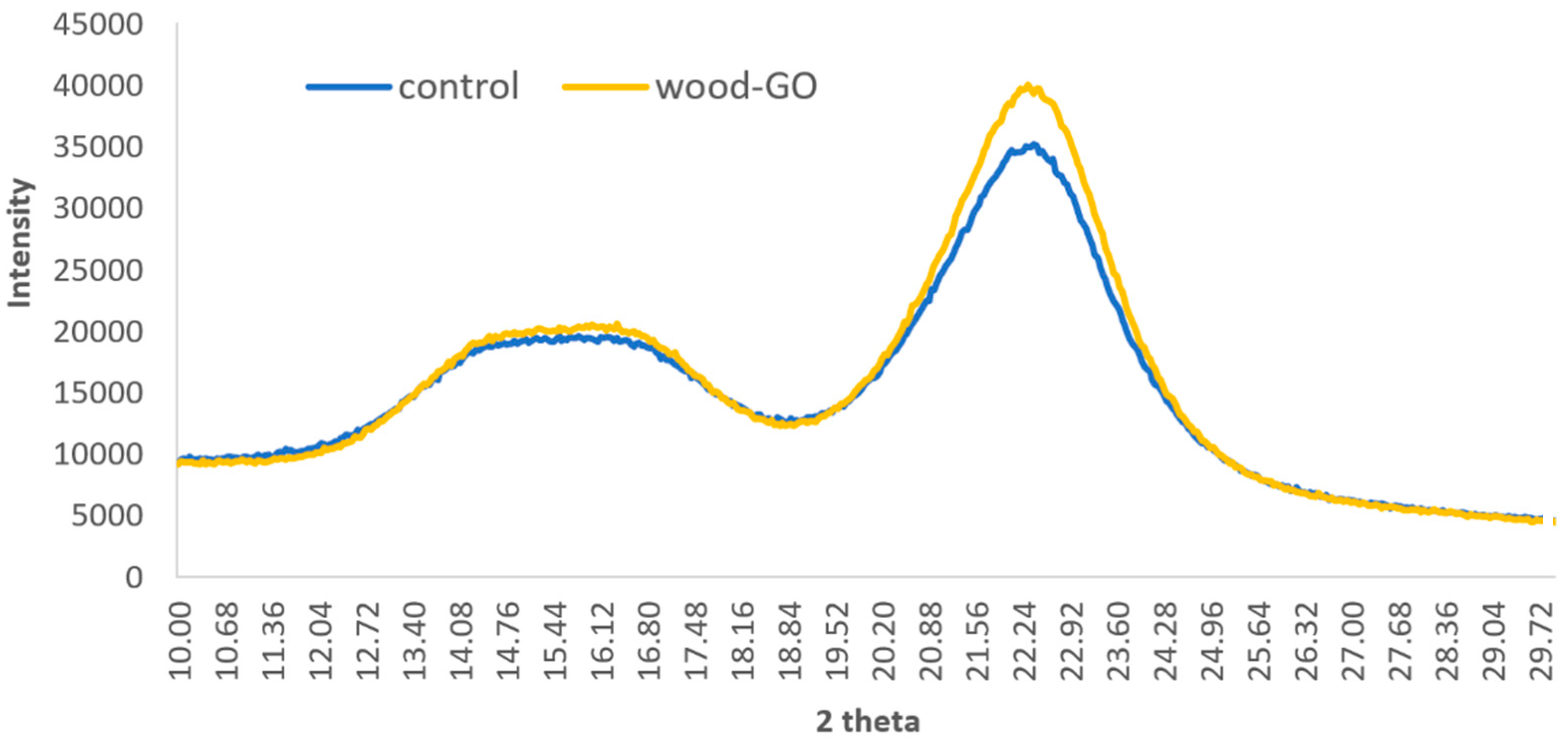

3.1.1. XRD Analysis and the Degree of Crystallinity

3.1.2. Thermal Properties

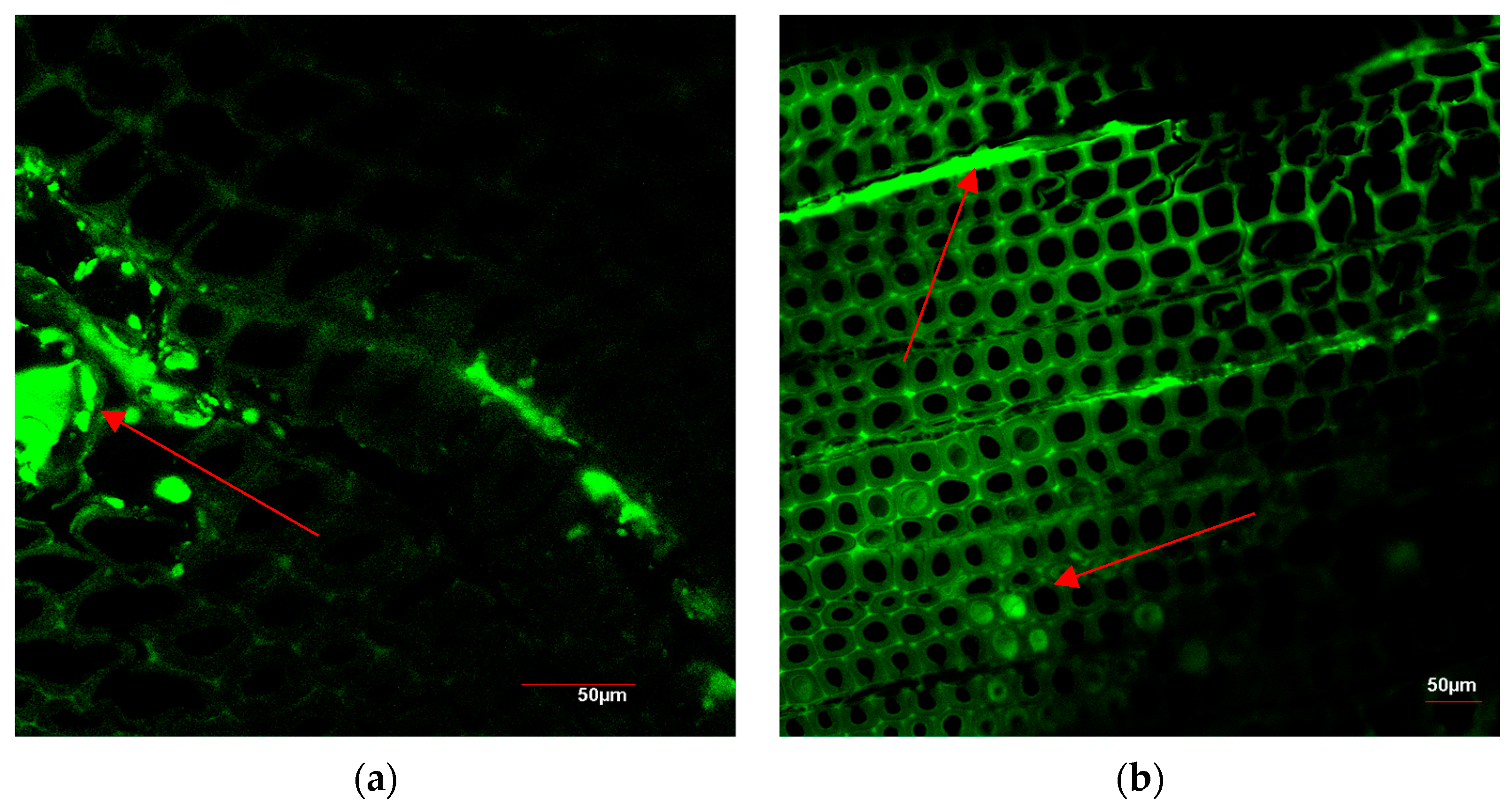

3.1.3. Analysis of Microscopic Results

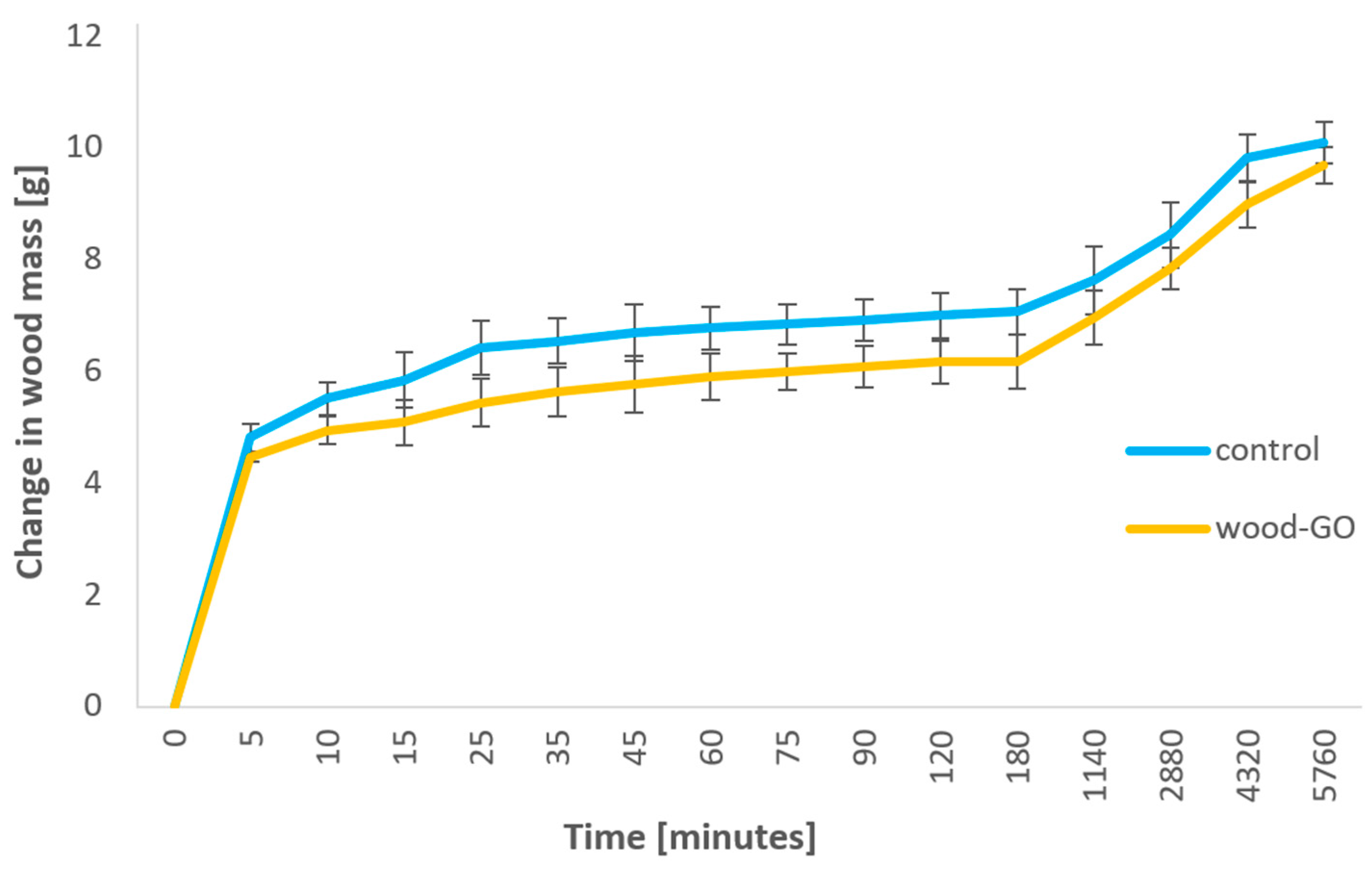

3.1.4. Test Results for Water Absorption

3.1.5. Growth of Fungi

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Martín, J.A.; López, R. Biological Deterioration and Natural Durability of Wood in Europe. Forests 2023, 14, 283. [Google Scholar] [CrossRef]

- Ibáñez, C.M.; Katzenstein, G.; Mantero, C.; Benítez, V.; Camargo, A.; Berberian, N.; Bollazzi, M. Ammoniacal Zinc Borate for Wood Protection against Fungi and Insects. Forests 2023, 14, 1152. [Google Scholar] [CrossRef]

- Kurkowiak, K.; Emmerich, L.; Militz, H. Biological Durability and Wood–Water Interactions of Sorbitol and Citric Acid (SorCA) Modified Wood. J. Wood Sci. 2023, 69, 34. [Google Scholar] [CrossRef]

- Zhang, N.; Mao, Y.; Wu, S.; Xu, W. Effects of the Ball Milling Process on the Particle Size of Graphene Oxide and Its Application in Enhancing the Thermal Conductivity of Wood. Forests 2022, 13, 1325. [Google Scholar] [CrossRef]

- He, Z.; Gu, Y.; Liu, H.; Sun, Y.; Liu, G.; Chang, S.; Bai, Y.; Hu, J. Encapsulation of Wood Capillary Channels by Electrostatically Self-Assembled Graphene Oxide for Enhanced Conductivity. J. Porous Mater. 2023, 30, 1643–1652. [Google Scholar] [CrossRef]

- Xu, D.; Liang, G.; Qi, Y.; Gong, R.; Zhang, X.; Zhang, Y.; Liu, B.; Kong, L.; Dong, X.; Li, Y. Enhancing the Mechanical Properties of Waterborne Polyurethane Paint by Graphene Oxide for Wood Products. Polymers 2022, 14, 5456. [Google Scholar] [CrossRef]

- Han, X.; Zhang, Q.; Yin, Y.; Pu, J. Fire Retardancy of Graphene Oxide/Wood Composite (GOW) Prepared by a Vacuum-Pulse Dipping Technique. Holzforschung 2018, 72, 375–378. [Google Scholar] [CrossRef]

- Ait Benhamou, A.; Salim, M.H.; Boussetta, A.; Mennani, M.; Essifi, K.; Kassab, Z.; El Achaby, M.; Moubarik, A. Graphene Oxide a Promising Formaldehyde Scavenger of Phenolic Resin-bonded Plywood: From Elaboration to Evaluation. J. Appl. Polym. Sci. 2024, 141, e55093. [Google Scholar] [CrossRef]

- Athulya, R.; Nandini, J.; Bhoi, T.K.; Sundararaj, R. Recent Advances of Nanotechnology in Wood Protection: A Comprehensive Review. Wood Mater. Sci. Eng. 2023. [Google Scholar] [CrossRef]

- Asif, A.H.; Mahajan, M.S.; Sreeharsha, N.; Gite, V.V.; Al-Dhubiab, B.E.; Kaliyadan, F.; Nanjappa, S.H.; Meravanige, G.; Aleyadhy, D.M. Enhancement of anticorrosive performance of cardanol based polyurethane coatings by incorporating magnetic hydroxyap-atite nanoparticles. Materials 2022, 15, 2308. [Google Scholar] [CrossRef]

- Łukawski, D.; Lekawa-Raus, A.; Lisiecki, F.; Koziol, K.; Dudkowiak, A. Towards the Development of Superhydrophobic Carbon Nanomaterial Coatings on Wood. Prog. Org. Coat. 2018, 125, 23–31. [Google Scholar] [CrossRef]

- Wang, J.; Zhou, Y.; Li, J.; Feng, Y.; Zhang, J.; Yu, H.; Zhuang, X. Improved Wettability and Dimensional Stability of Bamboo Timber by Coating Graphene/Silica Composites. Int. J. Polym. Sci. 2021, 2021, 7053143. [Google Scholar] [CrossRef]

- Candotto Carniel, F.; Fortuna, L.; Zanelli, D.; Garrido, M.; Vázquez, E.; González, V.J.; Prato, M.; Tretiach, M. Graphene Environmental Biodegradation: Wood Degrading and Saprotrophic Fungi Oxidize Few-Layer Graphene. J. Hazard. Mater. 2021, 414, 125553. [Google Scholar] [CrossRef]

- Borges, C.C.; Tonoli, G.H.D.; Cruz, T.M.; Duarte, P.J.; Junqueira, T.A. Nanoparticles-Based Wood Preservatives: The next Generation of Wood Protection? Cerne 2018, 24, 397–407. [Google Scholar] [CrossRef]

- Khazaei, J.; Jafari, S.S.; Noorolahi, S.; Jafari, S. Modeling Cyclic Water Absorption and Desorption Characteristics of Three Varieties of Wood. In Proceedings of the IAALD AFITA WCCA 2008 World Conference on Agricultural Information and IT, Tokyo, Japan, 24–27 August 2008. [Google Scholar]

- Gong, J.; Li, J.; Xu, J.; Xiang, Z.; Mo, L. Research on Cellulose Nanocrystals Produced from Cellulose Sources with Various Polymorphs. RSC Adv. 2017, 7, 33486–33493. [Google Scholar] [CrossRef]

- Zielińska, D.; Szentner, K.; Waśkiewicz, A.; Borysiak, S. Production of Nanocellulose by Enzymatic Treatment for Application in Polymer Composites. Materials 2021, 14, 2124. [Google Scholar] [CrossRef]

- Montoya-Escobar, N.; Ospina-Acero, D.; Velásquez-Cock, J.A.; Gómez-Hoyos, C.; Serpa Guerra, A.; Gañan Rojo, P.F.; Vélez Acosta, L.M.; Escobar, J.P.; Correa-Hincapié, N.; Triana-Chávez, O.; et al. Use of Fourier Series in X-ray Diffraction (XRD) Analysis and Fourier-Transform Infrared Spectroscopy (FTIR) for Estimation of Crystallinity in Cellulose from Different Sources. Polymers 2022, 14, 5199. [Google Scholar] [CrossRef]

- Agarwal, U.P.; Reiner, R.R.; Ralph, S.A. Cellulose Crystallinity of Woods, Wood Pulps, and Agricultural Fibers by FT-Raman Spectroscopy. Red 2011, 19, 67–69. [Google Scholar]

- Farivar, F.; Lay Yap, P.; Karunagaran, R.U.; Losic, D. Thermogravimetric Analysis (TGA) of Graphene Materials: Effect of Particle Size of Graphene, Graphene Oxide and Graphite on Thermal Parameters. C 2021, 7, 41. [Google Scholar] [CrossRef]

- Chen, T.; Wu, Z.; Hu, X.; Aladejana, J.T.; Niu, M.; Liu, Z.; Wei, Q.; Peng, X.; Xie, Y.; Wu, B. Constructing Hydrophobic Interfaces in Aluminophosphate Adhesives with Reduced Graphene Oxide to Improve the Performance of Wood-Based Boards. Compos. Part B Eng. 2020, 198, 108168. [Google Scholar] [CrossRef]

- Odalanowska, M.; Woźniak, M.; Ratajczak, I.; Zielińska, D.; Cofta, G.; Borysiak, S. Propolis and Organosilanes as Innovative Hybrid Modifiers in Wood-Based Polymer Composites. Materials 2021, 14, 464. [Google Scholar] [CrossRef] [PubMed]

- Mironova, M.; Makarov, I.; Golova, L.; Vinogradov, M.; Shandryuk, G.; Levin, I. Improvement in Carbonization Efficiency of Cellulosic Fibres Using Silylated Acetylene and Alkoxysilanes. Fibers 2019, 7, 84. [Google Scholar] [CrossRef]

- Rantuch, P.; Chrebet, T. Thermal Decomposition of Cellulose Insulation. Cellul. Chem. Technol. 2014, 48, 461–467. [Google Scholar]

- Shao, W.; Wang, S.; Liu, H.; Wu, J.; Zhang, R.; Min, H.; Huang, M. Preparation of Bacterial Cellulose/Graphene Nanosheets Composite Films with Enhanced Mechanical Performances. Carbohydr. Polym. 2016, 138, 166–171. [Google Scholar] [CrossRef] [PubMed]

- Kumar, N.; Kumar, B.; Gupta, H.; Kumar, A. Development and Evaluation of Cellulose/Graphene-Oxide Based Composite for Removing Phenol from Aqueous Solutions. Polymers 2023, 15, 572. [Google Scholar] [CrossRef]

- Kwon, D.J.; Kwon, I.J.; Kong, J.; Nam, S.Y. Investigation of Impediment Factors in Commercialization of Reinforced Adhesives. Polym. Test. 2021, 93, 106995. [Google Scholar] [CrossRef]

- Jia, M.Y.; Li, Y.; Xu, L.S.; Yao, C.L.; Jin, X.J. Wood Pulp Fiber Wrapped by Fish-Scale Graphene as Flexible and Free-Standing Supercapacitor Electrode. J. Wood Chem. Technol. 2018, 38, 417–429. [Google Scholar] [CrossRef]

- Nguyen, H.N.; Chaves-Lopez, C.; Oliveira, R.C.; Paparella, A.; Rodrigues, D.F.; Rodrigues, D.F. Cellular and Metabolic Approaches to Investigate the Effects of Graphene and graphene oxide in the fungi Aspergillus flavus and Aspergillus niger. Carbon 2019, 143, 419–429. [Google Scholar] [CrossRef]

- Li, L.; Qu, Q.; Tian, B.; Zhang, K.Q. Induction of Chlamydospores in Trichoderma harzianum and Gliocladium roseum by Antifungal Compounds Produced by Bacillus Subtilis C2. J. Phytopathol. 2005, 153, 686–693. [Google Scholar] [CrossRef]

| Samples | Solution Retention | Graphene Oxide Retention | ||

|---|---|---|---|---|

| Average Content | SD | Average Content | SD | |

| kg/m3 | ||||

| wood-GO | 636.22 | 26.32 | 0.25 | 0.01 |

| control | 637.75 | 8.01 | - | - |

| Samples | Degree of Crystallinity Xc/% |

|---|---|

| control | 57 |

| wood-GO | 64 |

| Samples | p-Value | α |

|---|---|---|

| Tukey’s Test | ||

| F statistic | 0.1674 | 0.05 |

| control | a | |

| wood-GO | a | |

| Concentration of Graphene Oxide in Growth Medium (mL/100 mL) | Day of Observation | p-Value | α | ||

|---|---|---|---|---|---|

| 2 | 4 | 6 | |||

| Growth Diameter of Mycelium (mm) | Tukey’s Test | ||||

| F Statistic | 8.79 × 10−2 | 0.05 | |||

| 0 (control) | 69.4 | 90.0 | 90.0 | a | |

| 0.01 | 51.0 | 82.3 | 83.8 | a | |

| 0.05 | 48.2 | 77.3 | 79.3 | a | |

| 0.1 | 48.2 | 74.7 | 76.7 | b | |

| 0.25 | 48.2 | 72.0 | 74.3 | b | |

| 0.5 | 45.5 | 70.3 | 72.7 | b | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Betlej, I.; Andres, B.; Borysiak, S.; Jaworski, S.; Kutwin, M.; Krajewski, K.; Boruszewski, P. Graphene Oxide as a Factor Modifying the Properties of Wood. Coatings 2024, 14, 321. https://doi.org/10.3390/coatings14030321

Betlej I, Andres B, Borysiak S, Jaworski S, Kutwin M, Krajewski K, Boruszewski P. Graphene Oxide as a Factor Modifying the Properties of Wood. Coatings. 2024; 14(3):321. https://doi.org/10.3390/coatings14030321

Chicago/Turabian StyleBetlej, Izabela, Bogusław Andres, Sławomir Borysiak, Sławomir Jaworski, Marta Kutwin, Krzysztof Krajewski, and Piotr Boruszewski. 2024. "Graphene Oxide as a Factor Modifying the Properties of Wood" Coatings 14, no. 3: 321. https://doi.org/10.3390/coatings14030321

APA StyleBetlej, I., Andres, B., Borysiak, S., Jaworski, S., Kutwin, M., Krajewski, K., & Boruszewski, P. (2024). Graphene Oxide as a Factor Modifying the Properties of Wood. Coatings, 14(3), 321. https://doi.org/10.3390/coatings14030321