Modeling of a Microscale Surface Using NURBS Technique

Abstract

:1. Introduction

2. Theory

2.1. General Forms of a NURBS Curve and a NURBS Surface

2.2. NURBS Curve Interpolation and Surface Interpolation

2.3. A 3D Surface Model Using NURBS Surface Interpolation

3. Modeling Results and Discussion

4. Conclusions

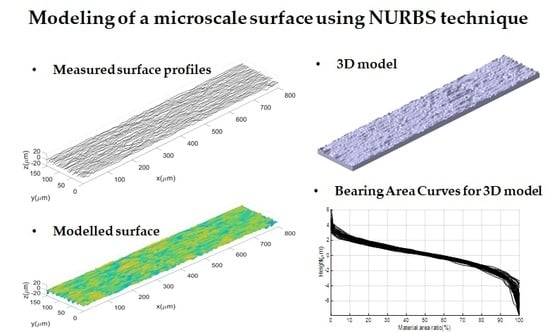

- The proposed model allows the creation of a curve passing surface roughness points and a single surface including all measured profile data. Thus, the surface similar to an actual surface can be generated on the condition that accurate measurement of the surface profile is carried out. Since the proposed model uses measured profile data, it is possible overcome the limitations of fractal and statistical methods.

- Surface topography was generated with the NURBS surface interpolation method. The surface modeled by the NURBS surface interpolation can be converted as an IGES file format with a 3D model. This 3D model will be useful for analyzing the contact found in the friction and wear behavior of materials. The method for the characterization of bearing capacity was described from the 3D model; it was identified that Bearing Area Curves (BAC) can be drawn with the proposed model. This method will reduce the time to evaluate the bearing capacity of a surface.

- Future work includes the application of the proposed modeling to contact analysis in sliding, fretting, and lubrication. Particularly, the developed 3D model would be directly used in finite element analysis and an isogeometric analysis of micro-contact problems.

Author Contributions

Funding

Conflicts of Interest

Appendix A

Appendix B

| BAC | bearing area curve |

| NURBS curve | |

| zero crossing density | |

| nonrational B-Spline basis function of -degree | |

| peak density | |

| , | degree of B-spline |

| control points | |

| control points net | |

| measured profile data | |

| measured profile data points net | |

| center-line average roughness | |

| rational basis functions of -degree | |

| root mean square roughness | |

| maximum height roughness | |

| NURBS surface | |

| , | parameter |

| , | element of knots vector |

| , | approximate parameter value determined by parameterization method |

| , | knots vector |

| weights | |

| weights net |

References

- Greenwood, J.A.; Williamson, J.B.P. Contact of nominally frat surface. Proc. R. Soc. Lond. A 1966, 295, 300–319. [Google Scholar]

- Whitehouse, D.J.; Archard, J.F. The properties of random surfaces of significance in their contact. Proc. R. Soc. Lond. A 1970, 316, 97–121. [Google Scholar] [CrossRef]

- Nayak, P.R. Random process model of rough surfaces. J. Lubr. Tech. 1971, 93, 398–407. [Google Scholar] [CrossRef]

- Onions, R.A.; Archard, J.F. The contact of the surfaces having a random structure. J. Phys. D 1973, 6, 289–304. [Google Scholar] [CrossRef]

- Wu, J.J. The properties of asperities of real surfaces. J. Tribol. 2000, 123, 872–883. [Google Scholar] [CrossRef]

- Majumdar, A.; Bhushan, B. Fractal model of elasto-plastic contact between rough surfaces. J. Tribol. 1991, 113, 1–11. [Google Scholar] [CrossRef]

- Majumdar, A.; Tien, C.L. Fractal characterization and simulation of rough surfaces. Wear 1990, 136, 313–327. [Google Scholar] [CrossRef]

- Zou, M.; Yu, B.; Feng, Y.; Xu, P. A monte carlo method for simulating fractal surfaces. Phys. A 2007, 386, 176–186. [Google Scholar] [CrossRef]

- Tao, Q.; Lee, H.P.; Lim, S.P. Contact mechanics of surfaces with various models of roughness descriptions. Wear 2001, 249, 539–545. [Google Scholar] [CrossRef]

- Zavarise, G.; Borri-Brunetto, M.; Paggi, M. On the resolution dependence of micromechanical contact models. Wear 2007, 262, 42–54. [Google Scholar] [CrossRef]

- Aramaki, H.; Cheng, H.S.; Chung, Y. The contact between rough surfaces with longitudinal texture, Part I. Average contact pressure and real contact area. J. Tribol. 1993, 115, 419–424. [Google Scholar] [CrossRef]

- Ciulli, E.; Ferreira, L.A.; Pugliese, G.; Tavares, S.M.O. Rough contacts between actual engineering surfaces, Part I. Simple models for roughness description. Wear 2008, 264, 1105–1115. [Google Scholar] [CrossRef]

- Wen, Y.; Tang, J.; Zhou, W.; Zhu, C. An improved simplified model of rough surface profile. Tribol. Int. 2018, 125, 75–84. [Google Scholar] [CrossRef]

- Piegl, L.; Tiller, W. The NURBS Books, 2nd ed.; Springer: Berlin, Germany, 1995. [Google Scholar]

- Lockyer, P.S. Controlling the Interpolation of NURBS Curves and Surfaces. Ph.D. Thesis, University of Birmingham, Birmingham, UK, 2007. [Google Scholar]

- Hughes, T.J.R.; Cottrell, J.A.; Bazilevs, Y. Isogeometric analysis: CAD, finite elements, NURBS, exact geometry and mesh refinement. Comput. Methods Appl. Mech. Eng. 2005, 194, 4135–4195. [Google Scholar] [CrossRef]

- Kim, K.; Lee, J. Determination of Nonconductive Coating Thickness Using Electrical Contact Conductance and Surface Profile. Coatings 2018, 8, 310. [Google Scholar] [CrossRef]

- Ma, L.; Eom, K.; Geringer, J.; Jun, T.-S.; Kim, K. Literature Review on Fretting Wear and Contact Mechanics of Tribological Coatings. Coatings 2019, 9, 501. [Google Scholar] [CrossRef] [Green Version]

- Stewart, M. A new approach to the use of bearing area curve. In Proceedings of the International Honing Technologies and Applications Conference, Novi, MI, USA, 1–3 May 1990. [Google Scholar]

- Lipa, Z.; Tomanickova, D. Choosing the most appropriate mathematical model to approximate the abbott curve. Mater. Sci. Technol. 2010, 4, 37–43. [Google Scholar]

| Specimen Number | No. 1 | No. 2 | No. 3 | |

|---|---|---|---|---|

| Mean | 1.4980 | 0.5770 | 0.3153 | |

| Standard deviation | 0.1578 | 0.0611 | 0.0506 | |

| Mean | 1.8961 | 0.7374 | 0.3937 | |

| Standard deviation | 0.2114 | 0.0799 | 0.0789 | |

| Mean | 10.3977 | 4.5556 | 2.0727 | |

| Standard deviation | 1.4259 | 0.6346 | 0.5572 | |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jang, J.; Kim, K. Modeling of a Microscale Surface Using NURBS Technique. Coatings 2019, 9, 775. https://doi.org/10.3390/coatings9120775

Jang J, Kim K. Modeling of a Microscale Surface Using NURBS Technique. Coatings. 2019; 9(12):775. https://doi.org/10.3390/coatings9120775

Chicago/Turabian StyleJang, Jeongki, and Kyungmok Kim. 2019. "Modeling of a Microscale Surface Using NURBS Technique" Coatings 9, no. 12: 775. https://doi.org/10.3390/coatings9120775