DLC and DLC-WS2 Coatings for Machining of Aluminium Alloys

Abstract

:1. Introduction

2. Materials and Methods

2.1. Deposition Parameters

2.1.1. Monolayer DLC Coatings

2.1.2. Multilayer DLC-WS2 Coatings

2.2. Aluminium Milling Performance and Characterisation Tests

3. Results and Discussion

3.1. Coating Structure and Composition

3.2. Coating Hardness

3.3. Frictional Properties

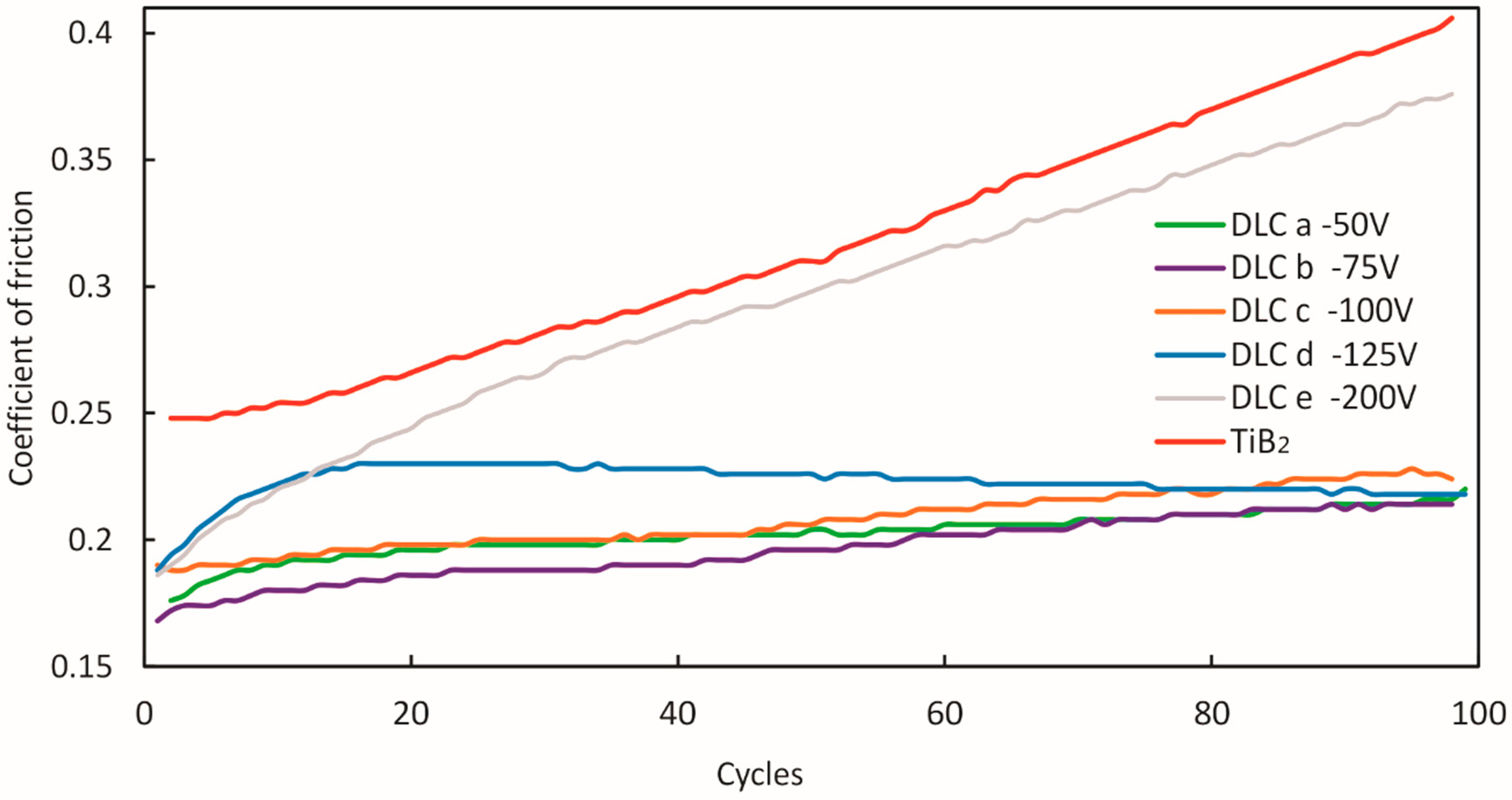

3.3.1. DLC Monolayers

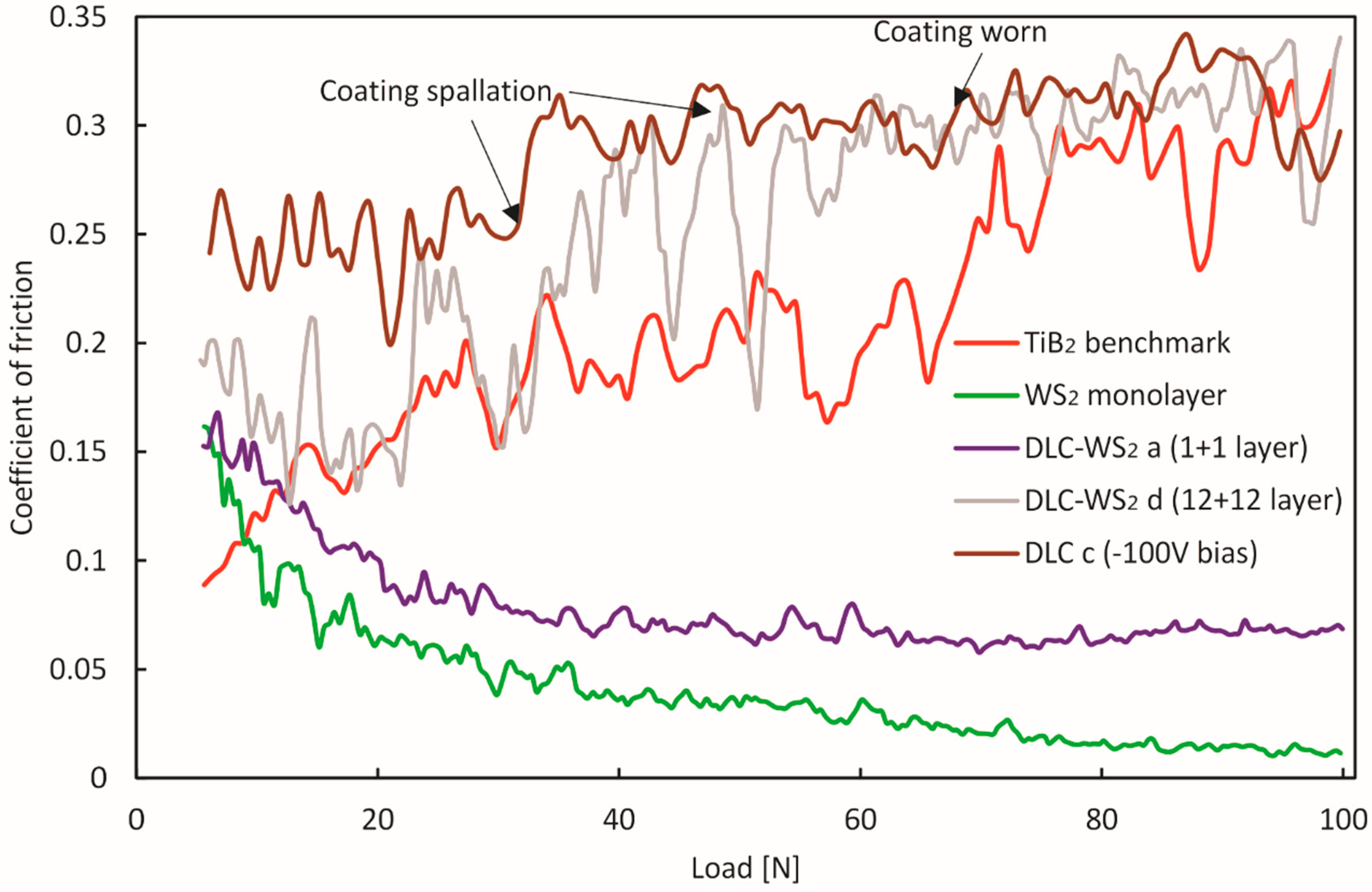

3.3.2. DLC-WS2 Multilayers

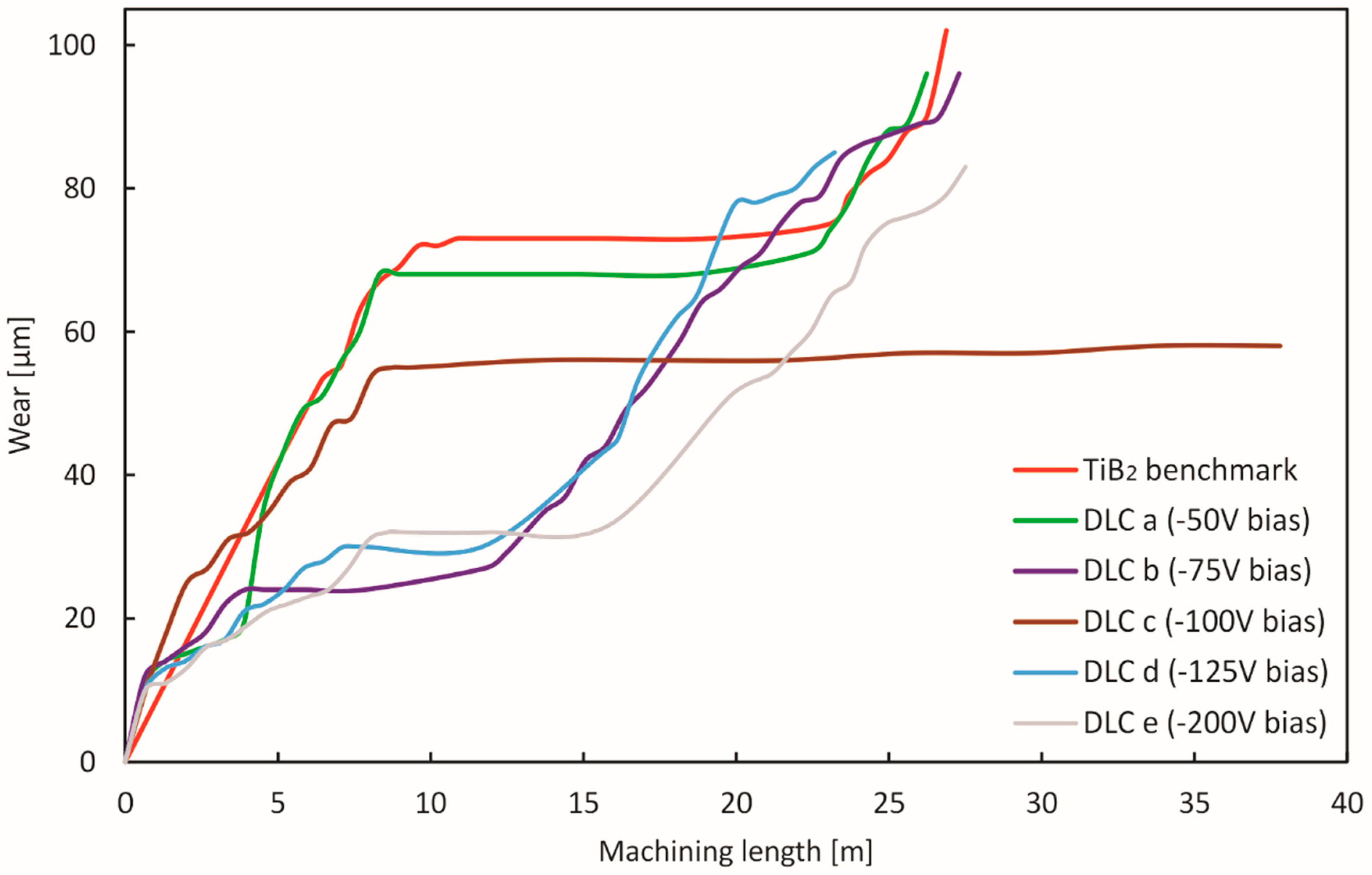

3.4. Machining Studies

3.4.1. DLC Monolayer

3.4.2. DLC-WS2 Multilayers

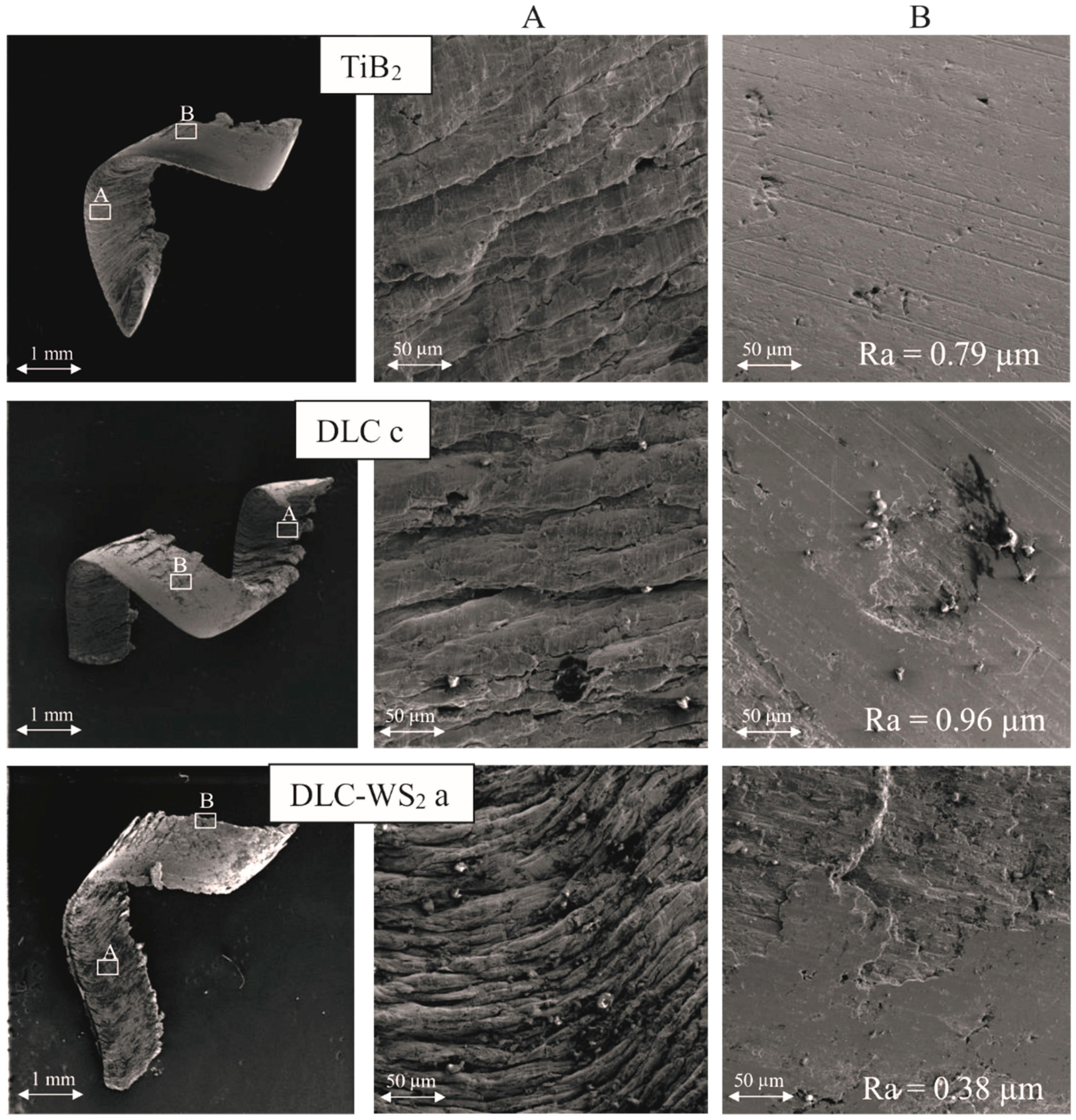

3.5. EDX Element Mapping

3.5.1. DLC Monolayer

3.5.2. DLC-WS2 multilayers

3.6. Chip Formation

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- German Fox-Rabinovich, G.E.T. Self-Organization During Friction: Advanced Surface-Engineered Materials and Systems Design; CRC Taylor & Francis: Boca Raton, FL, USA, 2013; Volume 53, ISBN 9788578110796. [Google Scholar]

- Jesudass Thomas, S.; Kalaichelvan, K. Comparative study of the effect of surface texturing on cutting tool in dry cutting. Mater. Manuf. Process. 2018, 33, 683–694. [Google Scholar] [CrossRef]

- Schaefer, A.; Reichenbach, M.; Fey, D. IAENG Transactions on Engineering Technologies; Springer: Dordrecht, The Netherlands, 2013; Volume 170, ISBN 978-94-007-4785-2. [Google Scholar]

- Chowdhury, M.S.I.; Chowdhury, S.; Yamamoto, K.; Beake, B.D.; Bose, B.; El, A.; Cavelli, D.; Dosbaeva, G.; Aramesh, M.; Fox-rabinovich, G.S.; et al. Wear behaviour of coated carbide tools during machining of Ti6Al4V aerospace alloy associated with strong built up edge formation. Surf. Coat. Technol. 2017, 313, 319–327. [Google Scholar] [CrossRef]

- Rao, J.; Cruz, R.; Lawson, K.J.; Nicholls, J.R. Carbon and titanium diboride (TiB2) multilayer coatings. Diam. Relat. Mater. 2004, 13, 2221–2225. [Google Scholar] [CrossRef]

- Rivero, A.; Aramendi, G.; Herranz, S.; De Lacalle, L.N.L. An experimental investigation of the effect of coatings and cutting parameters on the dry drilling performance of aluminium alloys. Int. J. Adv. Manuf. Technol. 2006, 28, 1–11. [Google Scholar] [CrossRef]

- Kishawy, H.A.; Dumitrescu, M.; Ng, E.G.; Elbestawi, M.A. Effect of coolant strategy on tool performance, chip morphology and surface quality during high-speed machining of A356 aluminum alloy. Int. J. Mach. Tools Manuf. 2005, 45, 219–227. [Google Scholar] [CrossRef]

- Zhu, L.; Wang, C.; Wang, H.; Xu, B.; Zhuang, D.; Liu, J.; Li, G. Microstructure and tribological properties of WS2/MoS2 multilayer films. Appl. Surf. Sci. 2012, 258, 1944–1948. [Google Scholar]

- Schultrich, B.; Scheibe, H.-J.; Drescher, D.; Ziegele, H. Deposition of superhard amorphous carbon films by pulsed vacuum arc deposition. Surf. Coat. Technol. 1998, 98, 1097–1101. [Google Scholar] [CrossRef]

- Fukui, H.; Okida, J.; Omori, N.; Moriguchi, H.; Tsuda, K. Cutting performance of DLC coated tools in dry machining aluminum alloys. Surf. Coat. Technol. 2004, 187, 70–76. [Google Scholar] [CrossRef]

- Konkhunthot, N.; Euaruksakul, C.; Photongkam, P.; Wongpanya, P. Characterization of Diamond-like Carbon (DLC) Films Deposited by Filtered Cathodic Vacuum arc Technique. J. Met. Mater. Miner. 2013, 23, 35–40. [Google Scholar]

- Mattox, D.M. Handbook of Physical Vapor Deposition (PVD) Processing: Film Formation, Adhesion, Surface Preparation and Contamination Control; Noyes Publications: Westwood, NJ, USA, 1998; ISBN 0815514220. [Google Scholar]

- Tsai, P.-C.; Hwang, Y.-F.; Chiang, J.-Y.; Chen, W.-J. The effects of deposition parameters on the structure and properties of titanium-containing DLC films synthesized by cathodic arc plasma evaporation. Surf. Coat. Technol. 2008, 202, 5350–5355. [Google Scholar] [CrossRef]

- Reinke, S.; Kulisch, W. Mechanisms in ion-assisted deposition of superhard coatings: Cubic boron nitride–tetrahedral amorphous carbon. Surf. Coat. Technol. 1997, 97, 23–32. [Google Scholar] [CrossRef]

- Robertson, J. Diamond-like amorphous carbon. Mater. Sci. Eng. R Rep. 2002, 37, 129–281. [Google Scholar] [CrossRef]

- Fallon, P.J.; Veerasamy, V.S.; Davis, C.A.; Robertson, J.; Amaratunga, G.A.J.; Milne, W.I.; Koskinen, J. Properties of filtered-ion-beam-deposited diamondlike carbon as a function of ion energy. Phys. Rev. B 1993, 48, 4777–4782. [Google Scholar] [CrossRef]

- Koçak, Y.; Akaltun, Y.; Gür, E. Magnetron sputtered WS2; Optical and structural analysis. J. Phys. Conf. Ser. 2016, 707. [Google Scholar] [CrossRef]

- Banerjee, T.; Chattopadhyay, A.K. Structural, mechanical and tribological properties of pulsed DC magnetron sputtered TiN–WSx/TiN bilayer coating. Surf. Coat. Technol. 2015, 282, 24–35. [Google Scholar] [CrossRef]

- Clauss, F.J. Solid Lubricants and Self-Lubricating Solids; Academic Press: New York, NY, USA, 1972. [Google Scholar]

- Banerjee, T.; Chattopadhyay, A.K. Structural, mechanical and tribological properties of WS2-Ti composite coating with and without hard under layer of TiN. Surf. Coat. Technol. 2014, 258, 849–860. [Google Scholar] [CrossRef]

- Särhammar, E.; Strandberg, E.; Sundberg, J.; Nyberg, H.; Kubart, T.; Jacobson, S.; Jansson, U.; Nyberg, T. Mechanisms for compositional variations of coatings sputtered from a WS2 target. Surf. Coat. Technol. 2014, 252, 186–190. [Google Scholar] [CrossRef]

- Yang, F.; Lu, Y.; Zhang, R.; Zhang, X.; Zheng, X. Microstructure and tribological properties of WSx/a-C multilayer films with various layer thickness ratios in different environments. Surf. Coat. Technol. 2017, 309, 187–194. [Google Scholar] [CrossRef]

- Brzezinka, T.; Rao, J.; Chowdhury, M.; Kohlscheen, J.; Fox Rabinovich, G.; Veldhuis, S.; Endrino, J. Hybrid Ti-MoS2 Coatings for Dry Machining of Aluminium Alloys. Coatings 2017, 7, 149. [Google Scholar] [CrossRef]

- Grill, A. Diamond-like carbon: State of the art. Diam. Relat. Mater. 1999, 8, 428–434. [Google Scholar] [CrossRef]

- Bull, S.J. Failure modes in scratch adhesion testing. Surf. Coat. Technol. 1991, 50, 25–32. [Google Scholar] [CrossRef]

- Anders, A. Cathodic Arcs Fom Fractal Spots to Energetic Condensation; Springer Inc.: New York, NY, USA, 2008; ISBN 9780387791074. [Google Scholar]

- Prakash, B.; Ftikos, C.; Celis, J.P. Fretting wear behavior of PVD TiB2 coatings. Surf. Coat. Technol. 2002, 154, 182–188. [Google Scholar] [CrossRef]

- Murthy, T.S.R.C.; Basu, B.; Srivastava, A.; Balasubramaniam, R.; Suri, A.K. Tribological properties of TiB2 and TiB2 - MoSi2 ceramic composites. J. Eur. Ceram. Soc. 2006, 26, 1293–1300. [Google Scholar] [CrossRef]

- Fontaine, J.; Donnet, C.; Erdemir, A. Fundamentals of the tribology of DLC coatings. Tribol. Diamond-Like Carbon Film. Fundam. Appl. 2008, 139–154. [Google Scholar] [CrossRef]

- Sutton, D.C.; Limbert, G.; Stewart, D.; Wood, R.J.K. The friction of diamond-like carbon coatings in a water environment. Friction 2013, 1, 210–221. [Google Scholar] [CrossRef]

- Guo, C.Q.; Pei, Z.L.; Fan, D.; Liu, R.D.; Gong, J.; Sun, C. Predicting multilayer film’s residual stress from its monolayers. Mater. Des. 2016, 110, 858–864. [Google Scholar] [CrossRef]

- List, G.; Nouari, M.; Géhin, D.; Gomez, S.; Manaud, J.P.; Le Petitcorps, Y.; Girot, F. Wear behaviour of cemented carbide tools in dry machining of aluminium alloy. Wear 2005, 259, 1177–1189. [Google Scholar] [CrossRef]

- Ramaswami, R. The effect of the built-up-edge(BUE) on the wear of cutting tools. Wear 1971, 18, 1–10. [Google Scholar] [CrossRef]

- Robertson, J. Properties of diamond-like carbon. Surf. Coat. Technol. 1992, 50, 185–203. [Google Scholar] [CrossRef]

- Heinrichs, J.; Olsson, M.; Jacobson, S. New understanding of the initiation of material transfer and transfer layer build-up in metal forming—In situ studies in the SEM. Wear 2012, 292–293, 61–73. [Google Scholar] [CrossRef]

- Vereschaka, A.A.; Grigoriev, S.N.; Vereschaka, A.S.; Popov, A.Y.; Batako, A.D. Nano-scale multilayered composite coatings for cutting tools operating under heavy cutting conditions. Procedia CIRP 2014, 14, 239–244. [Google Scholar] [CrossRef]

| Machine Tool | CNC Vertical Machining Centre |

|---|---|

| Number of cutting edges | 2 |

| Feed rate [mm/min] | 1880 |

| Feed per tooth ft [mm/tooth] | 0.05 |

| Cutter diameter [mm] | 25.4 |

| Tool speed RPM [rev/min] | 6265 |

| Axial Depth of cut ap [mm] | 10 |

| Radial Depth of cut [mm] | 1 |

| Cutting speed Vc [m/min] | 500 |

| Coolant rate flow [l/min] | 44 |

| Coolant concentration [%] | 6 |

| Workpiece material | Al-10Si |

| Sample ID | Dep Time [min] | Substrate Bias [V] | CoF after 100 Cycles | Coating Thickness [nm] |

|---|---|---|---|---|

| DLC a | 11 | −50 | 0.22 | 70 |

| DLC b | −75 | 0.21 | 80 | |

| DLC c | −100 | 0.22 | 100 | |

| DLC d | −125 | 0.22 | 80 | |

| DLC e | 5 | −200 | 0.37 | 45 |

| TiB2 benchmark | - | - | 0.4 | 2000 |

| Sample Name | DLC | WS2 | CoF after 100 Cycles | Total Coating Thickness [nm] | Hardness [GPa] | ||

|---|---|---|---|---|---|---|---|

| Number of Layers | Deposition Time of Each Layer [min] | Number of Layers | Deposition Time of Each Layer [min] | ||||

| WS2 | - | - | 1 | 36 | 0.32 | 450 | 2.4 |

| DLC-WS2 a | 1 | 12 | 1 | 24 | 0.18 | 320 | 2.7 |

| DLC-WS2 b | 3 | 4 | 3 | 8 | 0.19 | 310 | 4.3 |

| DLC-WS2 c | 6 | 2 | 6 | 4 | 0.50 | 290 | 5.1 |

| DLC-WS2 d | 12 | 1 | 12 | 2 | 0.49 | 250 | 6.6 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Brzezinka, T.L.; Rao, J.; Paiva, J.M.; Kohlscheen, J.; Fox-Rabinovich, G.S.; Veldhuis, S.C.; Endrino, J.L. DLC and DLC-WS2 Coatings for Machining of Aluminium Alloys. Coatings 2019, 9, 192. https://doi.org/10.3390/coatings9030192

Brzezinka TL, Rao J, Paiva JM, Kohlscheen J, Fox-Rabinovich GS, Veldhuis SC, Endrino JL. DLC and DLC-WS2 Coatings for Machining of Aluminium Alloys. Coatings. 2019; 9(3):192. https://doi.org/10.3390/coatings9030192

Chicago/Turabian StyleBrzezinka, Tomasz L., Jeff Rao, Jose M. Paiva, Joern Kohlscheen, German S. Fox-Rabinovich, Stephen C. Veldhuis, and Jose L. Endrino. 2019. "DLC and DLC-WS2 Coatings for Machining of Aluminium Alloys" Coatings 9, no. 3: 192. https://doi.org/10.3390/coatings9030192

APA StyleBrzezinka, T. L., Rao, J., Paiva, J. M., Kohlscheen, J., Fox-Rabinovich, G. S., Veldhuis, S. C., & Endrino, J. L. (2019). DLC and DLC-WS2 Coatings for Machining of Aluminium Alloys. Coatings, 9(3), 192. https://doi.org/10.3390/coatings9030192