Static and Dynamic Magnetization Investigation in Permalloy Electrodeposited onto High Resistive N-Type Silicon Substrates

Abstract

:1. Introduction

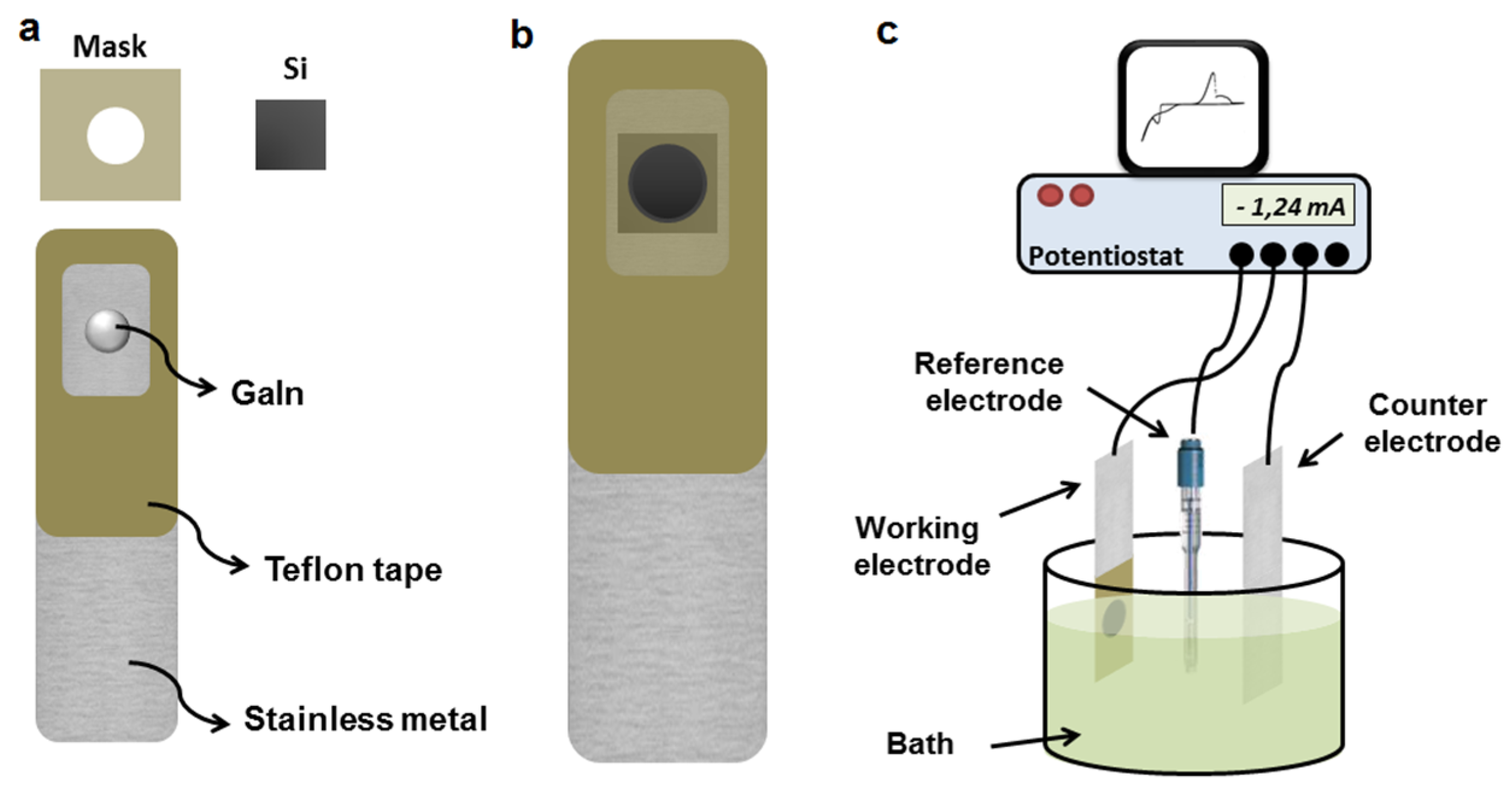

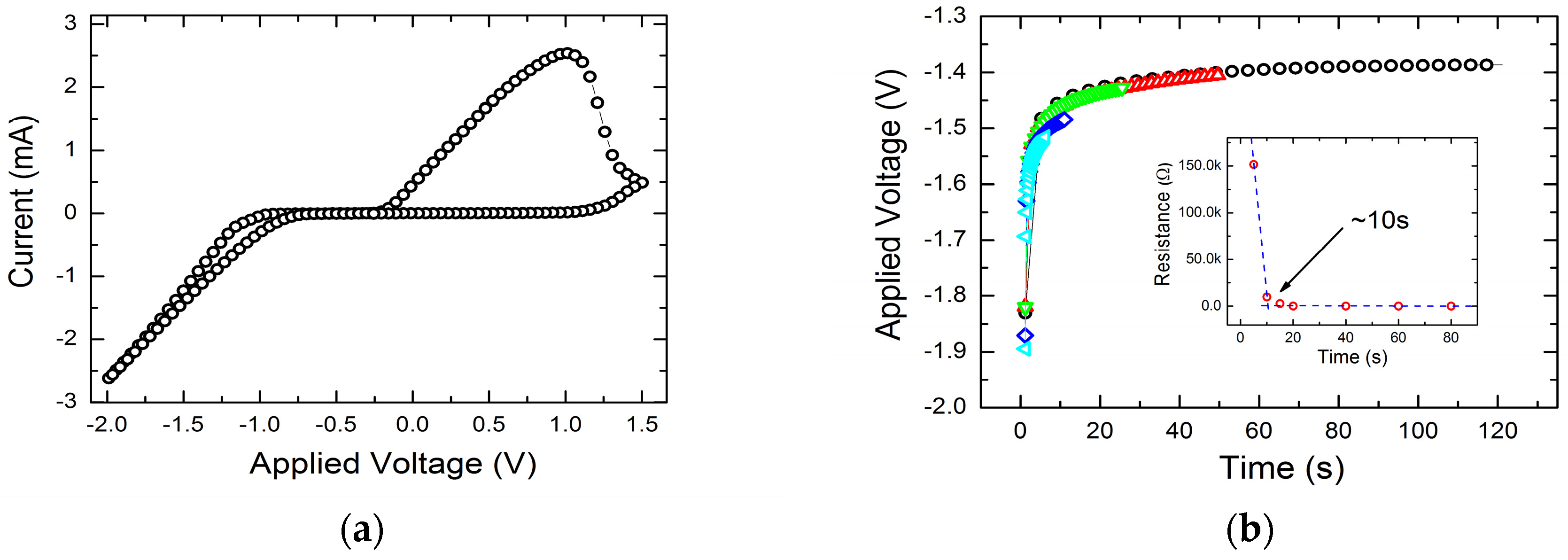

2. Materials and Methods

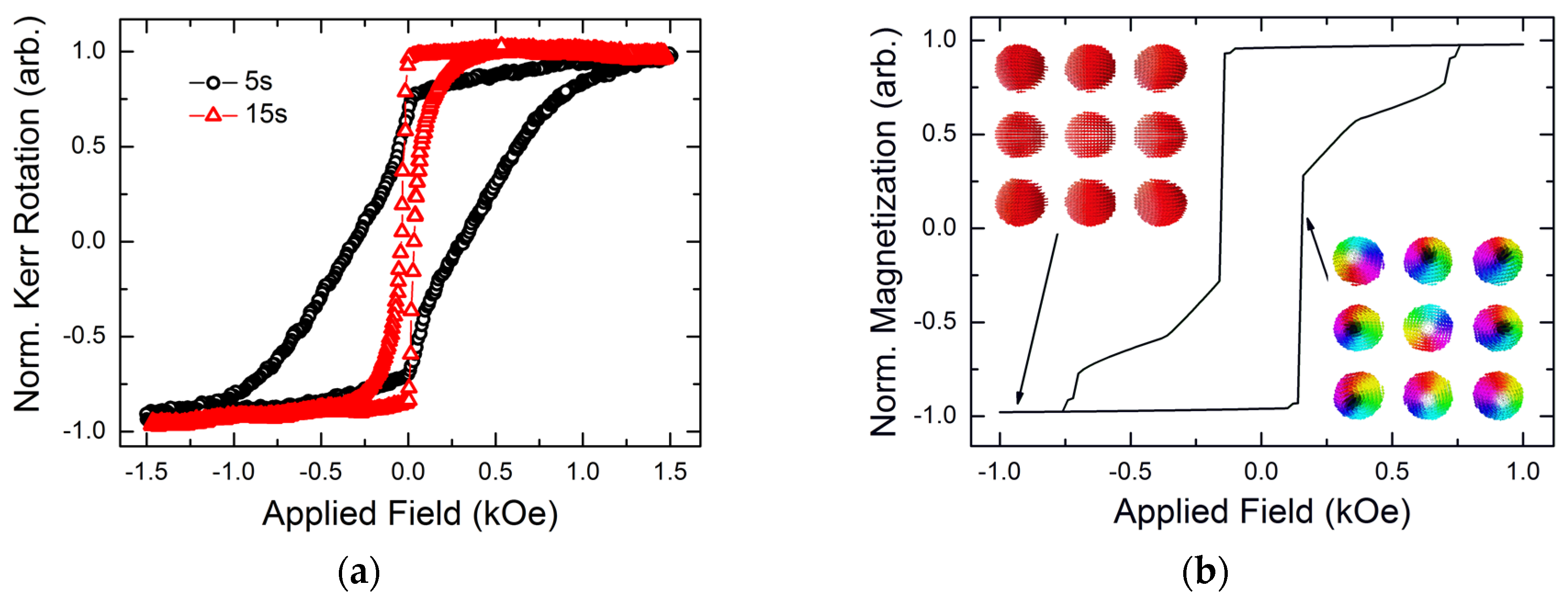

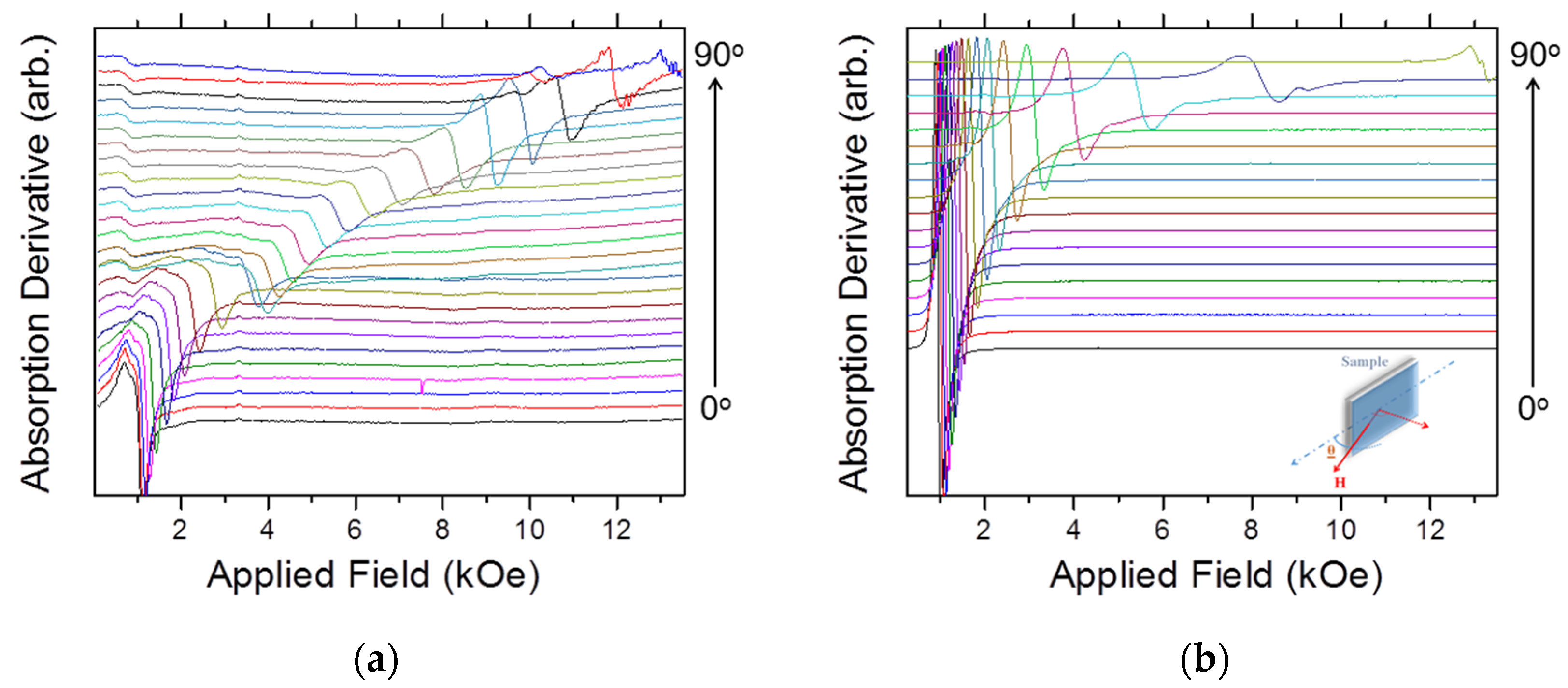

3. Results and Discussion

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Jeffers, F. High-density magnetic recording head. Proc. IEEE 1986, 74, 1540–1556. [Google Scholar] [CrossRef]

- Hunt, R. A magnetoresistive readout transducer. IEEE Trans. Magn. 1971, 7, 150–154. [Google Scholar] [CrossRef]

- Mcguire, T.R.; Potter, R.I. Anisotropic magnetoresistance in ferromagnetic 3d alloys. IEEE Trans. Magn. 1975, 11, 1018–1038. [Google Scholar] [CrossRef]

- Girard, R. The electrodeposition of thin magnetic permalloy films. J. Appl. Phys. 1967, 38, 1423–1430. [Google Scholar] [CrossRef]

- Stobiecki, T.; Bełtowska-Lehman, E.; Riesenkampf, A. The preparation and properties of electrodeposited permalloy films on substrates of evaporated permalloy. Thin Solid Films 1975, 29, 313–318. [Google Scholar] [CrossRef]

- Butta, M. Effect of saccharin in electroplated NiFe alloy on the noise of fluxgate. IEEE Trans. Magn. 2016, 52, 1–4. [Google Scholar] [CrossRef]

- Lamrani, S.; Guittoum, A.; Schäfer, R.; Hemmous, M.; Neu, V.; Pofahl, S.; Hadjersi, T.; Benbrahim, N. Morphology, structure and magnetic study of permalloy films electroplated on silicon nanowires. J. Magn. Magn. Mater. 2015, 396, 263–267. [Google Scholar] [CrossRef]

- IKamo, Y.; Miyamoto, T. Preparation and Magnetic Properties of Electrodeposited Permalloy Film. IEEE Trans. J. Magn. Jpn. 1985, 1, 502–504. [Google Scholar]

- Steven, D.L.; Shirley, R.; Daniel, T.S. Characterization of NixFe1−x (0.10 < x < 0.95) Electrodeposition from a Family of Sulfamate-Chloride Electrolytes. J. Electrochem. Soc. 1999, 146, 1431–1435. [Google Scholar]

- Monsma, D.J.; Lodder, J.C.; Popma, Th.J.A.; Dieny, B. Perpendicular Hot Electron Spin-Valve Effect in a New Magnetic Field Sensor: The Spin-Valve Transistor. Phys. Rev. Lett. 1995, 74, 5260. [Google Scholar] [CrossRef] [PubMed]

- Datta, S.; Das, B. Electronic analog of the electro-optic modulator. Appl. Phys. Lett. 1990, 56, 665. [Google Scholar] [CrossRef]

- Dlubak, B.; Martin, M.-B.; Deranlot, C.; Servet, B.; Xavier, S.; Mattana, R.; Sprinkle, M.; Berger, C.; De Heer, W.A.; Petroff, F.; et al. Highly efficient spin transport in epitaxial graphene on SiC. Nat. Phys. 2012, 8, 557–561. [Google Scholar] [CrossRef]

- Spada, E.R.; de Oliveira, L.S.; da Rocha, A.S.; Pasa, A.A.; Zangari, G.; Sartorelli, M.L. Thin films of FexNi1−x electroplated on silicon (100). J. Magn. Magn. Mater. 2004, 272, E891–E892. [Google Scholar] [CrossRef]

- De Araujo, C.I. L.; Munford, M.L.; Delatorre, R.G.; Da Cas, A.V.; Zoldan, V.C.; Pasa, A.A.; Garcia, N.G. Spin polarized current in permalloy clusters electrodeposited on silicon: Two-dimensional giant magnetoresistance. Appl. Phys. Lett. 2008, 92, 222101. [Google Scholar] [CrossRef]

- De Araujo, C.I.L.; Fonseca, J.M.; Sinnecker, J.P.; Delatorre, R.G.; Garcia, N.; Pasa, A.A. Circular single domains in hemispherical permalloy nanoclusters. J. Appl. Phys. 2014, 116, 183906. [Google Scholar] [CrossRef]

- Rahm, M.; Stah, J.; Weiss, D. Programmable logic elements based on ferromagnetic nanodisks containing two antidots. Appl. Phys. Lett. 2005, 87, 182107. [Google Scholar] [CrossRef]

- Iwasaki, J.; Mochizuki, M.; Nagaosa, N. Current-induced skyrmion dynamics in constricted geometries. Nat. Nanotechnol. 2013, 8, 742–747. [Google Scholar] [CrossRef] [PubMed]

- Kim, D.-H.; Rozhkova, E.A.; Ulasov, I.V.; Bader, S.D.; Rajh, T.; Lesniak, M.S.; Novosad, V. Biofunctionalized magnetic-vortex microdiscs for targeted cancer-cell destruction. Nat. Mater. 2010, 9, 165–171. [Google Scholar] [CrossRef] [PubMed]

- Metlov, K.L.; Lee, Y. Map of metastable states for thin circular magnetic nanocylinders. Appl. Phys. Lett. 2008, 92, 112506. [Google Scholar] [CrossRef]

- Cowburn, R.P.; Koltsov, D.K.; Adeyeye, A.O.; Welland, M.E.; Tricker, D.M. Single-Domain Circular Nanomagnets. Phys. Rev. Lett. 1999, 83, 1042. [Google Scholar] [CrossRef]

- Dzyaloshinsky, I. A thermodynamic theory of “weak” ferromagnetism of antiferromagnetics. J. Phys. Chem. Solids 1958, 4, 241–255. [Google Scholar] [CrossRef]

- Moriya, T. Anisotropic Superexchange Interaction and Weak Ferromagnetism. Phys. Rev. 1960, 120, 91. [Google Scholar] [CrossRef]

- De Araujo, C.I.L.; Alves, S.G.; Buda-Prejbeanu, L.D.; Dieny, B. Multilevel Thermally Assisted Magnetoresistive Random-Access Memory Based on Exchange-Biased Vortex Configurations. Phys. Rev. Appl. 2016, 6, 024015. [Google Scholar] [CrossRef]

- Chang, L.-T.; Fischer, I.A.; Tang, J.; Wang, C.-Y.; Yu, G.; Fan, Y.; Murata, K.; Nie, T.; Oehme, M.; Schulze, J.; et al. Electrical detection of spin transport in Si two-dimensional electron gas systems. Nanotechnology 2016, 27, 36. [Google Scholar] [CrossRef] [PubMed]

- Vansteenkiste, A.; Leliaert, J.; Dvornik, M.; Helsen, M.; Garcia-Sanchez, F.; Waeyenberge, B.V. The design and verification of MuMax3. AIP Adv. 2014, 4, 107133. [Google Scholar] [CrossRef] [Green Version]

- De Araujo, C.I.L.; Rizzi, L.G. µ-FMR—An analysis program to extract the ferromagnetic resonance absorption spectrum from micromagnetic simulations. To be submitted for publication. 2017. [Google Scholar]

- Kanak, J.; Stobiecki, T.; Wisniowski, P.; Gladyszewski, G.; Maass, W.; Szymanski, B. XRD study of the structure of NiFe/Au and NiFe/Cu Superlattices. J. Magn. Magn. Mater. 2002, 239, 329–331. [Google Scholar] [CrossRef]

- Samardak, A.; Sukovatitsina, E.; Ognev, A.; Stebliy, M.; Davydenko, A.; Chebotkevich, L.; Kim, Y.K.; Forough Nasirpouri, F.; Janjan, S.-M.; Nasirpouri, F. Magnetic vortex state and multi-domain pattern in electrodeposited hemispherical nanogranular nickel films. J. Magn. Magn. Mater. 2014, 371, 149–156. [Google Scholar] [CrossRef]

- Seavey, M.H., Jr.; Tannenwald, P.E. Direct observation of spin-wave resonance. Phys. Rev. Lett. 1958, 5, 168. [Google Scholar] [CrossRef]

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Freitas, K.; Toledo, J.R.; Figueiredo, L.C.; Morais, P.C.; Felix, J.F.; De Araujo, C.I.L. Static and Dynamic Magnetization Investigation in Permalloy Electrodeposited onto High Resistive N-Type Silicon Substrates. Coatings 2017, 7, 33. https://doi.org/10.3390/coatings7020033

Freitas K, Toledo JR, Figueiredo LC, Morais PC, Felix JF, De Araujo CIL. Static and Dynamic Magnetization Investigation in Permalloy Electrodeposited onto High Resistive N-Type Silicon Substrates. Coatings. 2017; 7(2):33. https://doi.org/10.3390/coatings7020033

Chicago/Turabian StyleFreitas, Kenedy, José R. Toledo, Leandro C. Figueiredo, Paulo C. Morais, Jorlandio F. Felix, and Clodoaldo I. L. De Araujo. 2017. "Static and Dynamic Magnetization Investigation in Permalloy Electrodeposited onto High Resistive N-Type Silicon Substrates" Coatings 7, no. 2: 33. https://doi.org/10.3390/coatings7020033