Concrete Damage in Field Conditions and Protective Sealer and Coating Systems

Abstract

:1. Introduction

2. Damage of Concrete

2.1. Scaling

2.2. Spalling

2.3. Popout

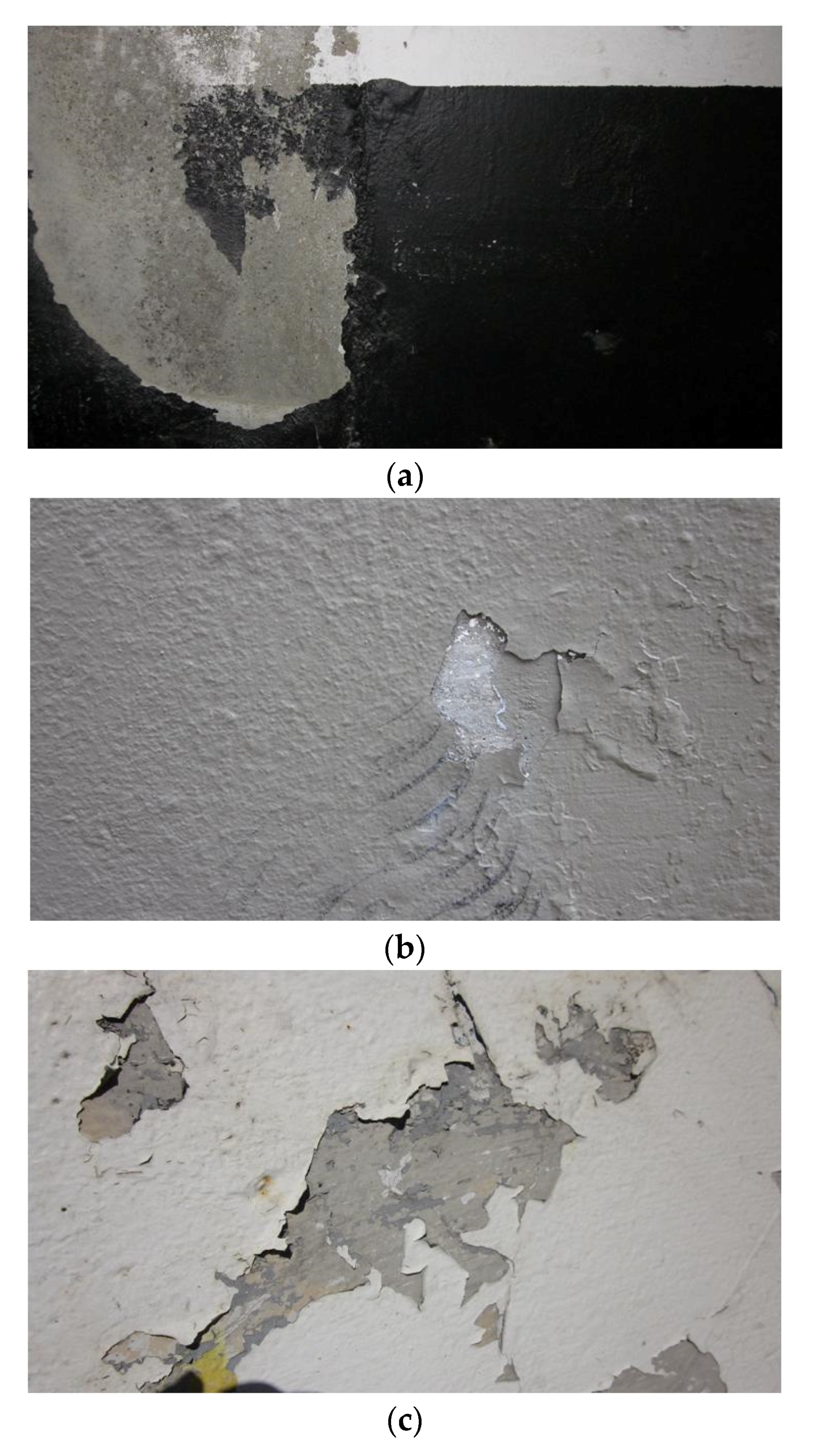

2.4. Delamination or Mortar Flaking

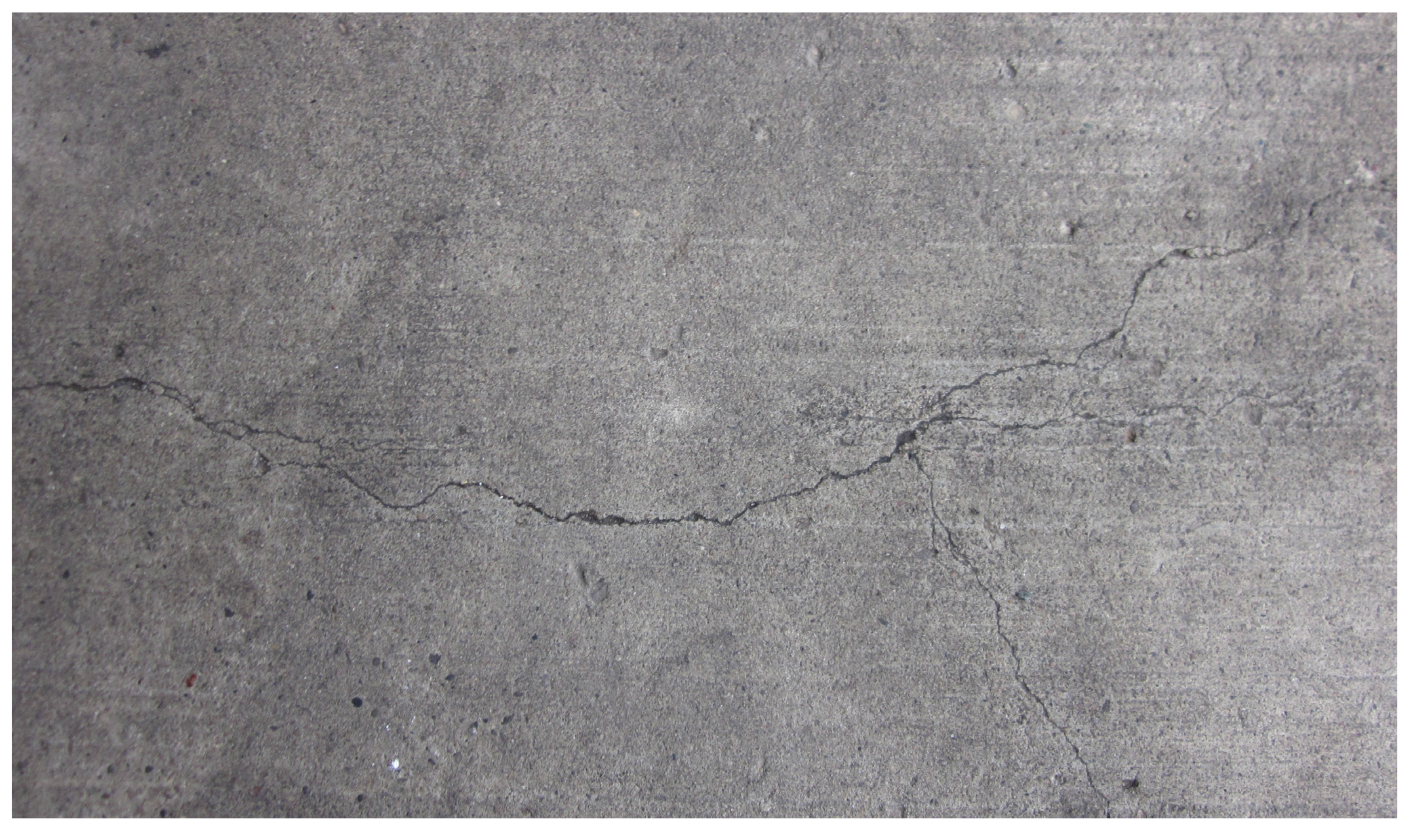

2.5. Drying Shrinkage Cracking

2.6. Map Cracking or Crazing

2.7. Corrosion-Induced Cracking

2.8. Stains

2.9. Discoloration

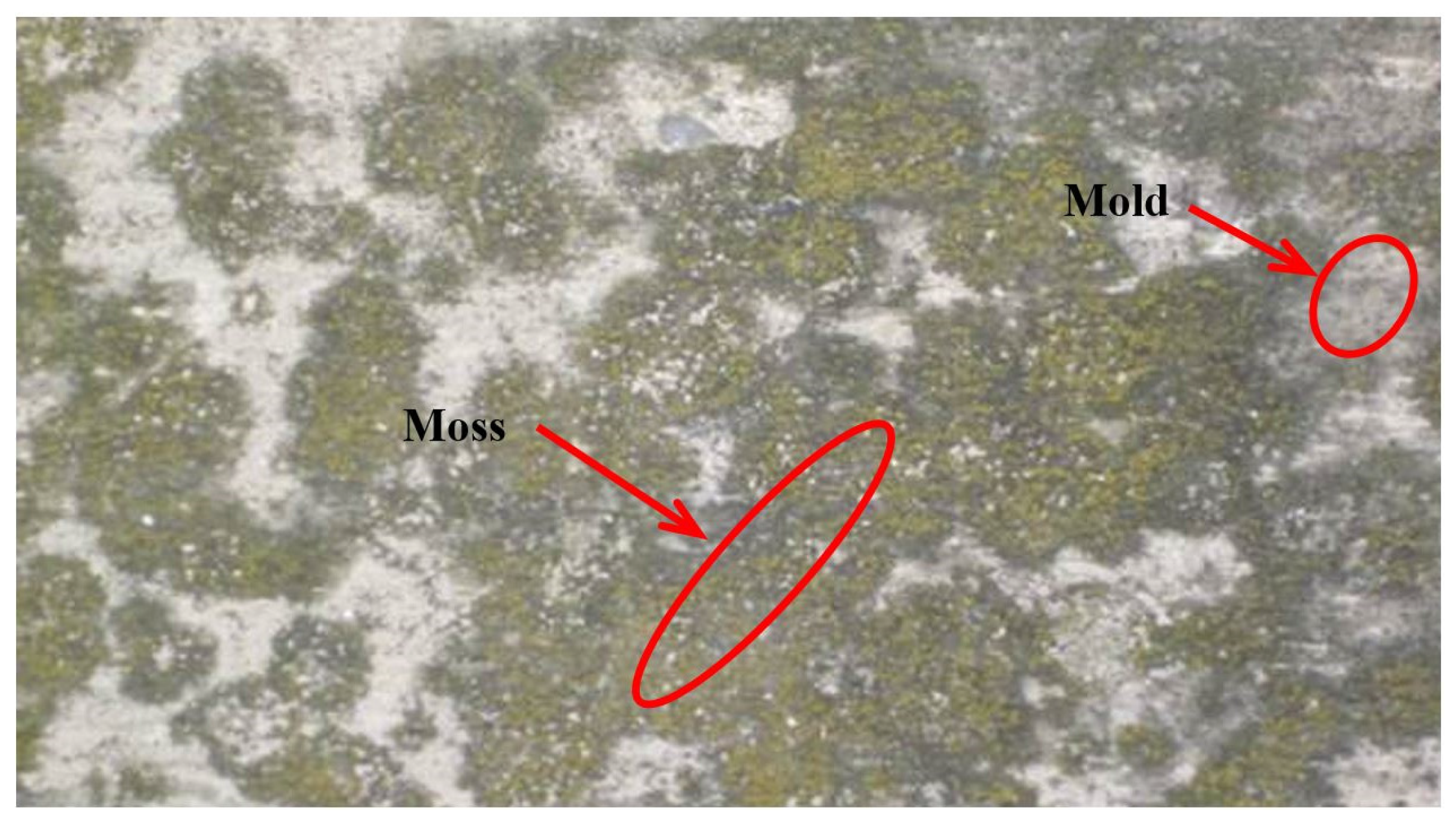

2.10. Moss and Mold Growths

3. Protective Sealer and Coating Systems

3.1. Types of Sealer and Coating Systems

- Penetrating sealers: low-viscosity materials, which are “flood coated” to achieve typically 1–3 mm penetration into concrete. These are mostly silane/siloxane or silicate based materials. Silane/siloxane based sealers produce a hydrophobic lining on the pore-wall of capillary pores to repel water and thus reduce the water ingress into concrete. In contrast, silicate based penetrating sealers can react chemically with calcium hydroxide (also known as portlandite), a by-product of the cement hydration in concrete, to produce additional C–S–H (calcium silicate hydrate) gel, which makes the concrete denser and potentially stronger by filling cracks and capillary pores [66].

- Surface sealers: medium-viscosity/low-solid materials, which form a thin film on the concrete surface; the thin film does not infiltrate the capillary pores present in concrete. These sealers must adhere to the concrete surface when they are applied to form a thin film. They are mainly epoxy, urethane or methyl methacrylate based materials.

- Barrier or surface coatings: high-viscosity/high-solid materials, which form a relatively thick film on concrete surfaces; this thick film does not infiltrate the capillary pores of concrete rather creates a protective barrier on concrete surfaces. These coatings must possess good adhesion with the concrete substrates for optimum performance in field conditions. They are mostly acrylic, epoxy or urethane based polymeric materials. These coatings can also be bituminous or cementitious materials.

- Impregnating polymers: ultra-low-viscosity materials, which are applied by special drying and vacuum techniques to ensure the deep penetration into concrete; they block the capillary pores in concrete. These are mainly styrene, acrylonitrile, or high-molecular-weight methacrylate based materials.

- Bituminous coatings: these coatings can be hot-applied or cold-applied; the cold application of bituminous materials employs asphalt emulsions as coating agents. They are asphalt, tar, or pitch based materials. These coatings are effective when the stresses (mostly in the forms of air pressure and hydrostatic pressure) on the surface are insignificant. In the cases of significant stresses on the concrete surface, several layers of bituminous coating are applied alternately with mineral or glass fibre felt. Moreover, the compatibility between concrete substrate and coating should be considered. Regarding the emulsified bituminous coatings, since both the aggregate and coating material have electrically charged surfaces, the compatibility between them are very important for optimum adhesion [69,70]. An example of an applied bituminous coating is shown in Figure 11.

- Cementitious coatings: these are high-density, high-strength waterproofing coatings; they include carefully graded solid materials (generally silica-based particles) in their composition, along with cementitious materials and liquid organic or inorganic chemicals. The dry components are mixed uniformly with the liquid chemicals to prepare these coatings. These coatings offer high durability for concrete structures. An example of an applied cementitious coating is shown in Figure 12.

- Polymeric coatings: These coatings are available with different fillers and texturing aggregates; they offer a variety of colors and attractive finishes for concrete structures. Also, these coatings offer good durability when they are applied with an adequate film thickness. They are usually acrylic, epoxy, urethane, or methyl methacrylate based materials. An example of an applied polymeric coating is shown in Figure 13.

3.2. Selection of Sealer and Coating Systems

3.3. Installtion of Sealer and Coating Systems

3.4. Performance of Sealer and Coating Systems

3.5. Evaluation of Sealer and Coating Systems

- AASHTO T161: Standard method of test for resistance of concrete to rapid freezing and thawing [80], ASTM C666/C666M: Standard test method for resistance of concrete to rapid freezing and thawing [81], and ASTM D2243: Standard test method for freeze-thaw resistance of water-borne coatings [82]. These test methods can be used for treated and untreated concretes to determine their freeze-thaw resistance.

- AASHTO T259: Standard method of test for resistance of concrete to chloride ion penetration [75], AASHTO T260: Sampling and testing for chloride ion in concrete and concrete raw materials [83], AASHTO T277: Standard method of test for electrical indication of concrete’s ability to resist chloride ion penetration [84], ASTM C1152/C1152M: Standard test method for acid-soluble chloride in mortar and concrete [85], ASTM C1202: Standard test method for electrical indication of concrete’s ability to resist chloride ion penetration [86], and ASTM C1543: Standard test method for determining the penetration of chloride ion into concrete by ponding [87]. These test methods can be used for treated and untreated concretes to determine their chloride ion penetration resistance.

- ASTM D822/D822M: Standard practice for filtered open-flame carbon-arc exposures of paint and related coatings [76] and ASTM D4587: Standard practice for fluorescent UV-condensation exposures of paint and related coating [88]. These practices can be used in the evaluation of the accelerated weathering resistance of concrete sealers or coatings.

- ASTM C672/C672M: Standard test method for scaling resistance of concrete surfaces exposed to de-icing chemicals [73]. This test, commonly known as salt scaling test, is carried out to determine the salt scaling resistance of treated and untreated concretes.

- ASTM B117: Standard practice for operating salt spray (fog) apparatus [77]. This practice can be used in determining the salt spray resistance of untreated and treated concretes.

- ASTM C642: Standard test method for density, absorption and voids in hardened concrete [74], ASTM D4585/D4585M: Standard practice for testing water resistance of coatings using controlled condensation [89], and ASTM D6489: Standard test method for determining the water absorption of hardened concrete treated with a water-repellent coating [90]. The test methods given in these ASTM standards can be used to determine the water penetration resistance of treated and untreated concretes.

- ASTM D1653: Standard test methods for water vapor transmission of organic coating films [91] and ASTM E96/E96M: Standard test methods for water vapor transmission of materials [92]. These test methods are used to determine the water vapor transmission capacity of sealer or coating systems installed on concrete substrates.

- ASTM D3273: Standard test method for resistance to growth of mold on the surface of interior coating in an environmental chamber [93] and ASTM D3274: Standard test method for evaluating degree of surface disfigurement of paint films by microbial (fungal and algal) growth or soil and dirt accumulation [94]. These tests can be performed to determine the resistance of treated and untreated concretes to microbial growth such as mold and moss growths.

- ASTM D4541: Standard test method for pull-off strength of coatings using portable adhesion testers [95]. This test is conducted to examine the adhesion or bond strength of coatings installed on concrete substrates.

- ASTM D2794: Standard test method for resistance of coatings to the effects of rapid deformation (impact) [96]. This test can be used to determine the impact resistance of coatings installed on concrete surfaces.

- ASTM D1654: Standard test method for evaluation of painted or coated specimens subjected to corrosive environments [97]. This test can be carried out to evaluate the basic corrosion performance (the blistering and loss of adhesion associated with corrosion) of coatings installed on concrete substrates.

4. Recommendations for Improved Performance of Sealer and Coating Systems

- Consider the following characteristics while selecting sealer or coating products for installation on concrete surface: (a) the ability to seal or coat new, old, or previously sealed/coated surface; (b) the capability to reduce or eliminate the ingress of moisture and chlorides; (c) the ability to transmit the moisture vapor from concrete (breathability); (d) salt scaling resistance; (e) chemical resistance; (f) the resistance to degradation from UV rays; (g) the penetration into concrete surface, and (h) the ability to provide good skid resistance.

- Before applying sealer or coating products on concrete substrates, (a) ensure that the new concrete is at least 28 days old; (b) remove contaminants (form oil, curing compound, grease, rubber, etc.) from concrete surfaces; (c) replace the defective surface layer of concrete with high quality mortar or concrete; (d) prepare a rough surface profile by abrasive-blasting, shot-blasting, or high pressure water-blasting as recommended by the manufacture for good adhesion of the coating and better penetration of the penetrating sealer through open surface pores; (e) repair cracks existing on concrete surfaces according to industry standards; (f) condition the prepared concrete substrate in accordance with the manufacture’s requirement; (g) use spray gun, roller, squeegee, brush, or broom as required by the manufacturer to apply the coating with the recommended coverage rate; and (h) consider a surface flooding or spraying technique to apply the penetrating sealer with the coverage rate as recommended by the manufacturer.

- Avoid using the more aggressive de-icing or anti-icing chemicals if possible; when applying the solution of de-icing or anti-icing chemicals, use the lowest possible concentration to lessen the degree of chemical attacks.

- Before installing sealer or coating systems on concrete substrates, examine (a) adhesion or bond strength; (b) scaling resistance to freeze-thaw and wet–dry cycles in the presence of de-icing or anti-icing chemicals; (c) water absorption; (d) moisture vapor transmission; and (e) chloride ion penetration resistance.

5. Conclusions

- Different forms of concrete damage, such as scaling, popout, map cracking, delamination, corrosion-induced cracking, spalling, drying shrinkage cracking, mold and moss growths, rust and salt stains, and discoloration occur in field conditions, depending on the nature and degree of exposure.

- Freezing and thawing cycles cause scaling, popout, delamination, and internal frost damage in concrete; these phenomena are intensified when water penetrates the concrete surface and remains in the pore structure of concrete.

- De-icing or anti-icing chemicals cause significant damage to concrete surfaces in the form of scaling and salt stains; they also aggravate the corrosion of steel reinforcement, resulting in cracking, spalling and rust stains in concrete.

- Concrete damage is considerably reduced when sealers or coatings are applied on concrete surfaces because they substantially decrease the infiltration of deleterious agents such as chlorides and carbon dioxide into concrete.

- Sealer and coating systems significantly lessen the ingress of water, which is essential for many damage mechanisms; in addition, many sealer and coating products enhance the transmission of water vapor from concrete upon drying and thus minimize the damaging effect of freeze-thaw cycles.

- Sealer and coating products perform better when they are applied on the concrete substrate with an adequate film thickness and possess good adhesion with concrete surfaces.

- Proper selection of products, appropriate surface preparation, use of less aggressive de-icing or anti-icing chemicals, and accurate evaluation before application will help to improve the performance of concrete sealer and coating systems in field conditions.

Acknowledgments

Conflicts of Interest

References

- Wittmann, F.H.; Zhao, T.; Zhang, P.; Jiang, F. Service life of reinforced concrete structures under combined mechanical and environmental loads. In 2nd International Symposium on Service Life Design for Infrastructure (Pro070); van Breugel, K., Ye, G., Yuan, Y., Eds.; RILEM Publications SARL: Paris, France, 2010; pp. 91–98. [Google Scholar]

- Bonić, Z.; Curčić, G.T.; Davidović, N.; Savić, J. Damage of concrete and reinforcement of reinforced-concrete foundations caused by environmental effects. Procedia Eng. 2015, 117, 411–418. [Google Scholar] [CrossRef]

- Berkowski, P.; Kosior-Kazberuk, M. Material and structural destruction of concrete elements in the industrial environment. Procedia Eng. 2017, 172, 96–103. [Google Scholar] [CrossRef]

- Types and Causes of Concrete Deterioration; Concrete Information, PCA R&D Serial No. 2617; Portland Cement Association (PCA): Skokie, IL, USA, 2002; p. 16.

- Pan, X.; Shi, Z.; Shi, C.; Ling, T.-C.; Li, N. A review on surface treatment for concrete—Part 2: Performance. Constr. Build. Mater. 2017, 133, 81–90. [Google Scholar] [CrossRef]

- Pan, X.; Shi, Z.; Shi, C.; Ling, T.-C.; Li, N. A review on concrete surface treatment Part I: Types and mechanisms. Constr. Build. Mater. 2017, 132, 578–590. [Google Scholar] [CrossRef]

- Litvan, G.G. The effect of sealers on the freeze-thaw resistance of mortar. Cem. Concr. Res. 1992, 22, 1141–1147. [Google Scholar] [CrossRef]

- McCarter, W.J. Assessing the protective qualities of treated and untreated concrete surfaces under cyclic wetting and drying. Build. Environ. 1996, 31, 551–556. [Google Scholar] [CrossRef]

- Scherer, G.W.; Valenza, J.J. Mechanisms of frost damage. In Materials Science of Concrete; American Ceramic Society: Westerville, OH, USA, 2005; Volume 3, pp. 209–246. [Google Scholar]

- Darwin, D.; Browning, J.; Gong, L.; Hughes, S.R. Effects of Deicers on Concrete Deterioration. In A Report on Research Sponsored by the Structural Engineering and Materials Laboratory; University of Kansas (SL Report 07–3); The University of Kansas Center for Research, Inc.: Lawrence, KS, USA, 2007. [Google Scholar]

- Darwin, D.; Browning, J.; Gong, L.; Hughes, S.R. Effects of deicers on concrete deterioration. ACI Mater. J. 2008, 105, 622–627. [Google Scholar]

- Hooton, R.D.; Julio-Betancourt, G.A. Investigation of the Effects of Various Deicing Chemicals, Curing Methods, and Concrete Placement on Salt Scaling Resistance of Concrete Surface; Final Report to Ready Mixed Concrete Association of Ontario; University of Toronto: Toronto, ON, Canada, 2005. [Google Scholar]

- Julio-Betancourt, G.A. Effect of De-icer and Anti-icer Chemicals on the Durability, Microstructure, and Properties of Cement-Based Materials. Ph.D. Thesis, University of Toronto, Toronto, ON, Canada, 2009. [Google Scholar]

- Kozikowski, R.L.; Taylor, P.C.; Pyc, W.A. Evaluation of Potential Concrete Deterioration Related to Magnesium Chloride (MgCl2) Deicing Salts; PCA R&D Serial No. 2770; Portland Cement Association (PCA): Skokie, IL, USA, 2007. [Google Scholar]

- Sutter, L.L.; Peterson, K.; Julio-Betancourt, G.; Hooton, D.; van dam, T.J.; Smith, K. The Deleterious Chemical Effects of Concentrated Deicing Solutions on Portland Cement Concrete. Study SD 2002-01 Implementation Guide; Michigan Tech Transportation Institute: Houghton, MI, USA, 2008. [Google Scholar]

- Seneviratne, A.M.G.; Sergi, G.; Page, C.L. Performance characteristics of surface coatings applied to concrete for control of reinforcement corrosion. Constr. Build. Mater. 2000, 14, 55–59. [Google Scholar] [CrossRef]

- Soudki, K.A.; Safiuddin, M.D.; Jeffs, P.; MacDonald, G.; Kroker, M. Chloride penetration resistance of concrete sealer and coating systems. J. Civil Eng. Manag. 2015, 21, 492–502. [Google Scholar] [CrossRef]

- Soudki, K.A.; Jeffs, P.; Safiuddin, M.D. Chloride Penetration Resistance of Concrete Coating Systems on Region of Waterloo Bridges; Final Research Report Submitted to the Region of Waterloo; Department of Civil and Environmental Engineering, Faculty of Engineering, University of Waterloo: Waterloo, ON, Canada, 2012. [Google Scholar]

- Dang, Y.; Xie, N.; Kessel, A.; McVey, E.; Pace, A.; Shi, X. Accelerated laboratory evaluation of surface treatments for protecting concrete bridge decks from salt scaling. Constr. Build. Mater. 2014, 55, 128–135. [Google Scholar] [CrossRef]

- Pigeon, M.; Talbot, C.; Marchand, J.; Hornain, H. Surface microstructure and scaling resistance of concrete. Cem. Concr. Res. 1996, 26, 1555–1566. [Google Scholar] [CrossRef]

- Al-Dulaijan, S.U.; Maslehuddin, M.; Al-Zahrani, M.M.; Al-Juraifani, E.A.; Al-Idi, S.H.; Al-Mehthel, M. Performance evaluation of cement-based surface coatings. In Repair, Rehabilitation, and Maintenance of Concrete Structures, and Innovations in Design and Construction, Proceedings of the ACI Fourth International Conference (ACI SP-193), Seoul, Korea, 19–22 September 2000; American Concrete Institute: Detroit, MI, USA, 2000; pp. 321–335. [Google Scholar]

- Almusallam, A.A.; Khan, F.M.; Dulaijan, S.U.; Al-Amoudi, O.S.B. Effectiveness of surface coatings in improving concrete durability. Cem. Concr. Compos. 2003, 25, 473–481. [Google Scholar] [CrossRef]

- Ibrahim, M.; Al-Gahtani, A.S.; Maslehuddin, M.; Dakhil, F.H. Use of surface treatment materials to improve concrete durability. ASCE J. Mater. Civ. Eng. 1999, 11, 36–40. [Google Scholar] [CrossRef]

- Jones, M.R.; Dhir, R.K.; Gill, J.P. Concrete surface treatment: Effect of exposure temperature on chloride diffusion resistance. Cem. Concr. Res. 1995, 25, 197–208. [Google Scholar] [CrossRef]

- Moon, H.Y.; Shin, D.G.; Choi, D.S. Evaluation of the durability of mortar and concrete applied with inorganic coating material and surface treatment system. Constr. Build. Mater. 2007, 21, 362–369. [Google Scholar] [CrossRef]

- Oshiro, T.; Tanigawa, S. Effect of surface coatings on the durability of concrete exposed to marine environment. In Concrete in Marine Environment, Proceedings of the Second International Conference on Concrete in Marine Environment (ACI SP-109), Okinawa, Japan, 21–26 August 1988; American Concrete Institute: Detroit, Michigan, USA, 1988; pp. 179–198. [Google Scholar]

- Porter, L.C. Some surface treatments increase concrete durability. In Durability of Concrete (ACI SP-47); American Concrete Institute: Detroit, MI, USA, 1975; pp. 211–232. [Google Scholar]

- Safiuddin, Md.; Soudki, K.A. Water vapor transmission and waterproofing performance of concrete sealer and coating systems. J. Civ. Eng. Manag. 2015, 21, 837–844. [Google Scholar] [CrossRef]

- Song, Z.; Xue, X.; Li, Y.; Yang, J.; He, Z.; Shen, S.; Jiang, L.; Zhang, W.; Xu, L.; Zhang, H.; et al. Experimental exploration of the waterproofing mechanism of inorganic sodium silicate-based concrete sealers. Constr. Build. Mater. 2016, 104, 276–283. [Google Scholar] [CrossRef]

- Shields, M.A.; Leek, D.S.; Lambert, P. Coatings for the protection of structural materials. Constr. Maint. Repair 1992, 6, 2–9. [Google Scholar]

- Suleiman, A.R.; Soliman, A.M.; Nehdi, M.L. Effect of surface treatment on durability of concrete exposed to physical sulfate attack. Constr. Build. Mater. 2014, 73, 674–681. [Google Scholar] [CrossRef]

- Ho, D.W.S.; Harrison, R.S. Influence of surface coatings on carbonation of concrete. ASCE J. Mater. Civ. Eng. 1990, 2, 35–44. [Google Scholar] [CrossRef]

- Zhou, Y.; Gencturk, B.; William, K.; Attar, A. Carbonation-induced and chloride-induced corrosion in reinforced concrete structures. ASCE J. Mater. Civ. Eng. 2015, 27, 04014245. [Google Scholar] [CrossRef]

- Palle, S.; Hopwood, T., Jr. Coatings, Sealants and Fillers to Address Bridge Concrete Deterioration and Aesthetics—Phase 1; Research Report No. KTC06-36/SPR 291-04-1F; Kentucky Transportation Center, College of Engineering, University of Kentucky: Lexington, KY, USA, 2006; p. 26. [Google Scholar]

- Wenzlick, J.D. Bridge Deck Concrete Sealers; Final Research Report RI 04-051; Missouri Department of Transportation: Jefferson City, MO, USA, 2007. [Google Scholar]

- Attanayaka, A.M.U.B.; Duyar, O.; Liang, X.; Aktan, H.M.; Ng, K.Y.S. Fundamentals of use of penetrating sealants for concrete bridge deck protection. In Proceedings of the TRB 2003 Annual Meeting, Washington, DC, USA, 12–16 January 2003. [Google Scholar]

- Cady, P.D. Sealers for Portland Cement Concrete Highway Facilities; NCHRP Synthesis of Highway Practice 209; Transportation Research Board (TRB), National Research Council: Washington, DC, USA, 1994. [Google Scholar]

- Pritzl, M.D.; Tabatabai, H.; Ghorbanpoor, A. Long-term chloride profiles in bridge decks treated with penetrating sealer or corrosion inhibitors. Constr. Build. Mater. 2015, 101, 1037–1046. [Google Scholar] [CrossRef]

- Filice, J.; Wong, J. Best Practice Guidelines for Selecting Concrete Bridge Deck Sealers; Alberta Transportation and Utilities: Edmonton, AB, Canada, 2001. [Google Scholar]

- Valenza, J.J.; Scherer, G.W. A review of salt scaling: II. Mechanisms. Cem. Concr. Rese. 2007, 37, 1022–1034. [Google Scholar] [CrossRef]

- Thomas, M.D.A. Optimizing the Use of Fly Ash in Concrete; Portland Cement Association (PCA): Skokie, IL, USA, 2007; p. 24. [Google Scholar]

- Wu, Z.; Shi, C.; Gao, P.; Wang, D.; Cao, Z. Effects of deicing salts on the scaling resistance of concrete. ASCE J. Mater. Civ. Eng. 2015, 27, 04014160. [Google Scholar] [CrossRef]

- Bei, S.; Zhixiang, L. Investigation on spalling resistance of ultra-high-strength concrete under rapid heating and rapid cooling. Case Stud. Constr. Mater. 2016, 4, 146–153. [Google Scholar] [CrossRef]

- Portland Cement Association (PCA). Control of air content in concrete. Concr. Technol. Today 1998, 19, 1–3. [Google Scholar]

- Concrete Slab Surface Defects: Causes, Prevention, Repair. Concrete Information; PCA R&D Serial No. 2155; Portland Cement Association (PCA): Skokie, IL, USA, 2001; p. 16.

- EKström, J.; Rempling, R.; Plos, M. Spalling in concrete subjected to shock wave blast. Eng. Struct. 2016, 122, 72–82. [Google Scholar] [CrossRef]

- Delamination of Troweled Concrete Surfaces (CIP-20); National Ready Mixed Concrete Association (NRMCA): Silver Spring, MD, USA, 2004; p. 2.

- Larosche, C.J. Types and causes of cracking in reinforced concrete. In Failure, Distress, and Repair of Concrete Structures; Delatte, N., Ed.; Woodhead Publishing Limited: Cambridge, UK, 2009; pp. 57–83. [Google Scholar]

- Bentz, D.P.; Weiss, W.J. Internal Curing: A 2010 State-of-the Art Review; NISTIR 7765; National Institute of Standards and Technology: Gaithersburg, MD, USA, 2011; p. 82. [Google Scholar]

- Crazing Concrete Surfaces (CIP-3); National Ready Mixed Concrete Association (NRMCA): Silver Spring, MD, USA, 2009; p. 2.

- Melchers, R.E.; Li, C.Q. Reinforcement corrosion initiation and activation times in concrete structures exposed to severe marine environments. Cem. Concr. Res. 2009, 39, 1068–1076. [Google Scholar] [CrossRef]

- Pruckner, F.; Gjørv, O.E. Effect of CaCl2 and NaCl additions on concrete corrosivity. Cem. Concr. Res. 2004, 34, 1209–1217. [Google Scholar] [CrossRef]

- Saremi, M.; Mahallati, E. A study on chloride-induced depassivation of mild steel in simulated concrete pore solution. Cem. Concr. Res. 2002, 32, 1915–1921. [Google Scholar] [CrossRef]

- Alonso, C.; Andrade, C.; Rodriguez, J.; Diez, J.M. Factors controlling cracking of concrete affected by reinforcement corrosion. Mater. Struct. 1998, 31, 435–441. [Google Scholar] [CrossRef]

- Liu, Y.; Weyers, R.E. Modeling the time-to-corrosion cracking in chloride contaminated reinforced concrete structures. ACI Mater. J. 1998, 95, 675–681. [Google Scholar]

- Allan, M.L. Probability of corrosion induced cracking in reinforced concrete. Cem. Concr. Res. 1995, 25, 1179–1190. [Google Scholar] [CrossRef]

- Cabrera, J.G. Deterioration of concrete due to reinforcement steel corrosion. Cem. Concr. Compos. 1996, 18, 47–59. [Google Scholar] [CrossRef]

- Chi, J.M.; Huang, R.; Yang, C.C. Effects of carbonation on mechanical properties and durability of concrete using accelerated testing method. J. Mar. Sci. Technol. 2002, 10, 14–20. [Google Scholar]

- Safiuddin, M.D. Performance of galvanized steel reinforcing bars against corrosion in concrete. BRAC Univ. J. 2005, 2, 93–102. [Google Scholar]

- Pietrosanto, J. Rust Coloured Stains on the Surface of Exposed Aggregate Concrete; Vic Mix, TJM Operations Pty Ltd.: Victoria, Australia, 2010; p. 6. [Google Scholar]

- Wong, H.S.; Zhao, Y.X.; Karimi, A.R.; Buenfeld, N.R.; Jin, W.L. Rust distribution in corrosion-induced cracking concrete. In Steel Corrosion-Induced Concrete Cracking; Butterworth Heinemann: Oxford, UK, 2016; pp. 93–109. [Google Scholar]

- Soudki, K.A.; Jeffs, P.; Safiuddin, M.D. Concrete Coating Systems on Region of Waterloo Bridges; Final Research Report Submitted to the Region of Waterloo; Department of Civil and Environmental Engineering, Faculty of Engineering, University of Waterloo: Waterloo, ON, Canada, 15 December 2011. [Google Scholar]

- Discoloration (CIP-23); National Ready Mixed Concrete Association (NRMCA): Silver Spring, MD, USA, 2007; p. 2.

- Cwalina, B. Biodeterioration of concrete, brick and mineral-based building materials. In Understanding Biocorrosion: Fundamentals and Applications; Woodhead Publishing Limited: Cambridge, UK, 2014; pp. 281–312. [Google Scholar]

- Annila, P.J.; Hellemaa, M.; Pakkala, T.A.; Lahdensivu, J.; Suonketo, J.; Pentti, M. Extent of moisture and mould damage in structures of public building. Case Stud. Constr. Mater. 2017, 6, 103–108. [Google Scholar] [CrossRef]

- Thompson, J.L.; Silsbee, M.R.; Gill, P.M.; Scheetz, B.E. Characterization of silicate sealers on concrete. Cem. Concr. Res. 1997, 27, 1561–1567. [Google Scholar] [CrossRef]

- Safiuddin, Md.; Soudki, K.A. Sealer and coating systems for the protection of bridge structures. Int. J. Phys. Sci. 2011, 6, 8188–8199. [Google Scholar] [CrossRef]

- Nair, P.S.; Gettu, R. Commercially available waterproofing agents in India: A review. Indian Concr. J. 2016, 90, 36–53. [Google Scholar]

- Ameri, M.; Behnood, A. Laboratory studies to investigate the properties of CIR mixes containing steel slag as a substitute for virgin aggregates. Constr. Build. Mater. 2012, 26, 475–480. [Google Scholar] [CrossRef]

- Behnood, A.; Gharehveran, M.M.; Asl, F.G.; Ameri, M. Effects of copper slag and recycled concrete aggregate on the properties of CIR mixes with bitumen emulsion, rice husk ash, Portland cement, and fly ash. Constr. Build. Mater. 2015, 96, 172–180. [Google Scholar] [CrossRef]

- Basheer, P.A.M.; Basheer, L.; Cleland, D.J.; Long, A.E. Surface treatments for concrete: Assessment methods and reported performance. Constr. Build. Mater. 1997, 11, 413–429. [Google Scholar] [CrossRef]

- Garbacz, A.; Courard, L.; Bissonnette, B. A surface engineering approach applicable to concrete repair engineering. Bull. Pol. Acad. Sci. Tech. Sci. 2013, 61, 73–84. [Google Scholar] [CrossRef]

- ASTM C672/C672M Standard Test Method for Scaling Resistance of Concrete Surfaces Exposed to De-icing Chemicals; ASTM International: West Conshohocken, PA, USA, 2012.

- ASTM C642 Standard Test Method for Density, Absorption and Voids in Hardened Concrete; ASTM International: West Conshohocken, PA, USA, 2013.

- AASHTO T259 Standard Method of Test for Resistance of Concrete to Chloride Ion Penetration; American Association of State Highway and Transportation Officials: Washington, DC, USA, 2002.

- ASTM D822/D822M Standard Practice for Filtered Open-Flame Carbon-Arc Exposures of Paint and Related Coatings; ASTM International: West Conshohocken, PA, USA, 2013.

- ASTM B117 Standard Practice for Operating Salt Spray (Fog) Apparatus; ASTM International: West Conshohocken, PA, USA, 2016.

- Test Procedure for Measuring the Vapour Transmission, Waterproofing and Hiding Power of Concrete Sealers (BT001); Technical Standards Branch, Alberta Transportation and Utilities (ATU): Edmonton, Alberta, Canada, 2000.

- Test Procedure for Measuring the Waterproofing Performance of Core Samples Taken from Sealed Concrete Surfaces (BT005); Technical Standards Branch, Alberta Transportation and Utilities (ATU): Edmonton, AB, Canada, 2000.

- AASHTO T161 Standard Method of Test for Resistance of Concrete to Rapid Freezing and Thawing; American Association of State Highway and Transportation Officials: Washington, DC, USA, 2008.

- ASTM C666/C666M Standard Test Method for Resistance of Concrete to Rapid Freezing and Thawing; ASTM International: West Conshohocken, PA, USA, 2015.

- ASTM D2243 Standard Test Method for Freeze-Thaw Resistance of Water-Borne Coatings; ASTM International: West Conshohocken, PA, USA, 2014.

- AASHTO T260 Sampling and Testing for Chloride Ion in Concrete and Concrete Raw Materials; American Association of State Highway and Transportation Officials: Washington, DC, USA, 2016.

- AASHTO T277 Standard Method of Test for Electrical Indication of Concrete’s Ability to Resist Chloride Ion Penetration; American Association of State Highway and Transportation Officials: Washington, DC, USA, 2015.

- ASTM C1152/C1152M Standard Test method for Acid-Soluble Chloride in Mortar and Concrete; ASTM International: West Conshohocken, PA, USA, 2012.

- ASTM C1202 Standard Test Method for Electrical Indication of Concrete’s Ability to Resist Chloride Ion Penetration; ASTM International: West Conshohocken, PA, USA, 2012.

- ASTM C1543 Standard Test Method for Determining the Penetration of Chloride Ion into Concrete by Ponding; ASTM International: West Conshohocken, PA, USA, 2010.

- ASTM D4587 Standard Practice for Fluorescent UV-Condensation Exposures of Paint and Related Coating; ASTM International: West Conshohocken, PA, USA, 2011.

- ASTM D4585/D4585M Standard Practice for Testing Water Resistance of Coatings using Controlled Condensation; ASTM International: West Conshohocken, PA, USA, 2013.

- ASTM D6489 Standard Test Method for Determining the Water Absorption of Hardened Concrete Treated with a Water-Repellent Coating; ASTM International: West Conshohocken, PA, USA, 2012.

- ASTM D1653 Standard Test Methods for Water Vapor Transmission of Organic Coating Films; ASTM International: West Conshohocken, PA, USA, 2013.

- ASTM E96/E96M Standard Test Methods for Water Vapor Transmission of Materials; ASTM International: West Conshohocken, PA, USA, 2016.

- ASTM D3273 Standard Test Method for Resistance to Growth of Mold on the Surface of Interior Coating in an Environmental Chamber; ASTM International: West Conshohocken, PA, USA, 2016.

- ASTM D3274 Standard Test Method for Evaluating Degree of Surface Disfigurement of Paint Films by Microbial (Fungal and Algal) Growth or Soil and Dirt Accumulation; ASTM International: West Conshohocken, PA, USA, 2013.

- ASTM D4541 Standard Test Method for Pull-off Strength of Coatings Using Portable Adhesion Testers; ASTM International: West Conshohocken, PA, USA, 2009.

- ASTM D2794 Standard Test Method for Resistance of Coatings to the Effects of Rapid Deformation (Impact); ASTM International: West Conshohocken, PA, USA, 2010.

- ASTM D1654 Standard Test Method for Evaluation of Painted or Coated Specimens Subjected to Corrosive Environments; ASTM International: West Conshohocken, PA, USA, 2016.

| Specific Factor | Consideration |

|---|---|

| Type of concrete substrate and its surface condition | Old or new concrete; any prior treatment, roughness, and contamination of concrete surface |

| Nature of exposure | Atmospheric, marine, or buried environment; presence of moisture, pollutants, and aggressive chemicals |

| Type of concrete protection | Protection from abrasion, acid or chemical attack, alkali–silica reaction, alkali–carbonate reaction, carbonation, chloride attack, freezing and thawing, wetting and drying, salt scaling, sulfate attack, and water ingress |

| Expected durability of sealers or coatings | Abrasion resistance, adhesion strength, chemical resistance, color retention, elasticity, film hardness, impact resistance, moisture vapor transmission, toxicity, UV resistance, and water resistance |

| Service condition | Skid resistance, load-bearing or non-load-bearing condition, and hydrostatic or air pressure |

| Installation of sealers or coatings | Methods of installation, surface preparation, influence of temperature, effect of substrate moisture, and location of site |

| Surface treatment costs | Coverage rate or required number of coats, film thickness, labor cost, material cost, and maintenance cost |

| Method | Property | Performance Criteria |

|---|---|---|

| Freeze-thaw/salt scaling resistance test as per ASTM C672/C672M [73] | Scaling resistance of concrete exposed to de-icing salts under freezing and thawing cycles | No visible damage (rating “0”) after 50 freeze-thaw cycles, rating “0”—no scaling after 100 cycles, and rating of 1 lower than that of untreated concrete surface in the case of scaling |

| Water absorption test based on cold water saturation technique given in ASTM C642 [74] | Water absorption (wt. %) as an indicator of concrete durability | Maximum 1% after 48 h and maximum 2% after 50 days |

| Chloride ion penetration test based on ponding technique given in AASHTO T259 [75] | Penetrated chloride value as an indicator of the corrosion resistance of concrete | 0.451–0.593 kg/m3 at 12.7–25.4 mm (0.76–1.0 pcy at 0.50–1.0 in.) depth after 90 days of ponding |

| Accelerated weathering test as per ASTM D822/D822M [76] | Weathering resistance of concrete | Slight color change on concrete surface |

| Salt spray resistance test according to ASTM B117 [77] | Adhesion or bond strength | No loss of adhesion after 300 freeze-thaw cycles |

| Electrical resistance test by Two-pin mode soil resistance meter | Electrical resistance of concrete | >200–400 kΩ |

| Sealer or Coating Type | Minimum Waterproofing Performance * (as Compared to Unsealed or Uncoated Specimens) | Minimum Vapor Transmission (as Compared to Unsealed or Uncoated Specimens) | |

|---|---|---|---|

| Before Abrasion | After Abrasion | ||

| Penetrating sealer for concrete surfaces with a relative moisture content ≤ 55% (Type 1a) | 82.5% | 75.0% | – |

| Penetrating sealer for concrete surfaces with a relative moisture content ≤70% (Type 1b) | – | 86.0% | 70.0% |

| High performance penetrating sealer for concrete surfaces with a relative moisture content ≤80% (Type 1c) | – | 85.0% | 85.0% |

| Clear film-forming one-component sealer or coating for concrete surfaces with a relative moisture content ≤70% (Type 2a) | 82.5% | N/A | 35.0% |

| Clear film-forming two-component sealer or coating for concrete surfaces with a relative moisture content ≤70% (Type 2b) | 90.0% | N/A | 20.0% |

| Colored film-forming sealer or surface coating for concrete surfaces (Type 3) | 75.0% | N/A | 35.0% |

© 2017 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Safiuddin, M. Concrete Damage in Field Conditions and Protective Sealer and Coating Systems. Coatings 2017, 7, 90. https://doi.org/10.3390/coatings7070090

Safiuddin M. Concrete Damage in Field Conditions and Protective Sealer and Coating Systems. Coatings. 2017; 7(7):90. https://doi.org/10.3390/coatings7070090

Chicago/Turabian StyleSafiuddin, Md. 2017. "Concrete Damage in Field Conditions and Protective Sealer and Coating Systems" Coatings 7, no. 7: 90. https://doi.org/10.3390/coatings7070090

APA StyleSafiuddin, M. (2017). Concrete Damage in Field Conditions and Protective Sealer and Coating Systems. Coatings, 7(7), 90. https://doi.org/10.3390/coatings7070090