Bacterial Biofilm Characterization and Microscopic Evaluation of the Antibacterial Properties of a Photocatalytic Coating Protecting Building Material

Abstract

:1. Introduction

2. Materials and Methods

2.1. Bacterial Cultivation

2.2. Coatings and Preparation of Supports

2.2.1. Coatings

2.2.2. Nature and Preparation of Supports

Glass Slides

Polycarbonate Membranes

Cementitious Supports

2.3. Photocatalysis Activation

2.4. Evaluation of Antibacterial Activity

2.5. Development of a Bacterial Biofilm under Accelerated Conditions

2.5.1. Biofilm Nutrient Broth

2.5.2. Procedure

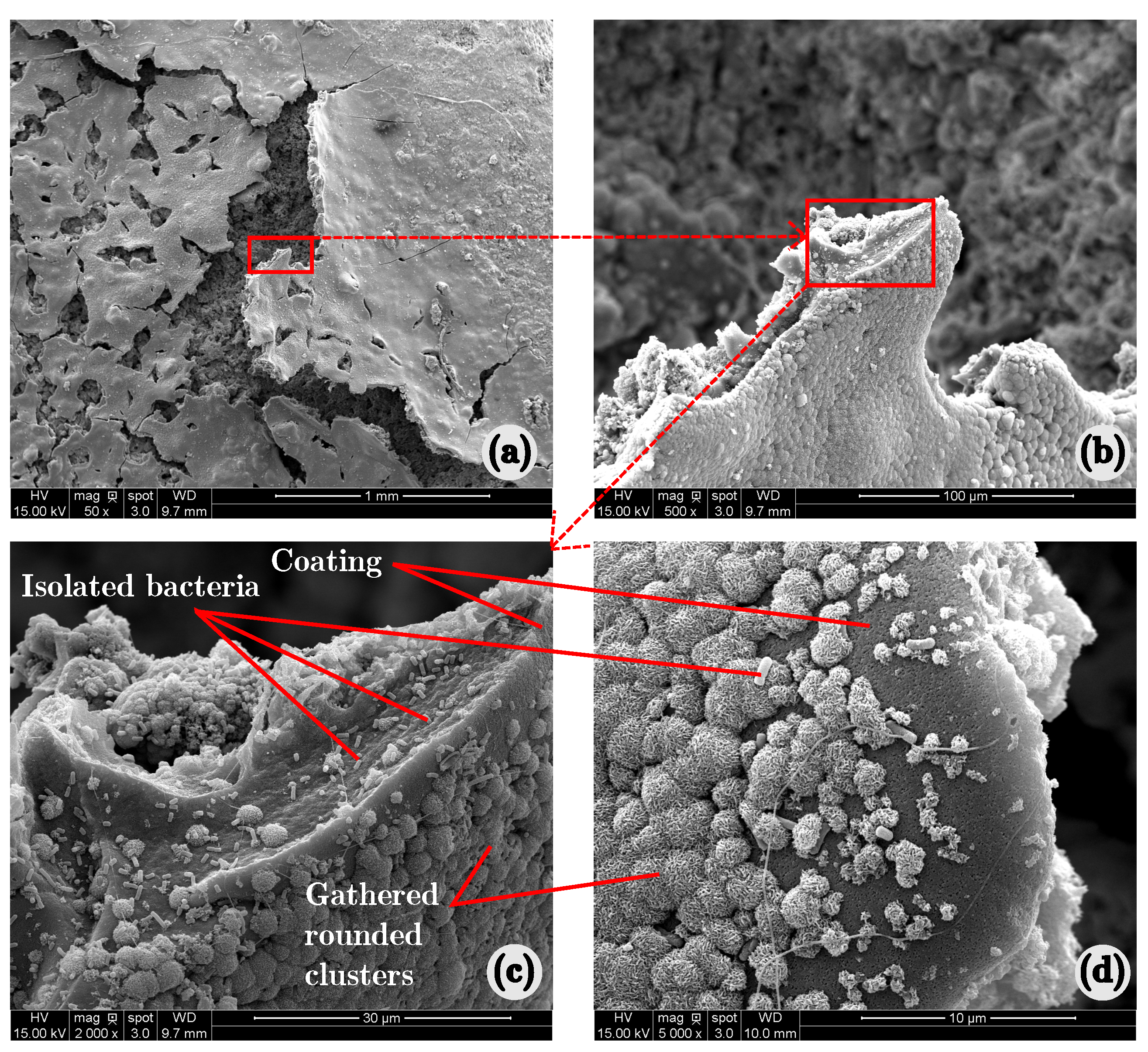

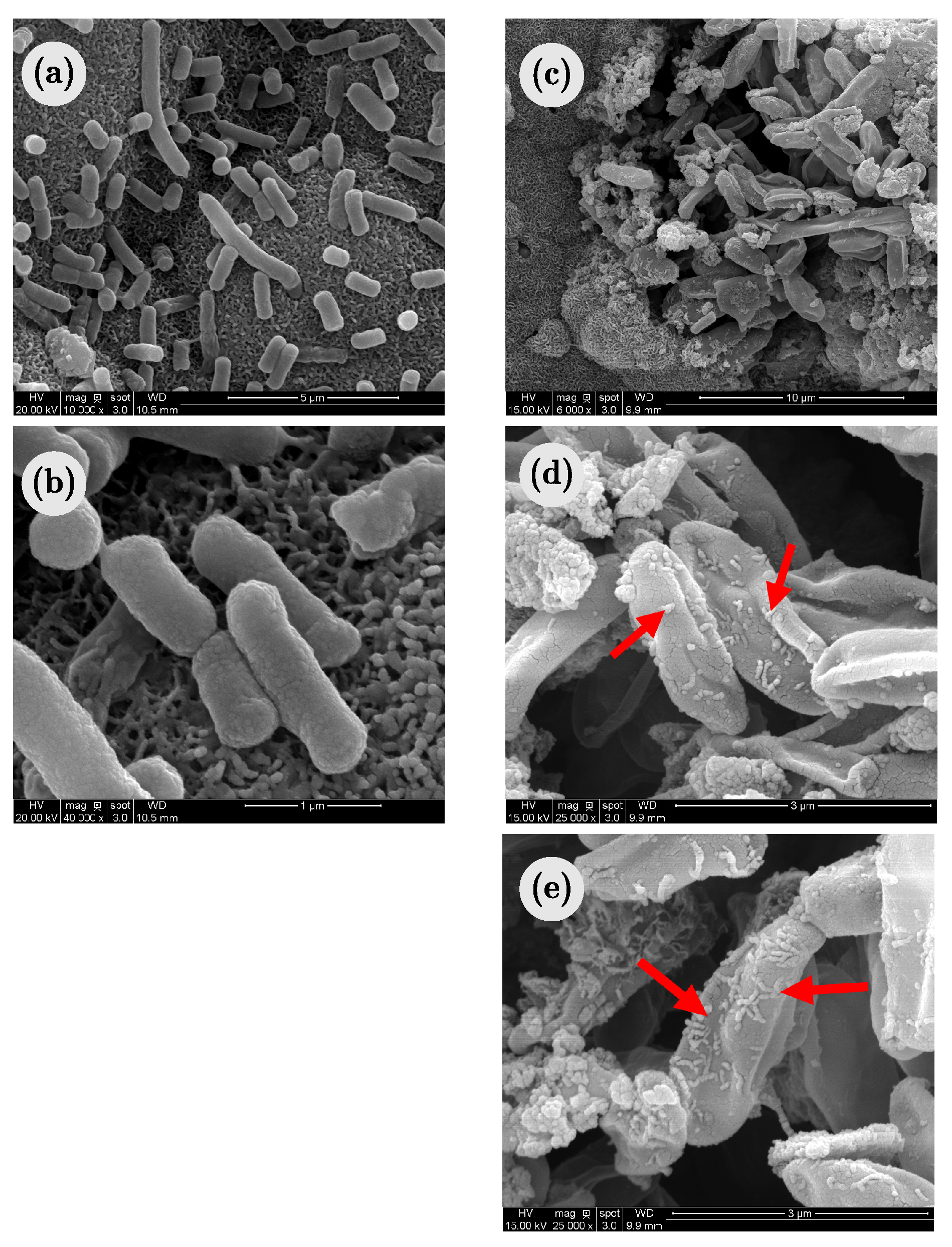

2.5.3. Scanning Electron Microscopy

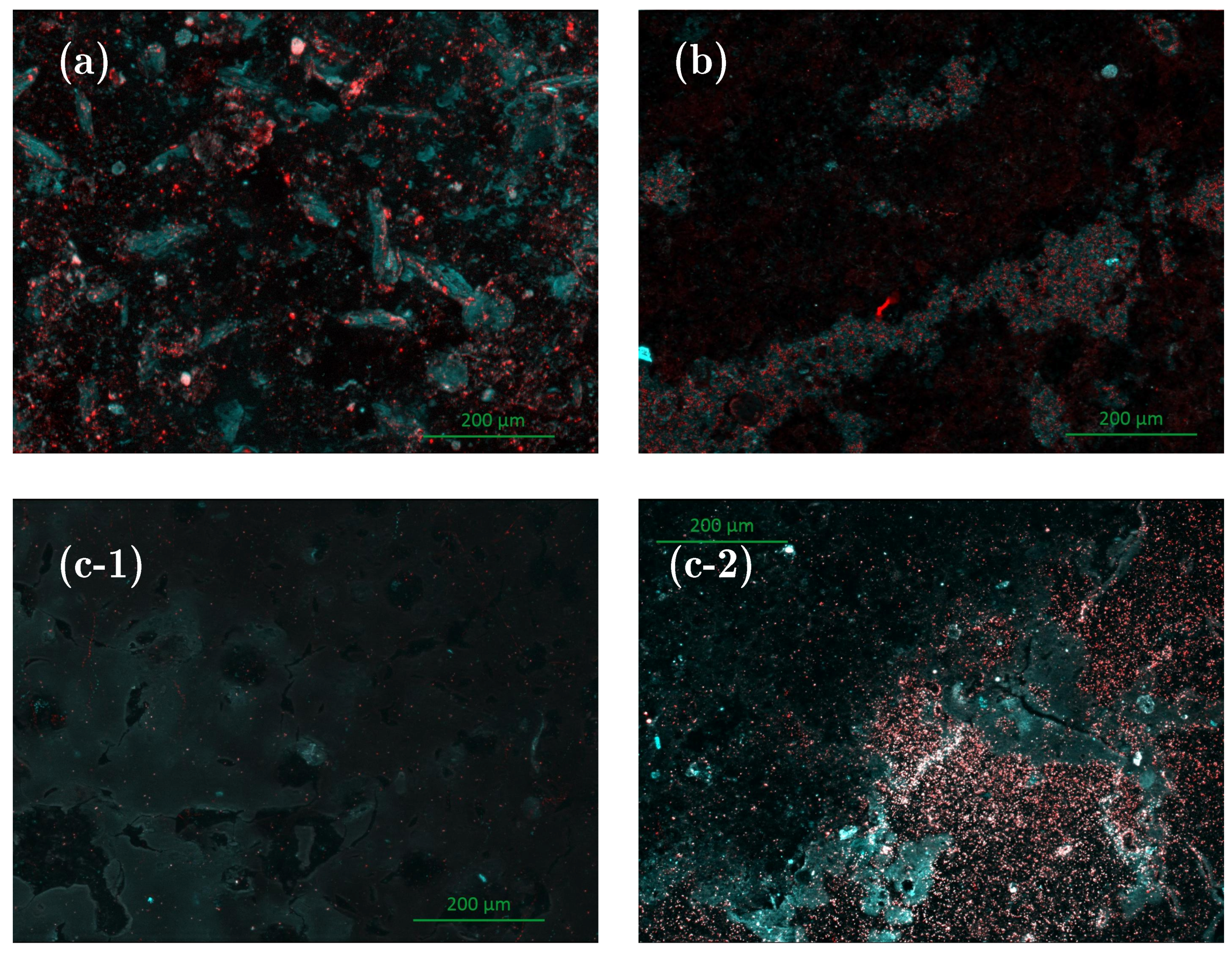

2.5.4. Epifluorescence Microscopy

3. Results and Discussions

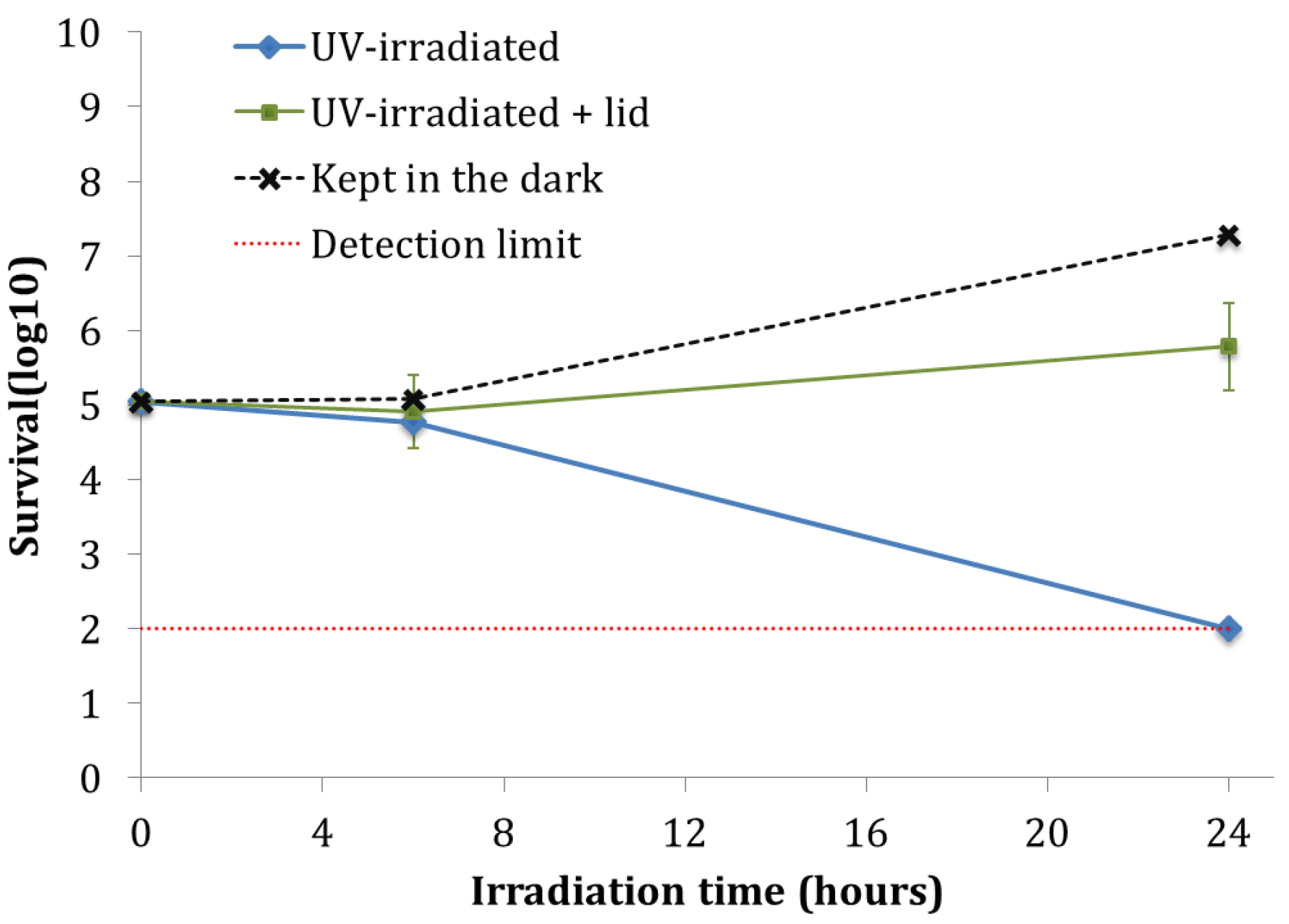

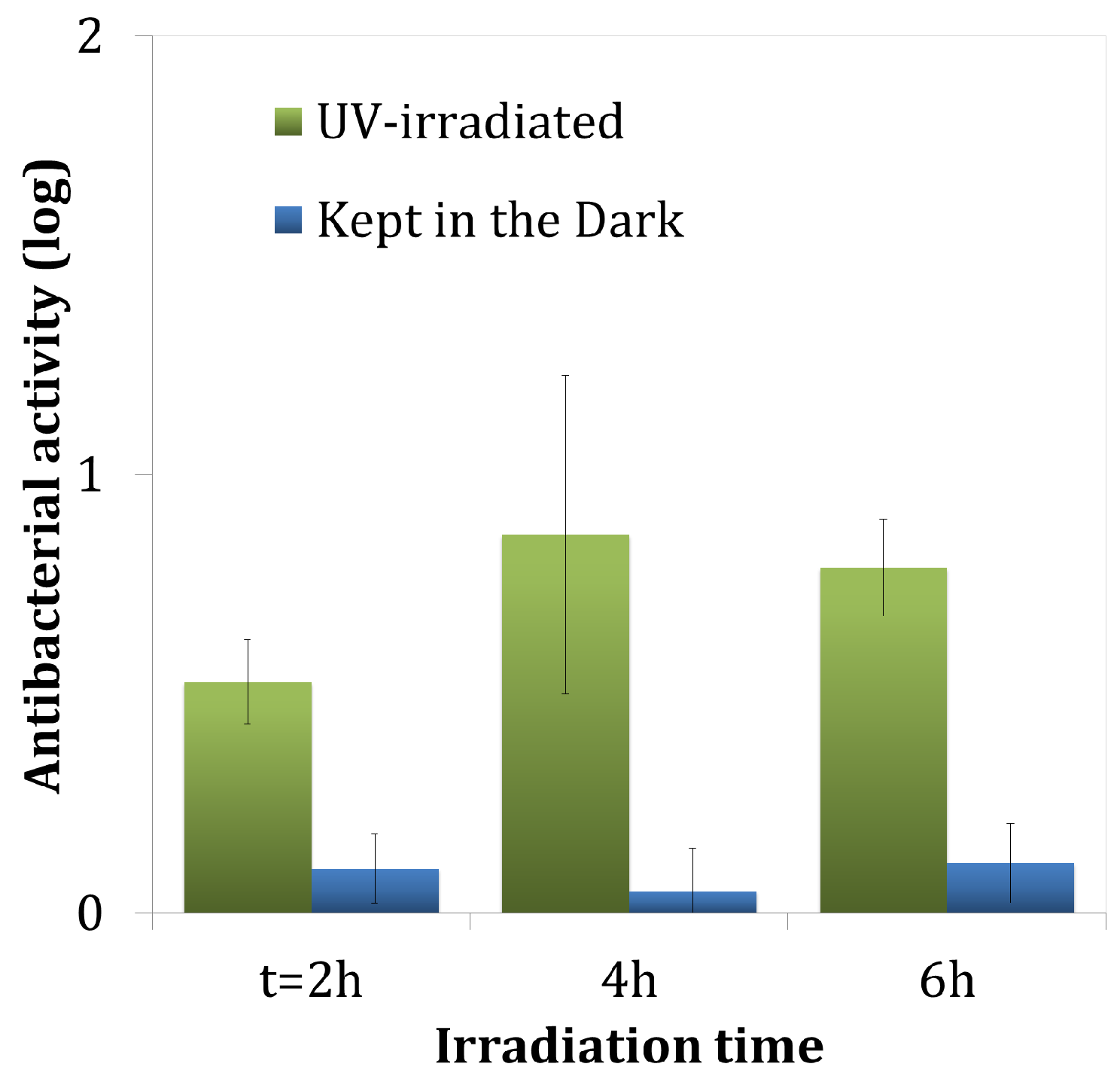

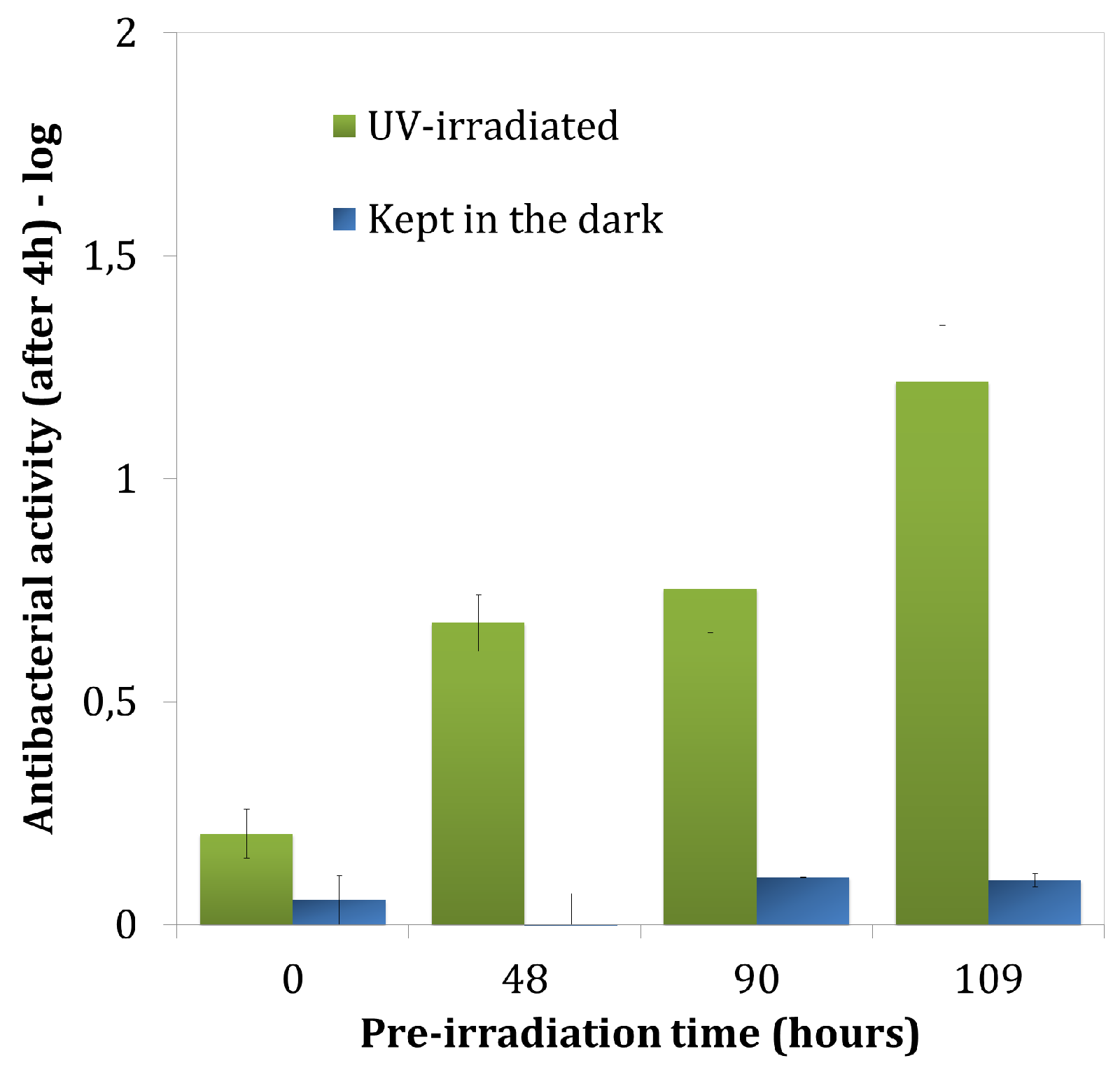

3.1. Antibacterial Activity

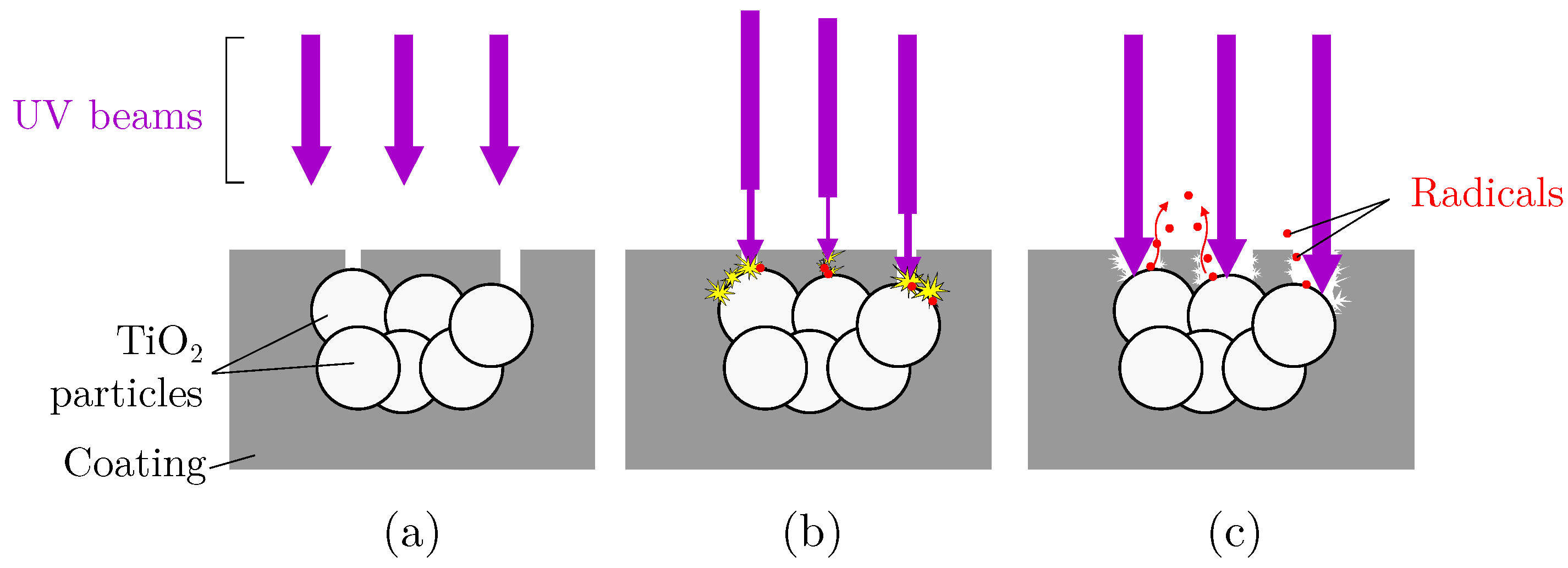

- The access of UV beams for photocatalytic activation.

- The access of the pollutants (here bacteria cells) to the particles.

- Diffusion of the reactive radicals produced by photocatalysis toward pollutants, as shown in Figure 4.

3.2. Developement of a Bacterial Biofilm under Accelerated Conditions

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Gutarowska, B.; Piotrowska, M. Methods of mycological analysis in buildings. Build. Environ. 2007, 42, 1843–1850. [Google Scholar] [CrossRef]

- Verdier, T.; Coutand, M.; Bertron, A.; Roques, C. A review of indoor microbial growth across building materials and sampling and analysis methods. Build. Environ. 2014, 80, 136–149. [Google Scholar] [CrossRef]

- Bertron, A. Understanding interactions between cementitious materials and microorganisms: A key to sustainable and safe concrete structures in various contexts. Mater. Struct. 2014, 47, 1787–1806. [Google Scholar] [CrossRef]

- Guidelines for Indoor Air Quality; WHO: Geneva, Switzerland, 2006.

- Escadeillas, G.; Bertron, A.; Blanc, P.; Dubosc, A. Accelerated testing of biological stain growth on external concrete walls. Part 1: Development of the growth tests. Mater. Struct. 2007, 40, 1061–1071. [Google Scholar] [CrossRef]

- Verdier, T.; Bertron, A.; Johansson, P. Overview of Indoor Microbial Growth on Building Materials. In Proceedings of the International RILEM Symposium on the Microorganisms-Cementitious materials Interactions (TC253-MCI), Delft, The Netherlands, 23 June 2016. [Google Scholar]

- Johansson, P.; Ekstrand-Tobin, A.; Svensson, T.; Bok, G. Laboratory study to determine the critical moisture level for mould growth on building materials. Int. Biodeterior. Biodeterior. 2012, 73, 23–32. [Google Scholar] [CrossRef]

- Pasanen, A.L. A Review: Fungal Exposure Assessment in Indoor Environments. Indoor Air 2001, 11, 87–98. [Google Scholar] [CrossRef] [PubMed]

- Warscheid, T.; Braams, J. Biodeterioration of stone: A review. Int. Biodeterior. Biodeterior. 2000, 46, 343–368. [Google Scholar] [CrossRef]

- Samson, R.; Flannigan, B.; Flannigan, M.; Verhoeff, A.; Adan, O.; Hoekstra, E. Health Implications of Fungi in Indoor Environments; Elsevier: Amsterdam, The Netherlands, 1994. [Google Scholar]

- Torvinen, E.; Meklin, T.; Torkko, P.; Suomalainen, S.; Reiman, M.; Katila, M.L.; Paulin, L.; Nevalainen, A. Mycobacteria and Fungi in Moisture-Damaged Building Materials. Appl. Environ. Microbiol. 2006, 72, 6822–6824. [Google Scholar] [CrossRef] [PubMed]

- Andersson, M.A.; Nikulin, M.; Köljalg, U.; Andersson, M.C.; Rainey, F.; Reijula, K.; Hintikka, E.L.; Salkinoja-Salonen, M. Bacteria, molds, and toxins in water-damaged building materials. Appl. Environ. Microbiol. 1997, 63, 387–393. [Google Scholar] [PubMed]

- Lacaze, I. Etude des Mécanismes de Colonisation des Produits de Construction Par les Micromycètes. Ph.D. Thesis, Microbiologie Procaryote Et Eucaryote, Université Paris-Diderot, Paris, France, 2016. (in French). [Google Scholar]

- Sharpe, R.A.; Cocq, K.L.; Nikolaou, V.; Osborne, N.J.; Thornton, C.R. Identifying risk factors for exposure to culturable allergenic moulds in energy efficient homes by using highly specific monoclonal antibodies. Environ. Res. 2016, 144, 32–42. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Flannigan, B.; Samson, R.A.; Miller, J.D. Microorganisms in Home and Indoor Work Environments: Diversity, Health Impacts, Investigation and Control, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2011; p. 529. [Google Scholar]

- Parat, S.; Perdrix, A.; Mann, S.; Cochet, C. A study of the relationship between airborne microbiological concentrations and symptoms in office in buildings. In Proceedings of the Healthy Buildings ’95: An International Conference on Healthy Buildings in Mild Climate, Milano, Italy, 10–14 September 1995; Volume III, pp. 1481–1486. [Google Scholar]

- Spilak, M.P.; Madsen, A.M.; Knudsen, S.M.; Kolarik, B.; Hansen, E.W.; Frederiksen, M.; Gunnarsen, L. Impact of dwelling characteristics on concentrations of bacteria, fungi, endotoxin and total inflammatory potential in settled dust. Build. Environ. 2015, 93, 64–71. [Google Scholar] [CrossRef]

- Prescott, L.M.; Harley, J.P.; Klein, D.A.; Willey, J.M.; Sherwood, L.M.; Woolverton, C.J. Microbiology, 7th ed.; McGraw-Hill: New York, NY, USA, 2007. [Google Scholar]

- Costerton, J.W.; Lewandowski, Z.; DeBeer, D.; Caldwell, D.; Korber, D.; James, G. Biofilms, the customized microniche. J. Bacteriol. 1994, 176, 2137–2142. [Google Scholar] [CrossRef] [PubMed]

- Davies, D.G.; Parsek, M.R.; Pearson, J.P.; Iglewski, B.H.; Costerton, J.W.; Greenberg, E.P. The Involvement of Cell-to-Cell Signals in the Development of a Bacterial Biofilm. Science 1998, 280, 295–298. [Google Scholar] [CrossRef] [PubMed]

- Shirakawa, M.A.; Tavares, R.G.; Gaylarde, C.C.; Taqueda, M.E.S.; Loh, K.; John, V.M. Climate as the most important factor determining anti-fungal biocide performance in paint films. Sci. Total Environ. 2010, 408, 5878–5886. [Google Scholar] [CrossRef] [PubMed]

- Gutarowska, B.; Pietrzak, K.; Machnowski, W.; Danielewicz, D.; Szynkowska, M.; Konca, P.; Surma-Slusarska, B. Application of Silver Nanoparticles for Disinfection of Materials to Protect Historical Objects. Curr. Nanosci. 2014, 10, 277–286. [Google Scholar] [CrossRef]

- Shirakawa, M.A.; Gaylarde, C.C.; Sahão, H.D.; Lima, J.R.B. Inhibition of Cladosporium growth on gypsum panels treated with nanosilver particles. Int. Biodeterior. Biodeterior. 2013, 85, 57–61. [Google Scholar] [CrossRef]

- De Niederhãusern, S.; Bondi, M.; Bondioli, F. Self-Cleaning and Antibacteric Ceramic Tile Surface. Int. J. Appl. Ceram. Technol. 2013, 10, 949–956. [Google Scholar] [CrossRef]

- Valentin, R.; Alignan, M.; Giacinti, G.; Renaud, F.N.R.; Raymond, B.; Mouloungui, Z. Pure short-chain glycerol fatty acid esters and glycerylic cyclocarbonic fatty acid esters as surface active and antimicrobial coagels protecting surfaces by promoting superhydrophilicity. J. Colloid Interface Sci. 2012, 365, 280–288. [Google Scholar] [CrossRef] [PubMed]

- Carp, O.; Huisman, C.; Reller, A. Photoinduced reactivity of titanium dioxide. Prog. Solid State Chem. 2004, 32, 33–177. [Google Scholar] [CrossRef]

- Chong, M.N.; Jin, B.; Chow, C.W.K.; Saint, C. Recent developments in photocatalytic water treatment technology: A review. Water Res. 2010, 44, 2997–3027. [Google Scholar] [CrossRef] [PubMed]

- Dalrymple, O.K.; Stefanakos, E.; Trotz, M.A.; Goswami, D.Y. A review of the mechanisms and modeling of photocatalytic disinfection. App. Catal. B Environ. 2010, 98, 27–38. [Google Scholar] [CrossRef]

- Foster, H.A.; Ditta, I.B.; Varghese, S.; Steele, A. Photocatalytic disinfection using titanium dioxide: Spectrum and mechanism of antimicrobial activity. Appl. Microbiol. Biotechnol. 2011, 90, 1847–1868. [Google Scholar] [CrossRef] [PubMed]

- Taylor, D.M. Transmissible Degenerative Encephalopathies: Inactivation of the Unconventional Causal Agents; John Wiley & Sons: Hoboken, NJ, USA, 2008; p. 324. [Google Scholar]

- Fujishima, A.; Rao, T.N.; Tryk, D.A. Titanium dioxide photocatalysis. J. Photochem. Photobiol. C Photochem. Rev. 2000, 1, 1–21. [Google Scholar] [CrossRef]

- Maury-Ramirez, A.; Muynck, W.D.; Stevens, R.; Demeestere, K.; Belie, N.D. Titanium dioxide based strategies to prevent algal fouling on cementitious materials. Cem. Concr. Compos. 2013, 36, 93–100. [Google Scholar] [CrossRef]

- Guo, M.Z.; Maury-Ramirez, A.; Poon, C.S. Self-cleaning ability of titanium dioxide clear paint coated architectural mortar and its potential in field application. J. Clean. Prod. 2016, 112, 3583–3588. [Google Scholar] [CrossRef]

- Maury-Ramirez, A.; Demeestere, K.; Belie, N.D.; Mäntylä, T.; Levänen, E. Titanium dioxide coated cementitious materials for air purifying purposes: Preparation, characterization and toluene removal potential. Build. Environ. 2010, 45, 832–838. [Google Scholar] [CrossRef]

- Boonen, E.; Beeldens, A. Recent Photocatalytic Applications for Air Purification in Belgium. Coatings 2014, 4, 553–573. [Google Scholar] [CrossRef]

- Martinez, T.; Bertron, A.; Ringot, E.; Escadeillas, G. Degradation of NO using photocatalytic coatings applied to different substrates. Build. Environ. 2011, 46, 1808–1816. [Google Scholar] [CrossRef]

- Hot, J.; Martinez, T.; Wayser, B.; Ringo, E.; Bertron, A. Photocatalytic degradation of NO/NO2 gas discharge in a 10 m3 experimental chamber. Environ. Sci. Pollut. Res. Int. 2016, 24, 12562–12570. [Google Scholar] [CrossRef] [PubMed]

- Maury-Ramirez, A.; Demeestere, K.; Belie, N.D. Photocatalytic activity of titanium dioxide nanoparticle coatings applied on autoclaved aerated concrete: Effect of weathering on coating physical characteristics and gaseous toluene removal. J. Hazard. Mater. 2012, 211–212, 218–225. [Google Scholar] [CrossRef] [PubMed]

- Verdier, T. Élaboration de Revêtements Pour Matériaux de Construction Visant à Lutter Contre la Prolifération Microbienne à L’intérieur des Bâtiments: Efficacité et Mode D’action. Ph.D. Thesis, Toulouse III-Paul Sabatier, Toulouse, France, 2015. (in French). [Google Scholar]

- Falco, G.D.; Porta, A.; Petrone, A.M.; Gaudio, P.D.; Hassanin, A.E.; Commodo, M.; Minutolo, P.; Squillace, A.; D’Anna, A. Antimicrobial activity of flame-synthesized nano-TiO2 coatings. Environ. Sci. Nano 2017, 4, 1095–1107. [Google Scholar] [CrossRef]

- Wiktor, V.; De Leo, F.; Urzì, C.; Guyonnet, R.; Grosseau, P.; Garcia-Diaz, E. Accelerated laboratory test to study fungal biodeterioration of cementitious matrix. Int. Biodeterior. Biodeterior. 2009, 63, 1061–1065. [Google Scholar] [CrossRef] [Green Version]

- Wiktor, V.; Grosseau, P.; Guyonnet, R.; Garcia-Diaz, E.; Lors, C. Accelerated weathering of cementitious matrix for the development of an accelerated laboratory test of biodeterioration. Mater. Struct. 2010, 44, 623–640. [Google Scholar] [CrossRef] [Green Version]

- Maness, P.C.; Smolinski, S.; Blake, D.M.; Huang, Z.; Wolfrum, E.J.; Jacoby, W.A. Bactericidal Activity of Photocatalytic TiO2 Reaction: toward an Understanding of Its Killing Mechanism. Appl. Environ. Microbiol. 1999, 65, 4094–4098. [Google Scholar] [PubMed]

- Sunada, K.; Watanabe, T.; Hashimoto, K. Studies on photokilling of bacteria on TiO2 thin film. J. Photochem. Photobiol. A Chem. 2003, 156, 227–233. [Google Scholar] [CrossRef]

- Blöß, S.P.; Elfenthal, L. Doped titanium dioxide as a photocatalyst for UV and visible light. In Proceedings of the International RILEM Symposium on Photocatalysis, Environment and Construction Materials TDP, Florence, Italy, 8–9 October 2007; pp. 31–38. [Google Scholar]

- Fujishima, A.; Zhang, X. Titanium dioxide photocatalysis: present situation and future approaches. Comptes Rendus Chim. 2006, 9, 750–760. [Google Scholar] [CrossRef]

- Husken, G.; Hunger, M.; Brouwers, H.J.H. Experimental study of photocatalytic concrete products for air purification. Build. Environ. 2009, 44, 2463–2474. [Google Scholar] [CrossRef]

- Martinez, T. Revêtements Photocatalytiques Pour les Matériaux de Construction: Formulation, Évaluation de L’efficacité de la Dépollution de L’air et Écotoxicité. Ph.D. Thesis, Toulouse III-Paul Sabatier, Toulouse, France, 2012. (in French). [Google Scholar]

- Ishiguro, H.; Nakano, R.; Yao, Y.; Kajioka, J.; Fujishima, A.; Sunada, K.; Minoshima, M.; Hashimoto, K.; Kubota, Y. Photocatalytic inactivation of bacteriophages by TiO2-coated glass plates under low-intensity, long-wavelength UV irradiation. Photochem. Photobiol. Sci. 2011, 10, 1825–1829. [Google Scholar] [CrossRef] [PubMed]

- ISO 27447 Fine Ceramics (Advanced Ceramics, Advanced Technical Ceramics)—Test Method for Antibacterial Activity of Semiconducting Photocatalytic Materials; International Organization for Standardization: Geneva, Switzerland, 2009.

- Verdier, T.; Coutand, M.; Bertron, A.; Roques, C. Antibacterial Activity of TiO2 Photocatalyst Alone or in Coatings on E. coli: The Influence of Methodological Aspects. Coatings 2014, 4, 670–686. [Google Scholar] [CrossRef]

- JIS Z 2801 Antibacterial Products—Test for Antibacterial Activity And Efficacy; Biosan Laboratories, Inc.: Warren, MI, USA, 2010.

- Alasri, A.; Roques, C.; Michel, G.; Cabassud, C.; Aptel, P. Bactericidal properties of peracetic acid and hydrogen peroxide, alone and in combination, and chlorine and formaldehyde against bacterial water strains. Can. J. Microbiol. 1992, 38, 635–642. [Google Scholar] [CrossRef]

- Pineau, L.; Roques, C.; Luc, J.; Michel, G. Automatic washer disinfector for flexible endoscopes: A new evaluation process. Endoscopy 1997, 29, 372–379. [Google Scholar] [CrossRef] [PubMed]

- Campanac, C.; Pineau, L.; Payard, A.; Baziard-Mouysset, G.; Roques, C. Interactions between Biocide Cationic Agents and Bacterial Biofilms. Antimicrob. Agents Chemother. 2002, 46, 1469–1474. [Google Scholar] [CrossRef] [PubMed]

- Ortelli, S.; Blosi, M.; Albonetti, S.; Vaccari, A.; Dondi, M.; Costa, A.L. TiO2 based nano-photocatalysis immobilized on cellulose substrates. J. Photochem. Photobiol. A Chem. 2014, 276, 58–64. [Google Scholar] [CrossRef]

- Saito, T.; Iwase, T.; Horie, J.; Morioka, T. Mode of photocatalytic bactericidal action of powdered semiconductor TiO2 on mutans streptococci. J. Photochem. Photobiol. B Biol. 1992, 14, 369–379. [Google Scholar] [CrossRef]

- Gogniat, G.; Thyssen, M.; Denis, M.; Pulgarin, C.; Dukan, S. The bactericidal effect of TiO2 photocatalysis involves adsorption onto catalyst and the loss of membrane integrity. FEMS Microbiol. Lett. 2006, 258, 18–24. [Google Scholar] [CrossRef] [PubMed]

- Dunlop, P.; Byrne, J.; Manga, N.; Eggins, B. The photocatalytic removal of bacterial pollutants from drinking water. J. Photochem. Photobiol. A Chem. 2001, 148, 355–363. [Google Scholar] [CrossRef]

- Rincón, A.G.; Pulgarin, C. Effect of pH, inorganic ions, organic matter and H2O2 on E. coli K12 photocatalytic inactivation by TiO2: Implications in solar water disinfection. Appl. Catal. B Environ. 2004, 51, 283–302. [Google Scholar] [CrossRef]

- Gogoi, S.K.; Gopinath, P.; Paul, A.; Ramesh, A.; Ghosh, S.S.; Chattopadhyay, A. Green Fluorescent Protein-Expressing Escherichia coli as a Model System for Investigating the Antimicrobial Activities of Silver Nanoparticles. Langmuir 2006, 22, 9322–9328. [Google Scholar] [CrossRef] [PubMed]

- Erable, B.; Vandecandelaere, I.; Faimali, M.; Delia, M.L.; Etcheverry, L.; Vandamme, P.; Bergel, A. Marine aerobic biofilm as biocathode catalyst. Bioelectrochemistry 2010, 78, 51–56. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Gregori, G.; Citterio, S.; Ghiani, A.; Labra, M.; Sgorbati, S.; Brown, S.; Denis, M. Resolution of Viable and Membrane-Compromised Bacteria in Freshwater and Marine Waters Based on Analytical Flow Cytometry and Nucleic Acid Double Staining. Appl. Environ. Microbiol. 2001, 67, 4662–4670. [Google Scholar] [CrossRef] [PubMed]

- Serra, D.O.; Richter, A.M.; Klauck, G.; Mika, F.; Hengge, R. Microanatomy at Cellular Resolution and Spatial Order of Physiological Differentiation in a Bacterial Biofilm. mBio 2013, 4, e00103-13. [Google Scholar] [CrossRef] [PubMed]

| Description | VLP5070 |

|---|---|

| TiO-Content | >85 % |

| Crystal modification | anatase |

| Crystallite size | approx. 15 nm |

| Specific surface area | >225 m/g |

| Components | Concentration (g/L) |

|---|---|

| FeSO, 7HO | 0.0005 |

| NaHPO | 1.25 |

| KHPO | 0.5 |

| (NH)SO | 0.1 |

| Glucose | 0.05 |

| MgSO, 7HO | 0.02 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Verdier, T.; Bertron, A.; Erable, B.; Roques, C. Bacterial Biofilm Characterization and Microscopic Evaluation of the Antibacterial Properties of a Photocatalytic Coating Protecting Building Material. Coatings 2018, 8, 93. https://doi.org/10.3390/coatings8030093

Verdier T, Bertron A, Erable B, Roques C. Bacterial Biofilm Characterization and Microscopic Evaluation of the Antibacterial Properties of a Photocatalytic Coating Protecting Building Material. Coatings. 2018; 8(3):93. https://doi.org/10.3390/coatings8030093

Chicago/Turabian StyleVerdier, Thomas, Alexandra Bertron, Benjamin Erable, and Christine Roques. 2018. "Bacterial Biofilm Characterization and Microscopic Evaluation of the Antibacterial Properties of a Photocatalytic Coating Protecting Building Material" Coatings 8, no. 3: 93. https://doi.org/10.3390/coatings8030093